combination meter SUBARU FORESTER 2004 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1275 of 2870

EN(H4SO)-177

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

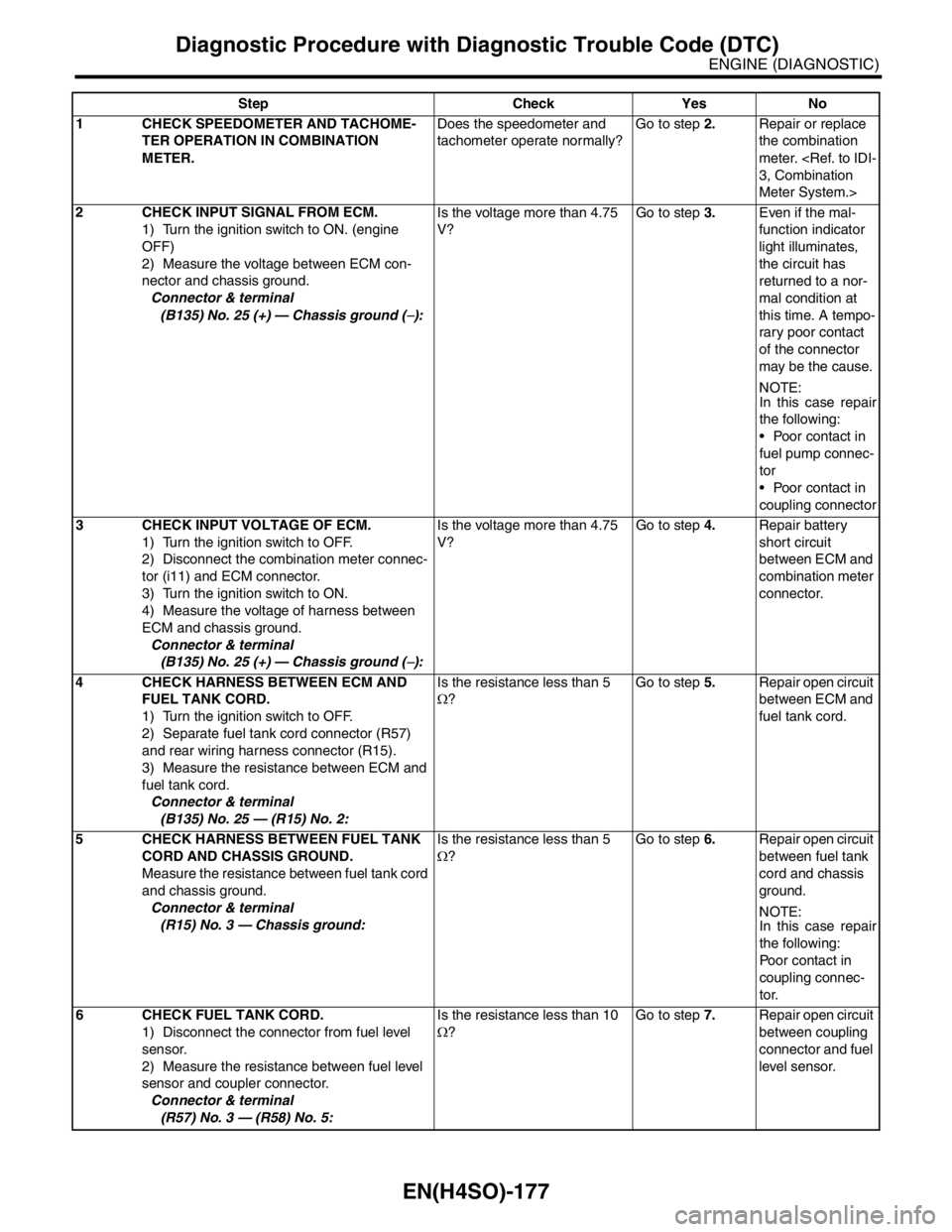

Step Check Yes No

1 CHECK SPEEDOMETER AND TACHOME-

TER OPERATION IN COMBINATION

METER.Does the speedometer and

tachometer operate normally?Go to step 2.Repair or replace

the combination

meter.

Meter System.>

2 CHECK INPUT SIGNAL FROM ECM.

1) Turn the ignition switch to ON. (engine

OFF)

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B135) No. 25 (+) — Chassis ground (

−):Is the voltage more than 4.75

V?Go to step 3.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector

may be the cause.

N

OTE:

In this case repair

the following:

Poor contact in

fuel pump connec-

tor

Poor contact in

coupling connector

3 CHECK INPUT VOLTAGE OF ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the combination meter connec-

tor (i11) and ECM connector.

3) Turn the ignition switch to ON.

4) Measure the voltage of harness between

ECM and chassis ground.

Connector & terminal

(B135) No. 25 (+) — Chassis ground (

−):Is the voltage more than 4.75

V?Go to step 4.Repair battery

short circuit

between ECM and

combination meter

connector.

4 CHECK HARNESS BETWEEN ECM AND

FUEL TANK CORD.

1) Turn the ignition switch to OFF.

2) Separate fuel tank cord connector (R57)

and rear wiring harness connector (R15).

3) Measure the resistance between ECM and

fuel tank cord.

Connector & terminal

(B135) No. 25 — (R15) No. 2:Is the resistance less than 5

Ω?Go to step 5.Repair open circuit

between ECM and

fuel tank cord.

5 CHECK HARNESS BETWEEN FUEL TANK

CORD AND CHASSIS GROUND.

Measure the resistance between fuel tank cord

and chassis ground.

Connector & terminal

(R15) No. 3 — Chassis ground:Is the resistance less than 5

Ω?Go to step 6.Repair open circuit

between fuel tank

cord and chassis

ground.

N

OTE:

In this case repair

the following:

Poor contact in

coupling connec-

tor.

6 CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel level

sensor.

2) Measure the resistance between fuel level

sensor and coupler connector.

Connector & terminal

(R57) No. 3 — (R58) No. 5:Is the resistance less than 10

Ω?Go to step 7.Repair open circuit

between coupling

connector and fuel

level sensor.

Page 1276 of 2870

EN(H4SO)-178

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

7 CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel sub

level sensor.

2) Measure the resistance between fuel level

sensor and fuel sub level sensor.

Connector & terminal

(R58) No. 3 — (R59) No. 2:Is the resistance less than 10

Ω?Go to step 8.Repair open circuit

between fuel level

sensor and fuel

sub level sensor.

8 CHECK FUEL TANK CORD.

Measure the resistance between fuel level sen-

sor and coupler connector.

Connector & terminal

(R57) No. 2 — (R59) No. 1:Is the resistance less than 10

Ω?Go to step 9.Repair open circuit

between coupling

connector and fuel

level sensor.

9 CHECK FUEL LEVEL SENSOR.

1) Remove the fuel pump assembly.

2) While moving the fuel level sensor float up

and down, measure resistance between fuel

level sensor terminals.

Te r m i n a l s

No. 3 — No. 5:Is the resistance more than

54.5 Ω?Replace the fuel

level sensor.

Fuel Level Sen-

sor.>Go to step 10.

10 CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

2) While moving the fuel sub level sensor float

up and down, measure resistance between

fuel sub level sensor terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance more than

41.5 Ω?Replace the fuel

sub level sensor.

Fuel Sub Level

Sensor.>Replace the com-

bination meter.

Meter Assembly.> Step Check Yes No

Page 1277 of 2870

EN(H4SO)-179

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

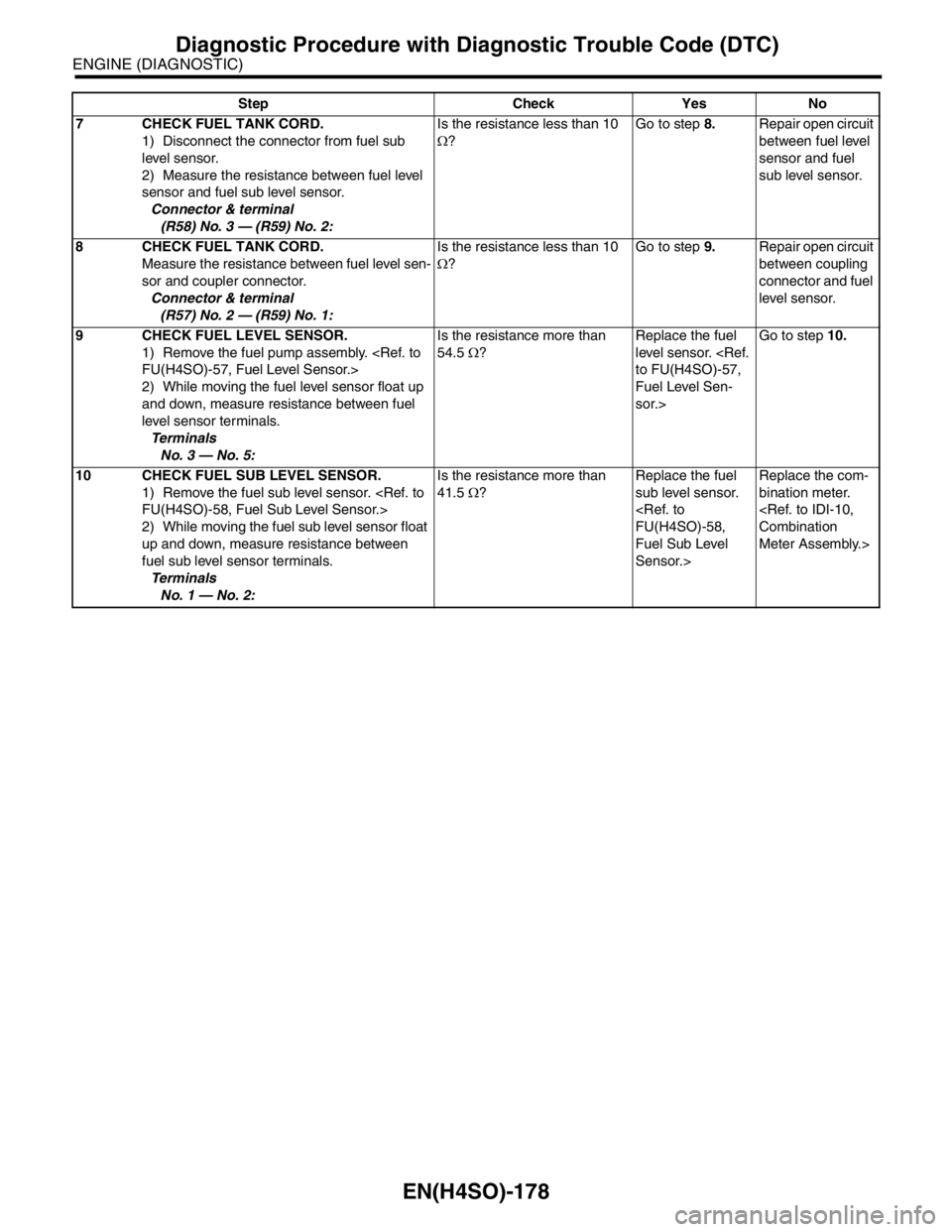

AT:DTC P0464 FUEL LEVEL SENSOR CIRCUIT INTERMITTENT

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

R59R58

R57

R15

B38i3

B98R2

B10

C1 B9

25

3

5

i10 B :

i11 C :B135ECM

EE

E

IGNITION

SWITCH

SBF-4SBF-14

COMBINATION

METERSBF-1

B72

14

FUEL SUB

LEVEL SENSOR

FUEL SUB

METER UNIT

FUEL LEVEL

SENSOR1

2

BATTERY

B38

i3

B38

i320E2

B211528

LHD

LHDRHD

RHDLHD

LHDRHD

RHD

2

16

B38i3

LHD

LHDRHD

RHD

4 3

B99R3

B38i3

LHD

LHDRHD

RHD

16

5

B37i2

EN-02393

2

3

B135

B72

R15R59i10R58

3412

13

456212123456789101112131415161718192021222324252627282930

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

i3

B99

12345678

i11

34 12 8567910

B37

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

B:

C:

B98

123

4

56

78

9

1011 12

1314 15 16

B21

Page 1283 of 2870

EN(H4SO)-185

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

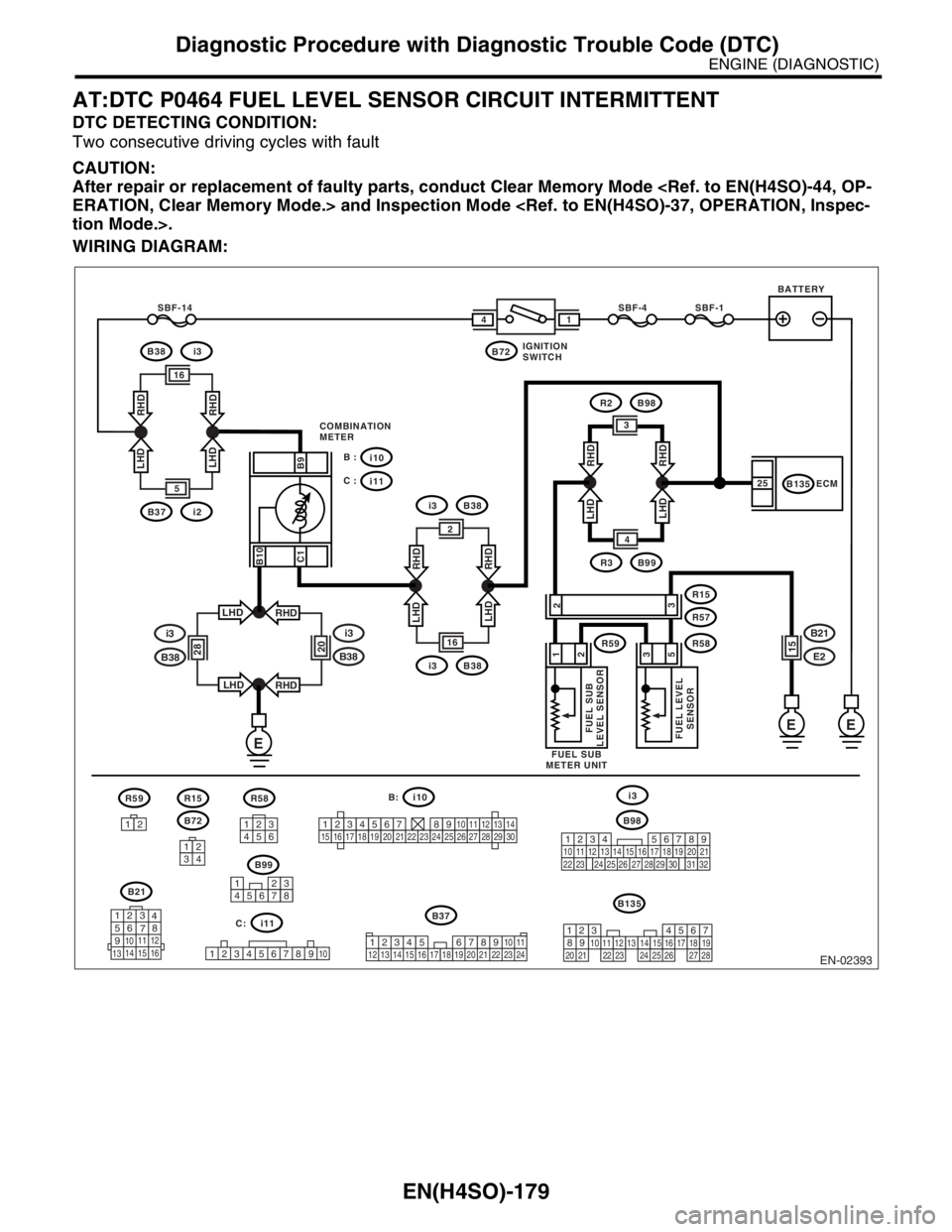

AW:DTC P0503 VEHICLE SPEED SENSOR CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02395

i10

BATTERY

12

10

ECM COMBINATION

METER

VEHICLE

SPEED

SENSOR

3

12

B17

B137

17

TCMB56

IGNITION

RELAY

No. 5

B225

B21

E216

MTATB17

123

B21

123

4

56

78

9

1011 12

1314 15 16B62

B:

B56

1234

10 11 12

19 20 21135614 1578916 17 18

22 23 24

112

B225

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

i10

123456789101112131415161718192021222324252627282930

B37

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

F45

B137

4

1

53

2618 15 167891011

17 19

20121314

F45

B38i3

B37i2

18

LHD

LHDRHD

RHD

RHD

RHD

LHDLHD

7B38

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

C:

*

1*

1 LHD MODEL : 9

RHD MODEL : 37*

2 LHD MODEL : 10

RHD MODEL : 38*

12345678910111213141516

B:C:

Page 1284 of 2870

EN(H4SO)-186

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

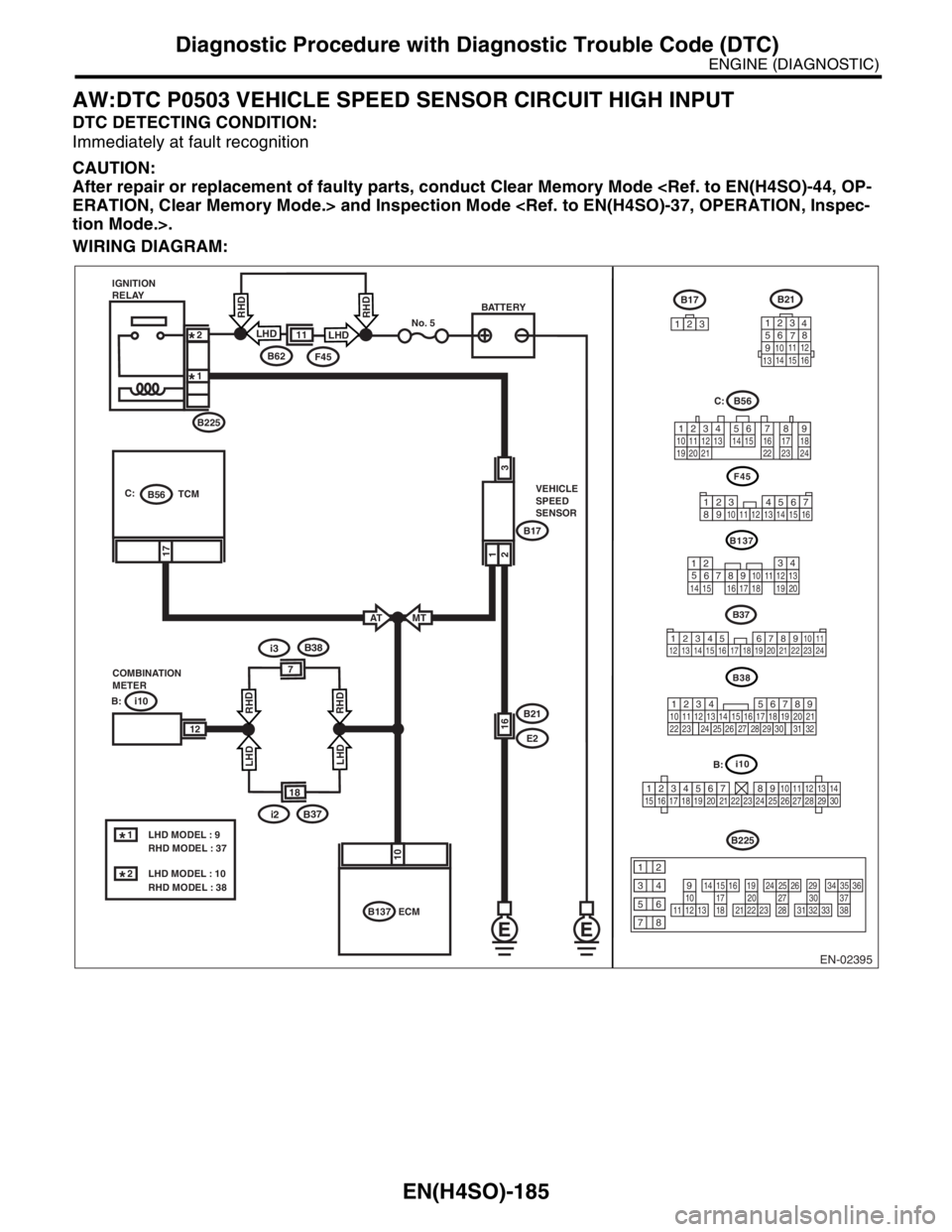

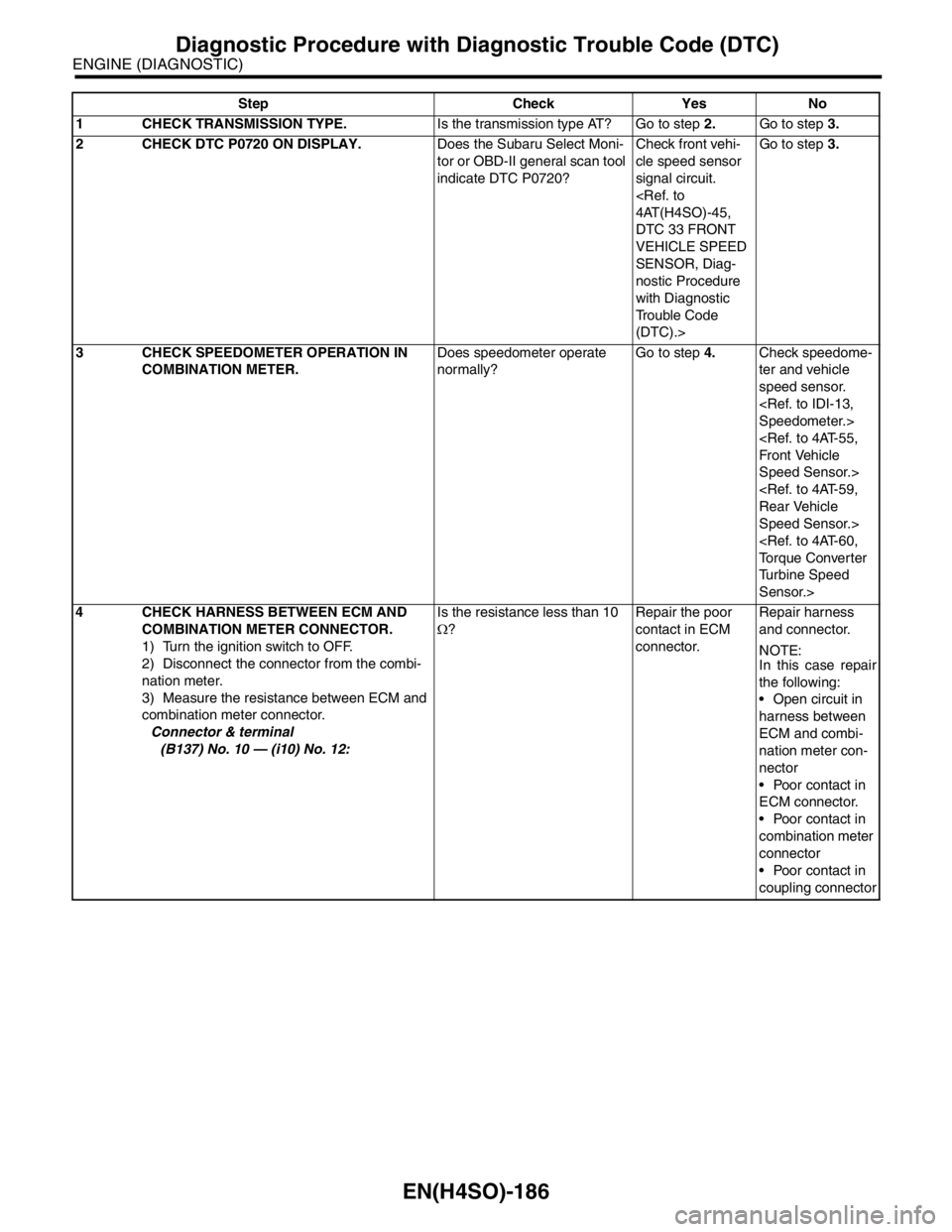

Step Check Yes No

1 CHECK TRANSMISSION TYPE.Is the transmission type AT? Go to step 2.Go to step 3.

2 CHECK DTC P0720 ON DISPLAY.Does the Subaru Select Moni-

tor or OBD-II general scan tool

indicate DTC P0720?Check front vehi-

cle speed sensor

signal circuit.

DTC 33 FRONT

VEHICLE SPEED

SENSOR, Diag-

nostic Procedure

with Diagnostic

Trouble Code

(DTC).>Go to step 3.

3 CHECK SPEEDOMETER OPERATION IN

COMBINATION METER.Does speedometer operate

normally?Go to step 4.Check speedome-

ter and vehicle

speed sensor.

Speed Sensor.>

Speed Sensor.>

Turbine Speed

Sensor.>

4 CHECK HARNESS BETWEEN ECM AND

COMBINATION METER CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the combi-

nation meter.

3) Measure the resistance between ECM and

combination meter connector.

Connector & terminal

(B137) No. 10 — (i10) No. 12:Is the resistance less than 10

Ω?Repair the poor

contact in ECM

connector.Repair harness

and connector.

NOTE:

In this case repair

the following:

Open circuit in

harness between

ECM and combi-

nation meter con-

nector

Poor contact in

ECM connector.

Poor contact in

combination meter

connector

Poor contact in

coupling connector

Page 1566 of 2870

ME(H4DOTC)-106

MECHANICAL

Cylinder Block

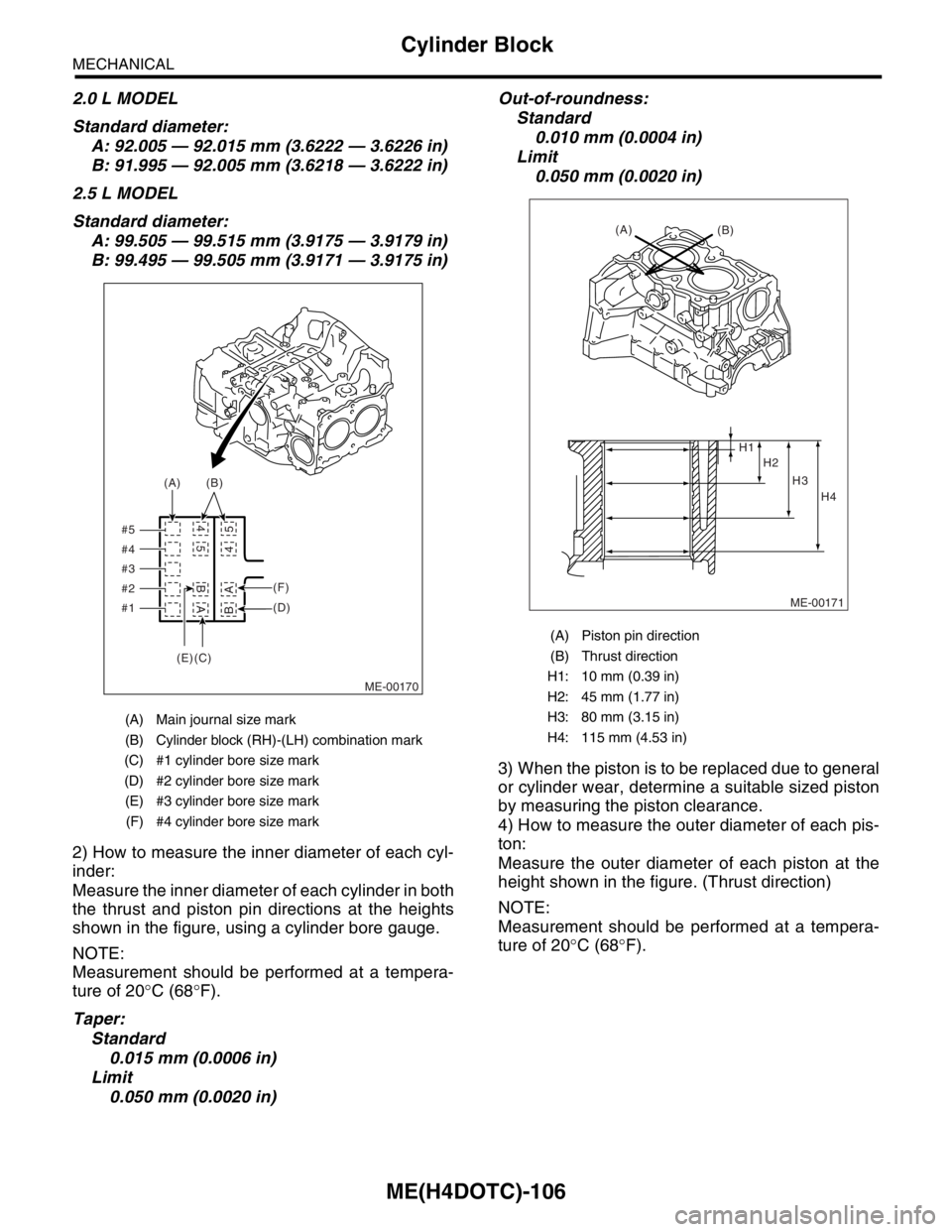

2.0 L MODEL

Standard diameter:

A: 92.005 — 92.015 mm (3.6222 — 3.6226 in)

B: 91.995 — 92.005 mm (3.6218 — 3.6222 in)

2.5 L MODEL

Standard diameter:

A: 99.505 — 99.515 mm (3.9175 — 3.9179 in)

B: 99.495 — 99.505 mm (3.9171 — 3.9175 in)

2) How to measure the inner diameter of each cyl-

inder:

Measure the inner diameter of each cylinder in both

the thrust and piston pin directions at the heights

shown in the figure, using a cylinder bore gauge.

NOTE:

Measurement should be performed at a tempera-

ture of 20°C (68°F).

Taper:

Standard

0.015 mm (0.0006 in)

Limit

0.050 mm (0.0020 in)Out-of-roundness:

Standard

0.010 mm (0.0004 in)

Limit

0.050 mm (0.0020 in)

3) When the piston is to be replaced due to general

or cylinder wear, determine a suitable sized piston

by measuring the piston clearance.

4) How to measure the outer diameter of each pis-

ton:

Measure the outer diameter of each piston at the

height shown in the figure. (Thrust direction)

NOTE:

Measurement should be performed at a tempera-

ture of 20°C (68°F).

(A) Main journal size mark

(B) Cylinder block (RH)-(LH) combination mark

(C) #1 cylinder bore size mark

(D) #2 cylinder bore size mark

(E) #3 cylinder bore size mark

(F) #4 cylinder bore size mark

ME-00170 #5

#4

#3

#2

#1(A)(B)

(F)

(D)

A BA B

5 45 4

(C) (E)

(A) Piston pin direction

(B) Thrust direction

H1: 10 mm (0.39 in)

H2: 45 mm (1.77 in)

H3: 80 mm (3.15 in)

H4: 115 mm (4.53 in)

ME-00171

(A)

(B)

H2 H1

H3

H4

Page 1637 of 2870

EN(H4DOTC)-7

ENGINE (DIAGNOSTIC)

General Description

12) Observe the following cautions when installing

a radio in MFI equipped models.

CAUTION:

The antenna must be kept as far apart as pos-

sible from the control unit. (The ECM is located

under the steering column, inside of the instru-

ment panel lower trim panel.)

The antenna feeder must be placed as far

apart as possible from the ECM and MFI har-

ness.

Carefully adjust the antenna for correct

matching.

When mounting a large power type radio, pay

special attention to the three items above men-

tioned.

Incorrect installation of the radio may affect

the operation of the ECM.

13) Before disconnecting the fuel hose, disconnect

the fuel pump connector and crank the engine for

more than five seconds to release pressure in the

fuel system.If engine starts during this operation,

run it until it stops.

14) Problems in the electronic-controlled automatic

transmission may be caused by failure of the en-

gine, the electronic control system, the transmis-

sion proper, or by a combination of these.These

three causes (engine, electronic control system,

transmission) must be distinguished clearly when

performing diagnostics.

15) Diagnostics should be conducted by rotating

with simple, easy operations and proceeding to

complicated, difficult operations.The most impor-

tant thing in diagnostics is to understand the cus-

tomer’s complaint, and distinguish between the

three causes.

16) On the model with ABS, when performing driv-

ing test in jacked-up or lifted-up position, some-

times the warning light may be lit, but this is not a

malfunction of the system.The reason for this is the

speed difference between the front and rear

wheels.After diagnosis of engine control system,

perform the ABS memory clearance procedure of

self-diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

items which might affect engine problems:

1. BATTERY

1) Measure battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.2602) Check the condition of the main and other fuses,

and harnesses and connectors.Also check for

proper grounding.

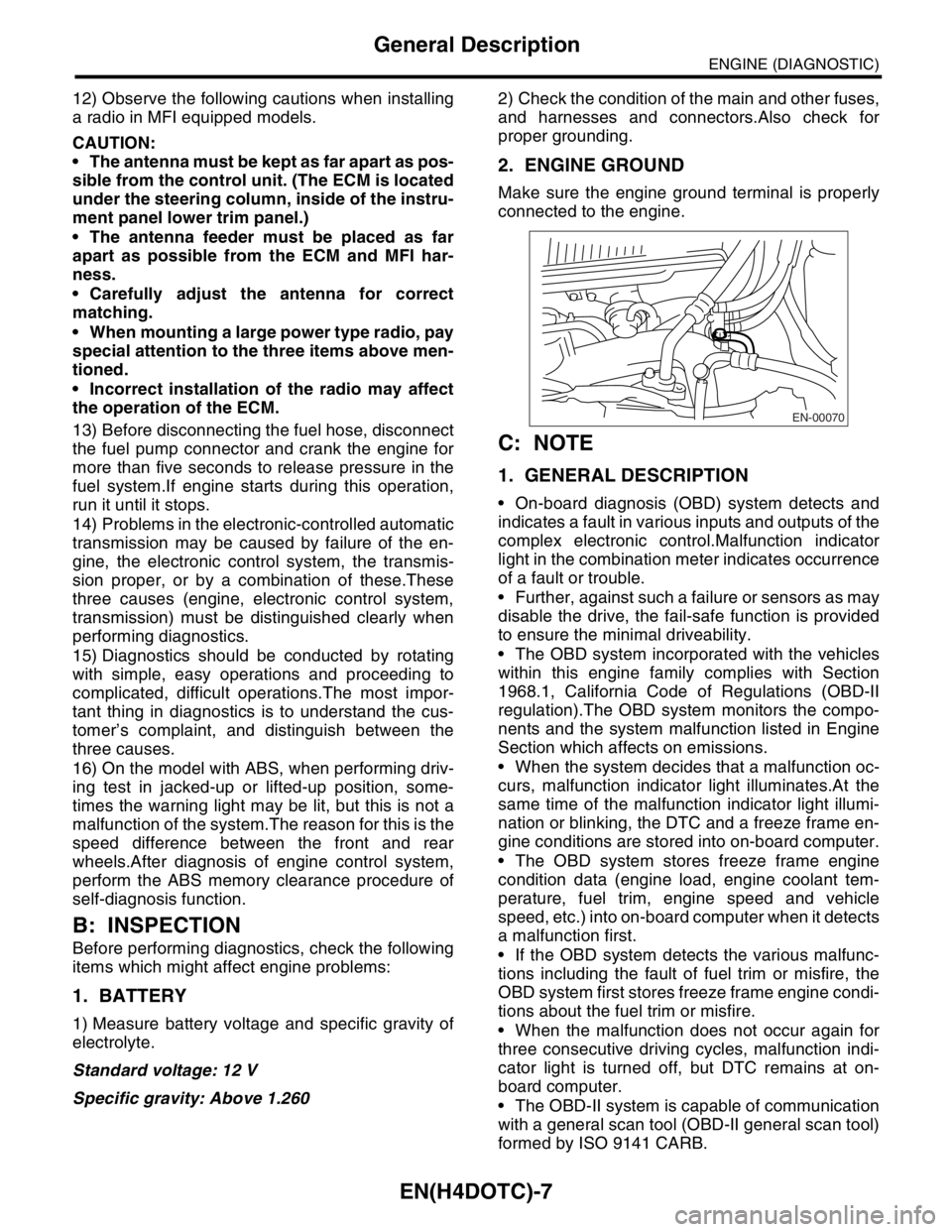

2. ENGINE GROUND

Make sure the engine ground terminal is properly

connected to the engine.

C: NOTE

1. GENERAL DESCRIPTION

On-board diagnosis (OBD) system detects and

indicates a fault in various inputs and outputs of the

complex electronic control.Malfunction indicator

light in the combination meter indicates occurrence

of a fault or trouble.

Further, against such a failure or sensors as may

disable the drive, the fail-safe function is provided

to ensure the minimal driveability.

The OBD system incorporated with the vehicles

within this engine family complies with Section

1968.1, California Code of Regulations (OBD-II

regulation).The OBD system monitors the compo-

nents and the system malfunction listed in Engine

Section which affects on emissions.

When the system decides that a malfunction oc-

curs, malfunction indicator light illuminates.At the

same time of the malfunction indicator light illumi-

nation or blinking, the DTC and a freeze frame en-

gine conditions are stored into on-board computer.

The OBD system stores freeze frame engine

condition data (engine load, engine coolant tem-

perature, fuel trim, engine speed and vehicle

speed, etc.) into on-board computer when it detects

a malfunction first.

If the OBD system detects the various malfunc-

tions including the fault of fuel trim or misfire, the

OBD system first stores freeze frame engine condi-

tions about the fuel trim or misfire.

When the malfunction does not occur again for

three consecutive driving cycles, malfunction indi-

cator light is turned off, but DTC remains at on-

board computer.

The OBD-II system is capable of communication

with a general scan tool (OBD-II general scan tool)

formed by ISO 9141 CARB.

EN-00070

Page 1681 of 2870

EN(H4DOTC)-51

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

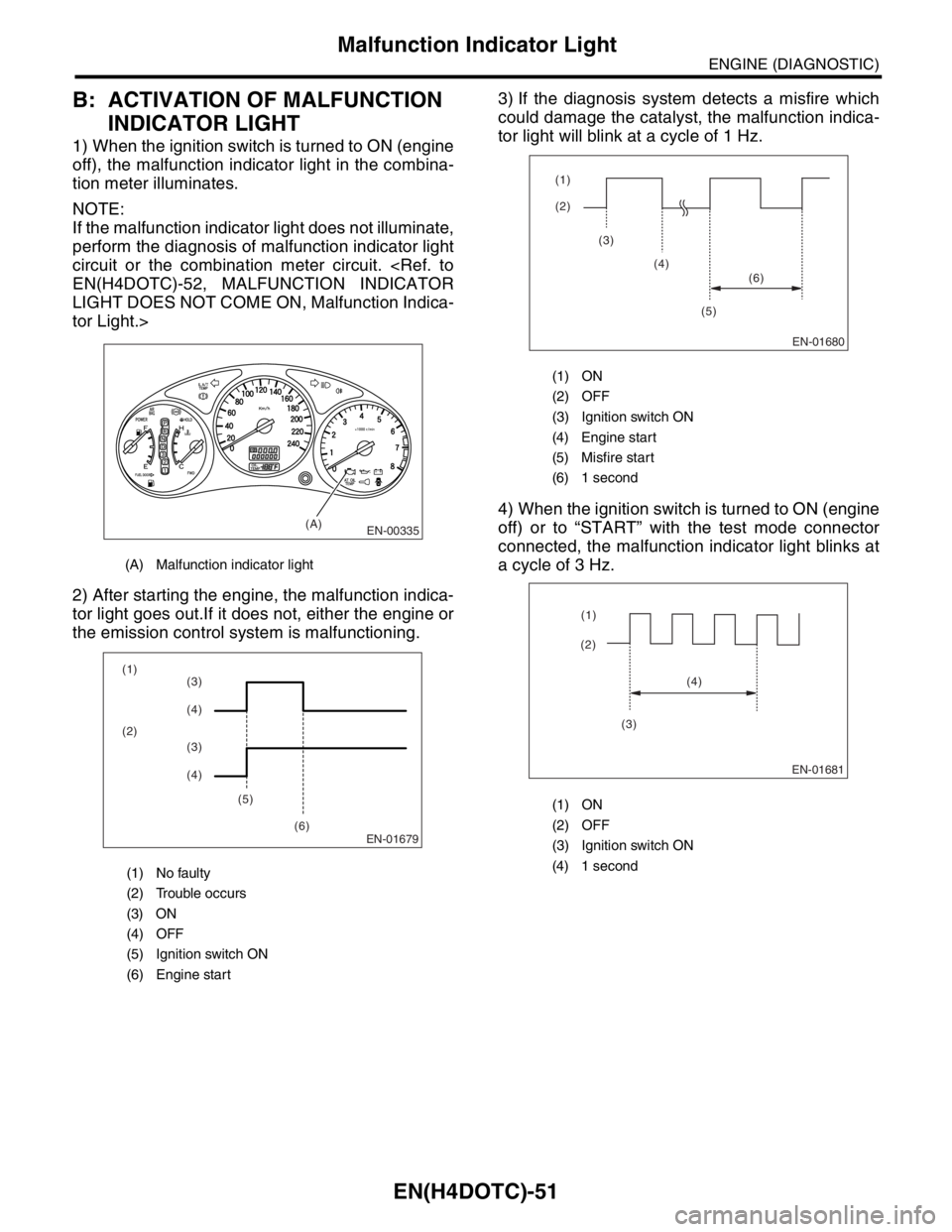

B: ACTIVATION OF MALFUNCTION

INDICATOR LIGHT

1) When the ignition switch is turned to ON (engine

off), the malfunction indicator light in the combina-

tion meter illuminates.

NOTE:

If the malfunction indicator light does not illuminate,

perform the diagnosis of malfunction indicator light

circuit or the combination meter circuit.

LIGHT DOES NOT COME ON, Malfunction Indica-

tor Light.>

2) After starting the engine, the malfunction indica-

tor light goes out.If it does not, either the engine or

the emission control system is malfunctioning.3) If the diagnosis system detects a misfire which

could damage the catalyst, the malfunction indica-

tor light will blink at a cycle of 1 Hz.

4) When the ignition switch is turned to ON (engine

off) or to “START” with the test mode connector

connected, the malfunction indicator light blinks at

a cycle of 3 Hz.

(A) Malfunction indicator light

(1) No faulty

(2) Trouble occurs

(3) ON

(4) OFF

(5) Ignition switch ON

(6) Engine start

EN-00335(A)

EN-01679

(1)

(2)

(5)

(6)(3)

(4)

(3)

(4)

(1) ON

(2) OFF

(3) Ignition switch ON

(4) Engine start

(5) Misfire start

(6) 1 second

(1) ON

(2) OFF

(3) Ignition switch ON

(4) 1 second

EN-01680

(2) (1)

(3)

(4)

(5)(6)

EN-01681

(2)(1)

(4)

(3)

Page 1682 of 2870

EN(H4DOTC)-52

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

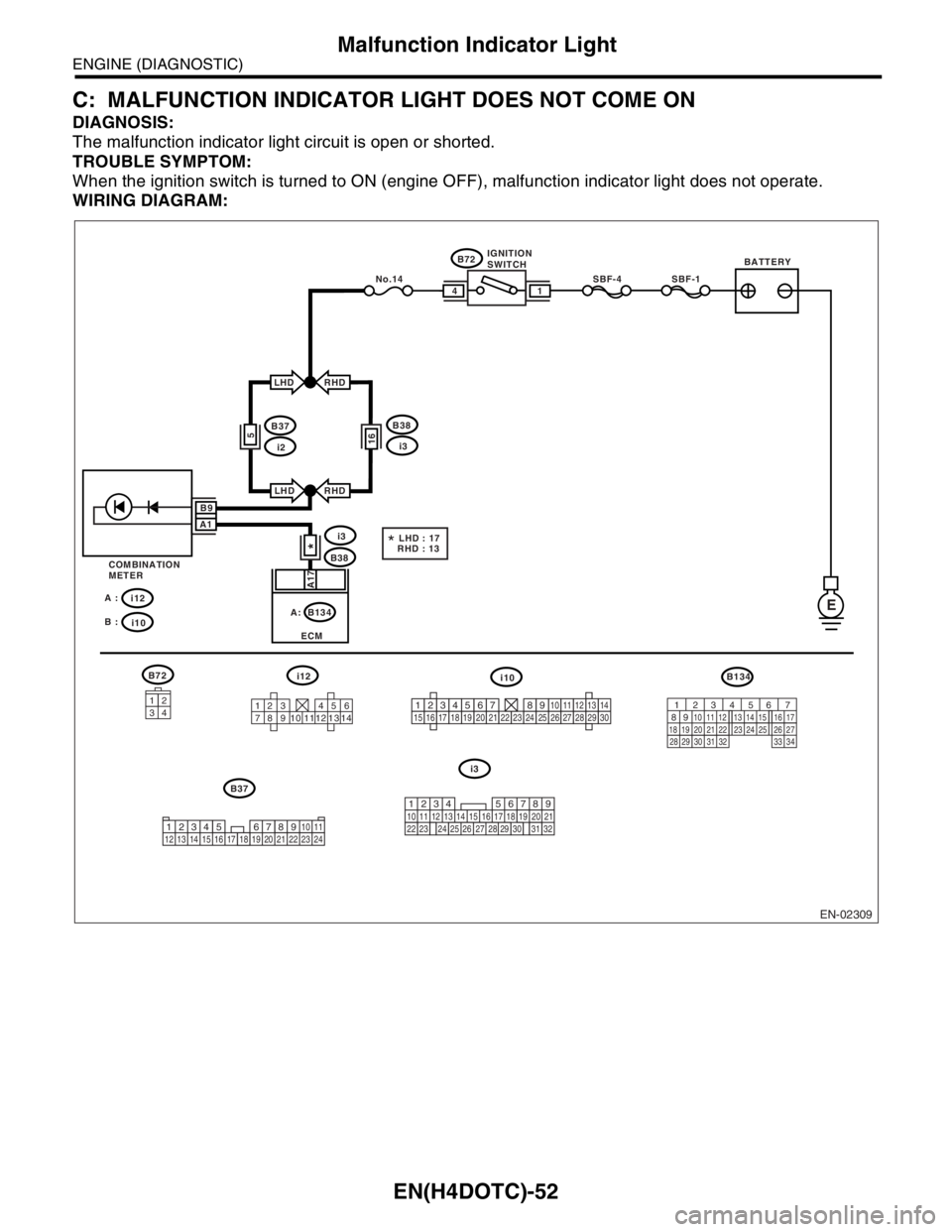

C: MALFUNCTION INDICATOR LIGHT DOES NOT COME ON

DIAGNOSIS:

The malfunction indicator light circuit is open or shorted.

TROUBLE SYMPTOM:

When the ignition switch is turned to ON (engine OFF), malfunction indicator light does not operate.

WIRING DIAGRAM:

EN-02309

BATTERYIGNITION

SWITCH

SBF-4SBF-1

B72

B72

B38

B134

ECM

i3

E

14

RHD

RHD

A17

B37

i12 A :

i10 B :

i12i10B134

i3

i2

LHD

LHD

5

COMBINATION

METER

3412

123 456

789 121310 11 14

*

16

B38

i3

B37No.14

*LHD : 17

RHD : 13

B9

A1

34

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

12345678910111213141516171819202122232425262728293056 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

A:

Page 1683 of 2870

EN(H4DOTC)-53

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

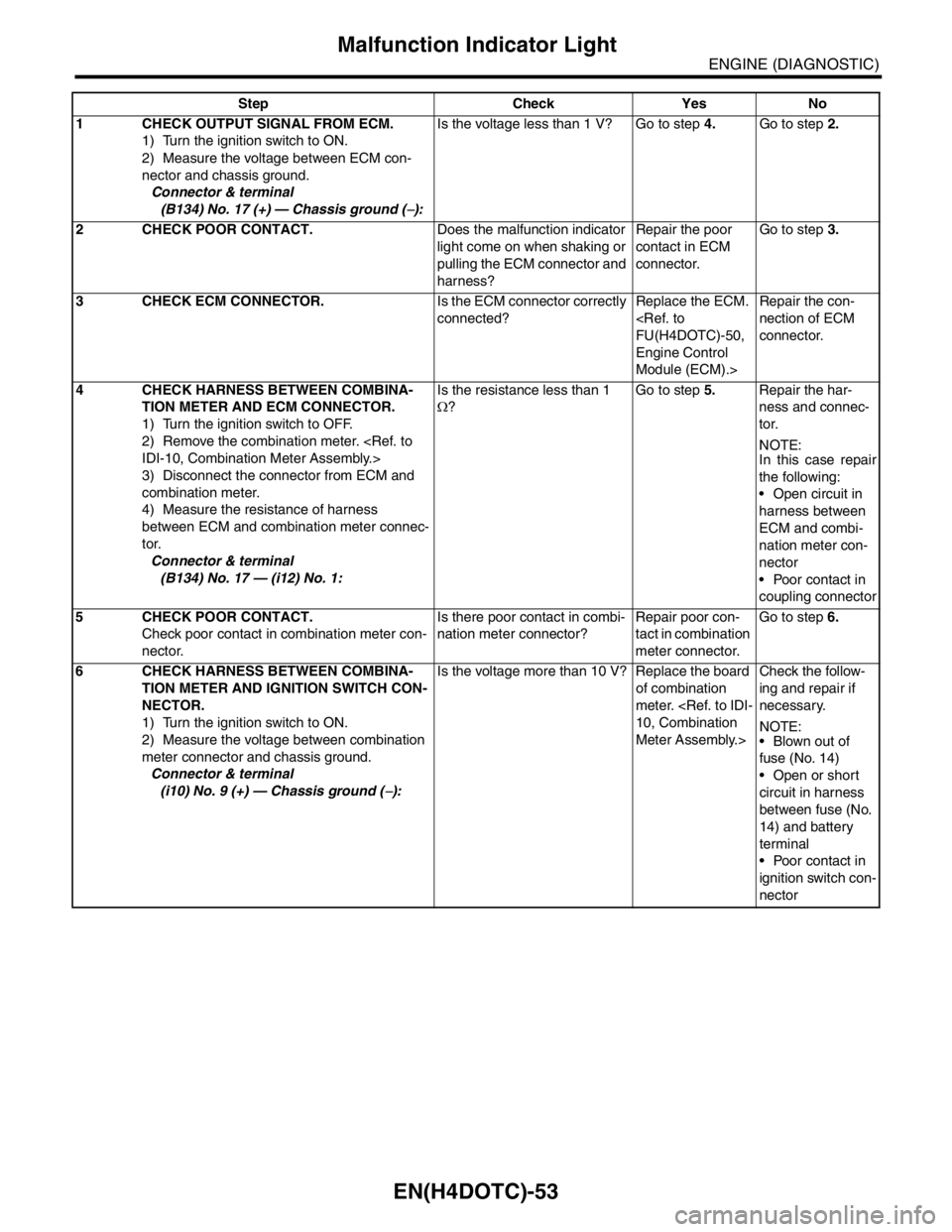

Step Check Yes No

1 CHECK OUTPUT SIGNAL FROM ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B134) No. 17 (+) — Chassis ground (

−):Is the voltage less than 1 V? Go to step 4.Go to step 2.

2 CHECK POOR CONTACT.Does the malfunction indicator

light come on when shaking or

pulling the ECM connector and

harness?Repair the poor

contact in ECM

connector.Go to step 3.

3 CHECK ECM CONNECTOR.Is the ECM connector correctly

connected?Replace the ECM.

Engine Control

Module (ECM).>Repair the con-

nection of ECM

connector.

4 CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Disconnect the connector from ECM and

combination meter.

4) Measure the resistance of harness

between ECM and combination meter connec-

tor.

Connector & terminal

(B134) No. 17 — (i12) No. 1:Is the resistance less than 1

Ω?Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:

In this case repair

the following:

Open circuit in

harness between

ECM and combi-

nation meter con-

nector

Poor contact in

coupling connector

5 CHECK POOR CONTACT.

Check poor contact in combination meter con-

nector.Is there poor contact in combi-

nation meter connector?Repair poor con-

tact in combination

meter connector.Go to step 6.

6 CHECK HARNESS BETWEEN COMBINA-

TION METER AND IGNITION SWITCH CON-

NECTOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 9 (+) — Chassis ground (

−):Is the voltage more than 10 V? Replace the board

of combination

meter.

Meter Assembly.>Check the follow-

ing and repair if

necessary.

N

OTE:

Blown out of

fuse (No. 14)

Open or short

circuit in harness

between fuse (No.

14) and battery

terminal

Poor contact in

ignition switch con-

nector