combination meter SUBARU FORESTER 2004 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1684 of 2870

EN(H4DOTC)-54

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

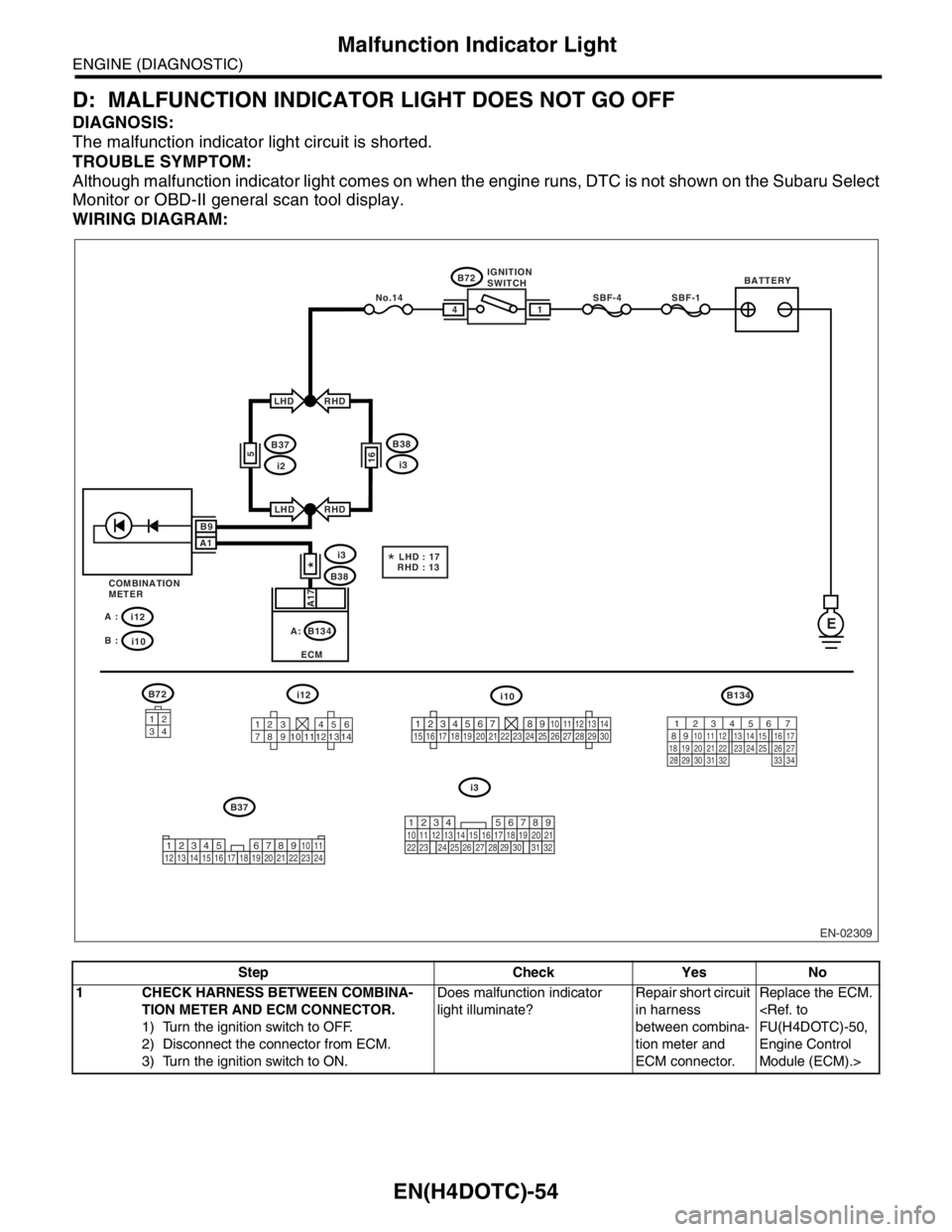

D: MALFUNCTION INDICATOR LIGHT DOES NOT GO OFF

DIAGNOSIS:

The malfunction indicator light circuit is shorted.

TROUBLE SYMPTOM:

Although malfunction indicator light comes on when the engine runs, DTC is not shown on the Subaru Select

Monitor or OBD-II general scan tool display.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Turn the ignition switch to ON.Does malfunction indicator

light illuminate?Repair short circuit

in harness

between combina-

tion meter and

ECM connector.Replace the ECM.

Engine Control

Module (ECM).>

EN-02309

BATTERYIGNITION

SWITCH

SBF-4SBF-1

B72

B72

B38

B134

ECM

i3

E

14

RHD

RHD

A17

B37

i12 A :

i10 B :

i12i10B134

i3

i2

LHD

LHD

5

COMBINATION

METER

3412

123 456

789 121310 11 14

*

16

B38

i3

B37No.14

*LHD : 17

RHD : 13

B9

A1

34

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

12345678910111213141516171819202122232425262728293056 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

A:

Page 1685 of 2870

EN(H4DOTC)-55

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

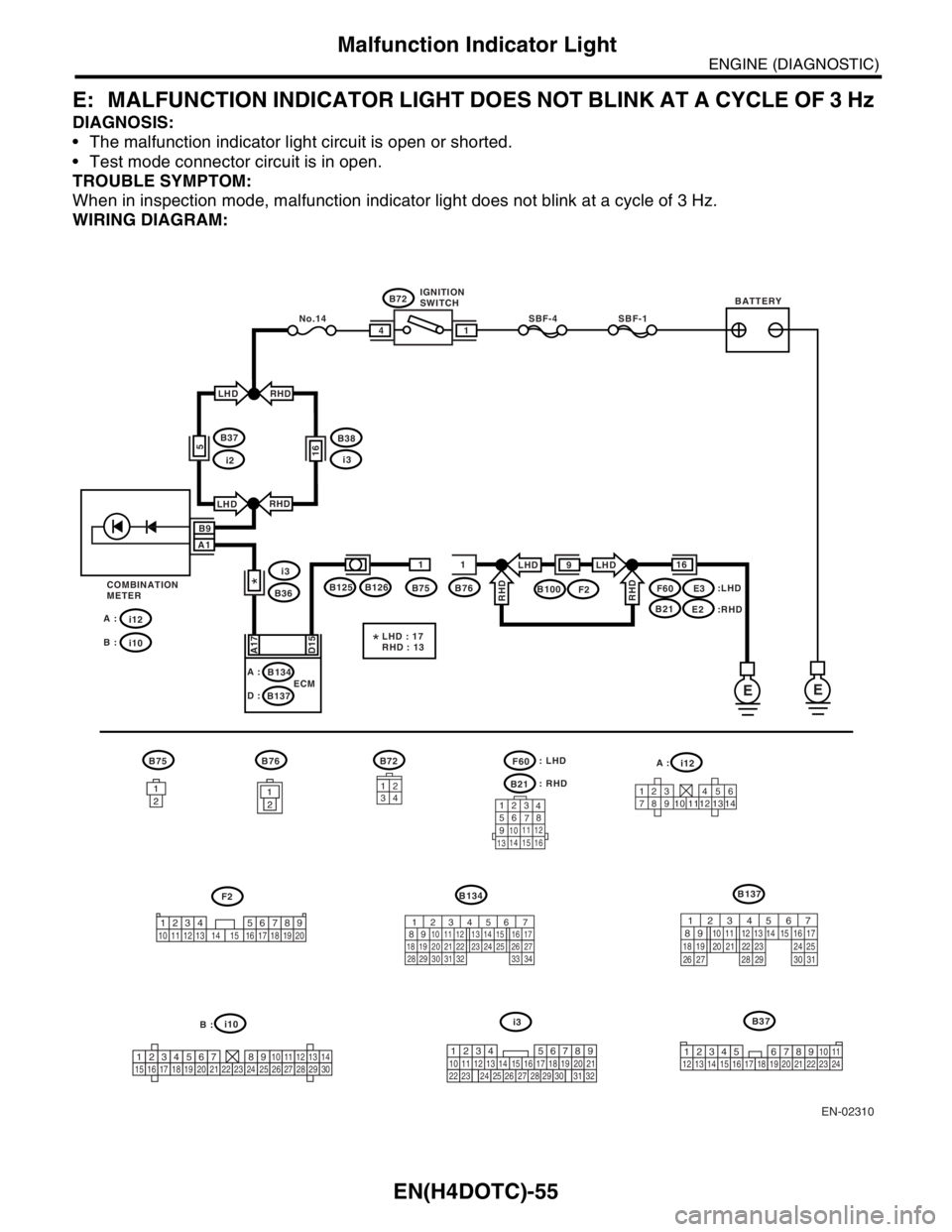

E: MALFUNCTION INDICATOR LIGHT DOES NOT BLINK AT A CYCLE OF 3 Hz

DIAGNOSIS:

The malfunction indicator light circuit is open or shorted.

Test mode connector circuit is in open.

TROUBLE SYMPTOM:

When in inspection mode, malfunction indicator light does not blink at a cycle of 3 Hz.

WIRING DIAGRAM:

EN-02310

BATTERYIGNITION

SWITCH

SBF-4SBF-1

B72

B36B75B76E3F2

E2

B134

B137ECM

i3

EE

14

1611

A17

D15

i12 A :

i10 B :

B125B100B126

A :LHD : 17

RHD : 13

*

D :

RHD

LHDLHD

RHD

9

B9

A1

:LHD

:RHD COMBINATION

METER

*

i2

B37

RHD

RHD

i3

B38

LHD

LHD

16

No.14

F60

B21

5

B72

B21

B75

B134

B76i12

i10

B137

i3: RHD

F60: LHD

34

12

123 456

789 121310 11 14

123

4

56

78

9

1011 12

1314 15 16

1

21

21

21

2

B37

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

123456789101112131415161718192021222324252627282930219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

2534

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

A :

B :

1234 5678910 11 12 13 14 15 16 17 18 19 20

F2

Page 1686 of 2870

EN(H4DOTC)-56

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

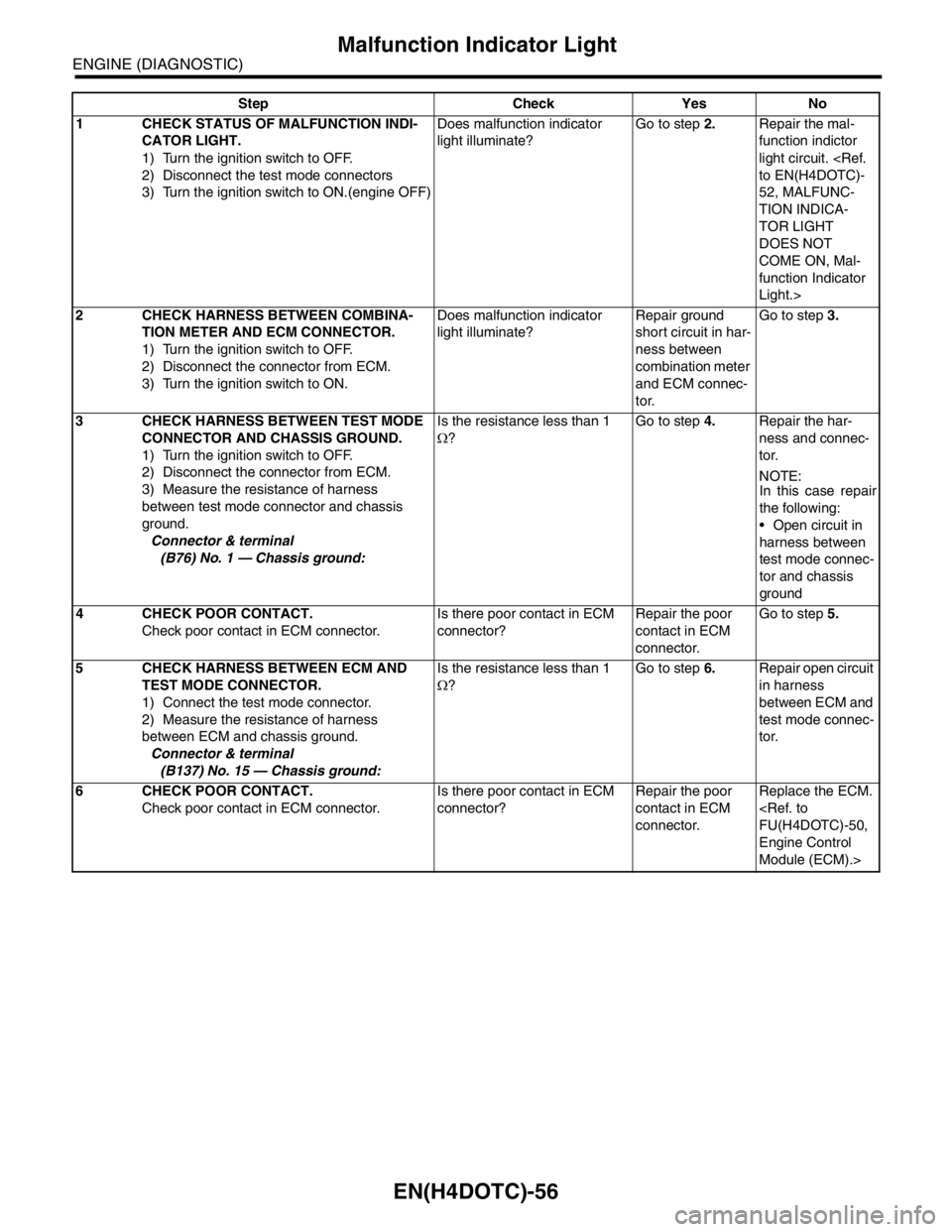

Step Check Yes No

1 CHECK STATUS OF MALFUNCTION INDI-

CATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the test mode connectors

3) Turn the ignition switch to ON.(engine OFF)Does malfunction indicator

light illuminate?Go to step 2.Repair the mal-

function indictor

light circuit.

52, MALFUNC-

TION INDICA-

TOR LIGHT

DOES NOT

COME ON, Mal-

function Indicator

Light.>

2 CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Turn the ignition switch to ON.Does malfunction indicator

light illuminate?Repair ground

short circuit in har-

ness between

combination meter

and ECM connec-

tor.Go to step 3.

3 CHECK HARNESS BETWEEN TEST MODE

CONNECTOR AND CHASSIS GROUND.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness

between test mode connector and chassis

ground.

Connector & terminal

(B76) No. 1 — Chassis ground:Is the resistance less than 1

Ω?Go to step 4.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

test mode connec-

tor and chassis

ground

4 CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Go to step 5.

5 CHECK HARNESS BETWEEN ECM AND

TEST MODE CONNECTOR.

1) Connect the test mode connector.

2) Measure the resistance of harness

between ECM and chassis ground.

Connector & terminal

(B137) No. 15 — Chassis ground:Is the resistance less than 1

Ω?Go to step 6.Repair open circuit

in harness

between ECM and

test mode connec-

tor.

6 CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM

connector?Repair the poor

contact in ECM

connector.Replace the ECM.

Engine Control

Module (ECM).>

Page 1687 of 2870

EN(H4DOTC)-57

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

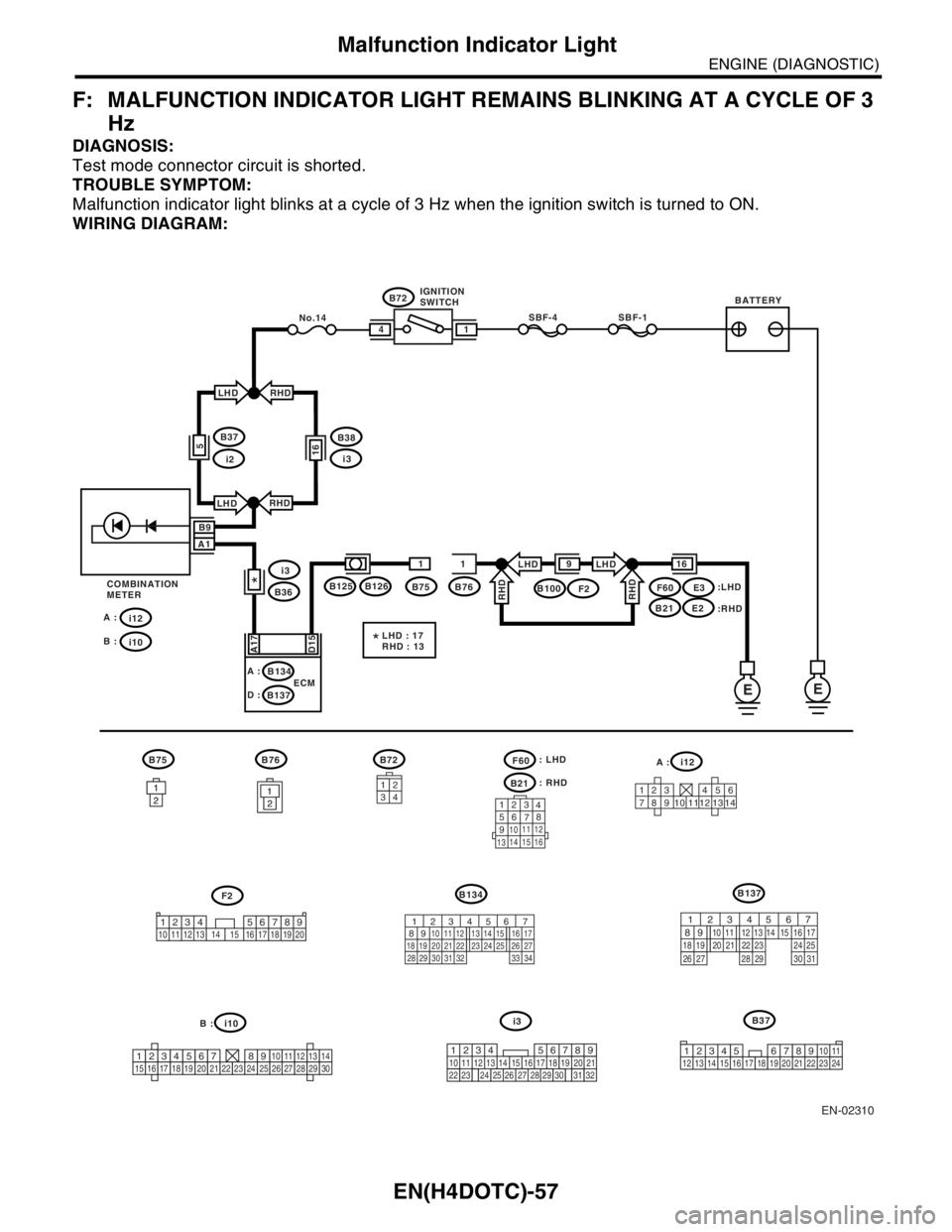

F: MALFUNCTION INDICATOR LIGHT REMAINS BLINKING AT A CYCLE OF 3

Hz

DIAGNOSIS:

Test mode connector circuit is shorted.

TROUBLE SYMPTOM:

Malfunction indicator light blinks at a cycle of 3 Hz when the ignition switch is turned to ON.

WIRING DIAGRAM:

EN-02310

BATTERYIGNITION

SWITCH

SBF-4SBF-1

B72

B36B75B76E3F2

E2

B134

B137ECM

i3

EE

14

1611

A17

D15

i12 A :

i10 B :

B125B100B126

A :LHD : 17

RHD : 13

*

D :

RHD

LHDLHD

RHD

9

B9

A1

:LHD

:RHD COMBINATION

METER

*

i2

B37

RHD

RHD

i3

B38

LHD

LHD

16

No.14

F60

B21

5

B72

B21

B75

B134

B76i12

i10

B137

i3: RHD

F60: LHD

34

12

123 456

789 121310 11 14

123

4

56

78

9

1011 12

1314 15 16

1

21

21

21

2

B37

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

123456789101112131415161718192021222324252627282930219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

2534

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

A :

B :

1234 5678910 11 12 13 14 15 16 17 18 19 20

F2

Page 1825 of 2870

EN(H4DOTC)-192

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

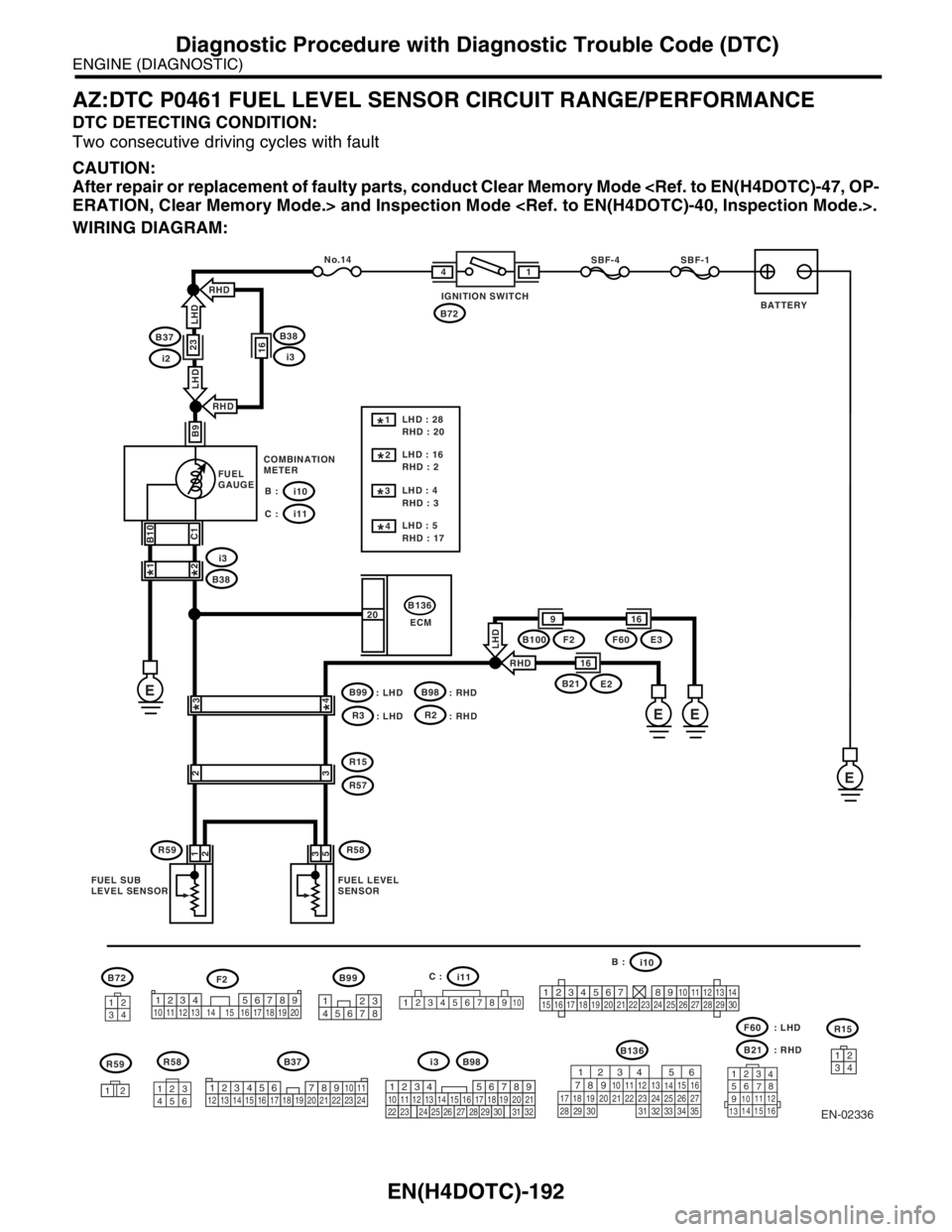

AZ:DTC P0461 FUEL LEVEL SENSOR CIRCUIT RANGE/PERFORMANCE

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

B72

R59R58

F60 : LHD

B21 : RHD

i10

B136

i11

1

23456789

10

R15

B136

ECM

i10

B38

B100F2F60E3

E2

B99

R3

i3

EE

E

RHD

RHD

LHD

FUEL

GAUGE

B :

i11 C :

C : B : COMBINATION

METER

B9 B10

C1

3*

*4

R15

R59

FUEL SUB

LEVEL SENSOR

R572

1

2R583

53

FUEL LEVEL

SENSOR

9

B21

16

16 20

3412

1213

4562123

4

56

78

9

1011 12

1314 15 16

F2LHD : 28

RHD : 20

LHD : 16

RHD : 2

*1

*2

LHD : 4

RHD : 3

LHD : 5

RHD : 17*3

*4

EN-02336

3412i3B98B37

B99

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 20123

45678

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

2534

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

: LHDB98

: RHD

: LHD

R2

: RHD

1*2*

B37

i223

IGNITION SWITCH

SBF-4SBF-1

B72

14

E

No.14

RHD

B38

i316

LHD

LHD

RHDBATTERY

Page 1827 of 2870

EN(H4DOTC)-194

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

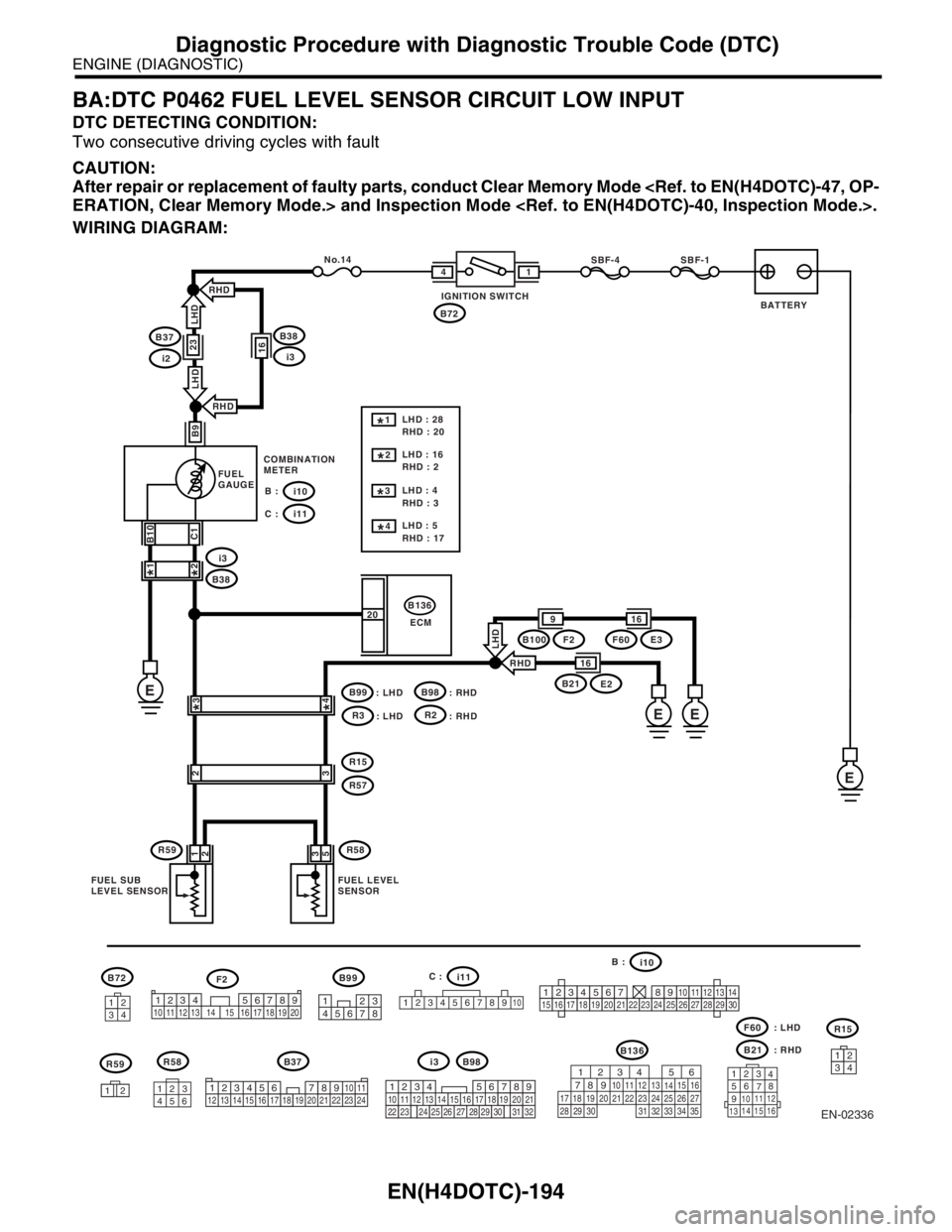

BA:DTC P0462 FUEL LEVEL SENSOR CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

B72

R59R58

F60 : LHD

B21 : RHD

i10

B136

i11

1

23456789

10

R15

B136

ECM

i10

B38

B100F2F60E3

E2

B99

R3

i3

EE

E

RHD

RHD

LHD

FUEL

GAUGE

B :

i11 C :

C : B : COMBINATION

METER

B9 B10

C1

3*

*4

R15

R59

FUEL SUB

LEVEL SENSOR

R572

1

2R583

53

FUEL LEVEL

SENSOR

9

B21

16

16 20

3412

1213

4562123

4

56

78

9

1011 12

1314 15 16

F2LHD : 28

RHD : 20

LHD : 16

RHD : 2

*1

*2

LHD : 4

RHD : 3

LHD : 5

RHD : 17*3

*4

EN-02336

3412i3B98B37

B99

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 20123

45678

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

2534

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

: LHDB98

: RHD

: LHD

R2

: RHD

1*2*

B37

i223

IGNITION SWITCH

SBF-4SBF-1

B72

14

E

No.14

RHD

B38

i316

LHD

LHD

RHDBATTERY

Page 1828 of 2870

EN(H4DOTC)-195

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

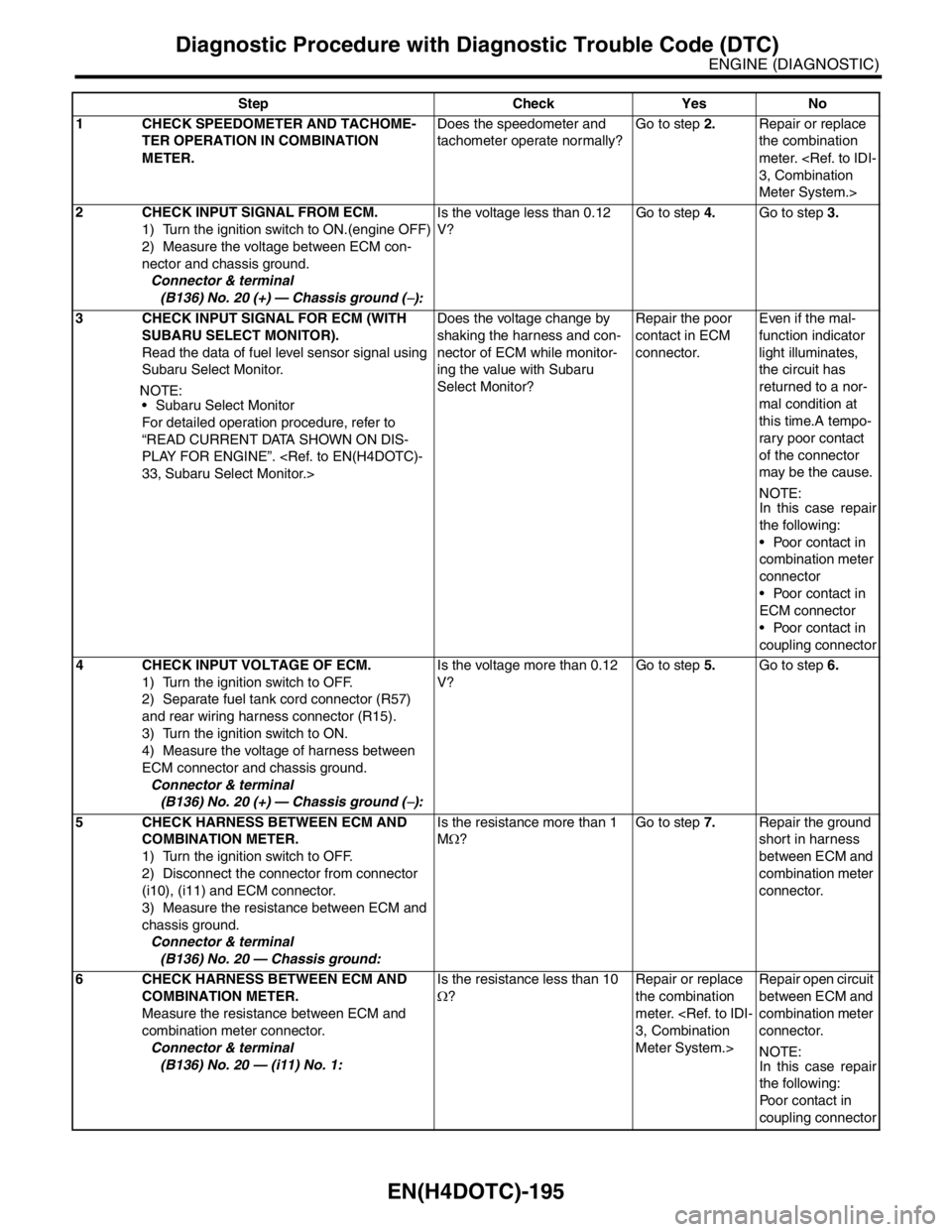

Step Check Yes No

1 CHECK SPEEDOMETER AND TACHOME-

TER OPERATION IN COMBINATION

METER.Does the speedometer and

tachometer operate normally?Go to step 2.Repair or replace

the combination

meter.

Meter System.>

2 CHECK INPUT SIGNAL FROM ECM.

1) Turn the ignition switch to ON.(engine OFF)

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (

−):Is the voltage less than 0.12

V?Go to step 4.Go to step 3.

3 CHECK INPUT SIGNAL FOR ECM (WITH

SUBARU SELECT MONITOR).

Read the data of fuel level sensor signal using

Subaru Select Monitor.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

shaking the harness and con-

nector of ECM while monitor-

ing the value with Subaru

Select Monitor?Repair the poor

contact in ECM

connector.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.A tempo-

rary poor contact

of the connector

may be the cause.

N

OTE:

In this case repair

the following:

Poor contact in

combination meter

connector

Poor contact in

ECM connector

Poor contact in

coupling connector

4 CHECK INPUT VOLTAGE OF ECM.

1) Turn the ignition switch to OFF.

2) Separate fuel tank cord connector (R57)

and rear wiring harness connector (R15).

3) Turn the ignition switch to ON.

4) Measure the voltage of harness between

ECM connector and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (

−):Is the voltage more than 0.12

V?Go to step 5.Go to step 6.

5 CHECK HARNESS BETWEEN ECM AND

COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from connector

(i10), (i11) and ECM connector.

3) Measure the resistance between ECM and

chassis ground.

Connector & terminal

(B136) No. 20 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 7.Repair the ground

short in harness

between ECM and

combination meter

connector.

6 CHECK HARNESS BETWEEN ECM AND

COMBINATION METER.

Measure the resistance between ECM and

combination meter connector.

Connector & terminal

(B136) No. 20 — (i11) No. 1:Is the resistance less than 10

Ω?Repair or replace

the combination

meter.

Meter System.>Repair open circuit

between ECM and

combination meter

connector.

N

OTE:

In this case repair

the following:

Poor contact in

coupling connector

Page 1829 of 2870

EN(H4DOTC)-196

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

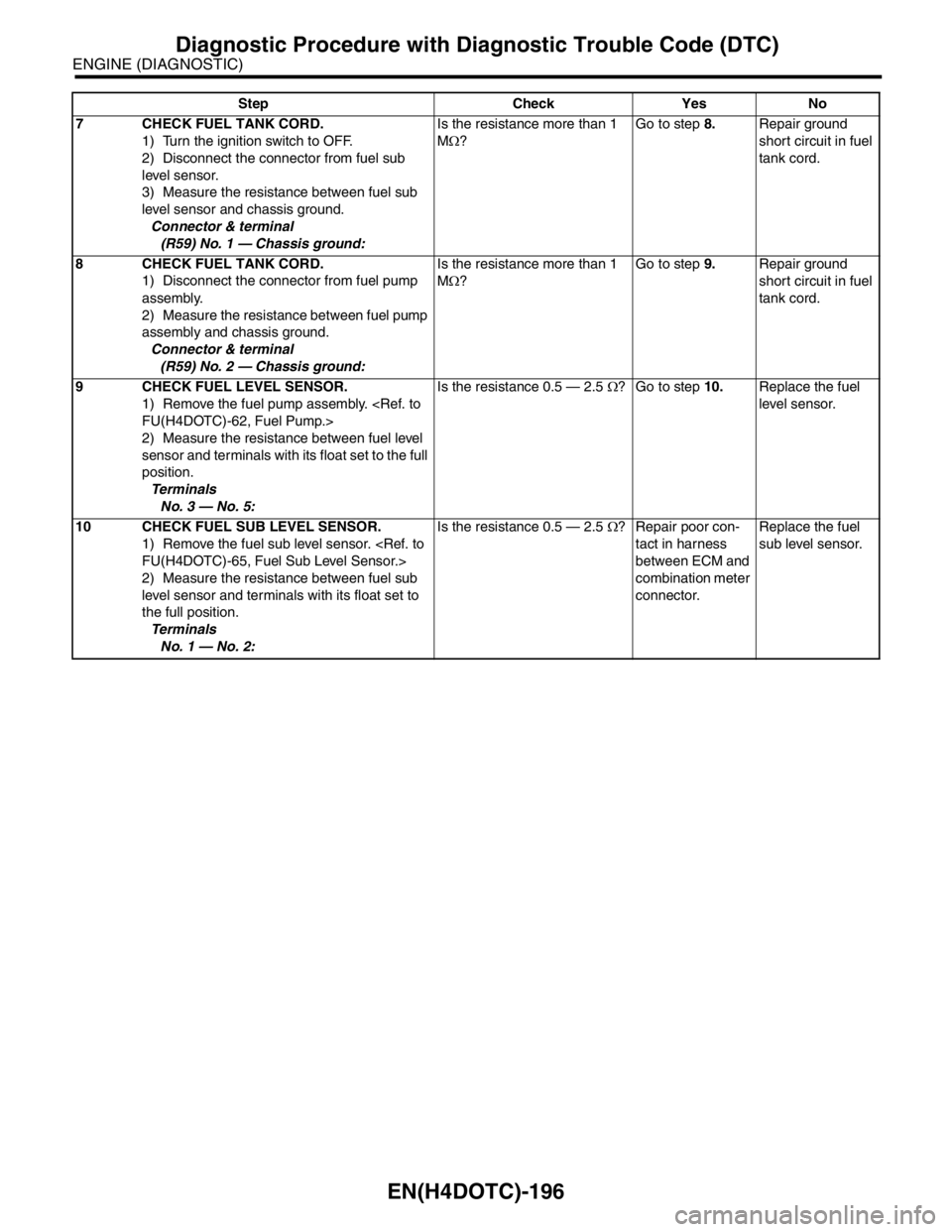

7 CHECK FUEL TANK CORD.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel sub

level sensor.

3) Measure the resistance between fuel sub

level sensor and chassis ground.

Connector & terminal

(R59) No. 1 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 8.Repair ground

short circuit in fuel

tank cord.

8 CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel pump

assembly.

2) Measure the resistance between fuel pump

assembly and chassis ground.

Connector & terminal

(R59) No. 2 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 9.Repair ground

short circuit in fuel

tank cord.

9 CHECK FUEL LEVEL SENSOR.

1) Remove the fuel pump assembly.

2) Measure the resistance between fuel level

sensor and terminals with its float set to the full

position.

Te r m i n a l s

No. 3 — No. 5:Is the resistance 0.5 — 2.5 Ω? Go to step 10.Replace the fuel

level sensor.

10 CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

2) Measure the resistance between fuel sub

level sensor and terminals with its float set to

the full position.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 0.5 — 2.5 Ω? Repair poor con-

tact in harness

between ECM and

combination meter

connector.Replace the fuel

sub level sensor. Step Check Yes No

Page 1830 of 2870

EN(H4DOTC)-197

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

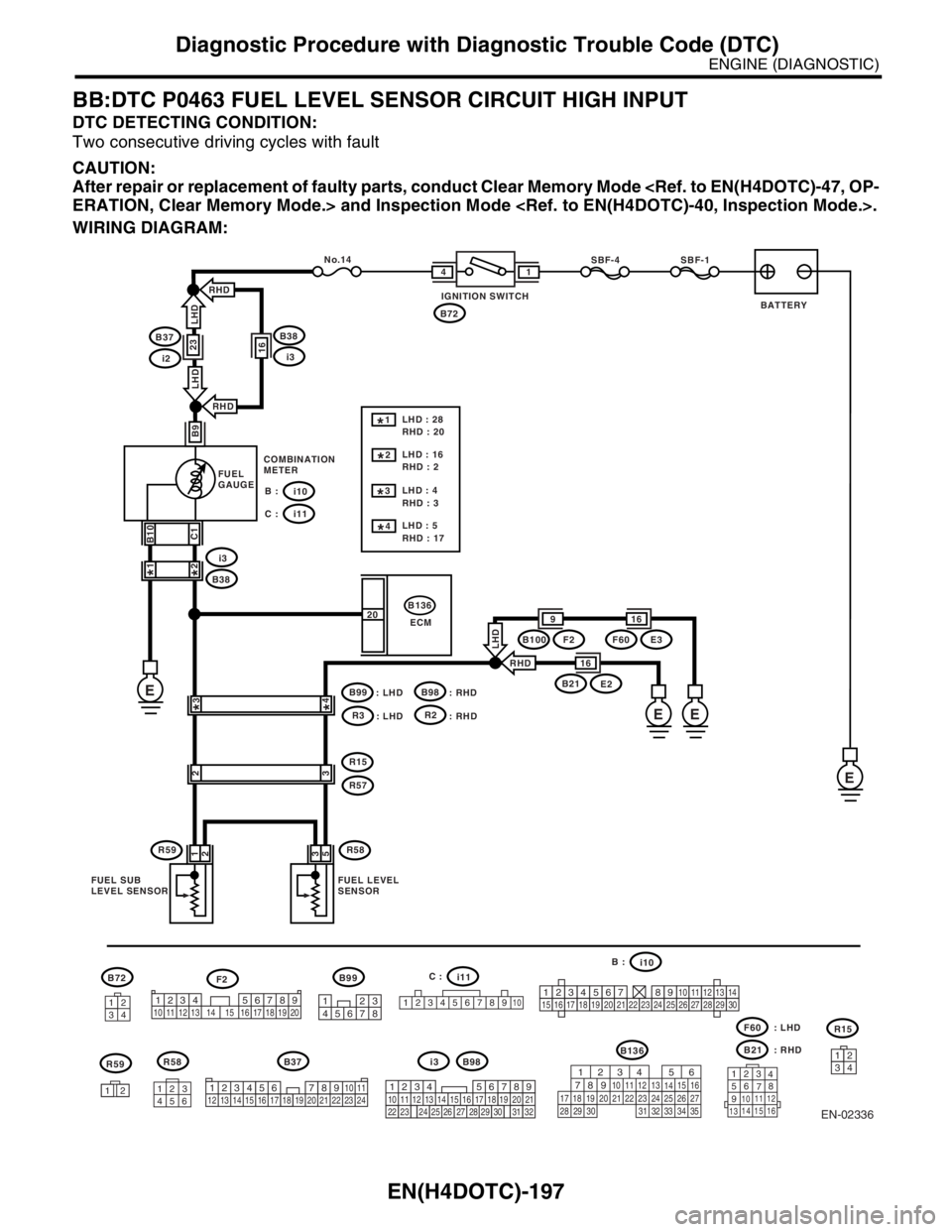

BB:DTC P0463 FUEL LEVEL SENSOR CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

B72

R59R58

F60 : LHD

B21 : RHD

i10

B136

i11

1

23456789

10

R15

B136

ECM

i10

B38

B100F2F60E3

E2

B99

R3

i3

EE

E

RHD

RHD

LHD

FUEL

GAUGE

B :

i11 C :

C : B : COMBINATION

METER

B9 B10

C1

3*

*4

R15

R59

FUEL SUB

LEVEL SENSOR

R572

1

2R583

53

FUEL LEVEL

SENSOR

9

B21

16

16 20

3412

1213

4562123

4

56

78

9

1011 12

1314 15 16

F2LHD : 28

RHD : 20

LHD : 16

RHD : 2

*1

*2

LHD : 4

RHD : 3

LHD : 5

RHD : 17*3

*4

EN-02336

3412i3B98B37

B99

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 20123

45678

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

2534

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

: LHDB98

: RHD

: LHD

R2

: RHD

1*2*

B37

i223

IGNITION SWITCH

SBF-4SBF-1

B72

14

E

No.14

RHD

B38

i316

LHD

LHD

RHDBATTERY

Page 1831 of 2870

EN(H4DOTC)-198

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

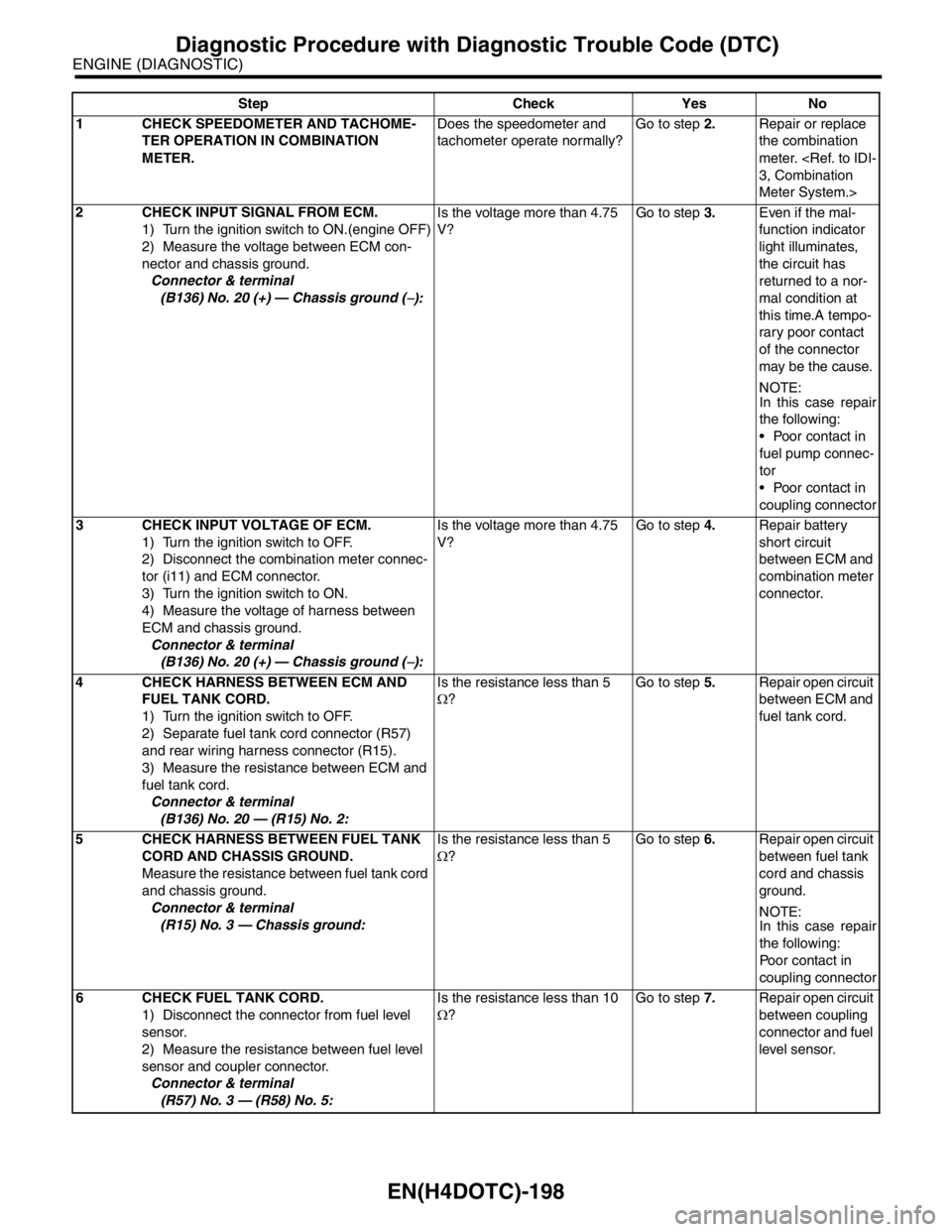

Step Check Yes No

1 CHECK SPEEDOMETER AND TACHOME-

TER OPERATION IN COMBINATION

METER.Does the speedometer and

tachometer operate normally?Go to step 2.Repair or replace

the combination

meter.

Meter System.>

2 CHECK INPUT SIGNAL FROM ECM.

1) Turn the ignition switch to ON.(engine OFF)

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (

−):Is the voltage more than 4.75

V?Go to step 3.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.A tempo-

rary poor contact

of the connector

may be the cause.

N

OTE:

In this case repair

the following:

Poor contact in

fuel pump connec-

tor

Poor contact in

coupling connector

3 CHECK INPUT VOLTAGE OF ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the combination meter connec-

tor (i11) and ECM connector.

3) Turn the ignition switch to ON.

4) Measure the voltage of harness between

ECM and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (

−):Is the voltage more than 4.75

V?Go to step 4.Repair battery

short circuit

between ECM and

combination meter

connector.

4 CHECK HARNESS BETWEEN ECM AND

FUEL TANK CORD.

1) Turn the ignition switch to OFF.

2) Separate fuel tank cord connector (R57)

and rear wiring harness connector (R15).

3) Measure the resistance between ECM and

fuel tank cord.

Connector & terminal

(B136) No. 20 — (R15) No. 2:Is the resistance less than 5

Ω?Go to step 5.Repair open circuit

between ECM and

fuel tank cord.

5 CHECK HARNESS BETWEEN FUEL TANK

CORD AND CHASSIS GROUND.

Measure the resistance between fuel tank cord

and chassis ground.

Connector & terminal

(R15) No. 3 — Chassis ground:Is the resistance less than 5

Ω?Go to step 6.Repair open circuit

between fuel tank

cord and chassis

ground.

N

OTE:

In this case repair

the following:

Poor contact in

coupling connector

6 CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel level

sensor.

2) Measure the resistance between fuel level

sensor and coupler connector.

Connector & terminal

(R57) No. 3 — (R58) No. 5:Is the resistance less than 10

Ω?Go to step 7.Repair open circuit

between coupling

connector and fuel

level sensor.