torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2638 of 2870

4AT(H4DOTC)-62

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

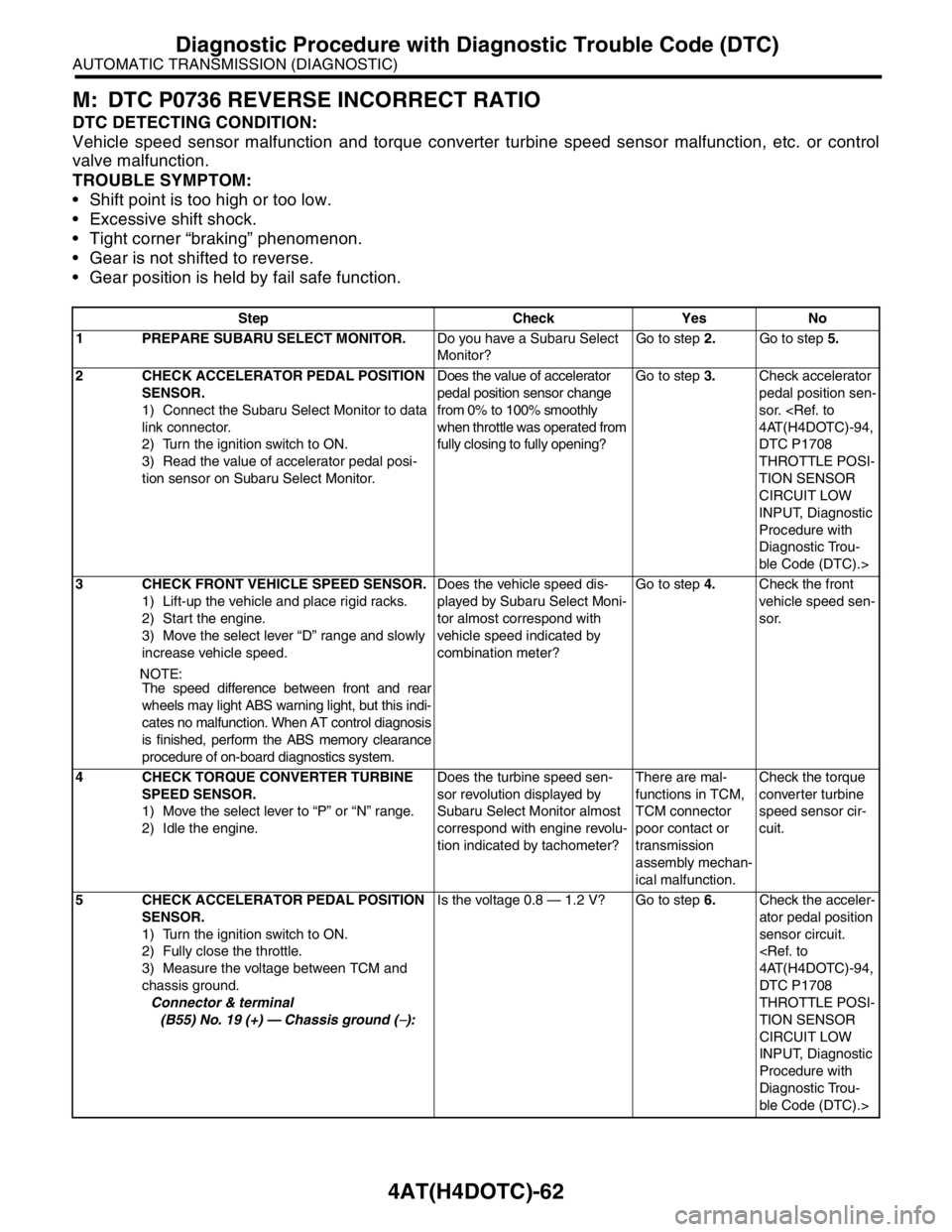

M: DTC P0736 REVERSE INCORRECT RATIO

DTC DETECTING CONDITION:

Vehicle speed sensor malfunction and torque converter turbine speed sensor malfunction, etc. or control

valve malfunction.

TROUBLE SYMPTOM:

Shift point is too high or too low.

Excessive shift shock.

Tight corner “braking” phenomenon.

Gear is not shifted to reverse.

Gear position is held by fail safe function.

Step Check Yes No

1 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 2.Go to step 5.

2 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch to ON.

3) Read the value of accelerator pedal posi-

tion sensor on Subaru Select Monitor.Does the value of accelerator

pedal position sensor change

from 0% to 100% smoothly

when throttle was operated from

fully closing to fully opening?Go to step 3.Check accelerator

pedal position sen-

sor.

DTC P1708

THROTTLE POSI-

TION SENSOR

CIRCUIT LOW

INPUT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

3 CHECK FRONT VEHICLE SPEED SENSOR.

1) Lift-up the vehicle and place rigid racks.

2) Start the engine.

3) Move the select lever “D” range and slowly

increase vehicle speed.

NOTE:

The speed difference between front and rear

wheels may light ABS warning light, but this indi-

cates no malfunction. When AT control diagnosis

is finished, perform the ABS memory clearance

procedure of on-board diagnostics system.Does the vehicle speed dis-

played by Subaru Select Moni-

tor almost correspond with

vehicle speed indicated by

combination meter?Go to step 4.Check the front

vehicle speed sen-

sor.

4 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Move the select lever to “P” or “N” range.

2) Idle the engine.Does the turbine speed sen-

sor revolution displayed by

Subaru Select Monitor almost

correspond with engine revolu-

tion indicated by tachometer?There are mal-

functions in TCM,

TCM connector

poor contact or

transmission

assembly mechan-

ical malfunction.Check the torque

converter turbine

speed sensor cir-

cuit.

5 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Turn the ignition switch to ON.

2) Fully close the throttle.

3) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage 0.8 — 1.2 V? Go to step 6.Check the acceler-

ator pedal position

sensor circuit.

DTC P1708

THROTTLE POSI-

TION SENSOR

CIRCUIT LOW

INPUT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

Page 2639 of 2870

4AT(H4DOTC)-63

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

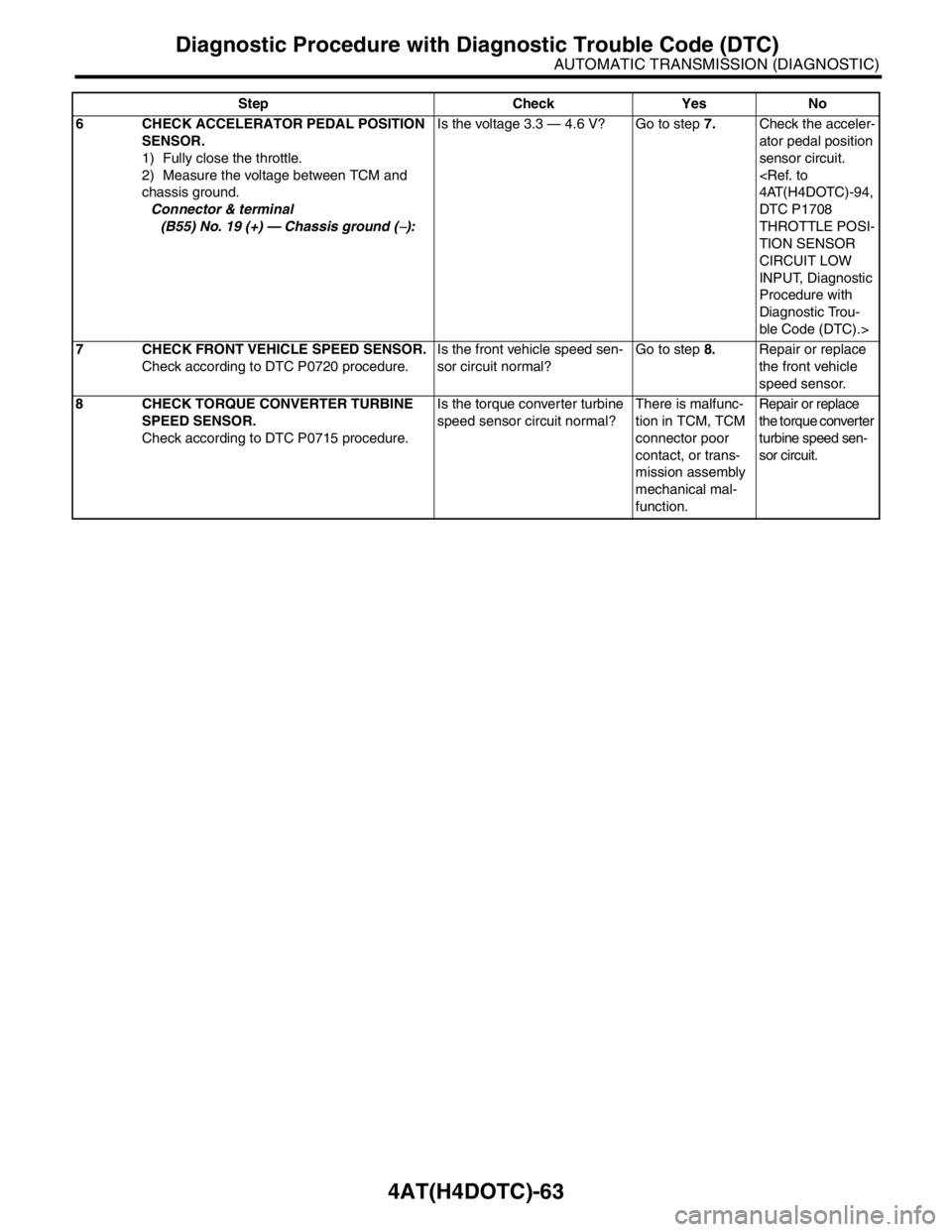

6 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Fully close the throttle.

2) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage 3.3 — 4.6 V? Go to step 7.Check the acceler-

ator pedal position

sensor circuit.

DTC P1708

THROTTLE POSI-

TION SENSOR

CIRCUIT LOW

INPUT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

7 CHECK FRONT VEHICLE SPEED SENSOR.

Check according to DTC P0720 procedure.Is the front vehicle speed sen-

sor circuit normal?Go to step 8.Repair or replace

the front vehicle

speed sensor.

8 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

Check according to DTC P0715 procedure.Is the torque converter turbine

speed sensor circuit normal?There is malfunc-

tion in TCM, TCM

connector poor

contact, or trans-

mission assembly

mechanical mal-

function.Repair or replace

the torque converter

turbine speed sen-

sor circuit. Step Check Yes No

Page 2640 of 2870

4AT(H4DOTC)-64

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

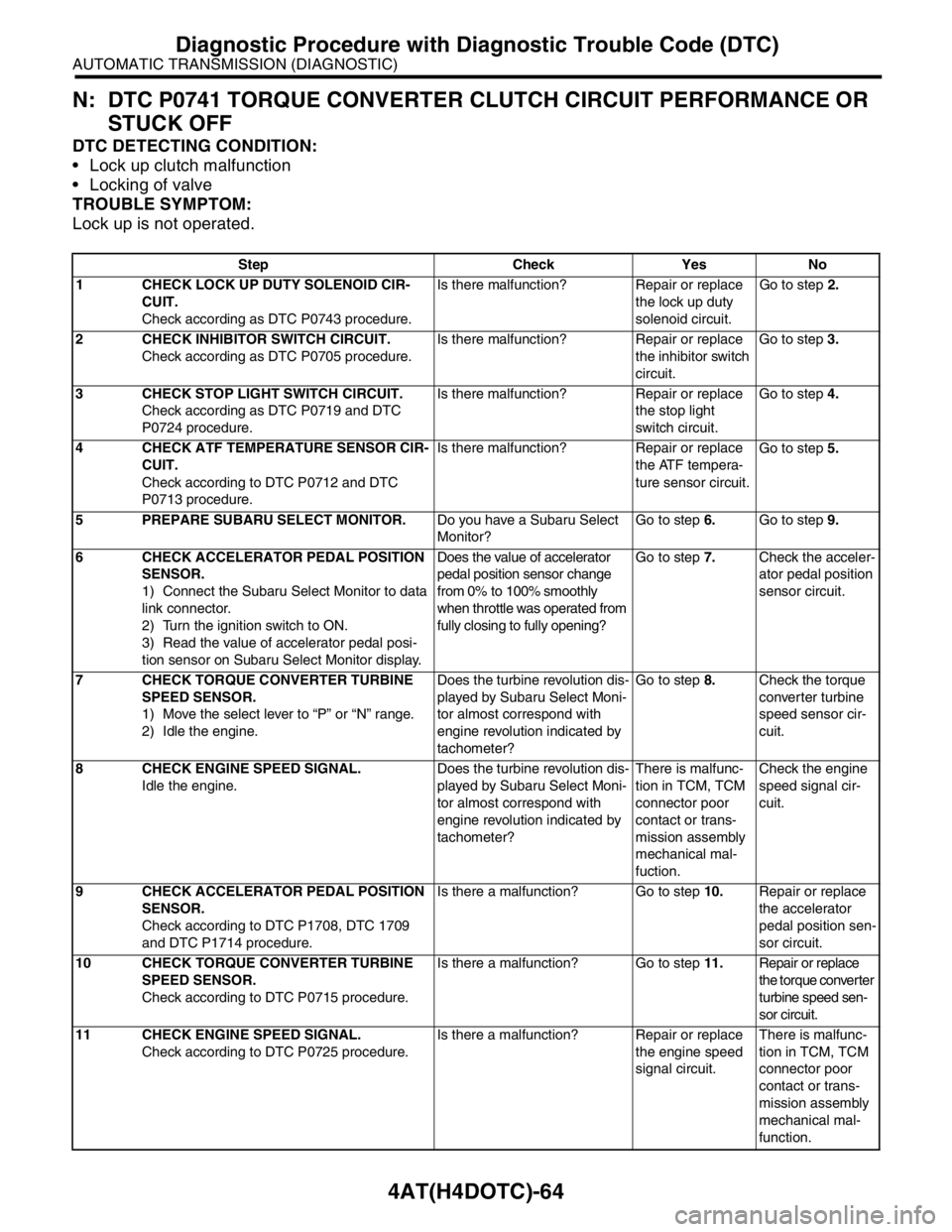

N: DTC P0741 TORQUE CONVERTER CLUTCH CIRCUIT PERFORMANCE OR

STUCK OFF

DTC DETECTING CONDITION:

Lock up clutch malfunction

Locking of valve

TROUBLE SYMPTOM:

Lock up is not operated.

Step Check Yes No

1 CHECK LOCK UP DUTY SOLENOID CIR-

CUIT.

Check according as DTC P0743 procedure.Is there malfunction? Repair or replace

the lock up duty

solenoid circuit.Go to step 2.

2 CHECK INHIBITOR SWITCH CIRCUIT.

Check according as DTC P0705 procedure.Is there malfunction? Repair or replace

the inhibitor switch

circuit.Go to step 3.

3 CHECK STOP LIGHT SWITCH CIRCUIT.

Check according as DTC P0719 and DTC

P0724 procedure.Is there malfunction? Repair or replace

the stop light

switch circuit.Go to step 4.

4 CHECK ATF TEMPERATURE SENSOR CIR-

CUIT.

Check according to DTC P0712 and DTC

P0713 procedure.Is there malfunction? Repair or replace

the ATF tempera-

ture sensor circuit.Go to step 5.

5 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 6.Go to step 9.

6 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch to ON.

3) Read the value of accelerator pedal posi-

tion sensor on Subaru Select Monitor display.Does the value of accelerator

pedal position sensor change

from 0% to 100% smoothly

when throttle was operated from

fully closing to fully opening?Go to step 7.Check the acceler-

ator pedal position

sensor circuit.

7 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Move the select lever to “P” or “N” range.

2) Idle the engine.Does the turbine revolution dis-

played by Subaru Select Moni-

tor almost correspond with

engine revolution indicated by

tachometer?Go to step 8.Check the torque

converter turbine

speed sensor cir-

cuit.

8 CHECK ENGINE SPEED SIGNAL.

Idle the engine.Does the turbine revolution dis-

played by Subaru Select Moni-

tor almost correspond with

engine revolution indicated by

tachometer?There is malfunc-

tion in TCM, TCM

connector poor

contact or trans-

mission assembly

mechanical mal-

fuction.Check the engine

speed signal cir-

cuit.

9 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Check according to DTC P1708, DTC 1709

and DTC P1714 procedure.Is there a malfunction? Go to step 10.Repair or replace

the accelerator

pedal position sen-

sor circuit.

10 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

Check according to DTC P0715 procedure.Is there a malfunction? Go to step 11.Repair or replace

the torque converter

turbine speed sen-

sor circuit.

11 CHECK ENGINE SPEED SIGNAL.

Check according to DTC P0725 procedure.Is there a malfunction? Repair or replace

the engine speed

signal circuit. There is malfunc-

tion in TCM, TCM

connector poor

contact or trans-

mission assembly

mechanical mal-

function.

Page 2641 of 2870

4AT(H4DOTC)-65

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

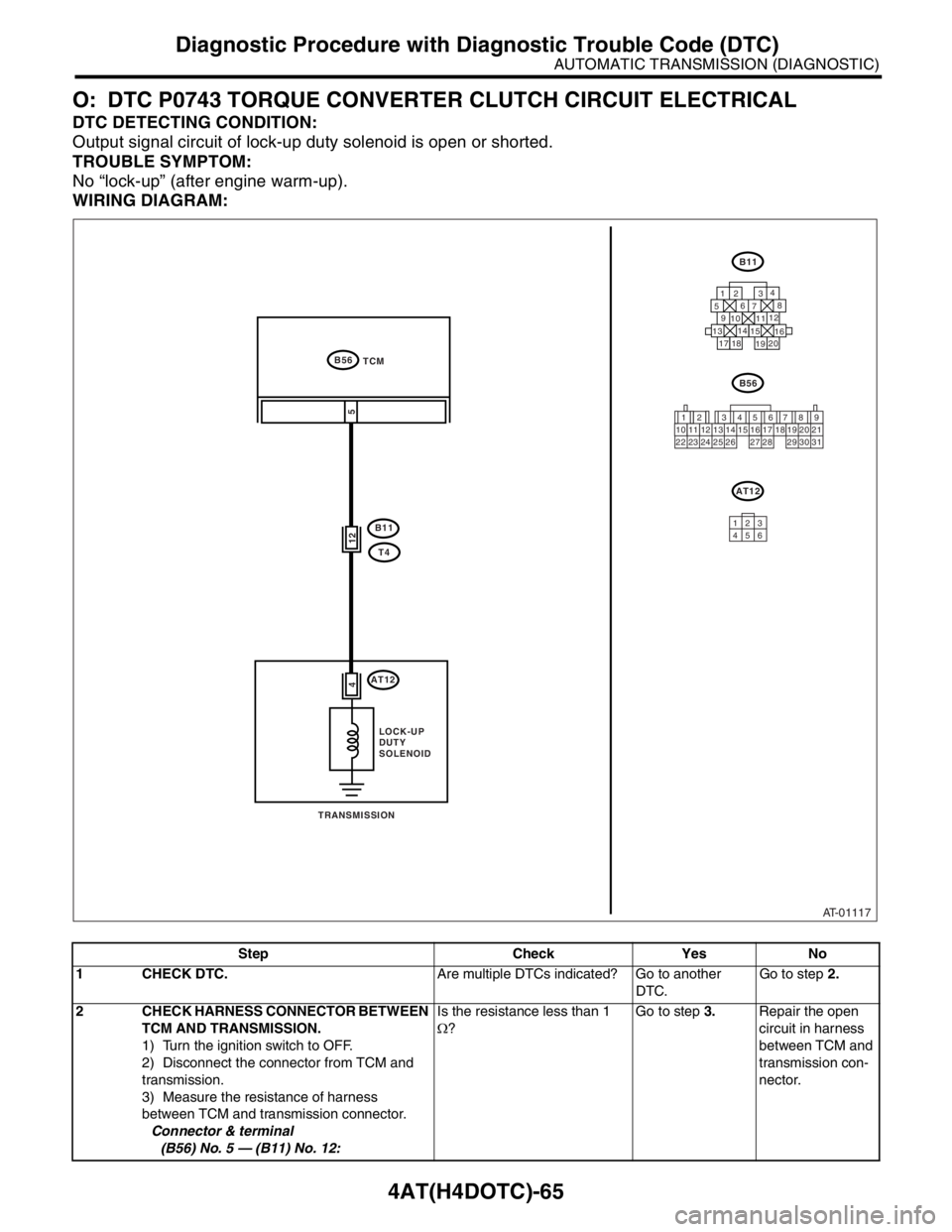

O: DTC P0743 TORQUE CONVERTER CLUTCH CIRCUIT ELECTRICAL

DTC DETECTING CONDITION:

Output signal circuit of lock-up duty solenoid is open or shorted.

TROUBLE SYMPTOM:

No “lock-up” (after engine warm-up).

WIRING DIAGRAM:

Step Check Yes No

1 CHECK DTC.Are multiple DTCs indicated? Go to another

DTC.Go to step 2.

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B56) No. 5 — (B11) No. 12:Is the resistance less than 1

Ω?Go to step 3.Repair the open

circuit in harness

between TCM and

transmission con-

nector.

AT-01117

B11

B56

AT12

1

234

56

78

9

1314

15

20

19 1716 10 1112

18

5

B56

B11

AT12

T4 TCM12 4

12 78 956 34

10 11 12 19 20 21

29 30 31 13 14 15 16 17

27 2818

22 23 24 25 26

13

4562

LOCK-UP

DUTY

SOLENOID

TRANSMISSION

Page 2703 of 2870

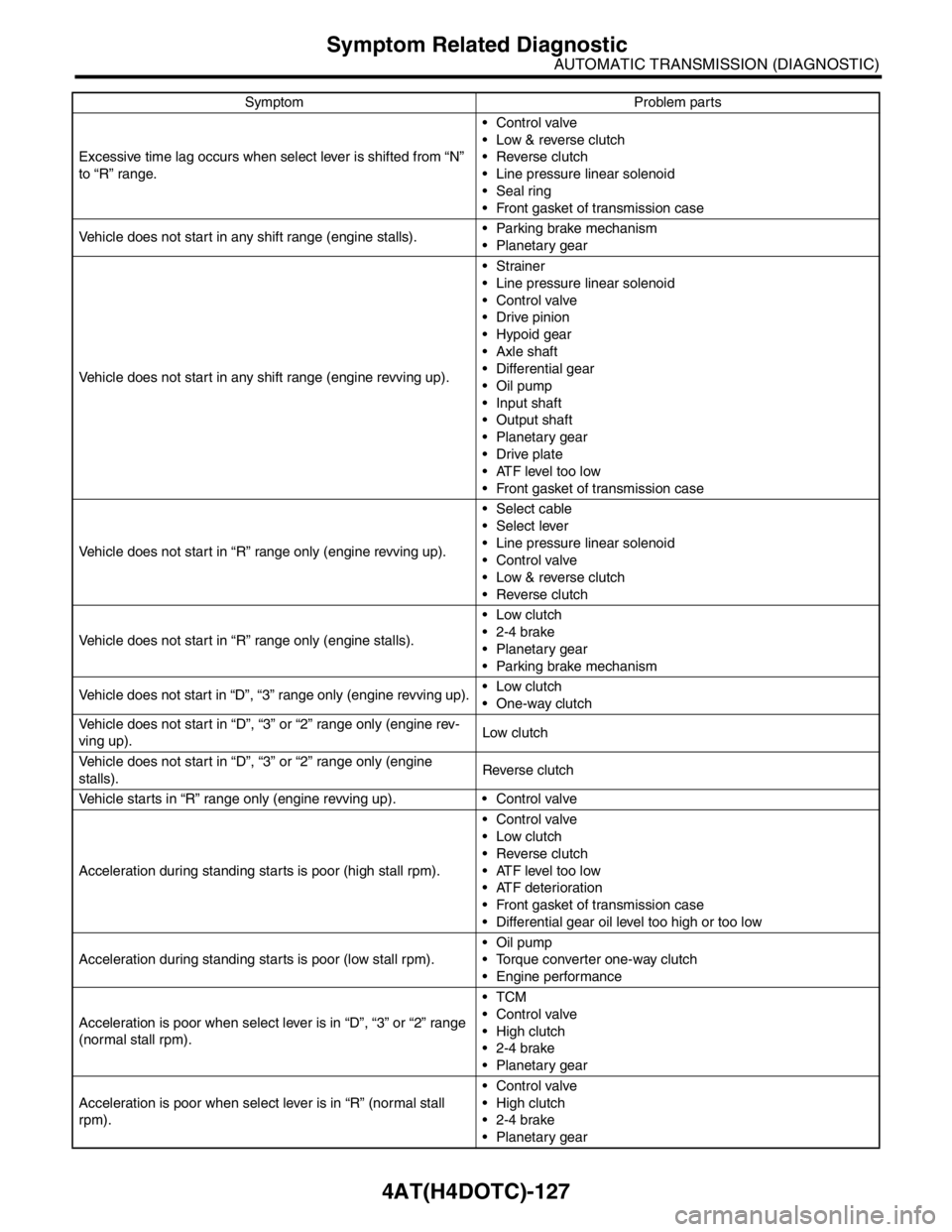

4AT(H4DOTC)-127

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

Excessive time lag occurs when select lever is shifted from “N”

to “R” range. Control valve

Low & reverse clutch

Reverse clutch

Line pressure linear solenoid

Seal ring

Front gasket of transmission case

Vehicle does not start in any shift range (engine stalls). Parking brake mechanism

Planetary gear

Vehicle does not start in any shift range (engine revving up). Strainer

Line pressure linear solenoid

Control valve

Drive pinion

Hypoid gear

Axle shaft

Differential gear

Oil pump

Input shaft

Output shaft

Planetary gear

Drive plate

ATF level too low

Front gasket of transmission case

Vehicle does not start in “R” range only (engine revving up). Select cable

Select lever

Line pressure linear solenoid

Control valve

Low & reverse clutch

Reverse clutch

Vehicle does not start in “R” range only (engine stalls). Low clutch

2-4 brake

Planetary gear

Parking brake mechanism

Vehicle does not start in “D”, “3” range only (engine revving up). Low clutch

One-way clutch

Vehicle does not start in “D”, “3” or “2” range only (engine rev-

ving up).Low clutch

Vehicle does not start in “D”, “3” or “2” range only (engine

stalls).Reverse clutch

Vehicle starts in “R” range only (engine revving up). Control valve

Acceleration during standing starts is poor (high stall rpm). Control valve

Low clutch

Reverse clutch

ATF level too low

ATF deterioration

Front gasket of transmission case

Differential gear oil level too high or too low

Acceleration during standing starts is poor (low stall rpm). Oil pump

Torque converter one-way clutch

Engine performance

Acceleration is poor when select lever is in “D”, “3” or “2” range

(normal stall rpm).TCM

Control valve

High clutch

2-4 brake

Planetary gear

Acceleration is poor when select lever is in “R” (normal stall

rpm). Control valve

High clutch

2-4 brake

Planetary gear Symptom Problem parts

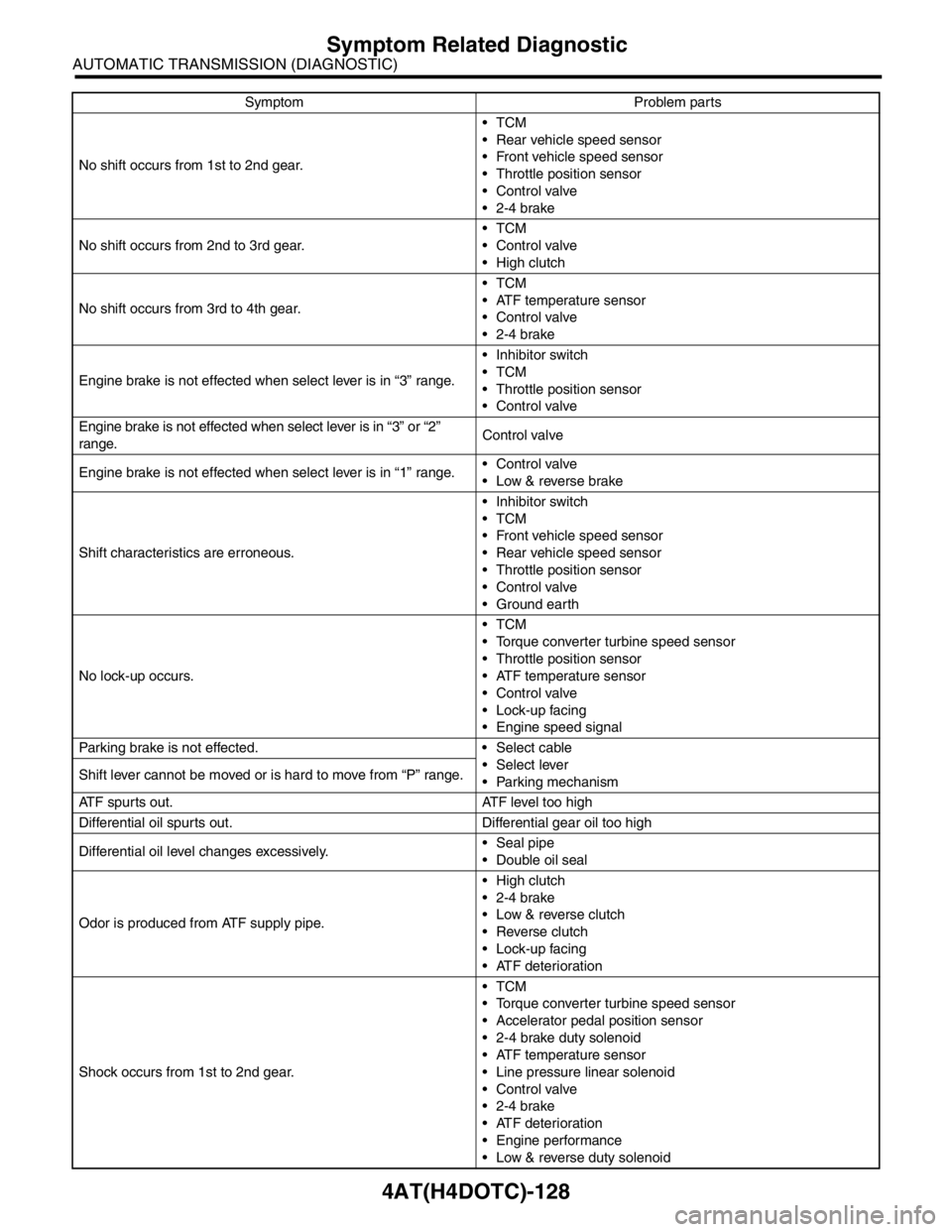

Page 2704 of 2870

4AT(H4DOTC)-128

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

No shift occurs from 1st to 2nd gear.TCM

Rear vehicle speed sensor

Front vehicle speed sensor

Throttle position sensor

Control valve

2-4 brake

No shift occurs from 2nd to 3rd gear.TCM

Control valve

High clutch

No shift occurs from 3rd to 4th gear.TCM

ATF temperature sensor

Control valve

2-4 brake

Engine brake is not effected when select lever is in “3” range. Inhibitor switch

TCM

Throttle position sensor

Control valve

Engine brake is not effected when select lever is in “3” or “2”

range.Control valve

Engine brake is not effected when select lever is in “1” range. Control valve

Low & reverse brake

Shift characteristics are erroneous. Inhibitor switch

TCM

Front vehicle speed sensor

Rear vehicle speed sensor

Throttle position sensor

Control valve

Ground earth

No lock-up occurs.TCM

Torque converter turbine speed sensor

Throttle position sensor

ATF temperature sensor

Control valve

Lock-up facing

Engine speed signal

Parking brake is not effected. Select cable

Select lever

Parking mechanism Shift lever cannot be moved or is hard to move from “P” range.

ATF spurts out. ATF level too high

Differential oil spurts out. Differential gear oil too high

Differential oil level changes excessively. Seal pipe

Double oil seal

Odor is produced from ATF supply pipe.High clutch

2-4 brake

Low & reverse clutch

Reverse clutch

Lock-up facing

ATF deterioration

Shock occurs from 1st to 2nd gear.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Control valve

2-4 brake

ATF deterioration

Engine performance

Low & reverse duty solenoid Symptom Problem parts

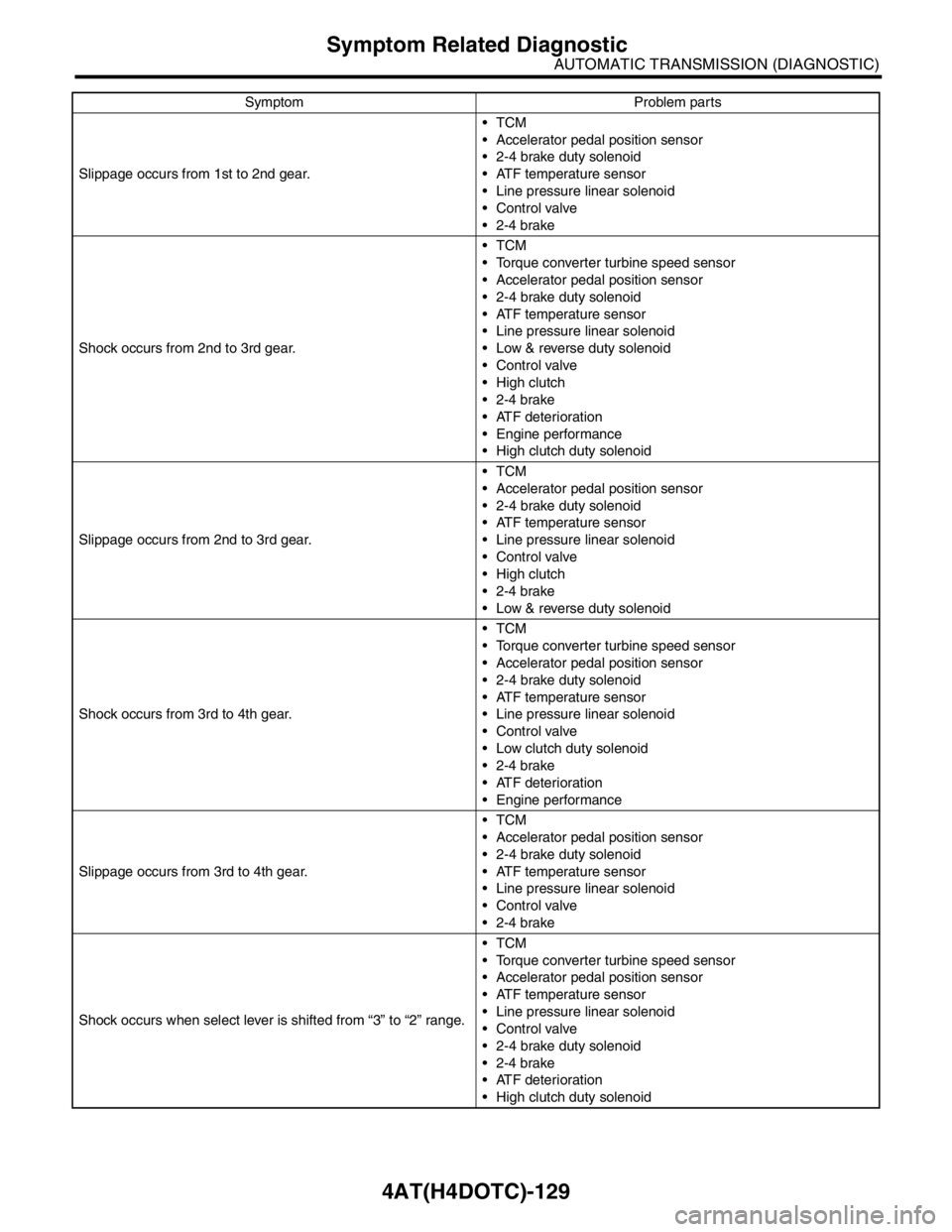

Page 2705 of 2870

4AT(H4DOTC)-129

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

Slippage occurs from 1st to 2nd gear.TCM

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Control valve

2-4 brake

Shock occurs from 2nd to 3rd gear.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Low & reverse duty solenoid

Control valve

High clutch

2-4 brake

ATF deterioration

Engine performance

High clutch duty solenoid

Slippage occurs from 2nd to 3rd gear.TCM

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Control valve

High clutch

2-4 brake

Low & reverse duty solenoid

Shock occurs from 3rd to 4th gear.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Control valve

Low clutch duty solenoid

2-4 brake

ATF deterioration

Engine performance

Slippage occurs from 3rd to 4th gear.TCM

Accelerator pedal position sensor

2-4 brake duty solenoid

ATF temperature sensor

Line pressure linear solenoid

Control valve

2-4 brake

Shock occurs when select lever is shifted from “3” to “2” range.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

2-4 brake duty solenoid

2-4 brake

ATF deterioration

High clutch duty solenoid Symptom Problem parts

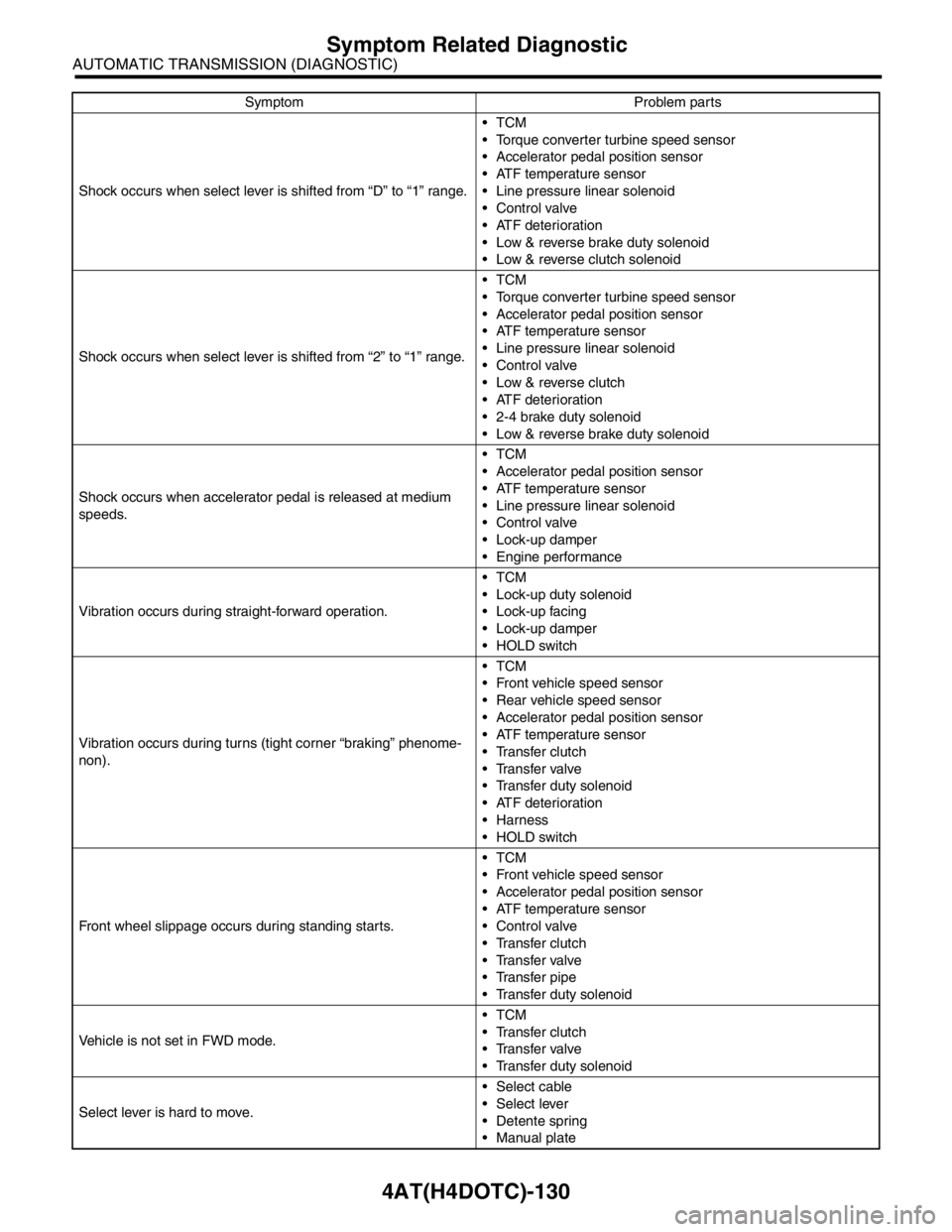

Page 2706 of 2870

4AT(H4DOTC)-130

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

Shock occurs when select lever is shifted from “D” to “1” range.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

ATF deterioration

Low & reverse brake duty solenoid

Low & reverse clutch solenoid

Shock occurs when select lever is shifted from “2” to “1” range.TCM

Torque converter turbine speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

Low & reverse clutch

ATF deterioration

2-4 brake duty solenoid

Low & reverse brake duty solenoid

Shock occurs when accelerator pedal is released at medium

speeds.TCM

Accelerator pedal position sensor

ATF temperature sensor

Line pressure linear solenoid

Control valve

Lock-up damper

Engine performance

Vibration occurs during straight-forward operation.TCM

Lock-up duty solenoid

Lock-up facing

Lock-up damper

HOLD switch

Vibration occurs during turns (tight corner “braking” phenome-

non).TCM

Front vehicle speed sensor

Rear vehicle speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Transfer clutch

Transfer valve

Transfer duty solenoid

ATF deterioration

Harness

HOLD switch

Front wheel slippage occurs during standing starts.TCM

Front vehicle speed sensor

Accelerator pedal position sensor

ATF temperature sensor

Control valve

Transfer clutch

Transfer valve

Transfer pipe

Transfer duty solenoid

Vehicle is not set in FWD mode.TCM

Transfer clutch

Transfer valve

Transfer duty solenoid

Select lever is hard to move. Select cable

Select lever

Detente spring

Manual plate Symptom Problem parts

Page 2715 of 2870

5MT-3

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

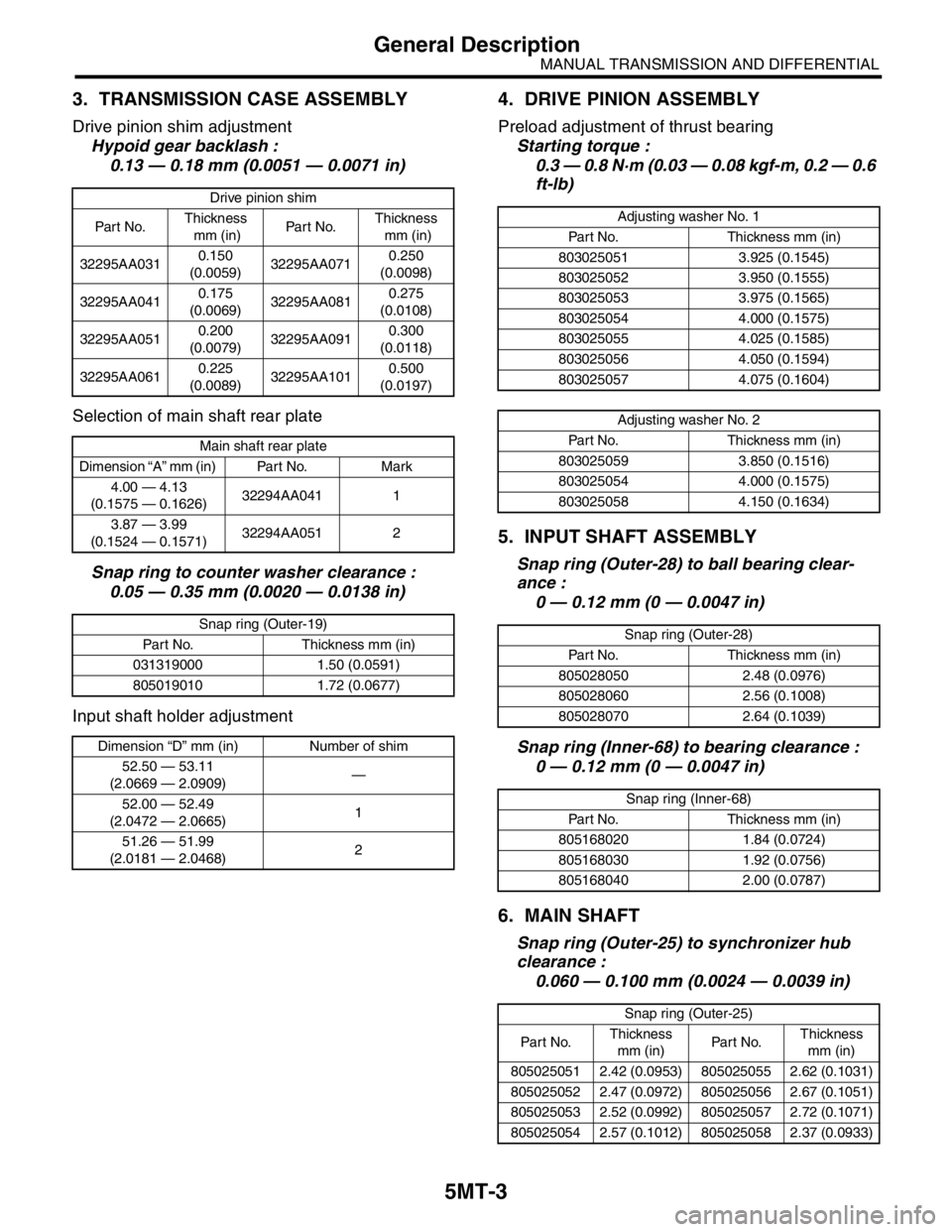

3. TRANSMISSION CASE ASSEMBLY

Drive pinion shim adjustment

Hypoid gear backlash :

0.13 — 0.18 mm (0.0051 — 0.0071 in)

Selection of main shaft rear plate

Snap ring to counter washer clearance :

0.05 — 0.35 mm (0.0020 — 0.0138 in)

Input shaft holder adjustment

4. DRIVE PINION ASSEMBLY

Preload adjustment of thrust bearing

Starting torque :

0.3 — 0.8 N·m (0.03 — 0.08 kgf-m, 0.2 — 0.6

ft-lb)

5. INPUT SHAFT ASSEMBLY

Snap ring (Outer-28) to ball bearing clear-

ance :

0 — 0.12 mm (0 — 0.0047 in)

Snap ring (Inner-68) to bearing clearance :

0 — 0.12 mm (0 — 0.0047 in)

6. MAIN SHAFT

Snap ring (Outer-25) to synchronizer hub

clearance :

0.060 — 0.100 mm (0.0024 — 0.0039 in)

Drive pinion shim

Par t No.Thickness

mm (in)Par t No.Thickness

mm (in)

32295AA0310.150

(0.0059) 32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069) 32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079) 32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089) 32295AA1010.500

(0.0197)

Main shaft rear plate

Dimension “A” mm (in) Part No. Mark

4.00 — 4.13

(0.1575 — 0.1626) 32294AA041 1

3.87 — 3.99

(0.1524 — 0.1571) 32294AA051 2

Snap ring (Outer-19)

Part No. Thickness mm (in)

031319000 1.50 (0.0591)

805019010 1.72 (0.0677)

Dimension “D” mm (in) Number of shim

52.50 — 53.11

(2.0669 — 2.0909)—

52.00 — 52.49

(2.0472 — 2.0665)1

51.26 — 51.99

(2.0181 — 2.0468)2

Adjusting washer No. 1

Part No. Thickness mm (in)

803025051 3.925 (0.1545)

803025052 3.950 (0.1555)

803025053 3.975 (0.1565)

803025054 4.000 (0.1575)

803025055 4.025 (0.1585)

803025056 4.050 (0.1594)

803025057 4.075 (0.1604)

Adjusting washer No. 2

Part No. Thickness mm (in)

803025059 3.850 (0.1516)

803025054 4.000 (0.1575)

803025058 4.150 (0.1634)

Snap ring (Outer-28)

Part No. Thickness mm (in)

805028050 2.48 (0.0976)

805028060 2.56 (0.1008)

805028070 2.64 (0.1039)

Snap ring (Inner-68)

Part No. Thickness mm (in)

805168020 1.84 (0.0724)

805168030 1.92 (0.0756)

805168040 2.00 (0.0787)

Snap ring (Outer-25)

Par t No.Thickness

mm (in)Par t No.Thickness

mm (in)

805025051 2.42 (0.0953) 805025055 2.62 (0.1031)

805025052 2.47 (0.0972) 805025056 2.67 (0.1051)

805025053 2.52 (0.0992) 805025057 2.72 (0.1071)

805025054 2.57 (0.1012) 805025058 2.37 (0.0933)

Page 2719 of 2870

5MT-7

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

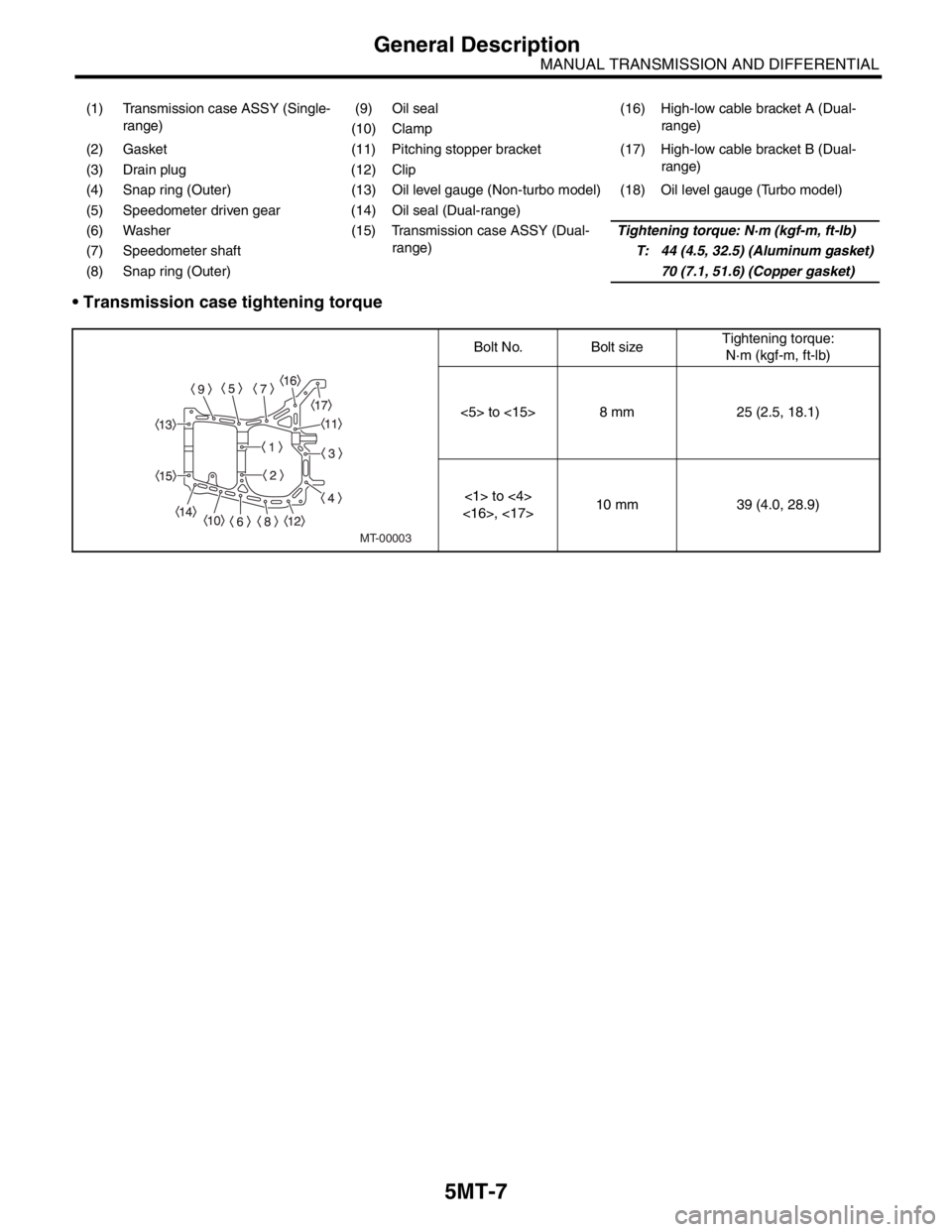

Transmission case tightening torque

(1) Transmission case ASSY (Single-

range)(9) Oil seal (16) High-low cable bracket A (Dual-

range)

(10) Clamp

(2) Gasket (11) Pitching stopper bracket (17) High-low cable bracket B (Dual-

range)

(3) Drain plug (12) Clip

(4) Snap ring (Outer) (13) Oil level gauge (Non-turbo model) (18) Oil level gauge (Turbo model)

(5) Speedometer driven gear (14) Oil seal (Dual-range)

(6) Washer (15) Transmission case ASSY (Dual-

range)Tightening torque: N·m (kgf-m, ft-lb)

(7) Speedometer shaftT: 44 (4.5, 32.5) (Aluminum gasket)

(8) Snap ring (Outer)70 (7.1, 51.6) (Copper gasket)

Bolt No. Bolt sizeTightening torque:

N·m (kgf-m, ft-lb)

<5> to <15> 8 mm 25 (2.5, 18.1)

<1> to <4>

<16>, <17> 10 mm 39 (4.0, 28.9)

MT-00003