torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2581 of 2870

4AT(H4DOTC)-5

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

General Description

3. General Description

A: CAUTION

Supplemental Restraint System “Airbag”

The airbag system wiring harness is routed near

the TCM.

CAUTION:

All airbag system wiring harness and con-

nectors are colored yellow. Do not use an elec-

trical test equipment on these circuit.

Be careful not to damage the airbag system

wiring harness when performing diagnostics and

servicing the TCM.

Measurement

When measuring the voltage and resistance of

ECM, TCM or each sensor, use a tapered pin with

diameter of less than 0.64 mm (0.025 in) in order to

avoid poor contact. Do not insert the pin more than

0.65 mm (0.026 in).

B: INSPECTION

1. BATTERY

Measure the battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

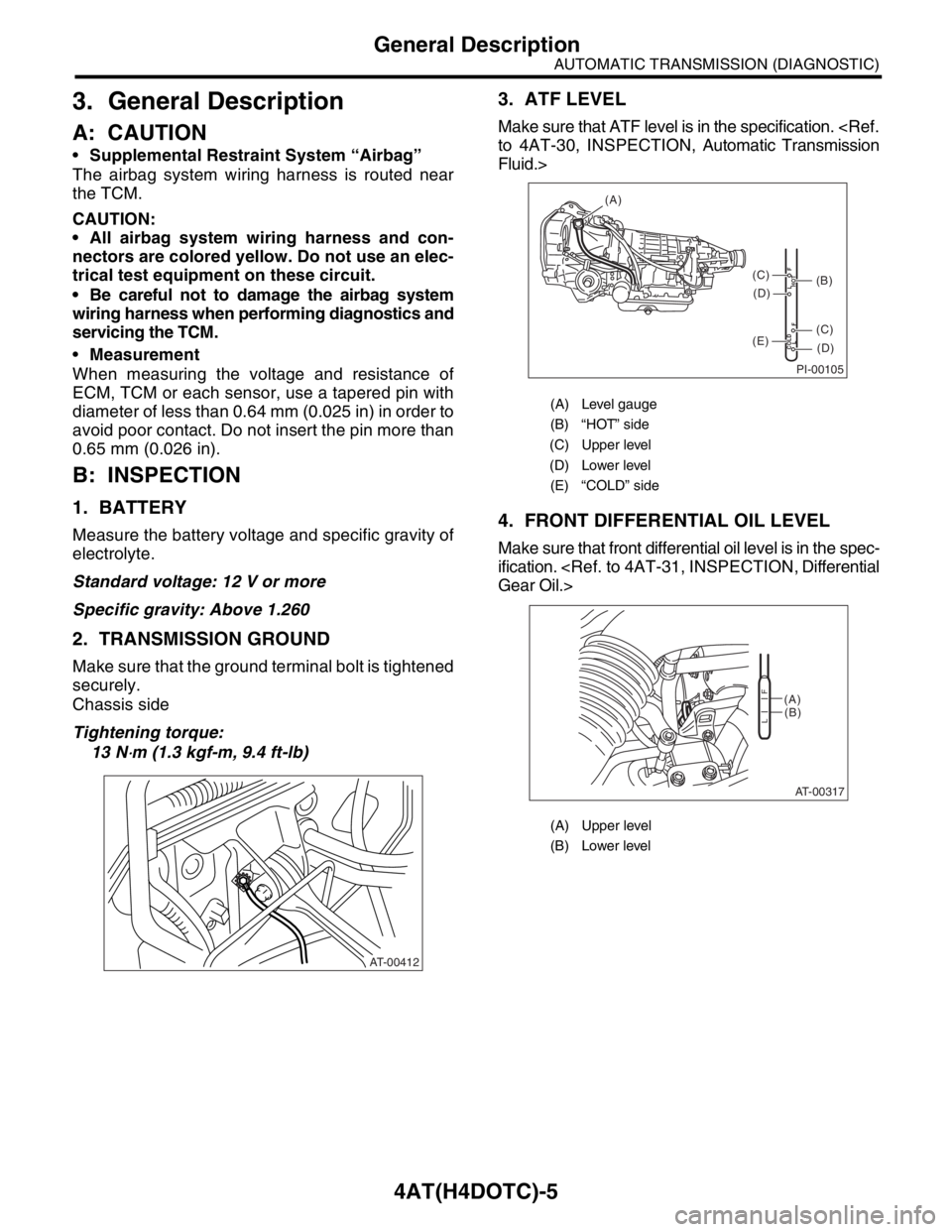

2. TRANSMISSION GROUND

Make sure that the ground terminal bolt is tightened

securely.

Chassis side

Tightening torque:

13 N

⋅m (1.3 kgf-m, 9.4 ft-lb)

3. ATF LEVEL

Make sure that ATF level is in the specification.

Fluid.>

4. FRONT DIFFERENTIAL OIL LEVEL

Make sure that front differential oil level is in the spec-

ification.

AT-00412

(A) Level gauge

(B) “HOT” side

(C) Upper level

(D) Lower level

(E) “COLD” side

(A) Upper level

(B) Lower level

PI-00105

COLD

LFHOT LF

(A)

(C)

(D)

(C)

(D)

(E)

(B)

AT-00317

(A)

(B)

LF

Page 2586 of 2870

4AT(H4DOTC)-10

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Electrical Components Location

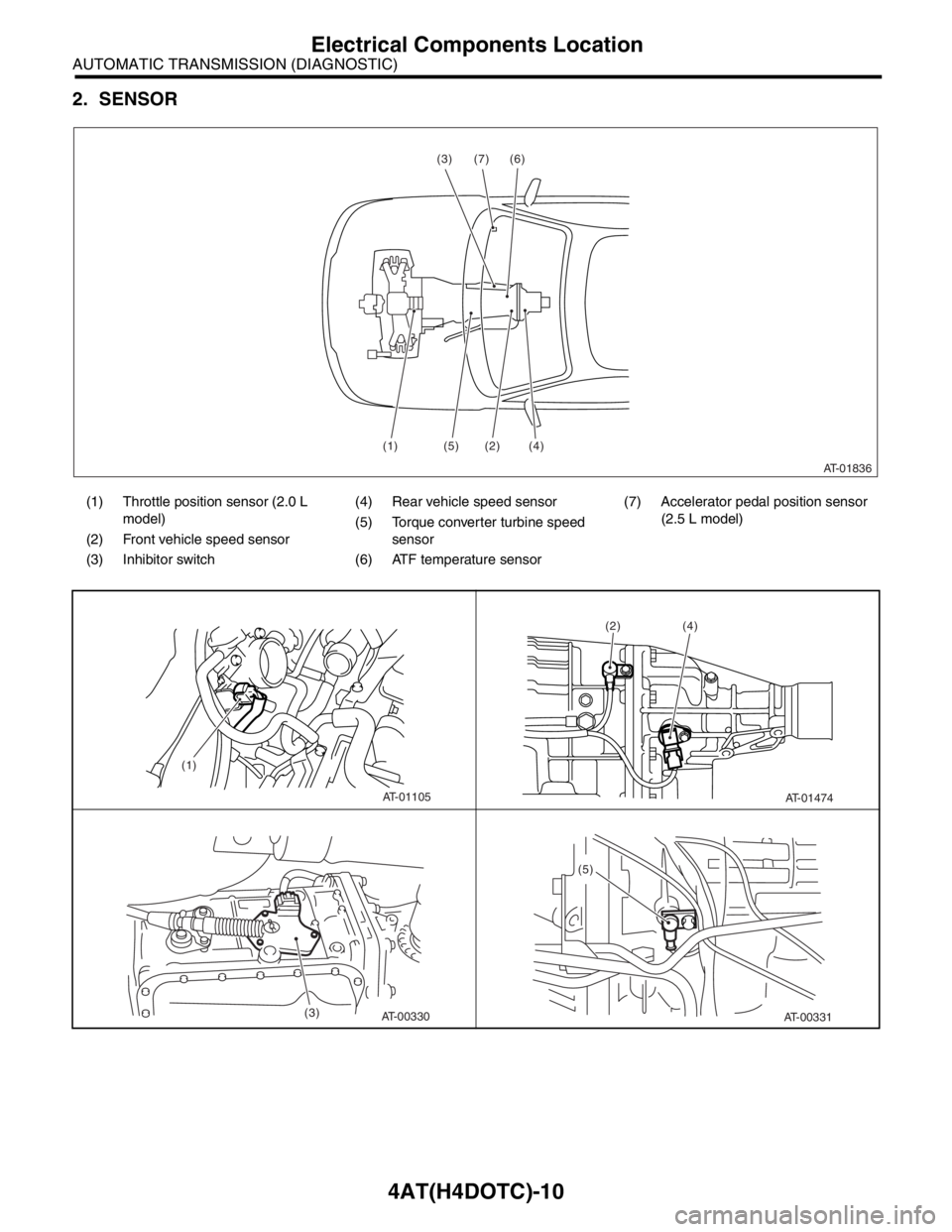

2. SENSOR

(1) Throttle position sensor (2.0 L

model)(4) Rear vehicle speed sensor (7) Accelerator pedal position sensor

(2.5 L model)

(5) Torque converter turbine speed

sensor (2) Front vehicle speed sensor

(3) Inhibitor switch (6) ATF temperature sensor

AT-01836

(3) (6)

(5) (1) (2) (4)(7)

(1)

AT-01105

AT-01474

(2)(4)

(3)AT-00330

(5)

AT-00331

Page 2589 of 2870

4AT(H4DOTC)-13

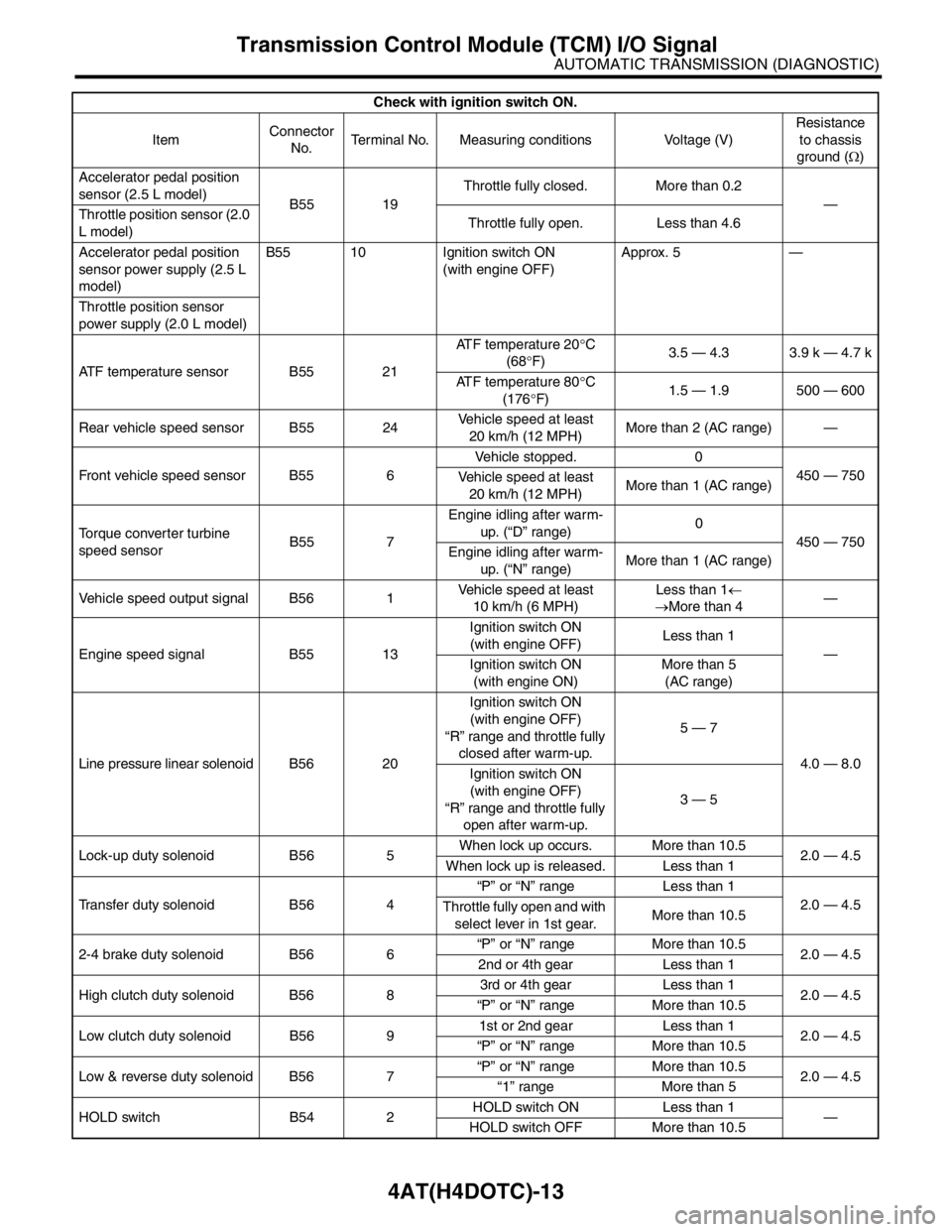

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Transmission Control Module (TCM) I/O Signal

Accelerator pedal position

sensor (2.5 L model)

B55 19Throttle fully closed. More than 0.2

—

Throttle position sensor (2.0

L model)Throttle fully open. Less than 4.6

Accelerator pedal position

sensor power supply (2.5 L

model)B55 10 Ignition switch ON

(with engine OFF)Approx. 5 —

Throttle position sensor

power supply (2.0 L model)

ATF temperature sensor B55 21ATF temperature 20°C

(68°F)3.5 — 4.3 3.9 k — 4.7 k

ATF temperature 80°C

(176°F)1.5 — 1.9 500 — 600

Rear vehicle speed sensor B55 24Vehicle speed at least

20 km/h (12 MPH)More than 2 (AC range) —

Front vehicle speed sensor B55 6Vehicle stopped. 0

450 — 750

Vehicle speed at least

20 km/h (12 MPH)More than 1 (AC range)

Torque converter turbine

speed sensorB55 7Engine idling after warm-

up. (“D” range)0

450 — 750

Engine idling after warm-

up. (“N” range)More than 1 (AC range)

Vehicle speed output signal B56 1Vehicle speed at least

10 km/h (6 MPH)Less than 1←

→More than 4—

Engine speed signal B55 13Ignition switch ON

(with engine OFF)Less than 1

—

Ignition switch ON

(with engine ON)More than 5

(AC range)

Line pressure linear solenoid B56 20Ignition switch ON

(with engine OFF)

“R” range and throttle fully

closed after warm-up.5 — 7

4.0 — 8.0

Ignition switch ON

(with engine OFF)

“R” range and throttle fully

open after warm-up.3 — 5

Lock-up duty solenoid B56 5When lock up occurs. More than 10.5

2.0 — 4.5

When lock up is released. Less than 1

Transfer duty solenoid B56 4“P” or “N” range Less than 1

2.0 — 4.5

Throttle fully open and with

select lever in 1st gear.More than 10.5

2-4 brake duty solenoid B56 6“P” or “N” range More than 10.5

2.0 — 4.5

2nd or 4th gear Less than 1

High clutch duty solenoid B56 83rd or 4th gear Less than 1

2.0 — 4.5

“P” or “N” range More than 10.5

Low clutch duty solenoid B56 91st or 2nd gear Less than 1

2.0 — 4.5

“P” or “N” range More than 10.5

Low & reverse duty solenoid B56 7“P” or “N” range More than 10.5

2.0 — 4.5

“1” range More than 5

HOLD switch B54 2HOLD switch ON Less than 1

—

HOLD switch OFF More than 10.5 Check with ignition switch ON.

ItemConnector

No.Terminal No. Measuring conditions Voltage (V)Resistance

to chassis

ground (Ω)

Page 2592 of 2870

4AT(H4DOTC)-16

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

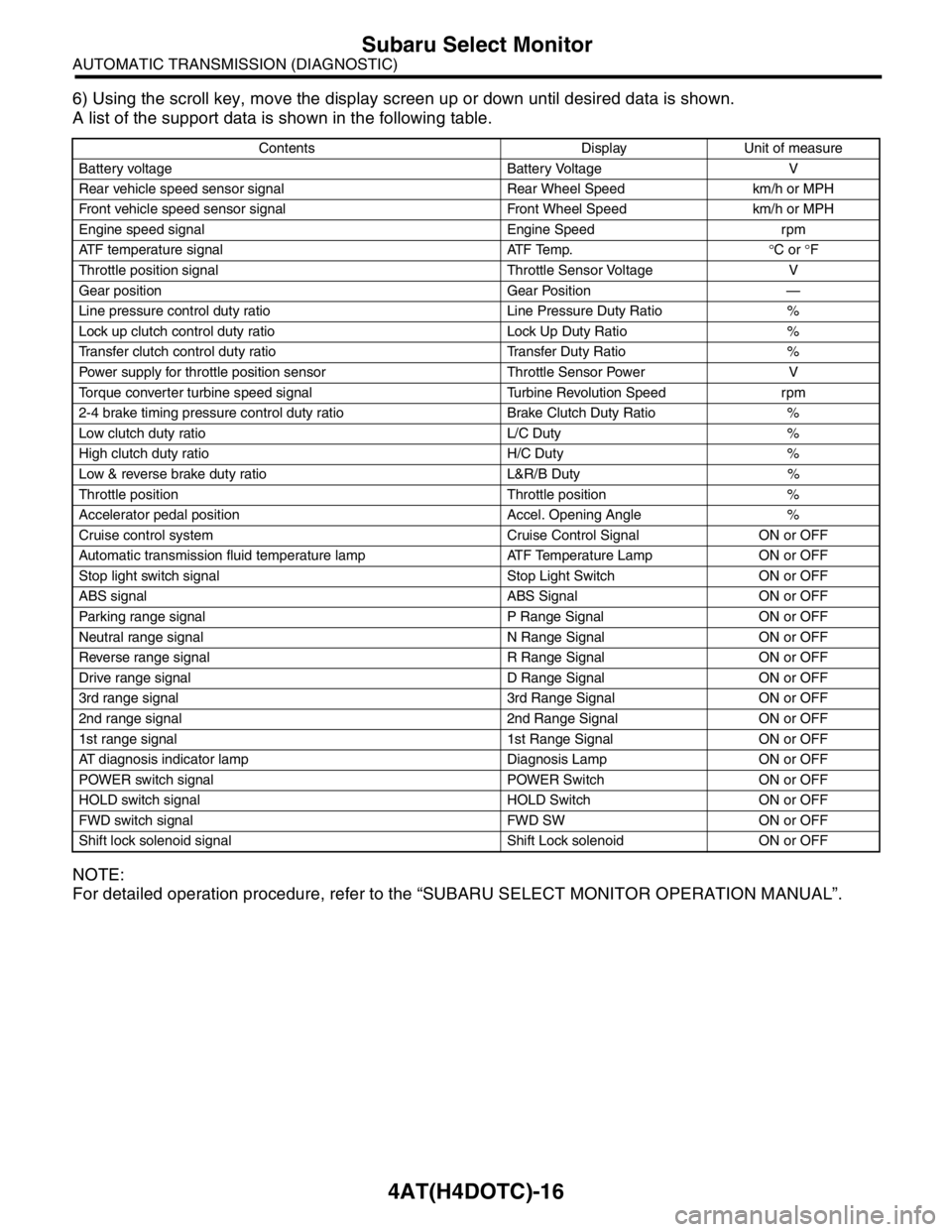

Subaru Select Monitor

6) Using the scroll key, move the display screen up or down until desired data is shown.

A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Contents Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine Speed rpm

ATF temperature signal ATF Temp.°C or °F

Throttle position signal Throttle Sensor Voltage V

Gear position Gear Position —

Line pressure control duty ratio Line Pressure Duty Ratio %

Lock up clutch control duty ratio Lock Up Duty Ratio %

Transfer clutch control duty ratio Transfer Duty Ratio %

Power supply for throttle position sensor Throttle Sensor Power V

Torque converter turbine speed signal Turbine Revolution Speed rpm

2-4 brake timing pressure control duty ratio Brake Clutch Duty Ratio %

Low clutch duty ratio L/C Duty %

High clutch duty ratio H/C Duty %

Low & reverse brake duty ratio L&R/B Duty %

Throttle position Throttle position %

Accelerator pedal position Accel. Opening Angle %

Cruise control system Cruise Control Signal ON or OFF

Automatic transmission fluid temperature lamp ATF Temperature Lamp ON or OFF

Stop light switch signal Stop Light Switch ON or OFF

ABS signal ABS Signal ON or OFF

Parking range signal P Range Signal ON or OFF

Neutral range signal N Range Signal ON or OFF

Reverse range signal R Range Signal ON or OFF

Drive range signal D Range Signal ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

AT diagnosis indicator lamp Diagnosis Lamp ON or OFF

POWER switch signal POWER Switch ON or OFF

HOLD switch signal HOLD Switch ON or OFF

FWD switch signal FWD SW ON or OFF

Shift lock solenoid signal Shift Lock solenoid ON or OFF

Page 2606 of 2870

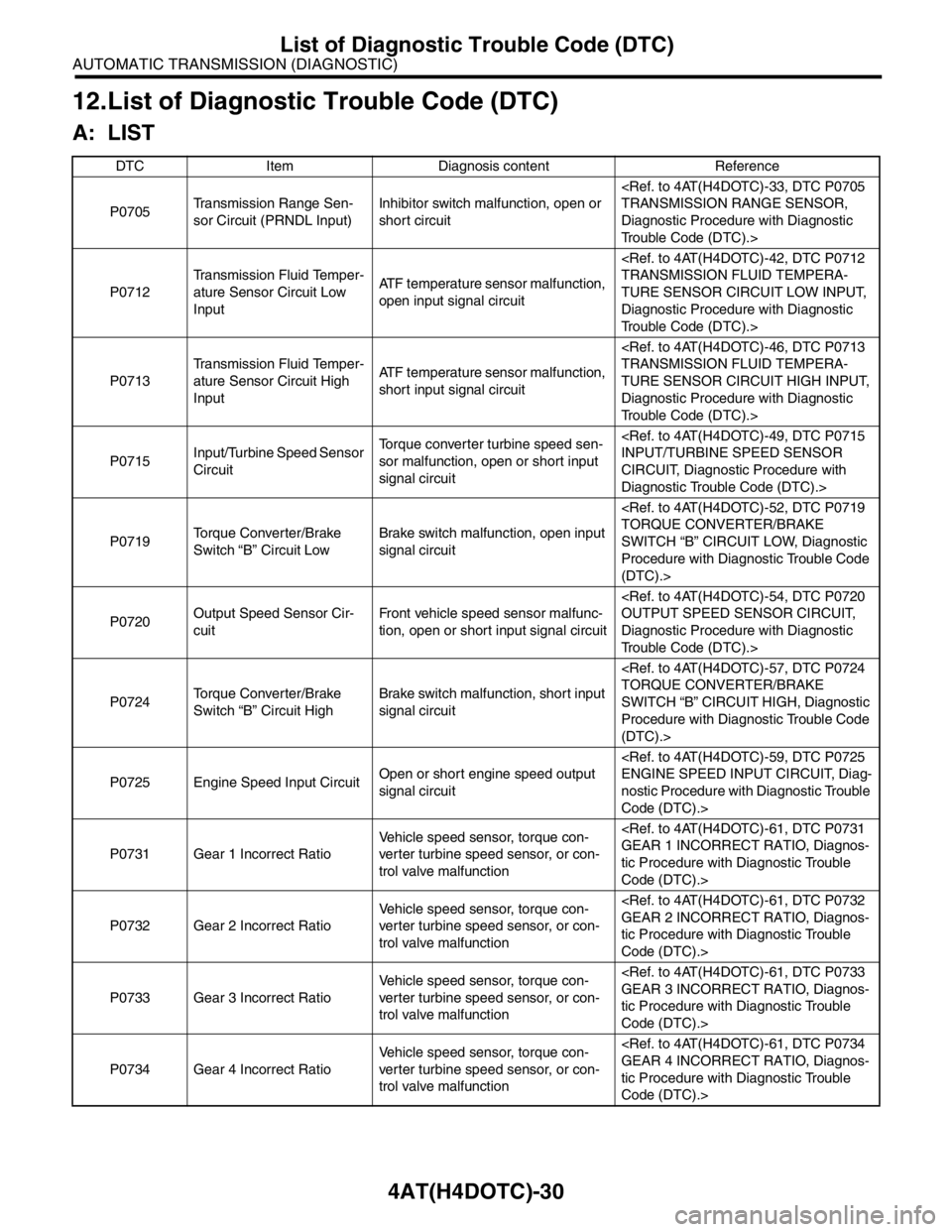

4AT(H4DOTC)-30

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

12.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Diagnosis content Reference

P0705Transmission Range Sen-

sor Circuit (PRNDL Input)Inhibitor switch malfunction, open or

short circuit

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0712Transmission Fluid Temper-

ature Sensor Circuit Low

InputATF temperature sensor malfunction,

open input signal circuit

TURE SENSOR CIRCUIT LOW INPUT,

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0713Transmission Fluid Temper-

ature Sensor Circuit High

InputATF temperature sensor malfunction,

short input signal circuit

TURE SENSOR CIRCUIT HIGH INPUT,

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0715Input/Turbine Speed Sensor

CircuitTorque converter turbine speed sen-

sor malfunction, open or short input

signal circuit

CIRCUIT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0719Torque Converter/Brake

Switch “B” Circuit Low Brake switch malfunction, open input

signal circuit

SWITCH “B” CIRCUIT LOW, Diagnostic

Procedure with Diagnostic Trouble Code

(DTC).>

P0720Output Speed Sensor Cir-

cuitFront vehicle speed sensor malfunc-

tion, open or short input signal circuit

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0724Torque Converter/Brake

Switch “B” Circuit HighBrake switch malfunction, short input

signal circuit

SWITCH “B” CIRCUIT HIGH, Diagnostic

Procedure with Diagnostic Trouble Code

(DTC).>

P0725 Engine Speed Input CircuitOpen or short engine speed output

signal circuit

nostic Procedure with Diagnostic Trouble

Code (DTC).>

P0731 Gear 1 Incorrect Ratio Vehicle speed sensor, torque con-

verter turbine speed sensor, or con-

trol valve malfunction

tic Procedure with Diagnostic Trouble

Code (DTC).>

P0732 Gear 2 Incorrect Ratio Vehicle speed sensor, torque con-

verter turbine speed sensor, or con-

trol valve malfunction

tic Procedure with Diagnostic Trouble

Code (DTC).>

P0733 Gear 3 Incorrect Ratio Vehicle speed sensor, torque con-

verter turbine speed sensor, or con-

trol valve malfunction

tic Procedure with Diagnostic Trouble

Code (DTC).>

P0734 Gear 4 Incorrect Ratio Vehicle speed sensor, torque con-

verter turbine speed sensor, or con-

trol valve malfunction

tic Procedure with Diagnostic Trouble

Code (DTC).>

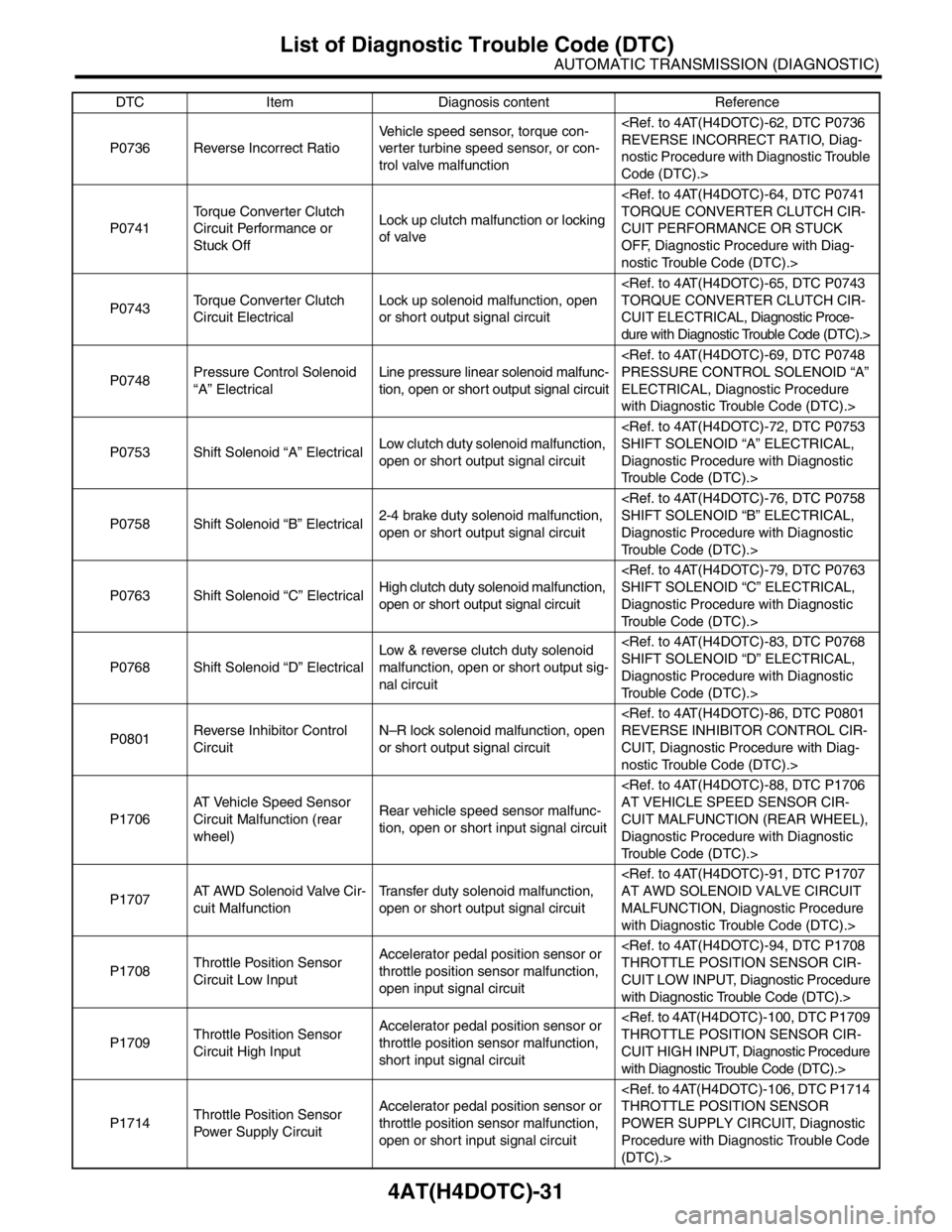

Page 2607 of 2870

4AT(H4DOTC)-31

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

P0736 Reverse Incorrect Ratio Vehicle speed sensor, torque con-

verter turbine speed sensor, or con-

trol valve malfunction

nostic Procedure with Diagnostic Trouble

Code (DTC).>

P0741Torque Converter Clutch

Circuit Performance or

Stuck OffLock up clutch malfunction or locking

of valve

CUIT PERFORMANCE OR STUCK

OFF, Diagnostic Procedure with Diag-

nostic Trouble Code (DTC).>

P0743Torque Converter Clutch

Circuit Electrical Lock up solenoid malfunction, open

or short output signal circuit

CUIT ELECTRICAL, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P0748Pressure Control Solenoid

“A” ElectricalLine pressure linear solenoid malfunc-

tion, open or short output signal circuit

ELECTRICAL, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P0753 Shift Solenoid “A” ElectricalLow clutch duty solenoid malfunction,

open or short output signal circuit

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0758 Shift Solenoid “B” Electrical2-4 brake duty solenoid malfunction,

open or short output signal circuit

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0763 Shift Solenoid “C” ElectricalHigh clutch duty solenoid malfunction,

open or short output signal circuit

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0768 Shift Solenoid “D” ElectricalLow & reverse clutch duty solenoid

malfunction, open or short output sig-

nal circuit

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P0801Reverse Inhibitor Control

CircuitN–R lock solenoid malfunction, open

or short output signal circuit

CUIT, Diagnostic Procedure with Diag-

nostic Trouble Code (DTC).>

P1706AT Vehicle Speed Sensor

Circuit Malfunction (rear

wheel)Rear vehicle speed sensor malfunc-

tion, open or short input signal circuit

CUIT MALFUNCTION (REAR WHEEL),

Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

P1707AT AWD Solenoid Valve Cir-

cuit MalfunctionTransfer duty solenoid malfunction,

open or short output signal circuit

MALFUNCTION, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1708Throttle Position Sensor

Circuit Low InputAccelerator pedal position sensor or

throttle position sensor malfunction,

open input signal circuit

CUIT LOW INPUT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1709Throttle Position Sensor

Circuit High InputAccelerator pedal position sensor or

throttle position sensor malfunction,

short input signal circuit

CUIT HIGH INPUT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1714Throttle Position Sensor

Power Supply CircuitAccelerator pedal position sensor or

throttle position sensor malfunction,

open or short input signal circuit

POWER SUPPLY CIRCUIT, Diagnostic

Procedure with Diagnostic Trouble Code

(DTC).> DTC Item Diagnosis content Reference

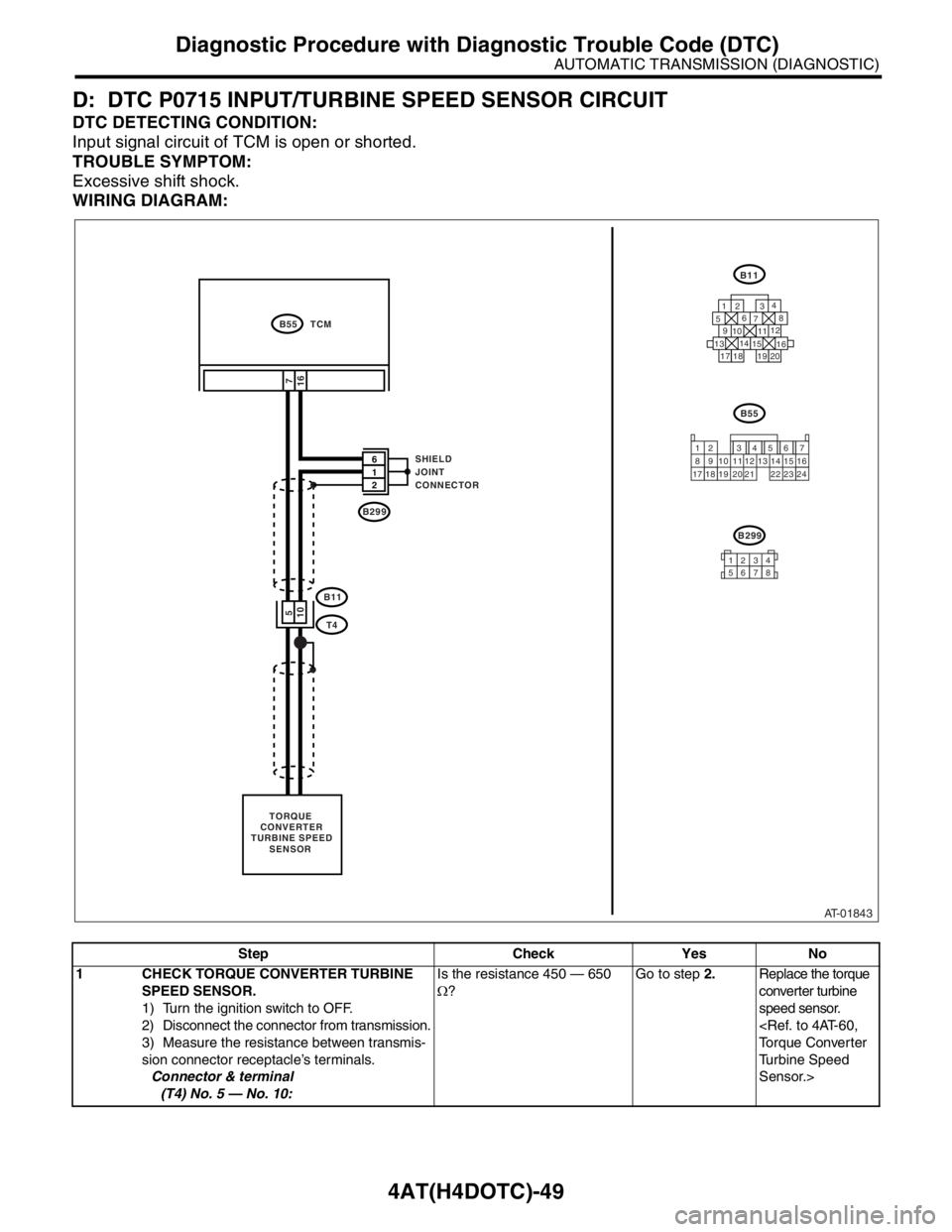

Page 2625 of 2870

4AT(H4DOTC)-49

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

D: DTC P0715 INPUT/TURBINE SPEED SENSOR CIRCUIT

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmission.

3) Measure the resistance between transmis-

sion connector receptacle’s terminals.

Connector & terminal

(T4) No. 5 — No. 10:Is the resistance 450 — 650

Ω?Go to step 2.Replace the torque

converter turbine

speed sensor.

Turbine Speed

Sensor.>

AT-01843

5

10B11

T4

TCMB55

7

16

B11

1

234

56

78

9

1314

15

20

19 1716 10 1112

18

B55

TORQUE

CONVERTER

TURBINE SPEED

SENSOR

B299SHIELD

JOINT

CONNECTOR

612

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

B299

12345678

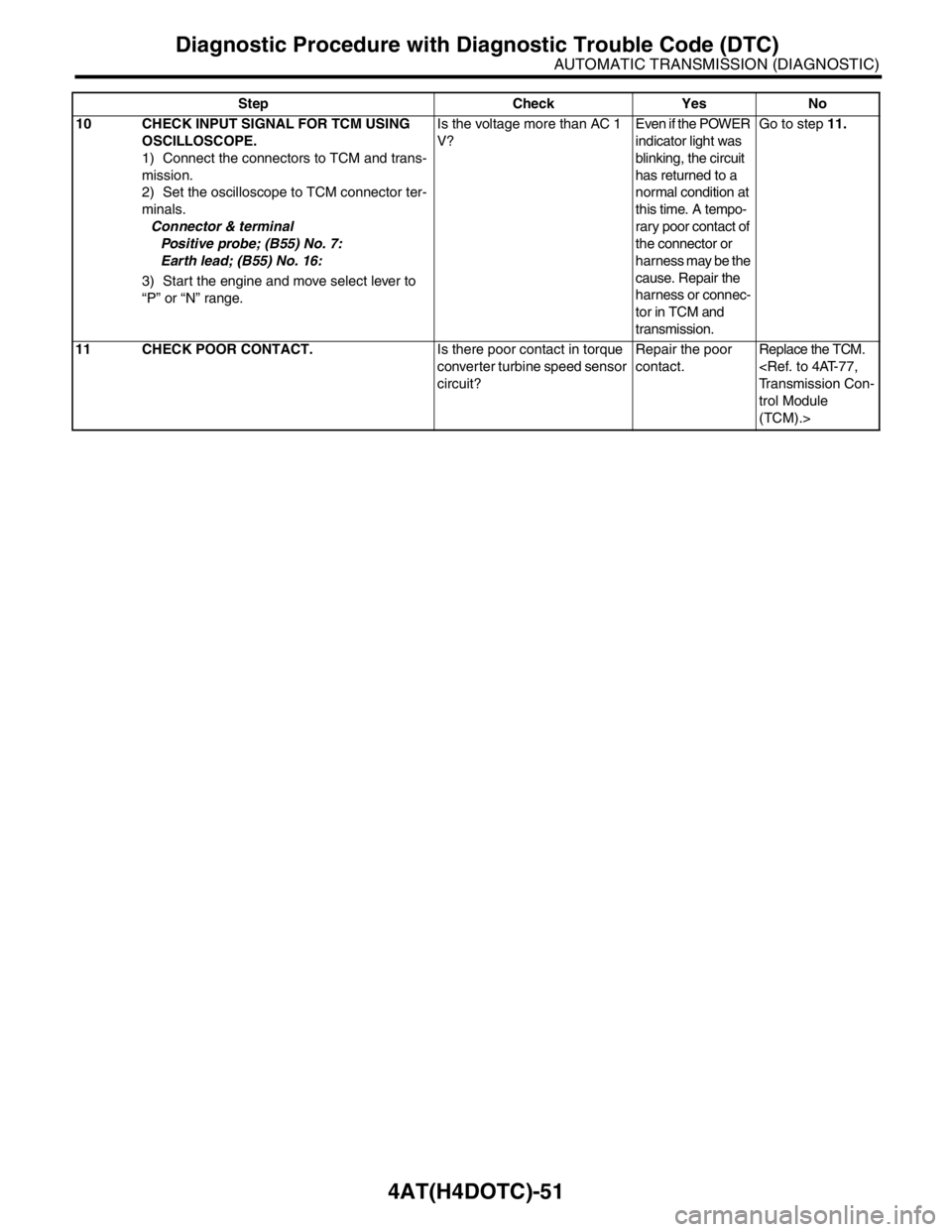

Page 2627 of 2870

4AT(H4DOTC)-51

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

10 CHECK INPUT SIGNAL FOR TCM USING

OSCILLOSCOPE.

1) Connect the connectors to TCM and trans-

mission.

2) Set the oscilloscope to TCM connector ter-

minals.

Connector & terminal

Positive probe; (B55) No. 7:

Earth lead; (B55) No. 16:

3) Start the engine and move select lever to

“P” or “N” range.Is the voltage more than AC 1

V?Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in TCM and

transmission.Go to step 11.

11 CHECK POOR CONTACT.Is there poor contact in torque

converter turbine speed sensor

circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2628 of 2870

4AT(H4DOTC)-52

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

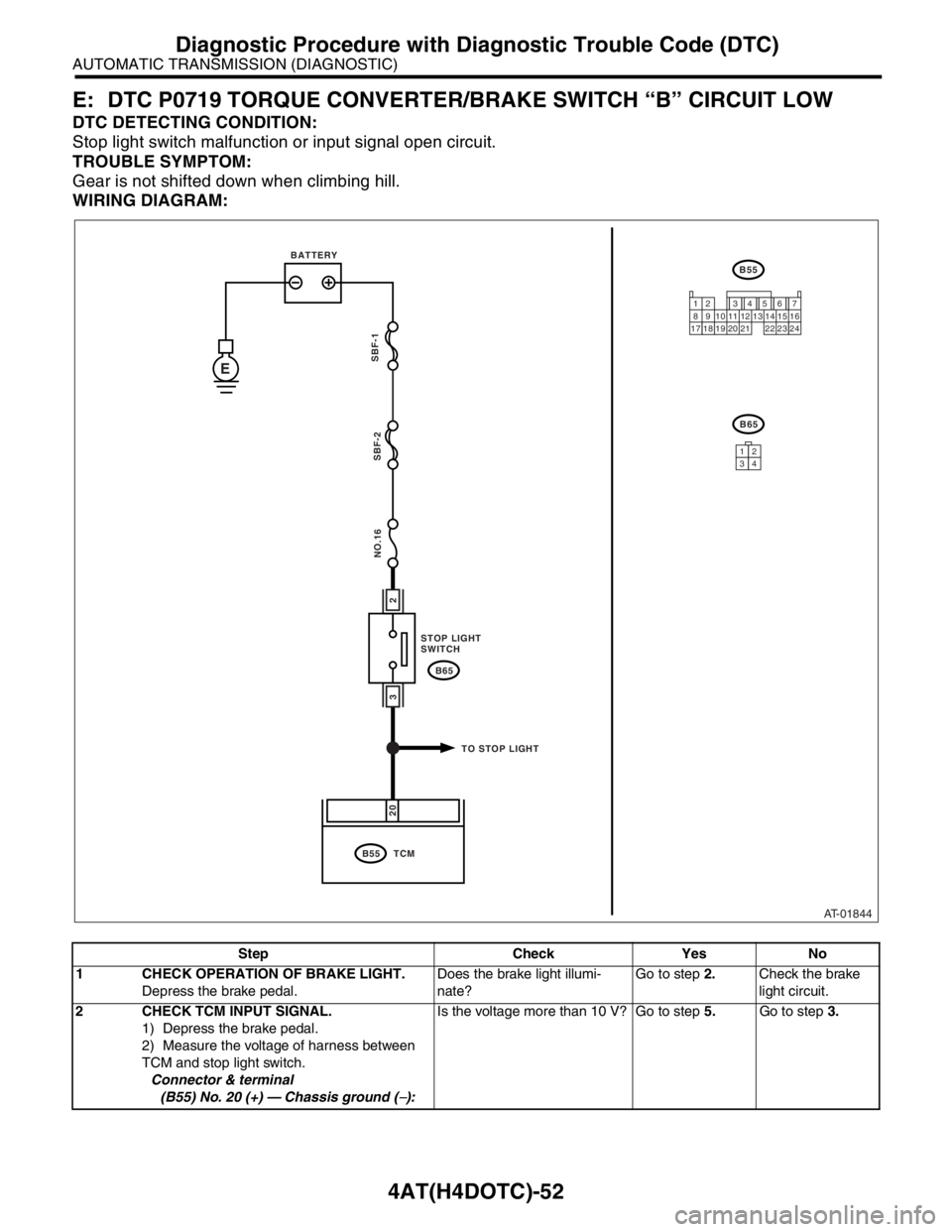

E: DTC P0719 TORQUE CONVERTER/BRAKE SWITCH “B” CIRCUIT LOW

DTC DETECTING CONDITION:

Stop light switch malfunction or input signal open circuit.

TROUBLE SYMPTOM:

Gear is not shifted down when climbing hill.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK OPERATION OF BRAKE LIGHT.

Depress the brake pedal.Does the brake light illumi-

nate?Go to step 2.Check the brake

light circuit.

2 CHECK TCM INPUT SIGNAL.

1) Depress the brake pedal.

2) Measure the voltage of harness between

TCM and stop light switch.

Connector & terminal

(B55) No. 20 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 5.Go to step 3.

AT-01844

B55

B65

E

2 3

SBF-1

SBF-2

NO.16

20

B55

B65

TCM

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

1234

BATTERY

STOP LIGHT

SWITCH

TO STOP LIGHT

Page 2633 of 2870

4AT(H4DOTC)-57

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

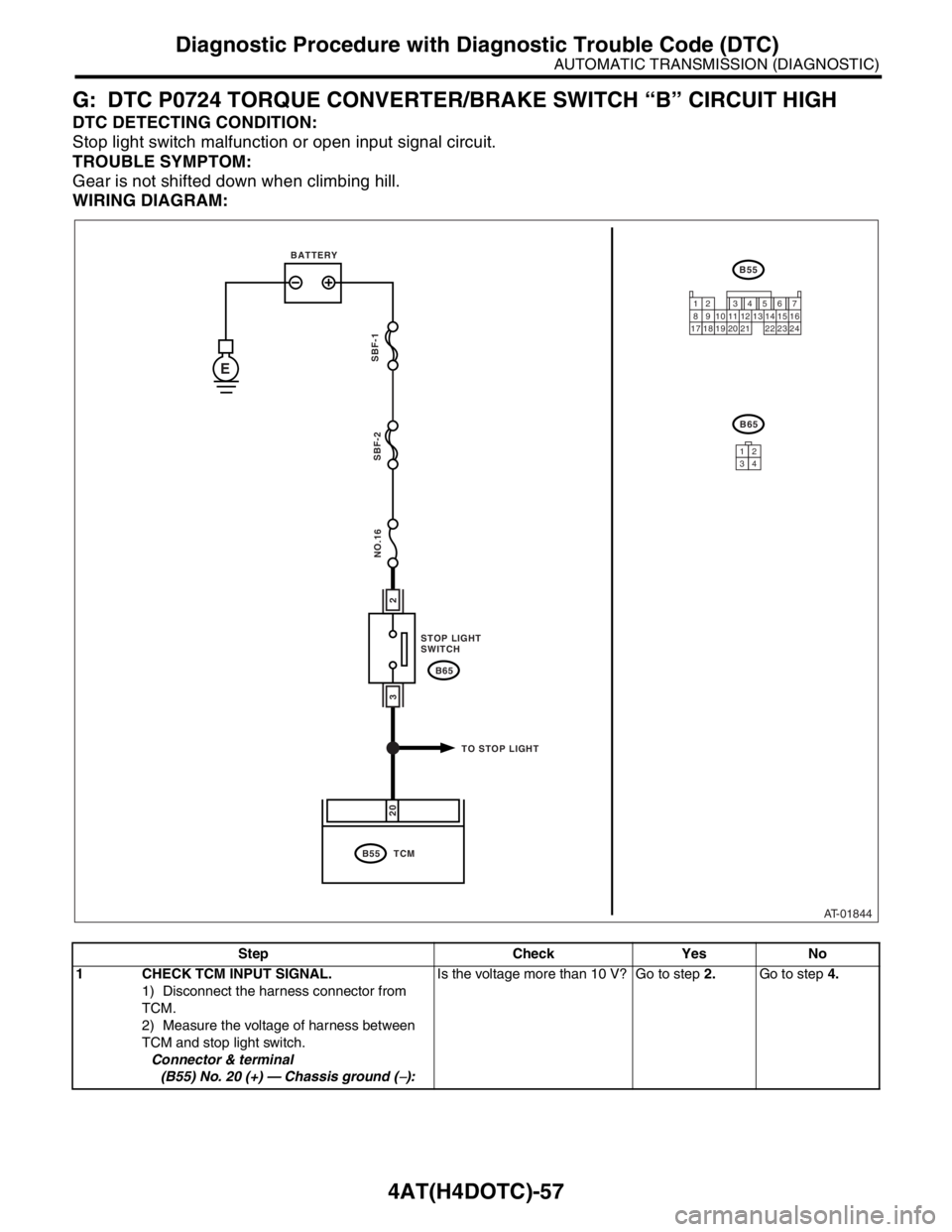

G: DTC P0724 TORQUE CONVERTER/BRAKE SWITCH “B” CIRCUIT HIGH

DTC DETECTING CONDITION:

Stop light switch malfunction or open input signal circuit.

TROUBLE SYMPTOM:

Gear is not shifted down when climbing hill.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK TCM INPUT SIGNAL.

1) Disconnect the harness connector from

TCM.

2) Measure the voltage of harness between

TCM and stop light switch.

Connector & terminal

(B55) No. 20 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 2.Go to step 4.

AT-01844

B55

B65

E

2 3

SBF-1

SBF-2

NO.16

20

B55

B65

TCM

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

1234

BATTERY

STOP LIGHT

SWITCH

TO STOP LIGHT