engine repair SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 27 of 2870

AC-25

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

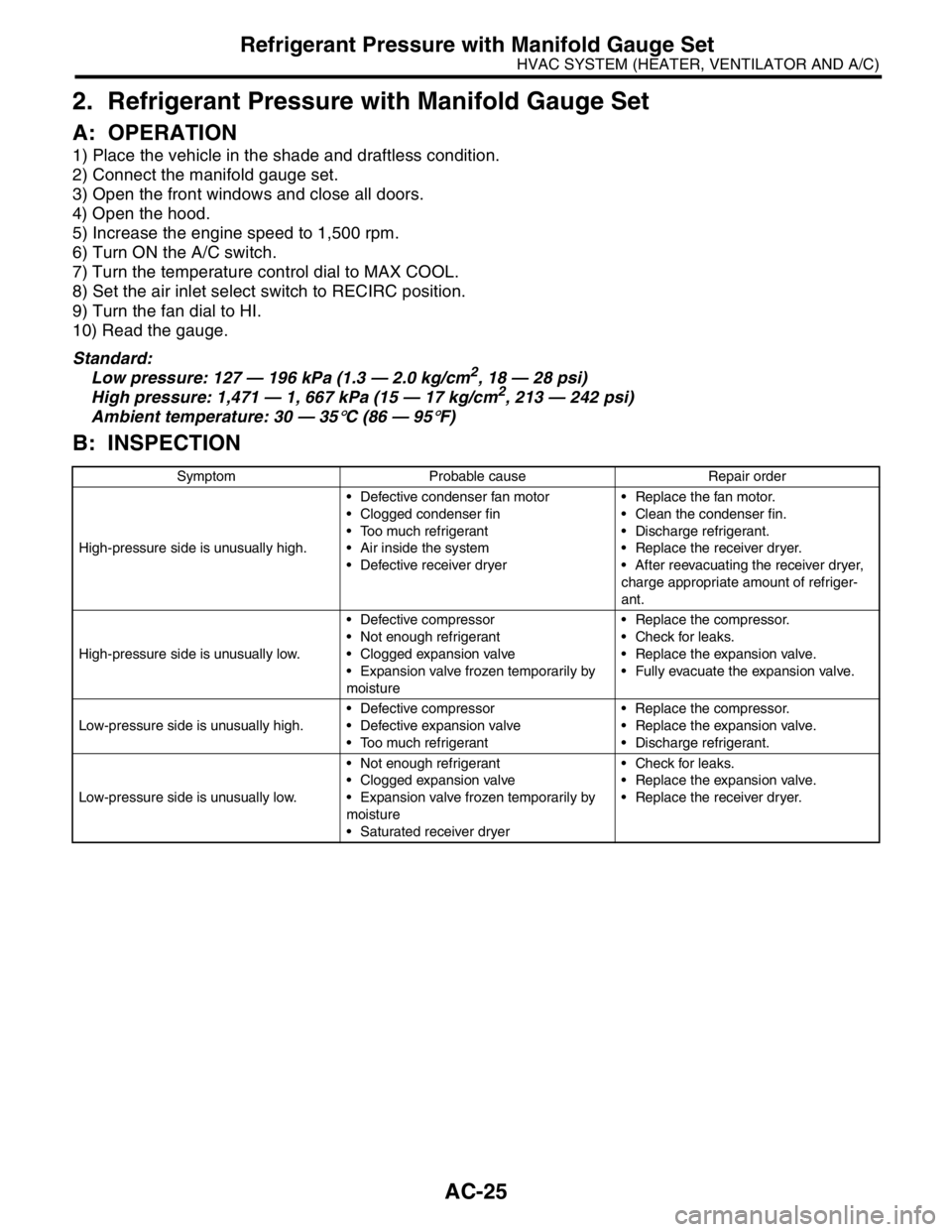

Refrigerant Pressure with Manifold Gauge Set

2. Refrigerant Pressure with Manifold Gauge Set

A: OPERATION

1) Place the vehicle in the shade and draftless condition.

2) Connect the manifold gauge set.

3) Open the front windows and close all doors.

4) Open the hood.

5) Increase the engine speed to 1,500 rpm.

6) Turn ON the A/C switch.

7) Turn the temperature control dial to MAX COOL.

8) Set the air inlet select switch to RECIRC position.

9) Turn the fan dial to HI.

10) Read the gauge.

Standard:

Low pressure: 127 — 196 kPa (1.3 — 2.0 kg/cm

2, 18 — 28 psi)

High pressure: 1,471 — 1, 667 kPa (15 — 17 kg/cm2, 213 — 242 psi)

Ambient temperature: 30 — 35

°C (86 — 95°F)

B: INSPECTION

Symptom Probable cause Repair order

High-pressure side is unusually high. Defective condenser fan motor

Clogged condenser fin

Too much refrigerant

Air inside the system

Defective receiver dryer Replace the fan motor.

Clean the condenser fin.

Discharge refrigerant.

Replace the receiver dryer.

After reevacuating the receiver dryer,

charge appropriate amount of refriger-

ant.

High-pressure side is unusually low. Defective compressor

Not enough refrigerant

Clogged expansion valve

Expansion valve frozen temporarily by

moisture Replace the compressor.

Check for leaks.

Replace the expansion valve.

Fully evacuate the expansion valve.

Low-pressure side is unusually high. Defective compressor

Defective expansion valve

Too much refrigerant Replace the compressor.

Replace the expansion valve.

Discharge refrigerant.

Low-pressure side is unusually low. Not enough refrigerant

Clogged expansion valve

Expansion valve frozen temporarily by

moisture

Saturated receiver dryer Check for leaks.

Replace the expansion valve.

Replace the receiver dryer.

Page 30 of 2870

AC-28

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

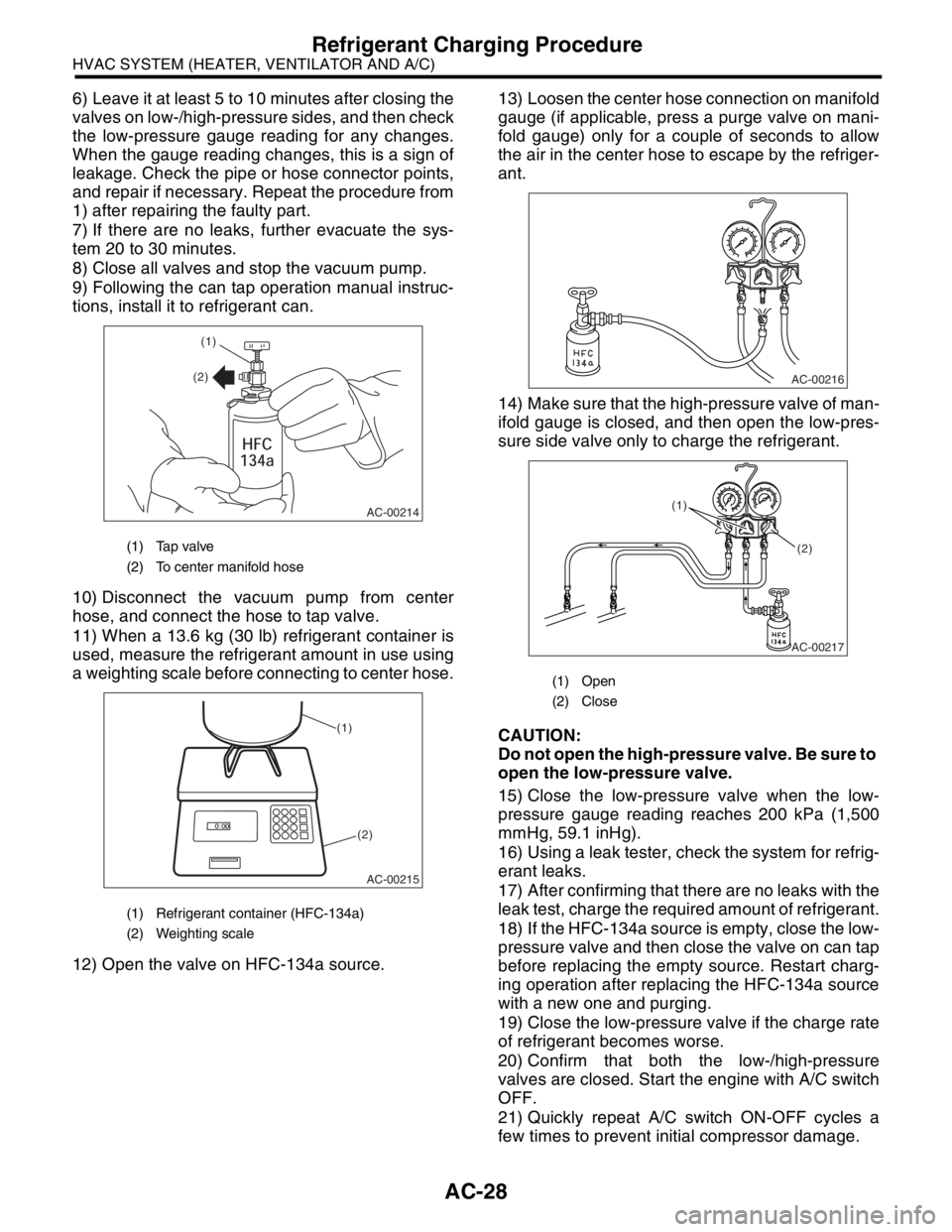

Refrigerant Charging Procedure

6) Leave it at least 5 to 10 minutes after closing the

valves on low-/high-pressure sides, and then check

the low-pressure gauge reading for any changes.

When the gauge reading changes, this is a sign of

leakage. Check the pipe or hose connector points,

and repair if necessary. Repeat the procedure from

1) after repairing the faulty part.

7) If there are no leaks, further evacuate the sys-

tem 20 to 30 minutes.

8) Close all valves and stop the vacuum pump.

9) Following the can tap operation manual instruc-

tions, install it to refrigerant can.

10) Disconnect the vacuum pump from center

hose, and connect the hose to tap valve.

11) When a 13.6 kg (30 lb) refrigerant container is

used, measure the refrigerant amount in use using

a weighting scale before connecting to center hose.

12) Open the valve on HFC-134a source.13) Loosen the center hose connection on manifold

gauge (if applicable, press a purge valve on mani-

fold gauge) only for a couple of seconds to allow

the air in the center hose to escape by the refriger-

ant.

14) Make sure that the high-pressure valve of man-

ifold gauge is closed, and then open the low-pres-

sure side valve only to charge the refrigerant.

CAUTION:

Do not open the high-pressure valve. Be sure to

open the low-pressure valve.

15) Close the low-pressure valve when the low-

pressure gauge reading reaches 200 kPa (1,500

mmHg, 59.1 inHg).

16) Using a leak tester, check the system for refrig-

erant leaks.

17) After confirming that there are no leaks with the

leak test, charge the required amount of refrigerant.

18) If the HFC-134a source is empty, close the low-

pressure valve and then close the valve on can tap

before replacing the empty source. Restart charg-

ing operation after replacing the HFC-134a source

with a new one and purging.

19) Close the low-pressure valve if the charge rate

of refrigerant becomes worse.

20) Confirm that both the low-/high-pressure

valves are closed. Start the engine with A/C switch

OFF.

21) Quickly repeat A/C switch ON-OFF cycles a

few times to prevent initial compressor damage.

(1) Tap valve

(2) To center manifold hose

(1) Refrigerant container (HFC-134a)

(2) Weighting scale

AC-00214

(1)

(2)

AC-00215

(1)

(2)

(1) Open

(2) Close

AC-00216

AC-00217

(1)

(2)

Page 33 of 2870

AC-31

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

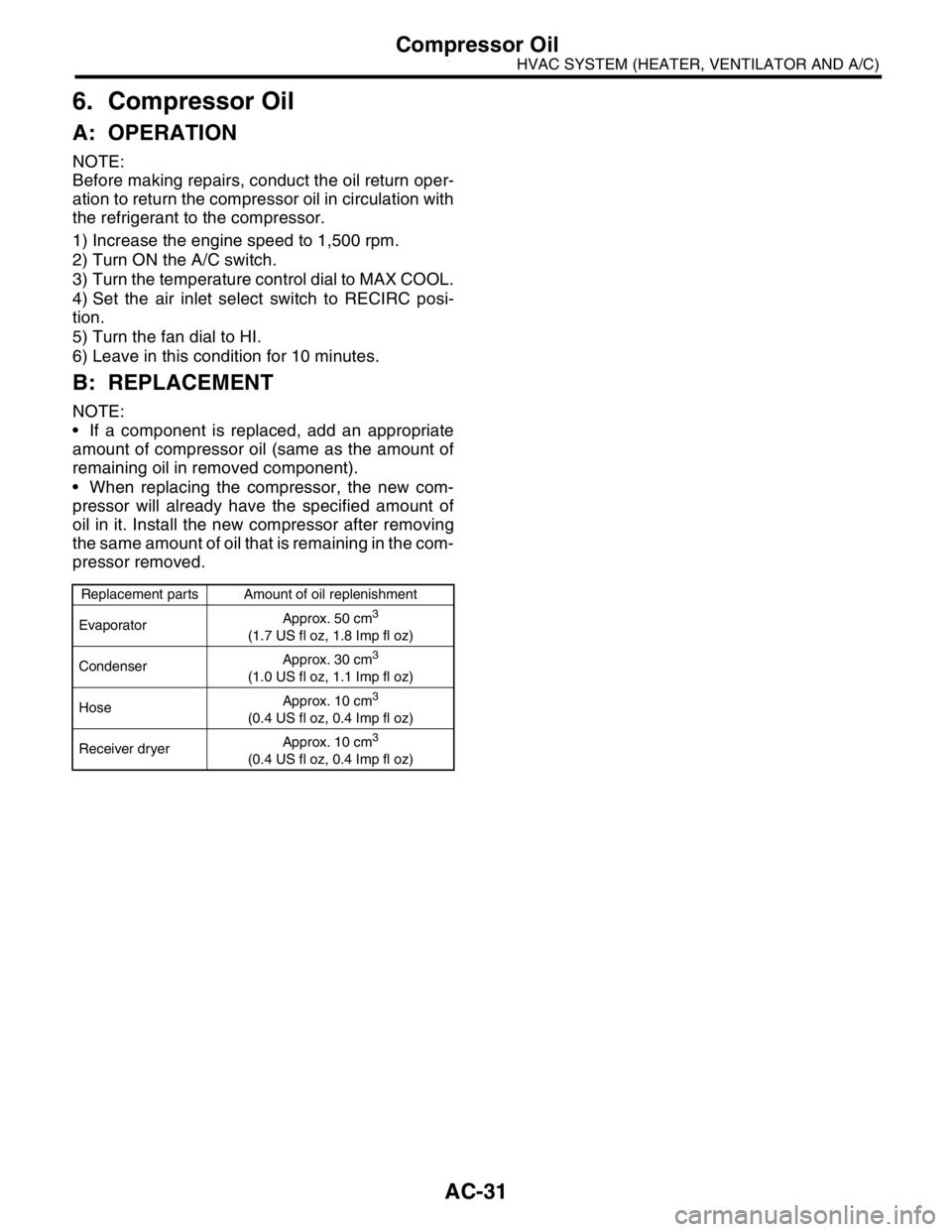

Compressor Oil

6. Compressor Oil

A: OPERATION

NOTE:

Before making repairs, conduct the oil return oper-

ation to return the compressor oil in circulation with

the refrigerant to the compressor.

1) Increase the engine speed to 1,500 rpm.

2) Turn ON the A/C switch.

3) Turn the temperature control dial to MAX COOL.

4) Set the air inlet select switch to RECIRC posi-

tion.

5) Turn the fan dial to HI.

6) Leave in this condition for 10 minutes.

B: REPLACEMENT

NOTE:

If a component is replaced, add an appropriate

amount of compressor oil (same as the amount of

remaining oil in removed component).

When replacing the compressor, the new com-

pressor will already have the specified amount of

oil in it. Install the new compressor after removing

the same amount of oil that is remaining in the com-

pressor removed.

Replacement parts Amount of oil replenishment

EvaporatorApprox. 50 cm

3

(1.7 US fl oz, 1.8 Imp fl oz)

CondenserApprox. 30 cm

3

(1.0 US fl oz, 1.1 Imp fl oz)

HoseApprox. 10 cm

3

(0.4 US fl oz, 0.4 Imp fl oz)

Receiver dryerApprox. 10 cm

3

(0.4 US fl oz, 0.4 Imp fl oz)

Page 52 of 2870

AC-50

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

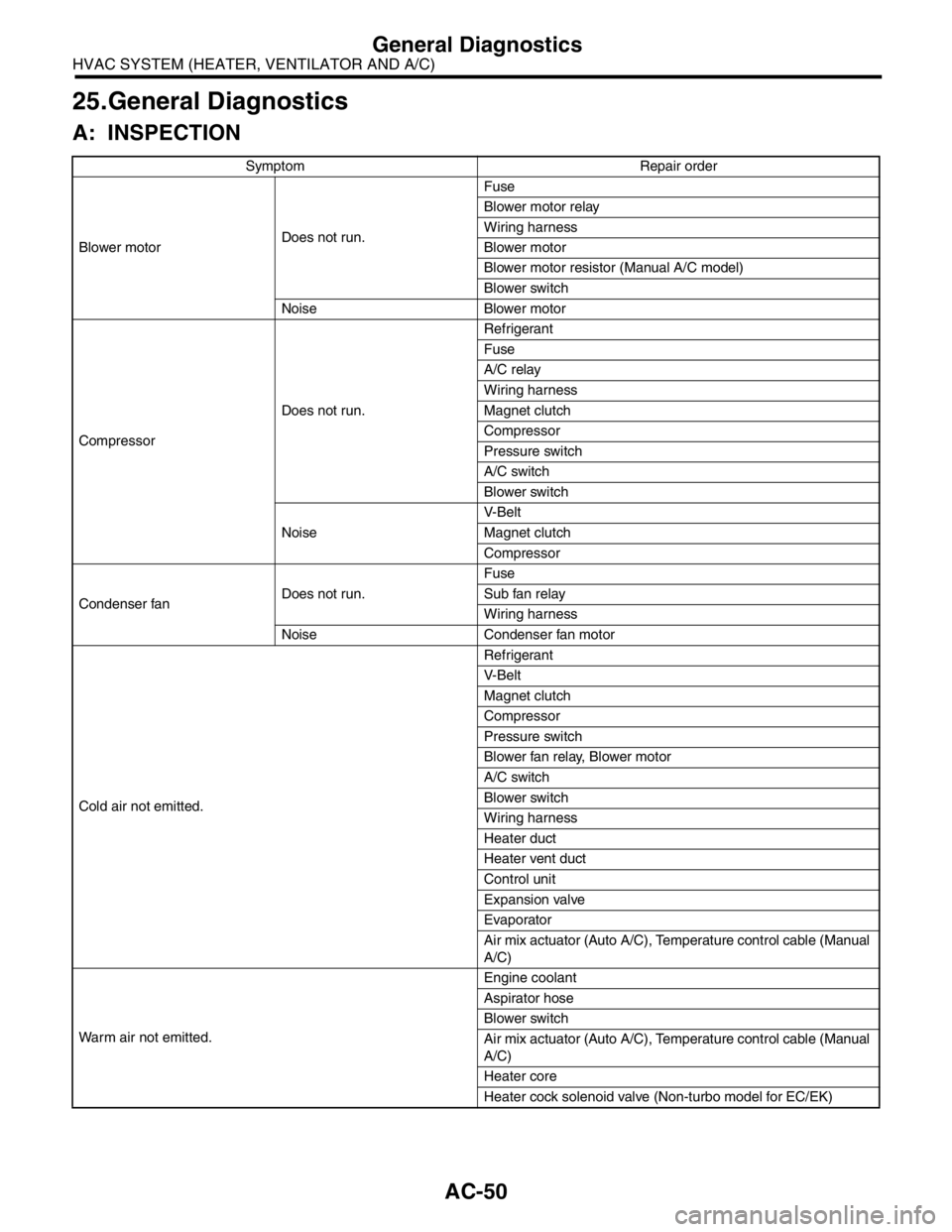

General Diagnostics

25.General Diagnostics

A: INSPECTION

Symptom Repair order

Blower motorDoes not run.Fuse

Blower motor relay

Wiring harness

Blower motor

Blower motor resistor (Manual A/C model)

Blower switch

Noise Blower motor

CompressorDoes not run.Refrigerant

Fuse

A/C relay

Wiring harness

Magnet clutch

Compressor

Pressure switch

A/C switch

Blower switch

NoiseV- B e l t

Magnet clutch

Compressor

Condenser fanDoes not run.Fuse

Sub fan relay

Wiring harness

Noise Condenser fan motor

Cold air not emitted.Refrigerant

V- B e l t

Magnet clutch

Compressor

Pressure switch

Blower fan relay, Blower motor

A/C switch

Blower switch

Wiring harness

Heater duct

Heater vent duct

Control unit

Expansion valve

Evaporator

Air mix actuator (Auto A/C), Temperature control cable (Manual

A/C)

Warm air not emitted.Engine coolant

Aspirator hose

Blower switch

Air mix actuator (Auto A/C), Temperature control cable (Manual

A/C)

Heater core

Heater cock solenoid valve (Non-turbo model for EC/EK)

Page 59 of 2870

AC-3

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

General Description

2. General Description

A: CAUTION

1) Never connect the battery in reverse polarity.

Auto A/C control module may be destroyed instant-

ly.

2) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as auto A/C control module,

etc.

3) Before disconnecting the connectors of each

sensor and the auto A/C control module, be sure to

turn off the ignition switch.

Auto A/C control module may be damaged.

4) Every A/C-related part is a precision part. Do not

drop them.

5) Airbag system wiring harness is routed near the

A/C control panel (auto A/C control module) and

junction box.

CAUTION:

For airbag system, yellow-colored wiring har-

ness and connectors are all used. Do not use

the electrical test equipment on these circuits.

Be careful not to damage the airbag system

wiring harness when servicing the A/C control

panel (auto A/C control module) and junction

box.

B: INSPECTION

Before performing the diagnosis, check the follow-

ing items which might affect A/C system problems.

1. BATTERY

1) Measure battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V

Specific gravity: More than 1.260

2) Check the condition of the fuses for A/C system

power supply and other fuses.

3) Check the condition of harness and harness

connector connections.

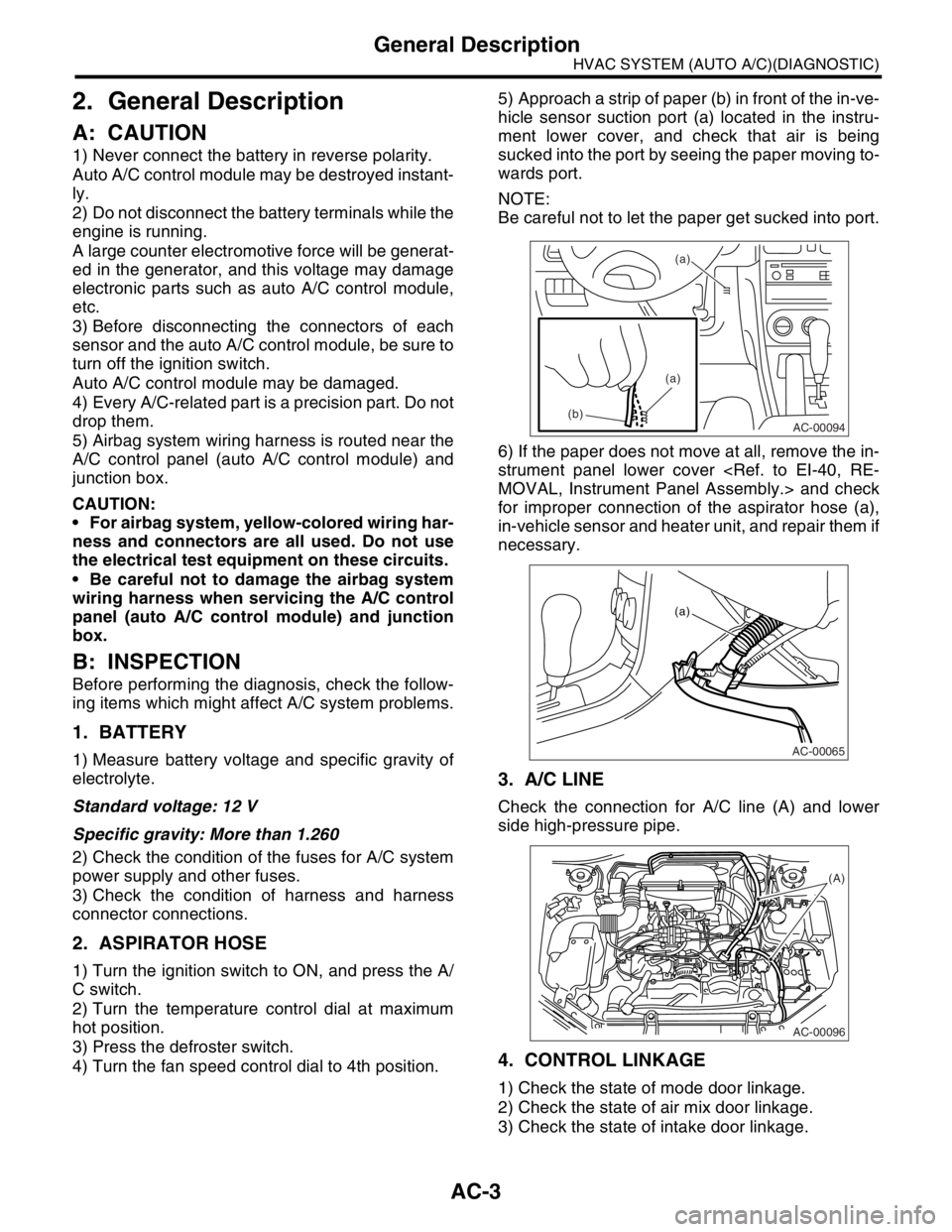

2. ASPIRATOR HOSE

1) Turn the ignition switch to ON, and press the A/

C switch.

2) Turn the temperature control dial at maximum

hot position.

3) Press the defroster switch.

4) Turn the fan speed control dial to 4th position.5) Approach a strip of paper (b) in front of the in-ve-

hicle sensor suction port (a) located in the instru-

ment lower cover, and check that air is being

sucked into the port by seeing the paper moving to-

wards port.

NOTE:

Be careful not to let the paper get sucked into port.

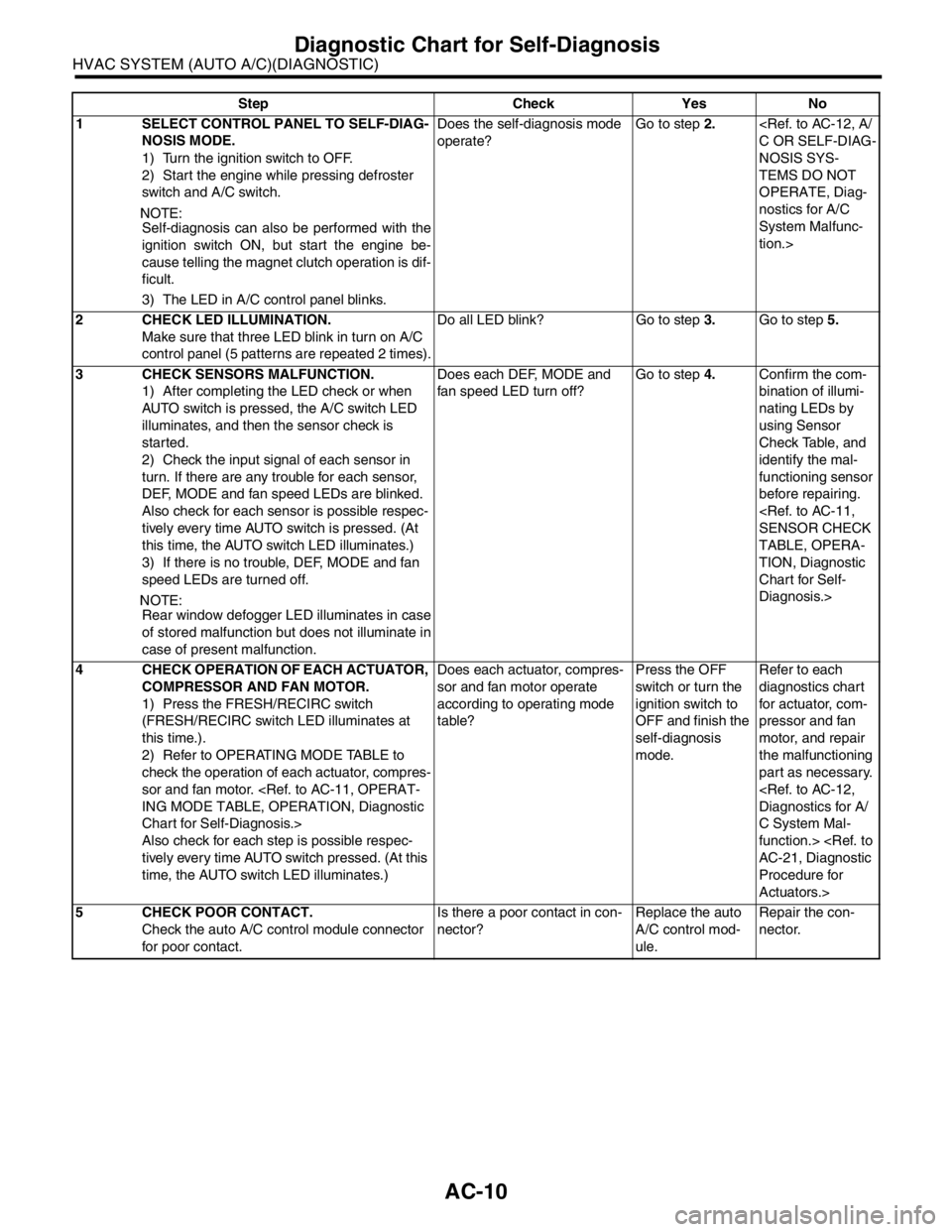

6) If the paper does not move at all, remove the in-

strument panel lower cover

for improper connection of the aspirator hose (a),

in-vehicle sensor and heater unit, and repair them if

necessary.

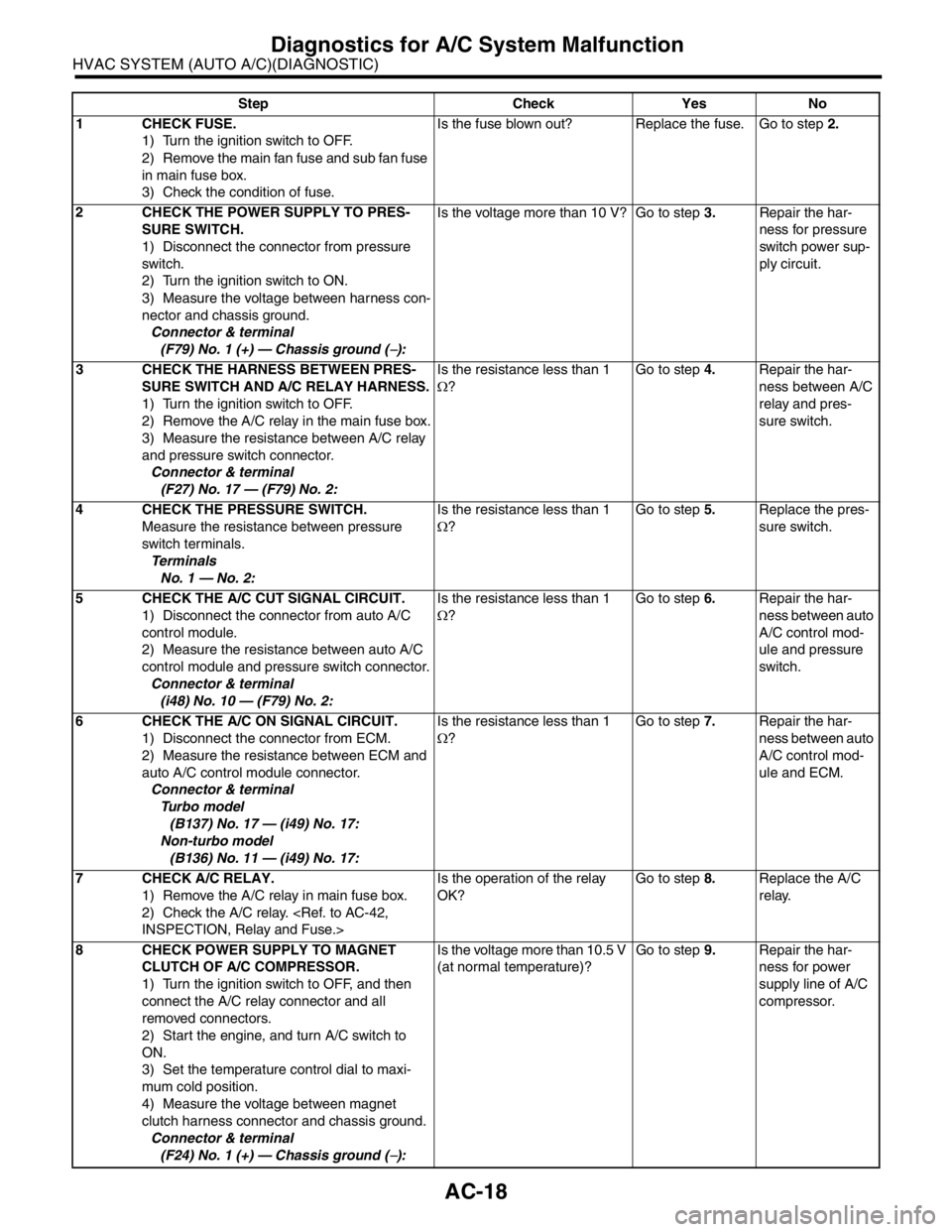

3. A/C LINE

Check the connection for A/C line (A) and lower

side high-pressure pipe.

4. CONTROL LINKAGE

1) Check the state of mode door linkage.

2) Check the state of air mix door linkage.

3) Check the state of intake door linkage.

AC-00094

(a)

(a)

(b)

AC-00065

(a)

AC-00096

(A)

Page 66 of 2870

AC-10

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

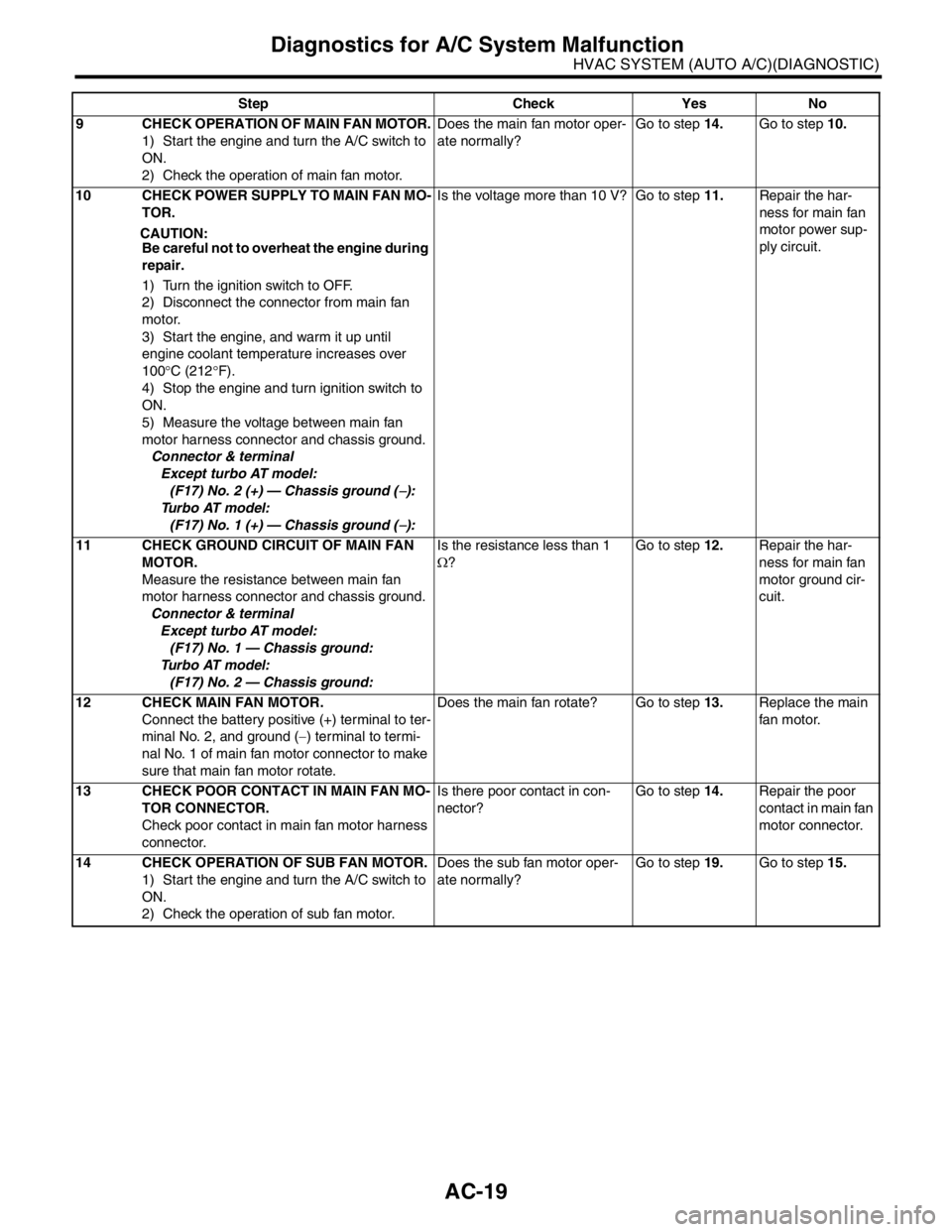

Diagnostic Chart for Self-Diagnosis

Step Check Yes No

1 SELECT CONTROL PANEL TO SELF-DIAG-

NOSIS MODE.

1) Turn the ignition switch to OFF.

2) Start the engine while pressing defroster

switch and A/C switch.

N

OTE:

Self-diagnosis can also be performed with the

ignition switch ON, but start the engine be-

cause telling the magnet clutch operation is dif-

ficult.

3) The LED in A/C control panel blinks.Does the self-diagnosis mode

operate?Go to step 2.

NOSIS SYS-

TEMS DO NOT

OPERATE, Diag-

nostics for A/C

System Malfunc-

tion.>

2 CHECK LED ILLUMINATION.

Make sure that three LED blink in turn on A/C

control panel (5 patterns are repeated 2 times).Do all LED blink? Go to step 3.Go to step 5.

3 CHECK SENSORS MALFUNCTION.

1) After completing the LED check or when

AUTO switch is pressed, the A/C switch LED

illuminates, and then the sensor check is

started.

2) Check the input signal of each sensor in

turn. If there are any trouble for each sensor,

DEF, MODE and fan speed LEDs are blinked.

Also check for each sensor is possible respec-

tively every time AUTO switch is pressed. (At

this time, the AUTO switch LED illuminates.)

3) If there is no trouble, DEF, MODE and fan

speed LEDs are turned off.

N

OTE:

Rear window defogger LED illuminates in case

of stored malfunction but does not illuminate in

case of present malfunction.Does each DEF, MODE and

fan speed LED turn off?Go to step 4.Confirm the com-

bination of illumi-

nating LEDs by

using Sensor

Check Table, and

identify the mal-

functioning sensor

before repairing.

TABLE, OPERA-

TION, Diagnostic

Chart for Self-

Diagnosis.>

4 CHECK OPERATION OF EACH ACTUATOR,

COMPRESSOR AND FAN MOTOR.

1) Press the FRESH/RECIRC switch

(FRESH/RECIRC switch LED illuminates at

this time.).

2) Refer to OPERATING MODE TABLE to

check the operation of each actuator, compres-

sor and fan motor.

Chart for Self-Diagnosis.>

Also check for each step is possible respec-

tively every time AUTO switch pressed. (At this

time, the AUTO switch LED illuminates.)Does each actuator, compres-

sor and fan motor operate

according to operating mode

table?Press the OFF

switch or turn the

ignition switch to

OFF and finish the

self-diagnosis

mode.Refer to each

diagnostics chart

for actuator, com-

pressor and fan

motor, and repair

the malfunctioning

par t as necessary.

C System Mal-

function.>

Procedure for

Actuators.>

5 CHECK POOR CONTACT.

Check the auto A/C control module connector

for poor contact.Is there a poor contact in con-

nector?Replace the auto

A/C control mod-

ule.Repair the con-

nector.

Page 74 of 2870

AC-18

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

Step Check Yes No

1 CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the main fan fuse and sub fan fuse

in main fuse box.

3) Check the condition of fuse.Is the fuse blown out? Replace the fuse. Go to step 2.

2 CHECK THE POWER SUPPLY TO PRES-

SURE SWITCH.

1) Disconnect the connector from pressure

switch.

2) Turn the ignition switch to ON.

3) Measure the voltage between harness con-

nector and chassis ground.

Connector & terminal

(F79) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for pressure

switch power sup-

ply circuit.

3 CHECK THE HARNESS BETWEEN PRES-

SURE SWITCH AND A/C RELAY HARNESS.

1) Turn the ignition switch to OFF.

2) Remove the A/C relay in the main fuse box.

3) Measure the resistance between A/C relay

and pressure switch connector.

Connector & terminal

(F27) No. 17 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 4.Repair the har-

ness between A/C

relay and pres-

sure switch.

4 CHECK THE PRESSURE SWITCH.

Measure the resistance between pressure

switch terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Go to step 5.Replace the pres-

sure switch.

5 CHECK THE A/C CUT SIGNAL CIRCUIT.

1) Disconnect the connector from auto A/C

control module.

2) Measure the resistance between auto A/C

control module and pressure switch connector.

Connector & terminal

(i48) No. 10 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 6.Repair the har-

ness between auto

A/C control mod-

ule and pressure

switch.

6 CHECK THE A/C ON SIGNAL CIRCUIT.

1) Disconnect the connector from ECM.

2) Measure the resistance between ECM and

auto A/C control module connector.

Connector & terminal

Turbo model

(B137) No. 17 — (i49) No. 17:

Non-turbo model

(B136) No. 11 — (i49) No. 17:Is the resistance less than 1

Ω?Go to step 7.Repair the har-

ness between auto

A/C control mod-

ule and ECM.

7 CHECK A/C RELAY.

1) Remove the A/C relay in main fuse box.

2) Check the A/C relay.

OK?Go to step 8.Replace the A/C

relay.

8 CHECK POWER SUPPLY TO MAGNET

CLUTCH OF A/C COMPRESSOR.

1) Turn the ignition switch to OFF, and then

connect the A/C relay connector and all

removed connectors.

2) Start the engine, and turn A/C switch to

ON.

3) Set the temperature control dial to maxi-

mum cold position.

4) Measure the voltage between magnet

clutch harness connector and chassis ground.

Connector & terminal

(F24) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10.5 V

(at normal temperature)?Go to step 9.Repair the har-

ness for power

supply line of A/C

compressor.

Page 75 of 2870

AC-19

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

9 CHECK OPERATION OF MAIN FAN MOTOR.

1) Start the engine and turn the A/C switch to

ON.

2) Check the operation of main fan motor.Does the main fan motor oper-

ate normally?Go to step 14.Go to step 10.

10 CHECK POWER SUPPLY TO MAIN FAN MO-

TOR.

CAUTION:

Be careful not to overheat the engine during

repair.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from main fan

motor.

3) Start the engine, and warm it up until

engine coolant temperature increases over

100°C (212°F).

4) Stop the engine and turn ignition switch to

ON.

5) Measure the voltage between main fan

motor harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F17) No. 2 (+) — Chassis ground (

−):

Turbo AT model:

(F17) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 11.Repair the har-

ness for main fan

motor power sup-

ply circuit.

11 CHECK GROUND CIRCUIT OF MAIN FAN

MOTOR.

Measure the resistance between main fan

motor harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F17) No. 1 — Chassis ground:

Turbo AT model:

(F17) No. 2 — Chassis ground:Is the resistance less than 1

Ω?Go to step 12.Repair the har-

ness for main fan

motor ground cir-

cuit.

12 CHECK MAIN FAN MOTOR.

Connect the battery positive (+) terminal to ter-

minal No. 2, and ground (−) terminal to termi-

nal No. 1 of main fan motor connector to make

sure that main fan motor rotate.Does the main fan rotate? Go to step 13.Replace the main

fan motor.

13 CHECK POOR CONTACT IN MAIN FAN MO-

TOR CONNECTOR.

Check poor contact in main fan motor harness

connector.Is there poor contact in con-

nector?Go to step 14.Repair the poor

contact in main fan

motor connector.

14 CHECK OPERATION OF SUB FAN MOTOR.

1) Start the engine and turn the A/C switch to

ON.

2) Check the operation of sub fan motor.Does the sub fan motor oper-

ate normally?Go to step 19.Go to step 15. Step Check Yes No

Page 76 of 2870

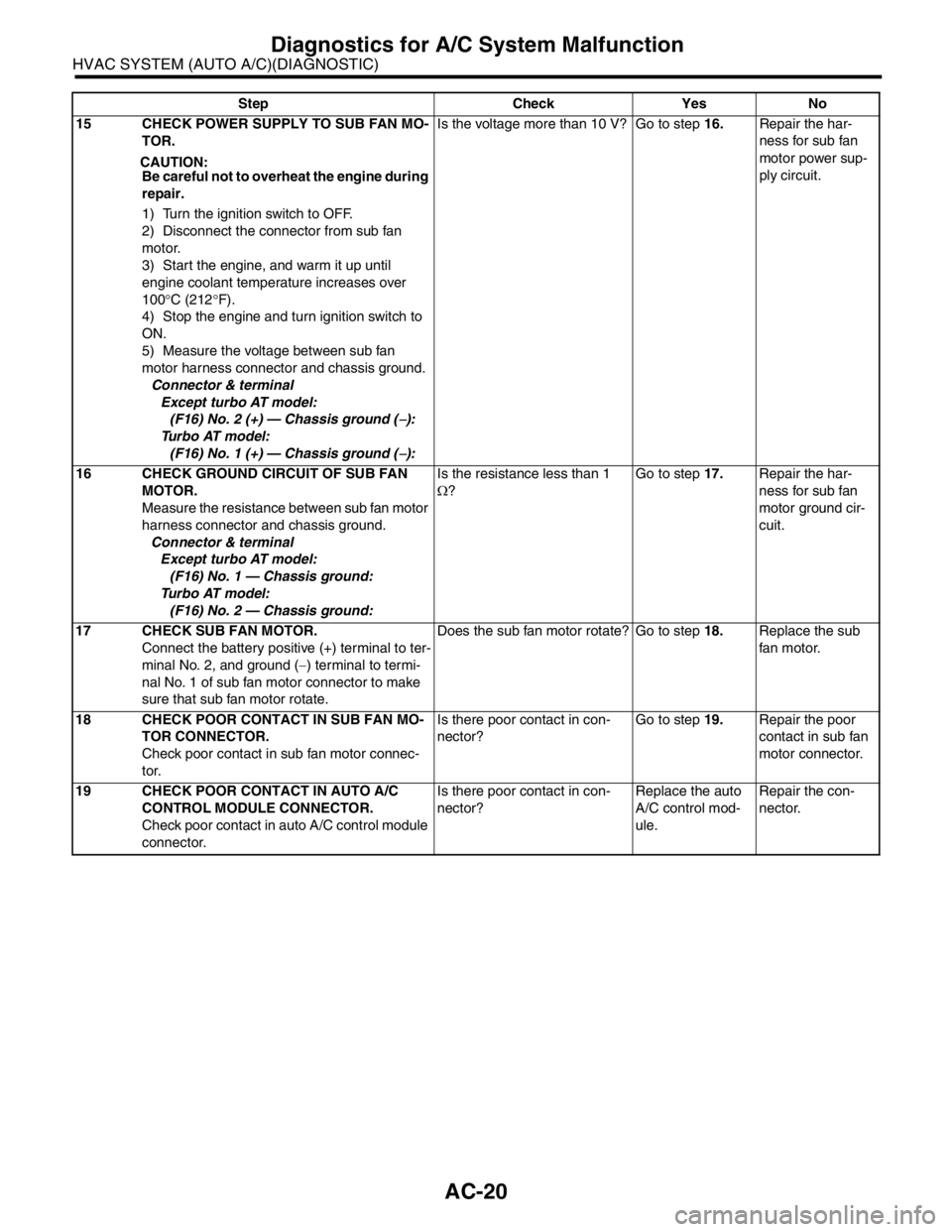

AC-20

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

15 CHECK POWER SUPPLY TO SUB FAN MO-

TOR.

CAUTION:

Be careful not to overheat the engine during

repair.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from sub fan

motor.

3) Start the engine, and warm it up until

engine coolant temperature increases over

100°C (212°F).

4) Stop the engine and turn ignition switch to

ON.

5) Measure the voltage between sub fan

motor harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F16) No. 2 (+) — Chassis ground (

−):

Turbo AT model:

(F16) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 16.Repair the har-

ness for sub fan

motor power sup-

ply circuit.

16 CHECK GROUND CIRCUIT OF SUB FAN

MOTOR.

Measure the resistance between sub fan motor

harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F16) No. 1 — Chassis ground:

Turbo AT model:

(F16) No. 2 — Chassis ground:Is the resistance less than 1

Ω?Go to step 17.Repair the har-

ness for sub fan

motor ground cir-

cuit.

17 CHECK SUB FAN MOTOR.

Connect the battery positive (+) terminal to ter-

minal No. 2, and ground (−) terminal to termi-

nal No. 1 of sub fan motor connector to make

sure that sub fan motor rotate.Does the sub fan motor rotate? Go to step 18.Replace the sub

fan motor.

18 CHECK POOR CONTACT IN SUB FAN MO-

TOR CONNECTOR.

Check poor contact in sub fan motor connec-

tor.Is there poor contact in con-

nector?Go to step 19.Repair the poor

contact in sub fan

motor connector.

19 CHECK POOR CONTACT IN AUTO A/C

CONTROL MODULE CONNECTOR.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Replace the auto

A/C control mod-

ule.Repair the con-

nector. Step Check Yes No

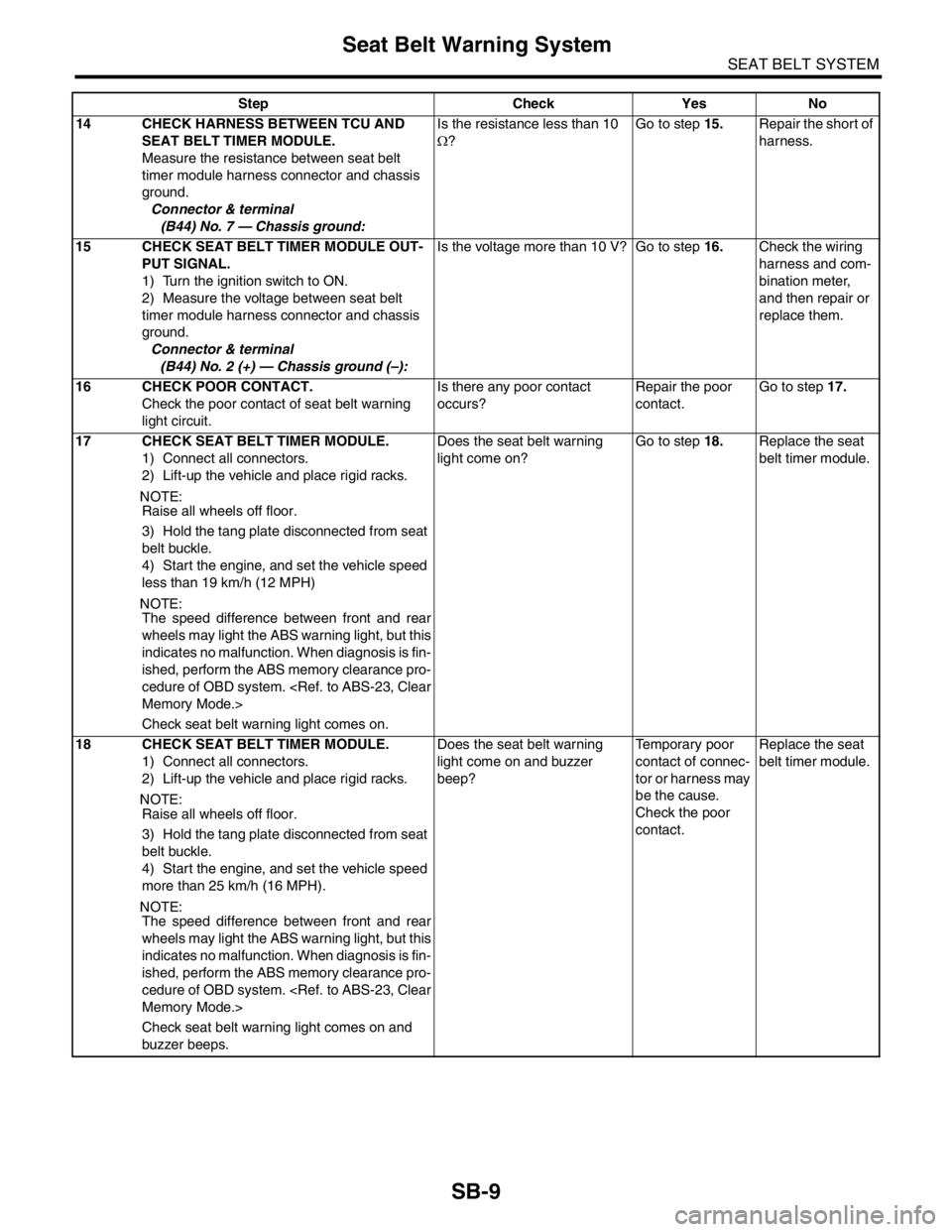

Page 243 of 2870

SB-9

SEAT BELT SYSTEM

Seat Belt Warning System

14 CHECK HARNESS BETWEEN TCU AND

SEAT BELT TIMER MODULE.

Measure the resistance between seat belt

timer module harness connector and chassis

ground.

Connector & terminal

(B44) No. 7 — Chassis ground:Is the resistance less than 10

Ω?Go to step 15.Repair the short of

harness.

15 CHECK SEAT BELT TIMER MODULE OUT-

PUT SIGNAL.

1) Turn the ignition switch to ON.

2) Measure the voltage between seat belt

timer module harness connector and chassis

ground.

Connector & terminal

(B44) No. 2 (+) — Chassis ground (–):Is the voltage more than 10 V? Go to step 16.Check the wiring

harness and com-

bination meter,

and then repair or

replace them.

16 CHECK POOR CONTACT.

Check the poor contact of seat belt warning

light circuit.Is there any poor contact

occurs?Repair the poor

contact.Go to step 17.

17 CHECK SEAT BELT TIMER MODULE.

1) Connect all connectors.

2) Lift-up the vehicle and place rigid racks.

NOTE:

Raise all wheels off floor.

3) Hold the tang plate disconnected from seat

belt buckle.

4) Start the engine, and set the vehicle speed

less than 19 km/h (12 MPH)

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When diagnosis is fin-

ished, perform the ABS memory clearance pro-

cedure of OBD system.

Check seat belt warning light comes on.Does the seat belt warning

light come on?Go to step 18.Replace the seat

belt timer module.

18 CHECK SEAT BELT TIMER MODULE.

1) Connect all connectors.

2) Lift-up the vehicle and place rigid racks.

N

OTE:

Raise all wheels off floor.

3) Hold the tang plate disconnected from seat

belt buckle.

4) Start the engine, and set the vehicle speed

more than 25 km/h (16 MPH).

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When diagnosis is fin-

ished, perform the ABS memory clearance pro-

cedure of OBD system.

Check seat belt warning light comes on and

buzzer beeps.Does the seat belt warning

light come on and buzzer

beep?Temporary poor

contact of connec-

tor or harness may

be the cause.

Check the poor

contact.Replace the seat

belt timer module. Step Check Yes No