SUBARU LEGACY 1999 Service Repair Manual

LEGACY 1999

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57435/w960_57435-0.png

SUBARU LEGACY 1999 Service Repair Manual

Trending: brake rotor, reset, heating, coolant, wheel size, Engine cooling, keyless entry

Page 141 of 1456

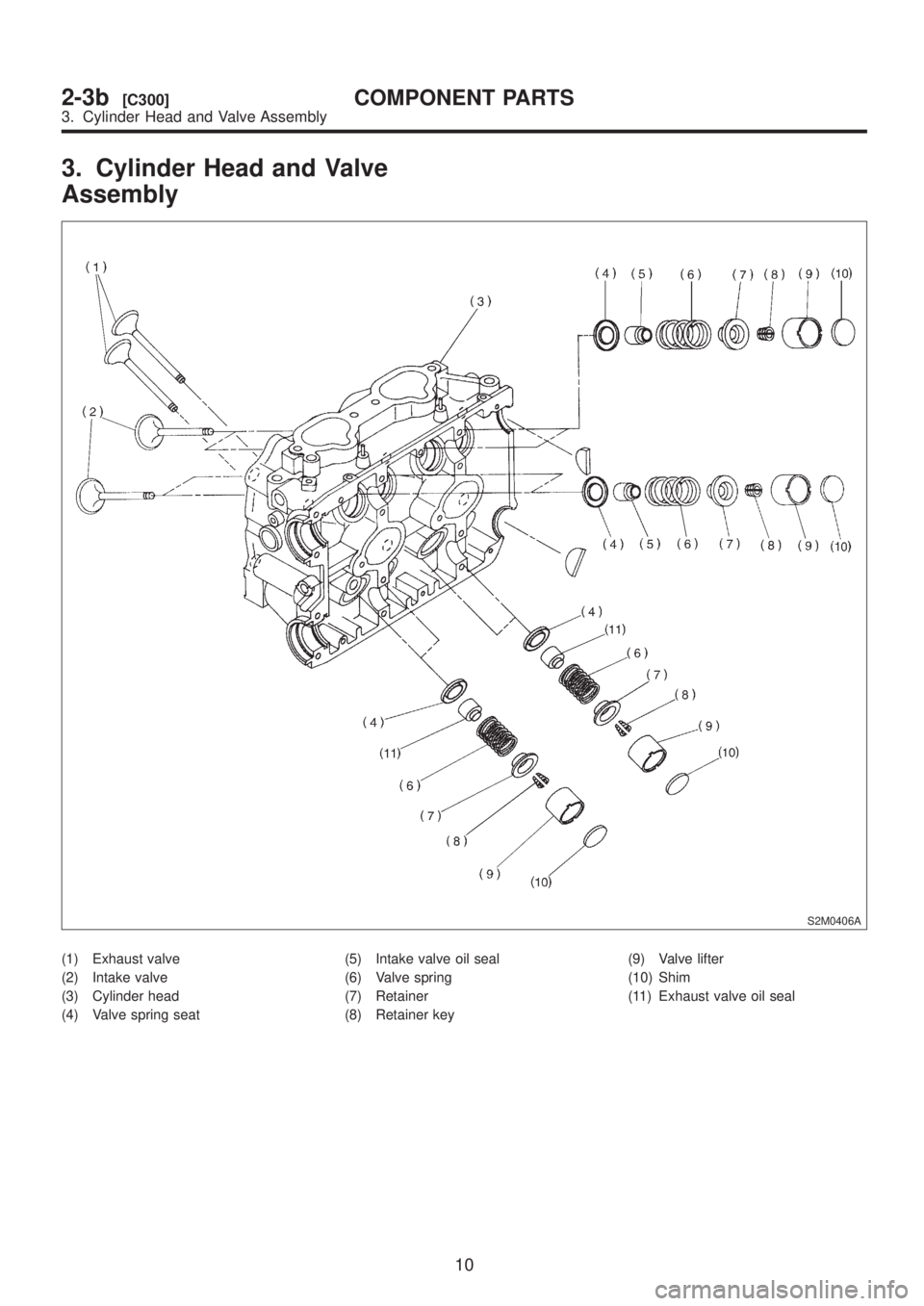

3. Cylinder Head and Valve

Assembly

S2M0406A

(1) Exhaust valve

(2) Intake valve

(3) Cylinder head

(4) Valve spring seat(5) Intake valve oil seal

(6) Valve spring

(7) Retainer

(8) Retainer key(9) Valve lifter

(10) Shim

(11) Exhaust valve oil seal

10

2-3b[C300]COMPONENT PARTS

3. Cylinder Head and Valve Assembly

Page 142 of 1456

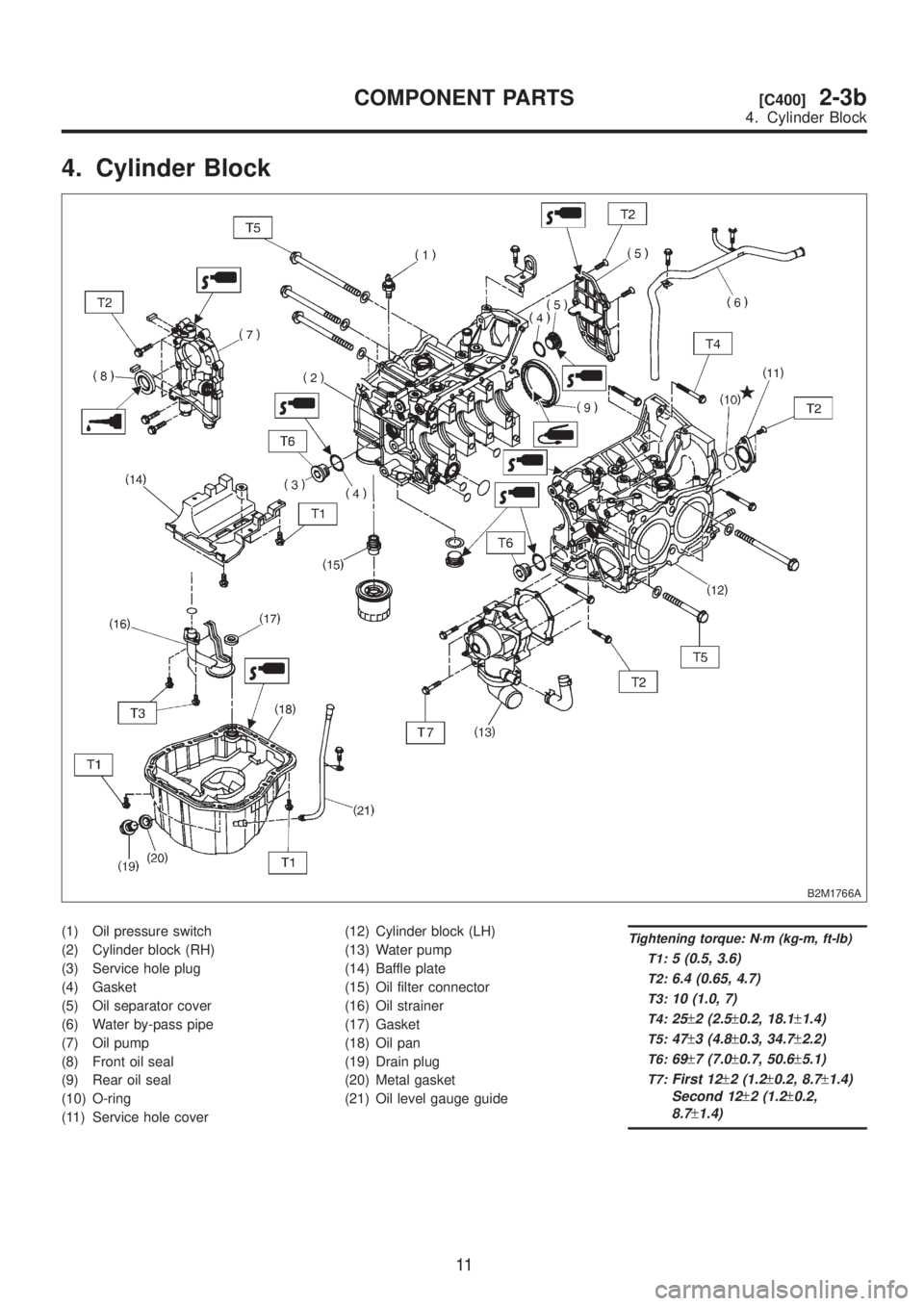

4. Cylinder Block

B2M1766A

(1) Oil pressure switch

(2) Cylinder block (RH)

(3) Service hole plug

(4) Gasket

(5) Oil separator cover

(6) Water by-pass pipe

(7) Oil pump

(8) Front oil seal

(9) Rear oil seal

(10) O-ring

(11) Service hole cover(12) Cylinder block (LH)

(13) Water pump

(14) Baffle plate

(15) Oil filter connector

(16) Oil strainer

(17) Gasket

(18) Oil pan

(19) Drain plug

(20) Metal gasket

(21) Oil level gauge guideTightening torque: N´m (kg-m, ft-lb)

T1:

5 (0.5, 3.6)

T2:6.4 (0.65, 4.7)

T3:10 (1.0, 7)

T4:25±2 (2.5±0.2, 18.1±1.4)

T5:47±3 (4.8±0.3, 34.7±2.2)

T6:69±7 (7.0±0.7, 50.6±5.1)

T7:First 12±2 (1.2±0.2, 8.7±1.4)

Second 12

±2 (1.2±0.2,

8.7

±1.4)

11

[C400]2-3bCOMPONENT PARTS

4. Cylinder Block

Page 143 of 1456

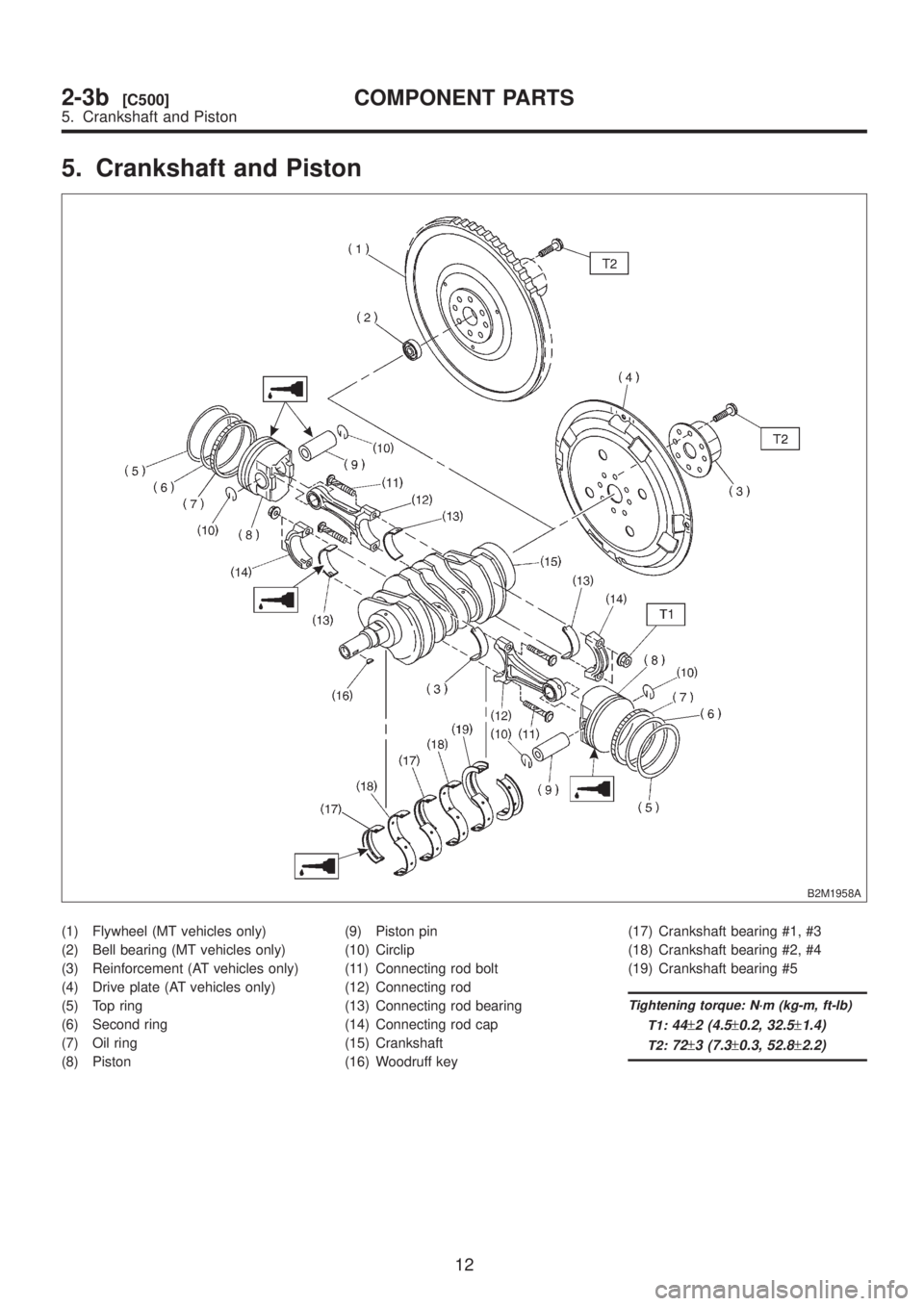

5. Crankshaft and Piston

B2M1958A

(1) Flywheel (MT vehicles only)

(2) Bell bearing (MT vehicles only)

(3) Reinforcement (AT vehicles only)

(4) Drive plate (AT vehicles only)

(5) Top ring

(6) Second ring

(7) Oil ring

(8) Piston(9) Piston pin

(10) Circlip

(11) Connecting rod bolt

(12) Connecting rod

(13) Connecting rod bearing

(14) Connecting rod cap

(15) Crankshaft

(16) Woodruff key(17) Crankshaft bearing #1, #3

(18) Crankshaft bearing #2, #4

(19) Crankshaft bearing #5

Tightening torque: N´m (kg-m, ft-lb)

T1:

44±2 (4.5±0.2, 32.5±1.4)

T2:72±3 (7.3±0.3, 52.8±2.2)

12

2-3b[C500]COMPONENT PARTS

5. Crankshaft and Piston

Page 144 of 1456

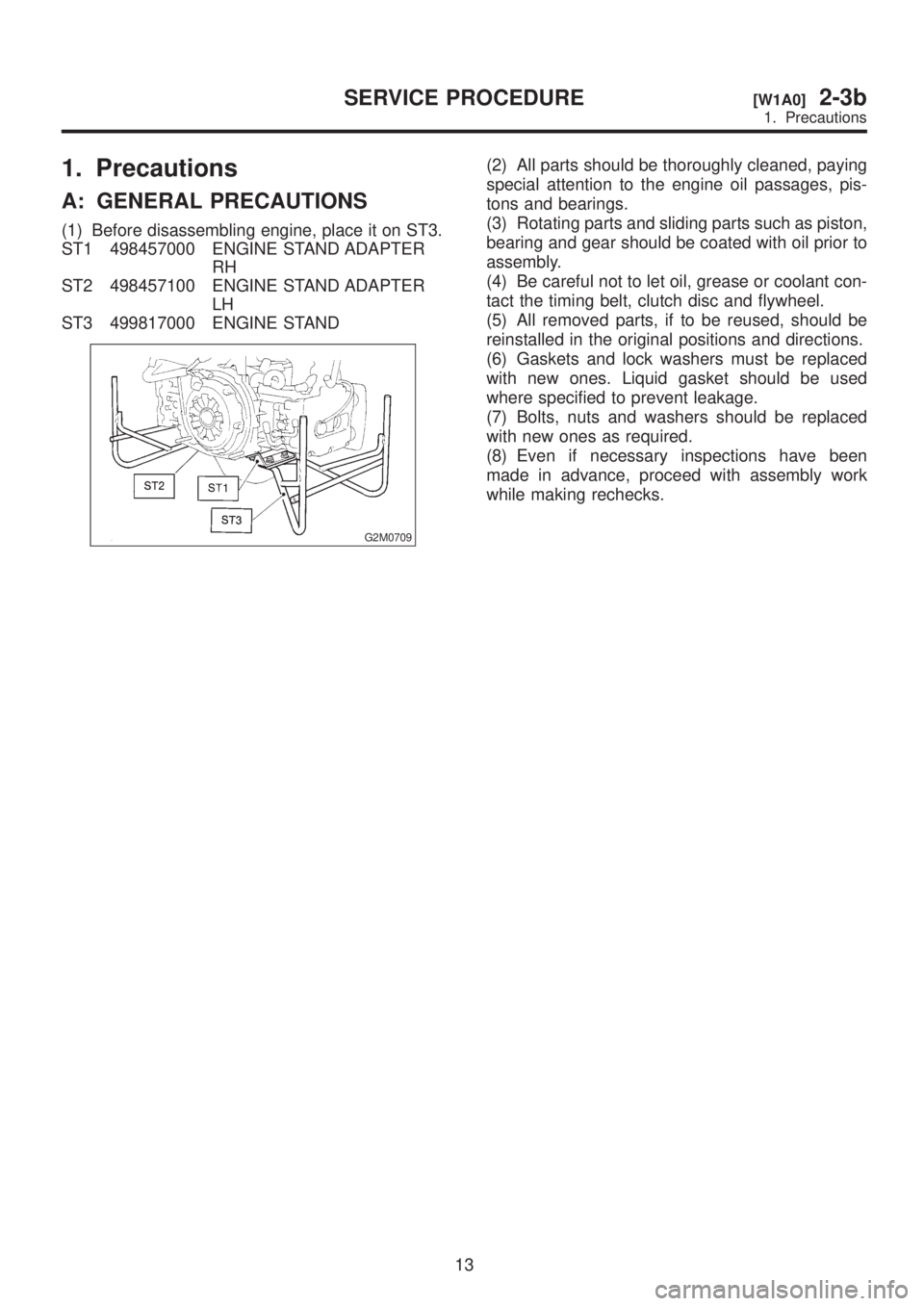

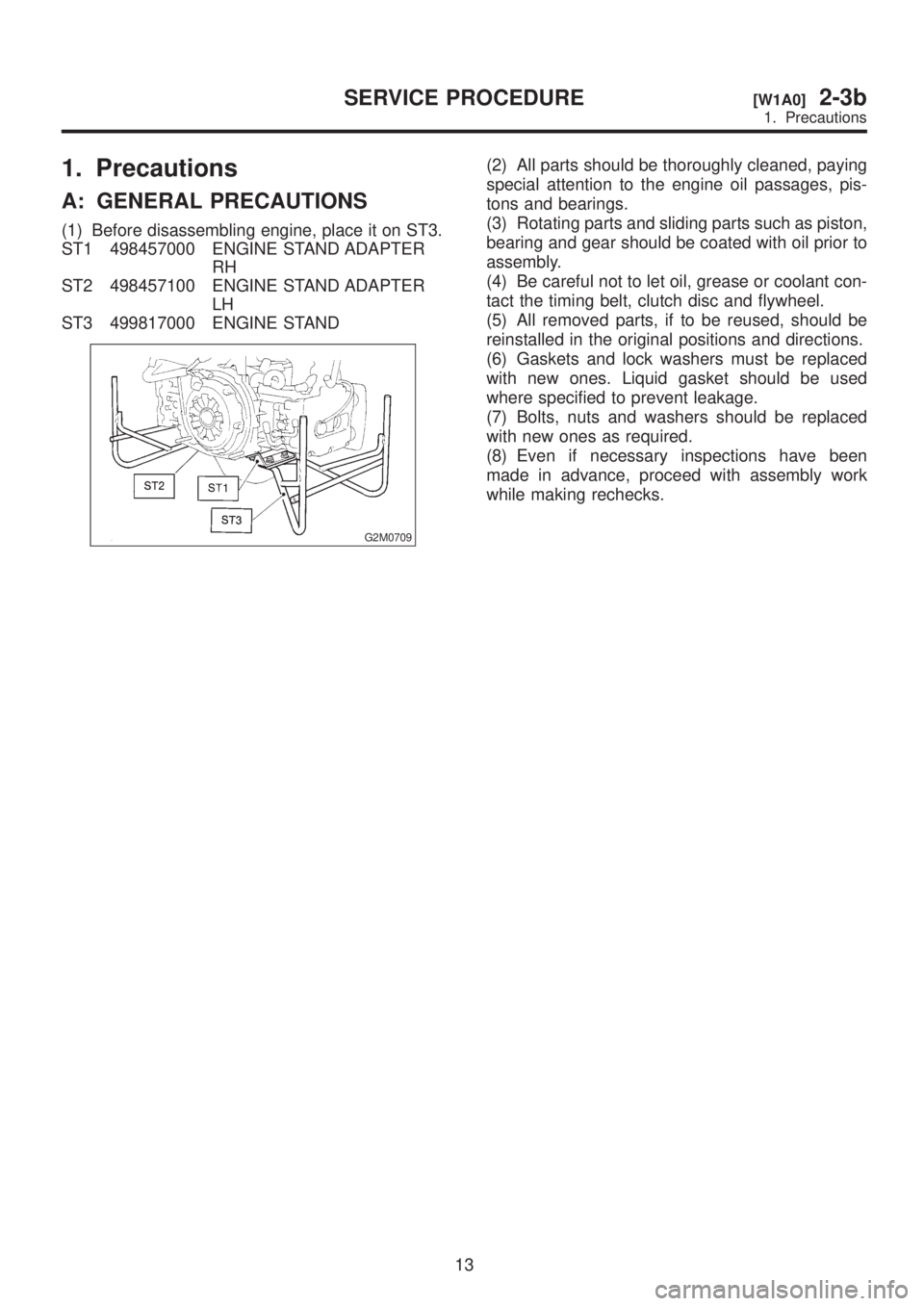

1. Precautions

A: GENERAL PRECAUTIONS

(1) Before disassembling engine, place it on ST3.

ST1 498457000 ENGINE STAND ADAPTER

RH

ST2 498457100 ENGINE STAND ADAPTER

LH

ST3 499817000 ENGINE STAND

G2M0709

(2) All parts should be thoroughly cleaned, paying

special attention to the engine oil passages, pis-

tons and bearings.

(3) Rotating parts and sliding parts such as piston,

bearing and gear should be coated with oil prior to

assembly.

(4) Be careful not to let oil, grease or coolant con-

tact the timing belt, clutch disc and flywheel.

(5) All removed parts, if to be reused, should be

reinstalled in the original positions and directions.

(6) Gaskets and lock washers must be replaced

with new ones. Liquid gasket should be used

where specified to prevent leakage.

(7) Bolts, nuts and washers should be replaced

with new ones as required.

(8) Even if necessary inspections have been

made in advance, proceed with assembly work

while making rechecks.

13

[W1A0]2-3bSERVICE PROCEDURE

1. Precautions

Page 145 of 1456

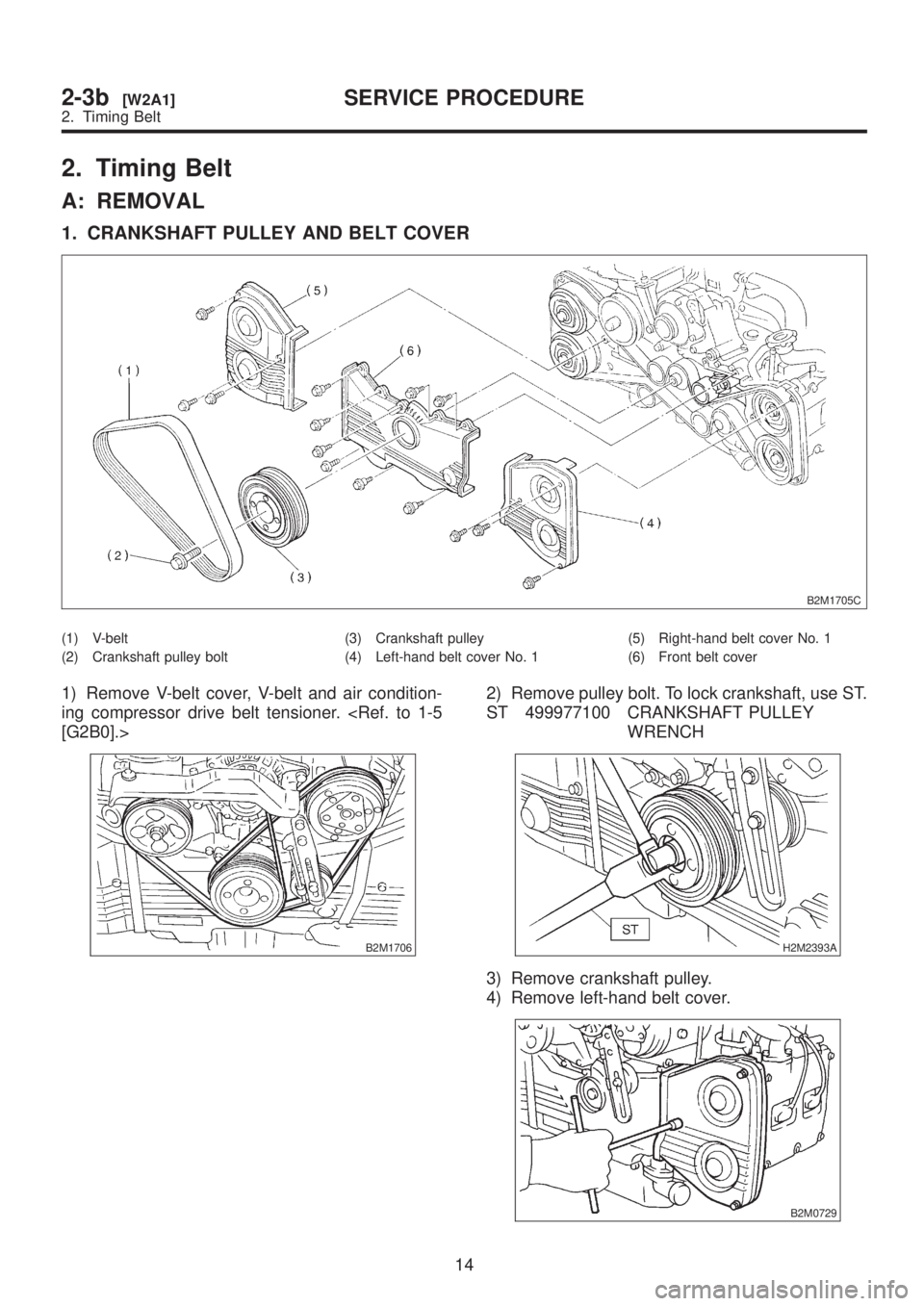

2. Timing Belt

A: REMOVAL

1. CRANKSHAFT PULLEY AND BELT COVER

B2M1705C

(1) V-belt

(2) Crankshaft pulley bolt(3) Crankshaft pulley

(4) Left-hand belt cover No. 1(5) Right-hand belt cover No. 1

(6) Front belt cover

1) Remove V-belt cover, V-belt and air condition-

ing compressor drive belt tensioner.

[G2B0].>

B2M1706

2) Remove pulley bolt. To lock crankshaft, use ST.

ST 499977100 CRANKSHAFT PULLEY

WRENCH

H2M2393A

3) Remove crankshaft pulley.

4) Remove left-hand belt cover.

B2M0729

14

2-3b[W2A1]SERVICE PROCEDURE

2. Timing Belt

Page 146 of 1456

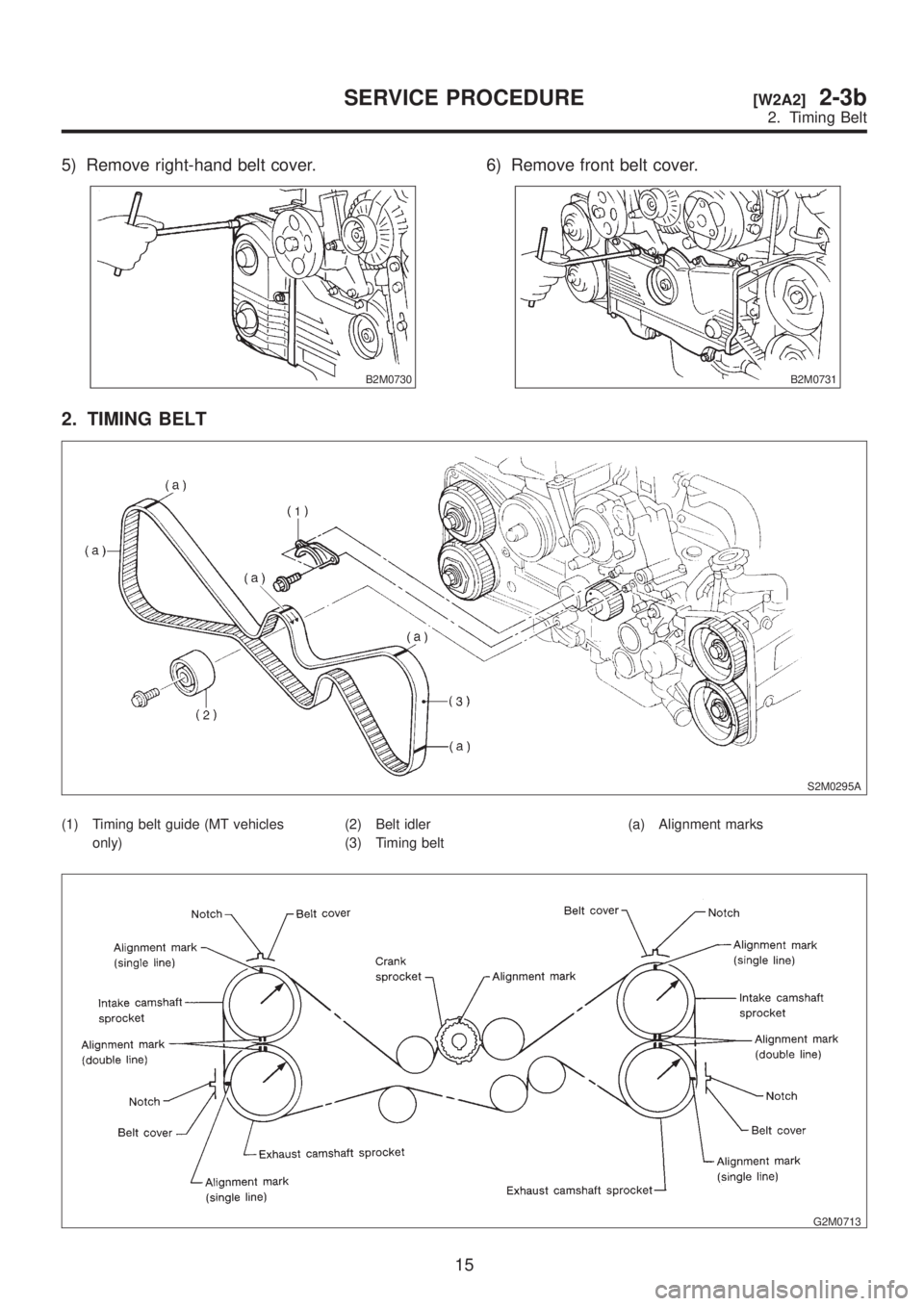

5) Remove right-hand belt cover.

B2M0730

6) Remove front belt cover.

B2M0731

2. TIMING BELT

S2M0295A

(1) Timing belt guide (MT vehicles

only)(2) Belt idler

(3) Timing belt(a) Alignment marks

G2M0713

15

[W2A2]2-3bSERVICE PROCEDURE

2. Timing Belt

Page 147 of 1456

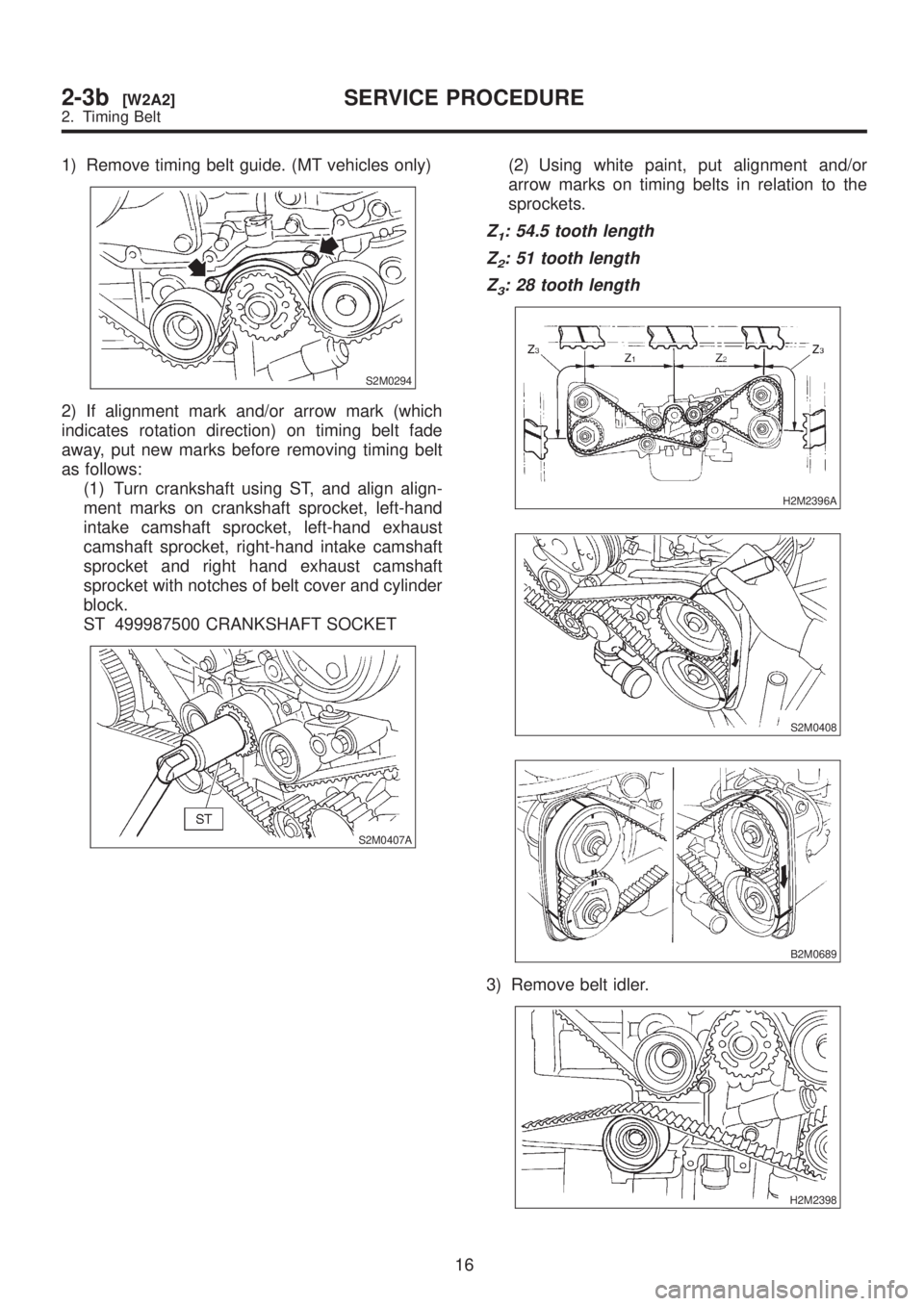

1) Remove timing belt guide. (MT vehicles only)

S2M0294

2) If alignment mark and/or arrow mark (which

indicates rotation direction) on timing belt fade

away, put new marks before removing timing belt

as follows:

(1) Turn crankshaft using ST, and align align-

ment marks on crankshaft sprocket, left-hand

intake camshaft sprocket, left-hand exhaust

camshaft sprocket, right-hand intake camshaft

sprocket and right hand exhaust camshaft

sprocket with notches of belt cover and cylinder

block.

ST 499987500 CRANKSHAFT SOCKET

S2M0407A

(2) Using white paint, put alignment and/or

arrow marks on timing belts in relation to the

sprockets.

Z1: 54.5 tooth length

Z

2: 51 tooth length

Z

3: 28 tooth length

H2M2396A

S2M0408

B2M0689

3) Remove belt idler.

H2M2398

16

2-3b[W2A2]SERVICE PROCEDURE

2. Timing Belt

Page 148 of 1456

4) Remove timing belt.

CAUTION:

After timing belt has been removed, never

rotate intake and exhaust, camshaft sprocket.

If camshaft sprocket is rotated, the intake and

exhaust valve heads strike together and valve

stems are bent.

S2M0409

3. BELT IDLER AND AUTOMATIC BELT TENSION ADJUSTER ASSEMBLY

H2M2400C

(1) Belt idler

(2) Belt idler No. 2(3) Automatic belt tension adjuster

ASSY

1) Remove belt idler.

S2M0410

2) Remove belt idler No. 2.

S2M0411

17

[W2A3]2-3bSERVICE PROCEDURE

2. Timing Belt

Page 149 of 1456

3) Remove automatic belt tension adjuster assem-

bly.

S2M0412

4. SPROCKET

H2M2404C

(1) Left-hand intake camshaft

sprocket

(2) Left-hand exhaust camshaft

sprocket(3) Right-hand intake camshaft

sprocket

(4) Right-hand exhaust camshaft

sprocket(5) Crankshaft sprocket

(6) Tensioner bracket

(7) Left-hand belt cover No. 2

(8) Right-hand belt cover No. 2

18

2-3b[W2A4]SERVICE PROCEDURE

2. Timing Belt

Page 150 of 1456

1) Remove left-hand intake camshaft sprocket.

2) Remove left-hand exhaust camshaft sprocket.

3) Remove right-hand intake camshaft sprocket.

4) Remove right-hand exhaust camshaft sprocket.

ST 499207300 CAMSHAFT SPROCKET

WRENCH

S2M0413A

5) Remove crankshaft sprocket.

S2M0414

6) Remove tensioner bracket.

H2M2407

7) Remove left-hand belt cover No. 2.

S2M0415

8) Remove right-hand belt cover No. 2.

B2M0738

B: INSPECTION

1. TIMING BELT

1) Check timing belt teeth for breaks, cracks and

wear. If any fault is found, replace belt.

2) Check the condition of back side of belt; if any

crack is found, replace belt.

CAUTION:

IBe careful not to let oil, grease or coolant

contact the belt. Remove quickly and thor-

oughly if this happens.

IDo not bend the belt sharply.

Bending radius: h

60 mm (2.36 in) or more

G2M0115

2. AUTOMATIC BELT TENSION

ADJUSTER

1) Visually check oil seals for leaks, and rod ends

for abnormal wear or scratches. If necessary,

replace automatic belt tension adjuster assembly.

CAUTION:

Slight traces of oil at rod's oil seal does not

indicate a problem.

2) Check that the adjuster rod does not move

when a pressure of 294 N (30 kg, 66 lb) is applied

to it. This is to check adjuster rod stiffness.

3) If the adjuster rod is not stiff and moves freely

when applying 294 N (30 kg, 66 lb), check it using

the following procedures:

19

[W2B2]2-3bSERVICE PROCEDURE

2. Timing Belt

Trending: weight, compressor, read, height, remote start, engine oil capacity, light