SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 101 of 1456

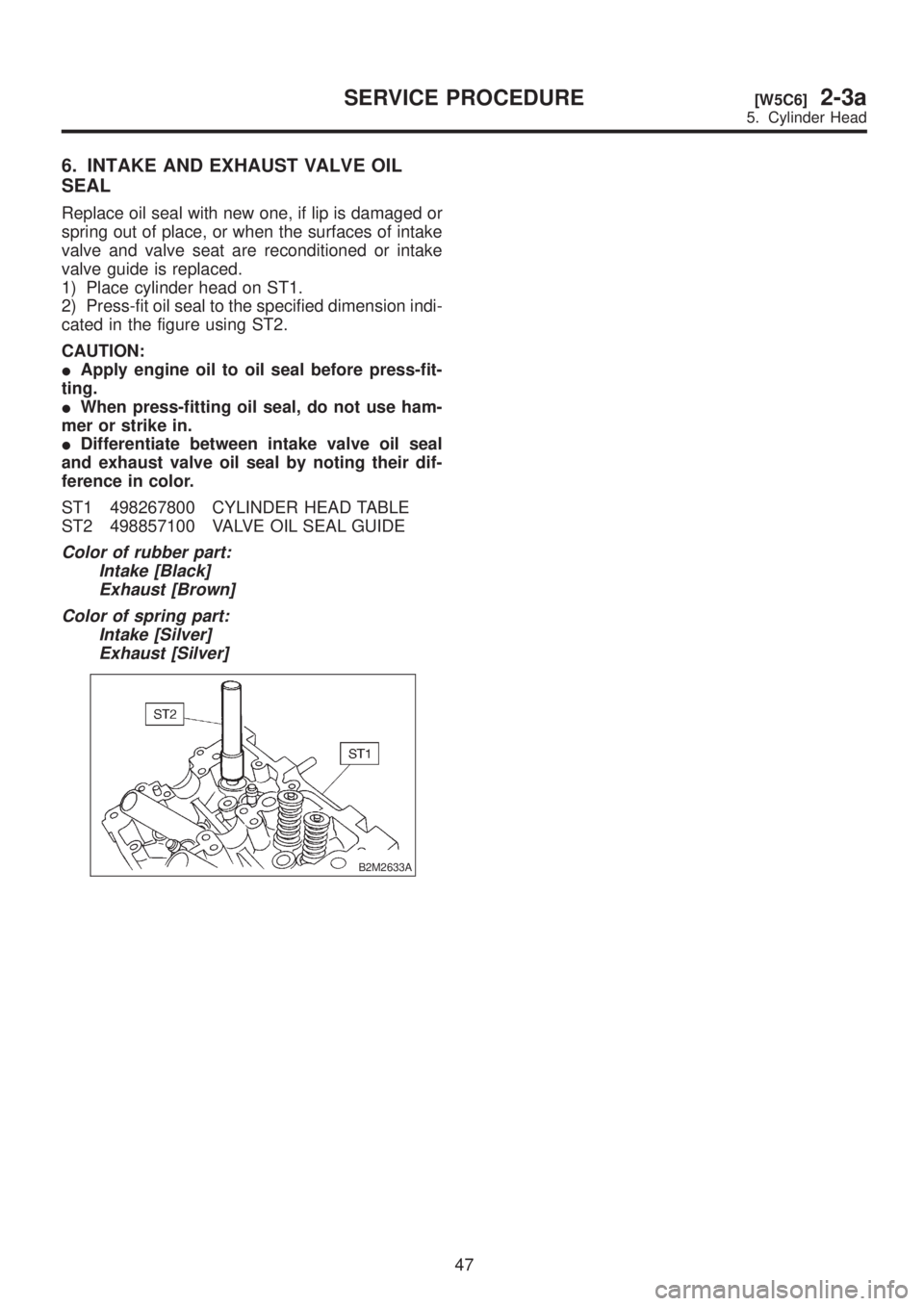

6. INTAKE AND EXHAUST VALVE OIL

SEAL

Replace oil seal with new one, if lip is damaged or

spring out of place, or when the surfaces of intake

valve and valve seat are reconditioned or intake

valve guide is replaced.

1) Place cylinder head on ST1.

2) Press-fit oil seal to the specified dimension indi-

cated in the figure using ST2.

CAUTION:

IApply engine oil to oil seal before press-fit-

ting.

IWhen press-fitting oil seal, do not use ham-

mer or strike in.

IDifferentiate between intake valve oil seal

and exhaust valve oil seal by noting their dif-

ference in color.

ST1 498267800 CYLINDER HEAD TABLE

ST2 498857100 VALVE OIL SEAL GUIDE

Color of rubber part:

Intake [Black]

Exhaust [Brown]

Color of spring part:

Intake [Silver]

Exhaust [Silver]

B2M2633A

47

[W5C6]2-3aSERVICE PROCEDURE

5. Cylinder Head

Page 102 of 1456

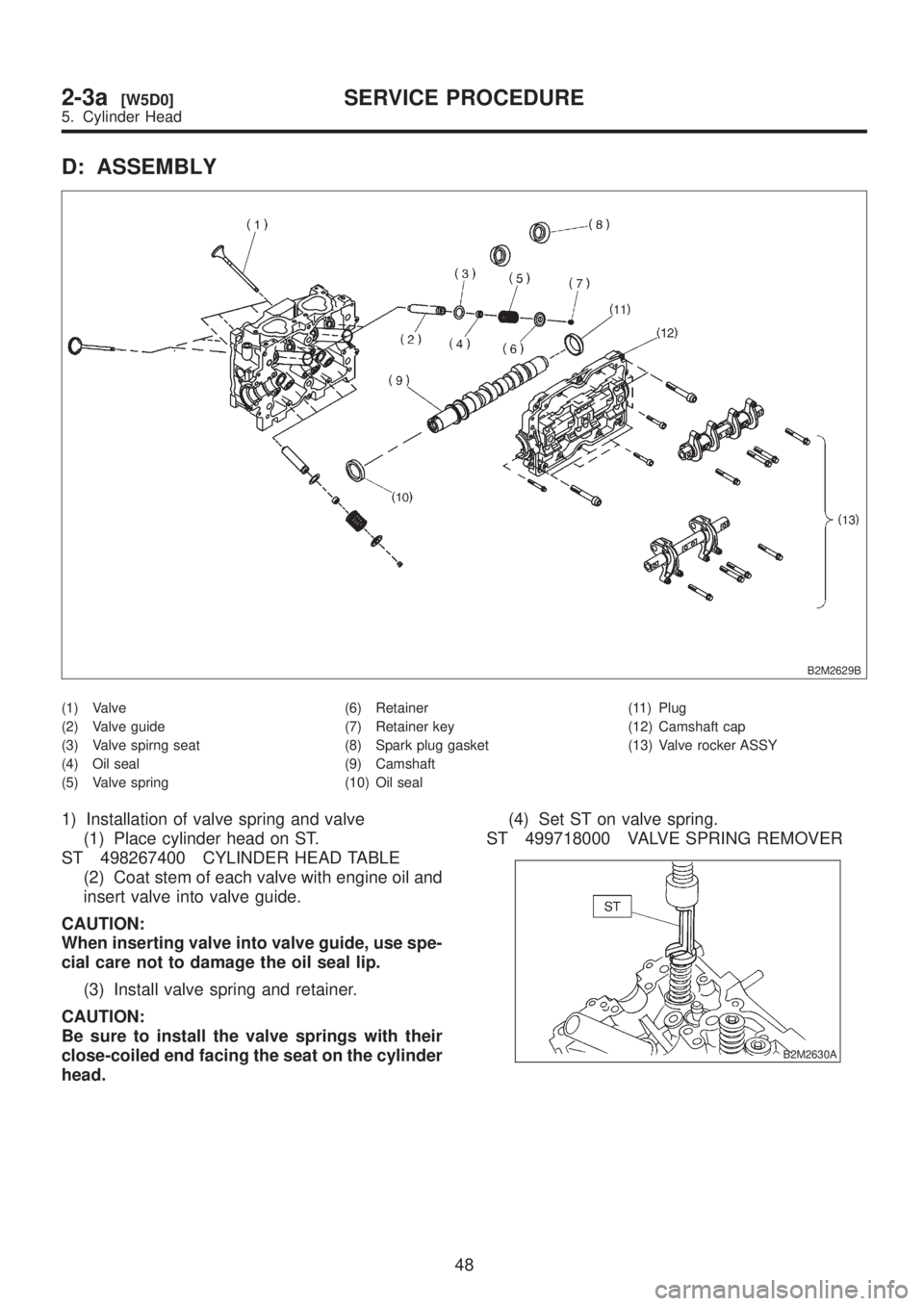

D: ASSEMBLY

B2M2629B

(1) Valve

(2) Valve guide

(3) Valve spirng seat

(4) Oil seal

(5) Valve spring(6) Retainer

(7) Retainer key

(8) Spark plug gasket

(9) Camshaft

(10) Oil seal(11) Plug

(12) Camshaft cap

(13) Valve rocker ASSY

1) Installation of valve spring and valve

(1) Place cylinder head on ST.

ST 498267400 CYLINDER HEAD TABLE

(2) Coat stem of each valve with engine oil and

insert valve into valve guide.

CAUTION:

When inserting valve into valve guide, use spe-

cial care not to damage the oil seal lip.

(3) Install valve spring and retainer.

CAUTION:

Be sure to install the valve springs with their

close-coiled end facing the seat on the cylinder

head.(4) Set ST on valve spring.

ST 499718000 VALVE SPRING REMOVER

B2M2630A

48

2-3a[W5D0]SERVICE PROCEDURE

5. Cylinder Head

Page 103 of 1456

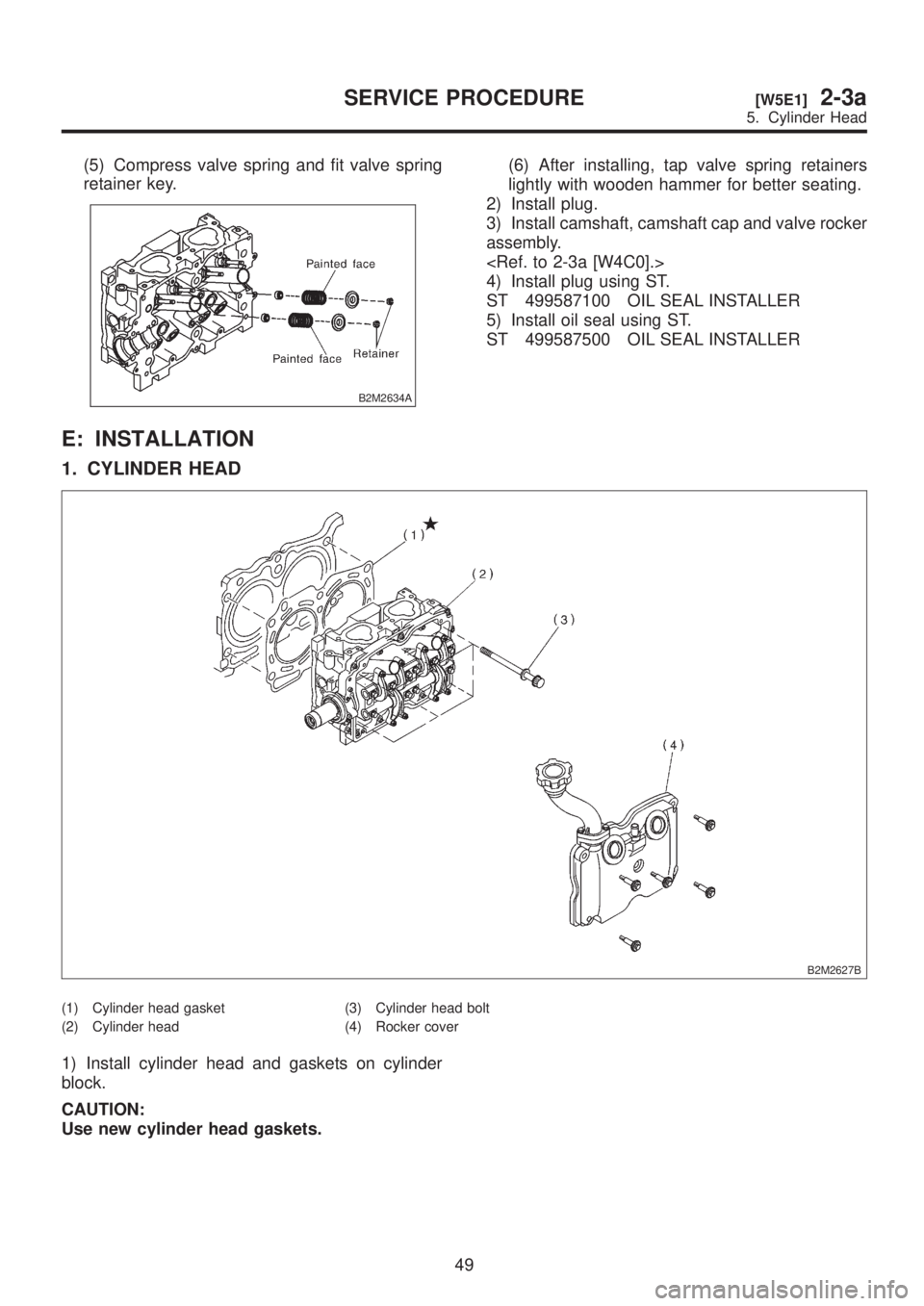

(5) Compress valve spring and fit valve spring

retainer key.

B2M2634A

(6) After installing, tap valve spring retainers

lightly with wooden hammer for better seating.

2) Install plug.

3) Install camshaft, camshaft cap and valve rocker

assembly.

4) Install plug using ST.

ST 499587100 OIL SEAL INSTALLER

5) Install oil seal using ST.

ST 499587500 OIL SEAL INSTALLER

E: INSTALLATION

1. CYLINDER HEAD

B2M2627B

(1) Cylinder head gasket

(2) Cylinder head(3) Cylinder head bolt

(4) Rocker cover

1) Install cylinder head and gaskets on cylinder

block.

CAUTION:

Use new cylinder head gaskets.

49

[W5E1]2-3aSERVICE PROCEDURE

5. Cylinder Head

Page 104 of 1456

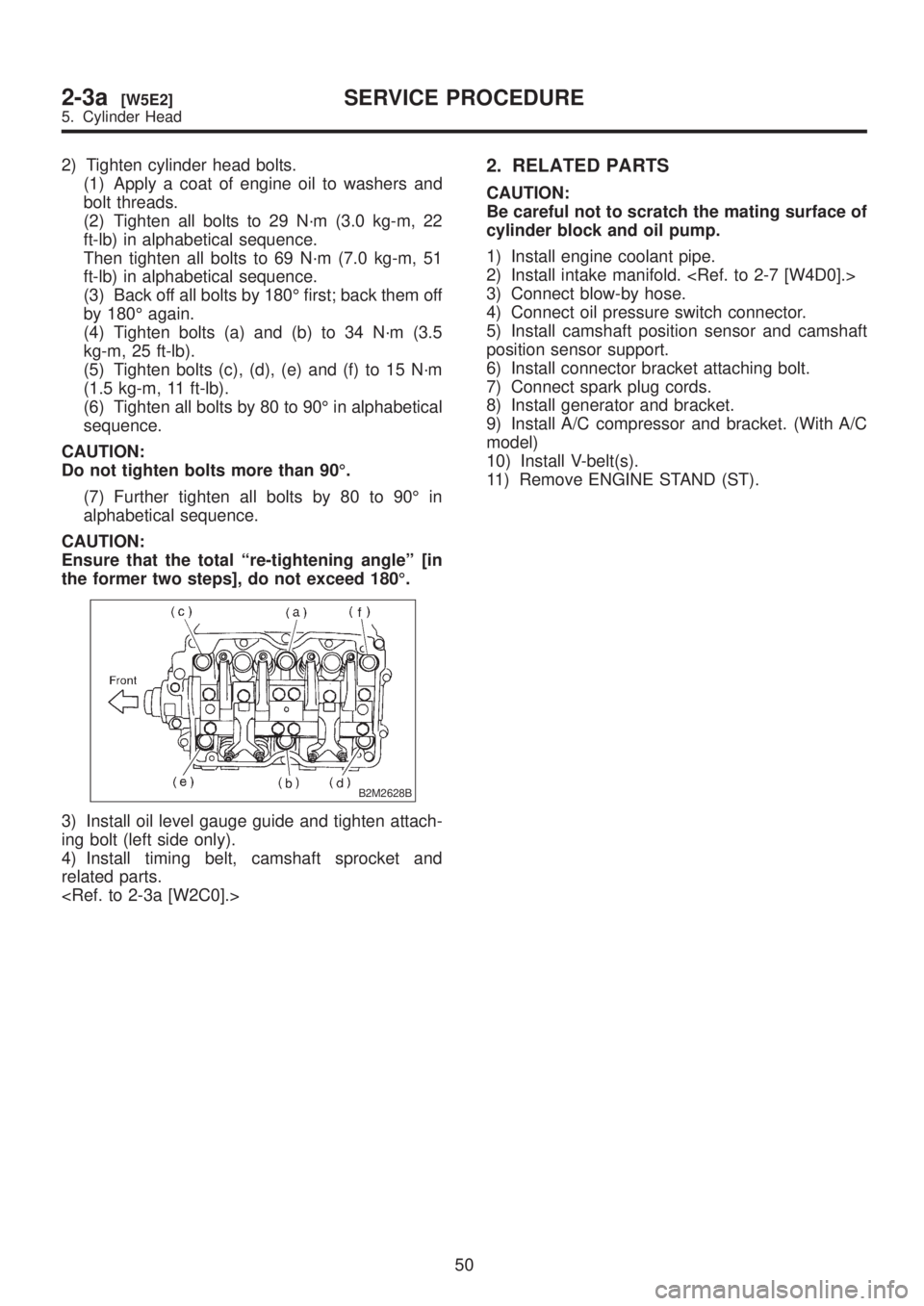

2) Tighten cylinder head bolts.

(1) Apply a coat of engine oil to washers and

bolt threads.

(2) Tighten all bolts to 29 N´m (3.0 kg-m, 22

ft-lb) in alphabetical sequence.

Then tighten all bolts to 69 N´m (7.0 kg-m, 51

ft-lb) in alphabetical sequence.

(3) Back off all bolts by 180É first; back them off

by 180É again.

(4) Tighten bolts (a) and (b) to 34 N´m (3.5

kg-m, 25 ft-lb).

(5) Tighten bolts (c), (d), (e) and (f) to 15 N´m

(1.5 kg-m, 11 ft-lb).

(6) Tighten all bolts by 80 to 90É in alphabetical

sequence.

CAUTION:

Do not tighten bolts more than 90É.

(7) Further tighten all bolts by 80 to 90É in

alphabetical sequence.

CAUTION:

Ensure that the total ªre-tightening angleº [in

the former two steps], do not exceed 180É.

B2M2628B

3) Install oil level gauge guide and tighten attach-

ing bolt (left side only).

4) Install timing belt, camshaft sprocket and

related parts.

2. RELATED PARTS

CAUTION:

Be careful not to scratch the mating surface of

cylinder block and oil pump.

1) Install engine coolant pipe.

2) Install intake manifold.

3) Connect blow-by hose.

4) Connect oil pressure switch connector.

5) Install camshaft position sensor and camshaft

position sensor support.

6) Install connector bracket attaching bolt.

7) Connect spark plug cords.

8) Install generator and bracket.

9) Install A/C compressor and bracket. (With A/C

model)

10) Install V-belt(s).

11) Remove ENGINE STAND (ST).

50

2-3a[W5E2]SERVICE PROCEDURE

5. Cylinder Head

Page 105 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 6. Cylinder Block

A: REMOVAL

1. RELATED PARTS

1) Remove timing belt, camshaft sprockets and

related parts.

<Ref. to 2-3a [W2A0].>

2) Remove cylinder heads. <Ref. to 2-3a

[W5A0].>

3) Remove water pipe. SUBARU LEGACY 1999 Service Repair Manual 6. Cylinder Block

A: REMOVAL

1. RELATED PARTS

1) Remove timing belt, camshaft sprockets and

related parts.

<Ref. to 2-3a [W2A0].>

2) Remove cylinder heads. <Ref. to 2-3a

[W5A0].>

3) Remove water pipe.](/img/17/57435/w960_57435-104.png)

6. Cylinder Block

A: REMOVAL

1. RELATED PARTS

1) Remove timing belt, camshaft sprockets and

related parts.

2) Remove cylinder heads.

3) Remove water pipe.

B2M2638

51

[W6A1]2-3aSERVICE PROCEDURE

6. Cylinder Block

Page 106 of 1456

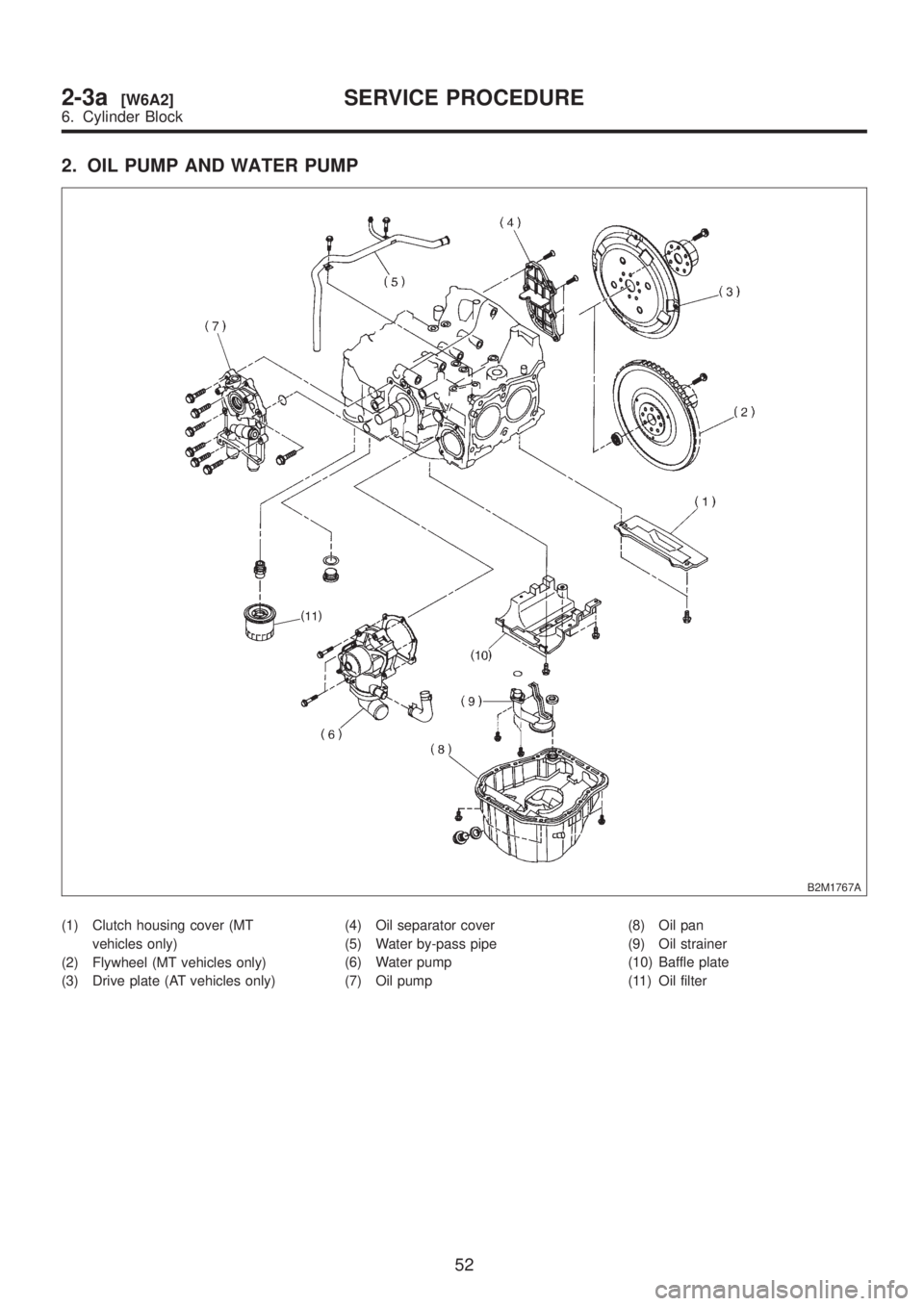

2. OIL PUMP AND WATER PUMP

B2M1767A

(1) Clutch housing cover (MT

vehicles only)

(2) Flywheel (MT vehicles only)

(3) Drive plate (AT vehicles only)(4) Oil separator cover

(5) Water by-pass pipe

(6) Water pump

(7) Oil pump(8) Oil pan

(9) Oil strainer

(10) Baffle plate

(11) Oil filter

52

2-3a[W6A2]SERVICE PROCEDURE

6. Cylinder Block

Page 107 of 1456

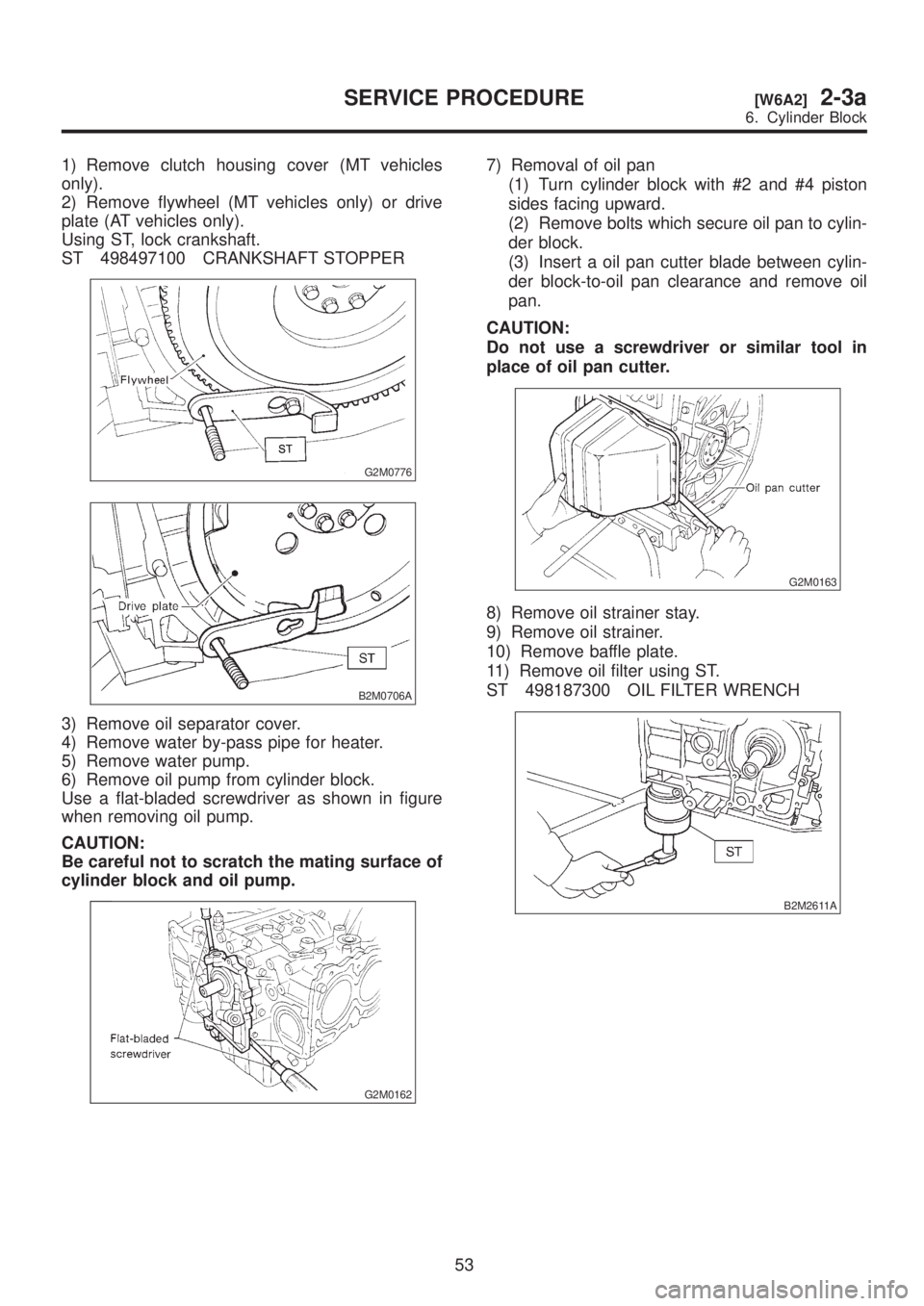

1) Remove clutch housing cover (MT vehicles

only).

2) Remove flywheel (MT vehicles only) or drive

plate (AT vehicles only).

Using ST, lock crankshaft.

ST 498497100 CRANKSHAFT STOPPER

G2M0776

B2M0706A

3) Remove oil separator cover.

4) Remove water by-pass pipe for heater.

5) Remove water pump.

6) Remove oil pump from cylinder block.

Use a flat-bladed screwdriver as shown in figure

when removing oil pump.

CAUTION:

Be careful not to scratch the mating surface of

cylinder block and oil pump.

G2M0162

7) Removal of oil pan

(1) Turn cylinder block with #2 and #4 piston

sides facing upward.

(2) Remove bolts which secure oil pan to cylin-

der block.

(3) Insert a oil pan cutter blade between cylin-

der block-to-oil pan clearance and remove oil

pan.

CAUTION:

Do not use a screwdriver or similar tool in

place of oil pan cutter.

G2M0163

8) Remove oil strainer stay.

9) Remove oil strainer.

10) Remove baffle plate.

11) Remove oil filter using ST.

ST 498187300 OIL FILTER WRENCH

B2M2611A

53

[W6A2]2-3aSERVICE PROCEDURE

6. Cylinder Block

Page 108 of 1456

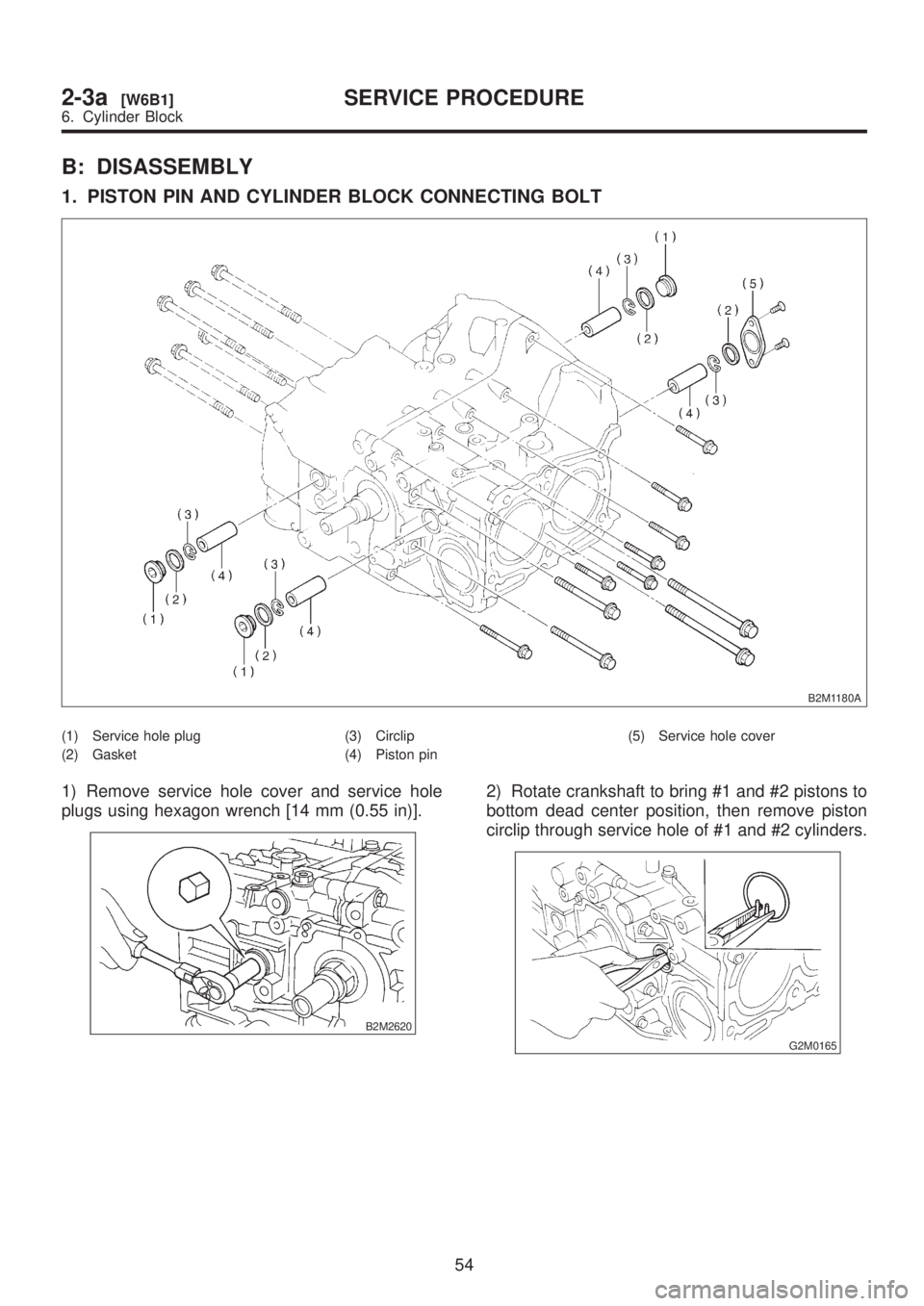

B: DISASSEMBLY

1. PISTON PIN AND CYLINDER BLOCK CONNECTING BOLT

B2M1180A

(1) Service hole plug

(2) Gasket(3) Circlip

(4) Piston pin(5) Service hole cover

1) Remove service hole cover and service hole

plugs using hexagon wrench [14 mm (0.55 in)].

B2M2620

2) Rotate crankshaft to bring #1 and #2 pistons to

bottom dead center position, then remove piston

circlip through service hole of #1 and #2 cylinders.

G2M0165

54

2-3a[W6B1]SERVICE PROCEDURE

6. Cylinder Block

Page 109 of 1456

3) Draw out piston pin from #1 and #2 pistons

using ST.

ST 499097700 PISTON PIN REMOVER

CAUTION:

Be careful not to confuse original combination

of piston, piston pin and cylinder.

G2M0166

4) Similarly remove piston pins from #3 and #4

pistons.

5) Remove bolts which connect cylinder block on

the side of #2 and #4 cylinders.

6) Back off bolts which connect cylinder block on

the side of #1 and #3 cylinders two or three turns.

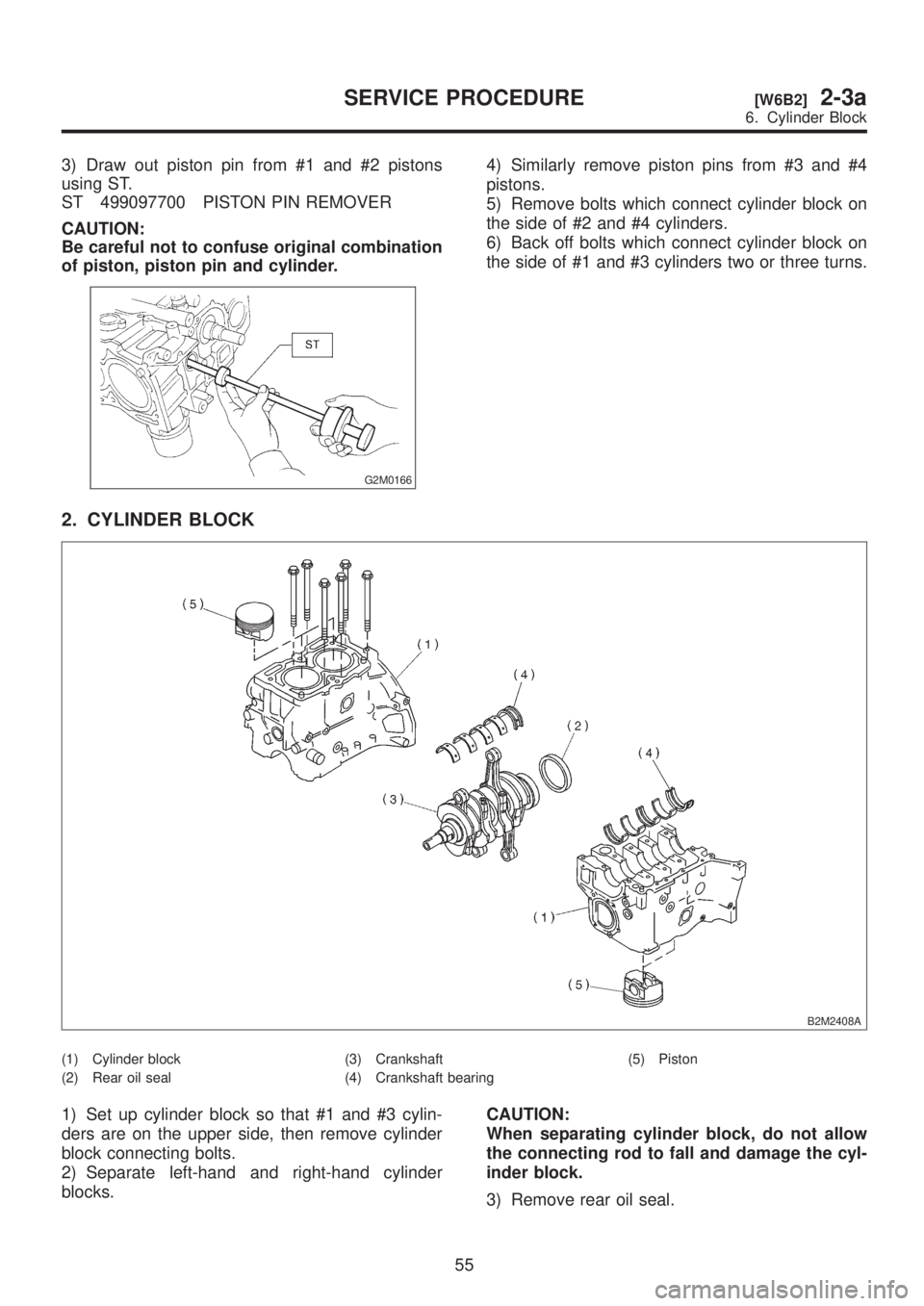

2. CYLINDER BLOCK

B2M2408A

(1) Cylinder block

(2) Rear oil seal(3) Crankshaft

(4) Crankshaft bearing(5) Piston

1) Set up cylinder block so that #1 and #3 cylin-

ders are on the upper side, then remove cylinder

block connecting bolts.

2) Separate left-hand and right-hand cylinder

blocks.CAUTION:

When separating cylinder block, do not allow

the connecting rod to fall and damage the cyl-

inder block.

3) Remove rear oil seal.

55

[W6B2]2-3aSERVICE PROCEDURE

6. Cylinder Block

Page 110 of 1456

4) Remove crankshaft together with connecting

rod.

5) Remove crankshaft bearings from cylinder

block using hammer handle.

CAUTION:

Do not confuse combination of crankshaft

bearings. Press bearing at the end opposite to

locking lip.6) Draw out each piston from cylinder block using

wooden bar or hammer handle.

CAUTION:

Do not confuse combination of piston and cyl-

inder.

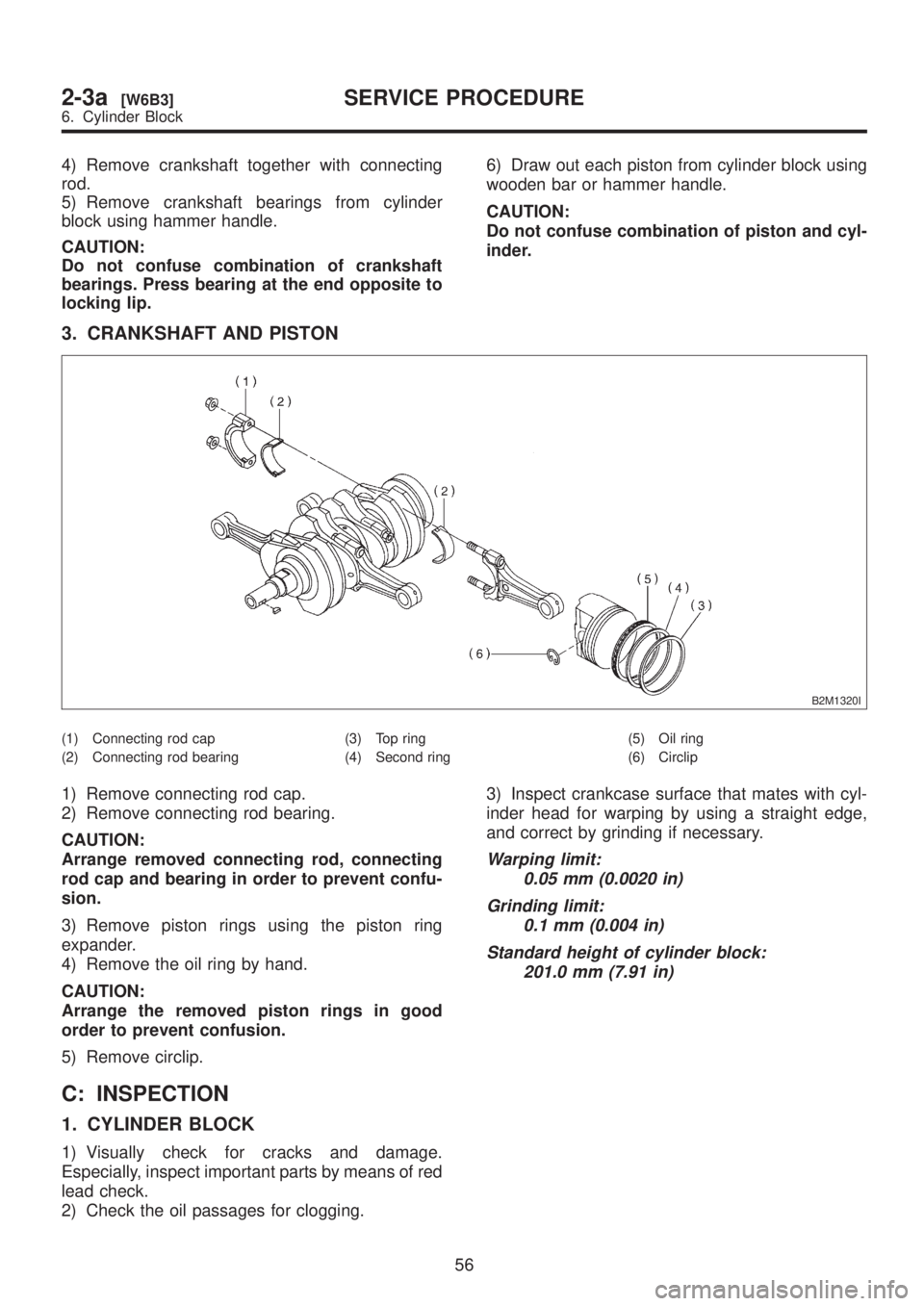

3. CRANKSHAFT AND PISTON

B2M1320I

(1) Connecting rod cap

(2) Connecting rod bearing(3) Top ring

(4) Second ring(5) Oil ring

(6) Circlip

1) Remove connecting rod cap.

2) Remove connecting rod bearing.

CAUTION:

Arrange removed connecting rod, connecting

rod cap and bearing in order to prevent confu-

sion.

3) Remove piston rings using the piston ring

expander.

4) Remove the oil ring by hand.

CAUTION:

Arrange the removed piston rings in good

order to prevent confusion.

5) Remove circlip.

C: INSPECTION

1. CYLINDER BLOCK

1) Visually check for cracks and damage.

Especially, inspect important parts by means of red

lead check.

2) Check the oil passages for clogging.3) Inspect crankcase surface that mates with cyl-

inder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

56

2-3a[W6B3]SERVICE PROCEDURE

6. Cylinder Block