SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 691 of 1456

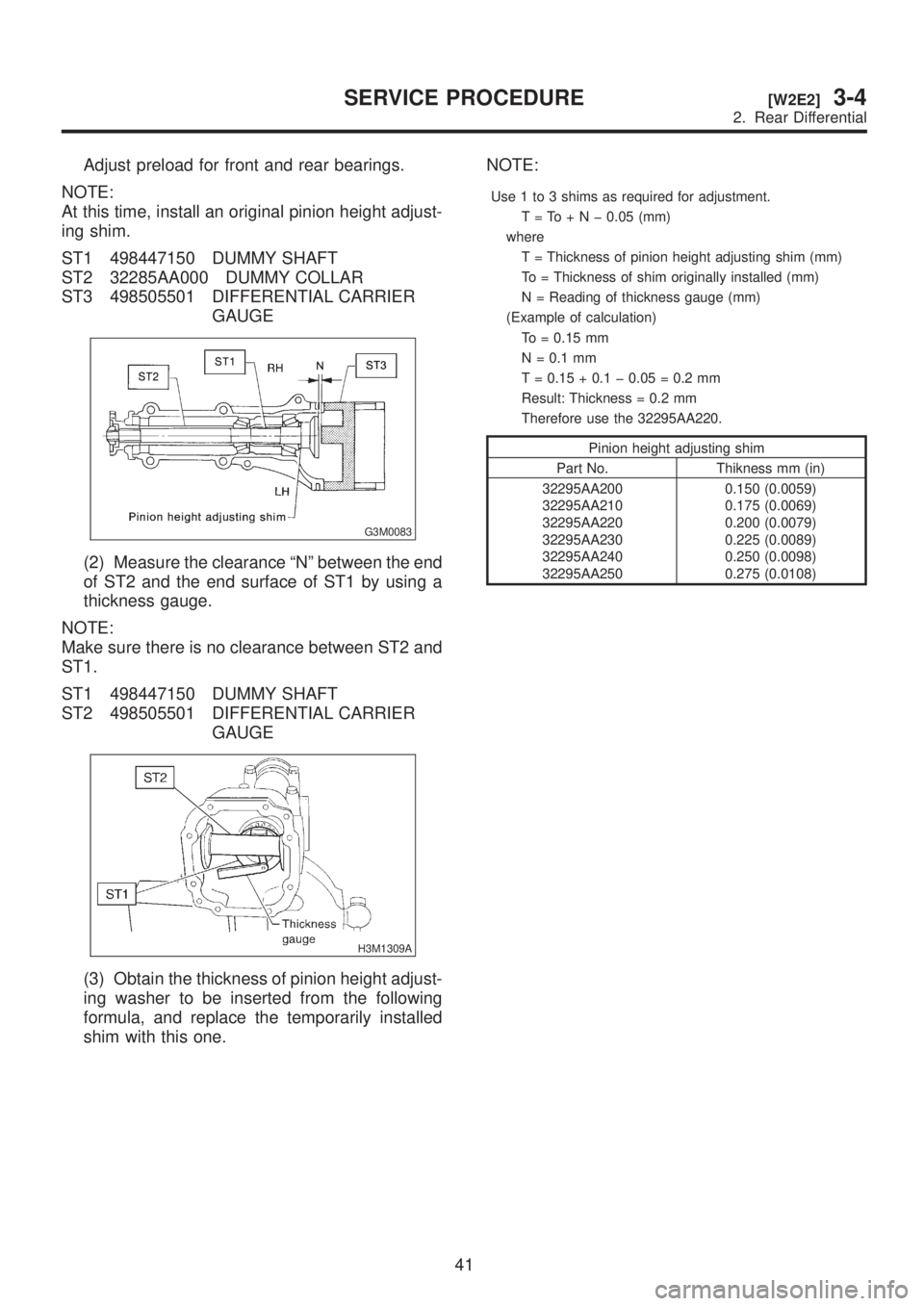

Adjust preload for front and rear bearings.

NOTE:

At this time, install an original pinion height adjust-

ing shim.

ST1 498447150 DUMMY SHAFT

ST2 32285AA000 DUMMY COLLAR

ST3 498505501 DIFFERENTIAL CARRIER

GAUGE

G3M0083

(2) Measure the clearance ªNº between the end

of ST2 and the end surface of ST1 by using a

thickness gauge.

NOTE:

Make sure there is no clearance between ST2 and

ST1.

ST1 498447150 DUMMY SHAFT

ST2 498505501 DIFFERENTIAL CARRIER

GAUGE

H3M1309A

(3) Obtain the thickness of pinion height adjust-

ing washer to be inserted from the following

formula, and replace the temporarily installed

shim with this one.NOTE:

Use 1 to 3 shims as required for adjustment.

T=To+Nþ0.05 (mm)

where

T = Thickness of pinion height adjusting shim (mm)

To = Thickness of shim originally installed (mm)

N = Reading of thickness gauge (mm)

(Example of calculation)

To = 0.15 mm

N = 0.1 mm

T = 0.15 + 0.1 þ 0.05 = 0.2 mm

Result: Thickness = 0.2 mm

Therefore use the 32295AA220.

Pinion height adjusting shim

Part No. Thikness mm (in)

32295AA200

32295AA210

32295AA220

32295AA230

32295AA240

32295AA2500.150 (0.0059)

0.175 (0.0069)

0.200 (0.0079)

0.225 (0.0089)

0.250 (0.0098)

0.275 (0.0108)

41

[W2E2]3-4SERVICE PROCEDURE

2. Rear Differential

Page 692 of 1456

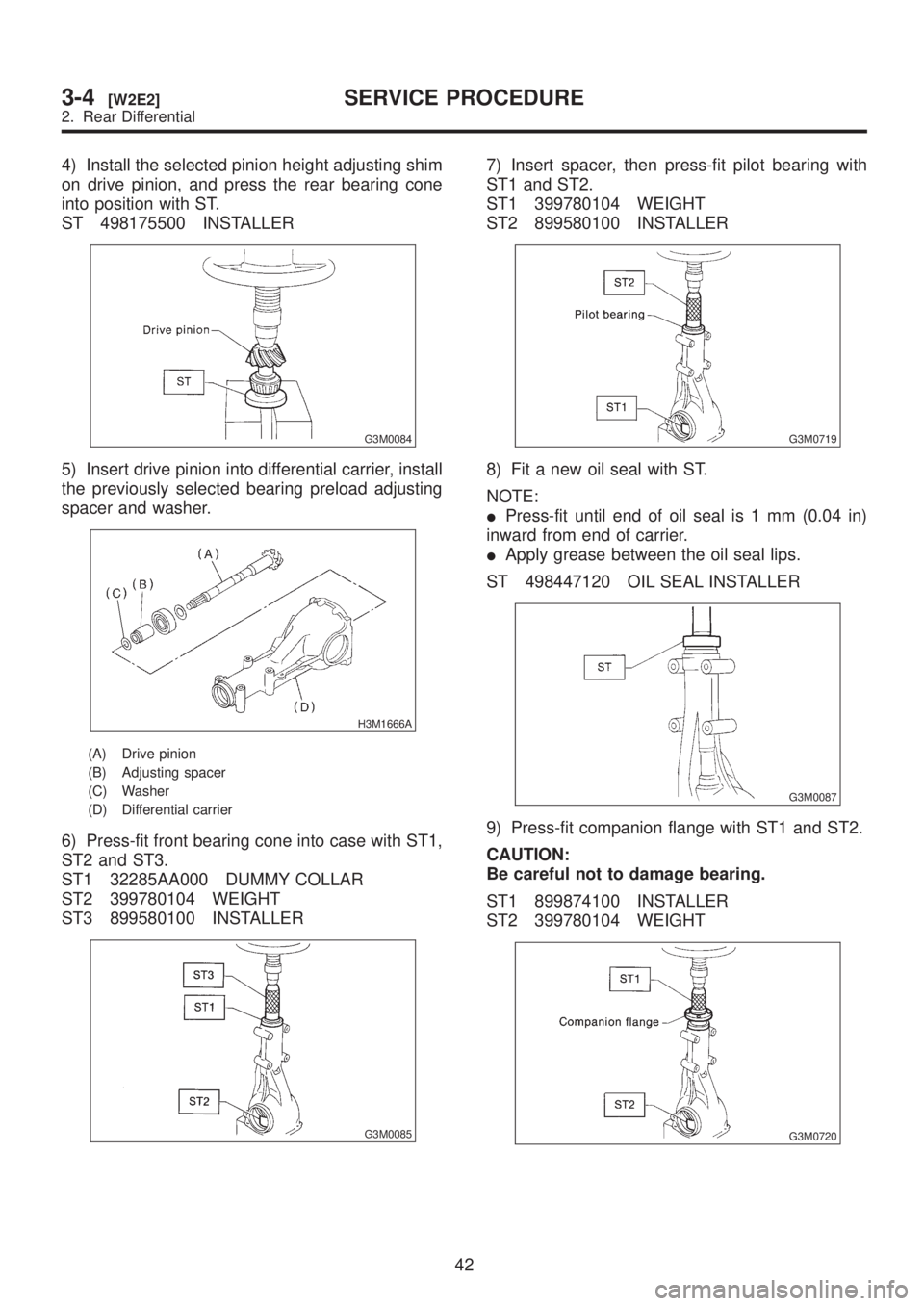

4) Install the selected pinion height adjusting shim

on drive pinion, and press the rear bearing cone

into position with ST.

ST 498175500 INSTALLER

G3M0084

5) Insert drive pinion into differential carrier, install

the previously selected bearing preload adjusting

spacer and washer.

H3M1666A

(A) Drive pinion

(B) Adjusting spacer

(C) Washer

(D) Differential carrier

6) Press-fit front bearing cone into case with ST1,

ST2 and ST3.

ST1 32285AA000 DUMMY COLLAR

ST2 399780104 WEIGHT

ST3 899580100 INSTALLER

G3M0085

7) Insert spacer, then press-fit pilot bearing with

ST1 and ST2.

ST1 399780104 WEIGHT

ST2 899580100 INSTALLER

G3M0719

8) Fit a new oil seal with ST.

NOTE:

IPress-fit until end of oil seal is 1 mm (0.04 in)

inward from end of carrier.

IApply grease between the oil seal lips.

ST 498447120 OIL SEAL INSTALLER

G3M0087

9) Press-fit companion flange with ST1 and ST2.

CAUTION:

Be careful not to damage bearing.

ST1 899874100 INSTALLER

ST2 399780104 WEIGHT

G3M0720

42

3-4[W2E2]SERVICE PROCEDURE

2. Rear Differential

Page 693 of 1456

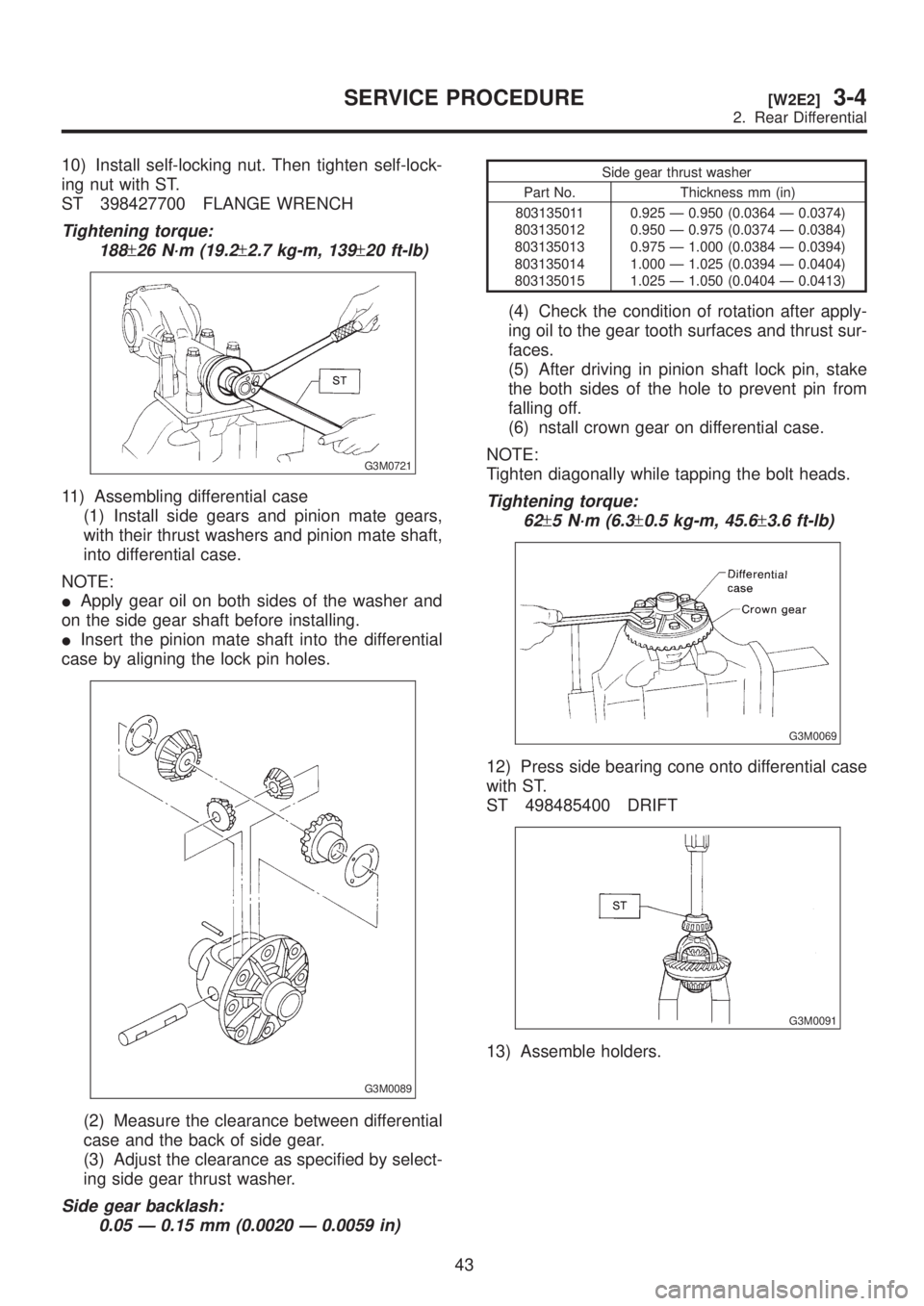

10) Install self-locking nut. Then tighten self-lock-

ing nut with ST.

ST 398427700 FLANGE WRENCH

Tightening torque:

188

±26 N´m (19.2±2.7 kg-m, 139±20 ft-lb)

G3M0721

11) Assembling differential case

(1) Install side gears and pinion mate gears,

with their thrust washers and pinion mate shaft,

into differential case.

NOTE:

IApply gear oil on both sides of the washer and

on the side gear shaft before installing.

IInsert the pinion mate shaft into the differential

case by aligning the lock pin holes.

G3M0089

(2) Measure the clearance between differential

case and the back of side gear.

(3) Adjust the clearance as specified by select-

ing side gear thrust washer.

Side gear backlash:

0.05 Ð 0.15 mm (0.0020 Ð 0.0059 in)

Side gear thrust washer

Part No. Thickness mm (in)

803135011

803135012

803135013

803135014

8031350150.925 Ð 0.950 (0.0364 Ð 0.0374)

0.950 Ð 0.975 (0.0374 Ð 0.0384)

0.975 Ð 1.000 (0.0384 Ð 0.0394)

1.000 Ð 1.025 (0.0394 Ð 0.0404)

1.025 Ð 1.050 (0.0404 Ð 0.0413)

(4) Check the condition of rotation after apply-

ing oil to the gear tooth surfaces and thrust sur-

faces.

(5) After driving in pinion shaft lock pin, stake

the both sides of the hole to prevent pin from

falling off.

(6) nstall crown gear on differential case.

NOTE:

Tighten diagonally while tapping the bolt heads.

Tightening torque:

62

±5 N´m (6.3±0.5 kg-m, 45.6±3.6 ft-lb)

G3M0069

12) Press side bearing cone onto differential case

with ST.

ST 498485400 DRIFT

G3M0091

13) Assemble holders.

43

[W2E2]3-4SERVICE PROCEDURE

2. Rear Differential

Page 694 of 1456

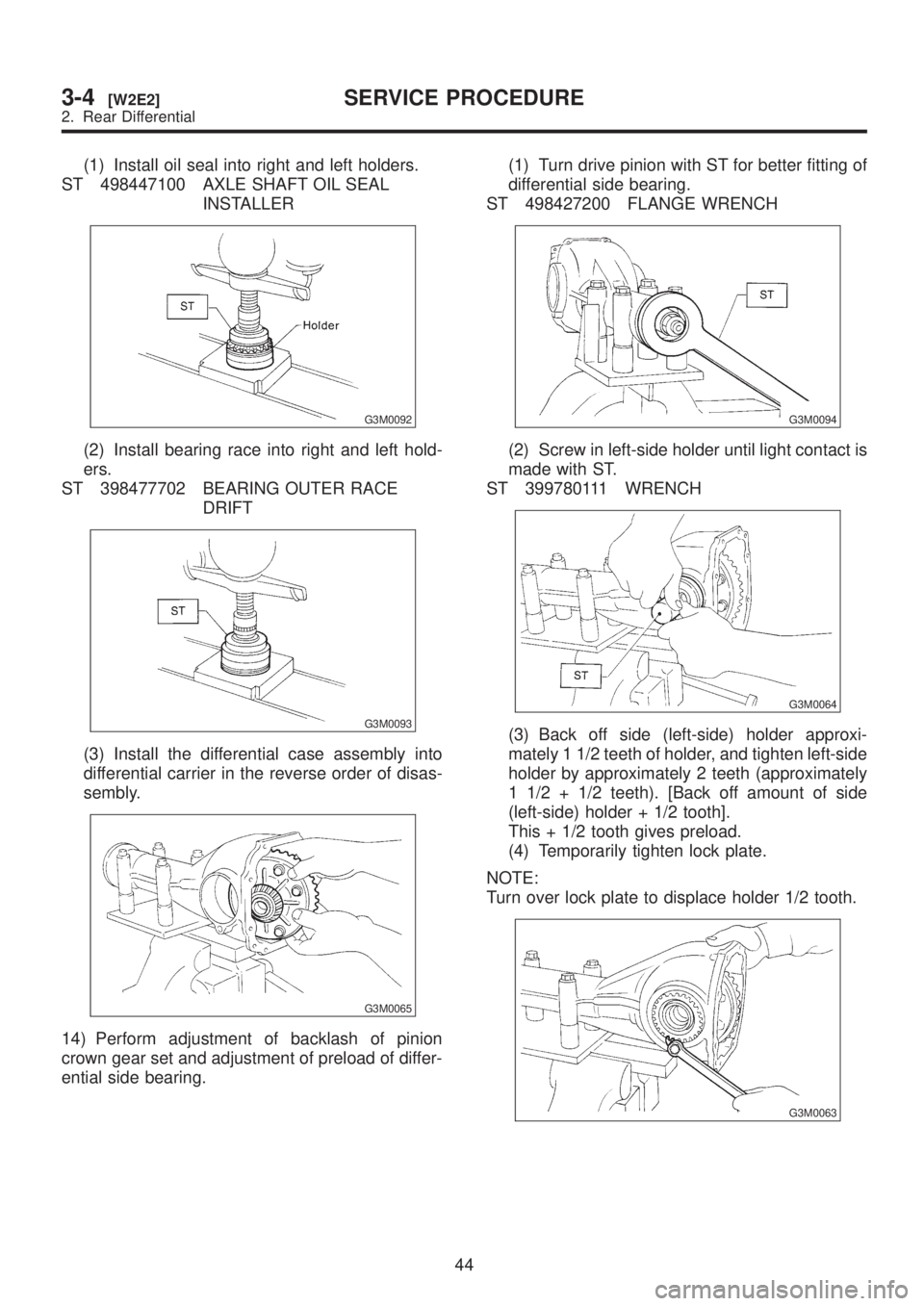

(1) Install oil seal into right and left holders.

ST 498447100 AXLE SHAFT OIL SEAL

INSTALLER

G3M0092

(2) Install bearing race into right and left hold-

ers.

ST 398477702 BEARING OUTER RACE

DRIFT

G3M0093

(3) Install the differential case assembly into

differential carrier in the reverse order of disas-

sembly.

G3M0065

14) Perform adjustment of backlash of pinion

crown gear set and adjustment of preload of differ-

ential side bearing.(1) Turn drive pinion with ST for better fitting of

differential side bearing.

ST 498427200 FLANGE WRENCH

G3M0094

(2) Screw in left-side holder until light contact is

made with ST.

ST 399780111 WRENCH

G3M0064

(3) Back off side (left-side) holder approxi-

mately 1 1/2 teeth of holder, and tighten left-side

holder by approximately 2 teeth (approximately

1 1/2 + 1/2 teeth). [Back off amount of side

(left-side) holder + 1/2 tooth].

This + 1/2 tooth gives preload.

(4) Temporarily tighten lock plate.

NOTE:

Turn over lock plate to displace holder 1/2 tooth.

G3M0063

44

3-4[W2E2]SERVICE PROCEDURE

2. Rear Differential

Page 695 of 1456

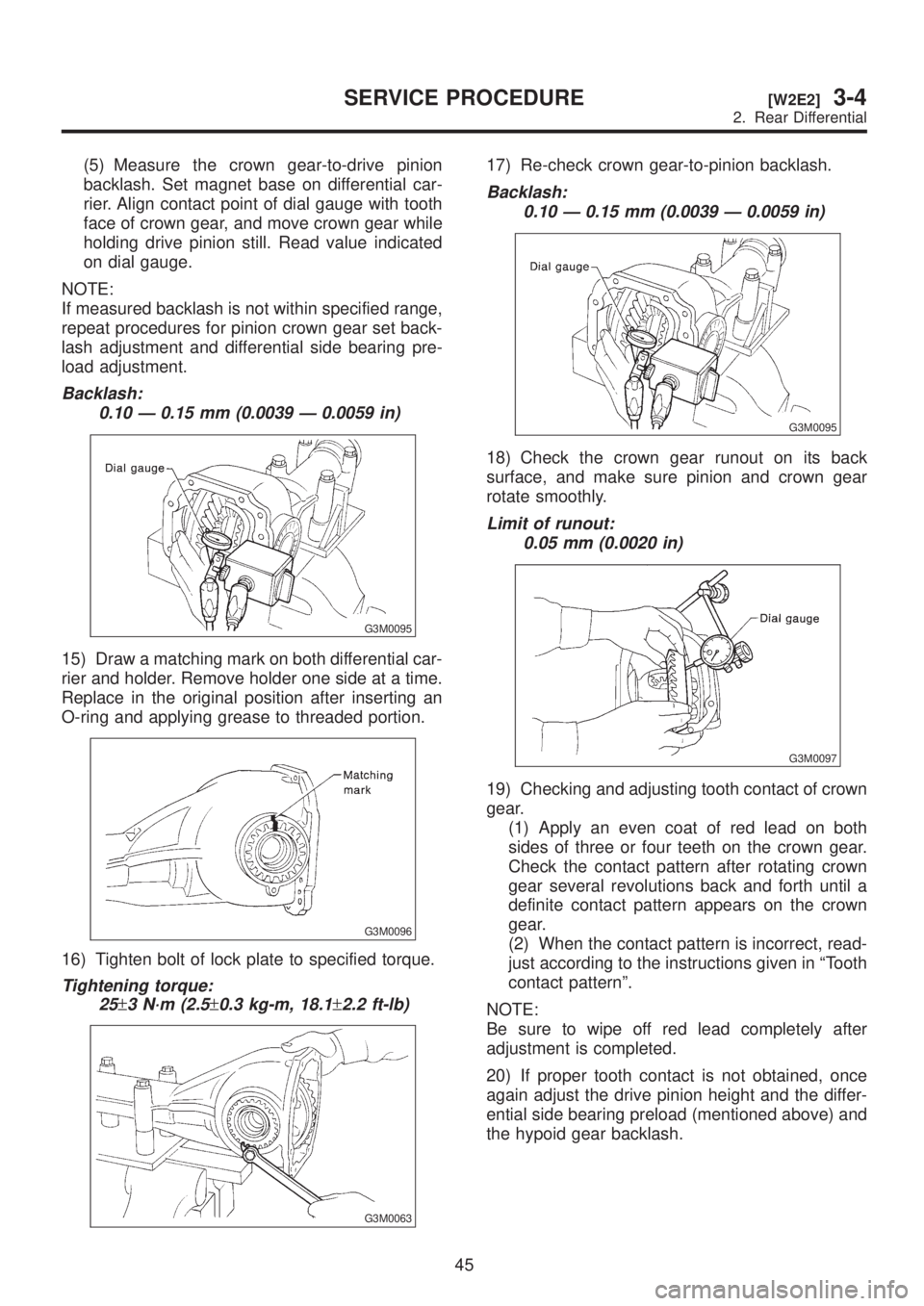

(5) Measure the crown gear-to-drive pinion

backlash. Set magnet base on differential car-

rier. Align contact point of dial gauge with tooth

face of crown gear, and move crown gear while

holding drive pinion still. Read value indicated

on dial gauge.

NOTE:

If measured backlash is not within specified range,

repeat procedures for pinion crown gear set back-

lash adjustment and differential side bearing pre-

load adjustment.

Backlash:

0.10 Ð 0.15 mm (0.0039 Ð 0.0059 in)

G3M0095

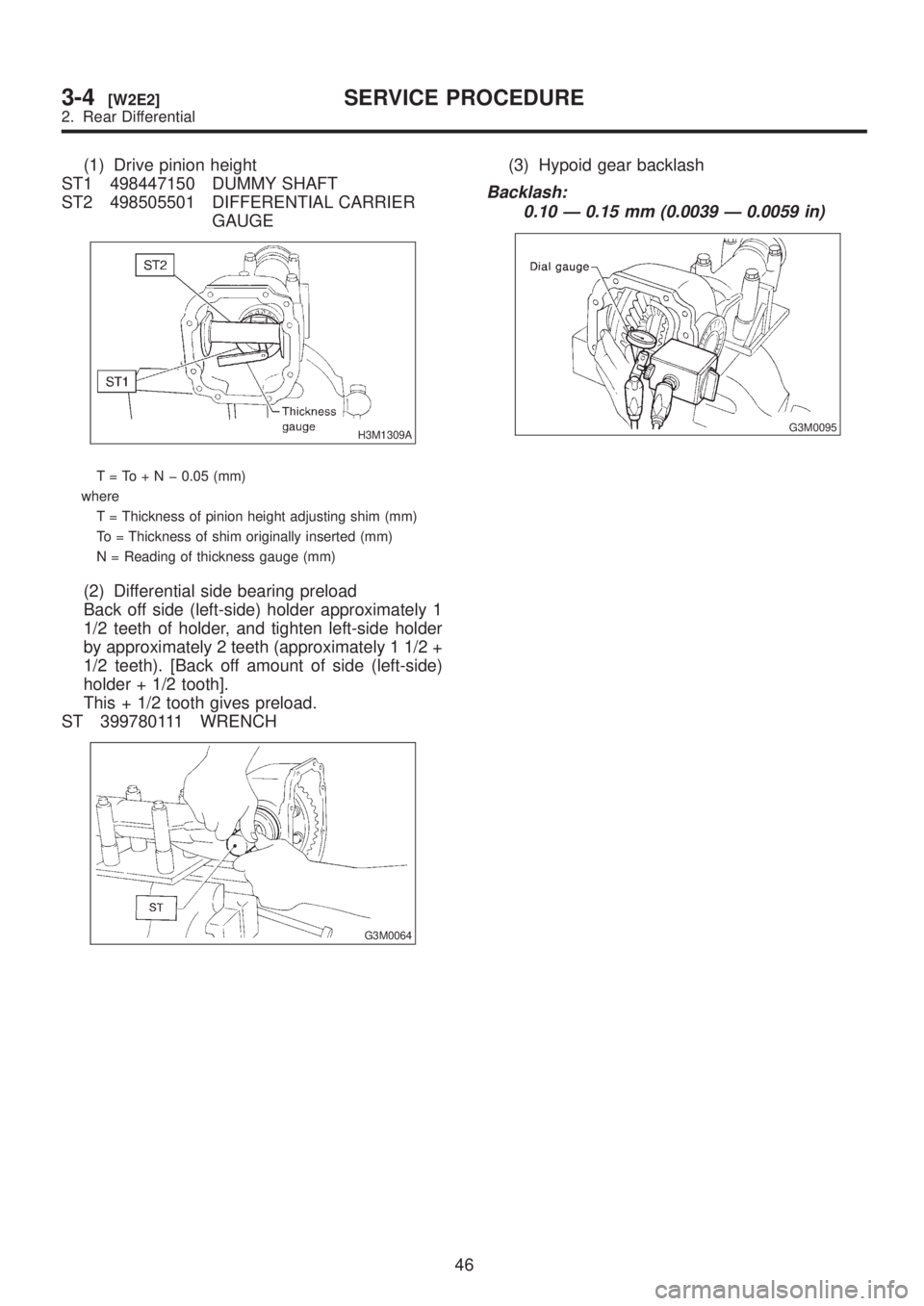

15) Draw a matching mark on both differential car-

rier and holder. Remove holder one side at a time.

Replace in the original position after inserting an

O-ring and applying grease to threaded portion.

G3M0096

16) Tighten bolt of lock plate to specified torque.

Tightening torque:

25

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

G3M0063

17) Re-check crown gear-to-pinion backlash.

Backlash:

0.10 Ð 0.15 mm (0.0039 Ð 0.0059 in)

G3M0095

18) Check the crown gear runout on its back

surface, and make sure pinion and crown gear

rotate smoothly.

Limit of runout:

0.05 mm (0.0020 in)

G3M0097

19) Checking and adjusting tooth contact of crown

gear.

(1) Apply an even coat of red lead on both

sides of three or four teeth on the crown gear.

Check the contact pattern after rotating crown

gear several revolutions back and forth until a

definite contact pattern appears on the crown

gear.

(2) When the contact pattern is incorrect, read-

just according to the instructions given in ªTooth

contact patternº.

NOTE:

Be sure to wipe off red lead completely after

adjustment is completed.

20) If proper tooth contact is not obtained, once

again adjust the drive pinion height and the differ-

ential side bearing preload (mentioned above) and

the hypoid gear backlash.

45

[W2E2]3-4SERVICE PROCEDURE

2. Rear Differential

Page 696 of 1456

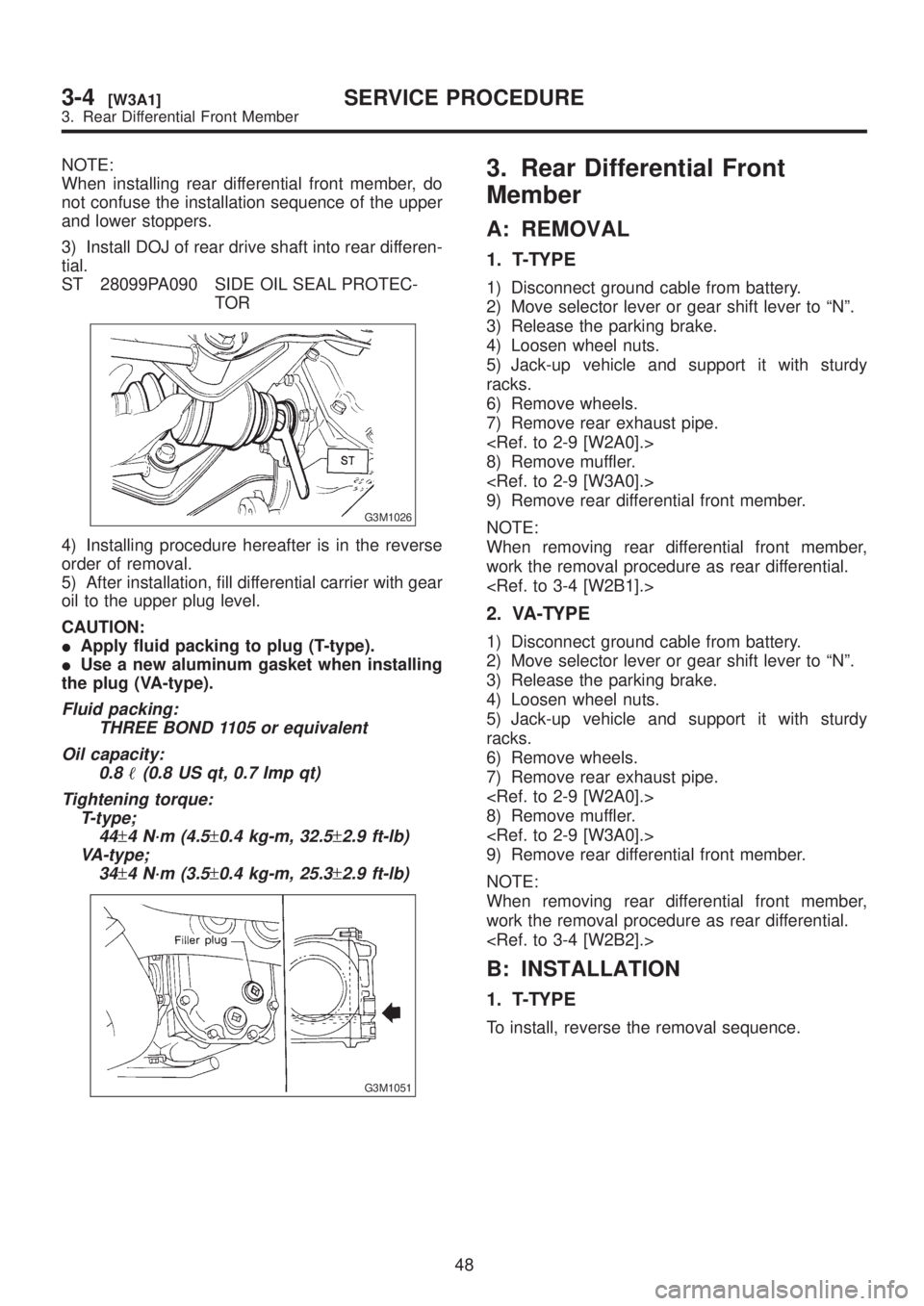

(1) Drive pinion height

ST1 498447150 DUMMY SHAFT

ST2 498505501 DIFFERENTIAL CARRIER

GAUGE

H3M1309A

T=To+Nþ0.05 (mm)

where

T = Thickness of pinion height adjusting shim (mm)

To = Thickness of shim originally inserted (mm)

N = Reading of thickness gauge (mm)

(2) Differential side bearing preload

Back off side (left-side) holder approximately 1

1/2 teeth of holder, and tighten left-side holder

by approximately 2 teeth (approximately 1 1/2 +

1/2 teeth). [Back off amount of side (left-side)

holder + 1/2 tooth].

This + 1/2 tooth gives preload.

ST 399780111 WRENCH

G3M0064

(3) Hypoid gear backlash

Backlash:

0.10 Ð 0.15 mm (0.0039 Ð 0.0059 in)

G3M0095

46

3-4[W2E2]SERVICE PROCEDURE

2. Rear Differential

Page 697 of 1456

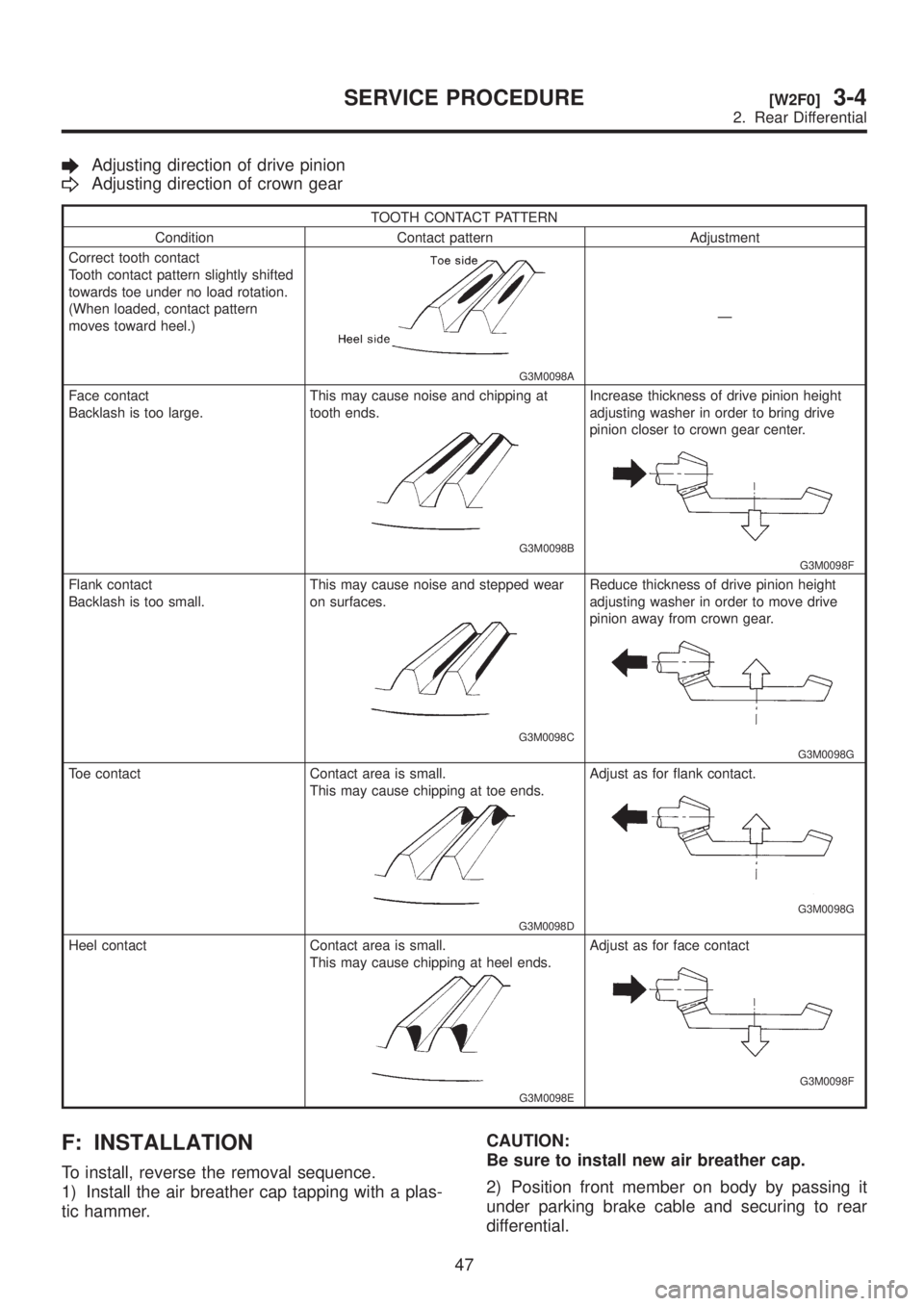

Adjusting direction of drive pinion

Adjusting direction of crown gear

TOOTH CONTACT PATTERN

Condition Contact pattern Adjustment

Correct tooth contact

Tooth contact pattern slightly shifted

towards toe under no load rotation.

(When loaded, contact pattern

moves toward heel.)

G3M0098A

Ð

Face contact

Backlash is too large.This may cause noise and chipping at

tooth ends.

G3M0098B

Increase thickness of drive pinion height

adjusting washer in order to bring drive

pinion closer to crown gear center.

G3M0098F

Flank contact

Backlash is too small.This may cause noise and stepped wear

on surfaces.

G3M0098C

Reduce thickness of drive pinion height

adjusting washer in order to move drive

pinion away from crown gear.

G3M0098G

Toe contact Contact area is small.

This may cause chipping at toe ends.

G3M0098D

Adjust as for flank contact.

G3M0098G

Heel contact Contact area is small.

This may cause chipping at heel ends.

G3M0098E

Adjust as for face contact

G3M0098F

F: INSTALLATION

To install, reverse the removal sequence.

1) Install the air breather cap tapping with a plas-

tic hammer.CAUTION:

Be sure to install new air breather cap.

2) Position front member on body by passing it

under parking brake cable and securing to rear

differential.

47

[W2F0]3-4SERVICE PROCEDURE

2. Rear Differential

Page 698 of 1456

NOTE:

When installing rear differential front member, do

not confuse the installation sequence of the upper

and lower stoppers.

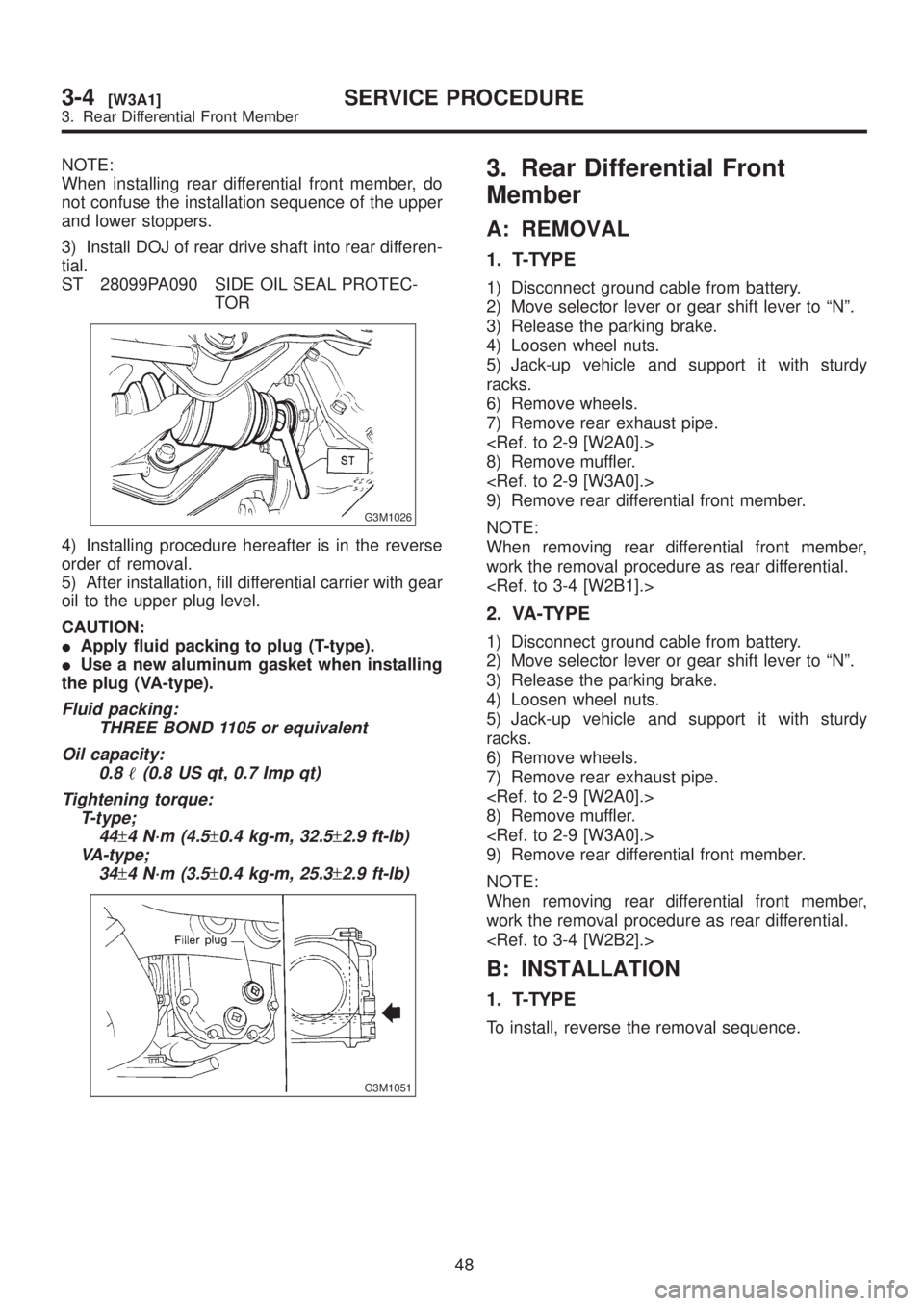

3) Install DOJ of rear drive shaft into rear differen-

tial.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

G3M1026

4) Installing procedure hereafter is in the reverse

order of removal.

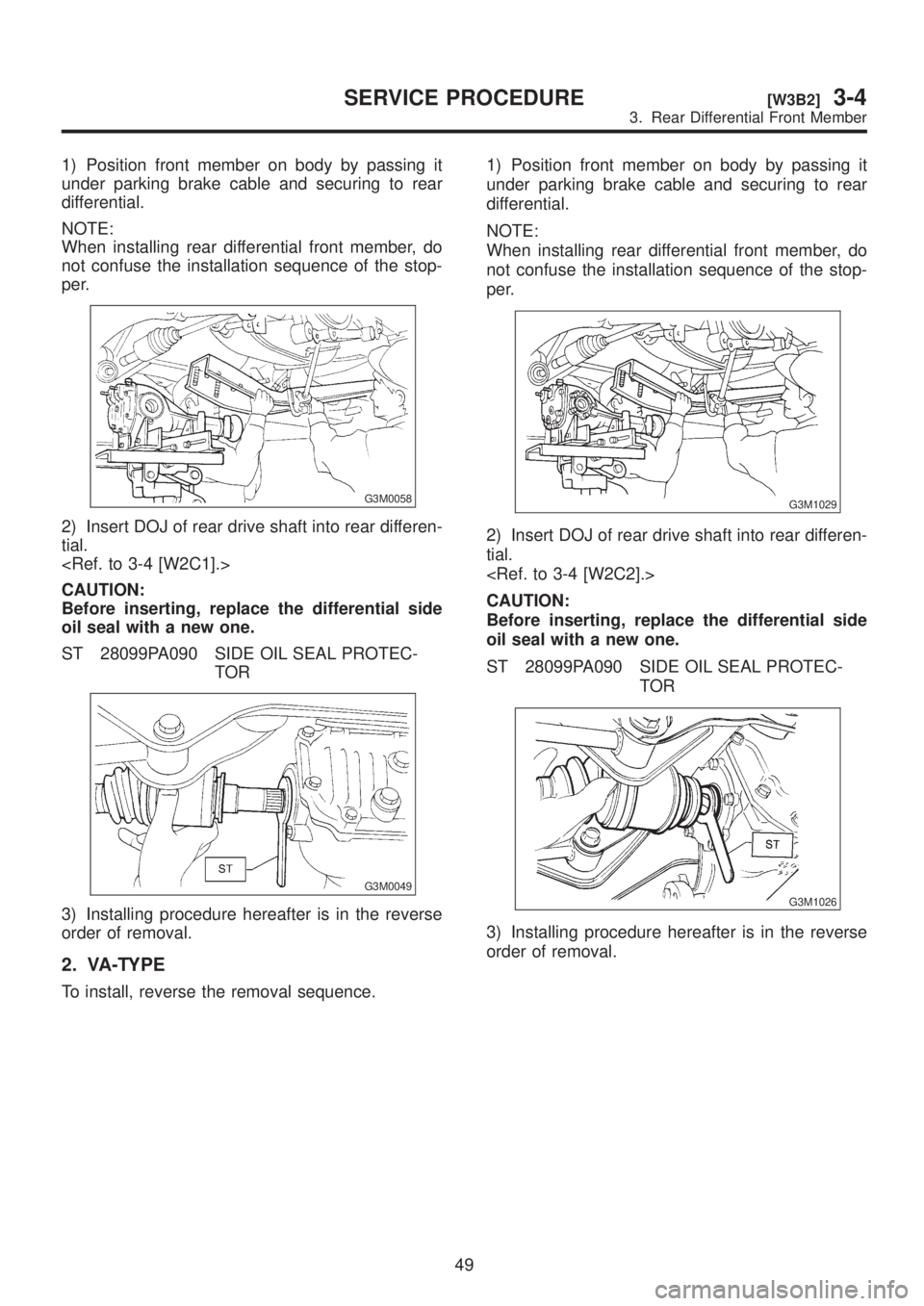

5) After installation, fill differential carrier with gear

oil to the upper plug level.

CAUTION:

IApply fluid packing to plug (T-type).

IUse a new aluminum gasket when installing

the plug (VA-type).

Fluid packing:

THREE BOND 1105 or equivalent

Oil capacity:

0.8

(0.8 US qt, 0.7 Imp qt)

Tightening torque:

T-type;

44

±4 N´m (4.5±0.4 kg-m, 32.5±2.9 ft-lb)

VA-type;

34

±4 N´m (3.5±0.4 kg-m, 25.3±2.9 ft-lb)

G3M1051

3. Rear Differential Front

Member

A: REMOVAL

1. T-TYPE

1) Disconnect ground cable from battery.

2) Move selector lever or gear shift lever to ªNº.

3) Release the parking brake.

4) Loosen wheel nuts.

5) Jack-up vehicle and support it with sturdy

racks.

6) Remove wheels.

7) Remove rear exhaust pipe.

8) Remove muffler.

9) Remove rear differential front member.

NOTE:

When removing rear differential front member,

work the removal procedure as rear differential.

2. VA-TYPE

1) Disconnect ground cable from battery.

2) Move selector lever or gear shift lever to ªNº.

3) Release the parking brake.

4) Loosen wheel nuts.

5) Jack-up vehicle and support it with sturdy

racks.

6) Remove wheels.

7) Remove rear exhaust pipe.

8) Remove muffler.

9) Remove rear differential front member.

NOTE:

When removing rear differential front member,

work the removal procedure as rear differential.

B: INSTALLATION

1. T-TYPE

To install, reverse the removal sequence.

48

3-4[W3A1]SERVICE PROCEDURE

3. Rear Differential Front Member

Page 699 of 1456

NOTE:

When installing rear differential front member, do

not confuse the installation sequence of the upper

and lower stoppers.

3) Install DOJ of rear drive shaft into rear differen-

tial.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

G3M1026

4) Installing procedure hereafter is in the reverse

order of removal.

5) After installation, fill differential carrier with gear

oil to the upper plug level.

CAUTION:

IApply fluid packing to plug (T-type).

IUse a new aluminum gasket when installing

the plug (VA-type).

Fluid packing:

THREE BOND 1105 or equivalent

Oil capacity:

0.8

(0.8 US qt, 0.7 Imp qt)

Tightening torque:

T-type;

44

±4 N´m (4.5±0.4 kg-m, 32.5±2.9 ft-lb)

VA-type;

34

±4 N´m (3.5±0.4 kg-m, 25.3±2.9 ft-lb)

G3M1051

3. Rear Differential Front

Member

A: REMOVAL

1. T-TYPE

1) Disconnect ground cable from battery.

2) Move selector lever or gear shift lever to ªNº.

3) Release the parking brake.

4) Loosen wheel nuts.

5) Jack-up vehicle and support it with sturdy

racks.

6) Remove wheels.

7) Remove rear exhaust pipe.

8) Remove muffler.

9) Remove rear differential front member.

NOTE:

When removing rear differential front member,

work the removal procedure as rear differential.

2. VA-TYPE

1) Disconnect ground cable from battery.

2) Move selector lever or gear shift lever to ªNº.

3) Release the parking brake.

4) Loosen wheel nuts.

5) Jack-up vehicle and support it with sturdy

racks.

6) Remove wheels.

7) Remove rear exhaust pipe.

8) Remove muffler.

9) Remove rear differential front member.

NOTE:

When removing rear differential front member,

work the removal procedure as rear differential.

B: INSTALLATION

1. T-TYPE

To install, reverse the removal sequence.

48

3-4[W3A1]SERVICE PROCEDURE

3. Rear Differential Front Member

Page 700 of 1456

1) Position front member on body by passing it

under parking brake cable and securing to rear

differential.

NOTE:

When installing rear differential front member, do

not confuse the installation sequence of the stop-

per.

G3M0058

2) Insert DOJ of rear drive shaft into rear differen-

tial.

CAUTION:

Before inserting, replace the differential side

oil seal with a new one.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

G3M0049

3) Installing procedure hereafter is in the reverse

order of removal.

2. VA-TYPE

To install, reverse the removal sequence.1) Position front member on body by passing it

under parking brake cable and securing to rear

differential.

NOTE:

When installing rear differential front member, do

not confuse the installation sequence of the stop-

per.

G3M1029

2) Insert DOJ of rear drive shaft into rear differen-

tial.

CAUTION:

Before inserting, replace the differential side

oil seal with a new one.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

G3M1026

3) Installing procedure hereafter is in the reverse

order of removal.

49

[W3B2]3-4SERVICE PROCEDURE

3. Rear Differential Front Member