SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 701 of 1456

MEMO:

50

3-4SERVICE PROCEDURE

Page 702 of 1456

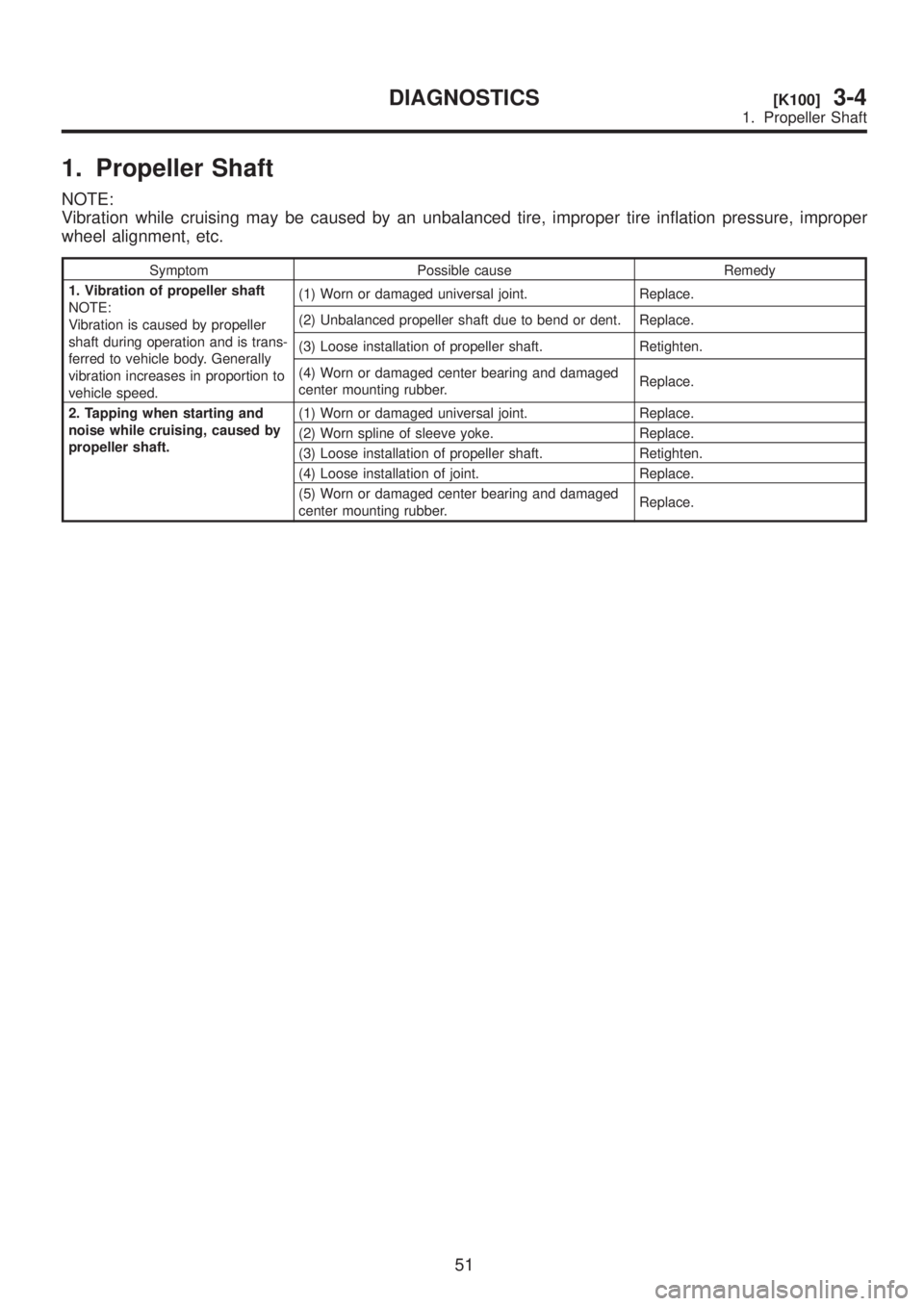

1. Propeller Shaft

NOTE:

Vibration while cruising may be caused by an unbalanced tire, improper tire inflation pressure, improper

wheel alignment, etc.

Symptom Possible cause Remedy

1. Vibration of propeller shaft

NOTE:

Vibration is caused by propeller

shaft during operation and is trans-

ferred to vehicle body. Generally

vibration increases in proportion to

vehicle speed.(1) Worn or damaged universal joint. Replace.

(2) Unbalanced propeller shaft due to bend or dent. Replace.

(3) Loose installation of propeller shaft. Retighten.

(4) Worn or damaged center bearing and damaged

center mounting rubber.Replace.

2. Tapping when starting and

noise while cruising, caused by

propeller shaft.(1) Worn or damaged universal joint. Replace.

(2) Worn spline of sleeve yoke. Replace.

(3) Loose installation of propeller shaft. Retighten.

(4) Loose installation of joint. Replace.

(5) Worn or damaged center bearing and damaged

center mounting rubber.Replace.

51

[K100]3-4DIAGNOSTICS

1. Propeller Shaft

Page 703 of 1456

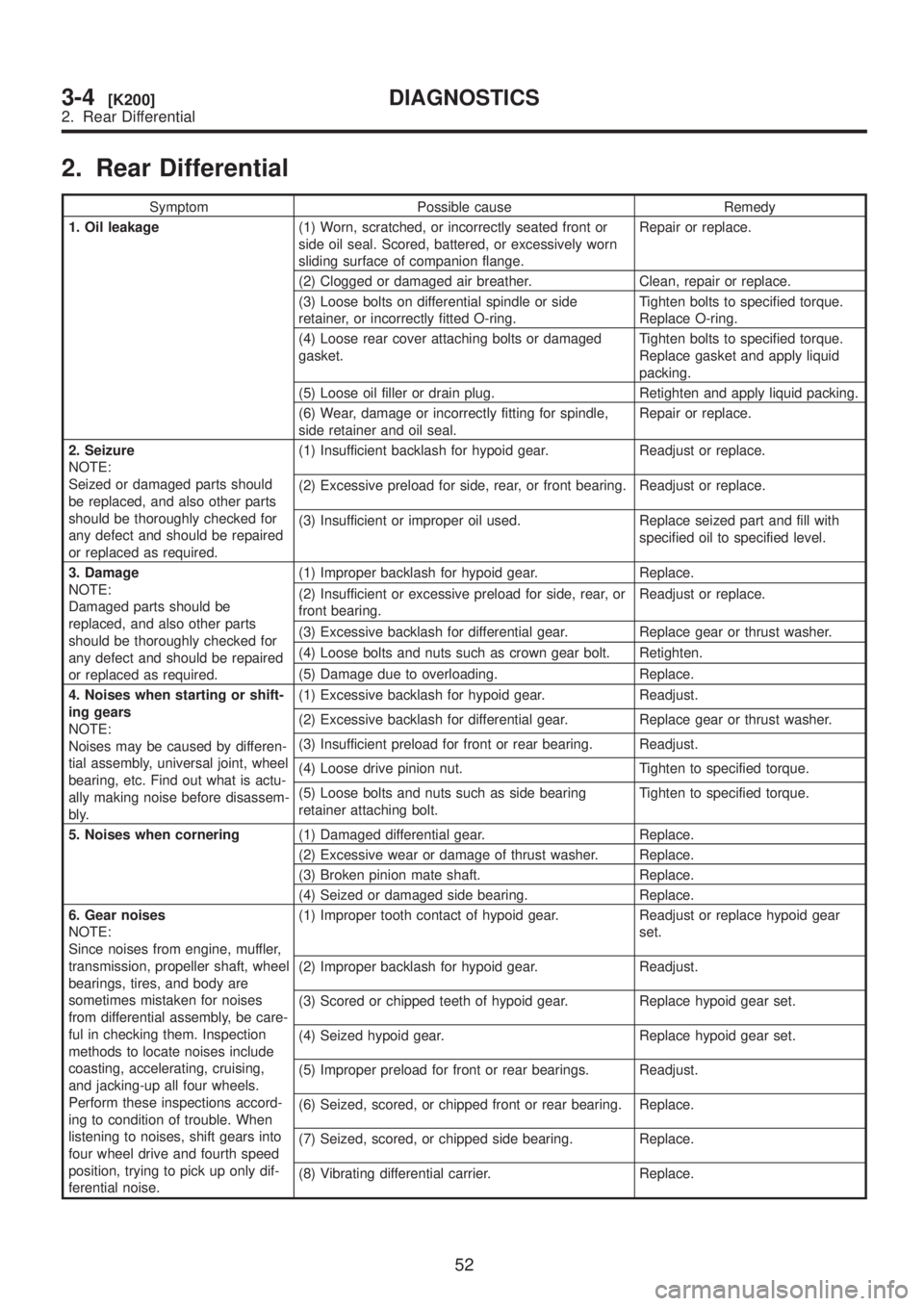

2. Rear Differential

Symptom Possible cause Remedy

1. Oil leakage(1) Worn, scratched, or incorrectly seated front or

side oil seal. Scored, battered, or excessively worn

sliding surface of companion flange.Repair or replace.

(2) Clogged or damaged air breather. Clean, repair or replace.

(3) Loose bolts on differential spindle or side

retainer, or incorrectly fitted O-ring.Tighten bolts to specified torque.

Replace O-ring.

(4) Loose rear cover attaching bolts or damaged

gasket.Tighten bolts to specified torque.

Replace gasket and apply liquid

packing.

(5) Loose oil filler or drain plug. Retighten and apply liquid packing.

(6) Wear, damage or incorrectly fitting for spindle,

side retainer and oil seal.Repair or replace.

2. Seizure

NOTE:

Seized or damaged parts should

be replaced, and also other parts

should be thoroughly checked for

any defect and should be repaired

or replaced as required.(1) Insufficient backlash for hypoid gear. Readjust or replace.

(2) Excessive preload for side, rear, or front bearing. Readjust or replace.

(3) Insufficient or improper oil used. Replace seized part and fill with

specified oil to specified level.

3. Damage

NOTE:

Damaged parts should be

replaced, and also other parts

should be thoroughly checked for

any defect and should be repaired

or replaced as required.(1) Improper backlash for hypoid gear. Replace.

(2) Insufficient or excessive preload for side, rear, or

front bearing.Readjust or replace.

(3) Excessive backlash for differential gear. Replace gear or thrust washer.

(4) Loose bolts and nuts such as crown gear bolt. Retighten.

(5) Damage due to overloading. Replace.

4. Noises when starting or shift-

ing gears

NOTE:

Noises may be caused by differen-

tial assembly, universal joint, wheel

bearing, etc. Find out what is actu-

ally making noise before disassem-

bly.(1) Excessive backlash for hypoid gear. Readjust.

(2) Excessive backlash for differential gear. Replace gear or thrust washer.

(3) Insufficient preload for front or rear bearing. Readjust.

(4) Loose drive pinion nut. Tighten to specified torque.

(5) Loose bolts and nuts such as side bearing

retainer attaching bolt.Tighten to specified torque.

5. Noises when cornering(1) Damaged differential gear. Replace.

(2) Excessive wear or damage of thrust washer. Replace.

(3) Broken pinion mate shaft. Replace.

(4) Seized or damaged side bearing. Replace.

6. Gear noises

NOTE:

Since noises from engine, muffler,

transmission, propeller shaft, wheel

bearings, tires, and body are

sometimes mistaken for noises

from differential assembly, be care-

ful in checking them. Inspection

methods to locate noises include

coasting, accelerating, cruising,

and jacking-up all four wheels.

Perform these inspections accord-

ing to condition of trouble. When

listening to noises, shift gears into

four wheel drive and fourth speed

position, trying to pick up only dif-

ferential noise.(1) Improper tooth contact of hypoid gear. Readjust or replace hypoid gear

set.

(2) Improper backlash for hypoid gear. Readjust.

(3) Scored or chipped teeth of hypoid gear. Replace hypoid gear set.

(4) Seized hypoid gear. Replace hypoid gear set.

(5) Improper preload for front or rear bearings. Readjust.

(6) Seized, scored, or chipped front or rear bearing. Replace.

(7) Seized, scored, or chipped side bearing. Replace.

(8) Vibrating differential carrier. Replace.

52

3-4[K200]DIAGNOSTICS

2. Rear Differential

Page 704 of 1456

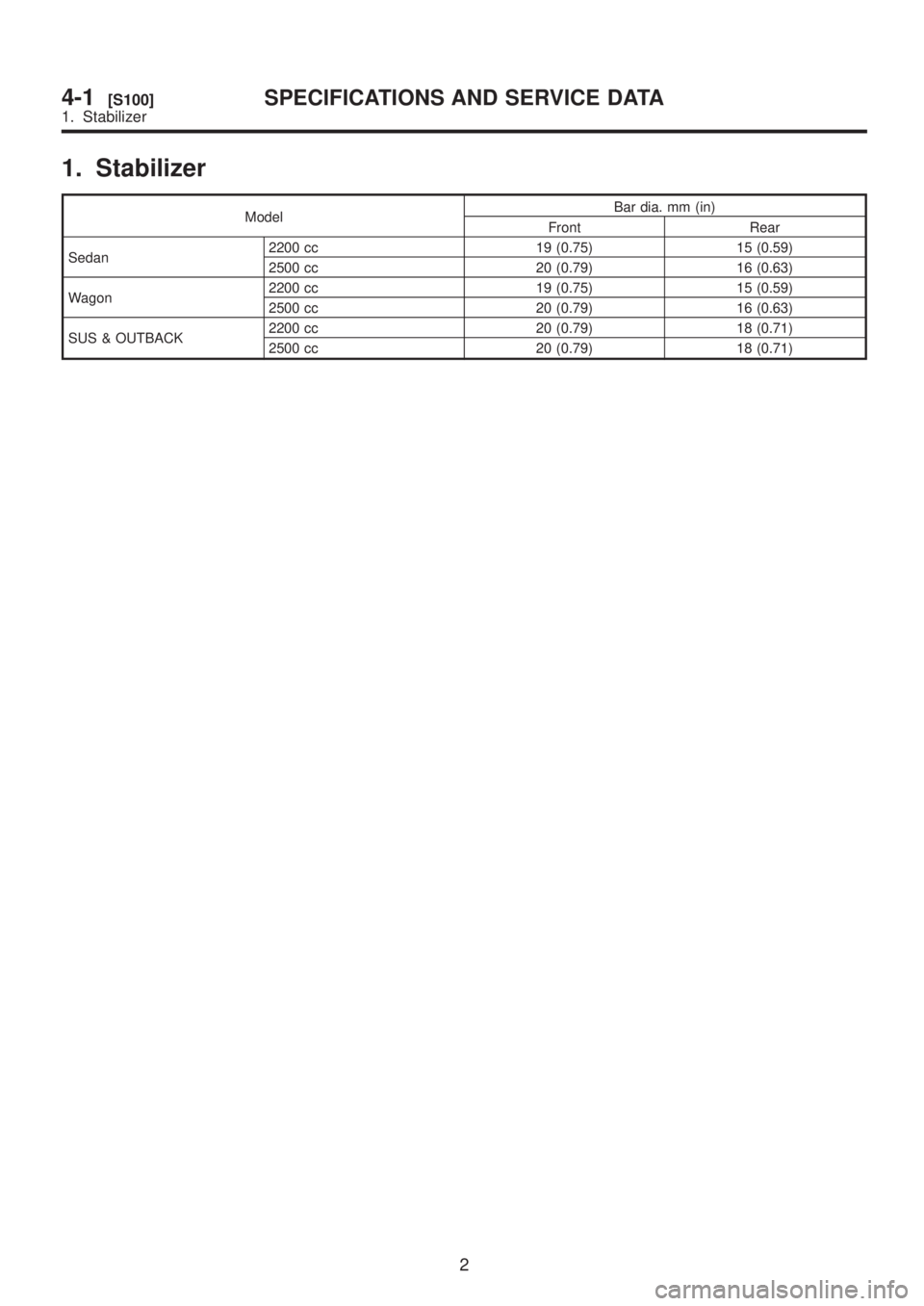

1. Stabilizer

ModelBar dia. mm (in)

Front Rear

Sedan2200 cc 19 (0.75) 15 (0.59)

2500 cc 20 (0.79) 16 (0.63)

Wagon2200 cc 19 (0.75) 15 (0.59)

2500 cc 20 (0.79) 16 (0.63)

SUS & OUTBACK2200 cc 20 (0.79) 18 (0.71)

2500 cc 20 (0.79) 18 (0.71)

2

4-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Stabilizer

Page 705 of 1456

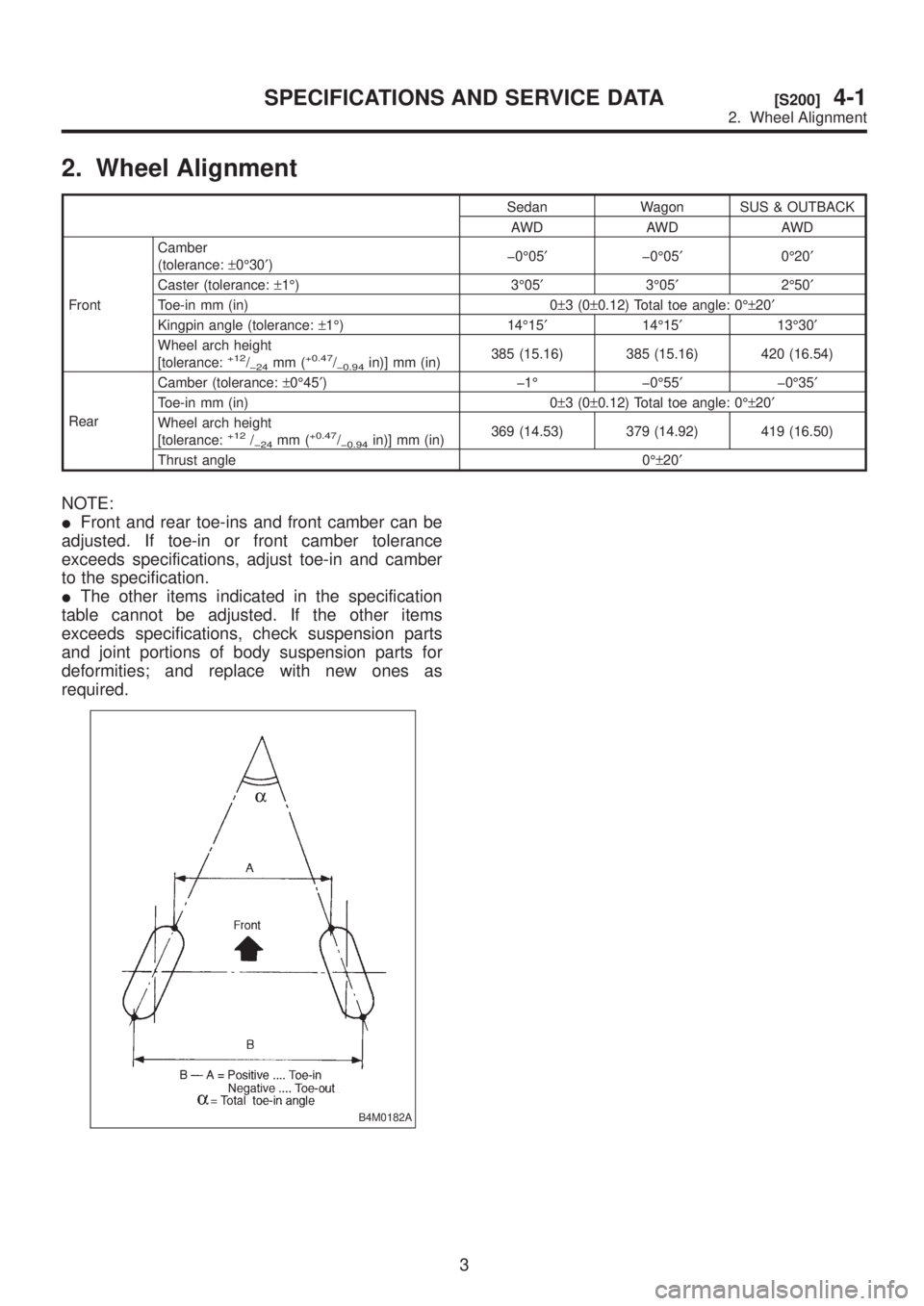

2. Wheel Alignment

Sedan Wagon SUS & OUTBACK

AWD AWD AWD

FrontCamber

(tolerance:±0É30¢)þ0É05¢þ0É05¢0É20¢

Caster (tolerance:±1É) 3É05¢3É05¢2É50¢

Toe-in mm (in) 0±3(0±0.12) Total toe angle: 0ɱ20¢

Kingpin angle (tolerance:±1É) 14É15¢14É15¢13É30¢

Wheel arch height

[tolerance:

+12/þ24mm (+0.47/þ0.94in)] mm (in)385 (15.16) 385 (15.16) 420 (16.54)

RearCamber (tolerance:±0É45¢) þ1É þ0É55¢þ0É35¢

Toe-in mm (in) 0±3(0±0.12) Total toe angle: 0ɱ20¢

Wheel arch height

[tolerance:

+12/þ24mm (+0.47/þ0.94in)] mm (in)369 (14.53) 379 (14.92) 419 (16.50)

Thrust angle 0ɱ20¢

NOTE:

IFront and rear toe-ins and front camber can be

adjusted. If toe-in or front camber tolerance

exceeds specifications, adjust toe-in and camber

to the specification.

IThe other items indicated in the specification

table cannot be adjusted. If the other items

exceeds specifications, check suspension parts

and joint portions of body suspension parts for

deformities; and replace with new ones as

required.

B4M0182A

3

[S200]4-1SPECIFICATIONS AND SERVICE DATA

2. Wheel Alignment

Page 706 of 1456

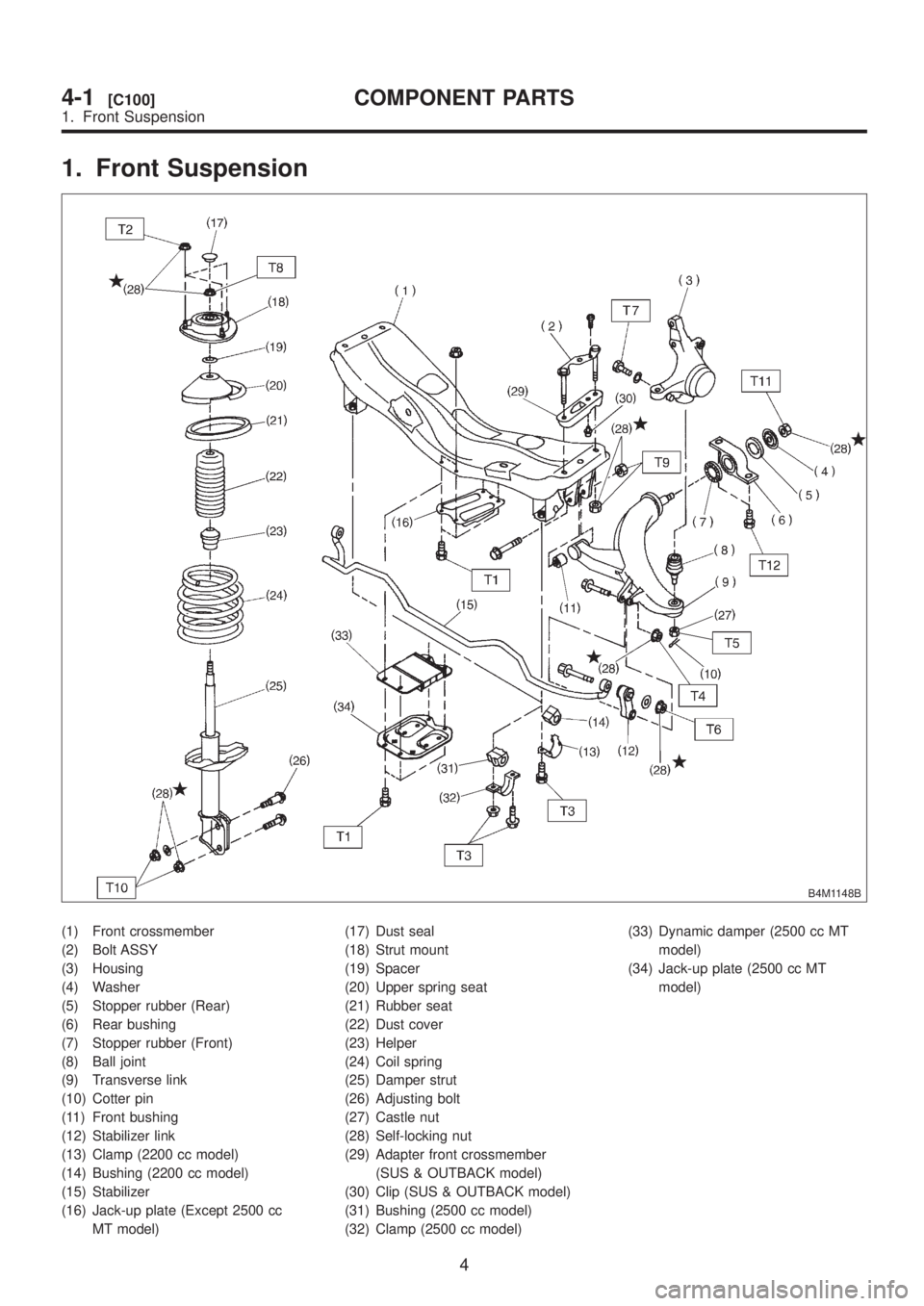

1. Front Suspension

B4M1148B

(1) Front crossmember

(2) Bolt ASSY

(3) Housing

(4) Washer

(5) Stopper rubber (Rear)

(6) Rear bushing

(7) Stopper rubber (Front)

(8) Ball joint

(9) Transverse link

(10) Cotter pin

(11) Front bushing

(12) Stabilizer link

(13) Clamp (2200 cc model)

(14) Bushing (2200 cc model)

(15) Stabilizer

(16) Jack-up plate (Except 2500 cc

MT model)(17) Dust seal

(18) Strut mount

(19) Spacer

(20) Upper spring seat

(21) Rubber seat

(22) Dust cover

(23) Helper

(24) Coil spring

(25) Damper strut

(26) Adjusting bolt

(27) Castle nut

(28) Self-locking nut

(29) Adapter front crossmember

(SUS & OUTBACK model)

(30) Clip (SUS & OUTBACK model)

(31) Bushing (2500 cc model)

(32) Clamp (2500 cc model)(33) Dynamic damper (2500 cc MT

model)

(34) Jack-up plate (2500 cc MT

model)

4

4-1[C100]COMPONENT PARTS

1. Front Suspension

Page 707 of 1456

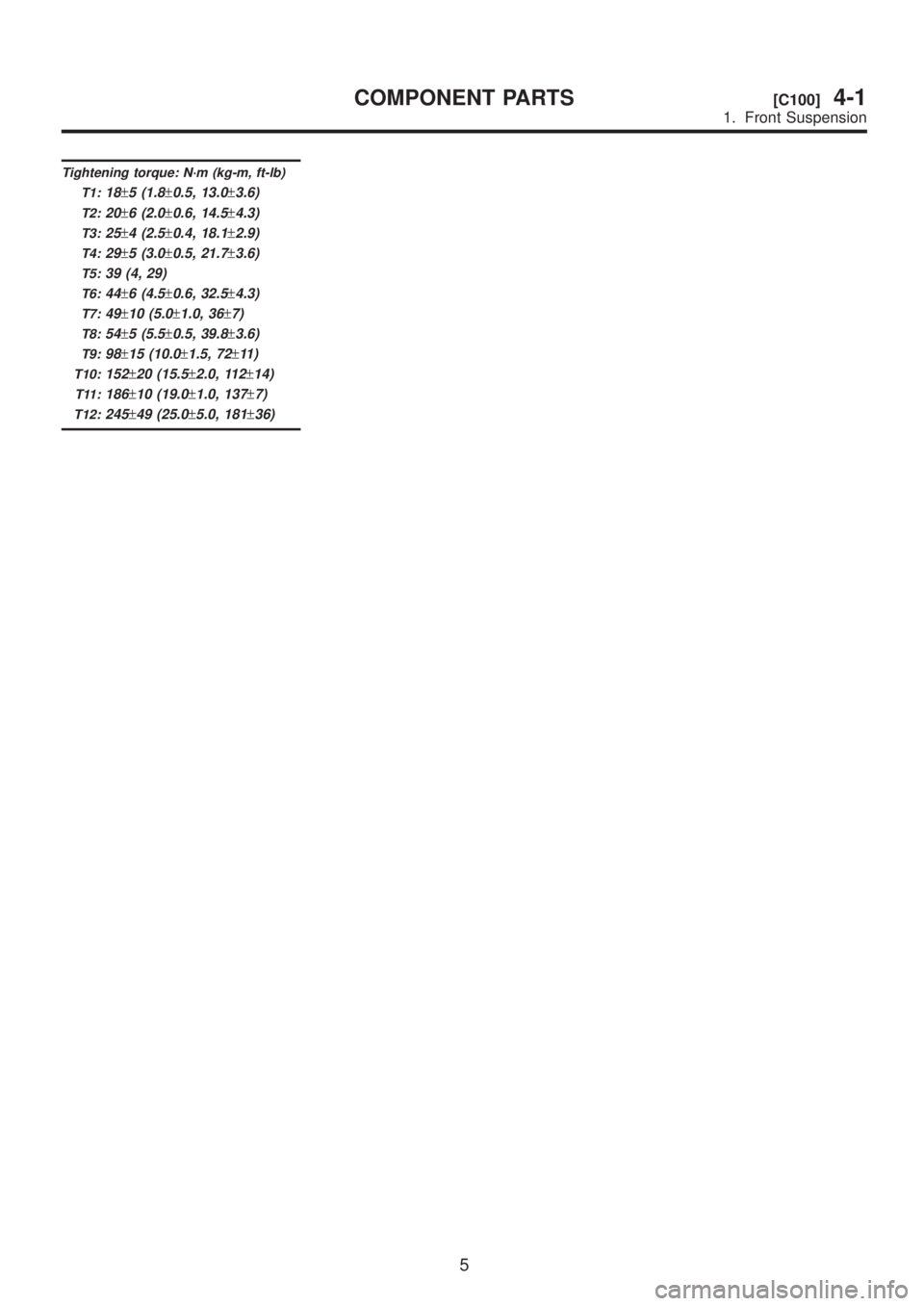

Tightening torque: N´m (kg-m, ft-lb)

T1:

18±5 (1.8±0.5, 13.0±3.6)

T2:20±6 (2.0±0.6, 14.5±4.3)

T3:25±4 (2.5±0.4, 18.1±2.9)

T4:29±5 (3.0±0.5, 21.7±3.6)

T5:39 (4, 29)

T6:44±6 (4.5±0.6, 32.5±4.3)

T7:49±10 (5.0±1.0, 36±7)

T8:54±5 (5.5±0.5, 39.8±3.6)

T9:98±15 (10.0±1.5, 72±11 )

T10:152±20 (15.5±2.0, 112±14)

T11:186±10 (19.0±1.0, 137±7)

T12:245±49 (25.0±5.0, 181±36)

5

[C100]4-1COMPONENT PARTS

1. Front Suspension

Page 708 of 1456

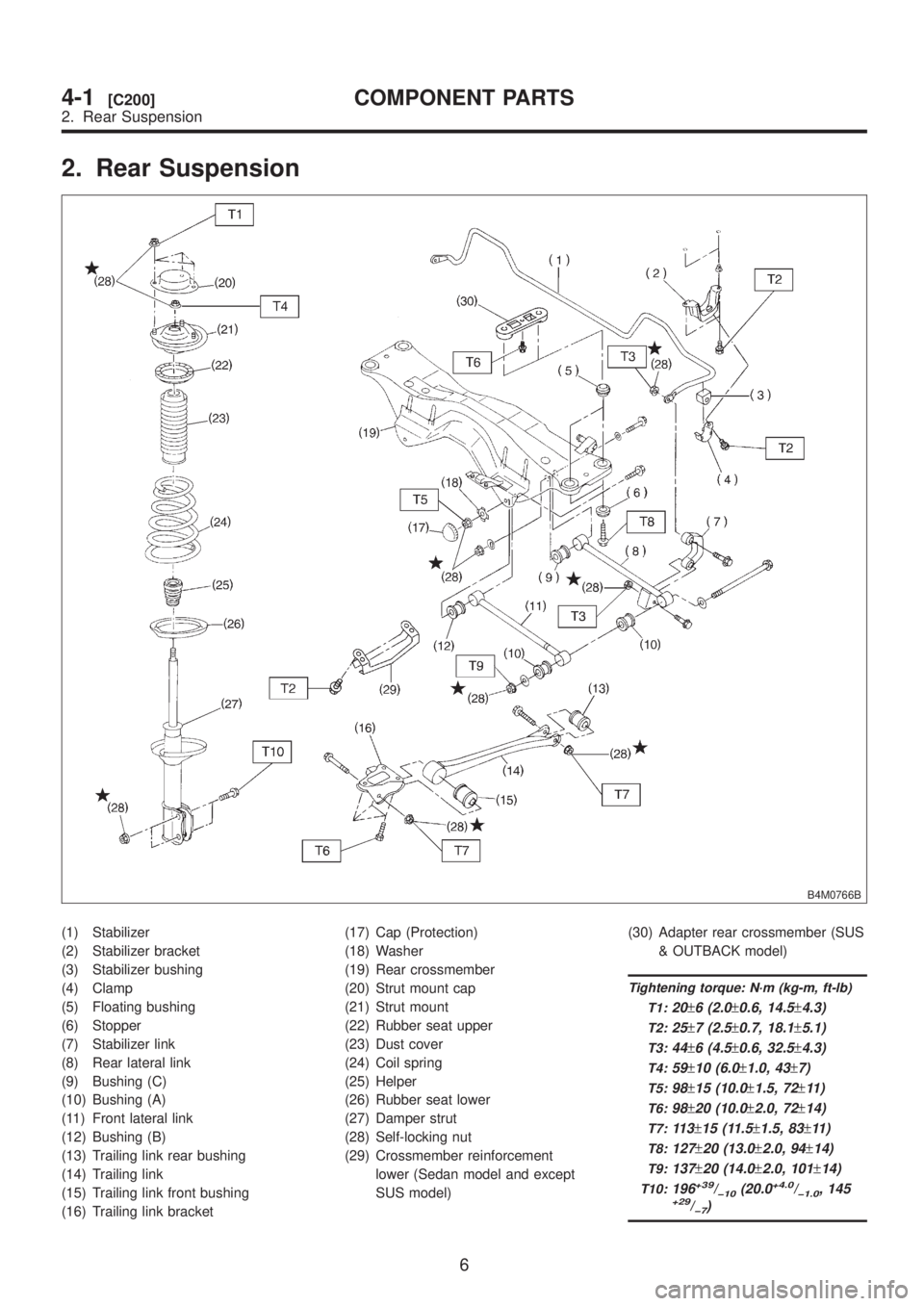

2. Rear Suspension

B4M0766B

(1) Stabilizer

(2) Stabilizer bracket

(3) Stabilizer bushing

(4) Clamp

(5) Floating bushing

(6) Stopper

(7) Stabilizer link

(8) Rear lateral link

(9) Bushing (C)

(10) Bushing (A)

(11) Front lateral link

(12) Bushing (B)

(13) Trailing link rear bushing

(14) Trailing link

(15) Trailing link front bushing

(16) Trailing link bracket(17) Cap (Protection)

(18) Washer

(19) Rear crossmember

(20) Strut mount cap

(21) Strut mount

(22) Rubber seat upper

(23) Dust cover

(24) Coil spring

(25) Helper

(26) Rubber seat lower

(27) Damper strut

(28) Self-locking nut

(29) Crossmember reinforcement

lower (Sedan model and except

SUS model)(30) Adapter rear crossmember (SUS

& OUTBACK model)

Tightening torque: N´m (kg-m, ft-lb)

T1:

20±6 (2.0±0.6, 14.5±4.3)

T2:25±7 (2.5±0.7, 18.1±5.1)

T3:44±6 (4.5±0.6, 32.5±4.3)

T4:59±10 (6.0±1.0, 43±7)

T5:98±15 (10.0±1.5, 72±11 )

T6:98±20 (10.0±2.0, 72±14)

T7:11 3±15 (11.5±1.5, 83±11 )

T8:127±20 (13.0±2.0, 94±14)

T9:137±20 (14.0±2.0, 101±14)

T10:196+39/þ10(20.0+4.0/þ1.0, 145+29/þ7)

6

4-1[C200]COMPONENT PARTS

2. Rear Suspension

Page 709 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 1. On-car Services

A: WHEEL ALIGNMENT

PROCEDURES

Check, adjust and/or measure wheel alignment in

accordance with procedures indicated in figure:

B4M1088A

7

[W1A0]4-1SERVICE PROCEDURE

1. On-car Service SUBARU LEGACY 1999 Service Repair Manual 1. On-car Services

A: WHEEL ALIGNMENT

PROCEDURES

Check, adjust and/or measure wheel alignment in

accordance with procedures indicated in figure:

B4M1088A

7

[W1A0]4-1SERVICE PROCEDURE

1. On-car Service](/img/17/57435/w960_57435-708.png)

1. On-car Services

A: WHEEL ALIGNMENT

PROCEDURES

Check, adjust and/or measure wheel alignment in

accordance with procedures indicated in figure:

B4M1088A

7

[W1A0]4-1SERVICE PROCEDURE

1. On-car Services

Page 710 of 1456

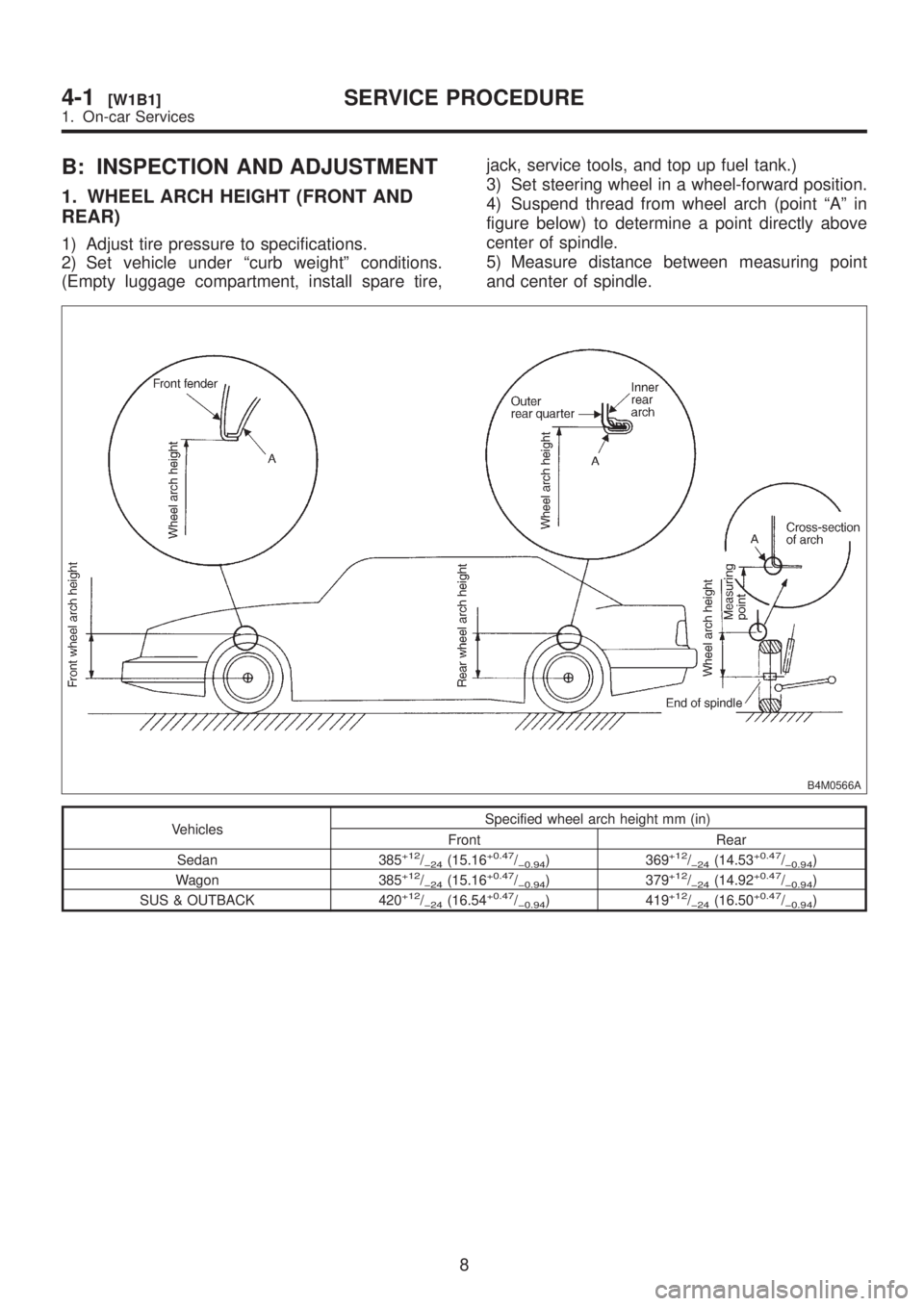

B: INSPECTION AND ADJUSTMENT

1. WHEEL ARCH HEIGHT (FRONT AND

REAR)

1) Adjust tire pressure to specifications.

2) Set vehicle under ªcurb weightº conditions.

(Empty luggage compartment, install spare tire,jack, service tools, and top up fuel tank.)

3) Set steering wheel in a wheel-forward position.

4) Suspend thread from wheel arch (point ªAº in

figure below) to determine a point directly above

center of spindle.

5) Measure distance between measuring point

and center of spindle.

B4M0566A

VehiclesSpecified wheel arch height mm (in)

Front Rear

Sedan 385

+12/þ24(15.16+0.47/þ0.94) 369+12/þ24(14.53+0.47/þ0.94)

Wagon 385+12/þ24(15.16+0.47/þ0.94) 379+12/þ24(14.92+0.47/þ0.94)

SUS & OUTBACK 420+12/þ24(16.54+0.47/þ0.94) 419+12/þ24(16.50+0.47/þ0.94)

8

4-1[W1B1]SERVICE PROCEDURE

1. On-car Services