Intake SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1738 of 2453

GD(H6DO)-126

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

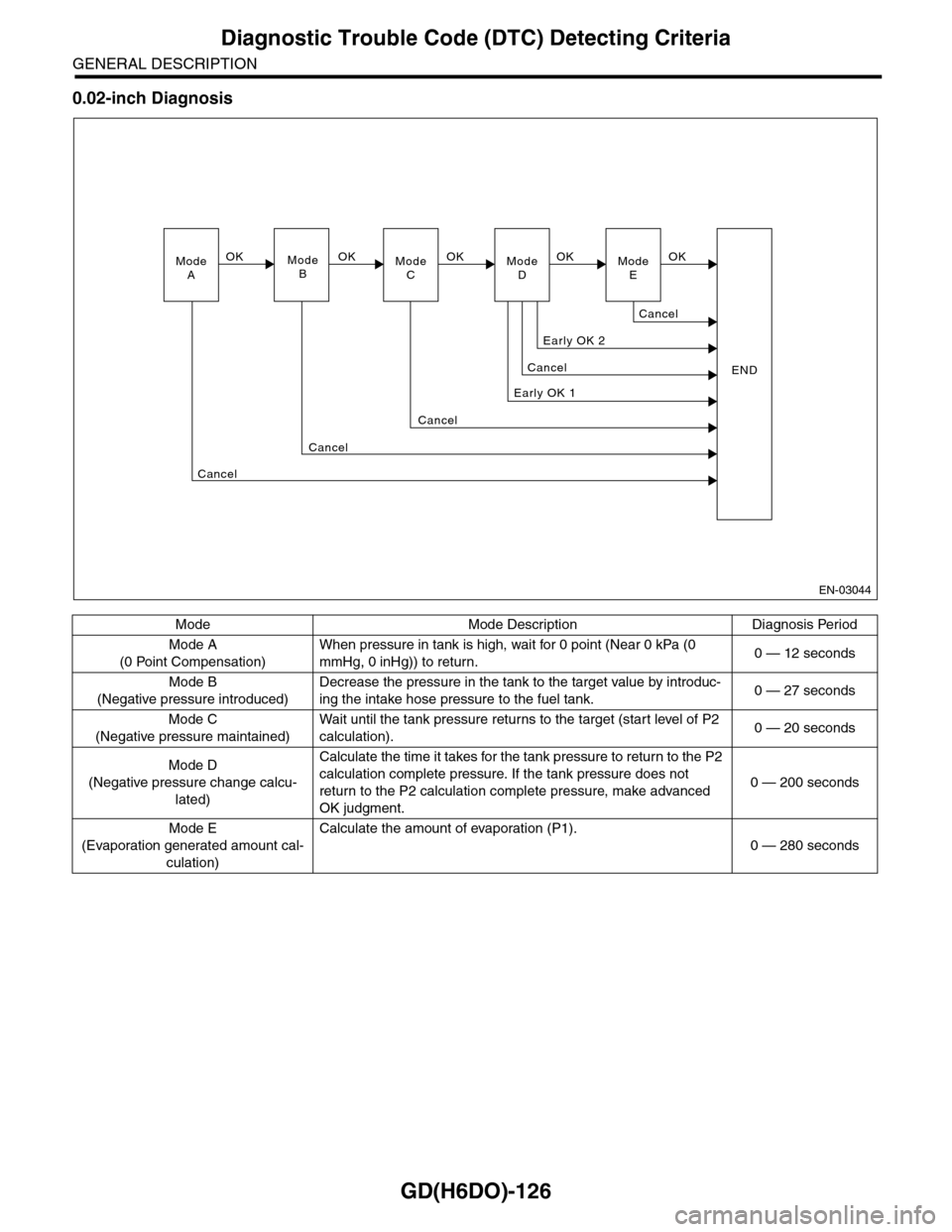

0.02-inch Diagnosis

Mode Mode Description Diagnosis Period

Mode A

(0 Point Compensation)

When pressure in tank is high, wait for 0 point (Near 0 kPa (0

mmHg, 0 inHg)) to return.0 — 12 seconds

Mode B

(Negative pressure introduced)

Decrease the pressure in the tank to the target value by introduc-

ing the intake hose pressure to the fuel tank.0 — 27 seconds

Mode C

(Negative pressure maintained)

Wa i t u nt i l t h e t a nk pr e ss ur e r et u r ns to t he t ar g e t ( s ta r t leve l o f P 2

calculation).0 — 20 seconds

Mode D

(Negative pressure change calcu-

lated)

Calculate the time it takes for the tank pressure to return to the P2

calculation complete pressure. If the tank pressure does not

return to the P2 calculation complete pressure, make advanced

OK judgment.

0 — 200 seconds

Mode E

(Evaporation generated amount cal-

culation)

Calculate the amount of evaporation (P1).

0 — 280 seconds

EN-03044

ModeAModeBModeCModeD

OKOKOK

Early OK 1

Cancel

Cancel

END

Cancel

Cancel

Early OK 2

OKModeE

Cancel

OK

Page 1739 of 2453

GD(H6DO)-127

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

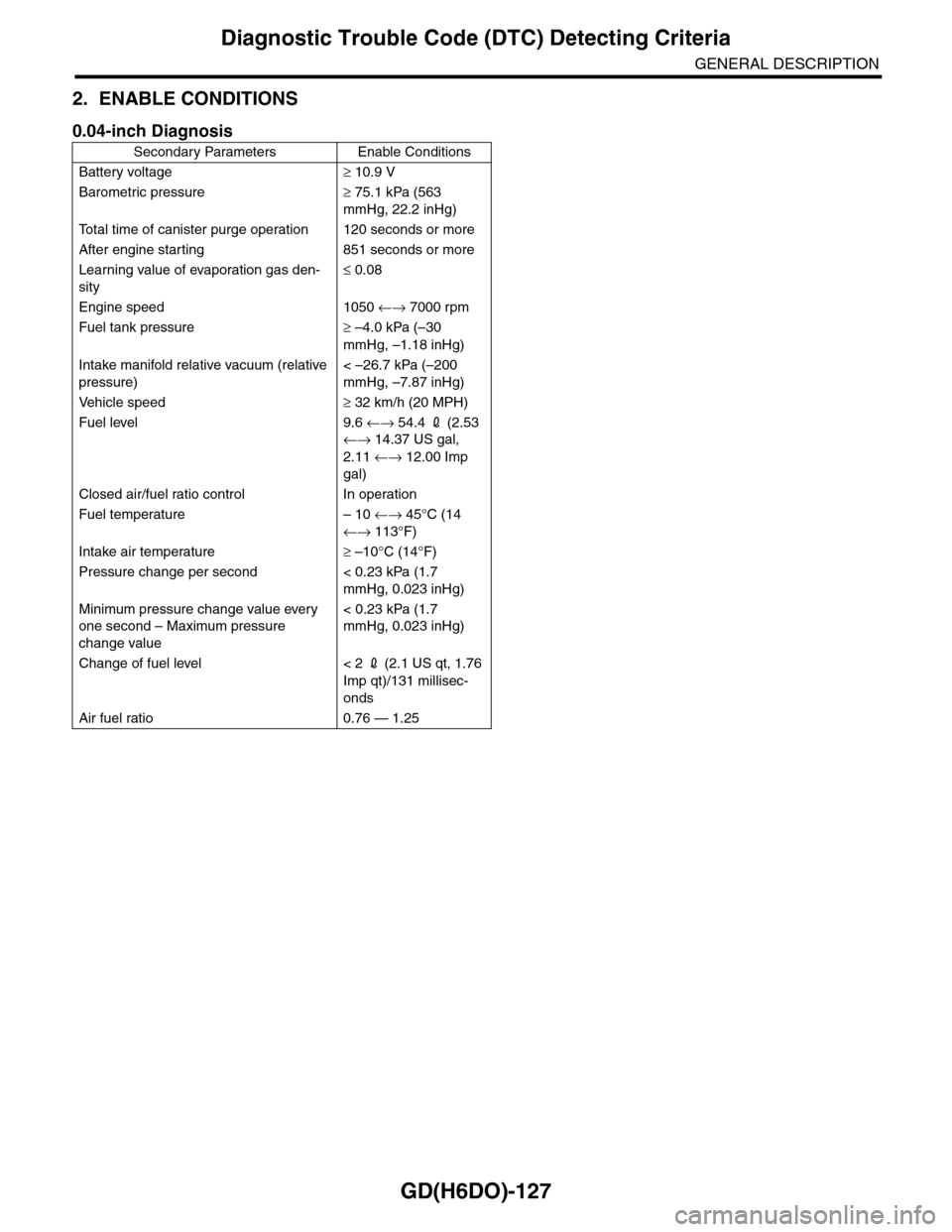

2. ENABLE CONDITIONS

0.04-inch Diagnosis

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Barometric pressure≥ 75.1 kPa (563

mmHg, 22.2 inHg)

To t a l t i m e o f c a n i s t e r p u r g e o p e r a t i o n 1 2 0 s e c o n d s o r m o r e

After engine starting 851 seconds or more

Learning value of evaporation gas den-

sity

≤ 0.08

Engine speed 1050 ←→ 7000 rpm

Fuel tank pressure≥ –4.0 kPa (–30

mmHg, –1.18 inHg)

Intake manifold relative vacuum (relative

pressure)

< –26.7 kPa (–200

mmHg, –7.87 inHg)

Ve h i c l e s p e e d≥ 32 km/h (20 MPH)

Fuel level 9.6 ←→ 54.4 2 (2.53

←→ 14.37 US gal,

2.11 ←→ 12.00 Imp

gal)

Closed air/fuel ratio control In operation

Fuel temperature – 10 ←→ 45°C (14

←→ 113°F)

Intake air temperature≥ –10°C (14°F)

Pressure change per second < 0.23 kPa (1.7

mmHg, 0.023 inHg)

Minimum pressure change value every

one second – Maximum pressure

change value

< 0.23 kPa (1.7

mmHg, 0.023 inHg)

Change of fuel level < 2 2 (2.1 US qt, 1.76

Imp qt)/131 millisec-

onds

Air fuel ratio 0.76 — 1.25

Page 1740 of 2453

GD(H6DO)-128

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

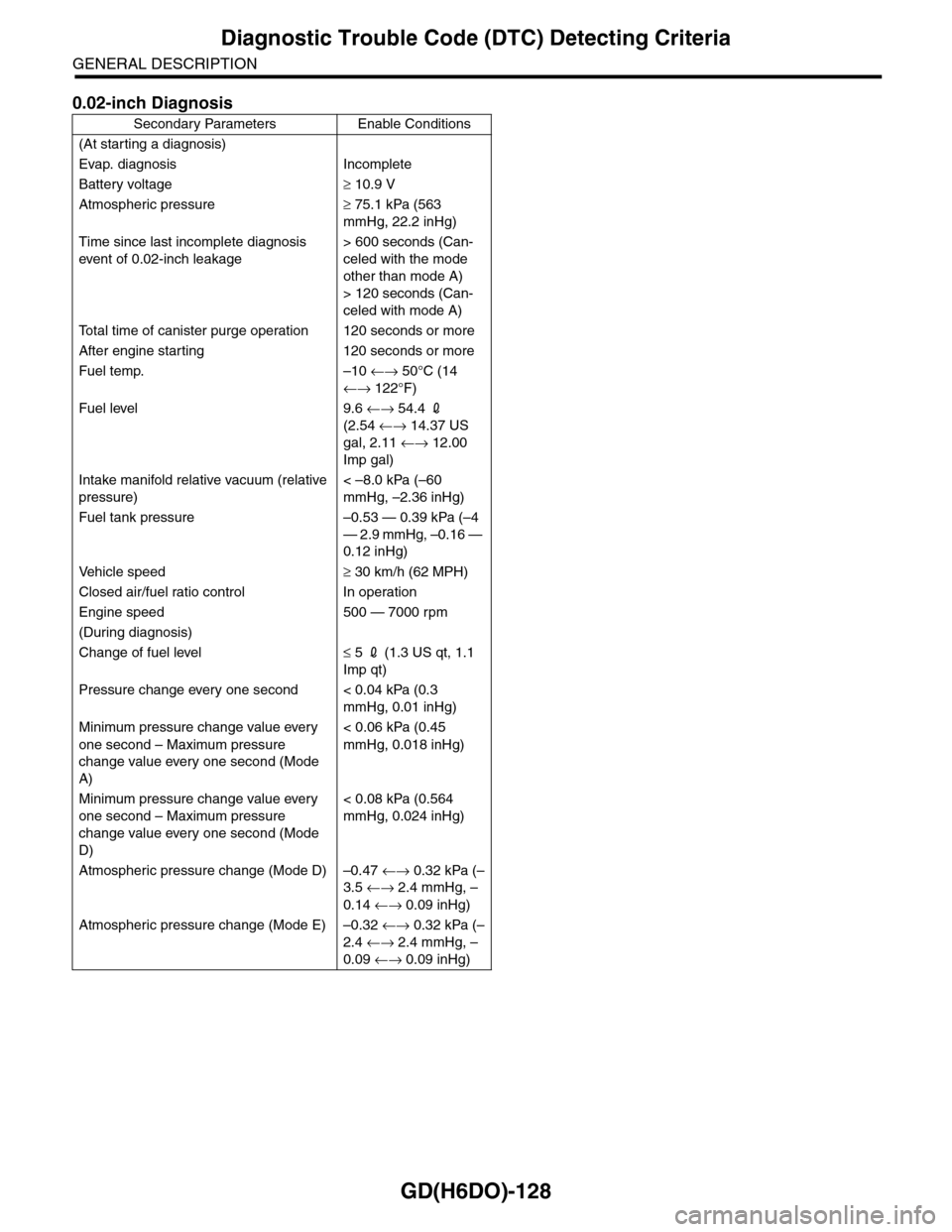

0.02-inch Diagnosis

Secondary Parameters Enable Conditions

(At starting a diagnosis)

Evap. diagnosis Incomplete

Battery voltage≥ 10.9 V

Atmospheric pressure≥ 75.1 kPa (563

mmHg, 22.2 inHg)

Time since last incomplete diagnosis

event of 0.02-inch leakage

> 600 seconds (Can-

celed with the mode

other than mode A)

> 120 seconds (Can-

celed with mode A)

To t a l t i m e o f c a n i s t e r p u r g e o p e r a t i o n 1 2 0 s e c o n d s o r m o r e

After engine starting 120 seconds or more

Fuel temp. –10 ←→ 50°C (14

←→ 122°F)

Fuel level 9.6 ←→ 54.4 2

(2.54 ←→ 14.37 US

gal, 2.11 ←→ 12.00

Imp gal)

Intake manifold relative vacuum (relative

pressure)

< –8.0 kPa (–60

mmHg, –2.36 inHg)

Fuel tank pressure –0.53 — 0.39 kPa (–4

— 2.9 mmHg, –0.16 —

0.12 inHg)

Ve h i c l e s p e e d≥ 30 km/h (62 MPH)

Closed air/fuel ratio control In operation

Engine speed 500 — 7000 rpm

(During diagnosis)

Change of fuel level≤ 5 2 (1.3 US qt, 1.1

Imp qt)

Pressure change every one second < 0.04 kPa (0.3

mmHg, 0.01 inHg)

Minimum pressure change value every

one second – Maximum pressure

change value every one second (Mode

A)

< 0.06 kPa (0.45

mmHg, 0.018 inHg)

Minimum pressure change value every

one second – Maximum pressure

change value every one second (Mode

D)

< 0.08 kPa (0.564

mmHg, 0.024 inHg)

Atmospheric pressure change (Mode D) –0.47 ←→ 0.32 kPa (–

3.5 ←→ 2.4 mmHg, –

0.14 ←→ 0.09 inHg)

Atmospheric pressure change (Mode E) –0.32 ←→ 0.32 kPa (–

2.4 ←→ 2.4 mmHg, –

0.09 ←→ 0.09 inHg)

Page 1744 of 2453

GD(H6DO)-132

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

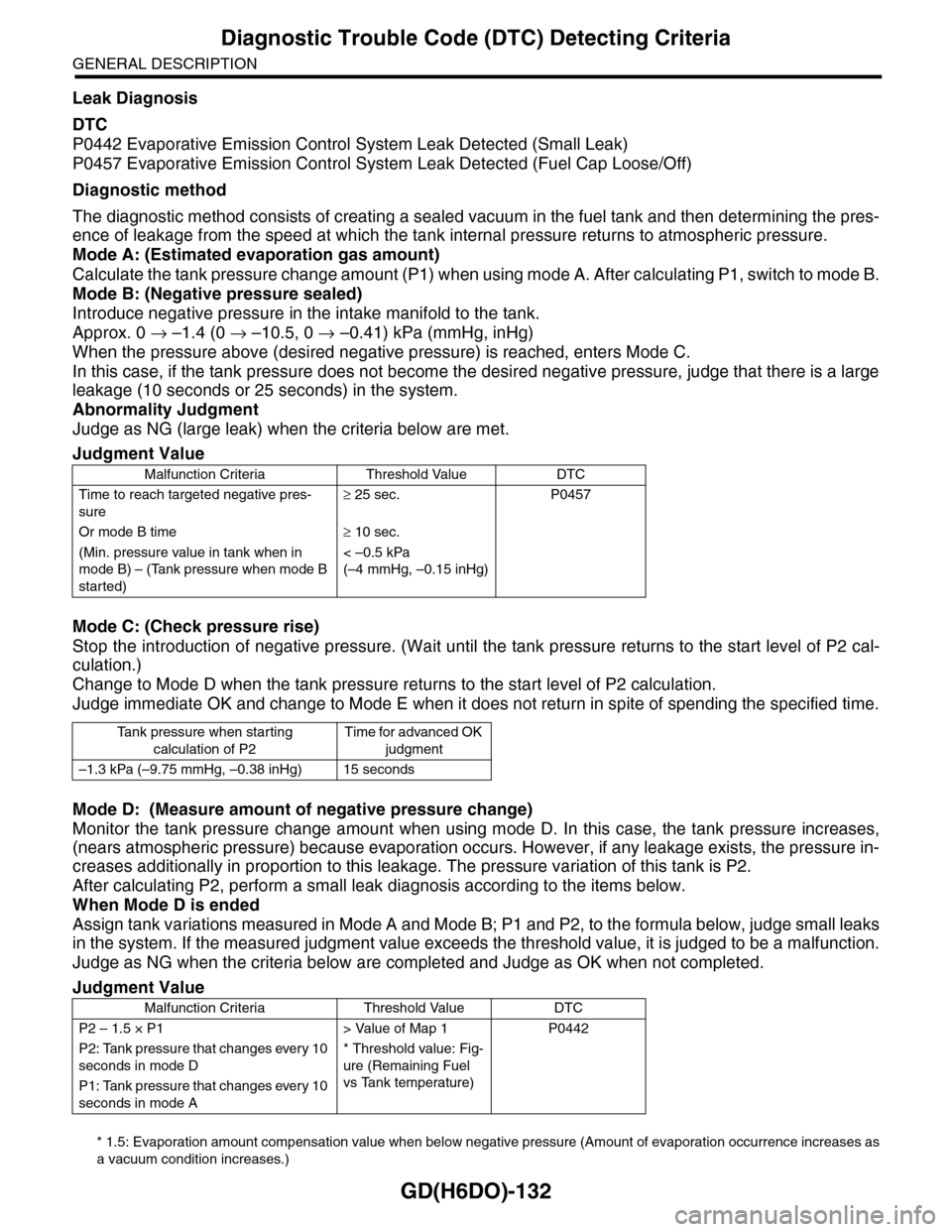

Leak Diagnosis

DTC

P0442 Evaporative Emission Control System Leak Detected (Small Leak)

P0457 Evaporative Emission Control System Leak Detected (Fuel Cap Loose/Off)

Diagnostic method

The diagnostic method consists of creating a sealed vacuum in the fuel tank and then determining the pres-

ence of leakage from the speed at which the tank internal pressure returns to atmospheric pressure.

Mode A: (Estimated evaporation gas amount)

Calculate the tank pressure change amount (P1) when using mode A. After calculating P1, switch to mode B.

Mode B: (Negative pressure sealed)

Introduce negative pressure in the intake manifold to the tank.

Approx. 0 → –1.4 (0 → –10.5, 0 → –0.41) kPa (mmHg, inHg)

When the pressure above (desired negative pressure) is reached, enters Mode C.

In this case, if the tank pressure does not become the desired negative pressure, judge that there is a large

leakage (10 seconds or 25 seconds) in the system.

Abnormality Judgment

Judge as NG (large leak) when the criteria below are met.

Mode C: (Check pressure rise)

Stop the introduction of negative pressure. (Wait until the tank pressure returns to the start level of P2 cal-

culation.)

Change to Mode D when the tank pressure returns to the start level of P2 calculation.

Judge immediate OK and change to Mode E when it does not return in spite of spending the specified time.

Mode D: (Measure amount of negative pressure change)

Monitor the tank pressure change amount when using mode D. In this case, the tank pressure increases,

(nears atmospheric pressure) because evaporation occurs. However, if any leakage exists, the pressure in-

creases additionally in proportion to this leakage. The pressure variation of this tank is P2.

After calculating P2, perform a small leak diagnosis according to the items below.

When Mode D is ended

Assign tank variations measured in Mode A and Mode B; P1 and P2, to the formula below, judge small leaks

in the system. If the measured judgment value exceeds the threshold value, it is judged to be a malfunction.

Judge as NG when the criteria below are completed and Judge as OK when not completed.

* 1.5: Evaporation amount compensation value when below negative pressure (Amount of evaporation occurrence increases as

a vacuum condition increases.)

Judgment Value

Malfunction Criteria Threshold Value DTC

Time to reach targeted negative pres-

sure

≥ 25 sec. P0457

Or mode B time≥ 10 sec.

(Min. pressure value in tank when in

mode B) – (Tank pressure when mode B

started)

< –0.5 kPa

(–4 mmHg, –0.15 inHg)

Ta n k p r e s s u r e w h e n s t a r t i n g

calculation of P2

Time for advanced OK

judgment

–1.3 kPa (–9.75 mmHg, –0.38 inHg) 15 seconds

Judgment Value

Malfunction Criteria Threshold Value DTC

P2 – 1.5 × P1 > Value of Map 1 P0442

P2: Tank pressure that changes every 10

seconds in mode D

* Threshold value: Fig-

ure (Remaining Fuel

vs Tank temperature)

P1: Tank pressure that changes every 10

seconds in mode A

Page 1745 of 2453

GD(H6DO)-133

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

Time Needed for Diagnosis: 30 to 100 seconds

0.02-inch Diagnosis

DTC

P0456 Evaporative Emission Control System Leak Detected (very small leak)

Diagnostic method

The diagnostic method consists of creating a sealed vacuum in the fuel tank and then determining the pres-

ence of leakage from the speed at which the tank internal pressure returns to atmospheric pressure.

Mode A: (0 Point Compensation)

When pressure in tank is high, wait for 0 point 0 kPa (Near 0 mmHg, 0 inHg) to return.Shift to mode B when

0 point returns.

Cancel the diagnosis when 0 point does not return in the specified time.

Mode B: (Negative pressure introduced)

Introduce negative pressure in the intake manifold to the tank.

Approx. 0 → –2.0 kPa (0 mmHg → –15 mmHg, 0 → –0.59 inHg)

When the pressure above (desired negative pressure) is reached, Mode C is entered.

Cancel the diagnosis when the targeted pressure in the tank is not reached.

Mode C: (Negative pressure maintained)

Stop the introduction of negative pressure and wait until the tank pressure returns to the start level of P2 cal-

culation.

Change to Mode D either when the tank pressure returns to the start level of P2 calculation, or when the pre-

determined amount of time has passed.

Mode D: (Calculate the amount of negative pressure change)

Monitor the tank pressure in mode D, calculate (P2) the pressure change in the tank, and measure the time

(evpdset) for the tank pressure to return when calculation of P2 is completed. Shift to mode E when pressure

returns. Make an advance OK judgment using the value of P2, or cancel, when the pressure in the tank does

not return after calculation of P2 is completed even when the predetermined amount of time has passed.

When the following conditions are established, it is OK.

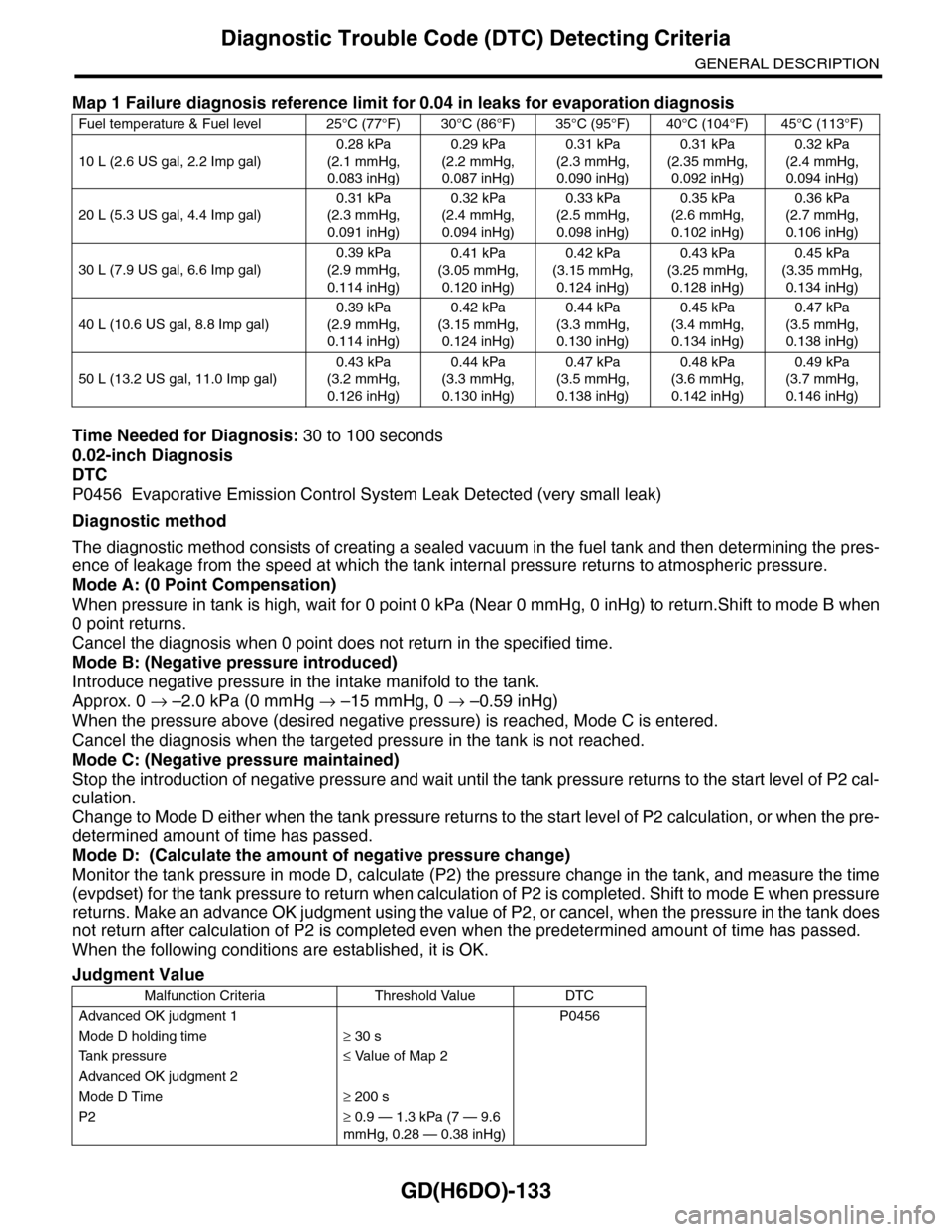

Map 1 Failure diagnosis reference limit for 0.04 in leaks for evaporation diagnosis

Fuel temperature & Fuel level 25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F) 45°C (113°F)

10 L (2.6 US gal, 2.2 Imp gal)

0.28 kPa

(2.1 mmHg,

0.083 inHg)

0.29 kPa

(2.2 mmHg,

0.087 inHg)

0.31 kPa

(2.3 mmHg,

0.090 inHg)

0.31 kPa

(2.35 mmHg,

0.092 inHg)

0.32 kPa

(2.4 mmHg,

0.094 inHg)

20 L (5.3 US gal, 4.4 Imp gal)

0.31 kPa

(2.3 mmHg,

0.091 inHg)

0.32 kPa

(2.4 mmHg,

0.094 inHg)

0.33 kPa

(2.5 mmHg,

0.098 inHg)

0.35 kPa

(2.6 mmHg,

0.102 inHg)

0.36 kPa

(2.7 mmHg,

0.106 inHg)

30 L (7.9 US gal, 6.6 Imp gal)

0.39 kPa

(2.9 mmHg,

0.114 inHg)

0.41 kPa

(3.05 mmHg,

0.120 inHg)

0.42 kPa

(3.15 mmHg,

0.124 inHg)

0.43 kPa

(3.25 mmHg,

0.128 inHg)

0.45 kPa

(3.35 mmHg,

0.134 inHg)

40 L (10.6 US gal, 8.8 Imp gal)

0.39 kPa

(2.9 mmHg,

0.114 inHg)

0.42 kPa

(3.15 mmHg,

0.124 inHg)

0.44 kPa

(3.3 mmHg,

0.130 inHg)

0.45 kPa

(3.4 mmHg,

0.134 inHg)

0.47 kPa

(3.5 mmHg,

0.138 inHg)

50 L (13.2 US gal, 11.0 Imp gal)

0.43 kPa

(3.2 mmHg,

0.126 inHg)

0.44 kPa

(3.3 mmHg,

0.130 inHg)

0.47 kPa

(3.5 mmHg,

0.138 inHg)

0.48 kPa

(3.6 mmHg,

0.142 inHg)

0.49 kPa

(3.7 mmHg,

0.146 inHg)

Judgment Value

Malfunction Criteria Threshold Value DTC

Advanced OK judgment 1 P0456

Mode D holding time≥ 30 s

Ta n k p r e s s u r e≤ Value of Map 2

Advanced OK judgment 2

Mode D Time≥ 200 s

P2≥ 0.9 — 1.3 kPa (7 — 9.6

mmHg, 0.28 — 0.38 inHg)

Page 1759 of 2453

GD(H6DO)-147

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

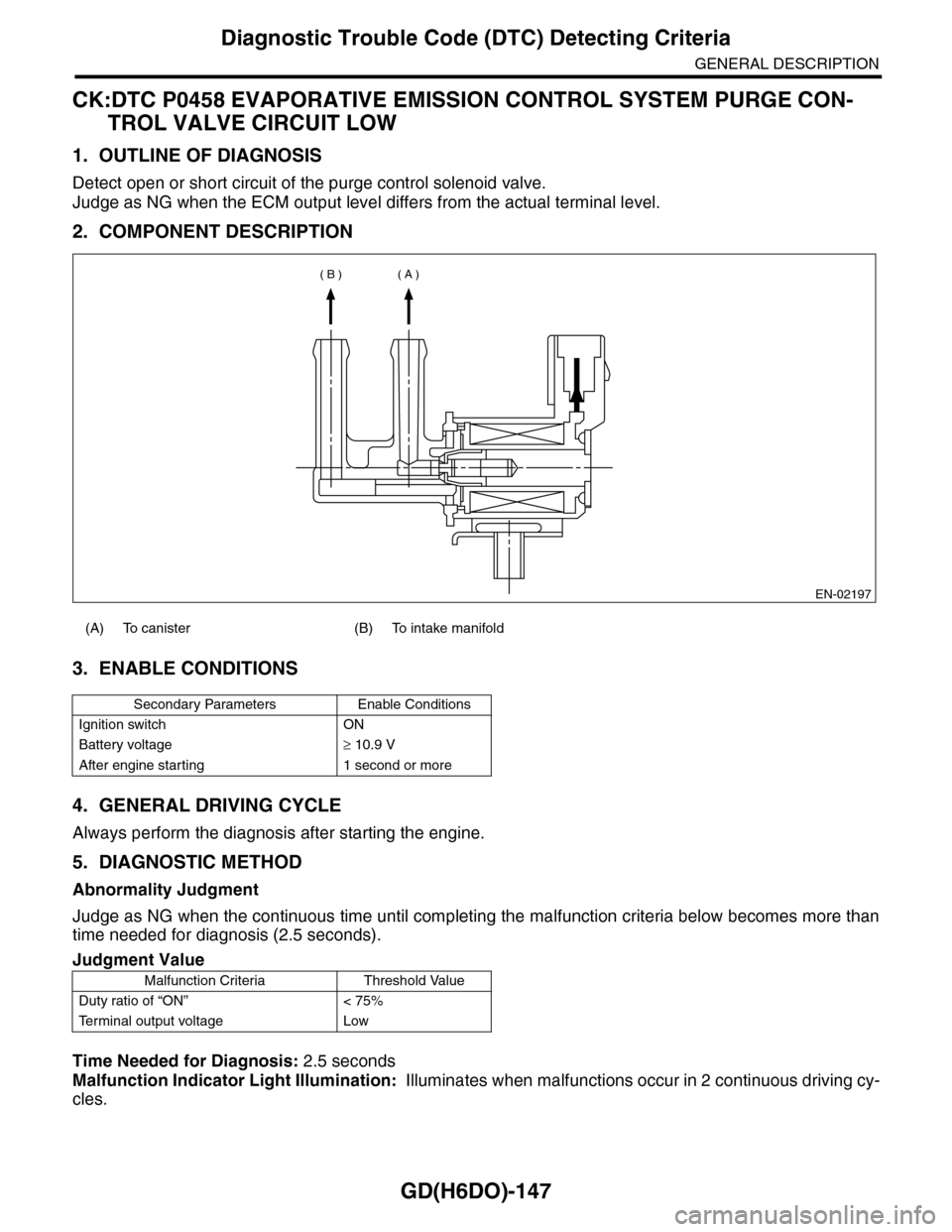

CK:DTC P0458 EVAPORATIVE EMISSION CONTROL SYSTEM PURGE CON-

TROL VALVE CIRCUIT LOW

1. OUTLINE OF DIAGNOSIS

Detect open or short circuit of the purge control solenoid valve.

Judge as NG when the ECM output level differs from the actual terminal level.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis after starting the engine.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes more than

time needed for diagnosis (2.5 seconds).

Time Needed for Diagnosis: 2.5 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

(A) To canister (B) To intake manifold

Secondary Parameters Enable Conditions

Ignition switch ON

Battery voltage≥ 10.9 V

After engine starting 1 second or more

Judgment Value

Malfunction Criteria Threshold Value

Duty ratio of “ON” < 75%

Te r m i n a l o u t p u t v o l t a g e L o w

EN-02197

( A )( B )

Page 1761 of 2453

GD(H6DO)-149

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

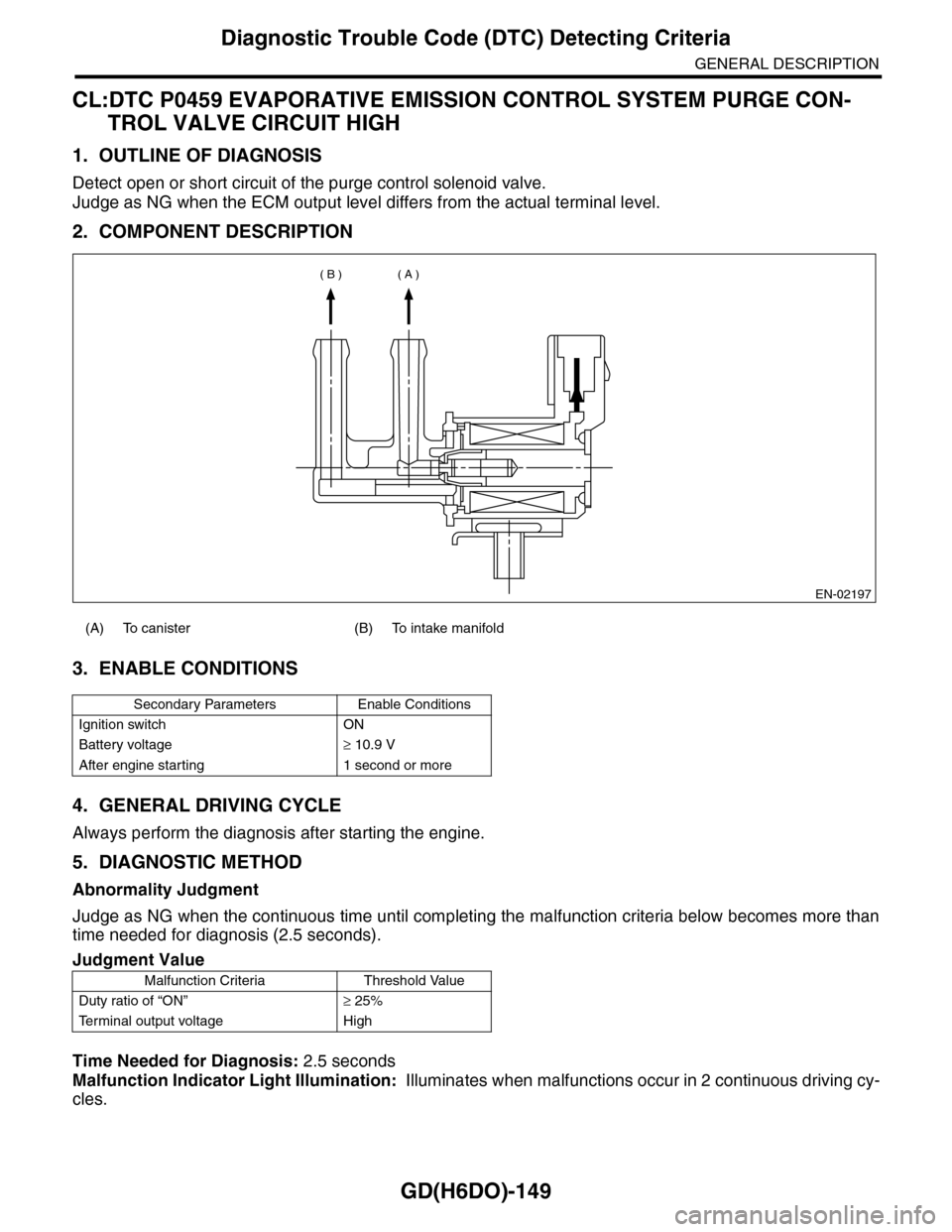

CL:DTC P0459 EVAPORATIVE EMISSION CONTROL SYSTEM PURGE CON-

TROL VALVE CIRCUIT HIGH

1. OUTLINE OF DIAGNOSIS

Detect open or short circuit of the purge control solenoid valve.

Judge as NG when the ECM output level differs from the actual terminal level.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis after starting the engine.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes more than

time needed for diagnosis (2.5 seconds).

Time Needed for Diagnosis: 2.5 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

(A) To canister (B) To intake manifold

Secondary Parameters Enable Conditions

Ignition switch ON

Battery voltage≥ 10.9 V

After engine starting 1 second or more

Judgment Value

Malfunction Criteria Threshold Value

Duty ratio of “ON”≥ 25%

Te r m i n a l o u t p u t v o l t a g e H i g h

EN-02197

( A )( B )

Page 1763 of 2453

GD(H6DO)-151

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

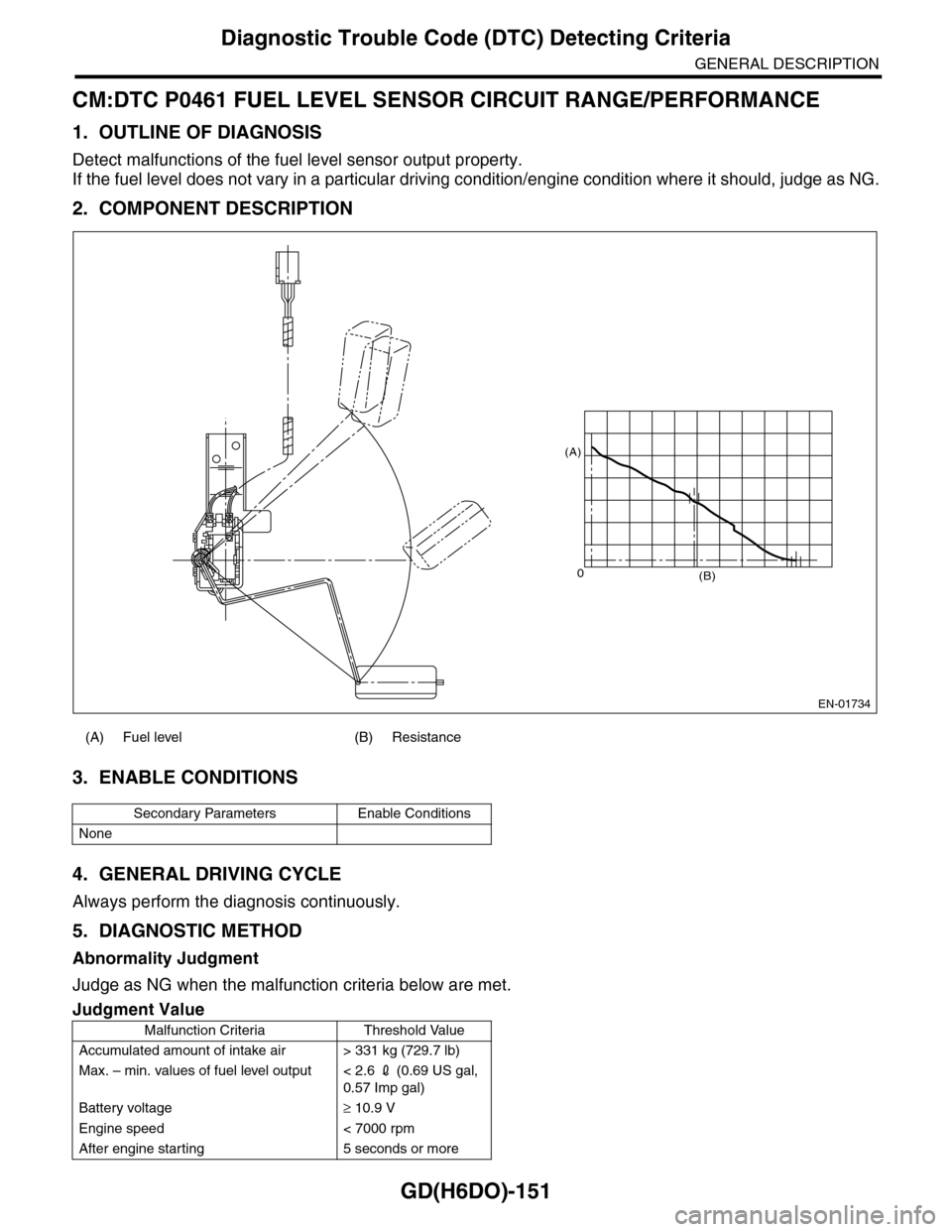

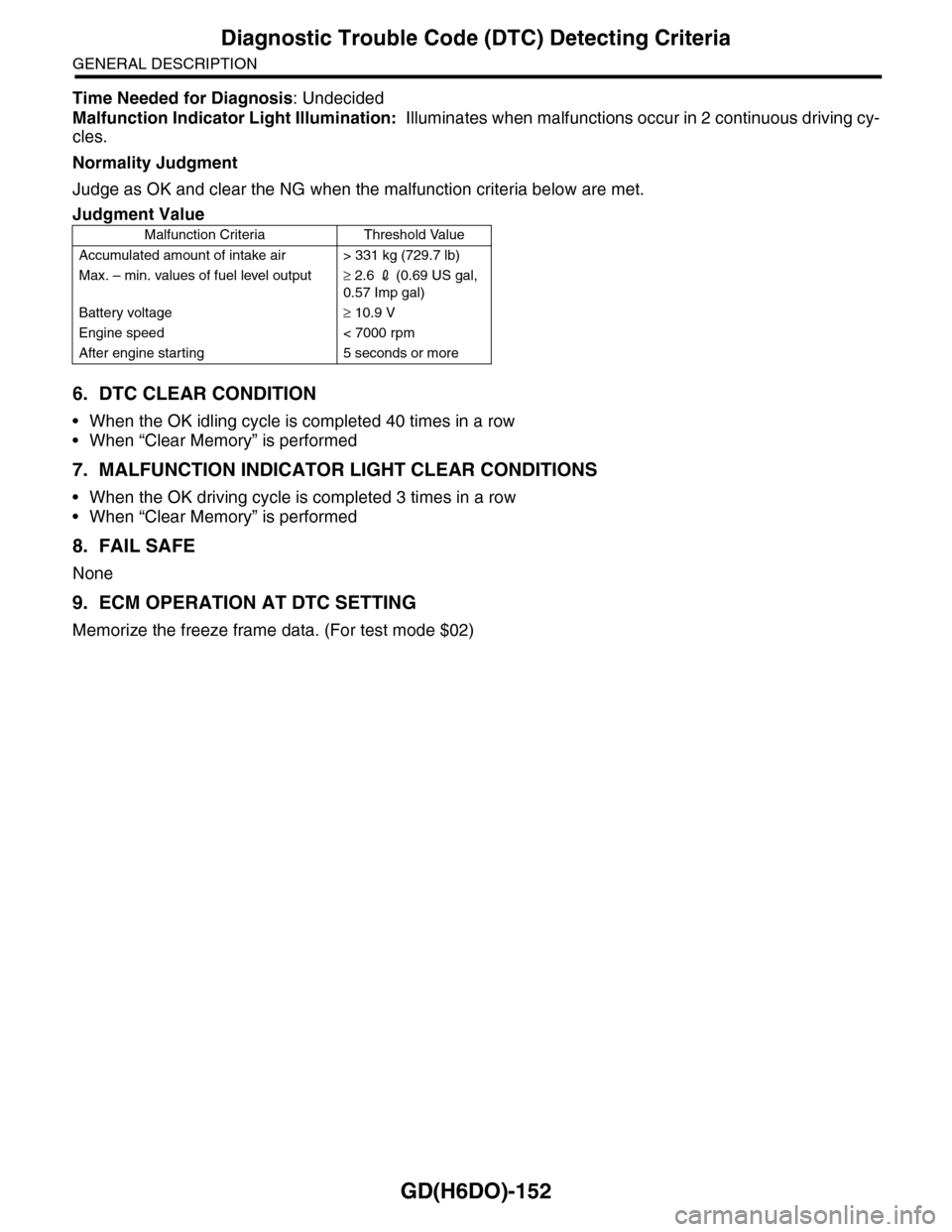

CM:DTC P0461 FUEL LEVEL SENSOR CIRCUIT RANGE/PERFORMANCE

1. OUTLINE OF DIAGNOSIS

Detect malfunctions of the fuel level sensor output property.

If the fuel level does not vary in a particular driving condition/engine condition where it should, judge as NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the malfunction criteria below are met.

(A) Fuel level (B) Resistance

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Accumulated amount of intake air > 331 kg (729.7 lb)

Max. – min. values of fuel level output < 2.6 2 (0.69 US gal,

0.57 Imp gal)

Battery voltage≥ 10.9 V

Engine speed < 7000 rpm

After engine starting 5 seconds or more

EN-01734

0(B)

(A)

Page 1764 of 2453

GD(H6DO)-152

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

Time Needed for Diagnosis: Undecided

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

None

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Judgment Value

Malfunction Criteria Threshold Value

Accumulated amount of intake air > 331 kg (729.7 lb)

Max. – min. values of fuel level output≥ 2.6 2 (0.69 US gal,

0.57 Imp gal)

Battery voltage≥ 10.9 V

Engine speed < 7000 rpm

After engine starting 5 seconds or more

Page 1775 of 2453

GD(H6DO)-163

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

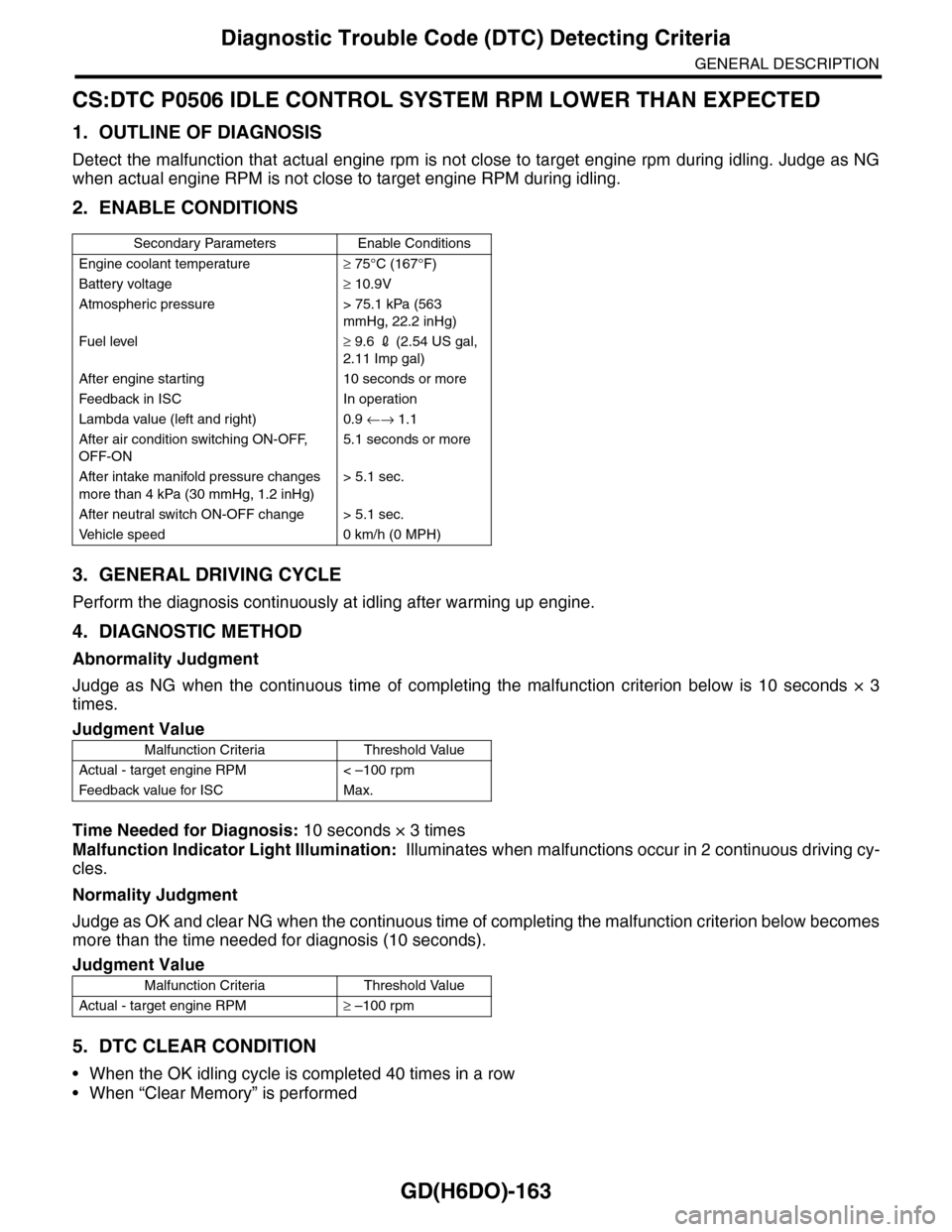

CS:DTC P0506 IDLE CONTROL SYSTEM RPM LOWER THAN EXPECTED

1. OUTLINE OF DIAGNOSIS

Detect the malfunction that actual engine rpm is not close to target engine rpm during idling. Judge as NG

when actual engine RPM is not close to target engine RPM during idling.

2. ENABLE CONDITIONS

3. GENERAL DRIVING CYCLE

Perform the diagnosis continuously at idling after warming up engine.

4. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time of completing the malfunction criterion below is 10 seconds × 3

times.

Time Needed for Diagnosis: 10 seconds × 3 times

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear NG when the continuous time of completing the malfunction criterion below becomes

more than the time needed for diagnosis (10 seconds).

5. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

Secondary Parameters Enable Conditions

Engine coolant temperature≥ 75°C (167°F)

Battery voltage≥ 10.9V

Atmospheric pressure > 75.1 kPa (563

mmHg, 22.2 inHg)

Fuel level≥ 9.6 2 (2.54 US gal,

2.11 Imp gal)

After engine starting 10 seconds or more

Feedback in ISC In operation

Lambda value (left and right) 0.9 ←→ 1.1

After air condition switching ON-OFF,

OFF-ON

5.1 seconds or more

After intake manifold pressure changes

more than 4 kPa (30 mmHg, 1.2 inHg)

> 5.1 sec.

After neutral switch ON-OFF change > 5.1 sec.

Ve h i c l e s p e e d 0 k m / h ( 0 M P H )

Judgment Value

Malfunction Criteria Threshold Value

Actual - target engine RPM < –100 rpm

Feedback value for ISC Max.

Judgment Value

Malfunction Criteria Threshold Value

Actual - target engine RPM≥ –100 rpm