Intake SUBARU TRIBECA 2009 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1585 of 2453

FU(H6DO)-24

Fuel Injector

FUEL INJECTION (FUEL SYSTEMS)

11.Fuel Injector

A: REMOVAL

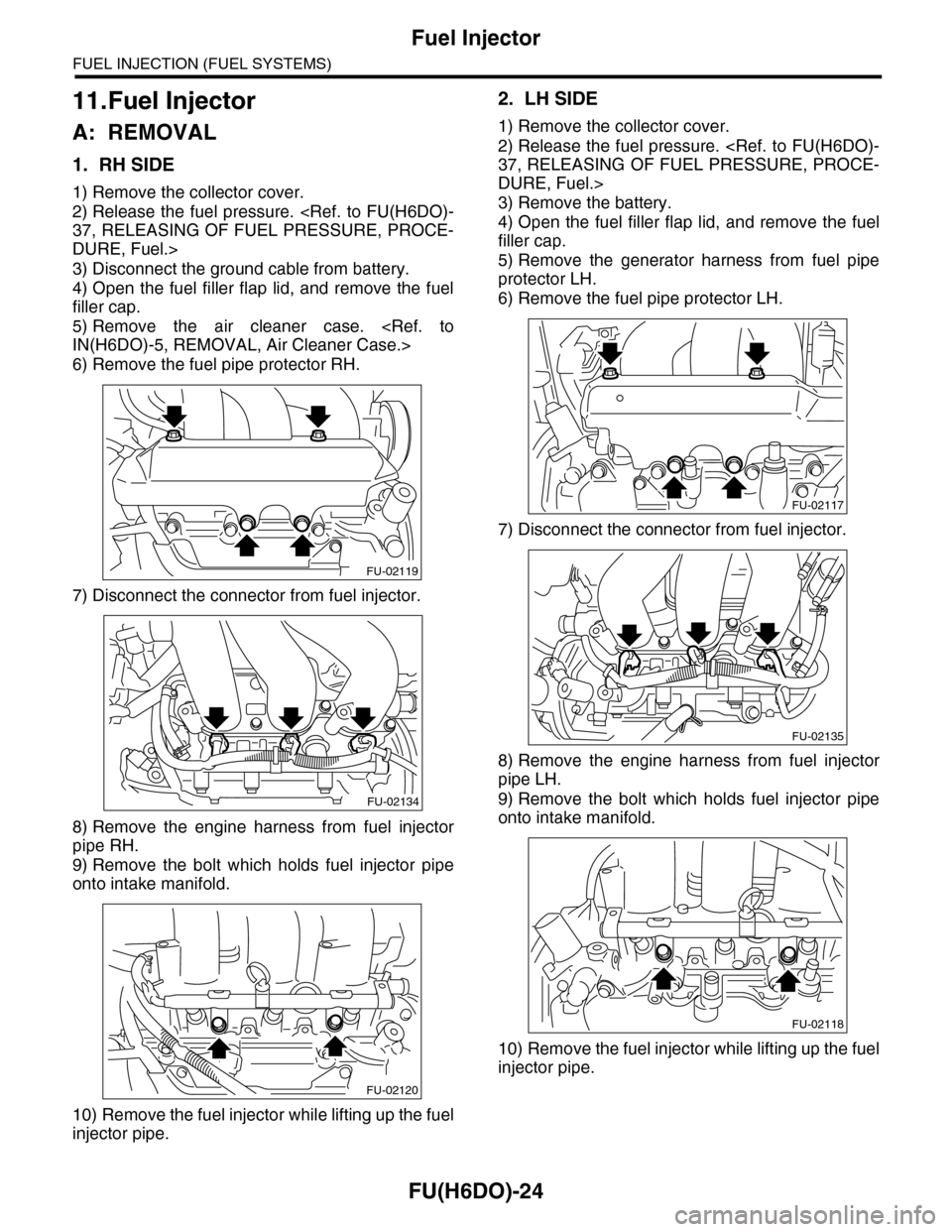

1. RH SIDE

1) Remove the collector cover.

2) Release the fuel pressure.

DURE, Fuel.>

3) Disconnect the ground cable from battery.

4) Open the fuel filler flap lid, and remove the fuel

filler cap.

5) Remove the air cleaner case.

6) Remove the fuel pipe protector RH.

7) Disconnect the connector from fuel injector.

8) Remove the engine harness from fuel injector

pipe RH.

9) Remove the bolt which holds fuel injector pipe

onto intake manifold.

10) Remove the fuel injector while lifting up the fuel

injector pipe.

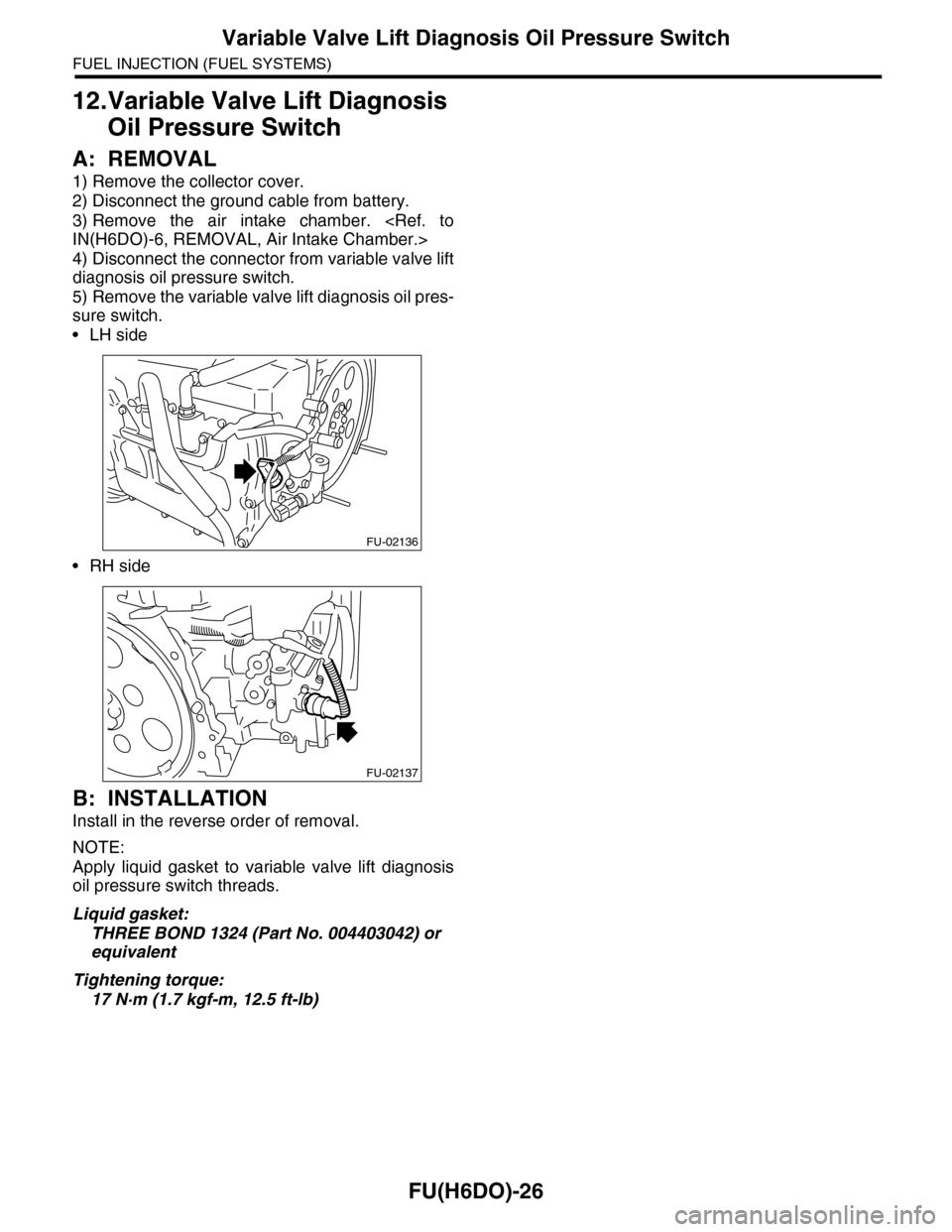

2. LH SIDE

1) Remove the collector cover.

2) Release the fuel pressure.

DURE, Fuel.>

3) Remove the battery.

4) Open the fuel filler flap lid, and remove the fuel

filler cap.

5) Remove the generator harness from fuel pipe

protector LH.

6) Remove the fuel pipe protector LH.

7) Disconnect the connector from fuel injector.

8) Remove the engine harness from fuel injector

pipe LH.

9) Remove the bolt which holds fuel injector pipe

onto intake manifold.

10) Remove the fuel injector while lifting up the fuel

injector pipe.

FU-02119

FU-02134

FU-02120

FU-02117

FU-02135

FU-02118

Page 1587 of 2453

FU(H6DO)-26

Variable Valve Lift Diagnosis Oil Pressure Switch

FUEL INJECTION (FUEL SYSTEMS)

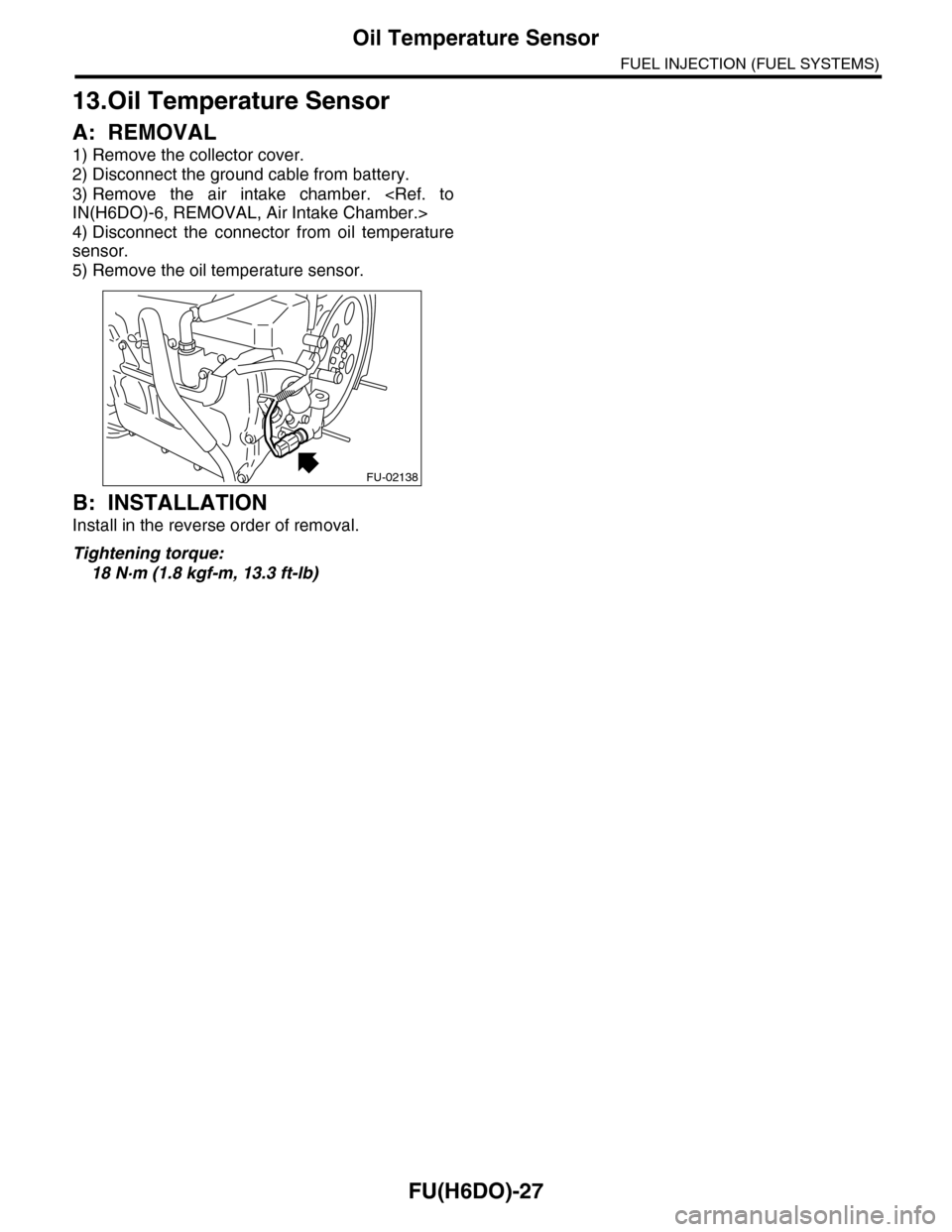

12.Variable Valve Lift Diagnosis

Oil Pressure Switch

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

4) Disconnect the connector from variable valve lift

diagnosis oil pressure switch.

5) Remove the variable valve lift diagnosis oil pres-

sure switch.

•LH side

•RH side

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Apply liquid gasket to variable valve lift diagnosis

oil pressure switch threads.

Liquid gasket:

THREE BOND 1324 (Part No. 004403042) or

equivalent

Tightening torque:

17 N·m (1.7 kgf-m, 12.5 ft-lb)

FU-02136

FU-02137

Page 1588 of 2453

FU(H6DO)-27

Oil Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

13.Oil Temperature Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

4) Disconnect the connector from oil temperature

sensor.

5) Remove the oil temperature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

FU-02138

Page 1614 of 2453

GD(H6DO)-2

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

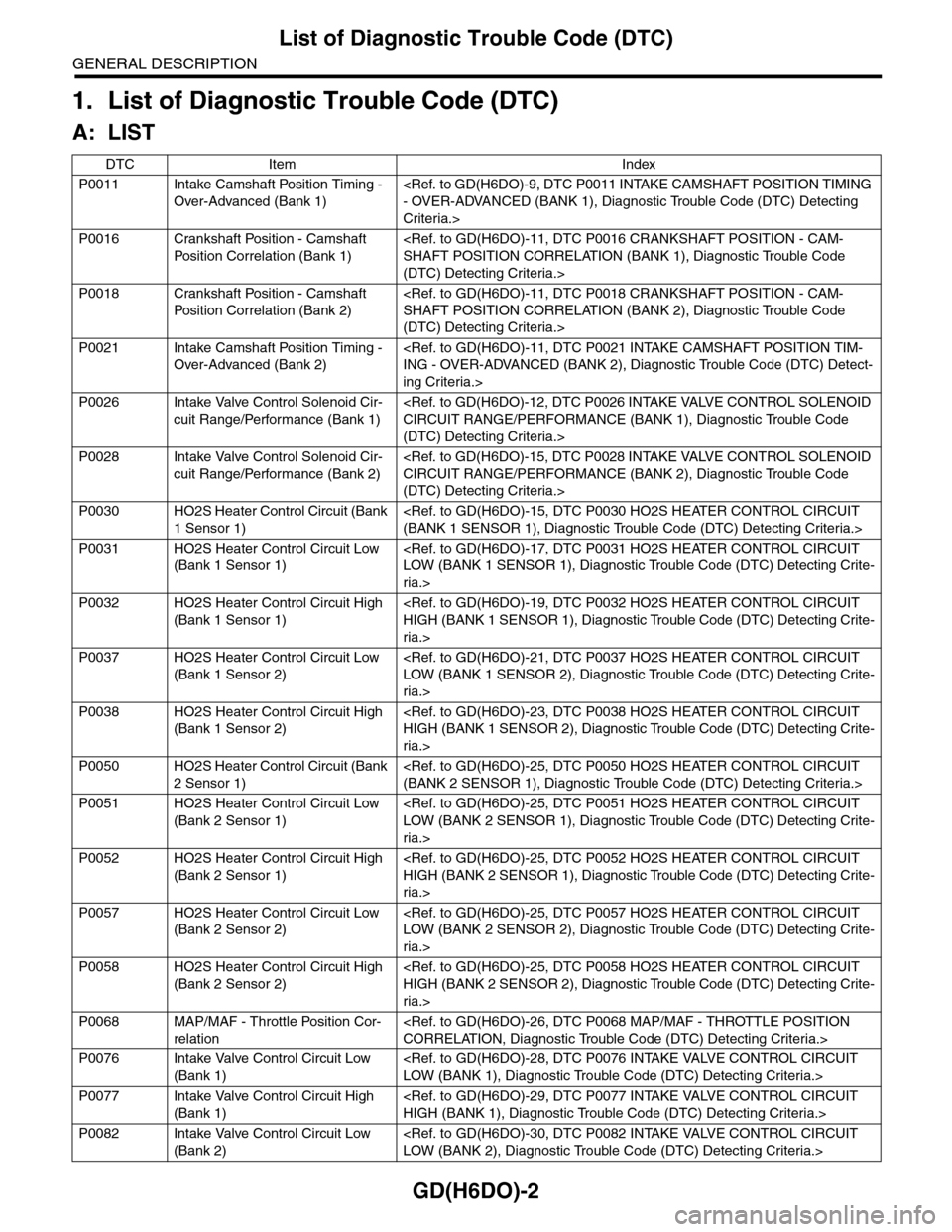

1. List of Diagnostic Trouble Code (DTC)

A: LIST

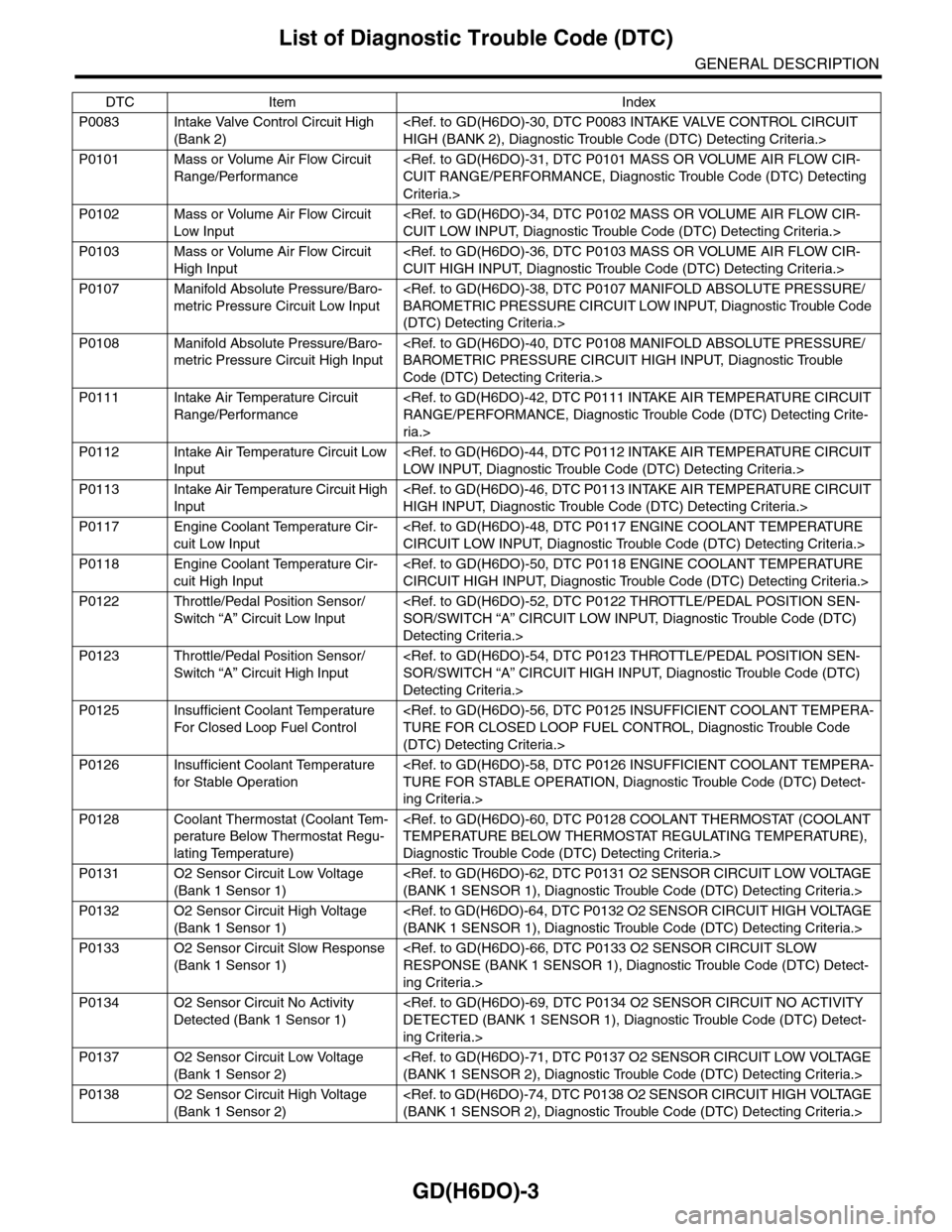

DTC Item Index

P0011 Intake Camshaft Position Timing -

Over-Advanced (Bank 1)

Criteria.>

P0016 Crankshaft Position - Camshaft

Pos it i o n C o r r el a ti o n ( B a nk 1)

(DTC) Detecting Criteria.>

P0018 Crankshaft Position - Camshaft

Pos it i o n C o r r el a ti o n ( B a nk 2)

(DTC) Detecting Criteria.>

P0021 Intake Camshaft Position Timing -

Over-Advanced (Bank 2)

ing Criteria.>

P0026 Intake Valve Control Solenoid Cir-

cuit Range/Performance (Bank 1)

(DTC) Detecting Criteria.>

P0028 Intake Valve Control Solenoid Cir-

cuit Range/Performance (Bank 2)

(DTC) Detecting Criteria.>

P0030 HO2S Heater Control Circuit (Bank

1 Sensor 1)

P0031 HO2S Heater Control Circuit Low

(Bank 1 Sensor 1)

ria.>

P0032 HO2S Heater Control Circuit High

(Bank 1 Sensor 1)

ria.>

P0037 HO2S Heater Control Circuit Low

(Bank 1 Sensor 2)

ria.>

P0038 HO2S Heater Control Circuit High

(Bank 1 Sensor 2)

ria.>

P0050 HO2S Heater Control Circuit (Bank

2 Sensor 1)

P0051 HO2S Heater Control Circuit Low

(Bank 2 Sensor 1)

ria.>

P0052 HO2S Heater Control Circuit High

(Bank 2 Sensor 1)

ria.>

P0057 HO2S Heater Control Circuit Low

(Bank 2 Sensor 2)

ria.>

P0058 HO2S Heater Control Circuit High

(Bank 2 Sensor 2)

ria.>

P0068 MAP/MAF - Throttle Position Cor-

relation

P0076 Intake Valve Control Circuit Low

(Bank 1)

P0077 Intake Valve Control Circuit High

(Bank 1)

P0082 Intake Valve Control Circuit Low

(Bank 2)

Page 1615 of 2453

GD(H6DO)-3

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

P0083 Intake Valve Control Circuit High

(Bank 2)

P0101 Mass or Volume Air Flow Circuit

Range/Performance

Criteria.>

P0102 Mass or Volume Air Flow Circuit

Low Input

P0103 Mass or Volume Air Flow Circuit

High Input

P0107 Manifold Absolute Pressure/Baro-

metric Pressure Circuit Low Input

(DTC) Detecting Criteria.>

P0108 Manifold Absolute Pressure/Baro-

metric Pressure Circuit High Input

Code (DTC) Detecting Criteria.>

P0111 Intake Air Temperature Circuit

Range/Performance

ria.>

P0112 Intake Air Temperature Circuit Low

Input

P0113 Intake Air Temperature Circuit High

Input

P0117 Engine Coolant Temperature Cir-

cuit Low Input

P0118 Engine Coolant Temperature Cir-

cuit High Input

P0122 Throttle/Pedal Position Sensor/

Switch “A” Circuit Low Input

Detecting Criteria.>

P0123 Throttle/Pedal Position Sensor/

Switch “A” Circuit High Input

Detecting Criteria.>

P0125 Insufficient Coolant Temperature

For Closed Loop Fuel Control

(DTC) Detecting Criteria.>

P0126 Insufficient Coolant Temperature

for Stable Operation

ing Criteria.>

P0128 Coolant Thermostat (Coolant Tem-

perature Below Thermostat Regu-

lating Temperature)

Diagnostic Trouble Code (DTC) Detecting Criteria.>

P0131 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 1)

P0132 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 1)

P0133 O2 Sensor Circuit Slow Response

(Bank 1 Sensor 1)

ing Criteria.>

P0134 O2 Sensor Circuit No Activity

Detected (Bank 1 Sensor 1)

ing Criteria.>

P0137 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 2)

P0138 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 2)

DTC Item Index

Page 1621 of 2453

GD(H6DO)-9

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

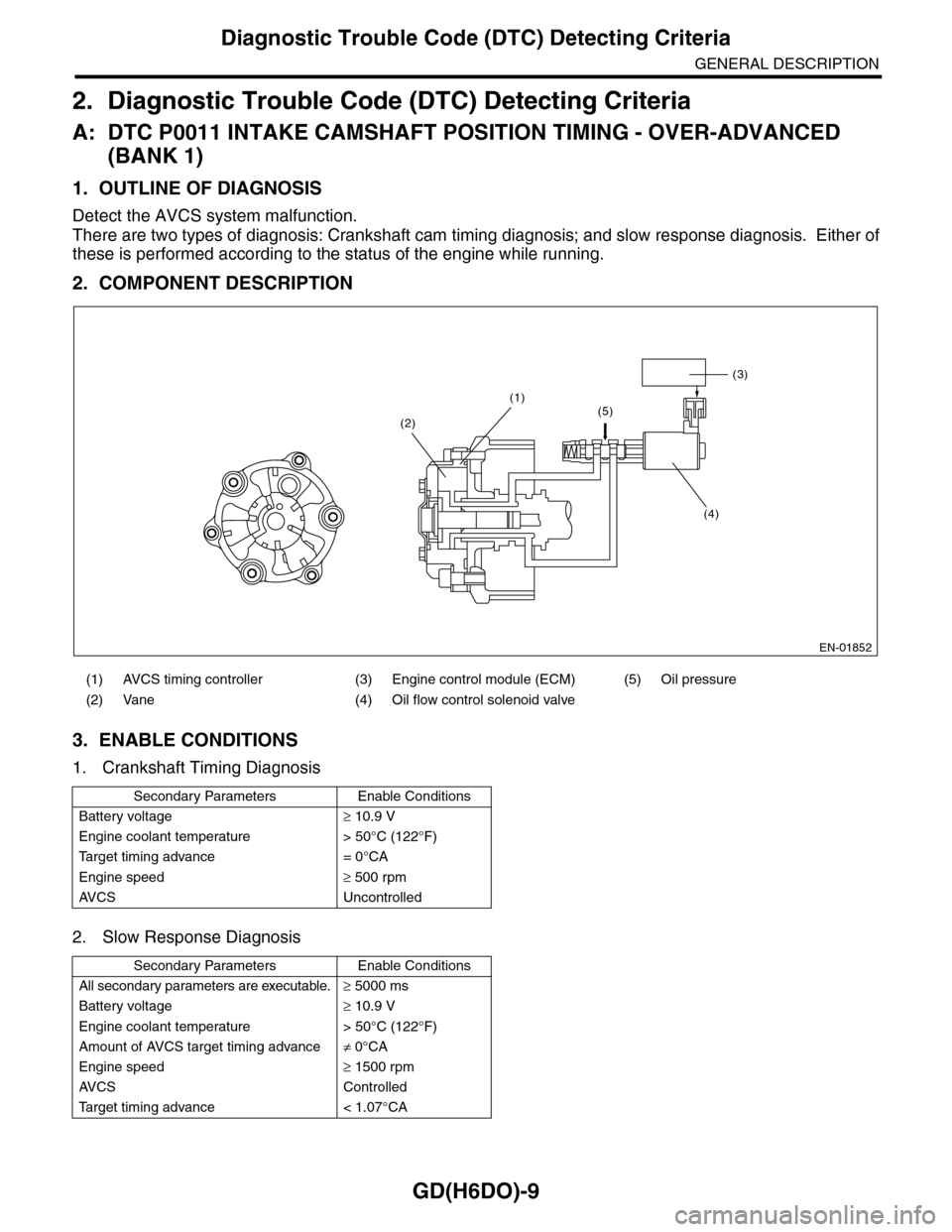

2. Diagnostic Trouble Code (DTC) Detecting Criteria

A: DTC P0011 INTAKE CAMSHAFT POSITION TIMING - OVER-ADVANCED

(BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect the AVCS system malfunction.

There are two types of diagnosis: Crankshaft cam timing diagnosis; and slow response diagnosis. Either of

these is performed according to the status of the engine while running.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

1. Crankshaft Timing Diagnosis

2. Slow Response Diagnosis

(1) AVCS timing controller (3) Engine control module (ECM) (5) Oil pressure

(2) Vane (4) Oil flow control solenoid valve

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Engine coolant temperature > 50°C (122°F)

Ta r g e t t i m i n g a d v a n c e = 0 ° C A

Engine speed≥ 500 rpm

AV C S U n c o n t r o l l e d

Secondary Parameters Enable Conditions

All secondary parameters are executable.≥ 5000 ms

Battery voltage≥ 10.9 V

Engine coolant temperature > 50°C (122°F)

Amount of AVCS target timing advance≠ 0°CA

Engine speed≥ 1500 rpm

AV C S C o n t r o l l e d

Ta r g e t t i m i n g a d v a n c e < 1 . 0 7 ° C A

EN-01852

(3)

(4)

(1)(5)(2)

Page 1623 of 2453

GD(H6DO)-11

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

Make the oil flow control solenoid valve driving duty a predetermined value (9.36%).

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

B: DTC P0016 CRANKSHAFT POSITION - CAMSHAFT POSITION CORRELA-

TION (BANK 1)

NOTE:

For the diagnostic procedure, refer to DTC P0011.

C: DTC P0018 CRANKSHAFT POSITION - CAMSHAFT POSITION CORRELA-

TION (BANK 2)

NOTE:

For the diagnostic procedure, refer to DTC P0011.

D: DTC P0021 INTAKE CAMSHAFT POSITION TIMING - OVER-ADVANCED

(BANK 2)

NOTE:

For the diagnostic procedure, refer to DTC P0011.

Page 1624 of 2453

GD(H6DO)-12

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

E: DTC P0026 INTAKE VALVE CONTROL SOLENOID CIRCUIT RANGE/PER-

FORMANCE (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detected as NG with either Low NG or High NG.

A variable valve lift diagnosis oil pressure switch is installed for diagnosis. It is possible to determine whether

the intake valve is in high mode (increase the amount of lift) or in low mode (suppressing the amount of lift)

when the variable valve lift diagnosis oil pressure switch is turned ON or OFF.

Normal

Low NG

When the variable valve lift diagnosis oil pressure switch remains OFF even though the intake valve tried to

enter high mode (oil switching solenoid valve duty is large), this is judged as a Low NG.

High NG

When the variable valve lift diagnosis oil pressure switch remains ON even though the intake valve tried to

enter low mode (oil switching solenoid valve duty is small), this is judged as a High NG.

Oil switching solenoid valve duty Intake valve Variable valve lift diagnosis oil pressure switch

Large High Mode ON

Minimum Low Mode OFF

Page 1625 of 2453

GD(H6DO)-13

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

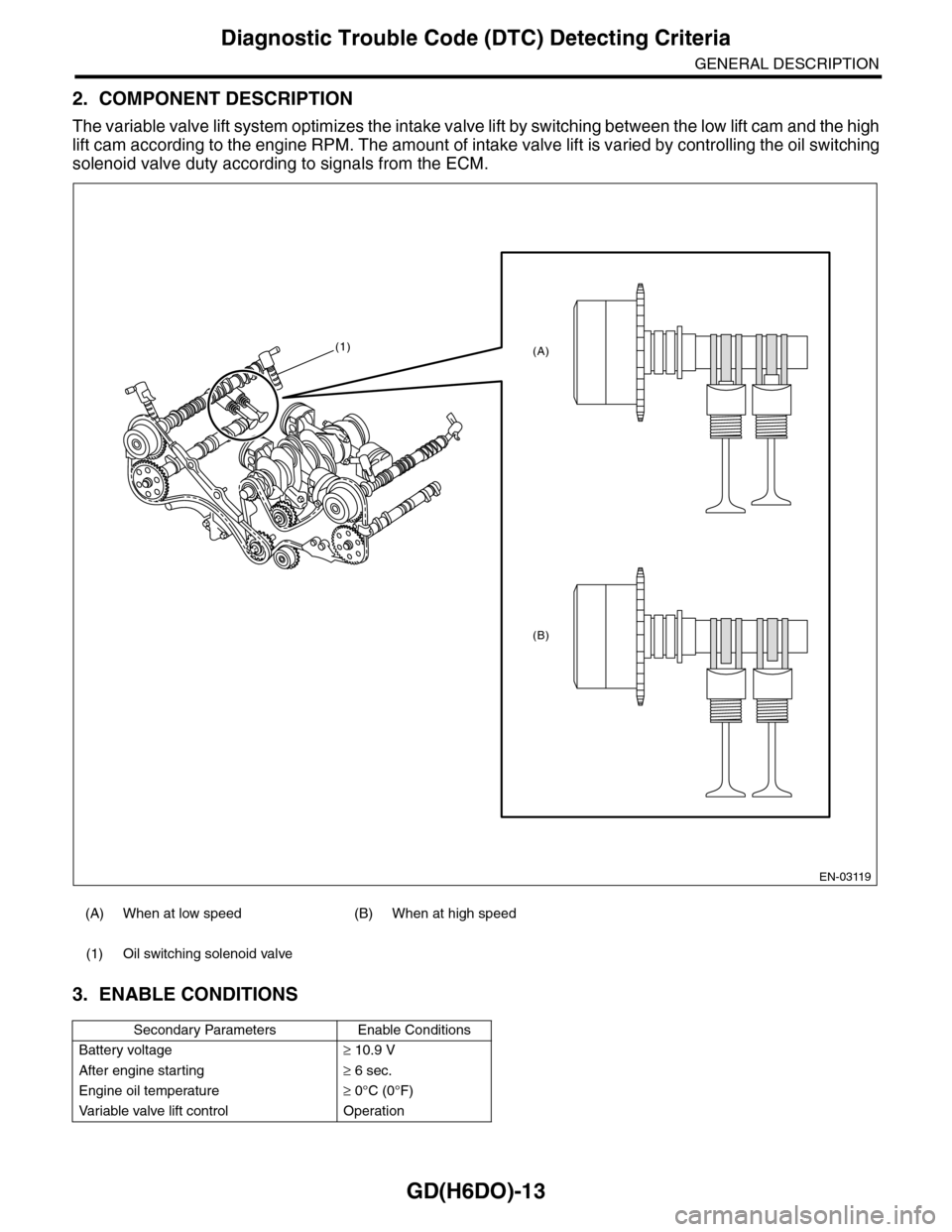

2. COMPONENT DESCRIPTION

The variable valve lift system optimizes the intake valve lift by switching between the low lift cam and the high

lift cam according to the engine RPM. The amount of intake valve lift is varied by controlling the oil switching

solenoid valve duty according to signals from the ECM.

3. ENABLE CONDITIONS

(A) When at low speed (B) When at high speed

(1) Oil switching solenoid valve

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

After engine starting≥ 6 sec.

Engine oil temperature≥ 0°C (0°F)

Va r i a b l e va l v e l i f t c o n t r o l O p e r a t i o n

EN-03119

(1)

(B)

(A)

Page 1627 of 2453

GD(H6DO)-15

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

F: DTC P0028 INTAKE VALVE CONTROL SOLENOID CIRCUIT RANGE/PER-

FORMANCE (BANK 2)

NOTE:

For diagnostic procedures, refer to DTC P0026.

Criteria.>

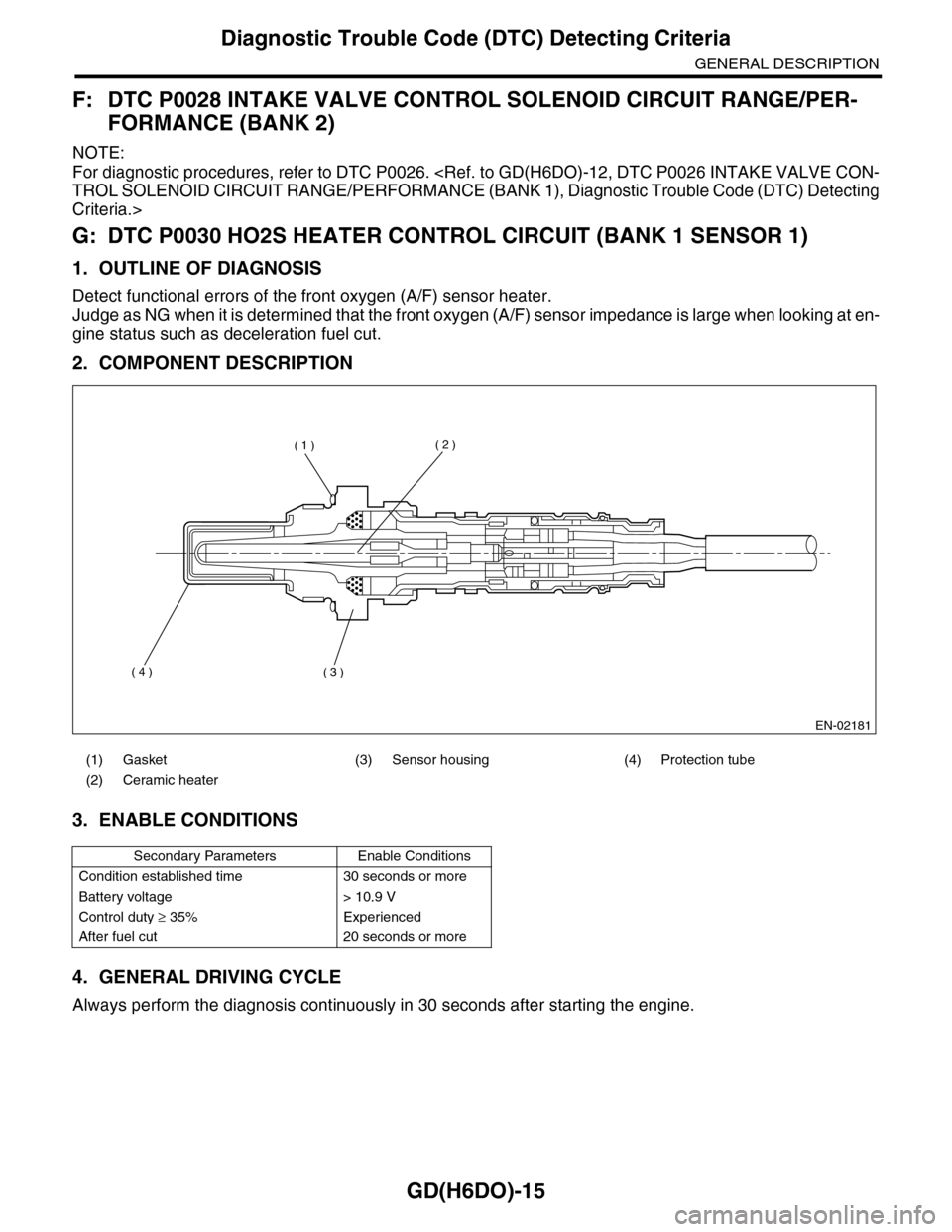

G: DTC P0030 HO2S HEATER CONTROL CIRCUIT (BANK 1 SENSOR 1)

1. OUTLINE OF DIAGNOSIS

Detect functional errors of the front oxygen (A/F) sensor heater.

Judge as NG when it is determined that the front oxygen (A/F) sensor impedance is large when looking at en-

gine status such as deceleration fuel cut.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously in 30 seconds after starting the engine.

(1) Gasket (3) Sensor housing (4) Protection tube

(2) Ceramic heater

Secondary Parameters Enable Conditions

Condition established time 30 seconds or more

Battery voltage > 10.9 V

Control duty ≥ 35% Experienced

After fuel cut 20 seconds or more

EN-02181

( 1 )( 2 )

( 3 )( 4 )