Intake SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1924 of 2453

ME(H6DO)-58

Cylinder Head

MECHANICAL

8) Install the front chain cover.

9) Install the crank pulley.

C: DISASSEMBLY

1) Set the cylinder head on ST.

ST 18250AA010 CYLINDER HEAD TABLE

2) Remove the valve lifter.

3) Set the ST on valve spring retainer. Compress

the valve spring and remove the valve spring re-

tainer key. Remove each valve and valve spring.

ST 499718000 VALVE SPRING REMOVER

NOTE:

Keep all the removed parts in order for re-installing

in their original positions.

CAUTION:

•Mark each valve to prevent confusion.

•Pay careful attention not to damage the lips

of intake valve oil seals and exhaust valve oil

seals.

D: ASSEMBLY

1) Installation of valve spring and valve:

(1) Set the cylinder head on ST.

ST 18250AA010 CYLINDER HEAD TABLE

(2) Coat the stem of each valve with engine oil

and insert the valve into valve guide.

NOTE:

When inserting the valve into valve guide, use spe-

cial care not to damage the oil seal lip.

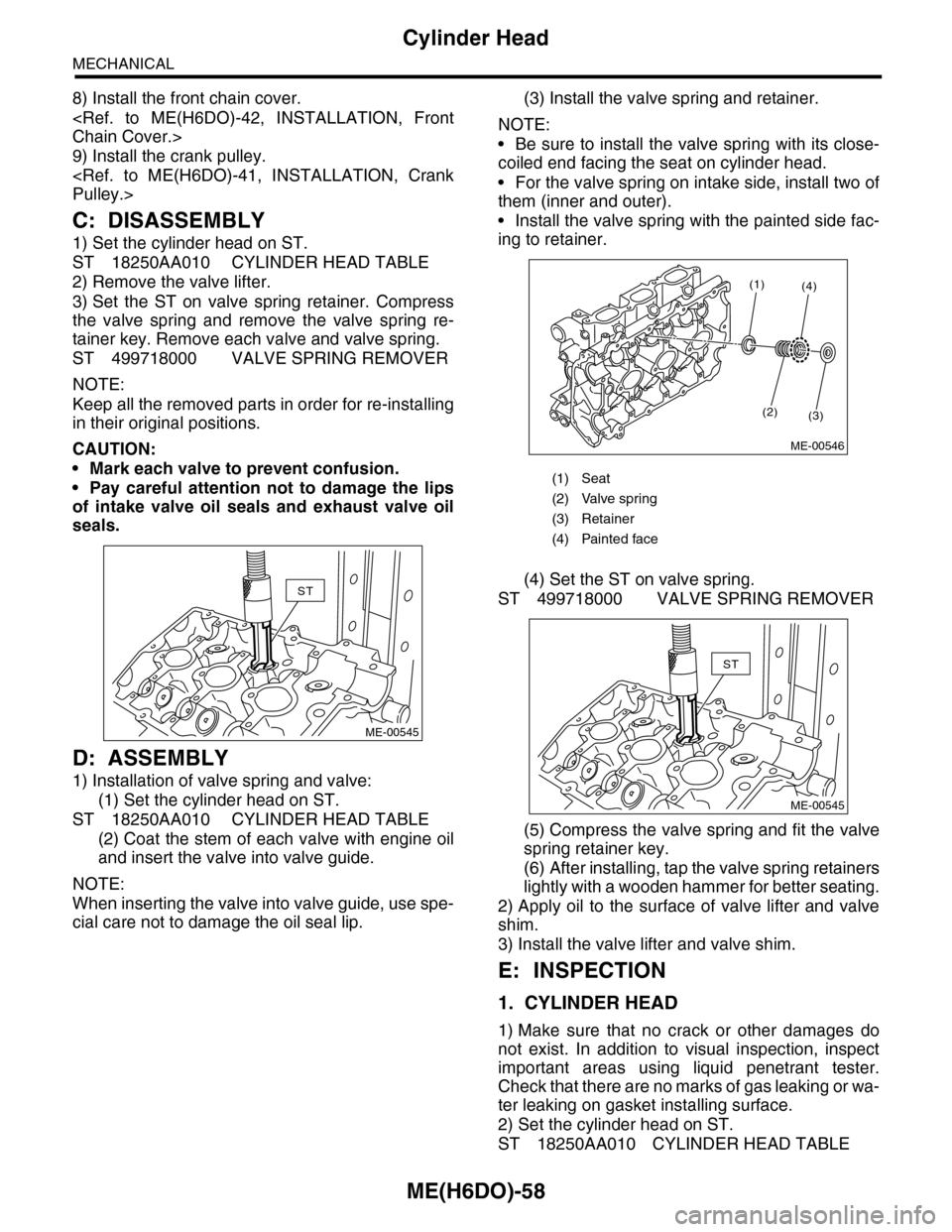

(3) Install the valve spring and retainer.

NOTE:

•Be sure to install the valve spring with its close-

coiled end facing the seat on cylinder head.

•For the valve spring on intake side, install two of

them (inner and outer).

•Install the valve spring with the painted side fac-

ing to retainer.

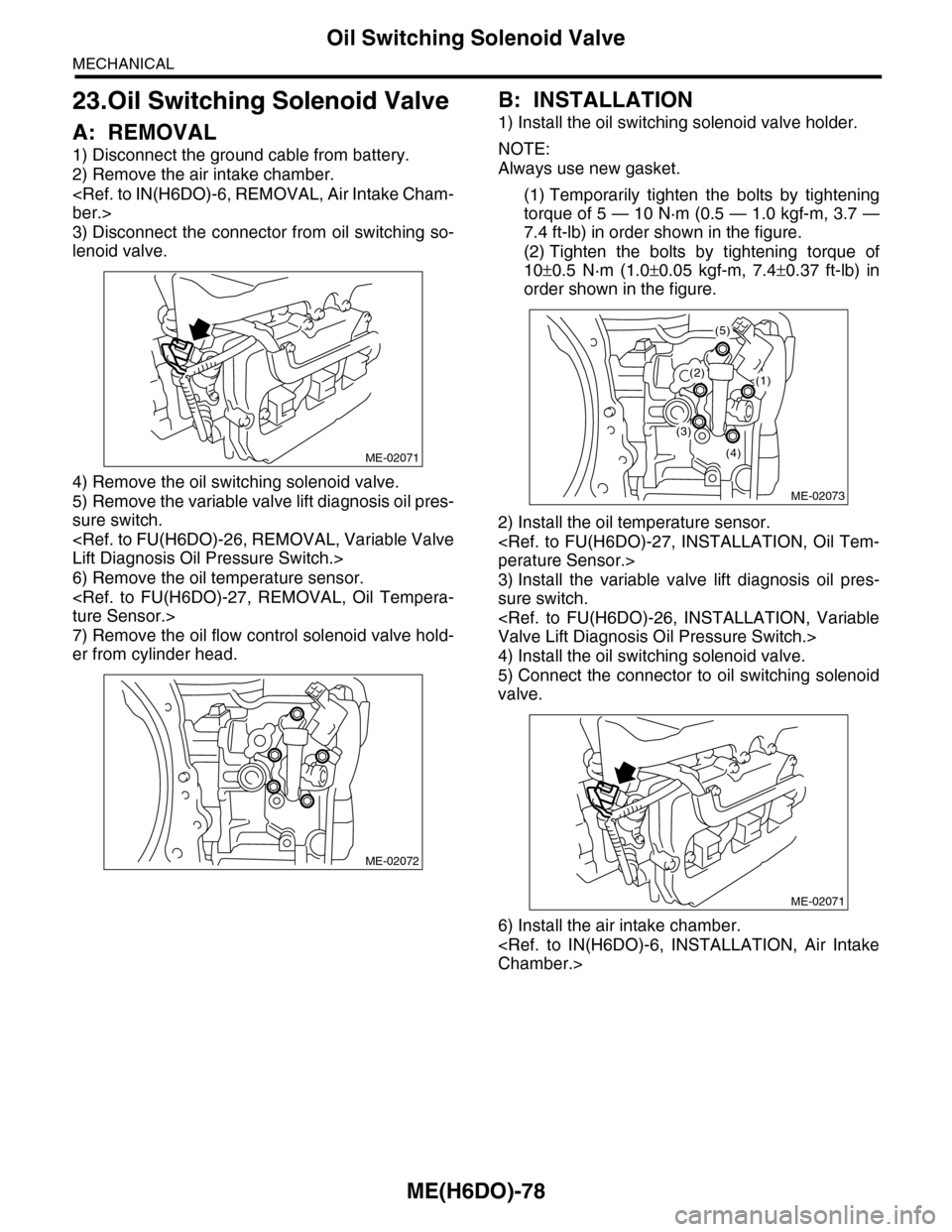

(4) Set the ST on valve spring.

ST 499718000 VALVE SPRING REMOVER

(5) Compress the valve spring and fit the valve

spring retainer key.

(6) After installing, tap the valve spring retainers

lightly with a wooden hammer for better seating.

2) Apply oil to the surface of valve lifter and valve

shim.

3) Install the valve lifter and valve shim.

E: INSPECTION

1. CYLINDER HEAD

1) Make sure that no crack or other damages do

not exist. In addition to visual inspection, inspect

important areas using liquid penetrant tester.

Check that there are no marks of gas leaking or wa-

ter leaking on gasket installing surface.

2) Set the cylinder head on ST.

ST 18250AA010 CYLINDER HEAD TABLE

ST

ME-00545

(1) Seat

(2) Valve spring

(3) Retainer

(4) Painted face

(1)

(2)(3)

(4)

ME-00546

ST

ME-00545

Page 1925 of 2453

ME(H6DO)-59

Cylinder Head

MECHANICAL

3) Measure the flatness of the cylinder head sur-

face that mates with crankcase using a straight

edge (A) and thickness gauge (B).

Flatness:

Standard

0.02 mm (0.0008 in)

Standard height of cylinder head:

124±0.05 mm (4.88±0.0020 in)

NOTE:

Uneven torque for the cylinder head nuts can

cause warping. When reinstalling, pay special at-

tention to the torque so as to tighten evenly.

2. VALVE SEAT

Inspect the intake and exhaust valve seats, and

correct the contact surfaces with a valve seat cutter

if they are defective or when valve guides are re-

placed.

Valve seat width W:

Intake

Standard

1.0 mm (0.039 in)

Exhaust

Standard

1.5 mm (0.059 in)

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measuring

respectively the outer diameter of valve stem and

inner diameter of valve guide with a micrometer.

Clearance between the valve guide and valve

stem:

Standard

Intake

0.030 — 0.057 mm (0.0012 — 0.0022 in)

Exhaust

0.040 — 0.067 mm (0.0016 — 0.0026 in)

2) If the clearance between valve guide and stem

exceeds the standard, replace the valve guide or

valve itself whichever shows greater amount of

wear or damaged and etc. See the following proce-

dure for valve guide replacement.

Valve guide inner diameter:

5.500 — 5.512 mm (0.2165 — 0.2170 in

Valve stem outer diameters:

Intake

5.455 — 5.470 mm (0.2148 — 0.2154 in)

Exhaust

5.445 — 5.460 mm (0.2144 — 0.2150 in)

(1) Place the cylinder head on ST1 with the

combustion chamber upward so that valve

guides fit the holes in ST1.

(2) Insert the ST2 into valve guide and press it

down to remove the valve guide.

ST1 18250AA010 CYLINDER HEAD TABLE

ST2 499765700 VALVE GUIDE REMOVER

(A)

(B)

ME-00551

ME-00127

WME-00553

Page 1926 of 2453

ME(H6DO)-60

Cylinder Head

MECHANICAL

(3) Turn the cylinder head upside down and

place the ST as shown in the figure.

ST 18251AA040 VALVE GUIDE ADJUSTER

(4) Before installing a new valve guide, make

sure that neither scratches nor damages exist

on the inner surface of valve guide holes in cyl-

inder head.

(5) Put a new valve guide, coated with sufficient

oil, in cylinder, and insert the ST1 into valve

guide. Press in until the valve guide upper end

is flush with the upper surface of ST2.

ST1 499765700 VALVE GUIDE REMOVER

ST2 18251AA040 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion L:

11.4 — 11.8 mm (0.449 — 0.465 in)

(7) Ream the inside of valve guide using ST.

Put the reamer in valve guide, and rotate the

reamer slowly clockwise while pushing it lightly.

Bring the reamer back while rotating it clock-

wise. After reaming, clean the valve guide to re-

move chips.

ST 499765900 VALVE GUIDE REAMER

NOTE:

•Apply engine oil to the reamer when reaming.

•If the inner surface of valve guide is damaged,

the edge of reamer should be slightly ground with

oil stone.

•If the inner surface of valve guide becomes lus-

trous and the reamer does not chip, use a new

reamer or remedy the reamer.

(8) Recheck the contact condition between

valve and valve seat after replacing the valve

guide.

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and re-

place if damaged, worn or deformed, or if “H” ex-

ceeds the standard, or offset wear occurs.

H:

Intake (A)

Standard

1.0 mm (0.039 in)

Exhaust (B)

Standard

1.2 mm (0.047 in)

Valve overall length:

Intake (A)

99.7 mm (3.925 in)

Exhaust (B)

105.2 mm (4.142 in)

2) Put a small amount of grinding compound on the

seat surface, and lap the valve and seat surface.

Install a new intake valve oil seal after lapping.

ME-00757

ST

L

ME-00130

ST1

ST2

ME-02096

H

H

(B)

(A)

90 0+1

90 0+1

Page 1927 of 2453

ME(H6DO)-61

Cylinder Head

MECHANICAL

5. VALVE SPRING

1) Check the valve springs for damage, free length,

and tension. Replace the valve spring if it is not

within the standard value presented in the table.

2) To measure the squareness of the valve spring,

stand the spring on a surface plate and measure its

deflection at the top of spring using a try square.

6. INTAKE AND EXHAUST VALVE OIL

SEAL

In the following case, pinch and remove the oil seal

from valve using pliers, and then replace it with a

new one.

•When the lip is damaged.

•When the spring is out of the specified position.

•When readjusting the surfaces of intake valve

and valve sheet.

•When replacing the intake valve guide.

1) Set the cylinder head on ST1.

2) Press-fit the oil seal to the specified dimension

indicated in the figure using ST2.

ST1 18250AA010 CYLINDER HEAD TABLE

ST2 499585500 VALVE OIL SEAL GUIDE

NOTE:

•Apply engine oil to oil seal before press-fitting.

•When press-fitting the oil seal, do not use a ham-

mer or strike in.

7. VALVE LIFTER

1) Check the valve lifter visually.

2) Measure the outer diameter of valve lifter.

Outer diameter:

32.959 — 32.975 mm (1.2976 — 1.2982 in)

3) Measure the inner diameter of valve lifter hole of

cylinder head.

Inner diameter:

32.994 — 33.016 mm (1.2990 — 1.2998 in)

NOTE:

If difference between outer diameter of valve lifter

and inner diameter of valve lifter hole is out of the

standard or offset wearing is emitted, replace the

cylinder head.

Standard:

0.019 — 0.057 mm (0.0007 — 0.0022 in)

Fr e e

lengthmm (in)

Intake

Inner39.55

(1.5571)

Outer41.18

(1.6213)

Exhaust46.32

(1.8236)

Squareness

Intake

Inner2.5°1.7 mm

(0.067 in)

Outer2.5°1.8 mm

(0.071 in)

Exhaust2.5°2.0 mm

(0.079 in)

ME-00132

ME-00548

ME-00134

ME-00550

Page 1944 of 2453

ME(H6DO)-78

Oil Switching Solenoid Valve

MECHANICAL

23.Oil Switching Solenoid Valve

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake chamber.

3) Disconnect the connector from oil switching so-

lenoid valve.

4) Remove the oil switching solenoid valve.

5) Remove the variable valve lift diagnosis oil pres-

sure switch.

6) Remove the oil temperature sensor.

7) Remove the oil flow control solenoid valve hold-

er from cylinder head.

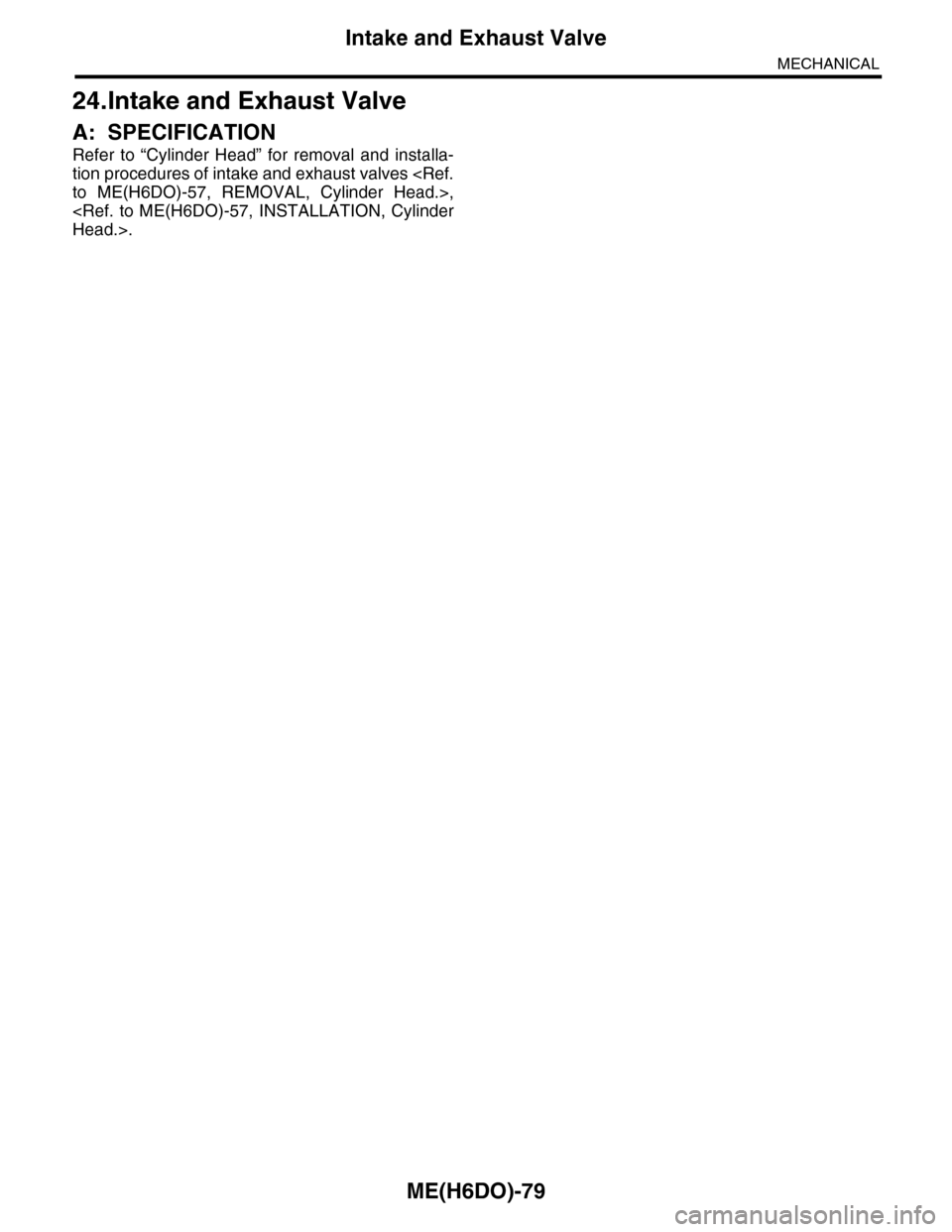

B: INSTALLATION

1) Install the oil switching solenoid valve holder.

NOTE:

Always use new gasket.

(1) Temporarily tighten the bolts by tightening

torque of 5 — 10 N·m (0.5 — 1.0 kgf-m, 3.7 —

7.4 ft-lb) in order shown in the figure.

(2) Tighten the bolts by tightening torque of

10±0.5 N·m (1.0±0.05 kgf-m, 7.4±0.37 ft-lb) in

order shown in the figure.

2) Install the oil temperature sensor.

3) Install the variable valve lift diagnosis oil pres-

sure switch.

4) Install the oil switching solenoid valve.

5) Connect the connector to oil switching solenoid

valve.

6) Install the air intake chamber.

ME-02071

ME-02072

ME-02073

(2)(1)

(5)

(4)

(3)

ME-02071

Page 1945 of 2453

ME(H6DO)-79

Intake and Exhaust Valve

MECHANICAL

24.Intake and Exhaust Valve

A: SPECIFICATION

Refer to “Cylinder Head” for removal and installa-

tion procedures of intake and exhaust valves

Page 1950 of 2453

ME(H6DO)-84

Engine Trouble in General

MECHANICAL

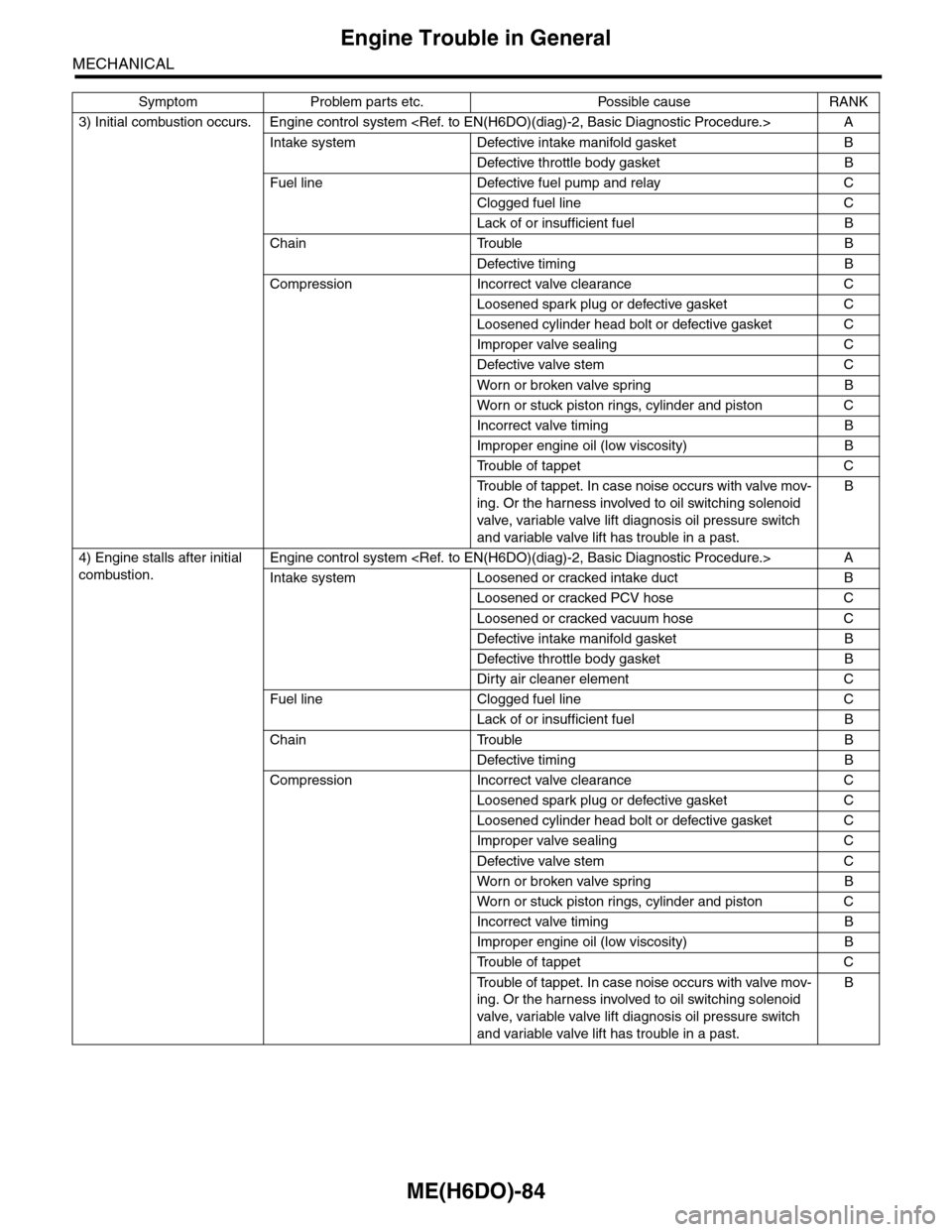

3) Initial combustion occurs. Engine control system

Intake system Defective intake manifold gasket B

Defective throttle body gasket B

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

4) Engine stalls after initial

combustion.

Engine control system

Intake system Loosened or cracked intake duct B

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose C

Defective intake manifold gasket B

Defective throttle body gasket B

Dirty air cleaner element C

Fuel line Clogged fuel line C

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Symptom Problem parts etc. Possible cause RANK

Page 1951 of 2453

ME(H6DO)-85

Engine Trouble in General

MECHANICAL

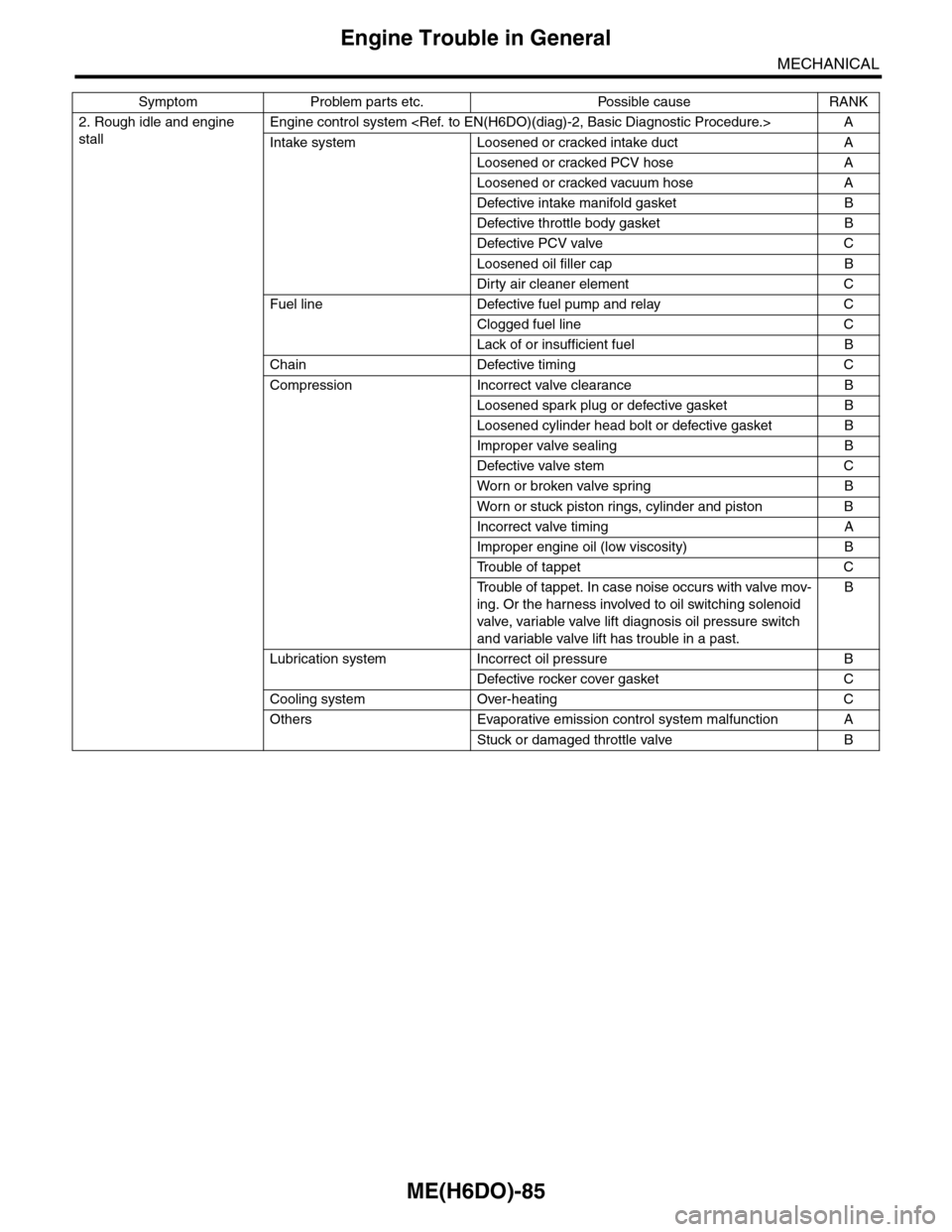

2. Rough idle and engine

stall

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve C

Loosened oil filler cap B

Dirty air cleaner element C

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Defective timing C

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston B

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Defective rocker cover gasket C

Cooling system Over-heating C

Others Evaporative emission control system malfunction A

Stuck or damaged throttle valve B

Symptom Problem parts etc. Possible cause RANK

Page 1952 of 2453

ME(H6DO)-86

Engine Trouble in General

MECHANICAL

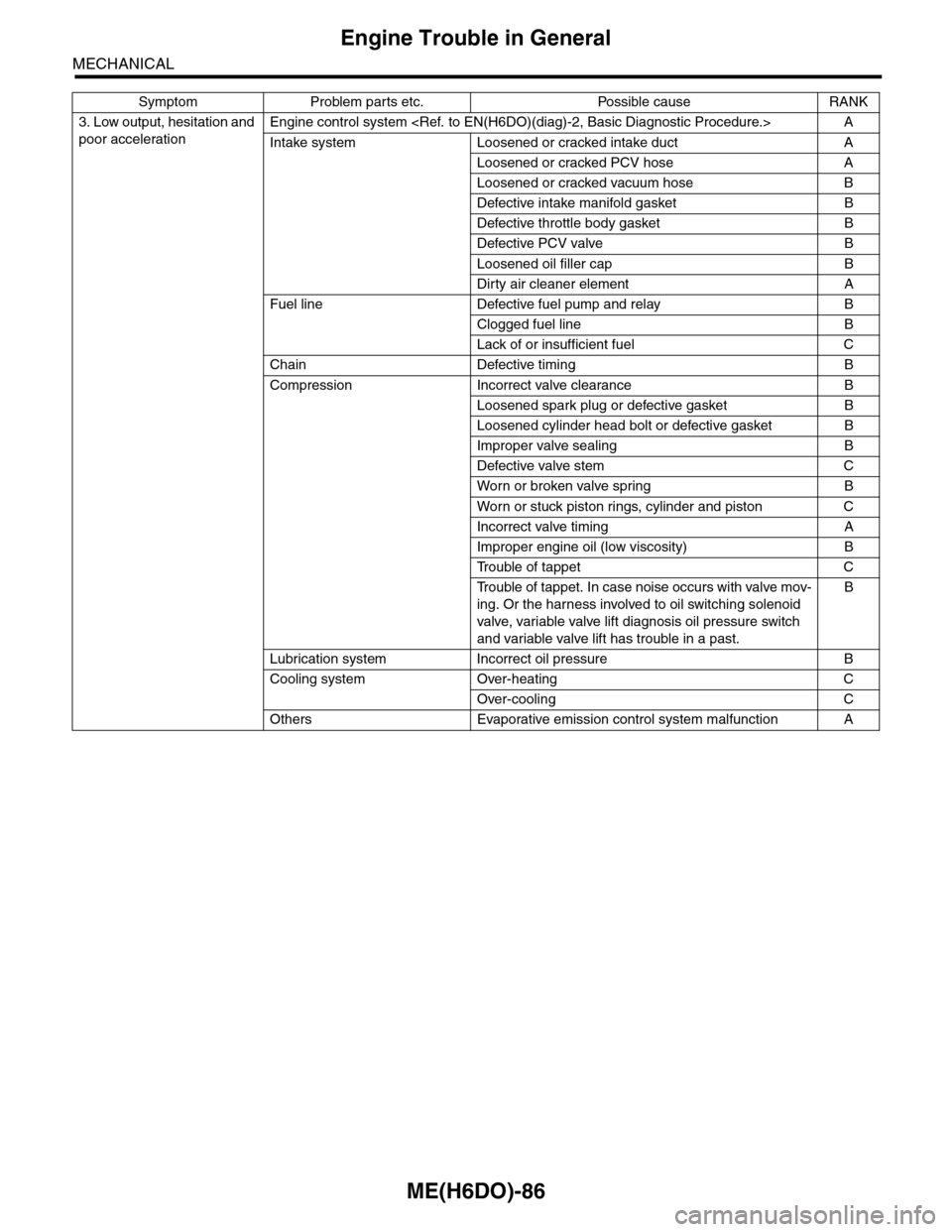

3. Low output, hesitation and

poor acceleration

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Cooling system Over-heating C

Over-cooling C

Others Evaporative emission control system malfunction A

Symptom Problem parts etc. Possible cause RANK

Page 1953 of 2453

ME(H6DO)-87

Engine Trouble in General

MECHANICAL

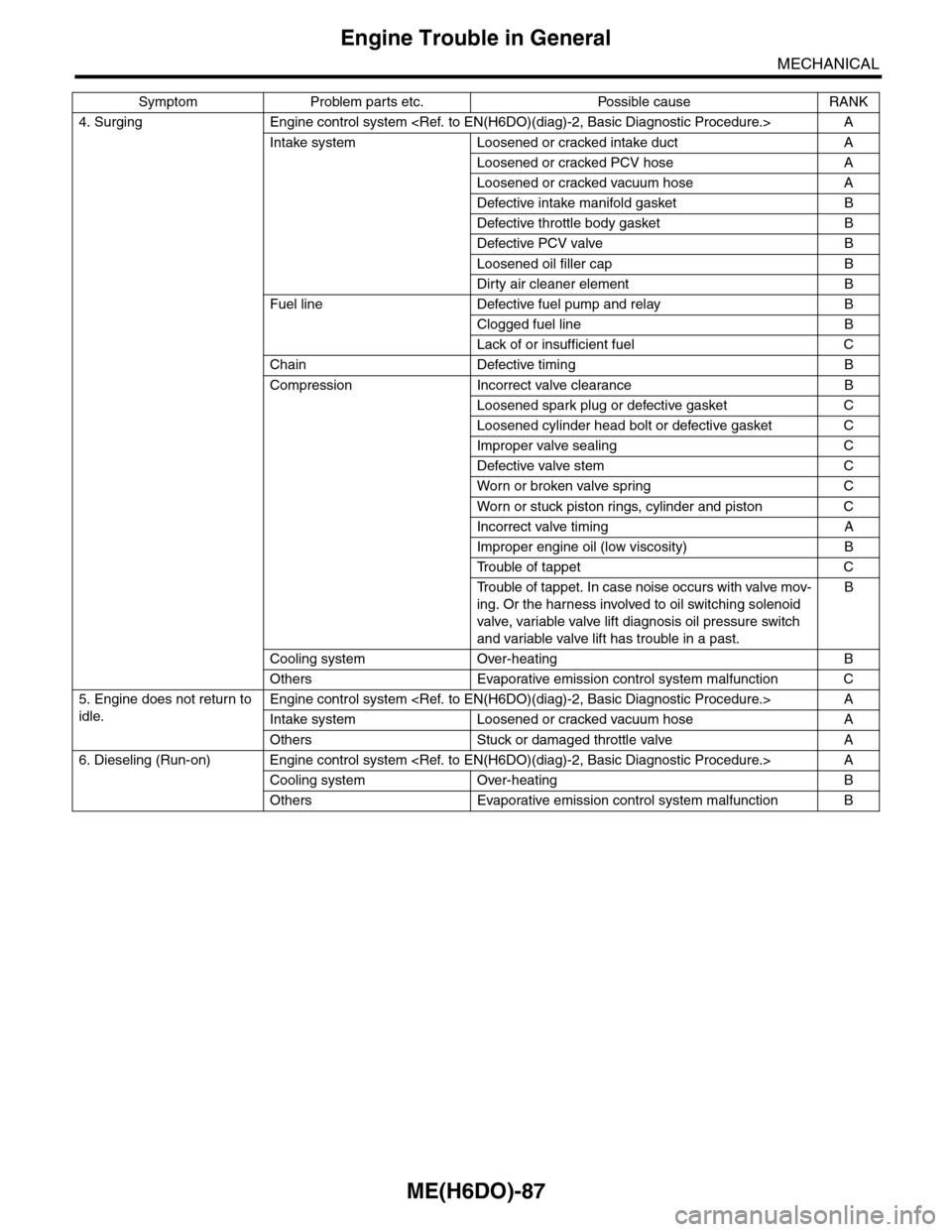

4. Surging Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element B

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating B

Others Evaporative emission control system malfunction C

5. Engine does not return to

idle.

Engine control system

Intake system Loosened or cracked vacuum hose A

Others Stuck or damaged throttle valve A

6. Dieseling (Run-on) Engine control system

Cooling system Over-heating B

Others Evaporative emission control system malfunction B

Symptom Problem parts etc. Possible cause RANK