Reverse SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 711 of 2453

WW-16

Front Wiper Motor and Link

WIPER AND WASHER SYSTEMS

8. Front Wiper Motor and Link

A: REMOVAL

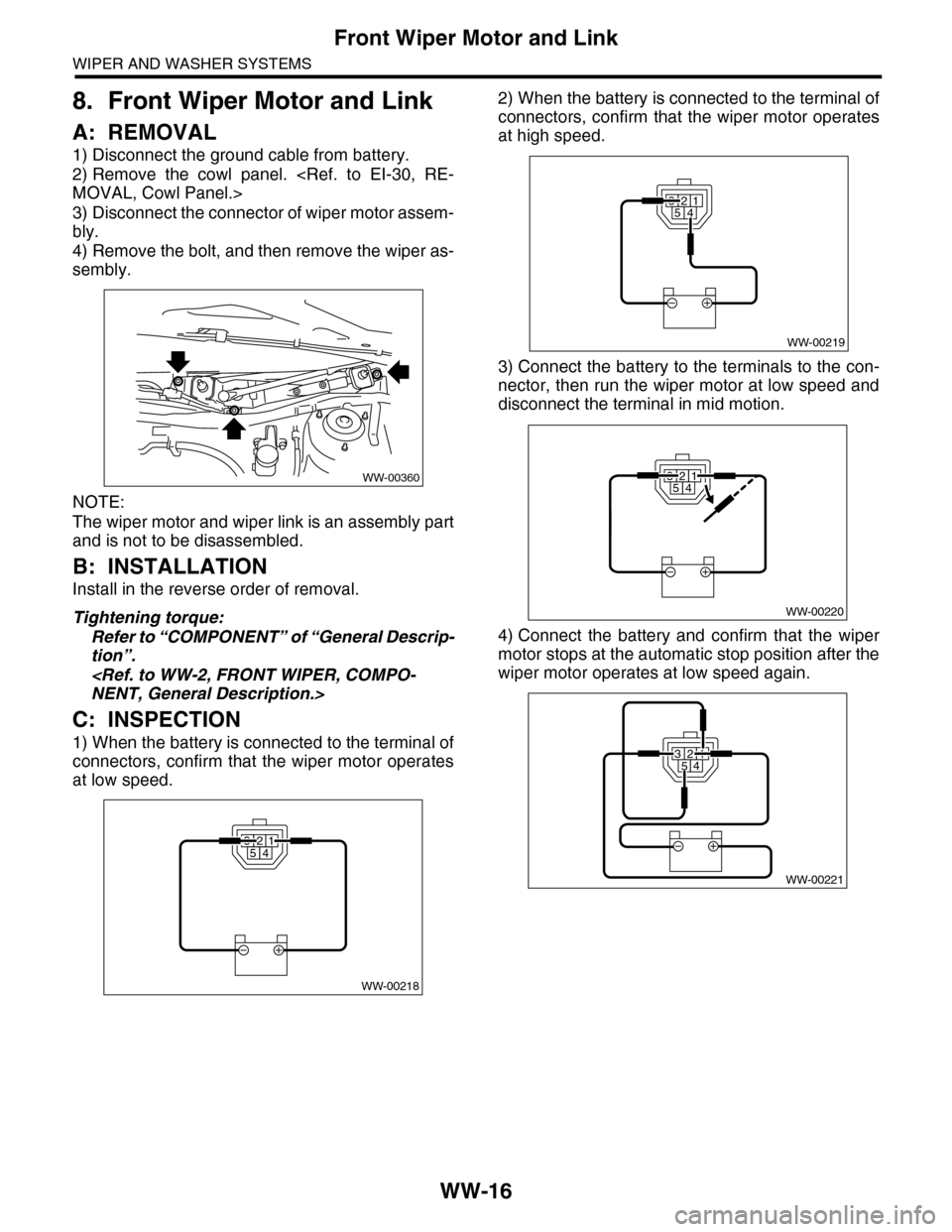

1) Disconnect the ground cable from battery.

2) Remove the cowl panel.

3) Disconnect the connector of wiper motor assem-

bly.

4) Remove the bolt, and then remove the wiper as-

sembly.

NOTE:

The wiper motor and wiper link is an assembly part

and is not to be disassembled.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

C: INSPECTION

1) When the battery is connected to the terminal of

connectors, confirm that the wiper motor operates

at low speed.

2) When the battery is connected to the terminal of

connectors, confirm that the wiper motor operates

at high speed.

3) Connect the battery to the terminals to the con-

nector, then run the wiper motor at low speed and

disconnect the terminal in mid motion.

4) Connect the battery and confirm that the wiper

motor stops at the automatic stop position after the

wiper motor operates at low speed again.

WW-00360

WW-00218

32541

32541

WW-00219

WW-00220

32541

WW-00221

32541

Page 712 of 2453

WW-17

Front Washer Nozzle

WIPER AND WASHER SYSTEMS

9. Front Washer Nozzle

A: REMOVAL

1) Remove the front hood insulator.

Front Hood.>

2) Hold the claw (A) of the washer nozzle towards

the direction of the arrow, and remove the washer

nozzle.

3) Remove the washer hose from the washer noz-

zle.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Adjust the washer nozzle position.

C: INSPECTION

•Make sure the nozzle and hose are not clogged.

•Make sure the hose is not bent.

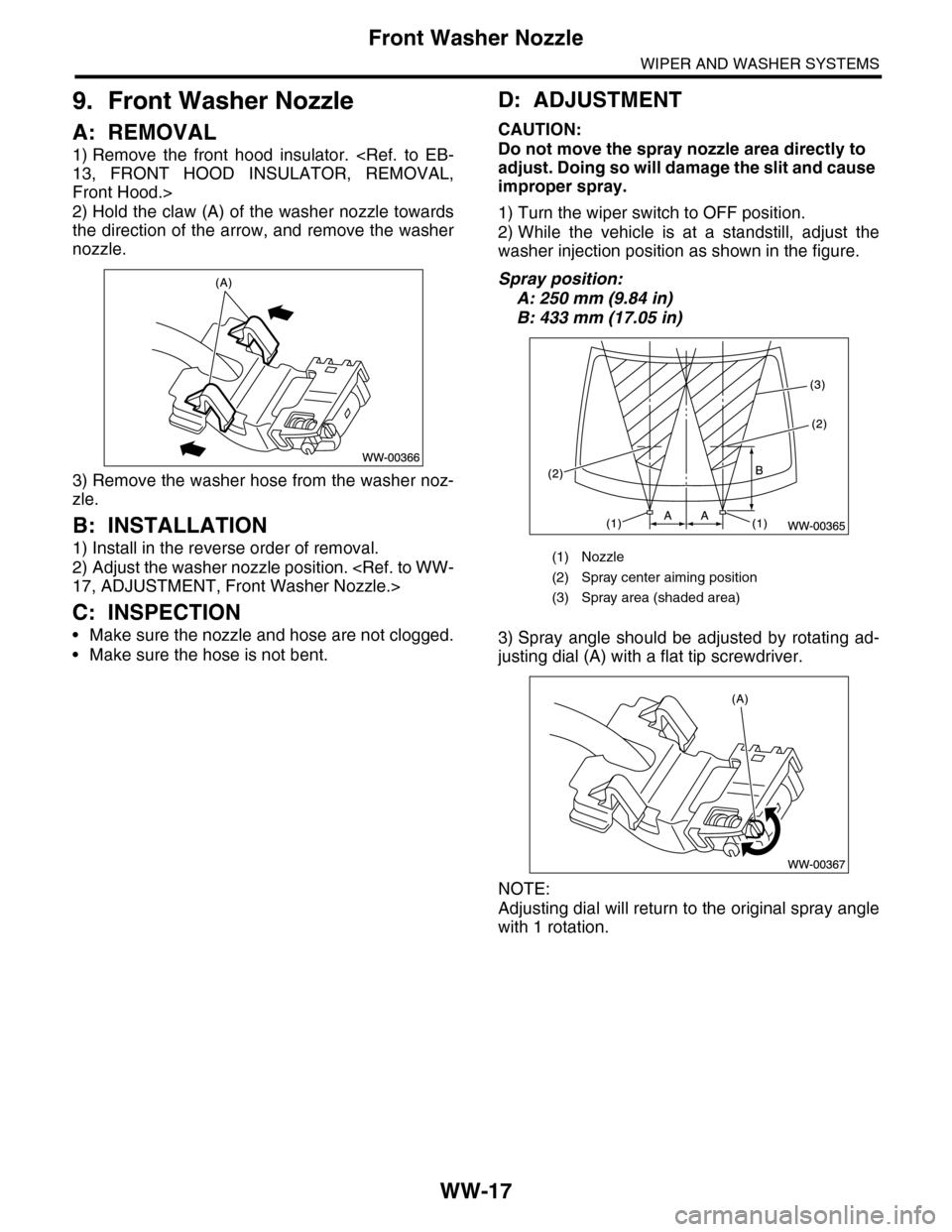

D: ADJUSTMENT

CAUTION:

Do not move the spray nozzle area directly to

adjust. Doing so will damage the slit and cause

improper spray.

1) Turn the wiper switch to OFF position.

2) While the vehicle is at a standstill, adjust the

washer injection position as shown in the figure.

Spray position:

A: 250 mm (9.84 in)

B: 433 mm (17.05 in)

3) Spray angle should be adjusted by rotating ad-

justing dial (A) with a flat tip screwdriver.

NOTE:

Adjusting dial will return to the original spray angle

with 1 rotation.

(1) Nozzle

(2) Spray center aiming position

(3) Spray area (shaded area)

Page 713 of 2453

WW-18

Rear Wiper Arm

WIPER AND WASHER SYSTEMS

10.Rear Wiper Arm

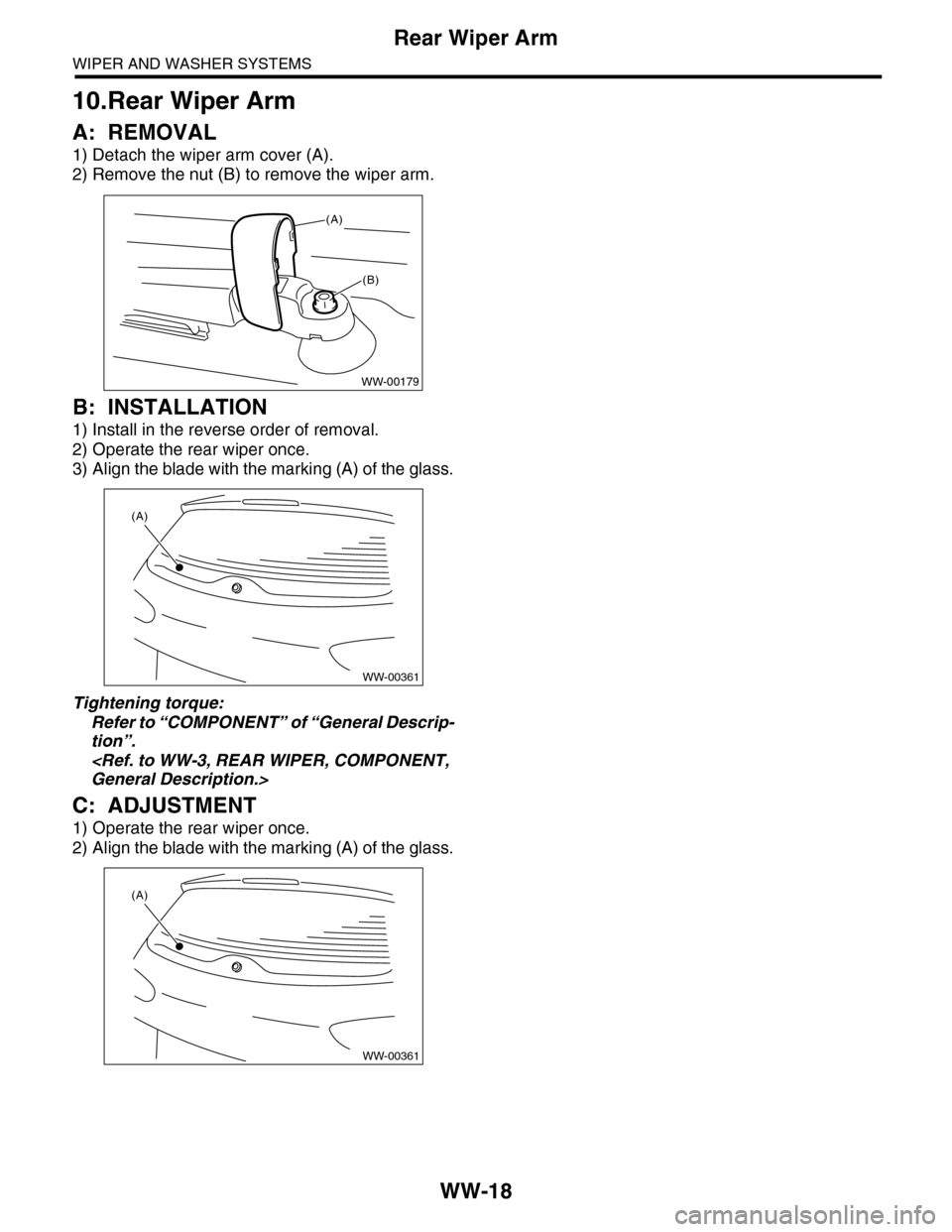

A: REMOVAL

1) Detach the wiper arm cover (A).

2) Remove the nut (B) to remove the wiper arm.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Operate the rear wiper once.

3) Align the blade with the marking (A) of the glass.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

C: ADJUSTMENT

1) Operate the rear wiper once.

2) Align the blade with the marking (A) of the glass.

WW-00179

(A)

(B)

WW-00361

(A)

WW-00361

(A)

Page 714 of 2453

WW-19

Rear Wiper Motor

WIPER AND WASHER SYSTEMS

11.Rear Wiper Motor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the rear wiper arm.

3) Remove the rear gate lower trim.

4) Disconnect the harness connector of wiper mo-

tor assembly.

5) Remove the bolts to remove wiper motor assem-

bly (A).

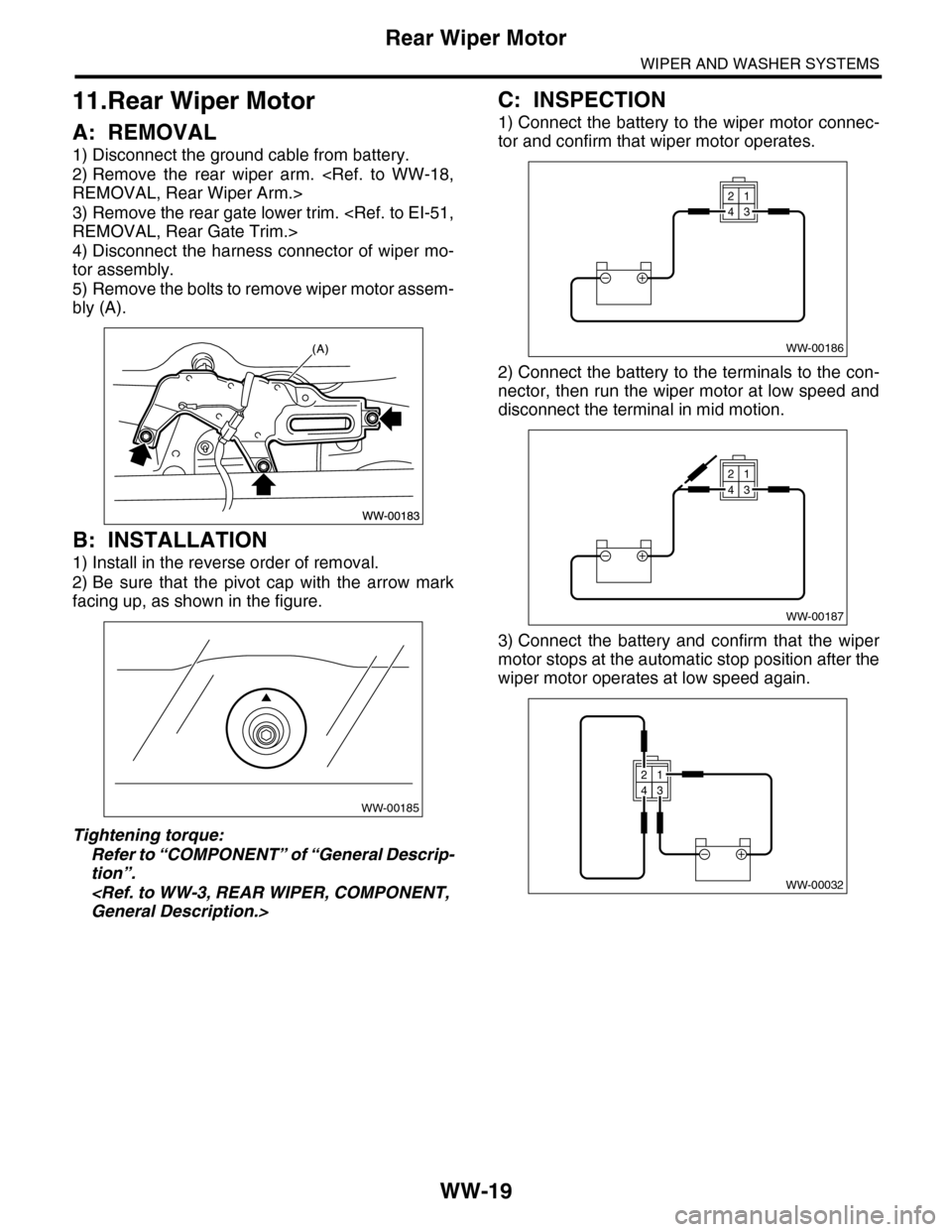

B: INSTALLATION

1) Install in the reverse order of removal.

2) Be sure that the pivot cap with the arrow mark

facing up, as shown in the figure.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

C: INSPECTION

1) Connect the battery to the wiper motor connec-

tor and confirm that wiper motor operates.

2) Connect the battery to the terminals to the con-

nector, then run the wiper motor at low speed and

disconnect the terminal in mid motion.

3) Connect the battery and confirm that the wiper

motor stops at the automatic stop position after the

wiper motor operates at low speed again.

WW-00185

WW-00186

21

43

WW-00187

21

43

WW-00032

21

43

Page 715 of 2453

WW-20

Rear Washer

WIPER AND WASHER SYSTEMS

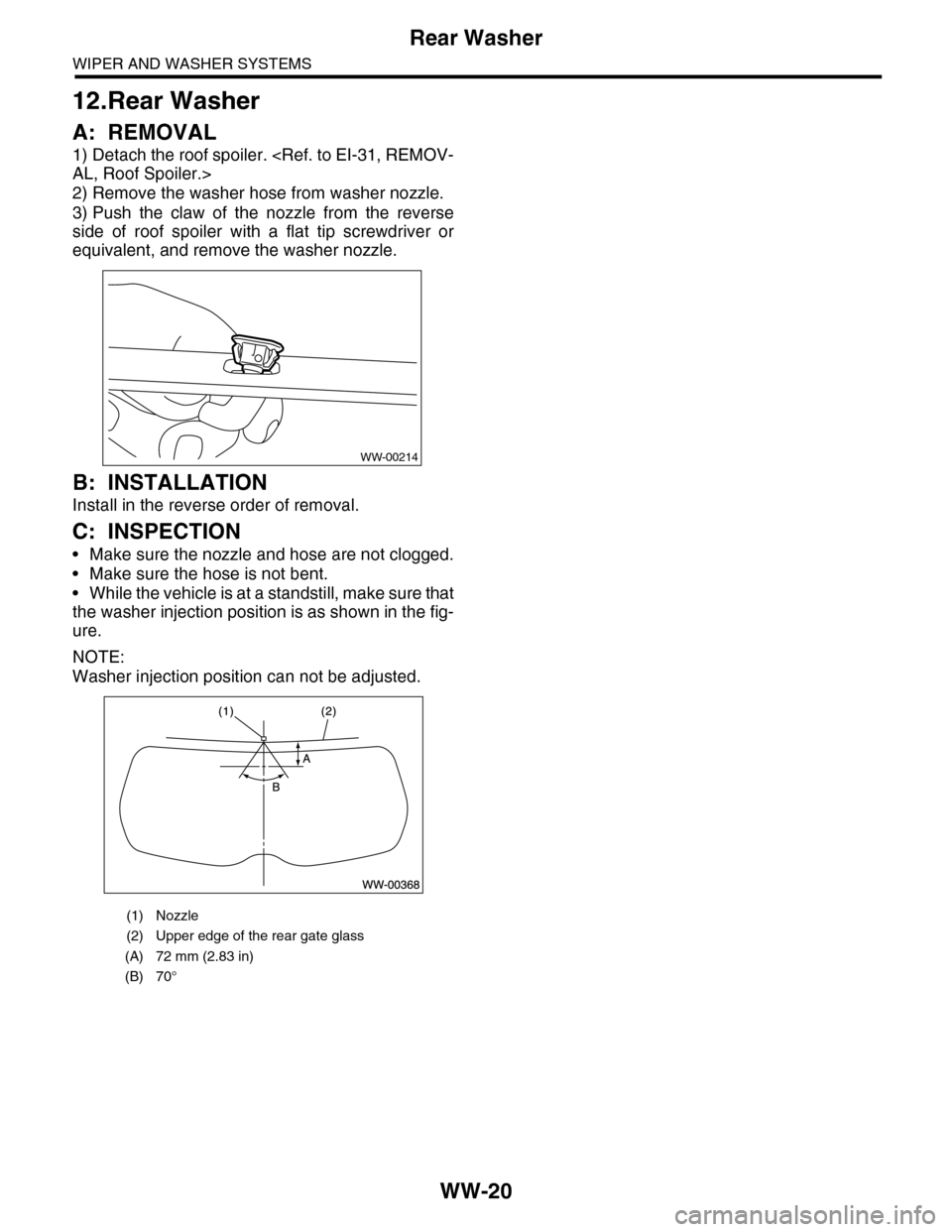

12.Rear Washer

A: REMOVAL

1) Detach the roof spoiler.

2) Remove the washer hose from washer nozzle.

3) Push the claw of the nozzle from the reverse

side of roof spoiler with a flat tip screwdriver or

equivalent, and remove the washer nozzle.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

•Make sure the nozzle and hose are not clogged.

•Make sure the hose is not bent.

•While the vehicle is at a standstill, make sure that

the washer injection position is as shown in the fig-

ure.

NOTE:

Washer injection position can not be adjusted.

(1) Nozzle

(2) Upper edge of the rear gate glass

(A) 72 mm (2.83 in)

(B) 70°

WW-00214

Page 734 of 2453

BR-20

Rear Disc Rotor

BRAKE

6. Rear Disc Rotor

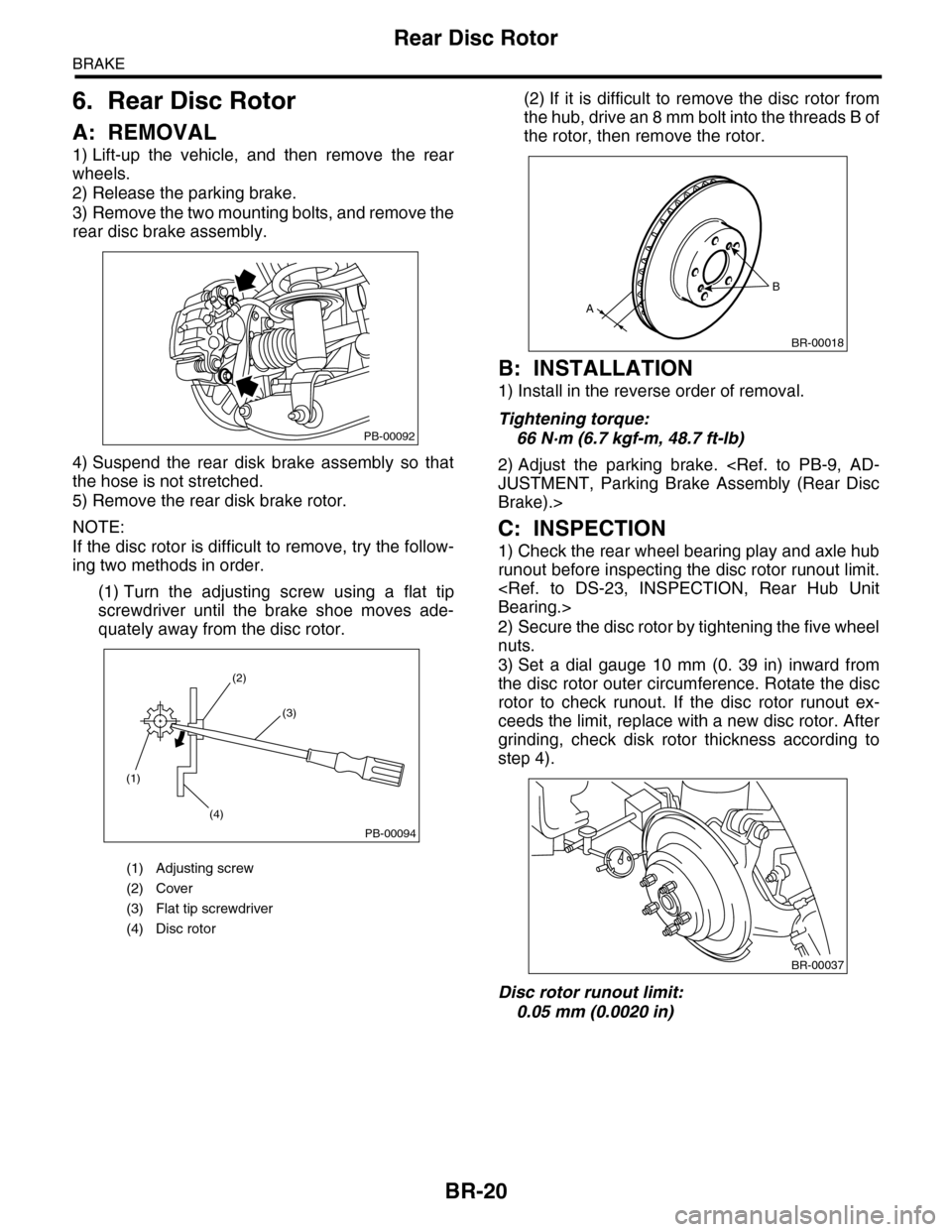

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Release the parking brake.

3) Remove the two mounting bolts, and remove the

rear disc brake assembly.

4) Suspend the rear disk brake assembly so that

the hose is not stretched.

5) Remove the rear disk brake rotor.

NOTE:

If the disc rotor is difficult to remove, try the follow-

ing two methods in order.

(1) Turn the adjusting screw using a flat tip

screwdriver until the brake shoe moves ade-

quately away from the disc rotor.

(2) If it is difficult to remove the disc rotor from

the hub, drive an 8 mm bolt into the threads B of

the rotor, then remove the rotor.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

66 N·m (6.7 kgf-m, 48.7 ft-lb)

2) Adjust the parking brake.

Brake).>

C: INSPECTION

1) Check the rear wheel bearing play and axle hub

runout before inspecting the disc rotor runout limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

(1) Adjusting screw

(2) Cover

(3) Flat tip screwdriver

(4) Disc rotor

PB-00092

(1)

(4)

(2)

(3)

PB-00094

B

A

BR-00018

BR-00037

Page 738 of 2453

BR-24

Master Cylinder

BRAKE

8. Master Cylinder

A: REMOVAL

CAUTION:

Do not allow brake fluid to come in contact with

vehicle body. If it does, wash off with water and

wipe away completely.

1) Drain brake fluid from the reservoir tank com-

pletely.

2) Disconnect the harness connector of the fluid

level gauge.

3) Remove the brake pipe from the master cylinder.

4) Remove the master cylinder mounting nuts, and

remove the master cylinder from the brake booster.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

Master cylinder mounting nut

25 N·m (2.5 kgf-m, 18.4 ft-lb)

Brake pipe

19 N·m (1.9 kgf-m, 14.0 ft-lb)

CAUTION:

Be sure to use recommended brake fluid.

2) Bleed air from brake system.

C: REPLACEMENT

1) Remove mud and dirt from the surface of brake

master cylinder.

2) Secure the master cylinder in a vise.

NOTE:

To avoid damaging the master cylinder, place be-

tween aluminum plates or other material when

holding with a vise.

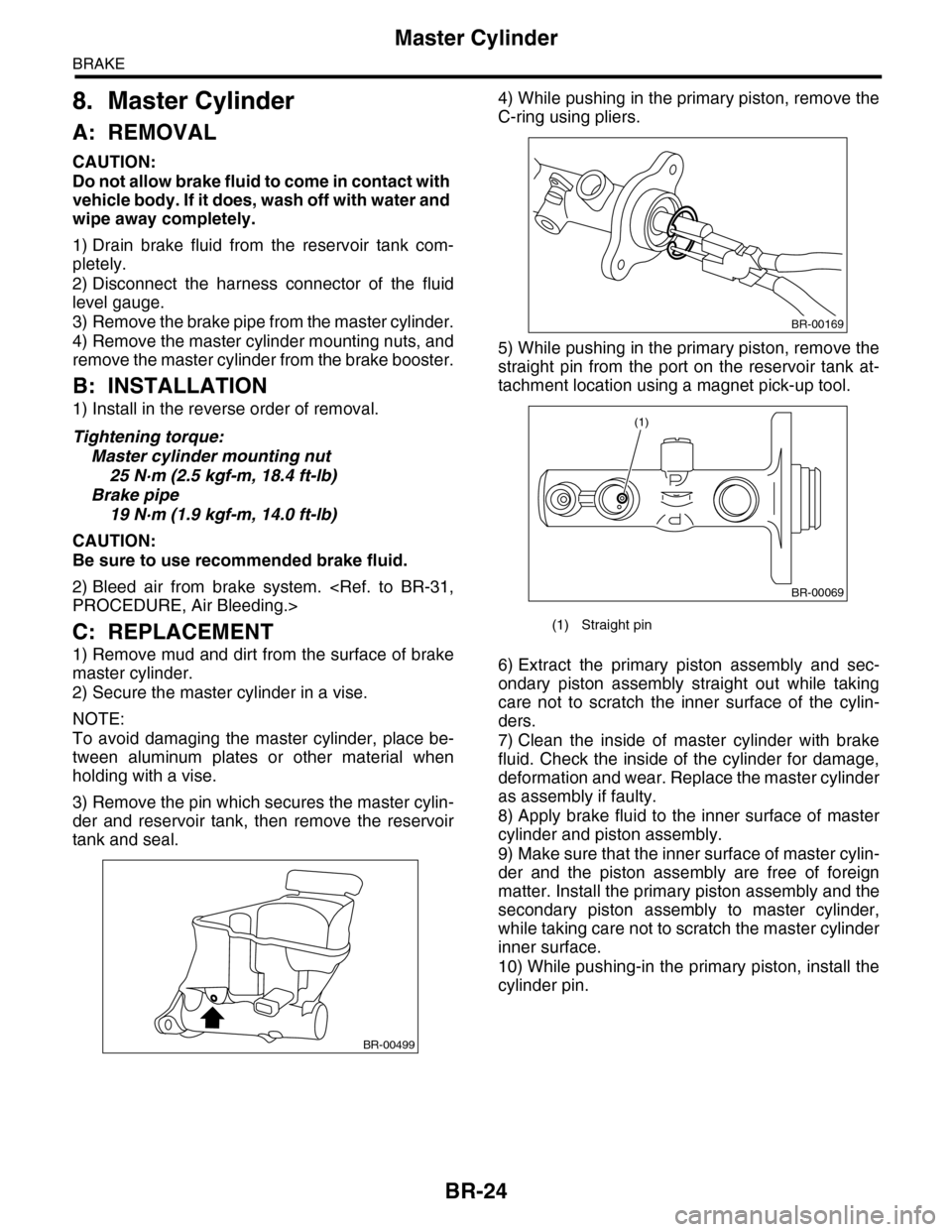

3) Remove the pin which secures the master cylin-

der and reservoir tank, then remove the reservoir

tank and seal.

4) While pushing in the primary piston, remove the

C-ring using pliers.

5) While pushing in the primary piston, remove the

straight pin from the port on the reservoir tank at-

tachment location using a magnet pick-up tool.

6) Extract the primary piston assembly and sec-

ondary piston assembly straight out while taking

care not to scratch the inner surface of the cylin-

ders.

7) Clean the inside of master cylinder with brake

fluid. Check the inside of the cylinder for damage,

deformation and wear. Replace the master cylinder

as assembly if faulty.

8) Apply brake fluid to the inner surface of master

cylinder and piston assembly.

9) Make sure that the inner surface of master cylin-

der and the piston assembly are free of foreign

matter. Install the primary piston assembly and the

secondary piston assembly to master cylinder,

while taking care not to scratch the master cylinder

inner surface.

10) While pushing-in the primary piston, install the

cylinder pin.

BR-00499

(1) Straight pin

BR-00169

(1)

BR-00069

Page 750 of 2453

BR-36

Brake Pedal

BRAKE

14.Brake Pedal

A: REMOVAL

1) Remove the steering shaft.

2) Disconnect the connector (stop light switch etc.)

from the pedal bracket.

3) Remove the clevis pin which secures the lever

and push rod.

4) Remove the bolt and nut which secures the ped-

al bracket.

B: INSTALLATION

1) Install in the reverse order of removal.

CAUTION:

Always use a new clevis pin.

2) Check the brake pedal after installation.

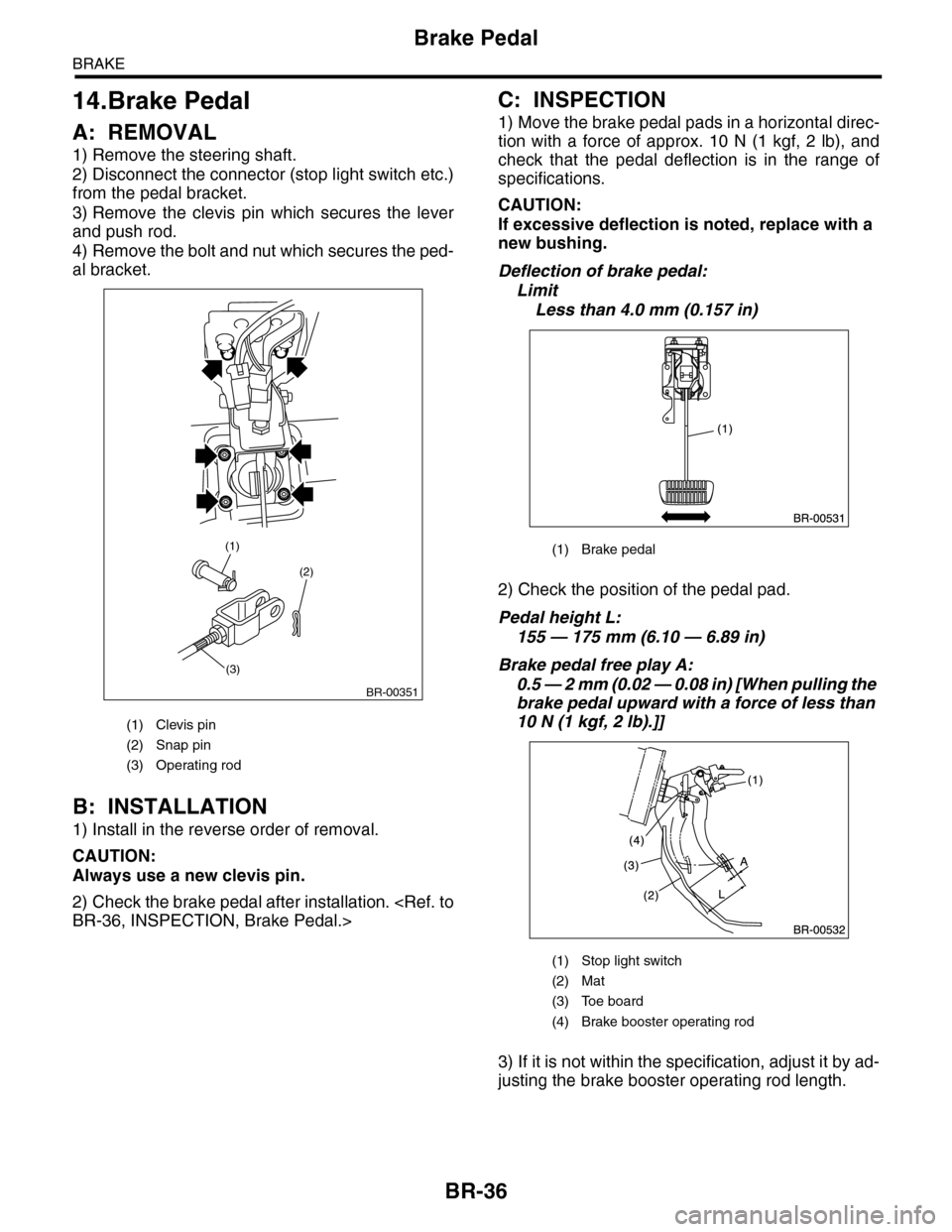

C: INSPECTION

1) Move the brake pedal pads in a horizontal direc-

tion with a force of approx. 10 N (1 kgf, 2 lb), and

check that the pedal deflection is in the range of

specifications.

CAUTION:

If excessive deflection is noted, replace with a

new bushing.

Deflection of brake pedal:

Limit

Less than 4.0 mm (0.157 in)

2) Check the position of the pedal pad.

Pedal height L:

155 — 175 mm (6.10 — 6.89 in)

Brake pedal free play A:

0.5 — 2 mm (0.02 — 0.08 in) [When pulling the

brake pedal upward with a force of less than

10 N (1 kgf, 2 lb).]]

3) If it is not within the specification, adjust it by ad-

justing the brake booster operating rod length.

(1) Clevis pin

(2) Snap pin

(3) Operating rod

(2)

(3)

(1)

BR-00351

(1) Brake pedal

(1) Stop light switch

(2) Mat

(3) Toe board

(4) Brake booster operating rod

Page 753 of 2453

BR-39

Brake Vacuum Pump

BRAKE

16.Brake Vacuum Pump

A: REMOVAL

1. BRAKE VACUUM PUMP

1) Disconnect the ground cable from the battery.

2) Disconnect the brake vacuum pump connector.

3) Remove the vacuum hose.

4) Remove the bolt, and remove the brake vacuum

pump.

2. VACUUM HOSE

Remove the clip and remove the vacuum hose.

B: INSTALLATION

1. BRAKE VACUUM PUMP

Install in the reverse order of removal.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

2. VACUUM HOSE

Install in the reverse order of removal.

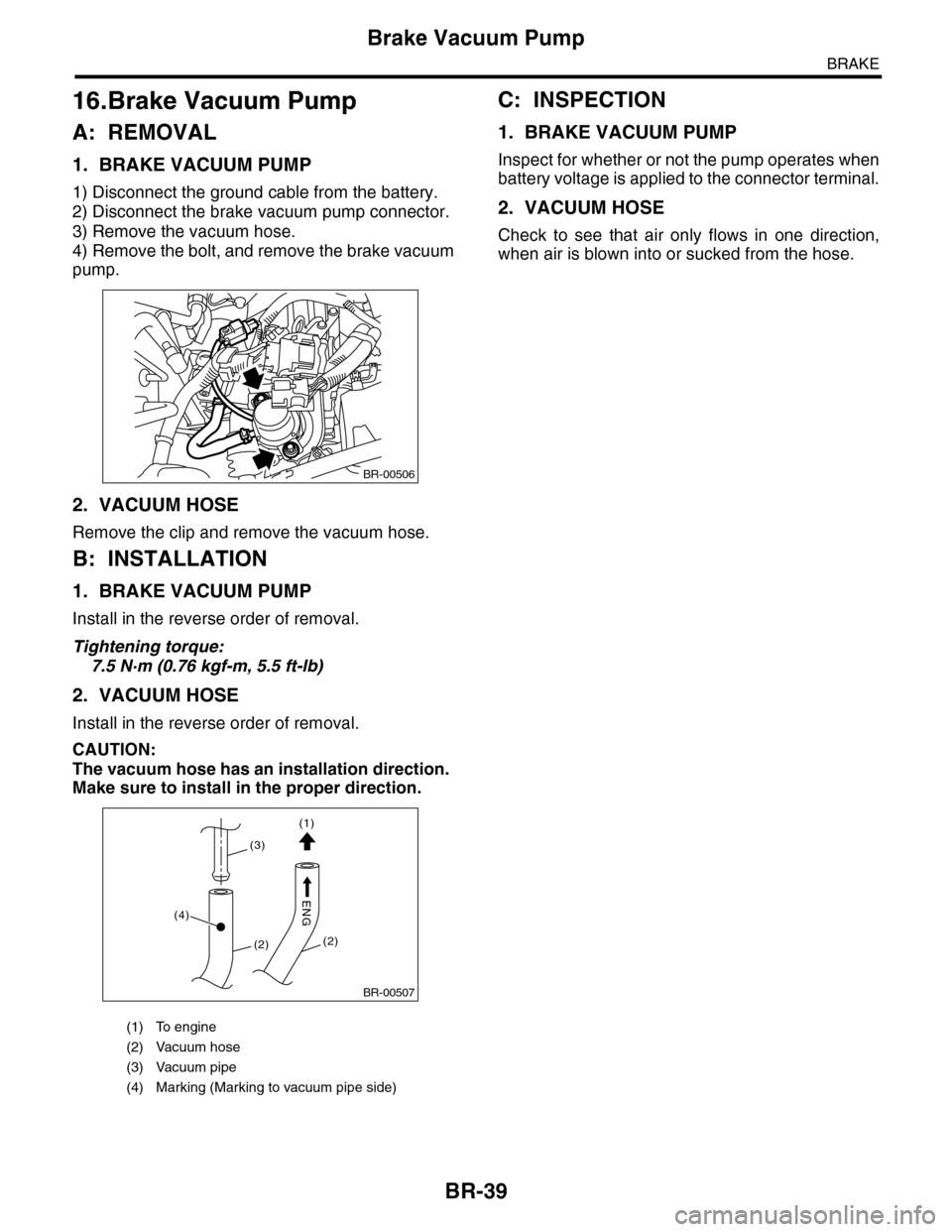

CAUTION:

The vacuum hose has an installation direction.

Make sure to install in the proper direction.

C: INSPECTION

1. BRAKE VACUUM PUMP

Inspect for whether or not the pump operates when

battery voltage is applied to the connector terminal.

2. VACUUM HOSE

Check to see that air only flows in one direction,

when air is blown into or sucked from the hose.

(1) To engine

(2) Vacuum hose

(3) Vacuum pipe

(4) Marking (Marking to vacuum pipe side)

BR-00506

BR-00507

(1)

(2)(2)

(4)

(3)

ENG

Page 754 of 2453

BR-40

Brake Vacuum Sensor

BRAKE

17.Brake Vacuum Sensor

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Disconnect the brake vacuum sensor connector.

3) Remove the vacuum hose from the brake vacu-

um sensor.

4) Remove the bolt, and remove the brake vacuum

sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

BR-00509