Reverse SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 803 of 2453

DI-19

Rear Differential (VA–type)

DIFFERENTIALS

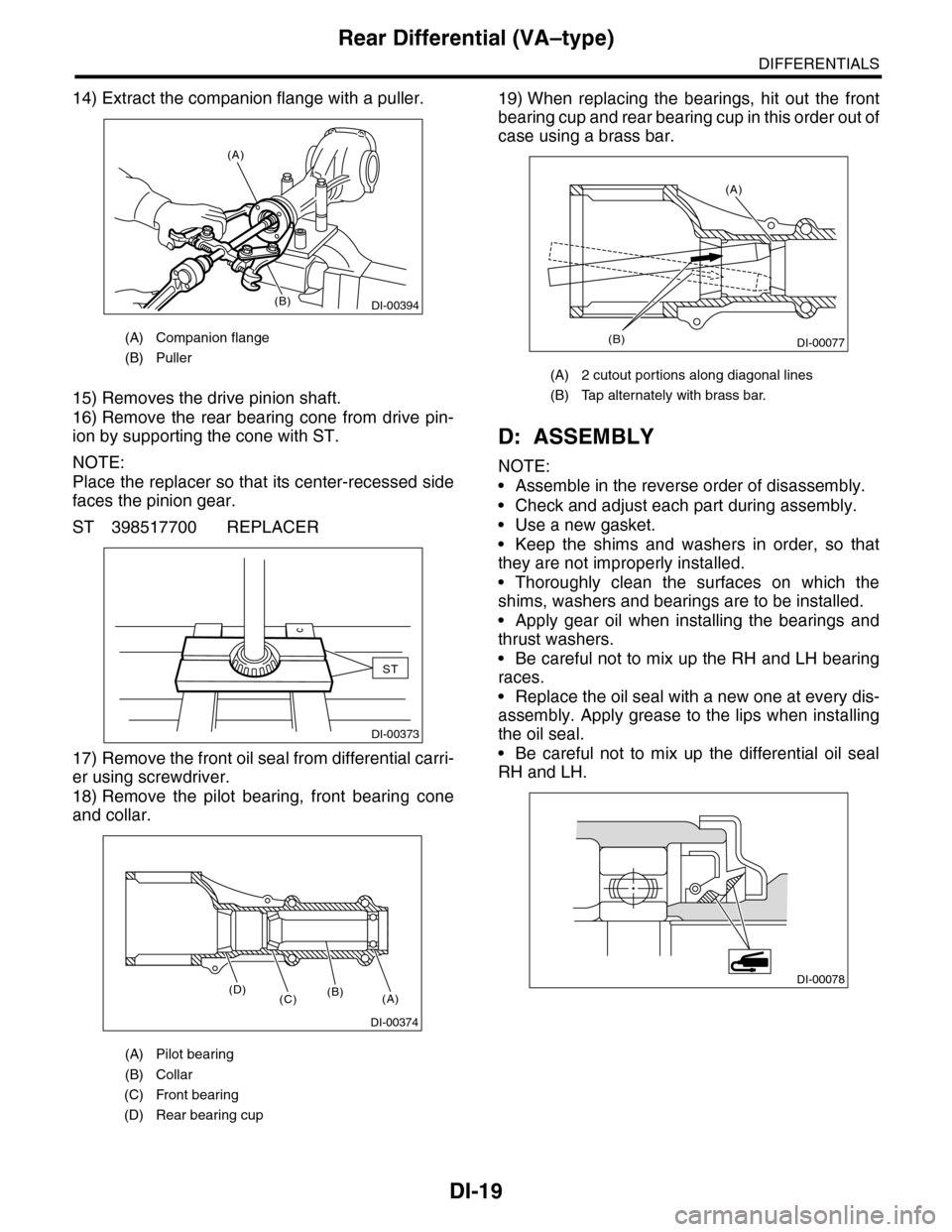

14) Extract the companion flange with a puller.

15) Removes the drive pinion shaft.

16) Remove the rear bearing cone from drive pin-

ion by supporting the cone with ST.

NOTE:

Place the replacer so that its center-recessed side

faces the pinion gear.

ST 398517700 REPLACER

17) Remove the front oil seal from differential carri-

er using screwdriver.

18) Remove the pilot bearing, front bearing cone

and collar.

19) When replacing the bearings, hit out the front

bearing cup and rear bearing cup in this order out of

case using a brass bar.

D: ASSEMBLY

NOTE:

•Assemble in the reverse order of disassembly.

•Check and adjust each part during assembly.

•Use a new gasket.

•Keep the shims and washers in order, so that

they are not improperly installed.

•Thoroughly clean the surfaces on which the

shims, washers and bearings are to be installed.

•Apply gear oil when installing the bearings and

thrust washers.

•Be careful not to mix up the RH and LH bearing

races.

•Replace the oil seal with a new one at every dis-

assembly. Apply grease to the lips when installing

the oil seal.

•Be careful not to mix up the differential oil seal

RH and LH.

(A) Companion flange

(B) Puller

(A) Pilot bearing

(B) Collar

(C) Front bearing

(D) Rear bearing cup

(B)

(A)

DI-00394

DI-00373

ST

(B)(A)(C)(D)

DI-00374

(A) 2 cutout portions along diagonal lines

(B) Tap alternately with brass bar.

(B)

(A)

DI-00077

DI-00078

Page 805 of 2453

DI-21

Rear Differential (VA–type)

DIFFERENTIALS

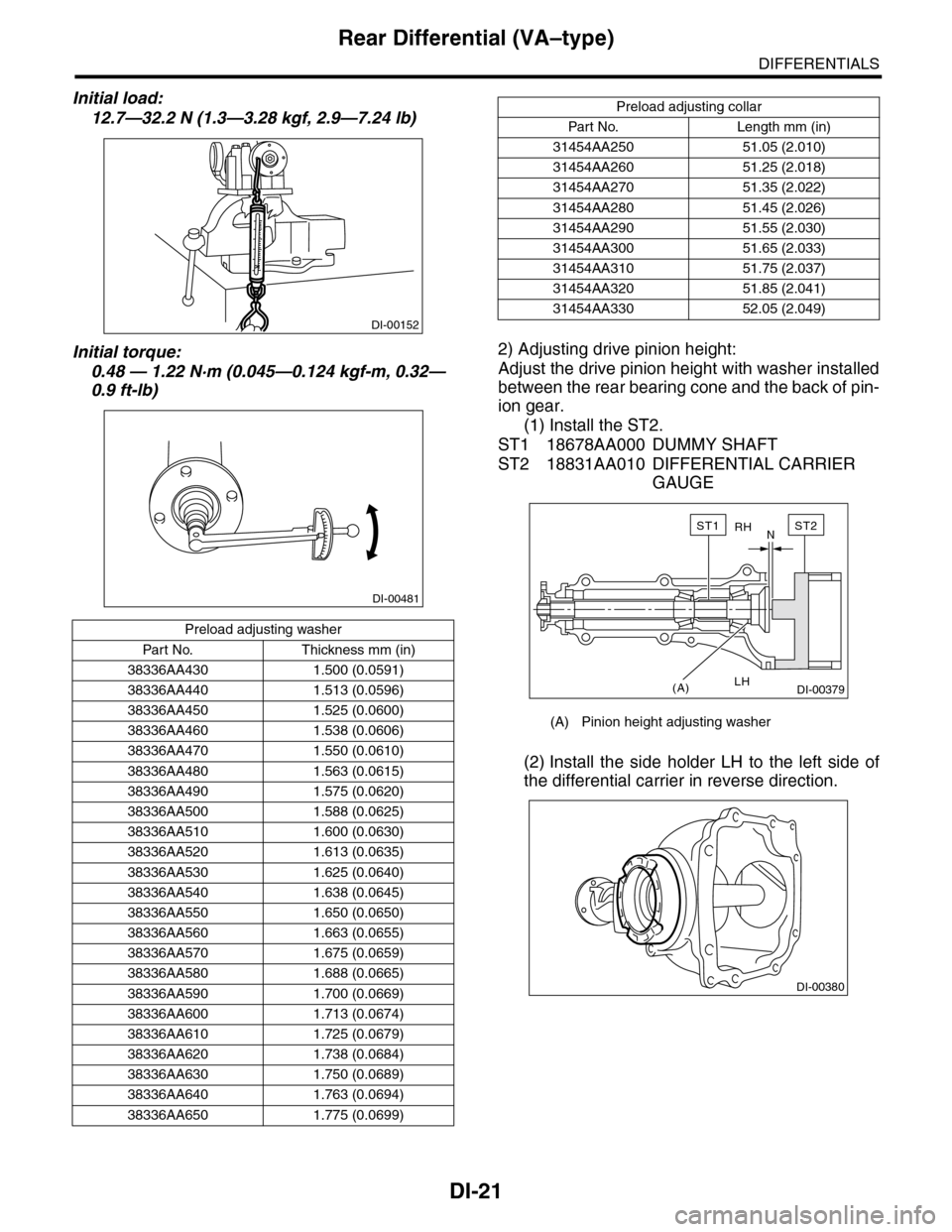

Initial load:

12.7—32.2 N (1.3—3.28 kgf, 2.9—7.24 lb)

Initial torque:

0.48 — 1.22 N·m (0.045—0.124 kgf-m, 0.32—

0.9 ft-lb)

2) Adjusting drive pinion height:

Adjust the drive pinion height with washer installed

between the rear bearing cone and the back of pin-

ion gear.

(1) Install the ST2.

ST1 18678AA000 DUMMY SHAFT

ST2 18831AA010 DIFFERENTIAL CARRIER

GAUGE

(2) Install the side holder LH to the left side of

the differential carrier in reverse direction.

Preload adjusting washer

Par t No. Thickness mm (in)

38336AA430 1.500 (0.0591)

38336AA440 1.513 (0.0596)

38336AA450 1.525 (0.0600)

38336AA460 1.538 (0.0606)

38336AA470 1.550 (0.0610)

38336AA480 1.563 (0.0615)

38336AA490 1.575 (0.0620)

38336AA500 1.588 (0.0625)

38336AA510 1.600 (0.0630)

38336AA520 1.613 (0.0635)

38336AA530 1.625 (0.0640)

38336AA540 1.638 (0.0645)

38336AA550 1.650 (0.0650)

38336AA560 1.663 (0.0655)

38336AA570 1.675 (0.0659)

38336AA580 1.688 (0.0665)

38336AA590 1.700 (0.0669)

38336AA600 1.713 (0.0674)

38336AA610 1.725 (0.0679)

38336AA620 1.738 (0.0684)

38336AA630 1.750 (0.0689)

38336AA640 1.763 (0.0694)

38336AA650 1.775 (0.0699)

DI-00152

DI-00481

Preload adjusting collar

Par t No. Length mm (in)

31454AA250 51.05 (2.010)

31454AA260 51.25 (2.018)

31454AA270 51.35 (2.022)

31454AA280 51.45 (2.026)

31454AA290 51.55 (2.030)

31454AA300 51.65 (2.033)

31454AA310 51.75 (2.037)

31454AA320 51.85 (2.041)

31454AA330 52.05 (2.049)

(A) Pinion height adjusting washer

RH

LH

N

(A)

ST2ST1

DI-00379

DI-00380

Page 808 of 2453

DI-24

Rear Differential (VA–type)

DIFFERENTIALS

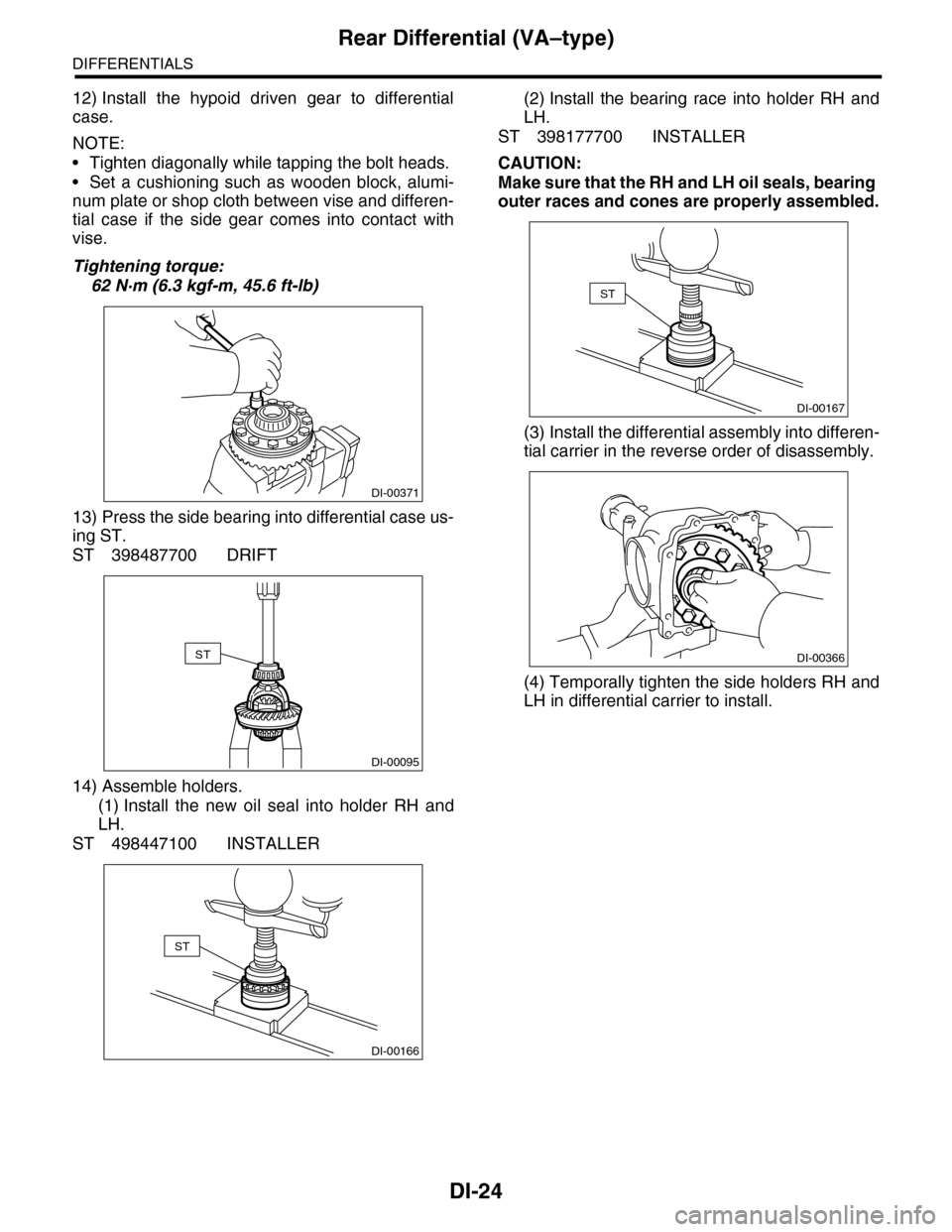

12) Install the hypoid driven gear to differential

case.

NOTE:

•Tighten diagonally while tapping the bolt heads.

•Set a cushioning such as wooden block, alumi-

num plate or shop cloth between vise and differen-

tial case if the side gear comes into contact with

vise.

Tightening torque:

62 N·m (6.3 kgf-m, 45.6 ft-lb)

13) Press the side bearing into differential case us-

ing ST.

ST 398487700 DRIFT

14) Assemble holders.

(1) Install the new oil seal into holder RH and

LH.

ST 498447100 INSTALLER

(2) Install the bearing race into holder RH and

LH.

ST 398177700 INSTALLER

CAUTION:

Make sure that the RH and LH oil seals, bearing

outer races and cones are properly assembled.

(3) Install the differential assembly into differen-

tial carrier in the reverse order of disassembly.

(4) Temporally tighten the side holders RH and

LH in differential carrier to install.

DI-00371

ST

DI-00095

ST

DI-00166

ST

DI-00167

DI-00366

Page 815 of 2453

DI-31

Rear Differential Front Oil Seal

DIFFERENTIALS

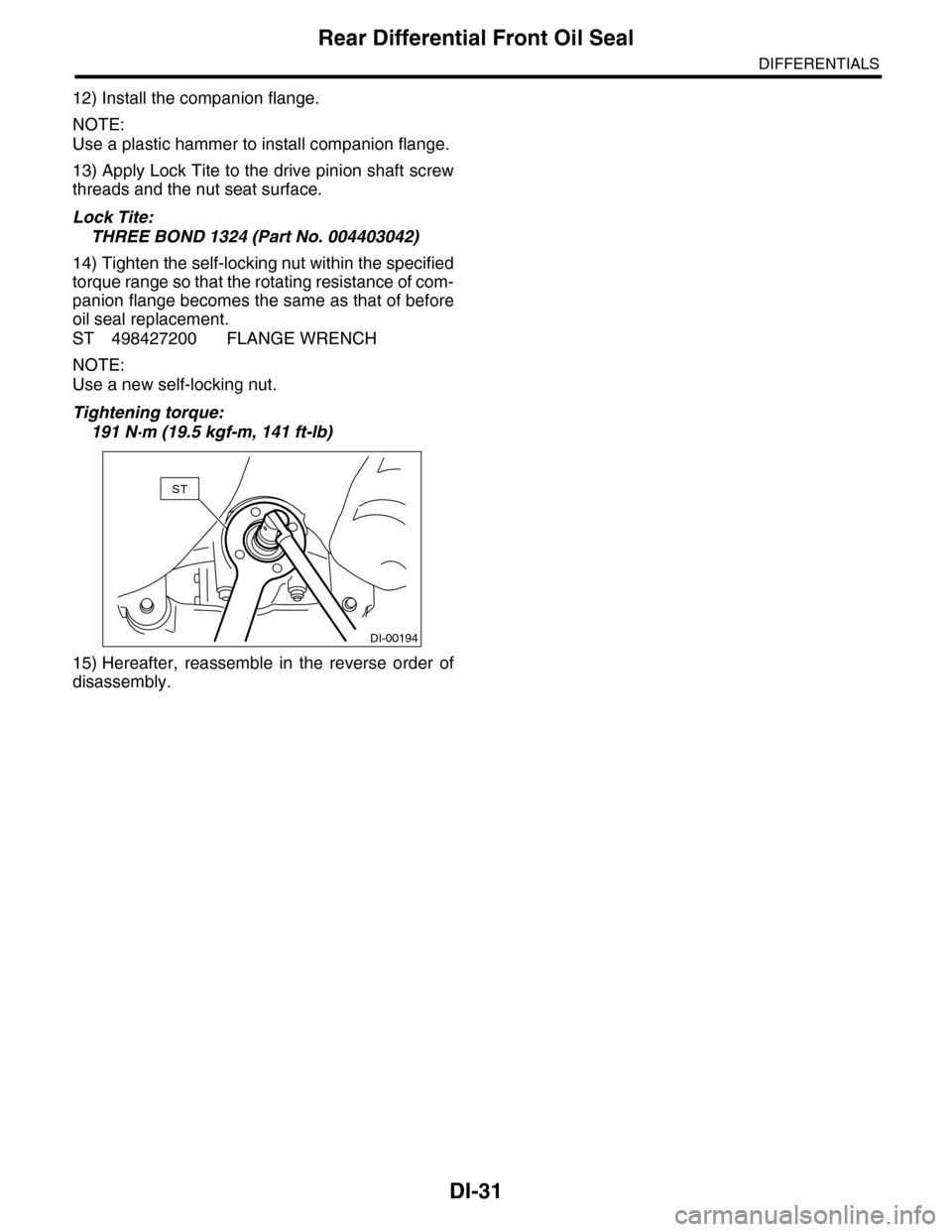

12) Install the companion flange.

NOTE:

Use a plastic hammer to install companion flange.

13) Apply Lock Tite to the drive pinion shaft screw

threads and the nut seat surface.

Lock Tite:

THREE BOND 1324 (Part No. 004403042)

14) Tighten the self-locking nut within the specified

torque range so that the rotating resistance of com-

panion flange becomes the same as that of before

oil seal replacement.

ST 498427200 FLANGE WRENCH

NOTE:

Use a new self-locking nut.

Tightening torque:

191 N·m (19.5 kgf-m, 141 ft-lb)

15) Hereafter, reassemble in the reverse order of

disassembly.

DI-00194

ST

Page 835 of 2453

DS-18

Rear Axle

DRIVE SHAFT SYSTEM

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

Install in the reverse order of removal.

Tightening torque:

Refer to COMPONENT of General Description

for tightening torque.

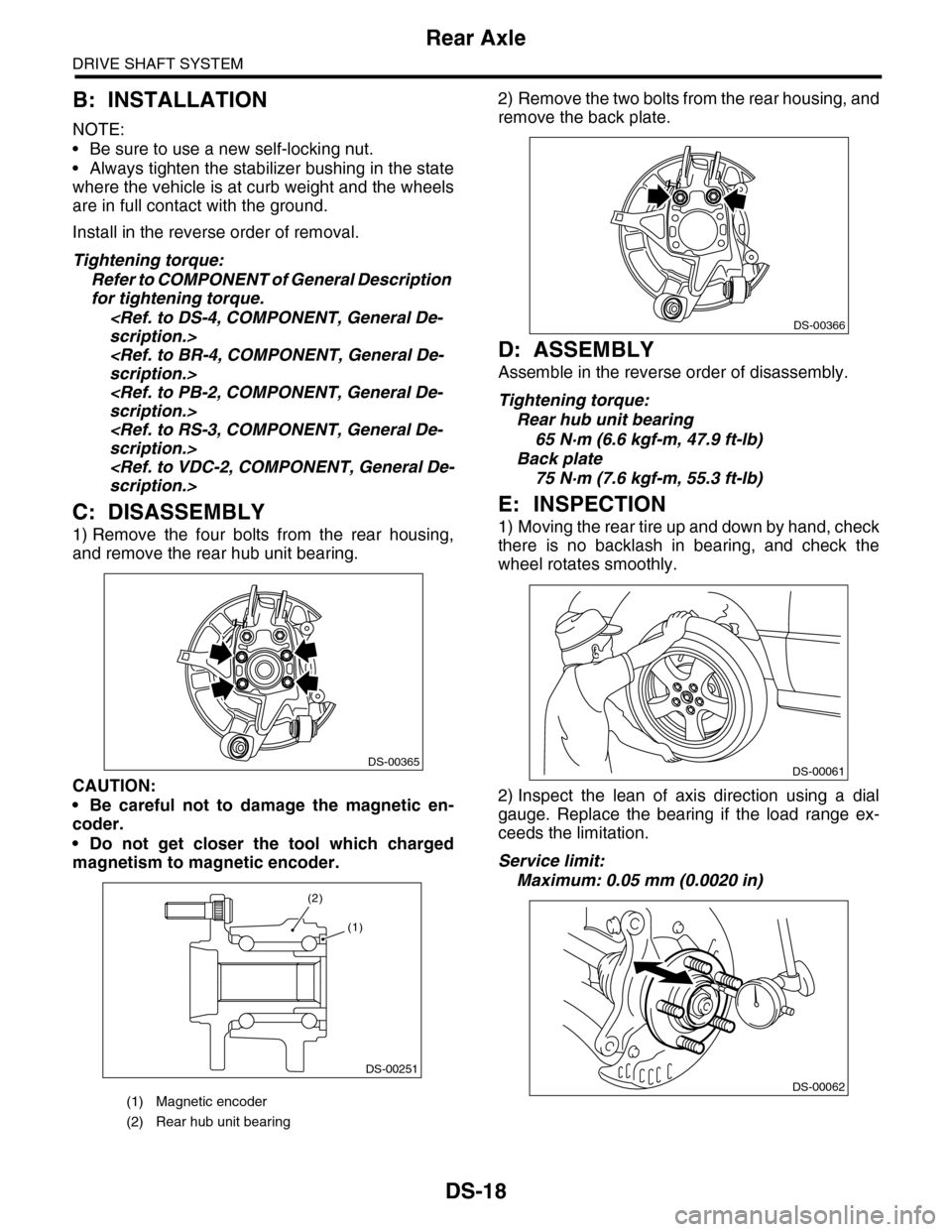

C: DISASSEMBLY

1) Remove the four bolts from the rear housing,

and remove the rear hub unit bearing.

CAUTION:

•Be careful not to damage the magnetic en-

coder.

•Do not get closer the tool which charged

magnetism to magnetic encoder.

2) Remove the two bolts from the rear housing, and

remove the back plate.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

Tightening torque:

Rear hub unit bearing

65 N·m (6.6 kgf-m, 47.9 ft-lb)

Back plate

75 N·m (7.6 kgf-m, 55.3 ft-lb)

E: INSPECTION

1) Moving the rear tire up and down by hand, check

there is no backlash in bearing, and check the

wheel rotates smoothly.

2) Inspect the lean of axis direction using a dial

gauge. Replace the bearing if the load range ex-

ceeds the limitation.

Service limit:

Maximum: 0.05 mm (0.0020 in)

(1) Magnetic encoder

(2) Rear hub unit bearing

DS-00365

DS-00251

(2)

(1)

DS-00366

DS-00061

DS-00062

Page 861 of 2453

FS-13

Front Crossmember Support Plate

FRONT SUSPENSION

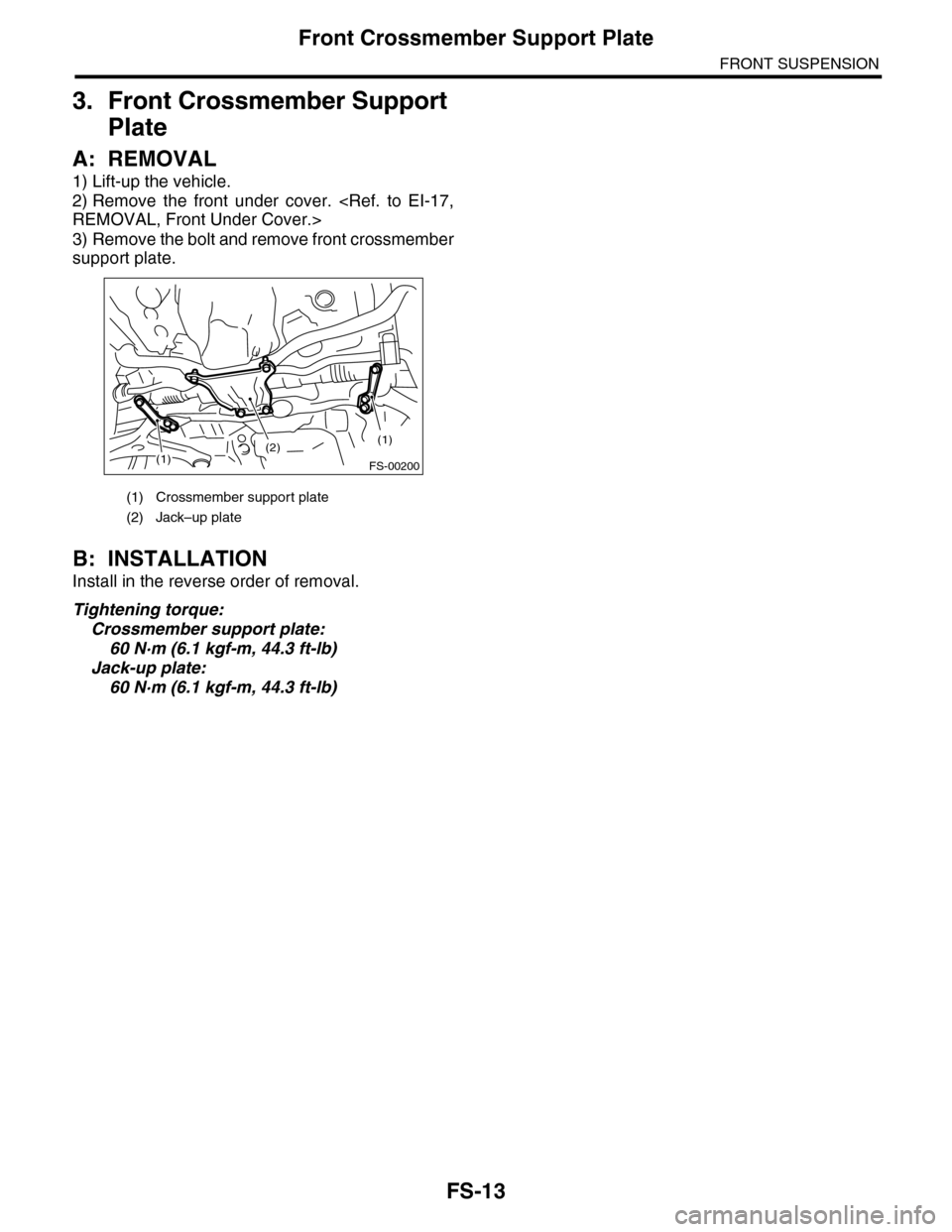

3. Front Crossmember Support

Plate

A: REMOVAL

1) Lift-up the vehicle.

2) Remove the front under cover.

3) Remove the bolt and remove front crossmember

support plate.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Crossmember support plate:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

Jack-up plate:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

(1) Crossmember support plate

(2) Jack–up plate

(2)(1)

(1)

FS-00200

Page 862 of 2453

FS-14

Front Stabilizer

FRONT SUSPENSION

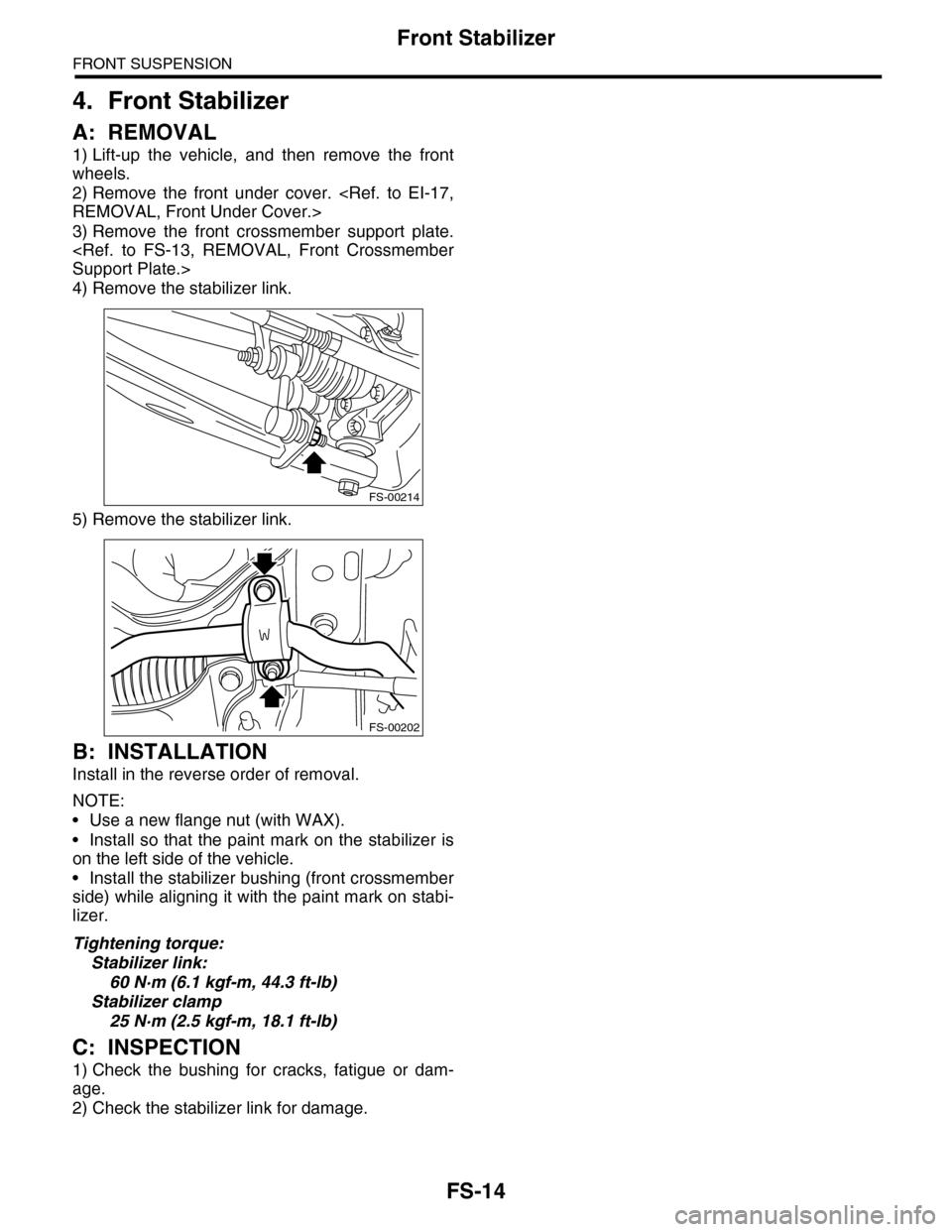

4. Front Stabilizer

A: REMOVAL

1) Lift-up the vehicle, and then remove the front

wheels.

2) Remove the front under cover.

3) Remove the front crossmember support plate.

4) Remove the stabilizer link.

5) Remove the stabilizer link.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

•Use a new flange nut (with WAX).

•Install so that the paint mark on the stabilizer is

on the left side of the vehicle.

•Install the stabilizer bushing (front crossmember

side) while aligning it with the paint mark on stabi-

lizer.

Tightening torque:

Stabilizer link:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

Stabilizer clamp

25 N·m (2.5 kgf-m, 18.1 ft-lb)

C: INSPECTION

1) Check the bushing for cracks, fatigue or dam-

age.

2) Check the stabilizer link for damage.

FS-00214

FS-00202

Page 865 of 2453

FS-17

Front Arm

FRONT SUSPENSION

C: DISASSEMBLY

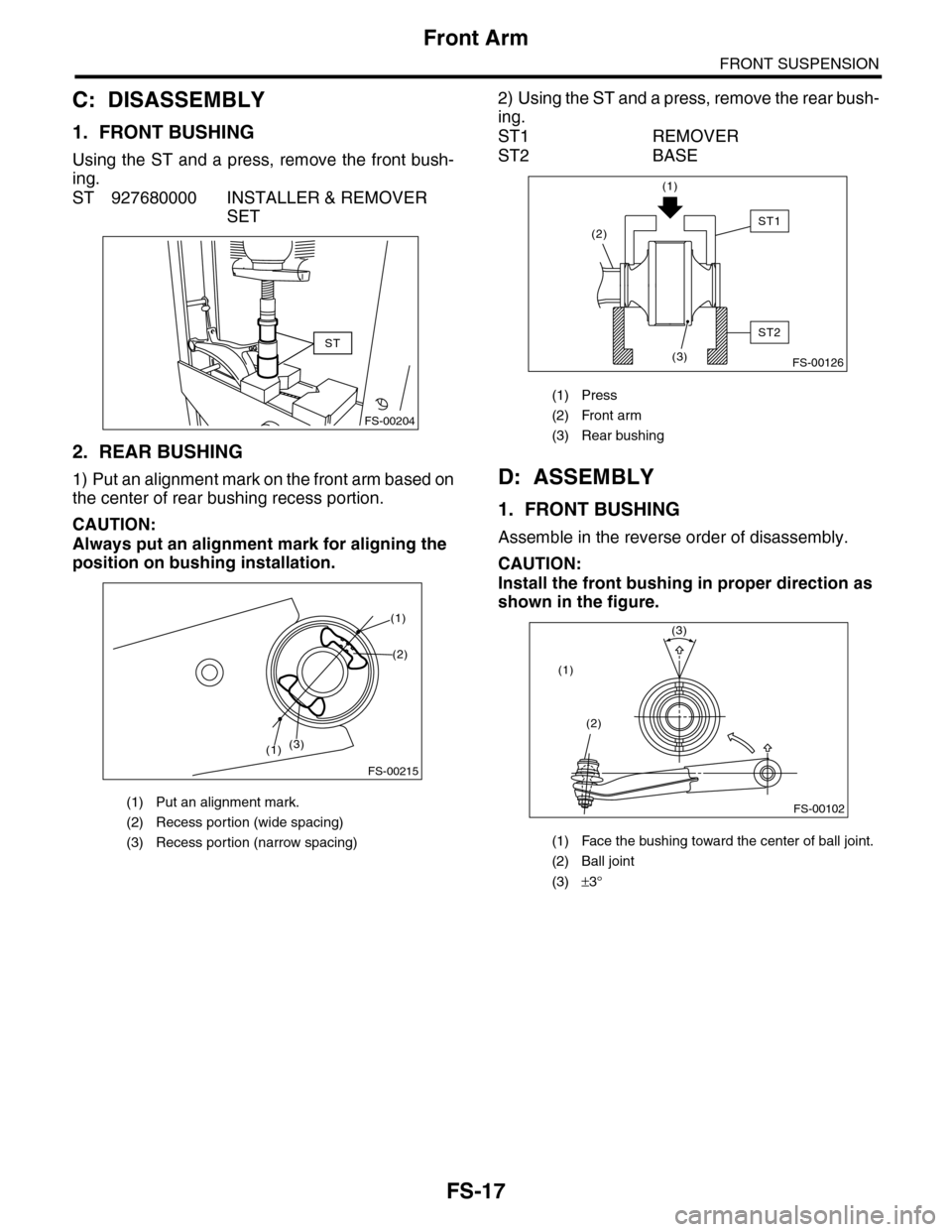

1. FRONT BUSHING

Using the ST and a press, remove the front bush-

ing.

ST 927680000 INSTALLER & REMOVER

SET

2. REAR BUSHING

1) Put an alignment mark on the front arm based on

the center of rear bushing recess portion.

CAUTION:

Always put an alignment mark for aligning the

position on bushing installation.

2) Using the ST and a press, remove the rear bush-

ing.

ST1 REMOVER

ST2 BASE

D: ASSEMBLY

1. FRONT BUSHING

Assemble in the reverse order of disassembly.

CAUTION:

Install the front bushing in proper direction as

shown in the figure.

(1) Put an alignment mark.

(2) Recess portion (wide spacing)

(3) Recess portion (narrow spacing)

ST

FS-00204

FS-00215

(2)

(1)

(1)(3)

(1) Press

(2) Front arm

(3) Rear bushing

(1) Face the bushing toward the center of ball joint.

(2) Ball joint

(3)±3°

(1)

(2)

(3)

ST2

ST1

FS-00126

FS-00102

(1)

(2)

(3)

Page 871 of 2453

FS-23

Front Crossmember

FRONT SUSPENSION

8. Front Crossmember

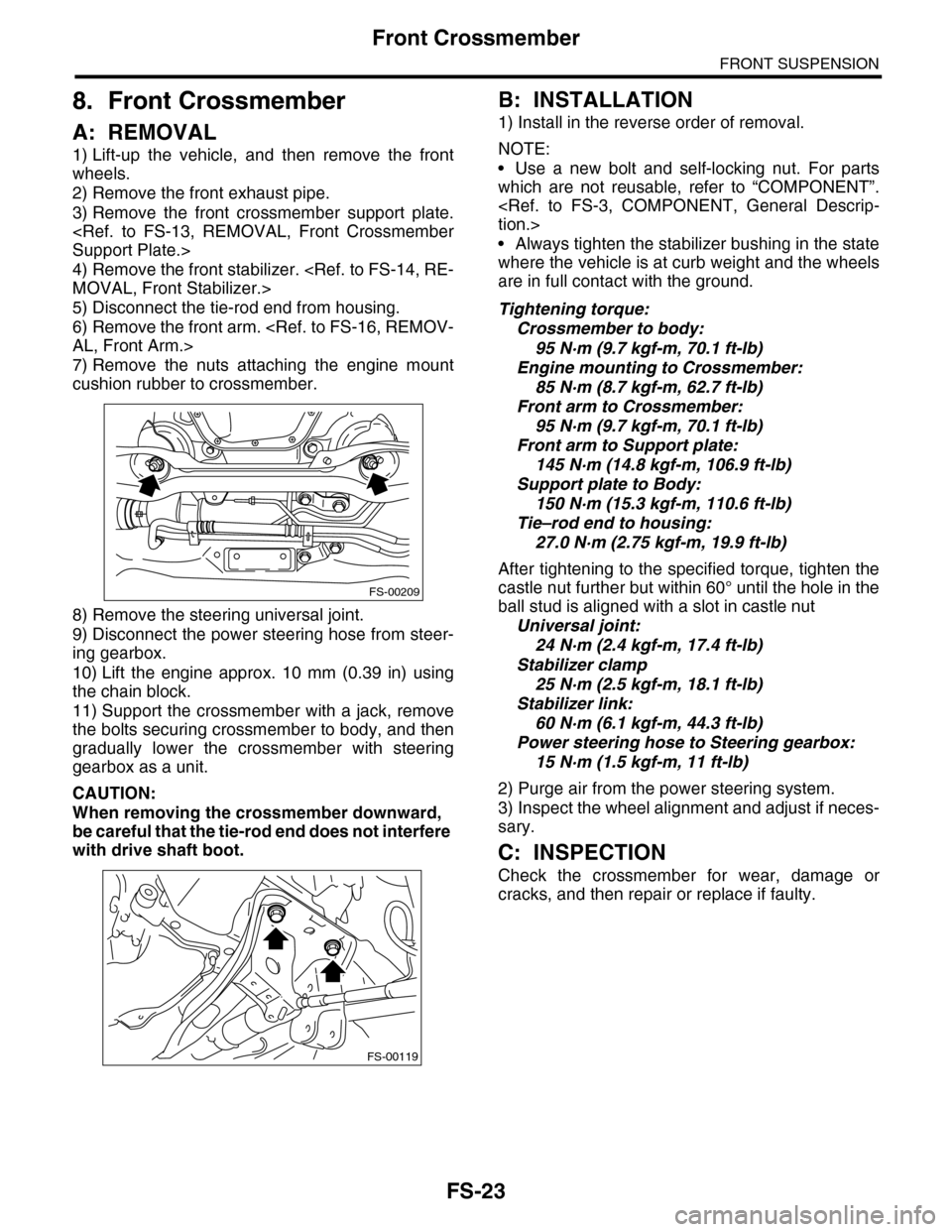

A: REMOVAL

1) Lift-up the vehicle, and then remove the front

wheels.

2) Remove the front exhaust pipe.

3) Remove the front crossmember support plate.

4) Remove the front stabilizer.

5) Disconnect the tie-rod end from housing.

6) Remove the front arm.

7) Remove the nuts attaching the engine mount

cushion rubber to crossmember.

8) Remove the steering universal joint.

9) Disconnect the power steering hose from steer-

ing gearbox.

10) Lift the engine approx. 10 mm (0.39 in) using

the chain block.

11) Support the crossmember with a jack, remove

the bolts securing crossmember to body, and then

gradually lower the crossmember with steering

gearbox as a unit.

CAUTION:

When removing the crossmember downward,

be careful that the tie-rod end does not interfere

with drive shaft boot.

B: INSTALLATION

1) Install in the reverse order of removal.

NOTE:

•Use a new bolt and self-locking nut. For parts

which are not reusable, refer to “COMPONENT”.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

Tightening torque:

Crossmember to body:

95 N·m (9.7 kgf-m, 70.1 ft-lb)

Engine mounting to Crossmember:

85 N·m (8.7 kgf-m, 62.7 ft-lb)

Front arm to Crossmember:

95 N·m (9.7 kgf-m, 70.1 ft-lb)

Front arm to Support plate:

145 N·m (14.8 kgf-m, 106.9 ft-lb)

Support plate to Body:

150 N·m (15.3 kgf-m, 110.6 ft-lb)

Tie–rod end to housing:

27.0 N·m (2.75 kgf-m, 19.9 ft-lb)

After tightening to the specified torque, tighten the

castle nut further but within 60° until the hole in the

ball stud is aligned with a slot in castle nut

Universal joint:

24 N·m (2.4 kgf-m, 17.4 ft-lb)

Stabilizer clamp

25 N·m (2.5 kgf-m, 18.1 ft-lb)

Stabilizer link:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

Power steering hose to Steering gearbox:

15 N·m (1.5 kgf-m, 11 ft-lb)

2) Purge air from the power steering system.

3) Inspect the wheel alignment and adjust if neces-

sary.

C: INSPECTION

Check the crossmember for wear, damage or

cracks, and then repair or replace if faulty.

FS-00209

FS-00119

Page 875 of 2453

PB-4

Parking Brake Pedal

PARKING BRAKE

2. Parking Brake Pedal

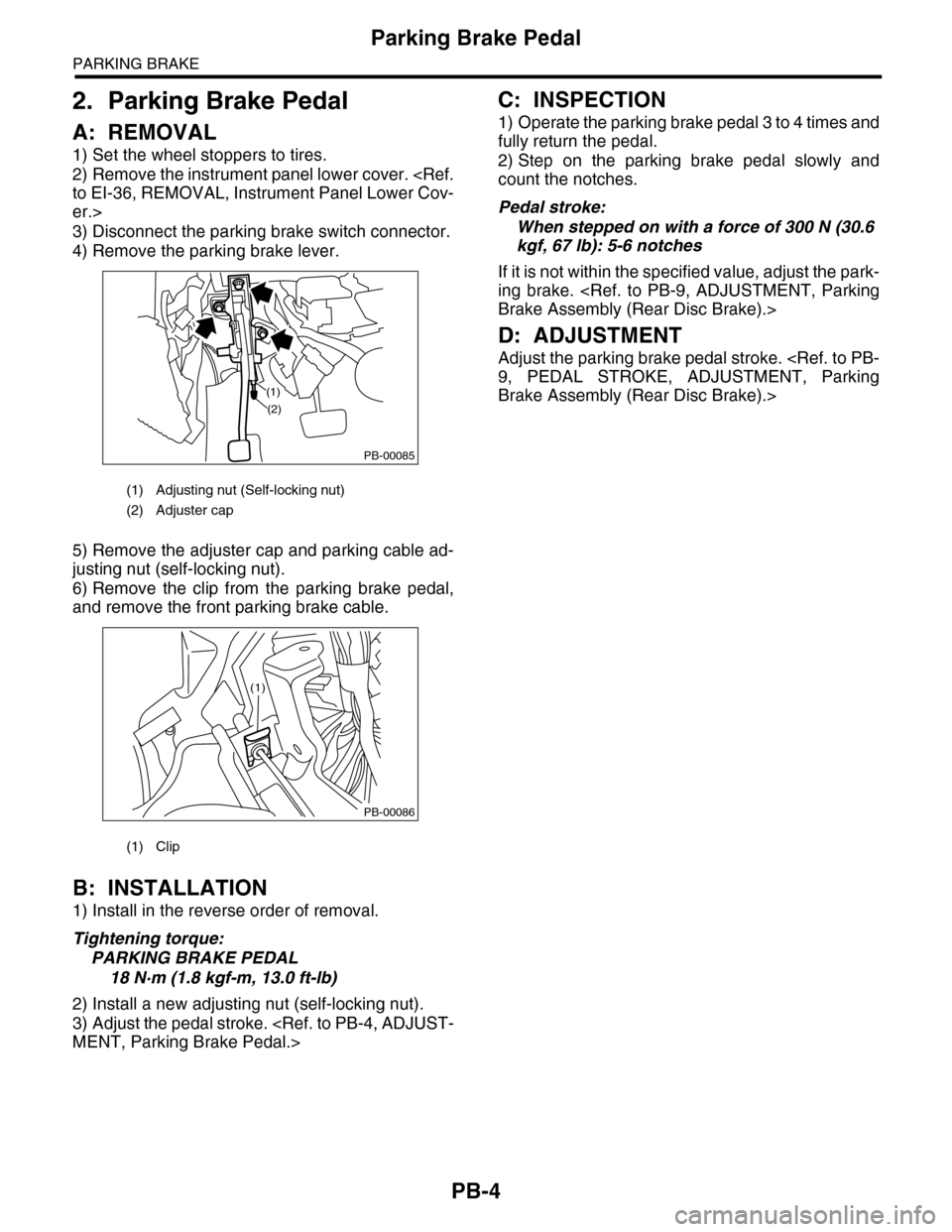

A: REMOVAL

1) Set the wheel stoppers to tires.

2) Remove the instrument panel lower cover.

er.>

3) Disconnect the parking brake switch connector.

4) Remove the parking brake lever.

5) Remove the adjuster cap and parking cable ad-

justing nut (self-locking nut).

6) Remove the clip from the parking brake pedal,

and remove the front parking brake cable.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

PARKING BRAKE PEDAL

18 N·m (1.8 kgf-m, 13.0 ft-lb)

2) Install a new adjusting nut (self-locking nut).

3) Adjust the pedal stroke.

C: INSPECTION

1) Operate the parking brake pedal 3 to 4 times and

fully return the pedal.

2) Step on the parking brake pedal slowly and

count the notches.

Pedal stroke:

When stepped on with a force of 300 N (30.6

kgf, 67 lb): 5-6 notches

If it is not within the specified value, adjust the park-

ing brake.

D: ADJUSTMENT

Adjust the parking brake pedal stroke.

Brake Assembly (Rear Disc Brake).>

(1) Adjusting nut (Self-locking nut)

(2) Adjuster cap

(1) Clip

PB-00085

(1)

(2)

PB-00086

(1)