Ecm SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 182 of 2453

CC(ETC)(diag)-15

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

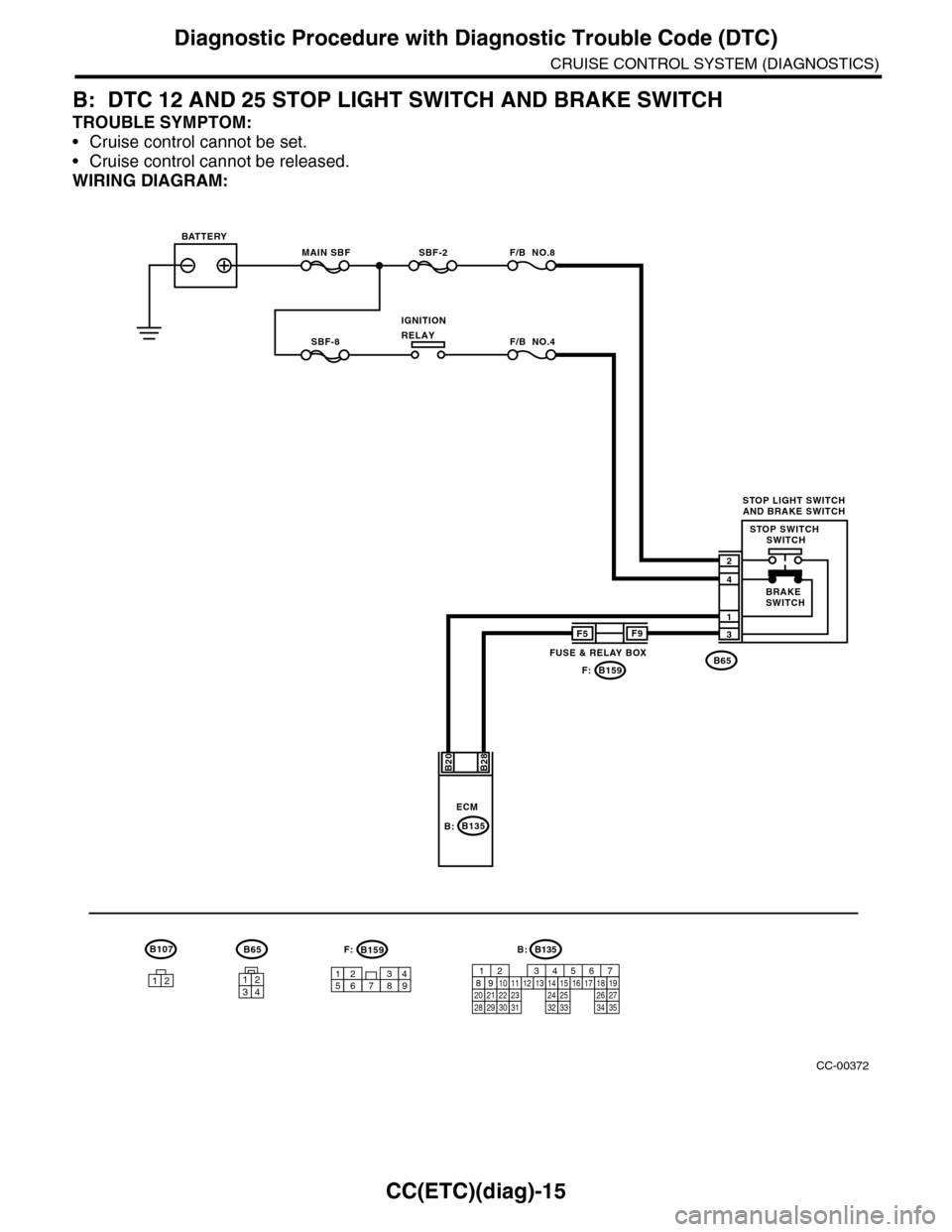

B: DTC 12 AND 25 STOP LIGHT SWITCH AND BRAKE SWITCH

TROUBLE SYMPTOM:

•Cruise control cannot be set.

•Cruise control cannot be released.

WIRING DIAGRAM:

CC-00372

B65

MAIN SBFSBF-2 F/B NO.8

B65

4

3

1

2

B28B20

1234

SBF-8 F/B NO.4

F5

B159

F9

F:

947621538

B159F:

ECM

BATTERY

STOP LIGHT SWITCHAND BRAKE SWITCH

BRAKESWITCH

STOP SWITCH SWITCH

IGNITIONRELAY

FUSE & RELAY BOX

12

B107

B135B:

B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

B:

Page 183 of 2453

CC(ETC)(diag)-16

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

Step Check Yes No

1CHECK STOP LIGHT SWITCH AND BRAKE

SWITCH CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the stop light switch and brake

switch harness connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(B65) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.•Check fuse No.

8 (in fuse & relay

box).

•Check for open

or short in the har-

ness between stop

light/brake switch

and fuse & relay

box.

2CHECK STOP LIGHT SWITCH AND BRAKE

SWITCH CIRCUIT.

Measure the voltage between harness connec-

tor terminal and chassis ground.

Connector & terminal

(B65) No. 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.•Check fuse No.

4 (in fuse & relay

box).

•Check for open

or short in the har-

ness between stop

light/brake switch

and fuse & relay

box.

3CHECK STOP LIGHT SWITCH AND BRAKE

SWITCH CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector of ECM.

3) Measure the resistance between ECM har-

ness connector terminal and stop light switch

and brake switch harness connector terminal.

Connector & terminal

(B135) No. 28 — (B65) No. 3:

(B135) No. 20 — (B65) No. 1:

Is the resistance less than 10

Ω?

Go to step 4.Repair the har-

ness.

4Check Stop Light Switch and Brake Switch

Remove and check the stop light switch and

brake switch.

Are the stop light switch and

brake switch OK?

Replace the ECM.

Engine Control

Module (ECM).>

Replace the stop

light switch and

brake switch.

Page 184 of 2453

CC(ETC)(diag)-17

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

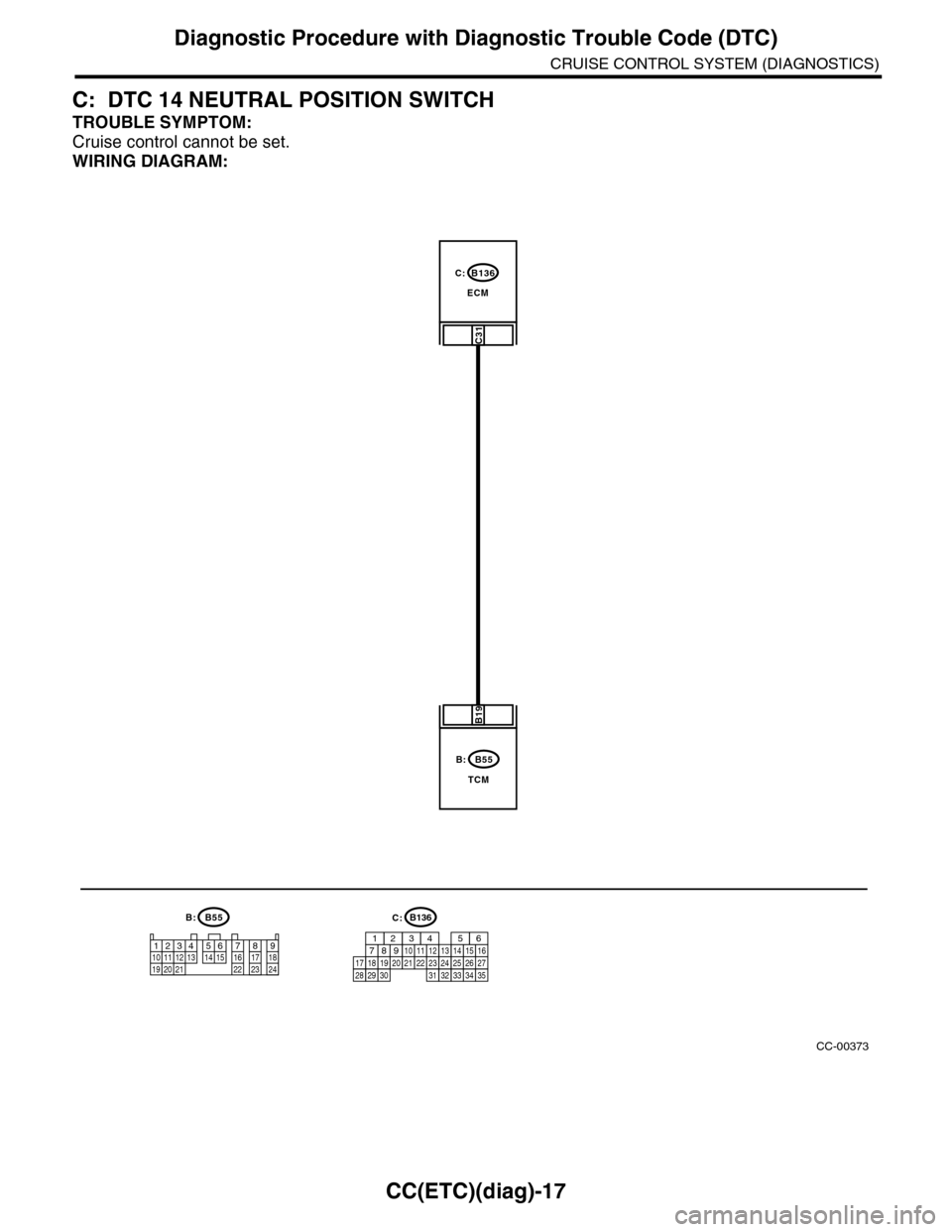

C: DTC 14 NEUTRAL POSITION SWITCH

TROUBLE SYMPTOM:

Cruise control cannot be set.

WIRING DIAGRAM:

CC-00373

B136

ECM

C31

C:

B19

B55

TCM

B:

12341011 1219 20 21135614 1578916 17 1822 23 24

B55B:C:B136

16101112131415252430

9871718192028212223293231

123456

2726333435

Page 185 of 2453

CC(ETC)(diag)-18

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

Step Check Yes No

1CHECK NEUTRAL POSITION SWITCH.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch and Subaru Select

Monitor switch to ON.

3) Select {Engine} from the main menu.

4) Then, select {Current Data Display &

Save}.

5) Check the neutral position switch signal by

shifting the select lever to “P” or “N” range.

Is Subaru Select Monitor ON

when select lever is shifted into

“P” or “N” range? Is Subaru

Select Monitor OFF when

select lever is shifted to a

range other than the “P” or “N”

range?

Replace the ECM.

Engine Control

Module (ECM).>

Go to step 2.

2CHECK TCM OUTPUT VOLTAGE.

1) Turn the ignition switch to ON.

2) Measure the voltage between TCM har-

ness connector terminal and chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (–):

Is voltage more than 10 V

when select lever is shifted to a

range other than “P” or “N”

range? Is voltage less than 1 V

when select lever is shifted into

“P” or “N” range?

Go to step 3.Check the TCM.

tic Procedure.>

3CHECK HARNESS BETWEEN TCM AND

ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

TCM and ECM.

3) Measure the resistance between TCM har-

ness connector terminal and ECM harness

connector terminal.

Connector & terminal

(B136) No. 31 — (B55) No. 19:

Is the resistance less than 10

Ω?

Replace the ECM.

Engine Control

Module (ECM).>

Repair the wiring

harness.

Page 186 of 2453

CC(ETC)(diag)-19

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

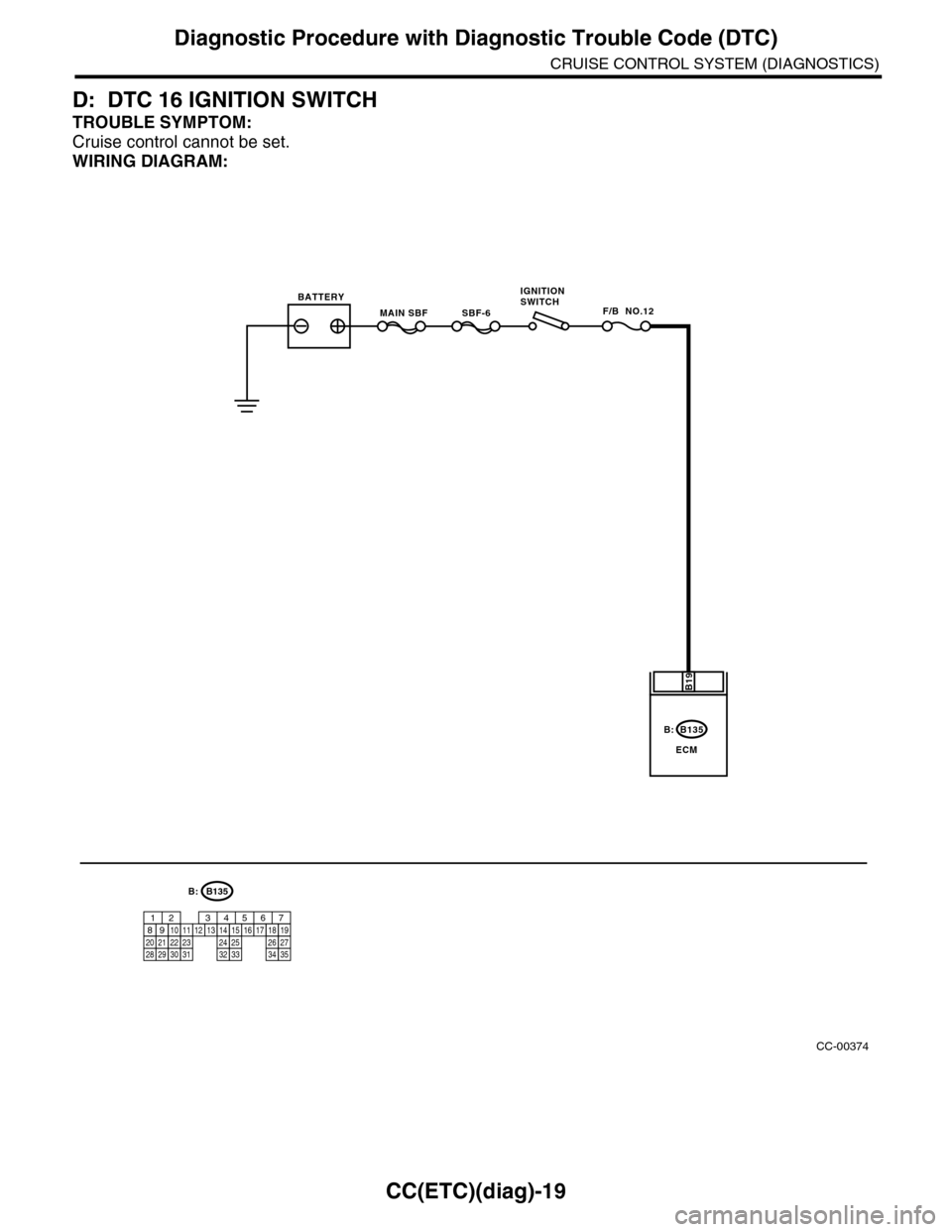

D: DTC 16 IGNITION SWITCH

TROUBLE SYMPTOM:

Cruise control cannot be set.

WIRING DIAGRAM:

CC-00374

B135

ECM

B19

B:

MAIN SBFF/B NO.12SBF-6

BATTERYIGNITIONSWITCH

B:B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

Page 187 of 2453

CC(ETC)(diag)-20

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

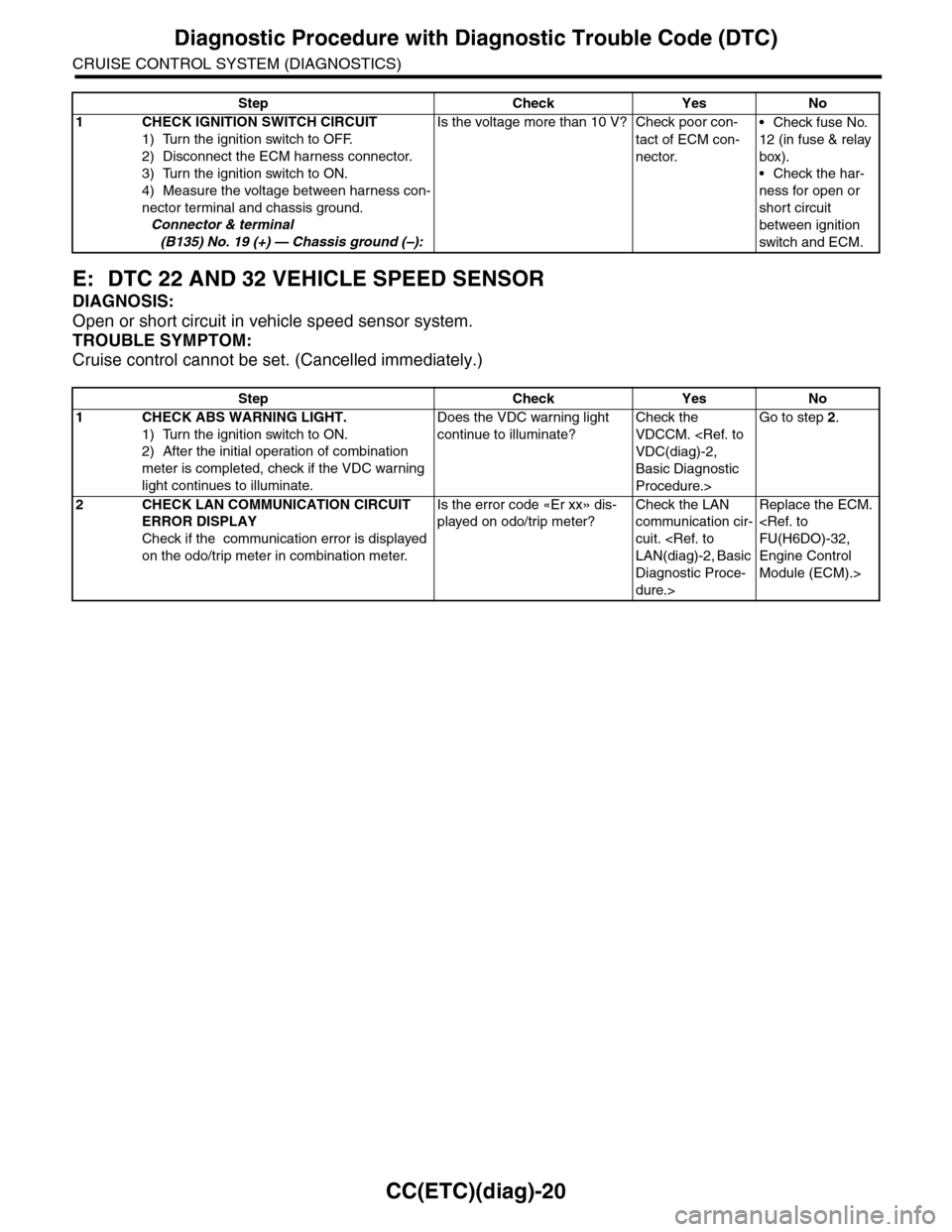

E: DTC 22 AND 32 VEHICLE SPEED SENSOR

DIAGNOSIS:

Open or short circuit in vehicle speed sensor system.

TROUBLE SYMPTOM:

Cruise control cannot be set. (Cancelled immediately.)

Step Check Yes No

1 CHECK IGNITION SWITCH CIRCUIT

1) Turn the ignition switch to OFF.

2) Disconnect the ECM harness connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(B135) No. 19 (+) — Chassis ground (–):

Is the voltage more than 10 V? Check poor con-

tact of ECM con-

nector.

•Check fuse No.

12 (in fuse & relay

box).

•Check the har-

ness for open or

short circuit

between ignition

switch and ECM.

Step Check Yes No

1CHECK ABS WARNING LIGHT.

1) Turn the ignition switch to ON.

2) After the initial operation of combination

meter is completed, check if the VDC warning

light continues to illuminate.

Does the VDC warning light

continue to illuminate?

Check the

VDCCM.

Basic Diagnostic

Procedure.>

Go to step 2.

2CHECK LAN COMMUNICATION CIRCUIT

ERROR DISPLAY

Check if the communication error is displayed

on the odo/trip meter in combination meter.

Is the error code «Er xx» dis-

played on odo/trip meter?

Check the LAN

communication cir-

cuit.

Diagnostic Proce-

dure.>

Replace the ECM.

Engine Control

Module (ECM).>

Page 364 of 2453

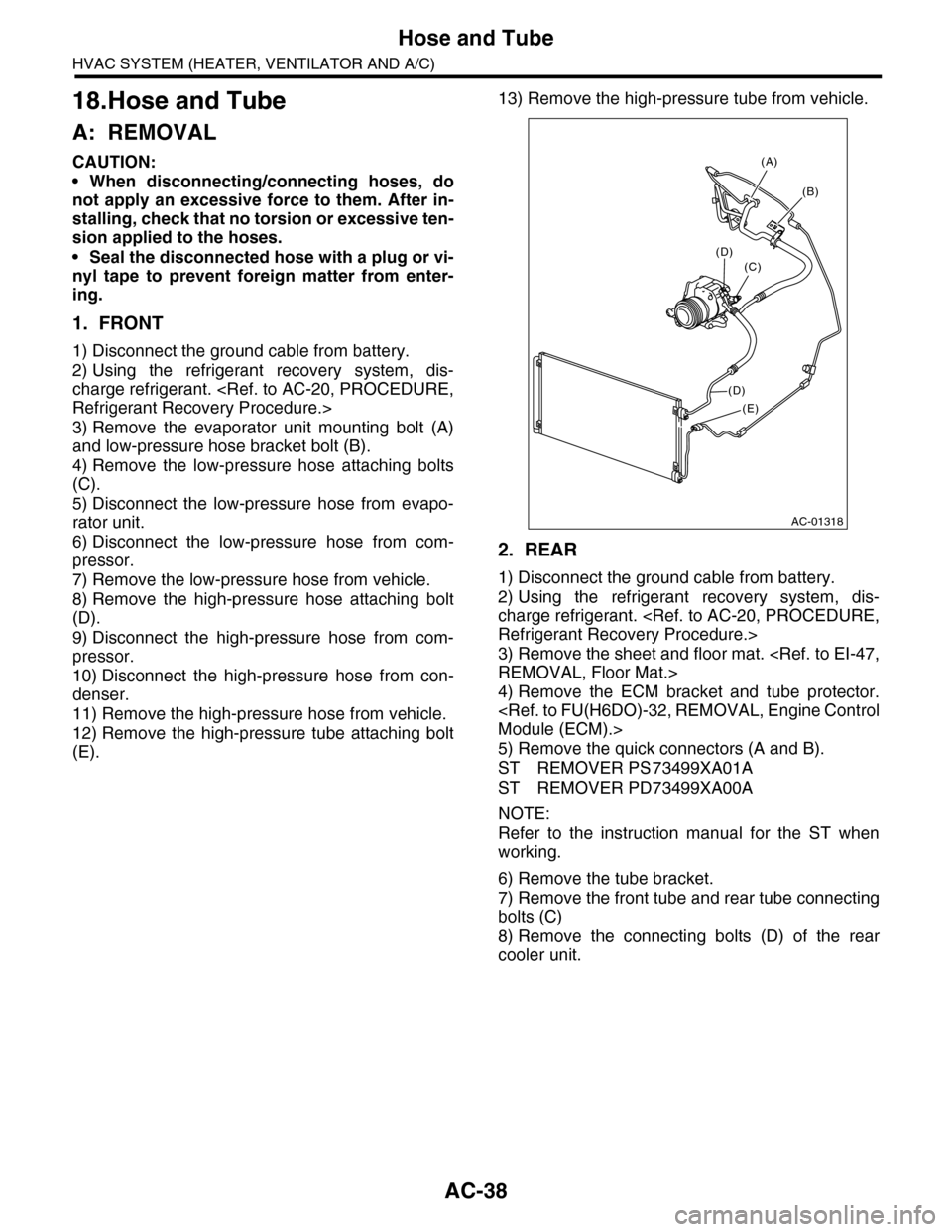

AC-38

Hose and Tube

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

18.Hose and Tube

A: REMOVAL

CAUTION:

•When disconnecting/connecting hoses, do

not apply an excessive force to them. After in-

stalling, check that no torsion or excessive ten-

sion applied to the hoses.

•Seal the disconnected hose with a plug or vi-

nyl tape to prevent foreign matter from enter-

ing.

1. FRONT

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge refrigerant.

3) Remove the evaporator unit mounting bolt (A)

and low-pressure hose bracket bolt (B).

4) Remove the low-pressure hose attaching bolts

(C).

5) Disconnect the low-pressure hose from evapo-

rator unit.

6) Disconnect the low-pressure hose from com-

pressor.

7) Remove the low-pressure hose from vehicle.

8) Remove the high-pressure hose attaching bolt

(D).

9) Disconnect the high-pressure hose from com-

pressor.

10) Disconnect the high-pressure hose from con-

denser.

11) Remove the high-pressure hose from vehicle.

12) Remove the high-pressure tube attaching bolt

(E).

13) Remove the high-pressure tube from vehicle.

2. REAR

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge refrigerant.

3) Remove the sheet and floor mat.

4) Remove the ECM bracket and tube protector.

5) Remove the quick connectors (A and B).

ST REMOVER PS 73499XA01A

ST REMOVER PD73499XA00A

NOTE:

Refer to the instruction manual for the ST when

working.

6) Remove the tube bracket.

7) Remove the front tube and rear tube connecting

bolts (C)

8) Remove the connecting bolts (D) of the rear

cooler unit.

AC-01318

(A)

(B)

(D)(C)

(D)

(E)

Page 388 of 2453

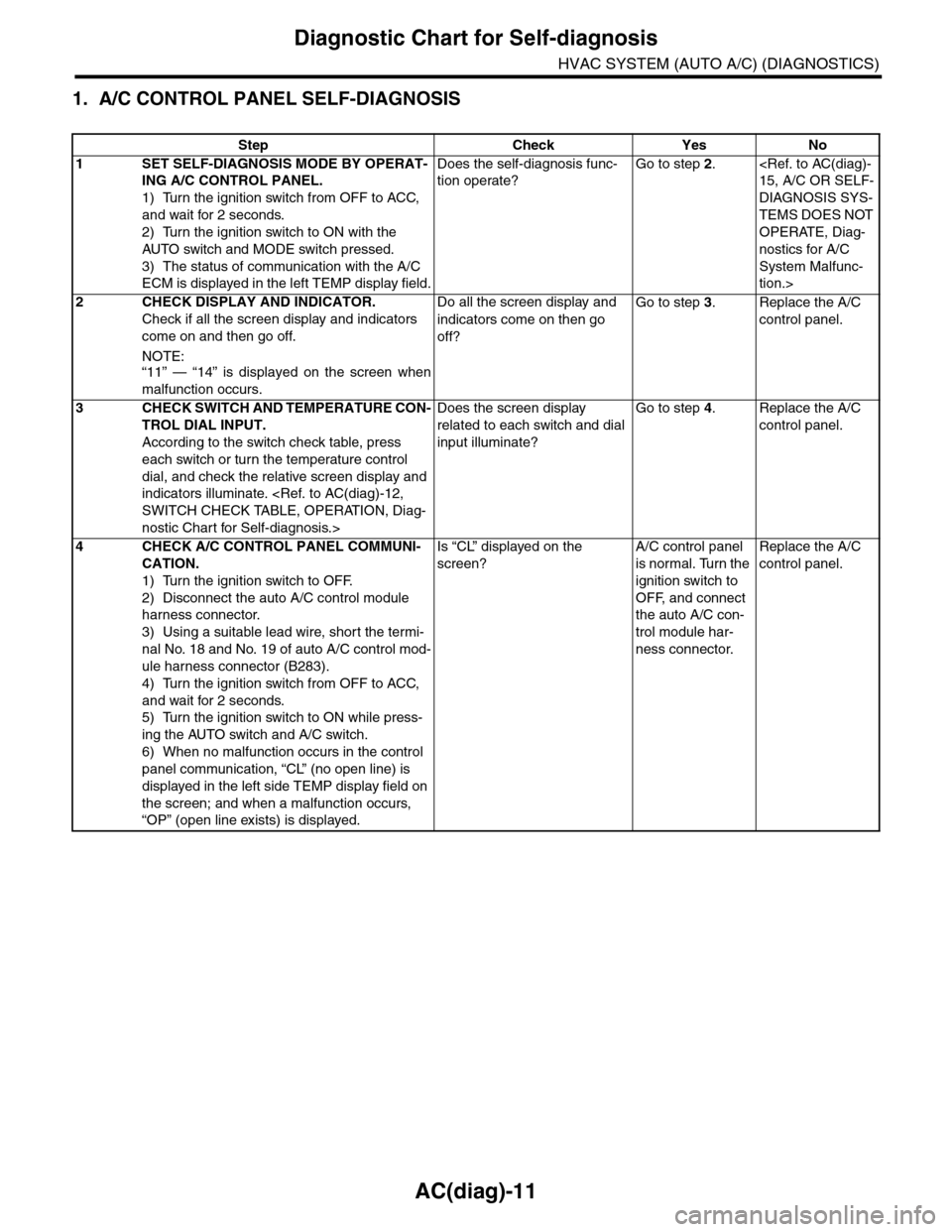

AC(diag)-11

Diagnostic Chart for Self-diagnosis

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

1. A/C CONTROL PANEL SELF-DIAGNOSIS

Step Check Yes No

1SET SELF-DIAGNOSIS MODE BY OPERAT-

ING A/C CONTROL PANEL.

1) Turn the ignition switch from OFF to ACC,

and wait for 2 seconds.

2) Turn the ignition switch to ON with the

AUTO switch and MODE switch pressed.

3) The status of communication with the A/C

ECM is displayed in the left TEMP display field.

Does the self-diagnosis func-

tion operate?

Go to step 2.

DIAGNOSIS SYS-

TEMS DOES NOT

OPERATE, Diag-

nostics for A/C

System Malfunc-

tion.>

2CHECK DISPLAY AND INDICATOR.

Check if all the screen display and indicators

come on and then go off.

NOTE:“11” — “14” is displayed on the screen when

malfunction occurs.

Do all the screen display and

indicators come on then go

off?

Go to step 3.Replace the A/C

control panel.

3CHECK SWITCH AND TEMPERATURE CON-

TROL DIAL INPUT.

According to the switch check table, press

each switch or turn the temperature control

dial, and check the relative screen display and

indicators illuminate.

nostic Chart for Self-diagnosis.>

Does the screen display

related to each switch and dial

input illuminate?

Go to step 4.Replace the A/C

control panel.

4CHECK A/C CONTROL PANEL COMMUNI-

CATION.

1) Turn the ignition switch to OFF.

2) Disconnect the auto A/C control module

harness connector.

3) Using a suitable lead wire, short the termi-

nal No. 18 and No. 19 of auto A/C control mod-

ule harness connector (B283).

4) Turn the ignition switch from OFF to ACC,

and wait for 2 seconds.

5) Turn the ignition switch to ON while press-

ing the AUTO switch and A/C switch.

6) When no malfunction occurs in the control

panel communication, “CL” (no open line) is

displayed in the left side TEMP display field on

the screen; and when a malfunction occurs,

“OP” (open line exists) is displayed.

Is “CL” displayed on the

screen?

A/C control panel

is normal. Turn the

ignition switch to

OFF, and connect

the auto A/C con-

trol module har-

ness connector.

Replace the A/C

control panel.

Page 397 of 2453

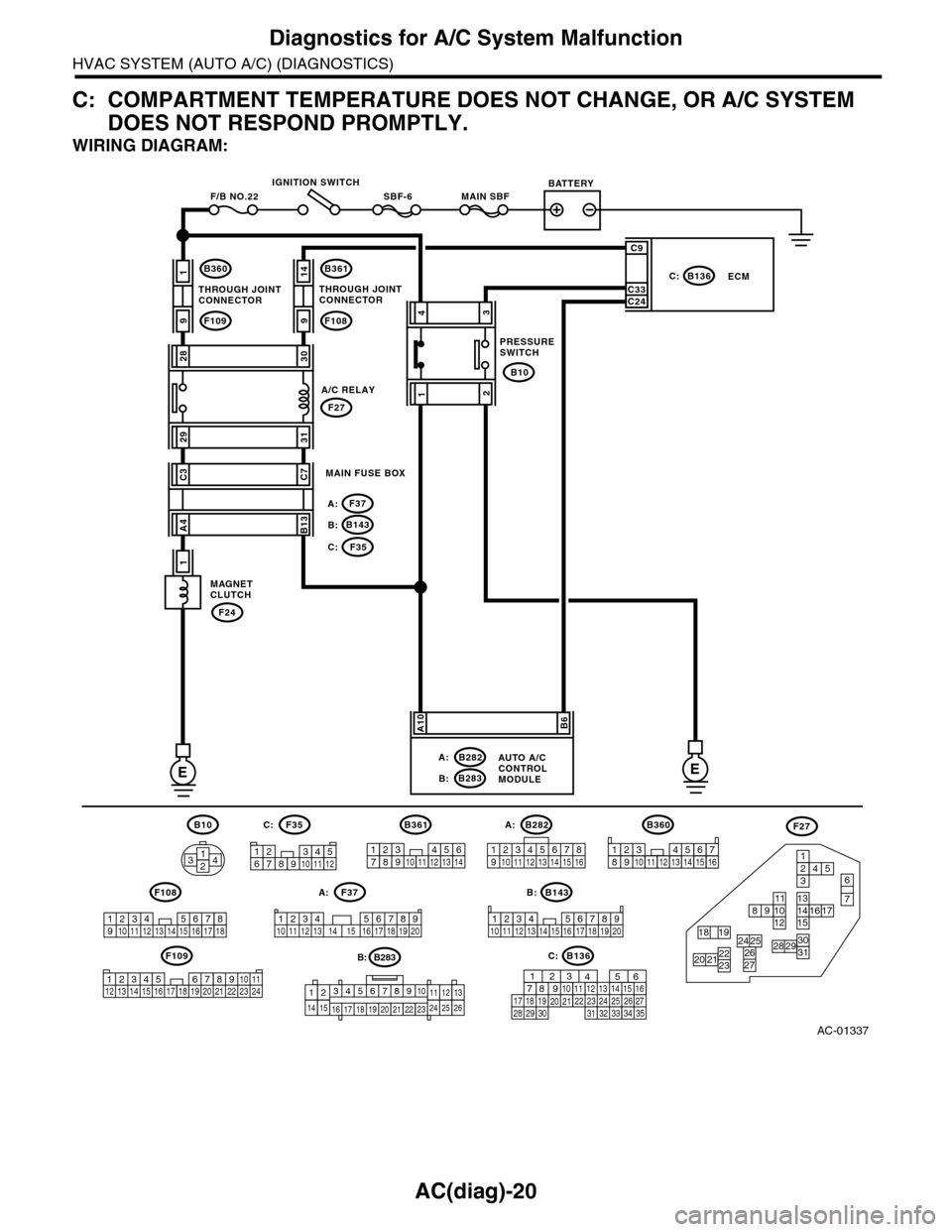

AC(diag)-20

Diagnostics for A/C System Malfunction

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

C: COMPARTMENT TEMPERATURE DOES NOT CHANGE, OR A/C SYSTEM

DOES NOT RESPOND PROMPTLY.

WIRING DIAGRAM:

AC-01337

MAIN SBFSBF-6F/B NO.22

B360

F109

B143B:

F37A:

F35C:

1

9

F24

1

B361

F108

B136C:ECM

B283B:

B282A:

F27

B10

14

9

2830

2931

EE

C3C7

A4B13

43

12

C9

C33C24

A10B6

AUTO A/CCONTROLMODULE

MAGNETCLUTCH

MAIN FUSE BOX

THROUGH JOINTCONNECTORTHROUGH JOINTCONNECTOR

IGNITION SWITCHBATTERY

PRESSURESWITCH

A/C RELAY

B282B10 A:

B143

B360

F109

F108B:F37A:

F35F27C:

12345678910 11 12 13 14 15 16

1234 5678910 11 12 13 14 15 16 17 18 19 20

1234567891011122314

234 567891112 13 14 17 18 19 201101516

B361

1234567891011121314

123 8910411 12 13 14 15 165671718

12389104111213 1415165671236

7

45

131415

11

3031

1617891012

2627

18 192928222320 21

24 25

3412 8910 1112 13 14 15 16 17 18 19 20 21 22 23 24567

B136C:

1289563410 11 121920 2129 3031

13 14 15161727281822 2324 25 267

32 3334 35

B283

345678910

16 17 18 19 20

121112132425262122231415

B:

Page 399 of 2453

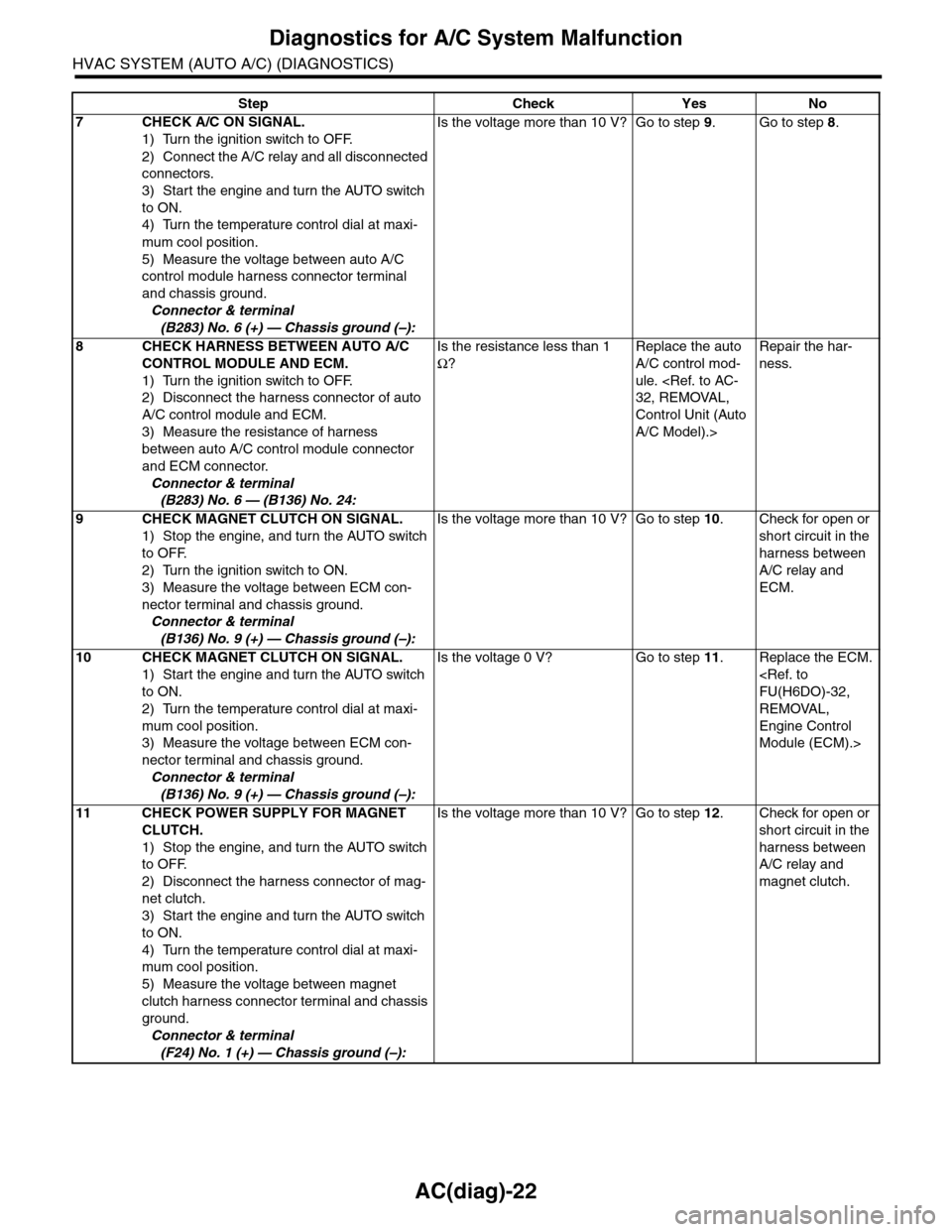

AC(diag)-22

Diagnostics for A/C System Malfunction

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

7CHECK A/C ON SIGNAL.

1) Turn the ignition switch to OFF.

2) Connect the A/C relay and all disconnected

connectors.

3) Start the engine and turn the AUTO switch

to ON.

4) Turn the temperature control dial at maxi-

mum cool position.

5) Measure the voltage between auto A/C

control module harness connector terminal

and chassis ground.

Connector & terminal

(B283) No. 6 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 9.Go to step 8.

8CHECK HARNESS BETWEEN AUTO A/C

CONTROL MODULE AND ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector of auto

A/C control module and ECM.

3) Measure the resistance of harness

between auto A/C control module connector

and ECM connector.

Connector & terminal

(B283) No. 6 — (B136) No. 24:

Is the resistance less than 1

Ω?

Replace the auto

A/C control mod-

ule.

Control Unit (Auto

A/C Model).>

Repair the har-

ness.

9CHECK MAGNET CLUTCH ON SIGNAL.

1) Stop the engine, and turn the AUTO switch

to OFF.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM con-

nector terminal and chassis ground.

Connector & terminal

(B136) No. 9 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 10.Check for open or

short circuit in the

harness between

A/C relay and

ECM.

10 CHECK MAGNET CLUTCH ON SIGNAL.

1) Start the engine and turn the AUTO switch

to ON.

2) Turn the temperature control dial at maxi-

mum cool position.

3) Measure the voltage between ECM con-

nector terminal and chassis ground.

Connector & terminal

(B136) No. 9 (+) — Chassis ground (–):

Is the voltage 0 V? Go to step 11.Replace the ECM.

REMOVAL,

Engine Control

Module (ECM).>

11 CHECK POWER SUPPLY FOR MAGNET

CLUTCH.

1) Stop the engine, and turn the AUTO switch

to OFF.

2) Disconnect the harness connector of mag-

net clutch.

3) Start the engine and turn the AUTO switch

to ON.

4) Turn the temperature control dial at maxi-

mum cool position.

5) Measure the voltage between magnet

clutch harness connector terminal and chassis

ground.

Connector & terminal

(F24) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 12.Check for open or

short circuit in the

harness between

A/C relay and

magnet clutch.

Step Check Yes No