Intake SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 925 of 2453

PS-45

Oil Pump

POWER ASSISTED SYSTEM (POWER STEERING)

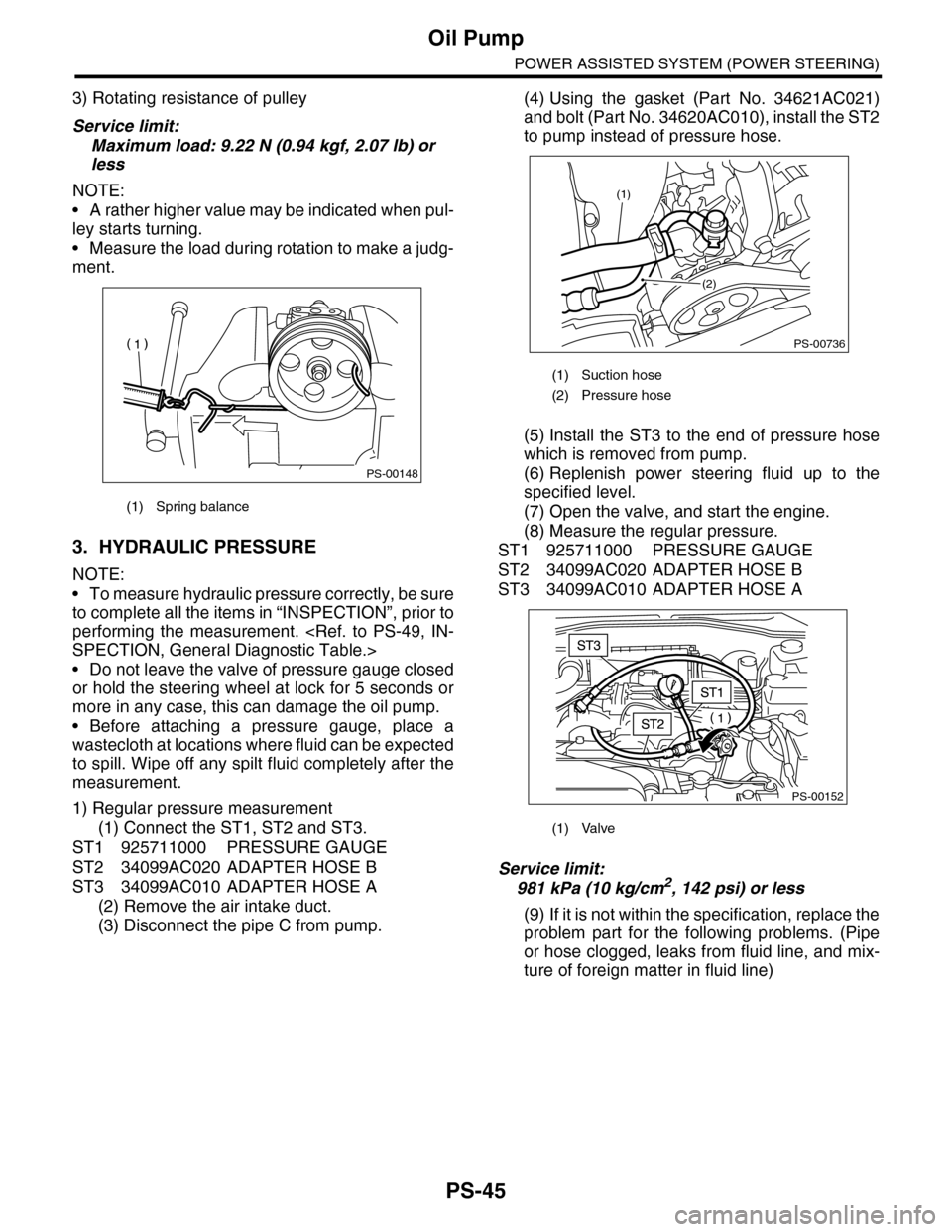

3) Rotating resistance of pulley

Service limit:

Maximum load: 9.22 N (0.94 kgf, 2.07 lb) or

less

NOTE:

•A rather higher value may be indicated when pul-

ley starts turning.

•Measure the load during rotation to make a judg-

ment.

3. HYDRAULIC PRESSURE

NOTE:

•To measure hydraulic pressure correctly, be sure

to complete all the items in “INSPECTION”, prior to

performing the measurement.

•Do not leave the valve of pressure gauge closed

or hold the steering wheel at lock for 5 seconds or

more in any case, this can damage the oil pump.

•Before attaching a pressure gauge, place a

wastecloth at locations where fluid can be expected

to spill. Wipe off any spilt fluid completely after the

measurement.

1) Regular pressure measurement

(1) Connect the ST1, ST2 and ST3.

ST1 925711000 PRESSURE GAUGE

ST2 34099AC020 ADAPTER HOSE B

ST3 34099AC010 ADAPTER HOSE A

(2) Remove the air intake duct.

(3) Disconnect the pipe C from pump.

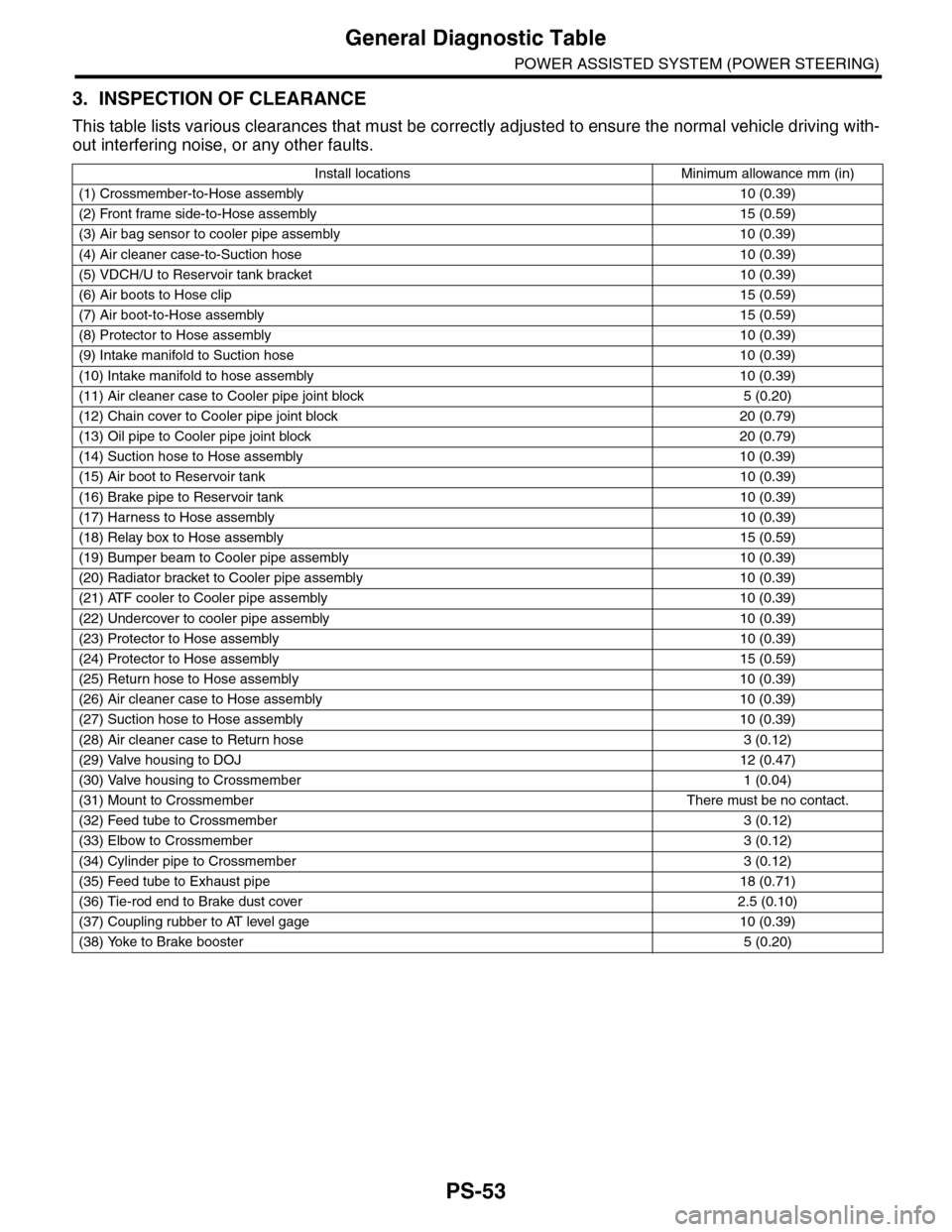

(4) Using the gasket (Part No. 34621AC021)

and bolt (Part No. 34620AC010), install the ST2

to pump instead of pressure hose.

(5) Install the ST3 to the end of pressure hose

which is removed from pump.

(6) Replenish power steering fluid up to the

specified level.

(7) Open the valve, and start the engine.

(8) Measure the regular pressure.

ST1 925711000 PRESSURE GAUGE

ST2 34099AC020 ADAPTER HOSE B

ST3 34099AC010 ADAPTER HOSE A

Service limit:

981 kPa (10 kg/cm2, 142 psi) or less

(9) If it is not within the specification, replace the

problem part for the following problems. (Pipe

or hose clogged, leaks from fluid line, and mix-

ture of foreign matter in fluid line)

(1) Spring balance

PS-00148

(1) Suction hose

(2) Pressure hose

(1) Valve

PS-00736

(1)

(2)

PS-00152

Page 933 of 2453

PS-53

General Diagnostic Table

POWER ASSISTED SYSTEM (POWER STEERING)

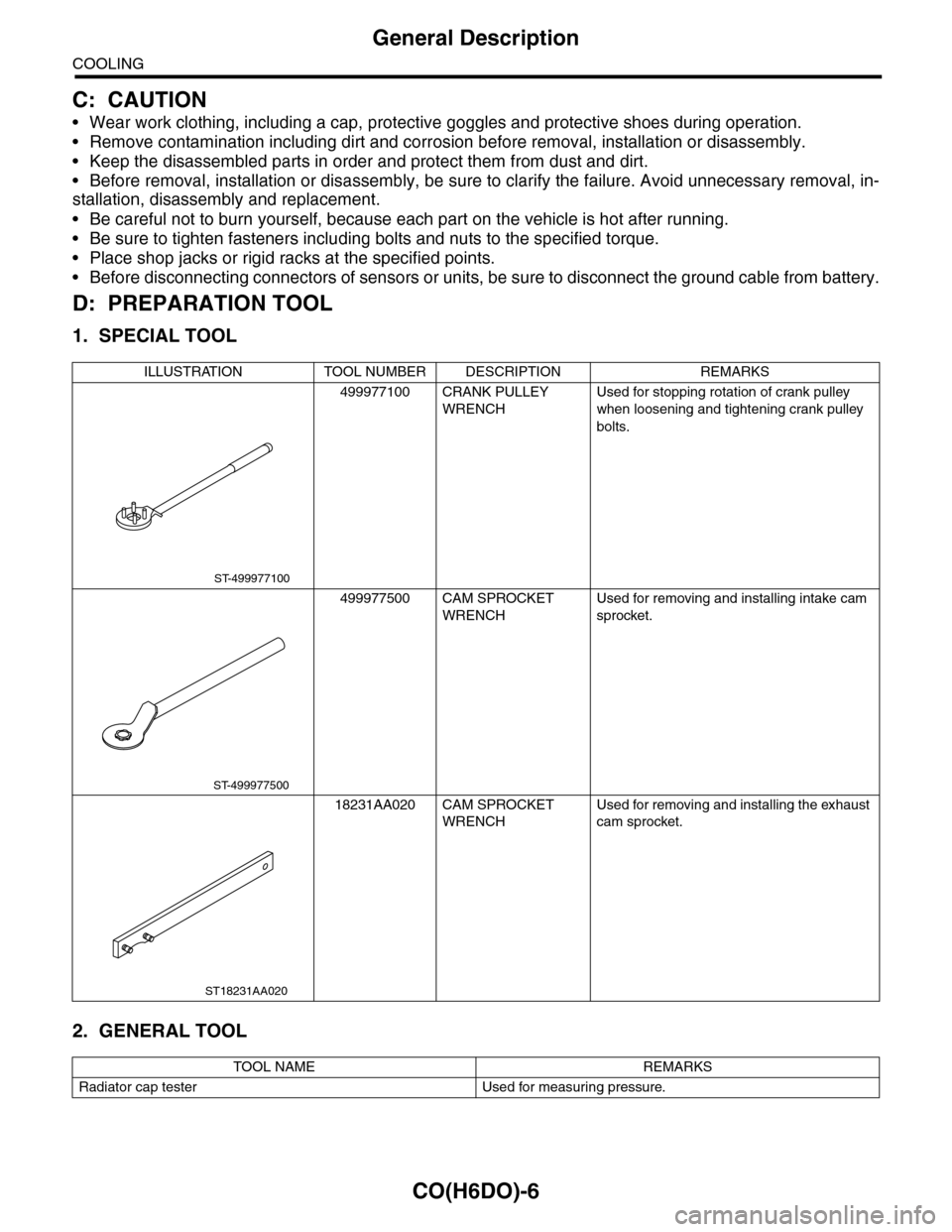

3. INSPECTION OF CLEARANCE

This table lists various clearances that must be correctly adjusted to ensure the normal vehicle driving with-

out interfering noise, or any other faults.

Install locations Minimum allowance mm (in)

(1) Crossmember-to-Hose assembly 10 (0.39)

(2) Front frame side-to-Hose assembly 15 (0.59)

(3) Air bag sensor to cooler pipe assembly 10 (0.39)

(4) Air cleaner case-to-Suction hose 10 (0.39)

(5) VDCH/U to Reservoir tank bracket 10 (0.39)

(6) Air boots to Hose clip15 (0.59)

(7) Air boot-to-Hose assembly15 (0.59)

(8) Protector to Hose assembly10 (0.39)

(9) Intake manifold to Suction hose 10 (0.39)

(10) Intake manifold to hose assembly 10 (0.39)

(11) Air cleaner case to Cooler pipe joint block 5 (0.20)

(12) Chain cover to Cooler pipe joint block 20 (0.79)

(13) Oil pipe to Cooler pipe joint block 20 (0.79)

(14) Suction hose to Hose assembly 10 (0.39)

(15) Air boot to Reservoir tank10 (0.39)

(16) Brake pipe to Reservoir tank10 (0.39)

(17) Harness to Hose assembly10 (0.39)

(18) Relay box to Hose assembly15 (0.59)

(19) Bumper beam to Cooler pipe assembly 10 (0.39)

(20) Radiator bracket to Cooler pipe assembly 10 (0.39)

(21) ATF cooler to Cooler pipe assembly 10 (0.39)

(22) Undercover to cooler pipe assembly 10 (0.39)

(23) Protector to Hose assembly10 (0.39)

(24) Protector to Hose assembly15 (0.59)

(25) Return hose to Hose assembly 10 (0.39)

(26) Air cleaner case to Hose assembly 10 (0.39)

(27) Suction hose to Hose assembly 10 (0.39)

(28) Air cleaner case to Return hose 3 (0.12)

(29) Valve housing to DOJ12 (0.47)

(30) Valve housing to Crossmember 1 (0.04)

(31) Mount to Crossmember There must be no contact.

(32) Feed tube to Crossmember3 (0.12)

(33) Elbow to Crossmember3 (0.12)

(34) Cylinder pipe to Crossmember 3 (0.12)

(35) Feed tube to Exhaust pipe18 (0.71)

(36) Tie-rod end to Brake dust cover 2.5 (0.10)

(37) Coupling rubber to AT level gage 10 (0.39)

(38) Yoke to Brake booster5 (0.20)

Page 1125 of 2453

CO(H6DO)-6

General Description

COOLING

C: CAUTION

•Wear work clothing, including a cap, protective goggles and protective shoes during operation.

•Remove contamination including dirt and corrosion before removal, installation or disassembly.

•Keep the disassembled parts in order and protect them from dust and dirt.

•Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, in-

stallation, disassembly and replacement.

•Be careful not to burn yourself, because each part on the vehicle is hot after running.

•Be sure to tighten fasteners including bolts and nuts to the specified torque.

•Place shop jacks or rigid racks at the specified points.

•Before disconnecting connectors of sensors or units, be sure to disconnect the ground cable from battery.

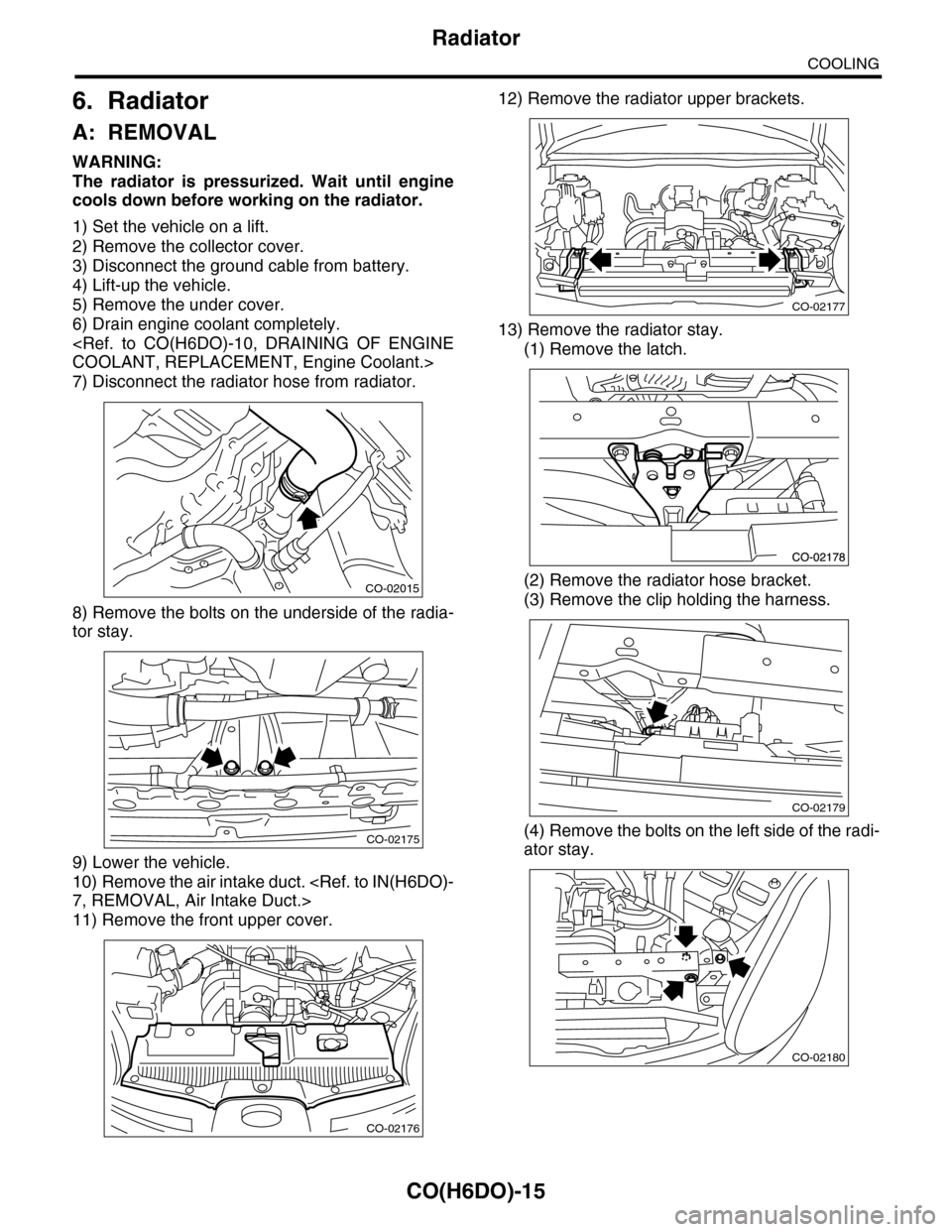

D: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

499977100 CRANK PULLEY

WRENCH

Used for stopping rotation of crank pulley

when loosening and tightening crank pulley

bolts.

499977500 CAM SPROCKET

WRENCH

Used for removing and installing intake cam

sprocket.

18231AA020 CAM SPROCKET

WRENCH

Used for removing and installing the exhaust

cam sprocket.

TOOL NAME REMARKS

Radiator cap tester Used for measuring pressure.

ST-499977100

ST-499977500

ST18231AA020

Page 1134 of 2453

CO(H6DO)-15

Radiator

COOLING

6. Radiator

A: REMOVAL

WARNING:

The radiator is pressurized. Wait until engine

cools down before working on the radiator.

1) Set the vehicle on a lift.

2) Remove the collector cover.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Remove the under cover.

6) Drain engine coolant completely.

7) Disconnect the radiator hose from radiator.

8) Remove the bolts on the underside of the radia-

tor stay.

9) Lower the vehicle.

10) Remove the air intake duct.

11) Remove the front upper cover.

12) Remove the radiator upper brackets.

13) Remove the radiator stay.

(1) Remove the latch.

(2) Remove the radiator hose bracket.

(3) Remove the clip holding the harness.

(4) Remove the bolts on the left side of the radi-

ator stay.

CO-02015

CO-02175

CO-02176

CO-02177

CO-02179

CO-02180

Page 1138 of 2453

CO(H6DO)-19

Radiator

COOLING

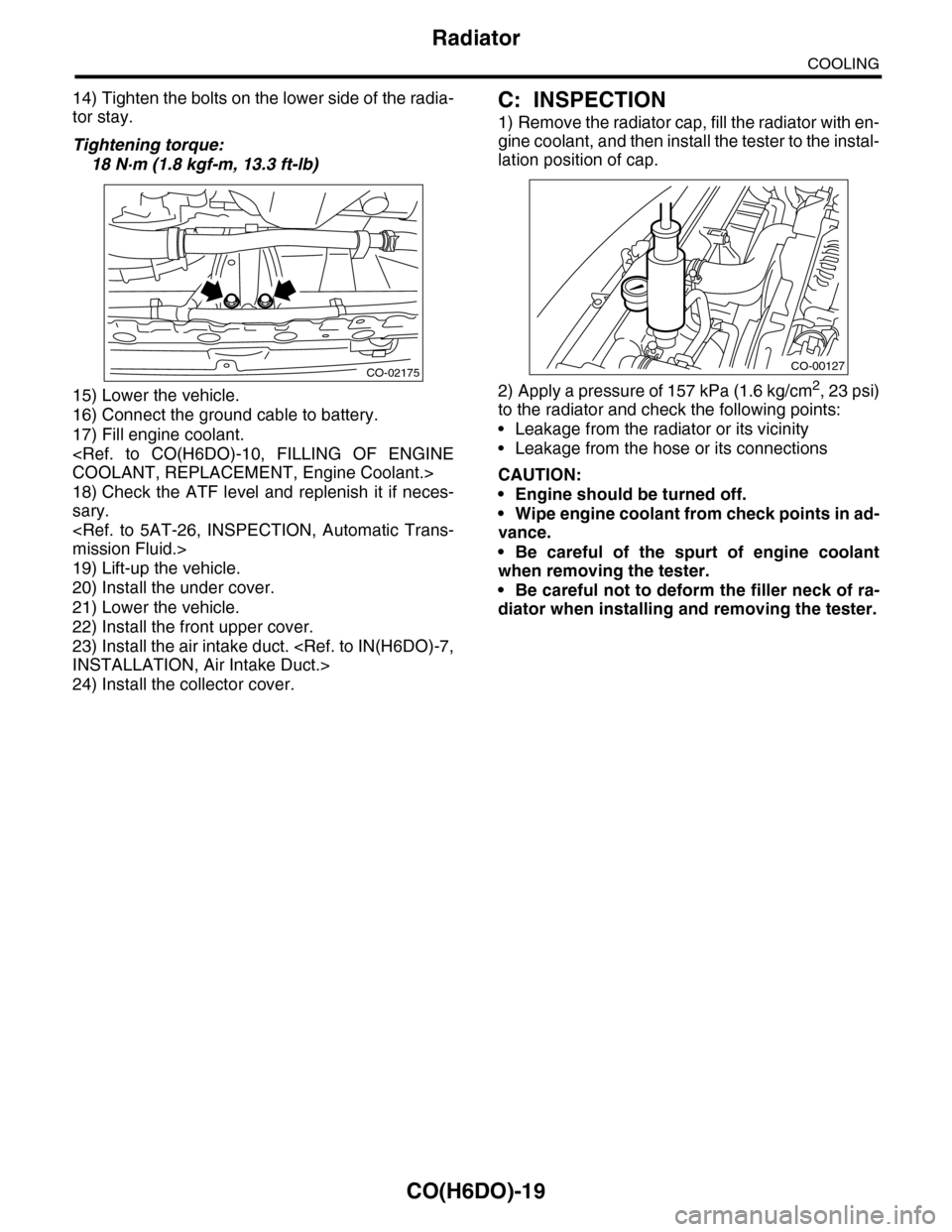

14) Tighten the bolts on the lower side of the radia-

tor stay.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

15) Lower the vehicle.

16) Connect the ground cable to battery.

17) Fill engine coolant.

18) Check the ATF level and replenish it if neces-

sary.

19) Lift-up the vehicle.

20) Install the under cover.

21) Lower the vehicle.

22) Install the front upper cover.

23) Install the air intake duct.

24) Install the collector cover.

C: INSPECTION

1) Remove the radiator cap, fill the radiator with en-

gine coolant, and then install the tester to the instal-

lation position of cap.

2) Apply a pressure of 157 kPa (1.6 kg/cm2, 23 psi)

to the radiator and check the following points:

•Leakage from the radiator or its vicinity

•Leakage from the hose or its connections

CAUTION:

•Engine should be turned off.

•Wipe engine coolant from check points in ad-

vance.

•Be careful of the spurt of engine coolant

when removing the tester.

•Be careful not to deform the filler neck of ra-

diator when installing and removing the tester.

CO-02175CO-00127

Page 1140 of 2453

CO(H6DO)-21

Radiator Main Fan and Fan Motor

COOLING

8. Radiator Main Fan and Fan

Motor

A: REMOVAL

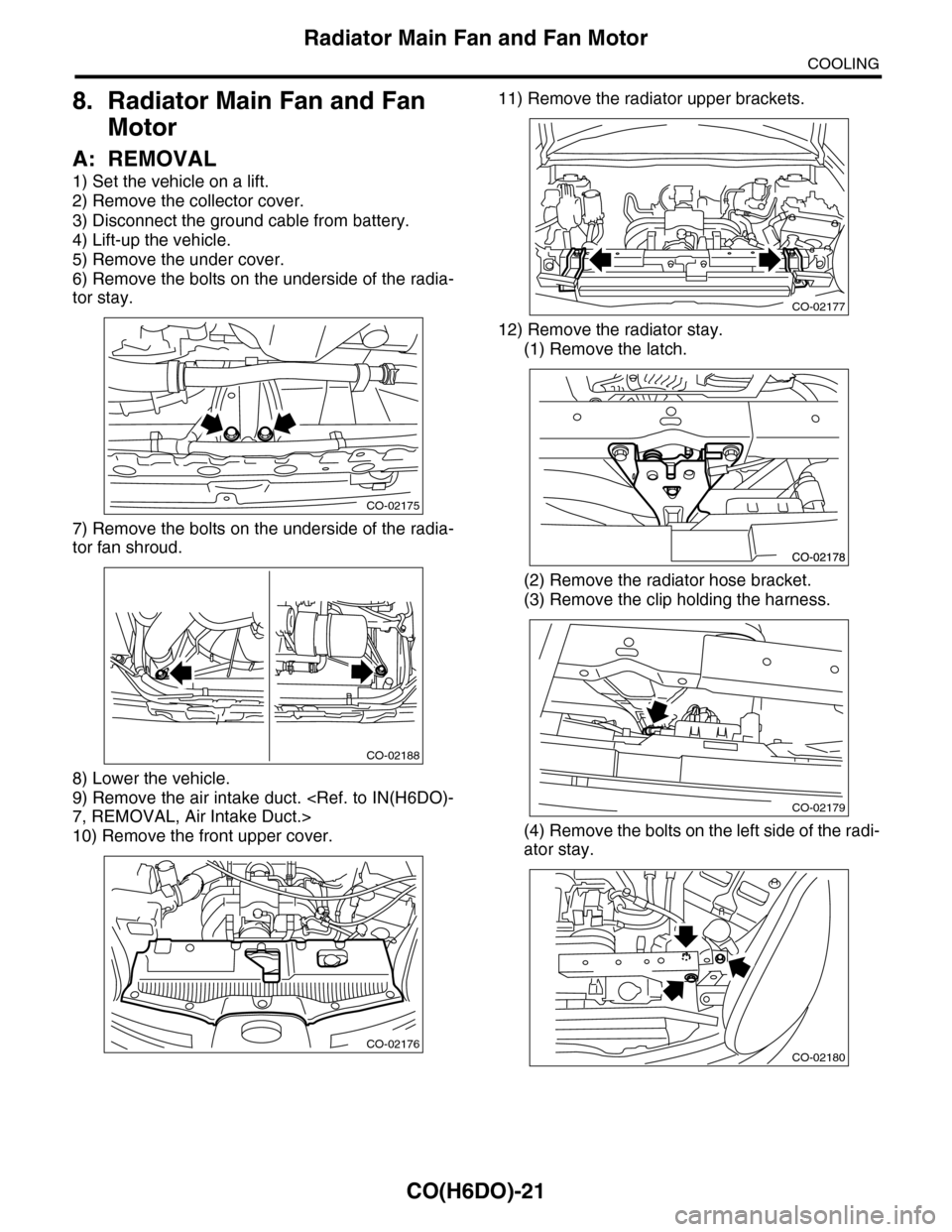

1) Set the vehicle on a lift.

2) Remove the collector cover.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Remove the under cover.

6) Remove the bolts on the underside of the radia-

tor stay.

7) Remove the bolts on the underside of the radia-

tor fan shroud.

8) Lower the vehicle.

9) Remove the air intake duct.

10) Remove the front upper cover.

11) Remove the radiator upper brackets.

12) Remove the radiator stay.

(1) Remove the latch.

(2) Remove the radiator hose bracket.

(3) Remove the clip holding the harness.

(4) Remove the bolts on the left side of the radi-

ator stay.

CO-02175

CO-02188

CO-02176

CO-02177

CO-02179

CO-02180

Page 1142 of 2453

CO(H6DO)-23

Radiator Main Fan and Fan Motor

COOLING

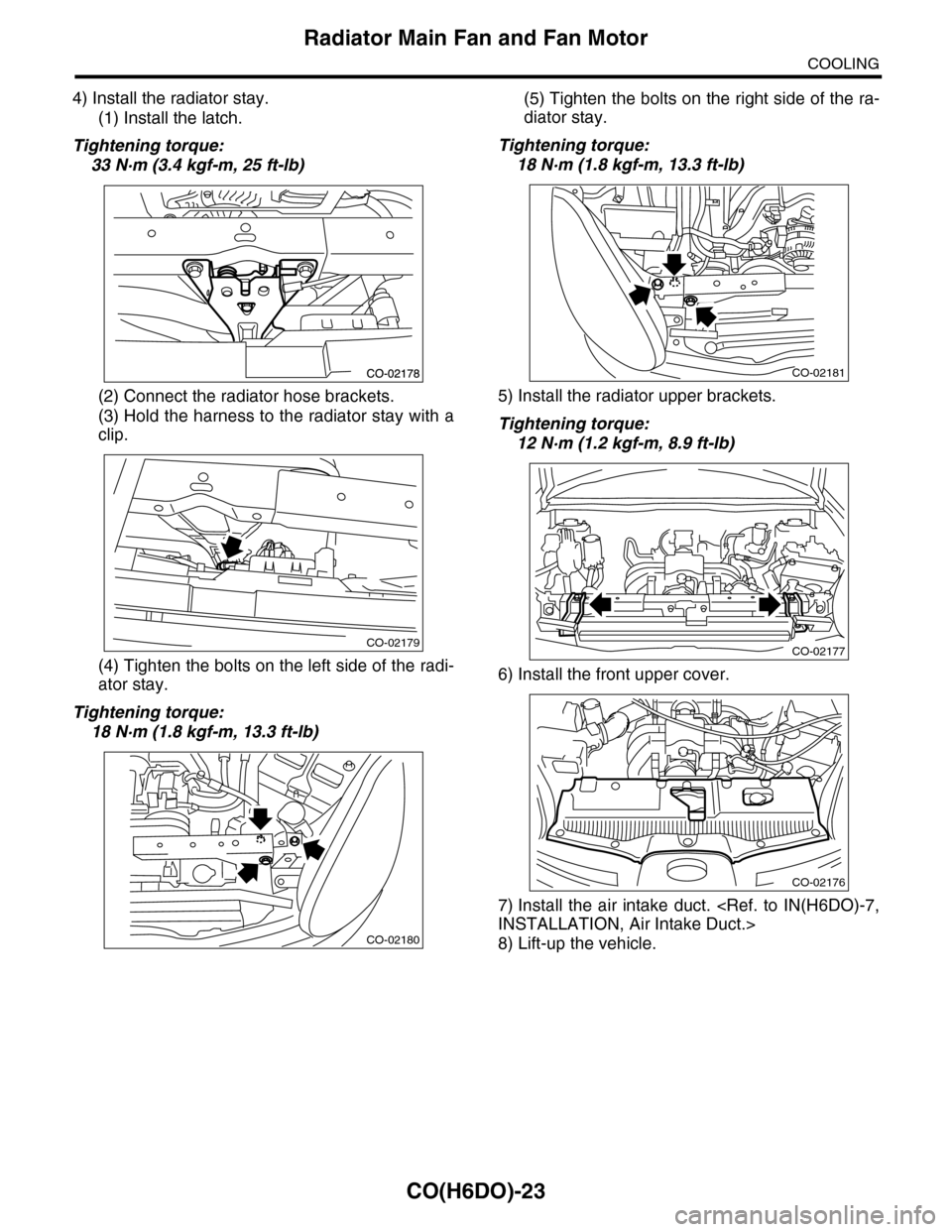

4) Install the radiator stay.

(1) Install the latch.

Tightening torque:

33 N·m (3.4 kgf-m, 25 ft-lb)

(2) Connect the radiator hose brackets.

(3) Hold the harness to the radiator stay with a

clip.

(4) Tighten the bolts on the left side of the radi-

ator stay.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

(5) Tighten the bolts on the right side of the ra-

diator stay.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

5) Install the radiator upper brackets.

Tightening torque:

12 N·m (1.2 kgf-m, 8.9 ft-lb)

6) Install the front upper cover.

7) Install the air intake duct.

8) Lift-up the vehicle.

CO-02179

CO-02180

CO-02181

CO-02177

CO-02176

Page 1145 of 2453

CO(H6DO)-26

Reservoir Tank

COOLING

10.Reservoir Tank

A: REMOVAL

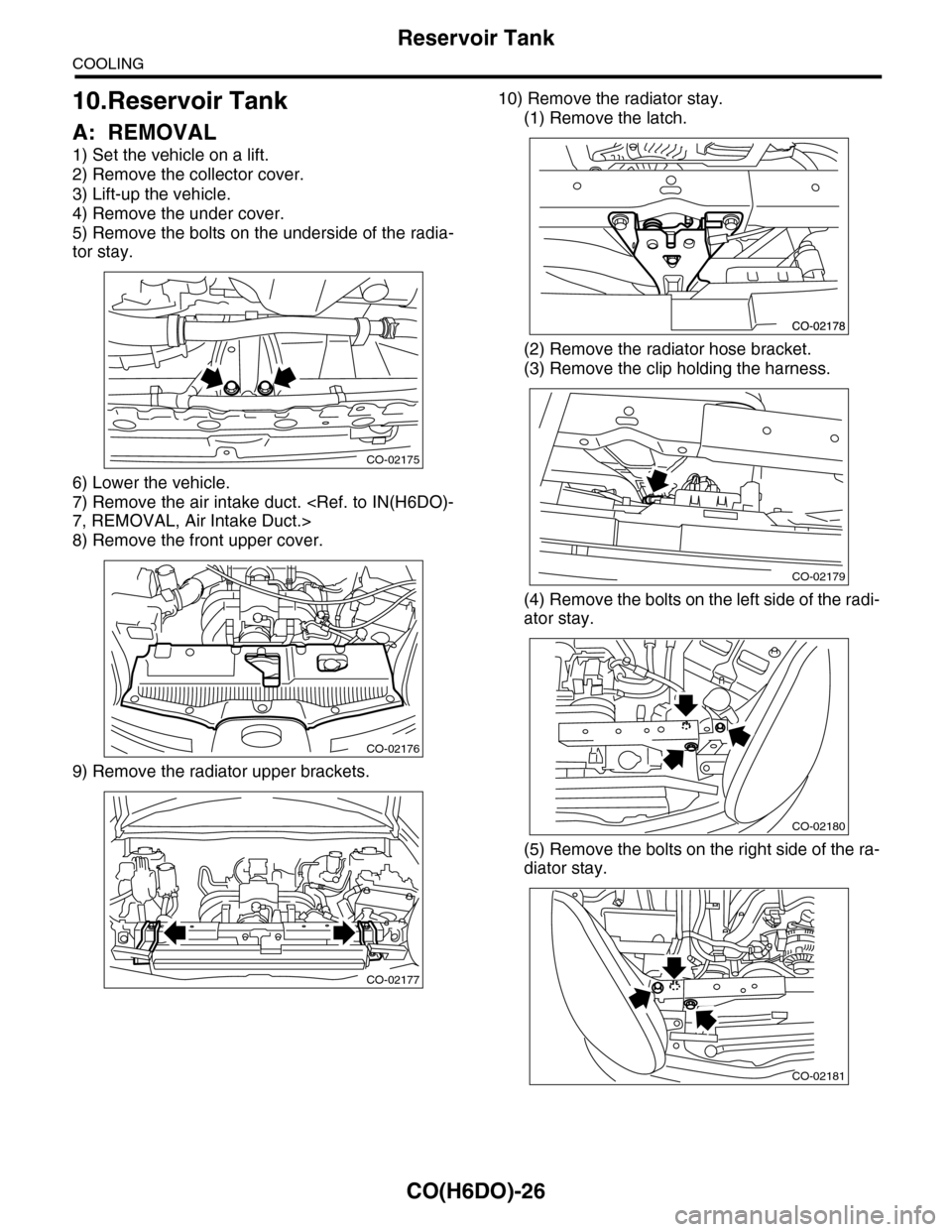

1) Set the vehicle on a lift.

2) Remove the collector cover.

3) Lift-up the vehicle.

4) Remove the under cover.

5) Remove the bolts on the underside of the radia-

tor stay.

6) Lower the vehicle.

7) Remove the air intake duct.

8) Remove the front upper cover.

9) Remove the radiator upper brackets.

10) Remove the radiator stay.

(1) Remove the latch.

(2) Remove the radiator hose bracket.

(3) Remove the clip holding the harness.

(4) Remove the bolts on the left side of the radi-

ator stay.

(5) Remove the bolts on the right side of the ra-

diator stay.

CO-02175

CO-02176

CO-02177

CO-02179

CO-02180

CO-02181

Page 1147 of 2453

CO(H6DO)-28

Reservoir Tank

COOLING

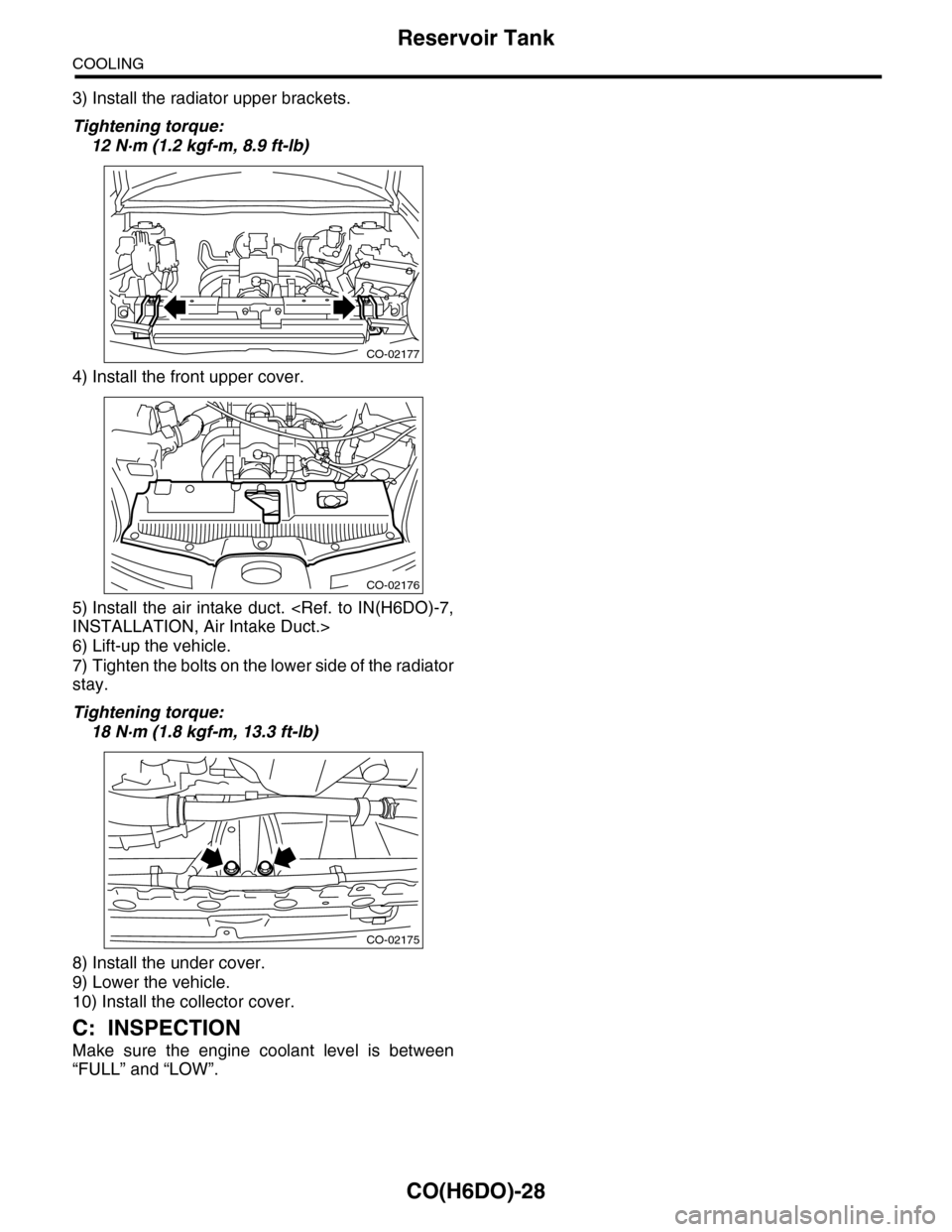

3) Install the radiator upper brackets.

Tightening torque:

12 N·m (1.2 kgf-m, 8.9 ft-lb)

4) Install the front upper cover.

5) Install the air intake duct.

6) Lift-up the vehicle.

7) Tighten the bolts on the lower side of the radiator

stay.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

8) Install the under cover.

9) Lower the vehicle.

10) Install the collector cover.

C: INSPECTION

Make sure the engine coolant level is between

“FULL” and “LOW”.

CO-02177

CO-02176

CO-02175

Page 1148 of 2453

CO(H6DO)-29

Radiator Fan Control Unit

COOLING

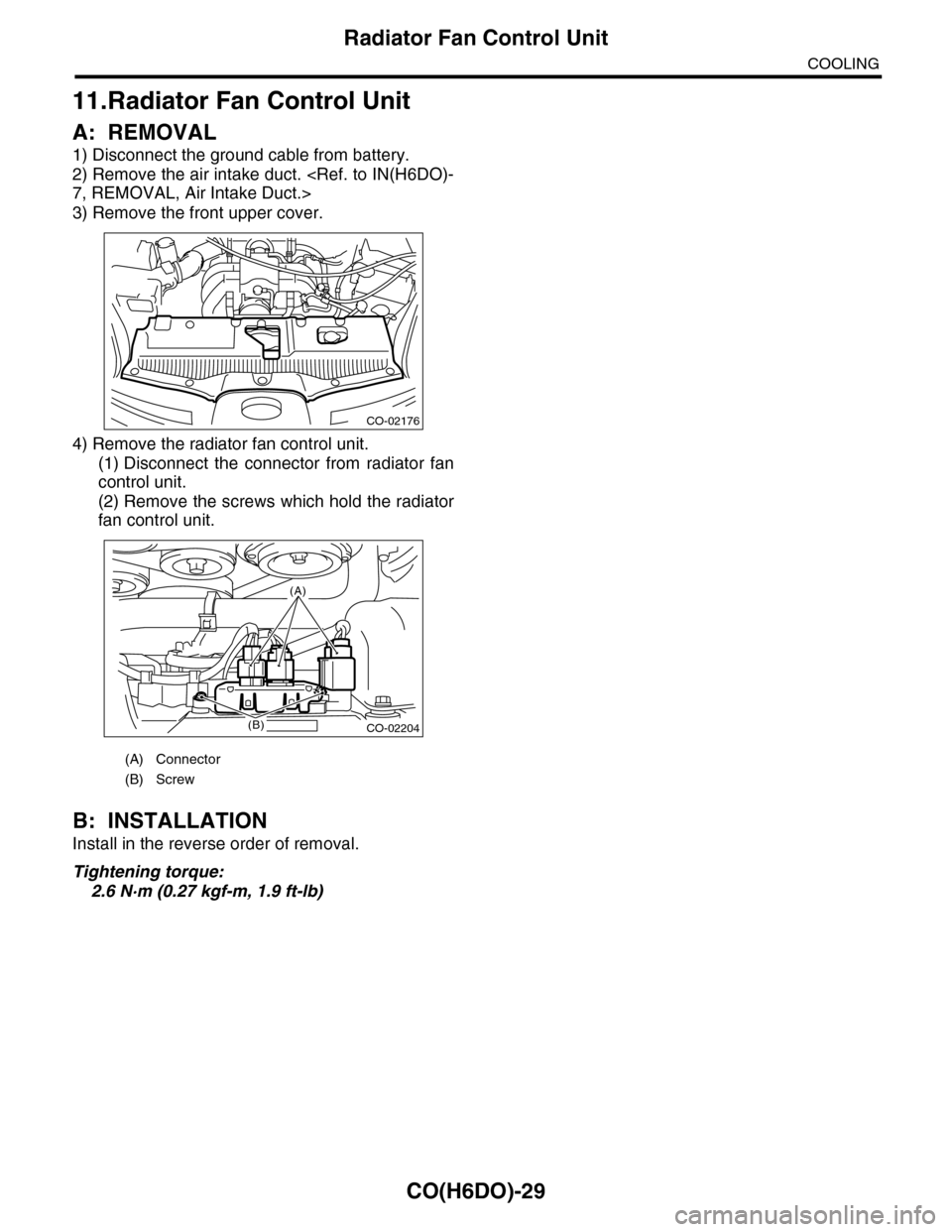

11.Radiator Fan Control Unit

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake duct.

3) Remove the front upper cover.

4) Remove the radiator fan control unit.

(1) Disconnect the connector from radiator fan

control unit.

(2) Remove the screws which hold the radiator

fan control unit.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

2.6 N·m (0.27 kgf-m, 1.9 ft-lb)

(A) Connector

(B) Screw

CO-02176

CO-02204

(A)

(B)