Negative SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1043 of 2453

VDC(diag)-51

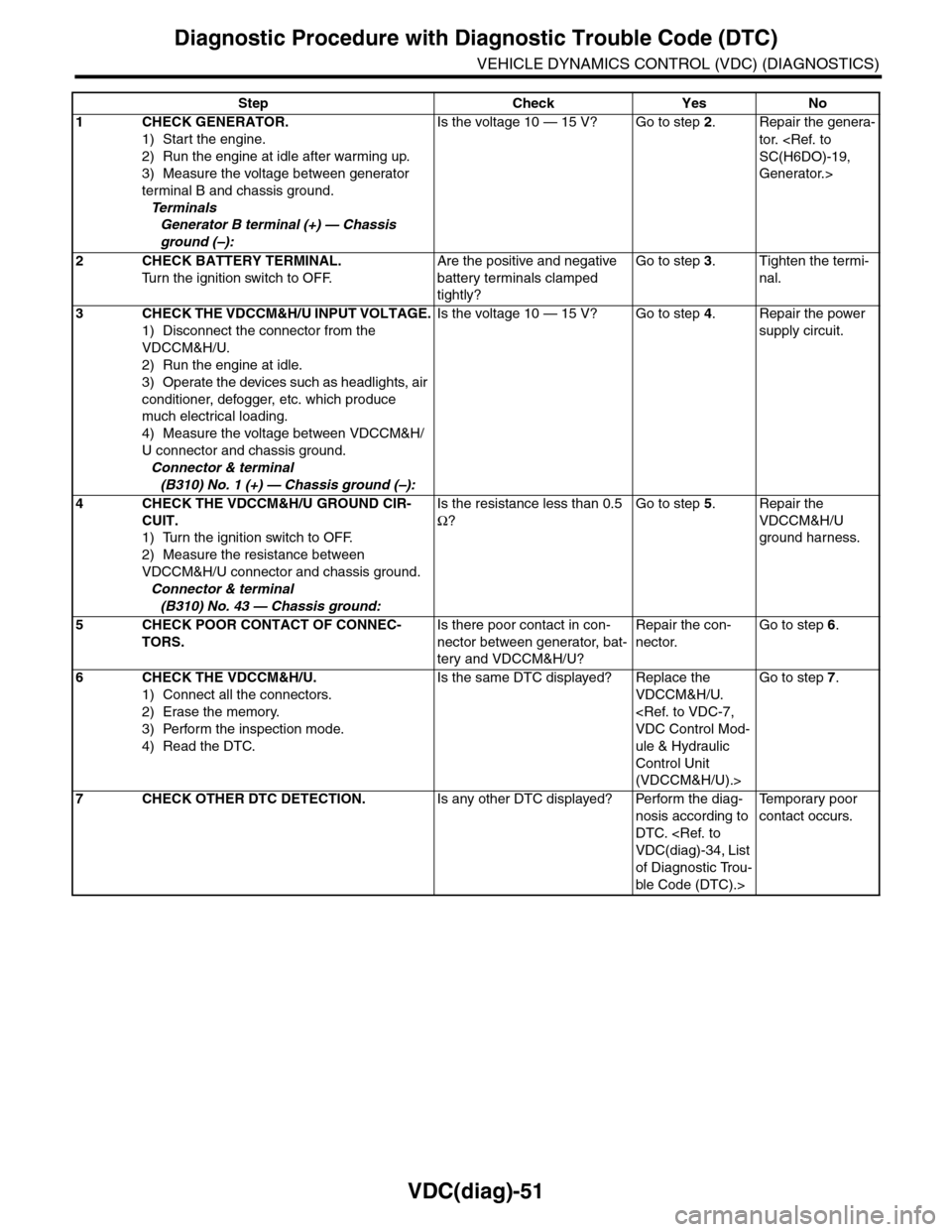

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

Step Check Yes No

1CHECK GENERATOR.

1) Start the engine.

2) Run the engine at idle after warming up.

3) Measure the voltage between generator

terminal B and chassis ground.

Te r m i n a l s

Generator B terminal (+) — Chassis

ground (–):

Is the voltage 10 — 15 V? Go to step 2.Repair the genera-

tor.

Generator.>

2CHECK BATTERY TERMINAL.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Are the positive and negative

battery terminals clamped

tightly?

Go to step 3.Tighten the termi-

nal.

3CHECK THE VDCCM&H/U INPUT VOLTAGE.

1) Disconnect the connector from the

VDCCM&H/U.

2) Run the engine at idle.

3) Operate the devices such as headlights, air

conditioner, defogger, etc. which produce

much electrical loading.

4) Measure the voltage between VDCCM&H/

U connector and chassis ground.

Connector & terminal

(B310) No. 1 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 4.Repair the power

supply circuit.

4CHECK THE VDCCM&H/U GROUND CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between

VDCCM&H/U connector and chassis ground.

Connector & terminal

(B310) No. 43 — Chassis ground:

Is the resistance less than 0.5

Ω?

Go to step 5.Repair the

VDCCM&H/U

ground harness.

5CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in con-

nector between generator, bat-

tery and VDCCM&H/U?

Repair the con-

nector.

Go to step 6.

6CHECK THE VDCCM&H/U.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

4) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 7.

7CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

of Diagnostic Trou-

ble Code (DTC).>

Te m p o r a r y p o o r

contact occurs.

Page 1622 of 2453

GD(H6DO)-10

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

4. GENERAL DRIVING CYCLE

1. Crankshaft Timing Diagnosis

Perform the diagnosis continuously after starting engine and while AVCS is not operating.

2. Slow Response Diagnosis

Perform the diagnosis continuously after warm-up, while AVCS is operating and the target timing advance is

small.

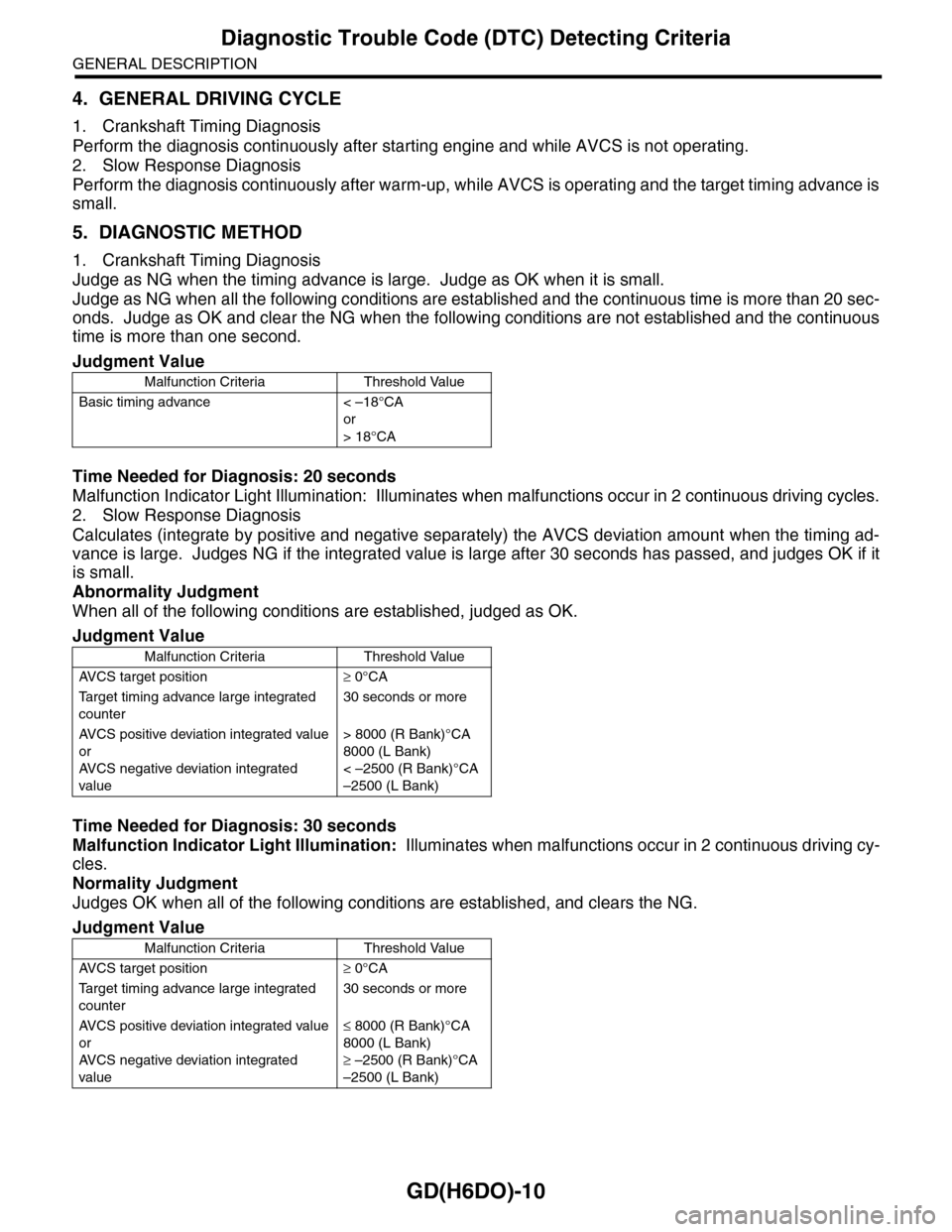

5. DIAGNOSTIC METHOD

1. Crankshaft Timing Diagnosis

Judge as NG when the timing advance is large. Judge as OK when it is small.

Judge as NG when all the following conditions are established and the continuous time is more than 20 sec-

onds. Judge as OK and clear the NG when the following conditions are not established and the continuous

time is more than one second.

Time Needed for Diagnosis: 20 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cycles.

2. Slow Response Diagnosis

Calculates (integrate by positive and negative separately) the AVCS deviation amount when the timing ad-

vance is large. Judges NG if the integrated value is large after 30 seconds has passed, and judges OK if it

is small.

Abnormality Judgment

When all of the following conditions are established, judged as OK.

Time Needed for Diagnosis: 30 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judges OK when all of the following conditions are established, and clears the NG.

Judgment Value

Malfunction Criteria Threshold Value

Basic timing advance < –18°CA

or

> 18°CA

Judgment Value

Malfunction Criteria Threshold Value

AV C S t a r g e t p o s i t i o n≥ 0°CA

Ta r g e t t i m i n g a d v a n c e l a r g e i n t e g r a t e d

counter

30 seconds or more

AV C S p o s i t i v e d ev i a t i o n i n t e g r a t e d va l u e

or

AV C S n e g a t i v e d ev i a t i o n i n t e g r a t e d

value

> 8000 (R Bank)°CA

8000 (L Bank)

< –2500 (R Bank)°CA

–2500 (L Bank)

Judgment Value

Malfunction Criteria Threshold Value

AV C S t a r g e t p o s i t i o n≥ 0°CA

Ta r g e t t i m i n g a d v a n c e l a r g e i n t e g r a t e d

counter

30 seconds or more

AV C S p o s i t i v e d ev i a t i o n i n t e g r a t e d va l u e

or

AV C S n e g a t i v e d ev i a t i o n i n t e g r a t e d

value

≤ 8000 (R Bank)°CA

8000 (L Bank)

≥ –2500 (R Bank)°CA

–2500 (L Bank)

Page 1718 of 2453

GD(H6DO)-106

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

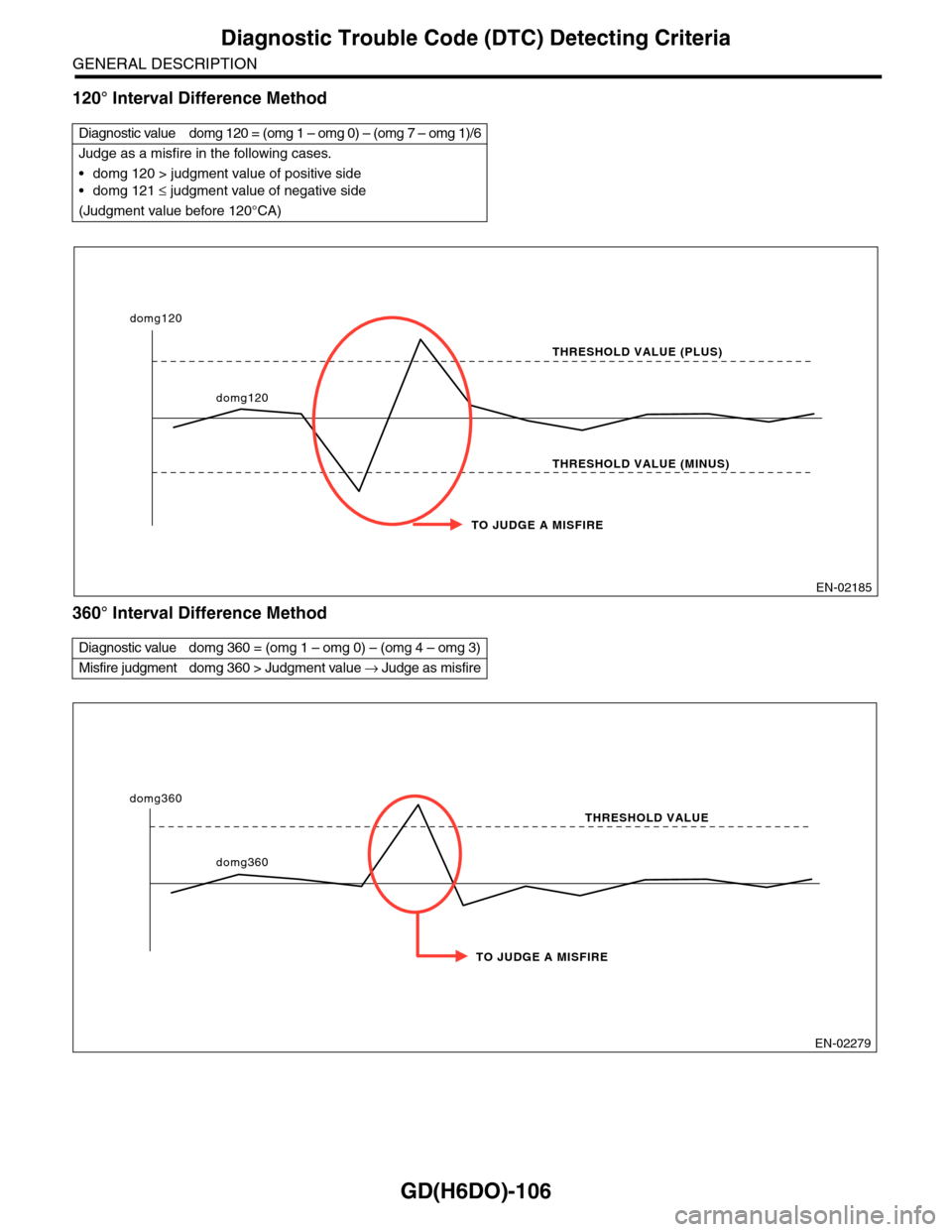

120° Interval Difference Method

360° Interval Difference Method

Diagnostic value domg 120 = (omg 1 – omg 0) – (omg 7 – omg 1)/6

Judge as a misfire in the following cases.

•domg 120 > judgment value of positive side

•domg 121 ≤ judgment value of negative side

(Judgment value before 120°CA)

Diagnostic value domg 360 = (omg 1 – omg 0) – (omg 4 – omg 3)

Misfire judgment domg 360 > Judgment value → Judge as misfire

EN-02185

TO JUDGE A MISFIRE

THRESHOLD VALUE (PLUS)

THRESHOLD VALUE (MINUS)

domg120

domg120

EN-02279

TO JUDGE A MISFIRE

THRESHOLD VALUE

domg360

domg360

Page 1737 of 2453

GD(H6DO)-125

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

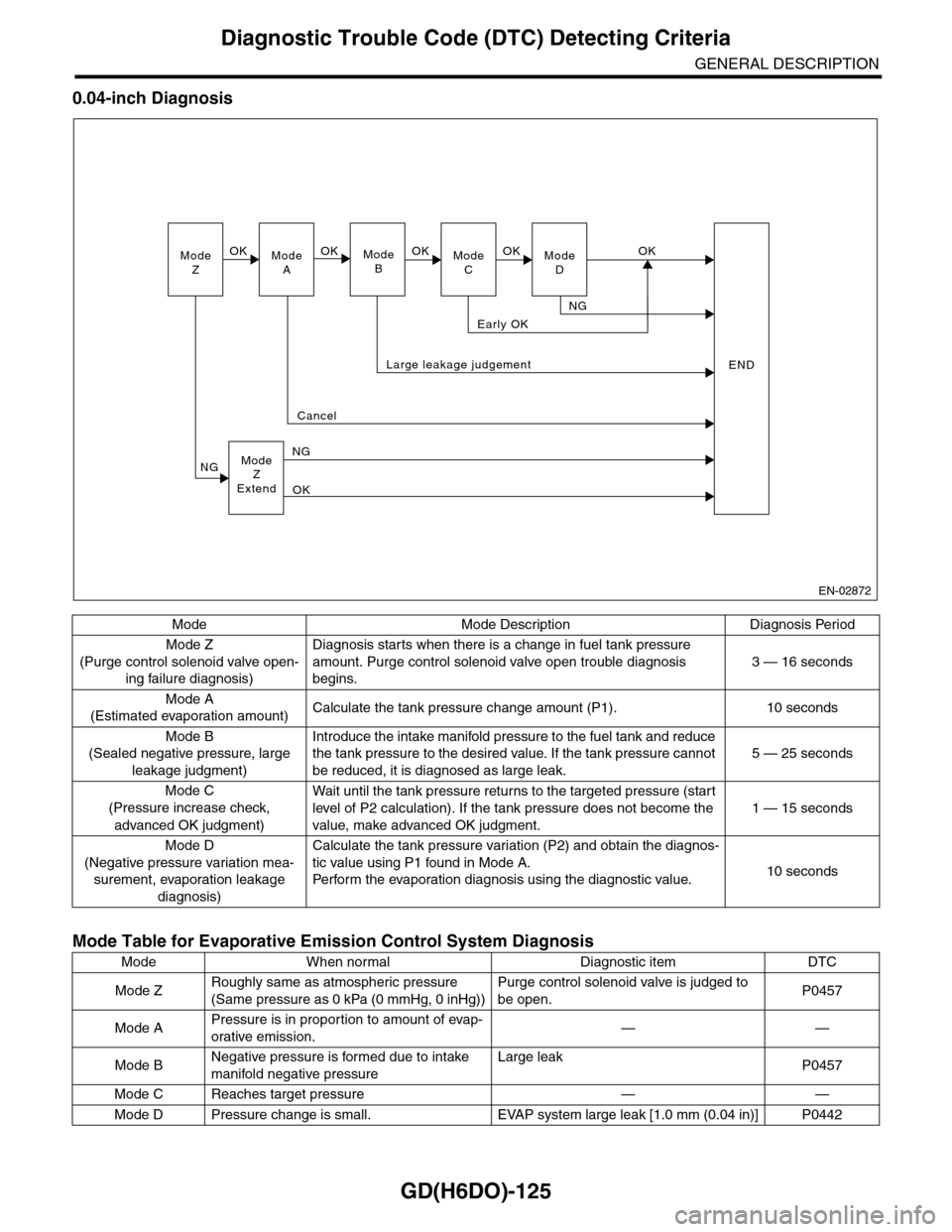

0.04-inch Diagnosis

Mode Mode Description Diagnosis Period

Mode Z

(Purge control solenoid valve open-

ing failure diagnosis)

Diagnosis starts when there is a change in fuel tank pressure

amount. Purge control solenoid valve open trouble diagnosis

begins.

3 — 16 seconds

Mode A

(Estimated evaporation amount)Calculate the tank pressure change amount (P1). 10 seconds

Mode B

(Sealed negative pressure, large

leakage judgment)

Introduce the intake manifold pressure to the fuel tank and reduce

the tank pressure to the desired value. If the tank pressure cannot

be reduced, it is diagnosed as large leak.

5 — 25 seconds

Mode C

(Pressure increase check,

advanced OK judgment)

Wait until the tank pressure retur ns to the targeted pressure (star t

level of P2 calculation). If the tank pressure does not become the

value, make advanced OK judgment.

1 — 15 seconds

Mode D

(Negative pressure variation mea-

surement, evaporation leakage

diagnosis)

Calculate the tank pressure variation (P2) and obtain the diagnos-

tic value using P1 found in Mode A.

Pe r fo r m t he eva po ra ti o n d ia g no si s u si n g t h e d ia g no st i c val u e.10 seconds

Mode Table for Evaporative Emission Control System Diagnosis

Mode When normal Diagnostic item DTC

Mode ZRoughly same as atmospheric pressure

(Same pressure as 0 kPa (0 mmHg, 0 inHg))

Purge control solenoid valve is judged to

be open.P0457

Mode APressure is in proportion to amount of evap-

orative emission.——

Mode BNegative pressure is formed due to intake

manifold negative pressure

Large leakP0457

Mode C Reaches target pressure — —

Mode D Pressure change is small. EVAP system large leak [1.0 mm (0.04 in)] P0442

ModeZModeAModeBModeCModeD

OKOKOKOKOK

NG

Early OK

Large leakage judgement

Cancel

ModeZExtend

NG

NG

OK

END

EN-02872

Page 1738 of 2453

GD(H6DO)-126

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

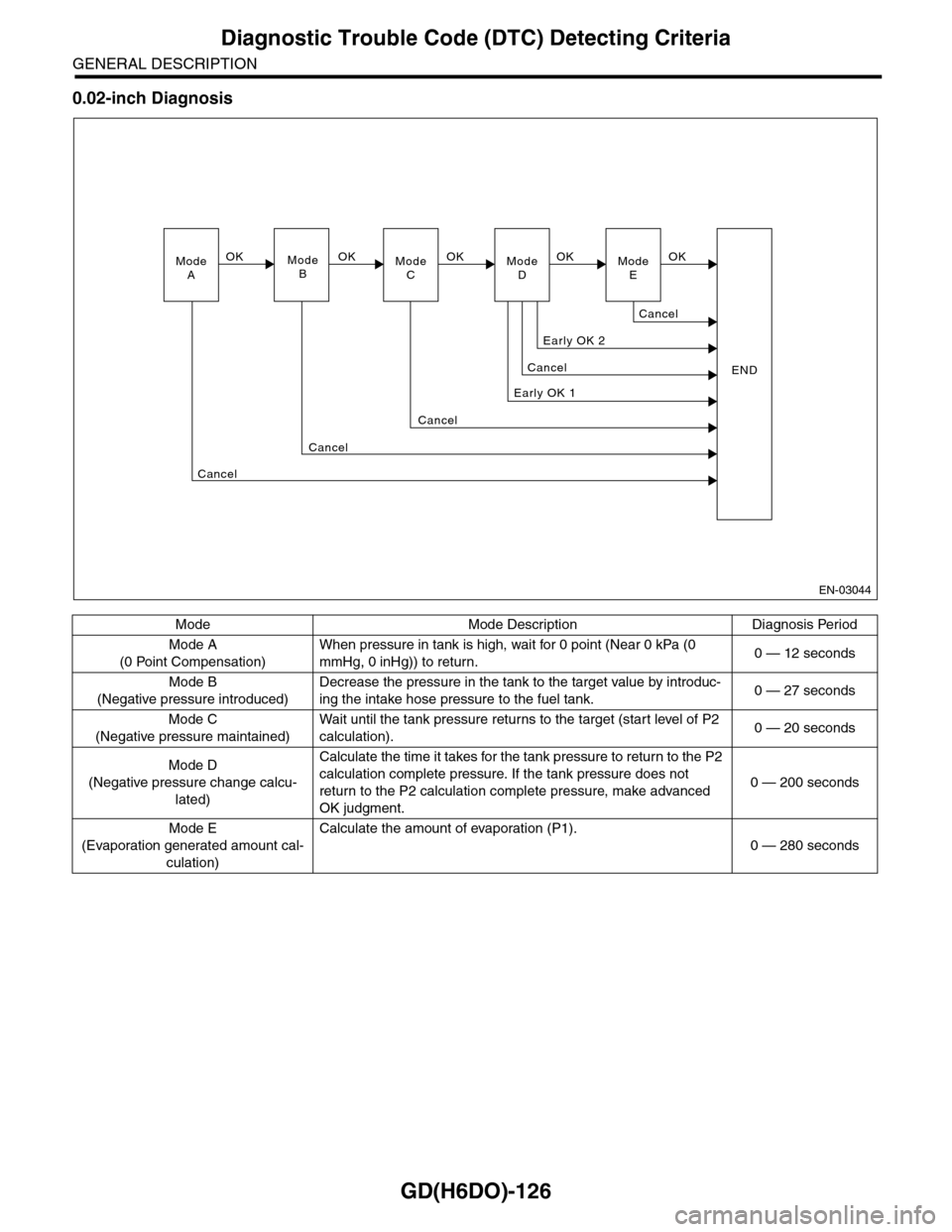

0.02-inch Diagnosis

Mode Mode Description Diagnosis Period

Mode A

(0 Point Compensation)

When pressure in tank is high, wait for 0 point (Near 0 kPa (0

mmHg, 0 inHg)) to return.0 — 12 seconds

Mode B

(Negative pressure introduced)

Decrease the pressure in the tank to the target value by introduc-

ing the intake hose pressure to the fuel tank.0 — 27 seconds

Mode C

(Negative pressure maintained)

Wa i t u nt i l t h e t a nk pr e ss ur e r et u r ns to t he t ar g e t ( s ta r t leve l o f P 2

calculation).0 — 20 seconds

Mode D

(Negative pressure change calcu-

lated)

Calculate the time it takes for the tank pressure to return to the P2

calculation complete pressure. If the tank pressure does not

return to the P2 calculation complete pressure, make advanced

OK judgment.

0 — 200 seconds

Mode E

(Evaporation generated amount cal-

culation)

Calculate the amount of evaporation (P1).

0 — 280 seconds

EN-03044

ModeAModeBModeCModeD

OKOKOK

Early OK 1

Cancel

Cancel

END

Cancel

Cancel

Early OK 2

OKModeE

Cancel

OK

Page 1744 of 2453

GD(H6DO)-132

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

Leak Diagnosis

DTC

P0442 Evaporative Emission Control System Leak Detected (Small Leak)

P0457 Evaporative Emission Control System Leak Detected (Fuel Cap Loose/Off)

Diagnostic method

The diagnostic method consists of creating a sealed vacuum in the fuel tank and then determining the pres-

ence of leakage from the speed at which the tank internal pressure returns to atmospheric pressure.

Mode A: (Estimated evaporation gas amount)

Calculate the tank pressure change amount (P1) when using mode A. After calculating P1, switch to mode B.

Mode B: (Negative pressure sealed)

Introduce negative pressure in the intake manifold to the tank.

Approx. 0 → –1.4 (0 → –10.5, 0 → –0.41) kPa (mmHg, inHg)

When the pressure above (desired negative pressure) is reached, enters Mode C.

In this case, if the tank pressure does not become the desired negative pressure, judge that there is a large

leakage (10 seconds or 25 seconds) in the system.

Abnormality Judgment

Judge as NG (large leak) when the criteria below are met.

Mode C: (Check pressure rise)

Stop the introduction of negative pressure. (Wait until the tank pressure returns to the start level of P2 cal-

culation.)

Change to Mode D when the tank pressure returns to the start level of P2 calculation.

Judge immediate OK and change to Mode E when it does not return in spite of spending the specified time.

Mode D: (Measure amount of negative pressure change)

Monitor the tank pressure change amount when using mode D. In this case, the tank pressure increases,

(nears atmospheric pressure) because evaporation occurs. However, if any leakage exists, the pressure in-

creases additionally in proportion to this leakage. The pressure variation of this tank is P2.

After calculating P2, perform a small leak diagnosis according to the items below.

When Mode D is ended

Assign tank variations measured in Mode A and Mode B; P1 and P2, to the formula below, judge small leaks

in the system. If the measured judgment value exceeds the threshold value, it is judged to be a malfunction.

Judge as NG when the criteria below are completed and Judge as OK when not completed.

* 1.5: Evaporation amount compensation value when below negative pressure (Amount of evaporation occurrence increases as

a vacuum condition increases.)

Judgment Value

Malfunction Criteria Threshold Value DTC

Time to reach targeted negative pres-

sure

≥ 25 sec. P0457

Or mode B time≥ 10 sec.

(Min. pressure value in tank when in

mode B) – (Tank pressure when mode B

started)

< –0.5 kPa

(–4 mmHg, –0.15 inHg)

Ta n k p r e s s u r e w h e n s t a r t i n g

calculation of P2

Time for advanced OK

judgment

–1.3 kPa (–9.75 mmHg, –0.38 inHg) 15 seconds

Judgment Value

Malfunction Criteria Threshold Value DTC

P2 – 1.5 × P1 > Value of Map 1 P0442

P2: Tank pressure that changes every 10

seconds in mode D

* Threshold value: Fig-

ure (Remaining Fuel

vs Tank temperature)

P1: Tank pressure that changes every 10

seconds in mode A

Page 1745 of 2453

GD(H6DO)-133

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

Time Needed for Diagnosis: 30 to 100 seconds

0.02-inch Diagnosis

DTC

P0456 Evaporative Emission Control System Leak Detected (very small leak)

Diagnostic method

The diagnostic method consists of creating a sealed vacuum in the fuel tank and then determining the pres-

ence of leakage from the speed at which the tank internal pressure returns to atmospheric pressure.

Mode A: (0 Point Compensation)

When pressure in tank is high, wait for 0 point 0 kPa (Near 0 mmHg, 0 inHg) to return.Shift to mode B when

0 point returns.

Cancel the diagnosis when 0 point does not return in the specified time.

Mode B: (Negative pressure introduced)

Introduce negative pressure in the intake manifold to the tank.

Approx. 0 → –2.0 kPa (0 mmHg → –15 mmHg, 0 → –0.59 inHg)

When the pressure above (desired negative pressure) is reached, Mode C is entered.

Cancel the diagnosis when the targeted pressure in the tank is not reached.

Mode C: (Negative pressure maintained)

Stop the introduction of negative pressure and wait until the tank pressure returns to the start level of P2 cal-

culation.

Change to Mode D either when the tank pressure returns to the start level of P2 calculation, or when the pre-

determined amount of time has passed.

Mode D: (Calculate the amount of negative pressure change)

Monitor the tank pressure in mode D, calculate (P2) the pressure change in the tank, and measure the time

(evpdset) for the tank pressure to return when calculation of P2 is completed. Shift to mode E when pressure

returns. Make an advance OK judgment using the value of P2, or cancel, when the pressure in the tank does

not return after calculation of P2 is completed even when the predetermined amount of time has passed.

When the following conditions are established, it is OK.

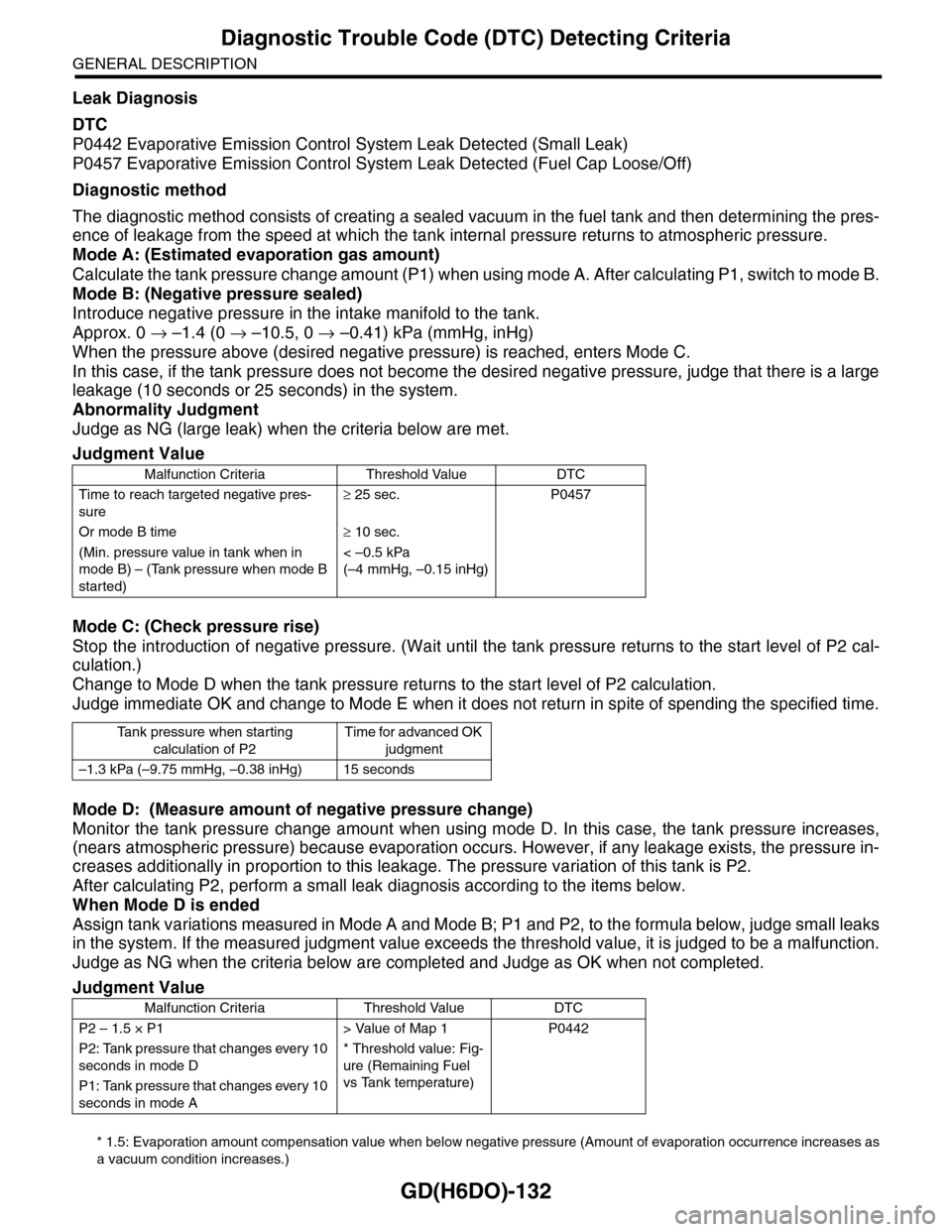

Map 1 Failure diagnosis reference limit for 0.04 in leaks for evaporation diagnosis

Fuel temperature & Fuel level 25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F) 45°C (113°F)

10 L (2.6 US gal, 2.2 Imp gal)

0.28 kPa

(2.1 mmHg,

0.083 inHg)

0.29 kPa

(2.2 mmHg,

0.087 inHg)

0.31 kPa

(2.3 mmHg,

0.090 inHg)

0.31 kPa

(2.35 mmHg,

0.092 inHg)

0.32 kPa

(2.4 mmHg,

0.094 inHg)

20 L (5.3 US gal, 4.4 Imp gal)

0.31 kPa

(2.3 mmHg,

0.091 inHg)

0.32 kPa

(2.4 mmHg,

0.094 inHg)

0.33 kPa

(2.5 mmHg,

0.098 inHg)

0.35 kPa

(2.6 mmHg,

0.102 inHg)

0.36 kPa

(2.7 mmHg,

0.106 inHg)

30 L (7.9 US gal, 6.6 Imp gal)

0.39 kPa

(2.9 mmHg,

0.114 inHg)

0.41 kPa

(3.05 mmHg,

0.120 inHg)

0.42 kPa

(3.15 mmHg,

0.124 inHg)

0.43 kPa

(3.25 mmHg,

0.128 inHg)

0.45 kPa

(3.35 mmHg,

0.134 inHg)

40 L (10.6 US gal, 8.8 Imp gal)

0.39 kPa

(2.9 mmHg,

0.114 inHg)

0.42 kPa

(3.15 mmHg,

0.124 inHg)

0.44 kPa

(3.3 mmHg,

0.130 inHg)

0.45 kPa

(3.4 mmHg,

0.134 inHg)

0.47 kPa

(3.5 mmHg,

0.138 inHg)

50 L (13.2 US gal, 11.0 Imp gal)

0.43 kPa

(3.2 mmHg,

0.126 inHg)

0.44 kPa

(3.3 mmHg,

0.130 inHg)

0.47 kPa

(3.5 mmHg,

0.138 inHg)

0.48 kPa

(3.6 mmHg,

0.142 inHg)

0.49 kPa

(3.7 mmHg,

0.146 inHg)

Judgment Value

Malfunction Criteria Threshold Value DTC

Advanced OK judgment 1 P0456

Mode D holding time≥ 30 s

Ta n k p r e s s u r e≤ Value of Map 2

Advanced OK judgment 2

Mode D Time≥ 200 s

P2≥ 0.9 — 1.3 kPa (7 — 9.6

mmHg, 0.28 — 0.38 inHg)

Page 1974 of 2453

SC(H6DO)-16

Starter

STARTING/CHARGING SYSTEMS

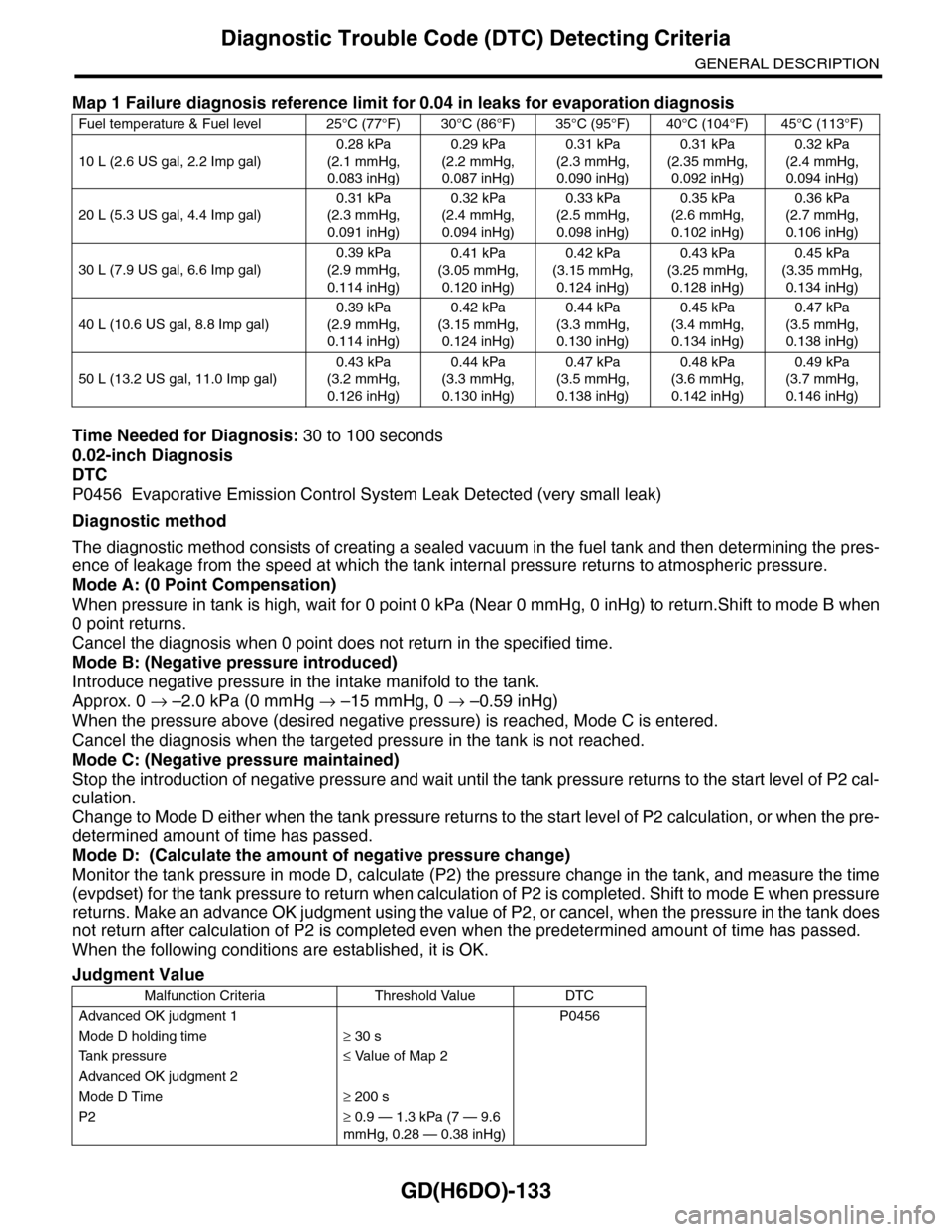

2) Brush movement

Be sure the brush moves smoothly inside brush

holder.

3) Brush holder discontinuity test

Using a circuit tester, bring one probe into contact

with positive side brush holder and the other with

negative side brush holder.

No continuity is normal.

4. SWITCH ASSEMBLY

1) Return spring check

Make sure the plunger returns to its original posi-

tion immediately after pressed-in then released.

2) Magnet switch continuity test

Be sure there is continuity between the terminals S

and M, and between terminal S and ground. Use a

circuit tester.

Also check to be sure there is no continuity be-

tween terminal M and B.

Terminal/Resistance:

S — M/1 Ω or less

S — Ground/1 Ω or less

M — B/1 MΩ or more

5. FRONT BEARING

Check the front bearing to make sure there are no

damage or rust.

Also, insert the shaft into front bearing to make sure

the front bearing rotates smoothly when the shaft is

rotated.

Replace the front bearing if faulty.

(A) Positive side

(B) Negative side

(C) Circuit tester

(A) Plunger

SC-02081

(B)

(A)(C)

SC-02082

(A)

(A) Front bracket

(B) Shaft

SC-00075

B

M

S

SC-02083

(A)

(B)

Page 1976 of 2453

SC(H6DO)-18

Starter

STARTING/CHARGING SYSTEMS

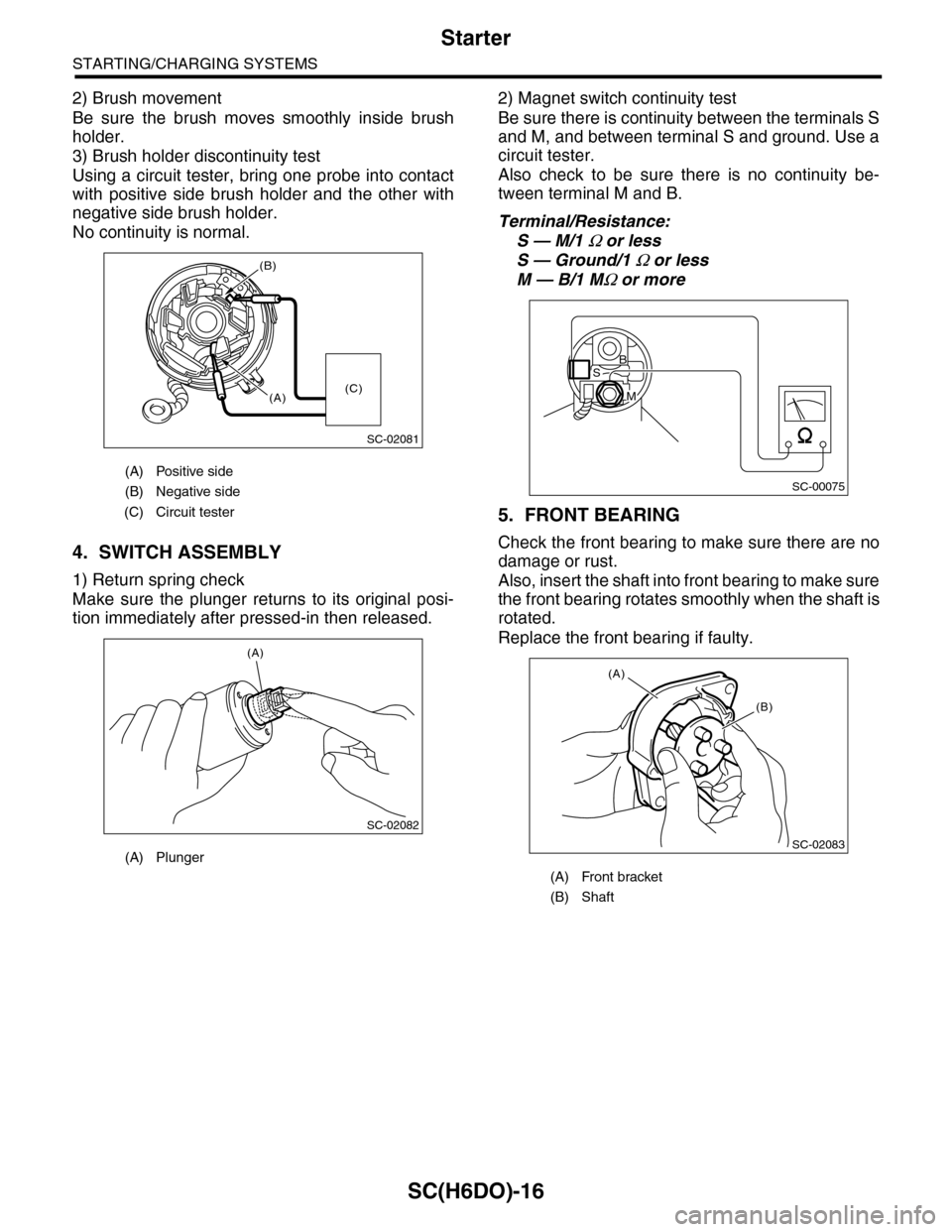

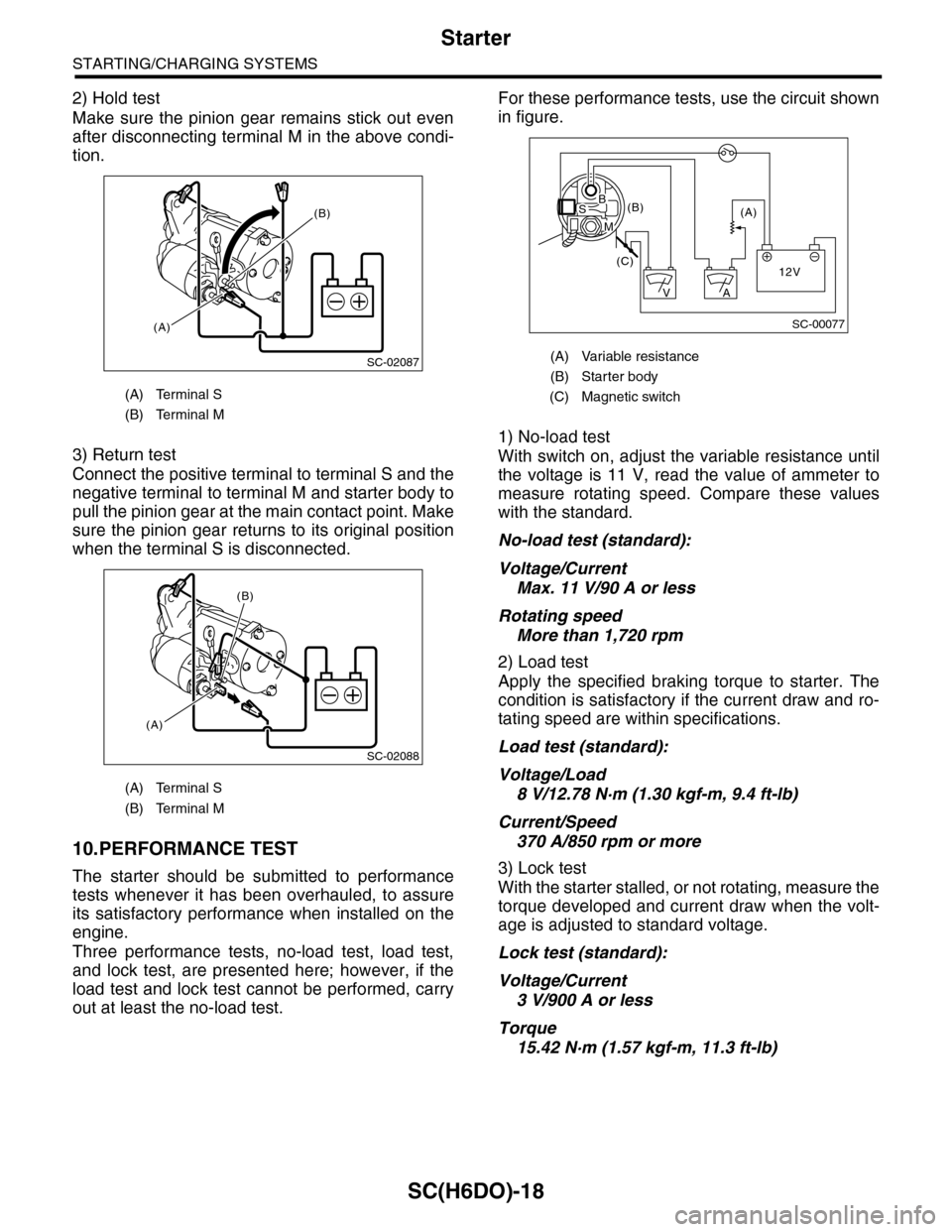

2) Hold test

Make sure the pinion gear remains stick out even

after disconnecting terminal M in the above condi-

tion.

3) Return test

Connect the positive terminal to terminal S and the

negative terminal to terminal M and starter body to

pull the pinion gear at the main contact point. Make

sure the pinion gear returns to its original position

when the terminal S is disconnected.

10.PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

1) No-load test

With switch on, adjust the variable resistance until

the voltage is 11 V, read the value of ammeter to

measure rotating speed. Compare these values

with the standard.

No-load test (standard):

Voltage/Current

Max. 11 V/90 A or less

Rotating speed

More than 1,720 rpm

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and ro-

tating speed are within specifications.

Load test (standard):

Voltage/Load

8 V/12.78 N·m (1.30 kgf-m, 9.4 ft-lb)

Current/Speed

370 A/850 rpm or more

3) Lock test

With the starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to standard voltage.

Lock test (standard):

Voltage/Current

3 V/900 A or less

Torque

15.42 N·m (1.57 kgf-m, 11.3 ft-lb)

(A) Terminal S

(B) Terminal M

(A) Terminal S

(B) Terminal M

SC-02087

(B)

(A)

SC-02088

(A)

(B)

(A) Variable resistance

(B) Starter body

(C) Magnetic switch

SC-00077

(A)(B)

(C)12V

+

AV

BS

M

Page 1980 of 2453

SC(H6DO)-22

Generator

STARTING/CHARGING SYSTEMS

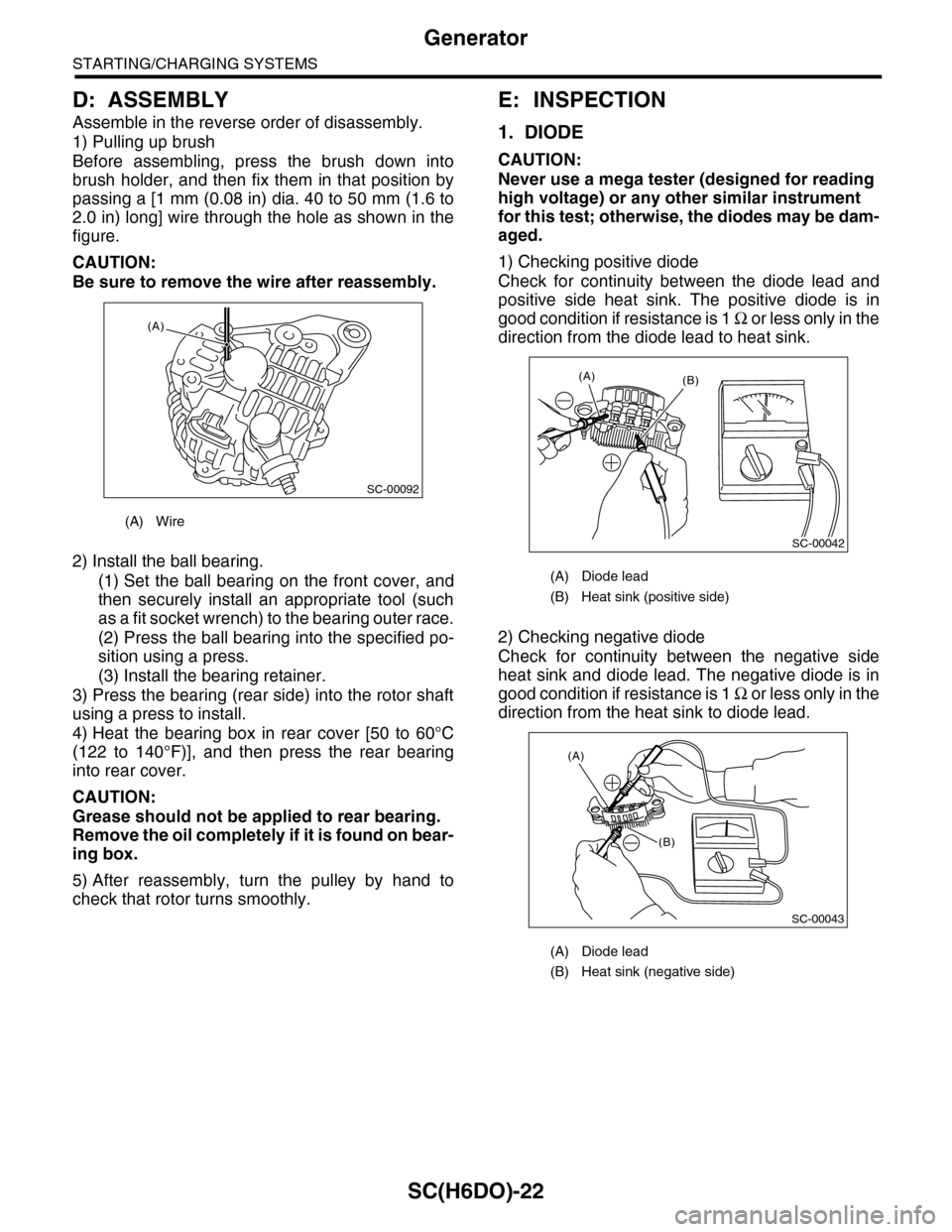

D: ASSEMBLY

Assemble in the reverse order of disassembly.

1) Pulling up brush

Before assembling, press the brush down into

brush holder, and then fix them in that position by

passing a [1 mm (0.08 in) dia. 40 to 50 mm (1.6 to

2.0 in) long] wire through the hole as shown in the

figure.

CAUTION:

Be sure to remove the wire after reassembly.

2) Install the ball bearing.

(1) Set the ball bearing on the front cover, and

then securely install an appropriate tool (such

as a fit socket wrench) to the bearing outer race.

(2) Press the ball bearing into the specified po-

sition using a press.

(3) Install the bearing retainer.

3) Press the bearing (rear side) into the rotor shaft

using a press to install.

4) Heat the bearing box in rear cover [50 to 60°C

(122 to 140°F)], and then press the rear bearing

into rear cover.

CAUTION:

Grease should not be applied to rear bearing.

Remove the oil completely if it is found on bear-

ing box.

5) After reassembly, turn the pulley by hand to

check that rotor turns smoothly.

E: INSPECTION

1. DIODE

CAUTION:

Never use a mega tester (designed for reading

high voltage) or any other similar instrument

for this test; otherwise, the diodes may be dam-

aged.

1) Checking positive diode

Check for continuity between the diode lead and

positive side heat sink. The positive diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the diode lead to heat sink.

2) Checking negative diode

Check for continuity between the negative side

heat sink and diode lead. The negative diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the heat sink to diode lead.

(A) Wire

SC-00092

(A)

(A) Diode lead

(B) Heat sink (positive side)

(A) Diode lead

(B) Heat sink (negative side)

SC-00042

(B)(A)

(A)

(B)

SC-00043