SUBARU TRIBECA 2009 1.G Service Workshop Manual

TRIBECA 2009 1.G

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/7322/w960_7322-0.png

SUBARU TRIBECA 2009 1.G Service Workshop Manual

Page 1578 of 2453

FU(H6DO)-17

Engine Coolant Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

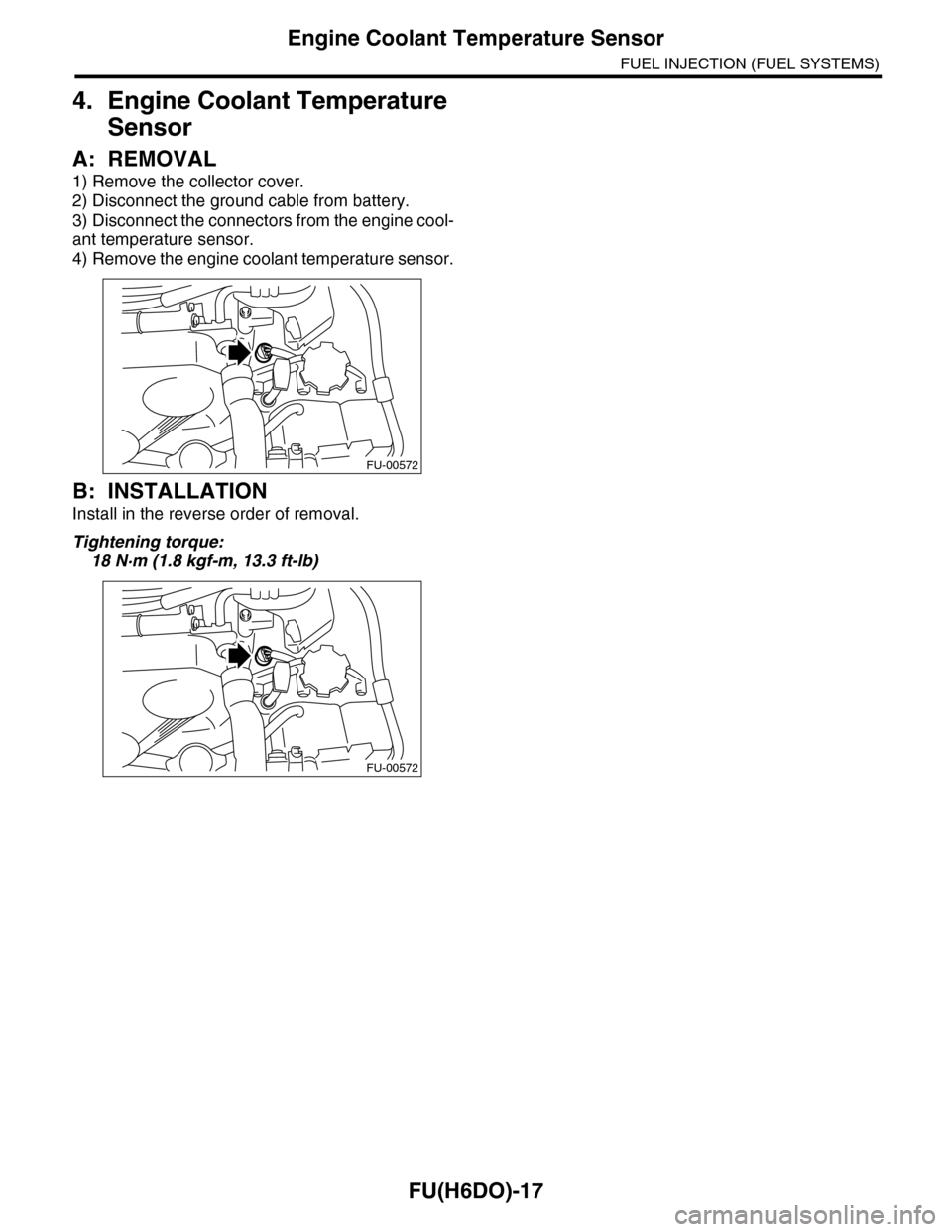

4. Engine Coolant Temperature

Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Disconnect the connectors from the engine cool-

ant temperature sensor.

4) Remove the engine coolant temperature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

FU-00572

FU-00572

Page 1579 of 2453

FU(H6DO)-18

Crankshaft Position Sensor

FUEL INJECTION (FUEL SYSTEMS)

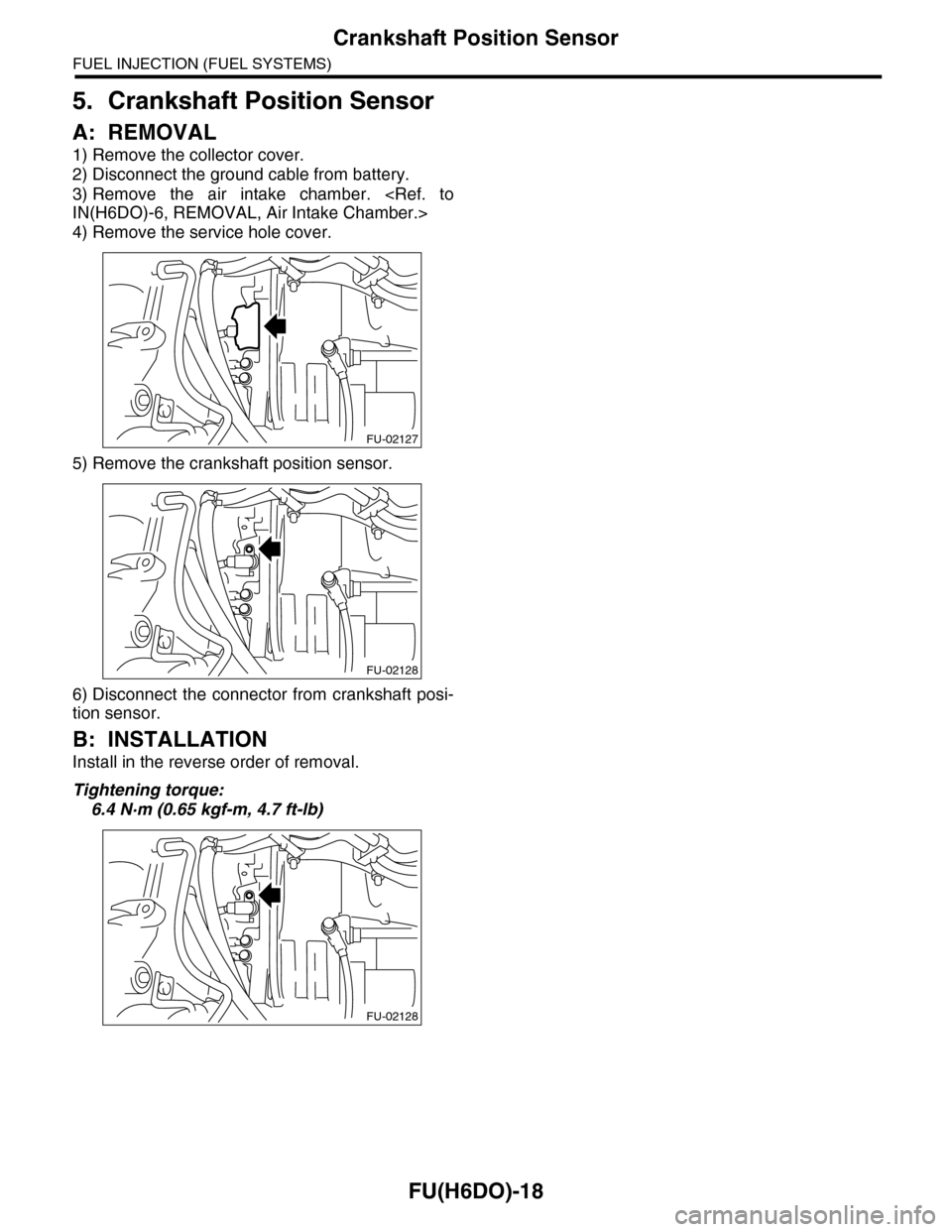

5. Crankshaft Position Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

IN(H6DO)-6, REMOVAL, Air Intake Chamber.>

4) Remove the service hole cover.

5) Remove the crankshaft position sensor.

6) Disconnect the connector from crankshaft posi-

tion sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

FU-02127

FU-02128

FU-02128

Page 1580 of 2453

FU(H6DO)-19

Camshaft Position Sensor

FUEL INJECTION (FUEL SYSTEMS)

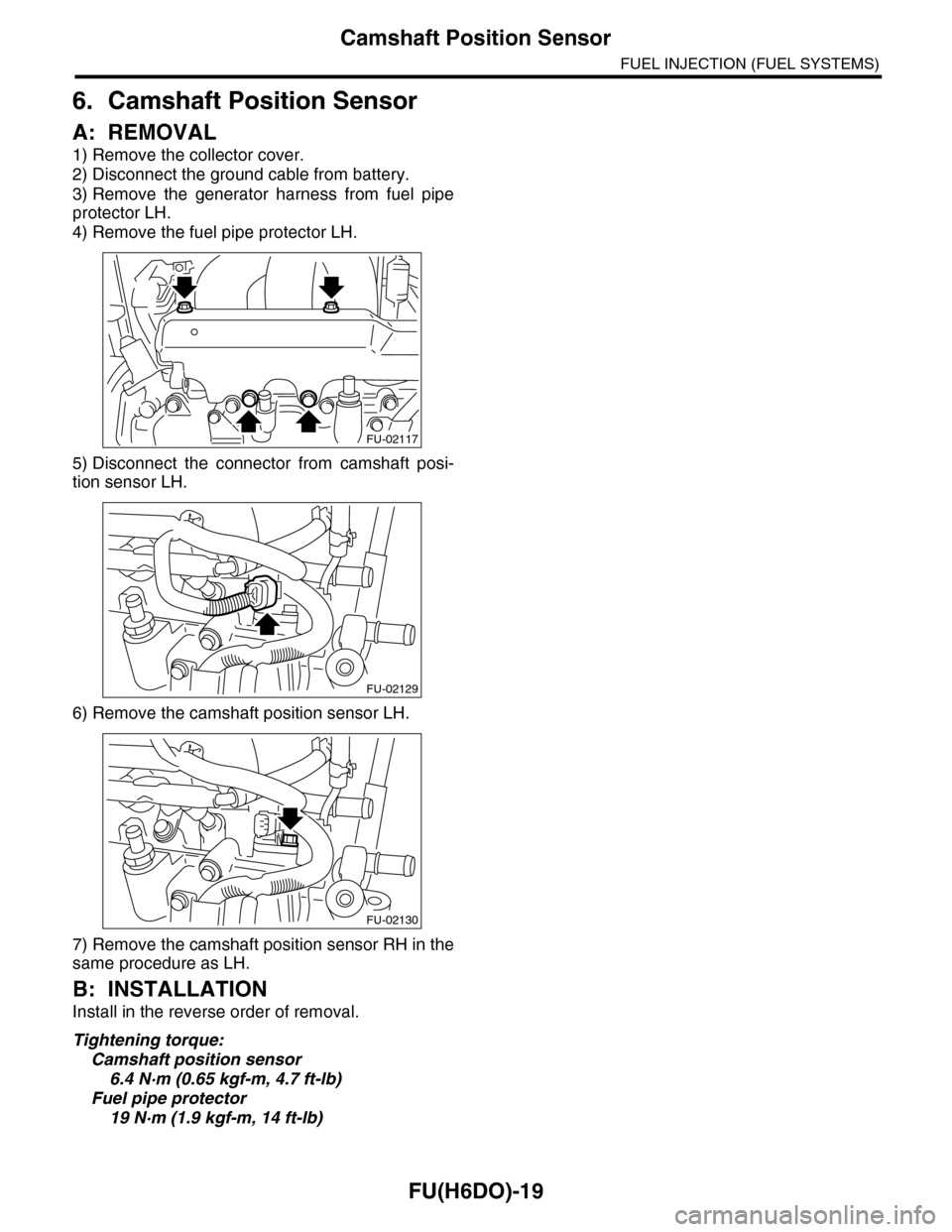

6. Camshaft Position Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the generator harness from fuel pipe

protector LH.

4) Remove the fuel pipe protector LH.

5) Disconnect the connector from camshaft posi-

tion sensor LH.

6) Remove the camshaft position sensor LH.

7) Remove the camshaft position sensor RH in the

same procedure as LH.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Camshaft position sensor

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

Fuel pipe protector

19 N·m (1.9 kgf-m, 14 ft-lb)

FU-02117

FU-02129

FU-02130

Page 1583 of 2453

FU(H6DO)-22

Manifold Absolute Pressure Sensor

FUEL INJECTION (FUEL SYSTEMS)

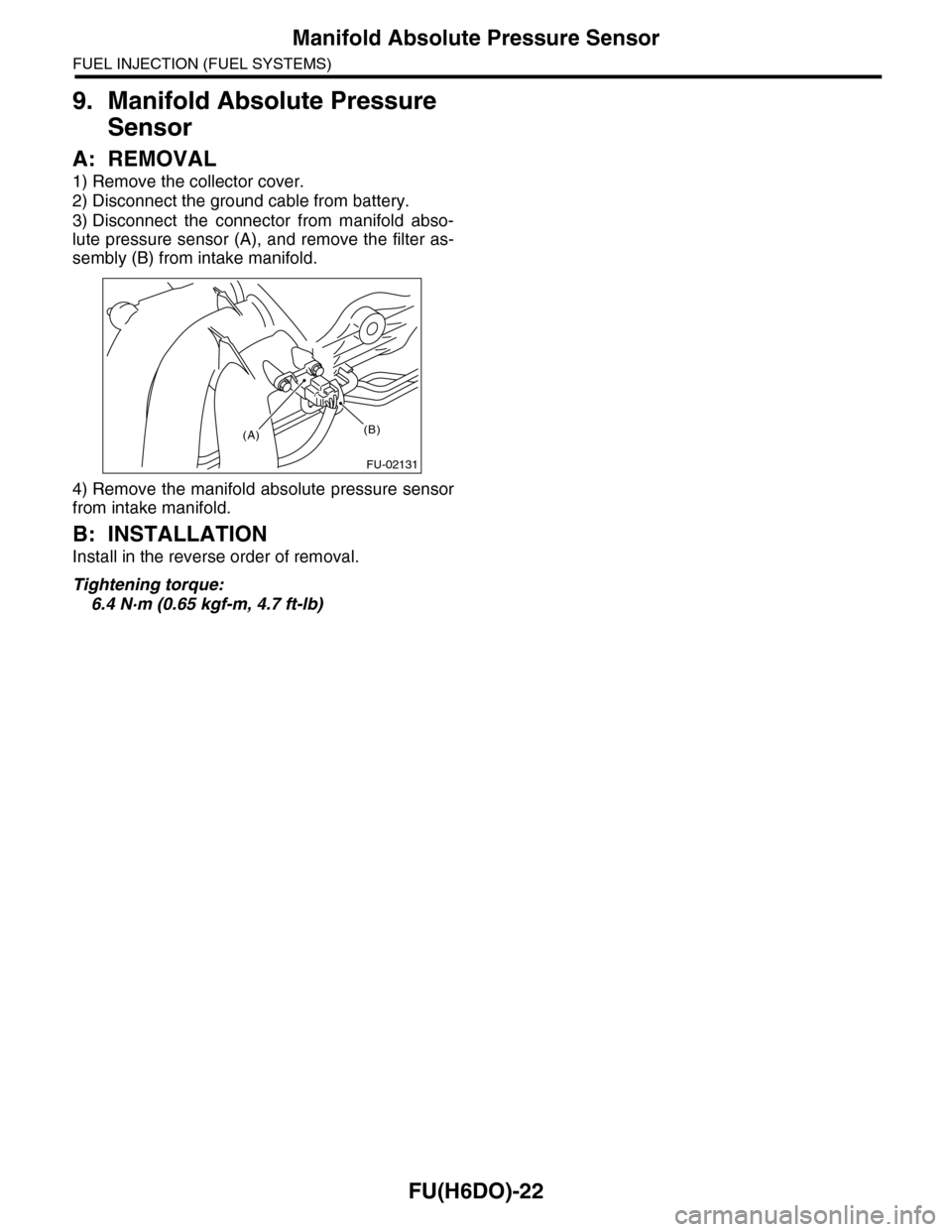

9. Manifold Absolute Pressure

Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Disconnect the connector from manifold abso-

lute pressure sensor (A), and remove the filter as-

sembly (B) from intake manifold.

4) Remove the manifold absolute pressure sensor

from intake manifold.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

FU-02131

(B)(A)

Page 1584 of 2453

FU(H6DO)-23

Mass Air Flow and Intake Air Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

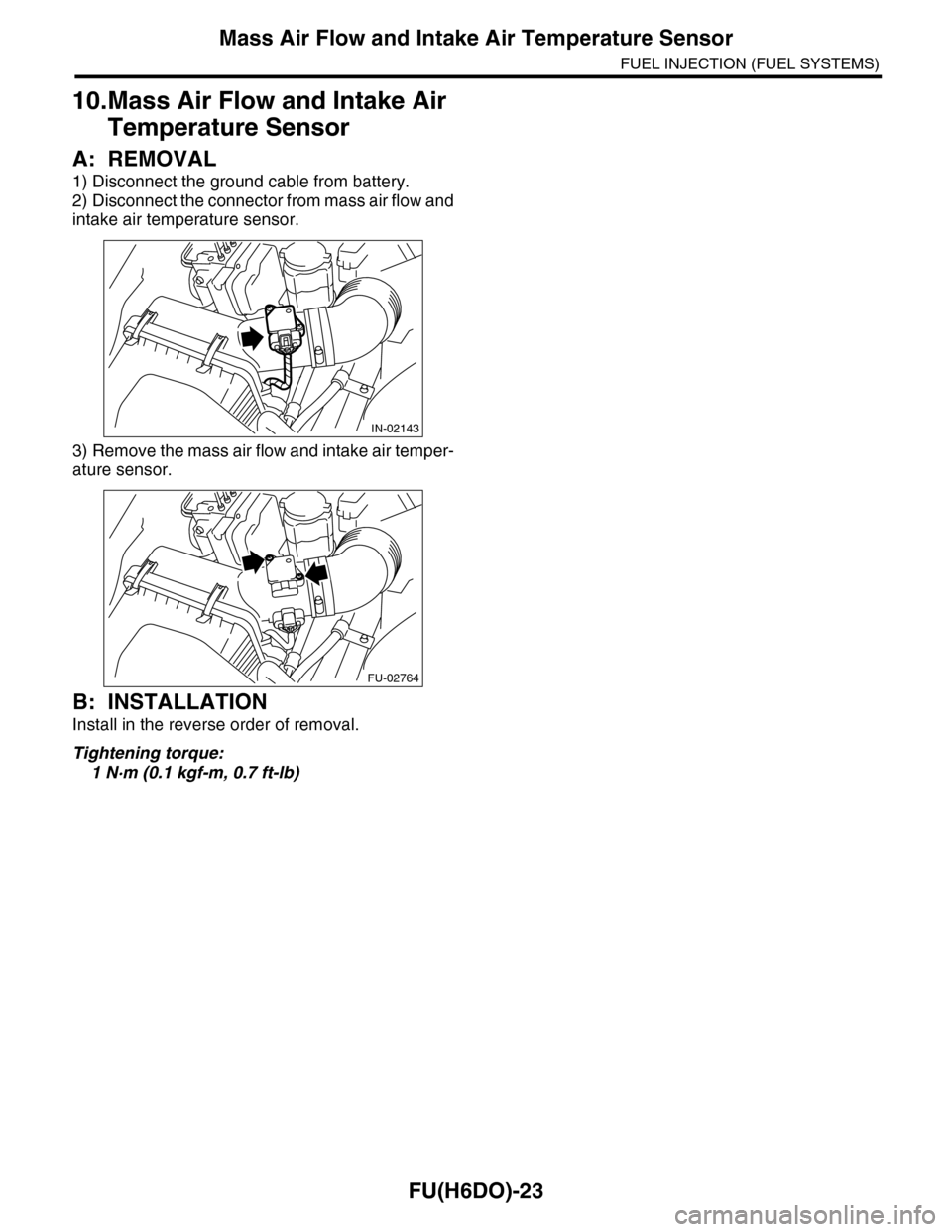

10.Mass Air Flow and Intake Air

Temperature Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Disconnect the connector from mass air flow and

intake air temperature sensor.

3) Remove the mass air flow and intake air temper-

ature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

1 N·m (0.1 kgf-m, 0.7 ft-lb)

IN-02143

FU-02764

Page 1586 of 2453

FU(H6DO)-25

Fuel Injector

FUEL INJECTION (FUEL SYSTEMS)

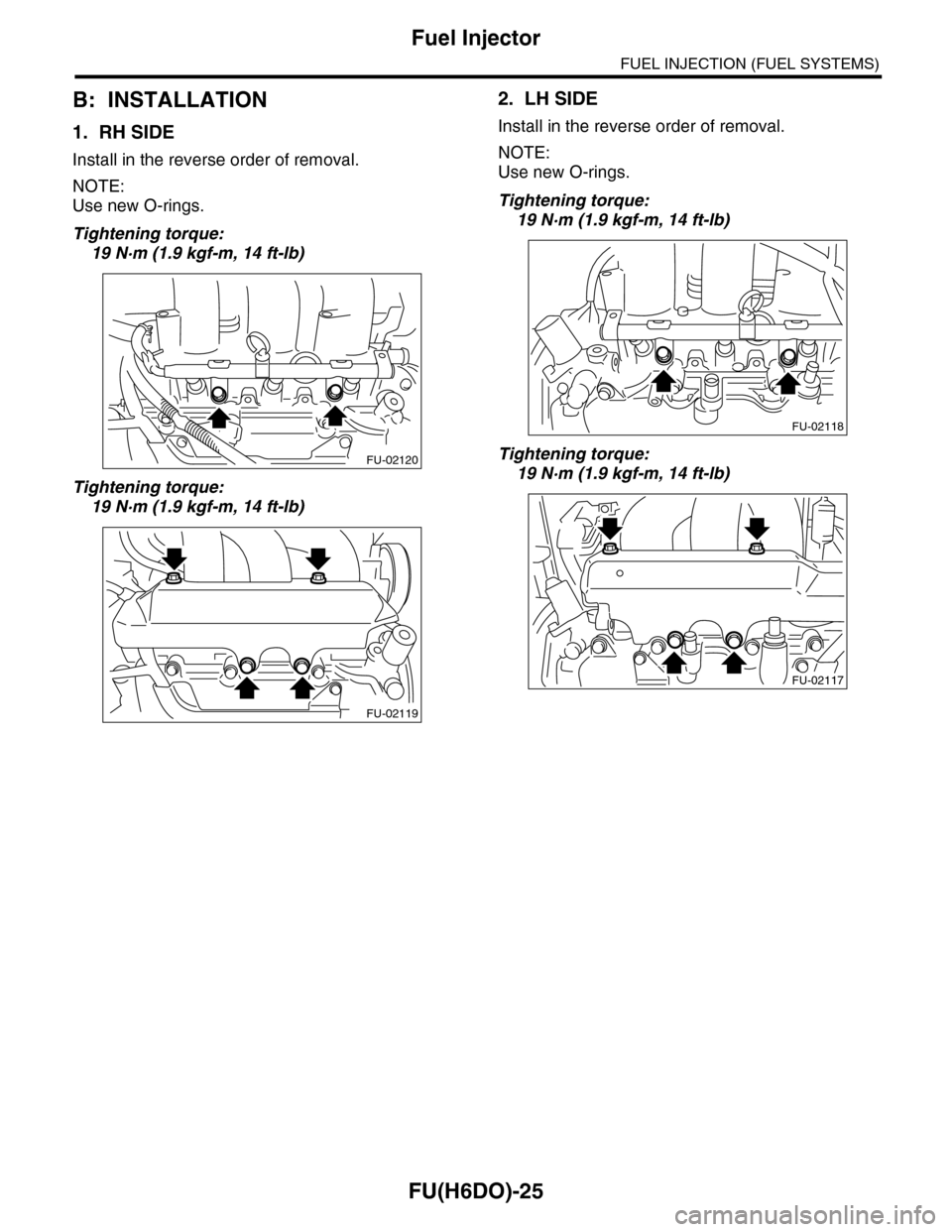

B: INSTALLATION

1. RH SIDE

Install in the reverse order of removal.

NOTE:

Use new O-rings.

Tightening torque:

19 N·m (1.9 kgf-m, 14 ft-lb)

Tightening torque:

19 N·m (1.9 kgf-m, 14 ft-lb)

2. LH SIDE

Install in the reverse order of removal.

NOTE:

Use new O-rings.

Tightening torque:

19 N·m (1.9 kgf-m, 14 ft-lb)

Tightening torque:

19 N·m (1.9 kgf-m, 14 ft-lb)FU-02120

FU-02119

FU-02118

FU-02117

Page 1587 of 2453

FU(H6DO)-26

Variable Valve Lift Diagnosis Oil Pressure Switch

FUEL INJECTION (FUEL SYSTEMS)

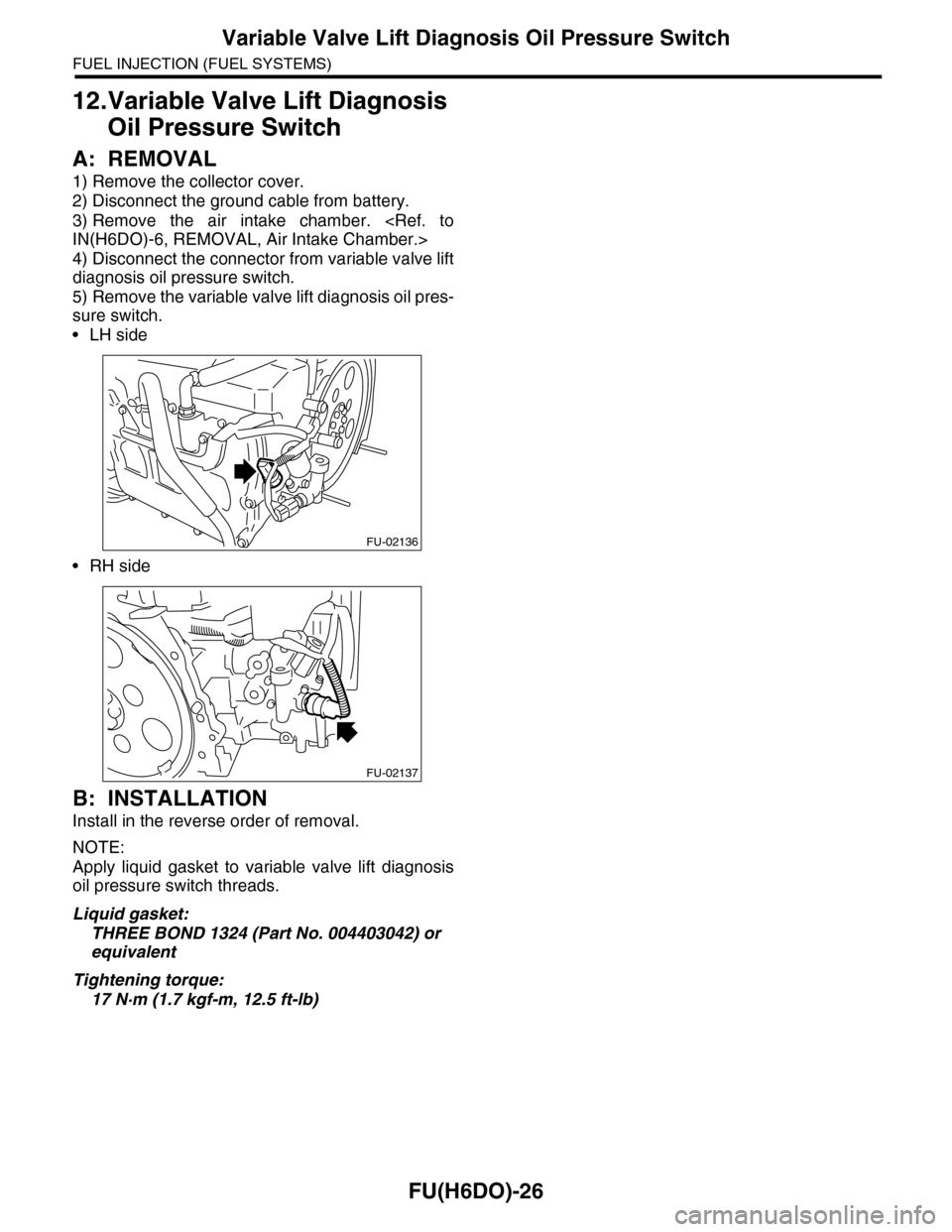

12.Variable Valve Lift Diagnosis

Oil Pressure Switch

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

IN(H6DO)-6, REMOVAL, Air Intake Chamber.>

4) Disconnect the connector from variable valve lift

diagnosis oil pressure switch.

5) Remove the variable valve lift diagnosis oil pres-

sure switch.

•LH side

•RH side

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Apply liquid gasket to variable valve lift diagnosis

oil pressure switch threads.

Liquid gasket:

THREE BOND 1324 (Part No. 004403042) or

equivalent

Tightening torque:

17 N·m (1.7 kgf-m, 12.5 ft-lb)

FU-02136

FU-02137

Page 1588 of 2453

FU(H6DO)-27

Oil Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

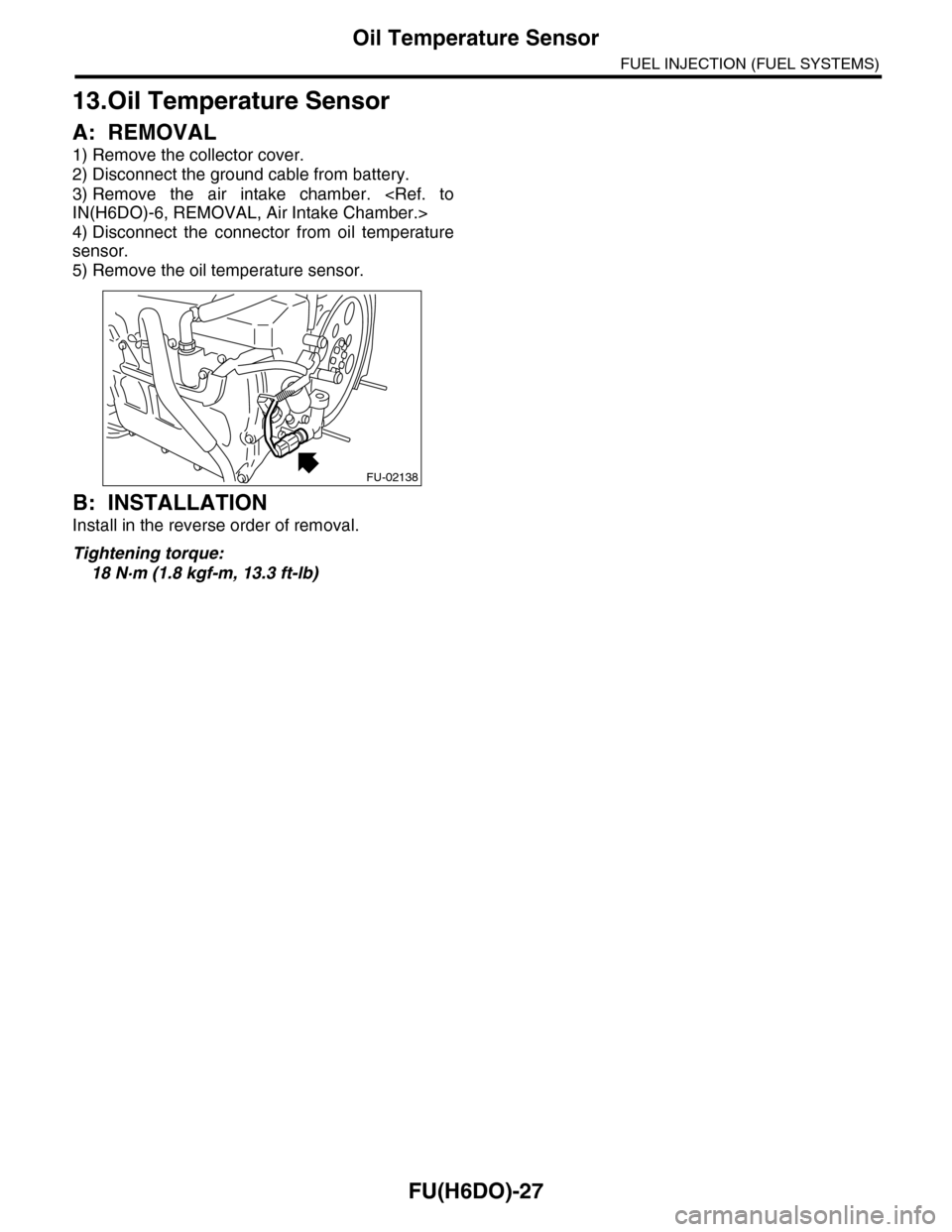

13.Oil Temperature Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

IN(H6DO)-6, REMOVAL, Air Intake Chamber.>

4) Disconnect the connector from oil temperature

sensor.

5) Remove the oil temperature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

FU-02138

Page 1593 of 2453

FU(H6DO)-32

Engine Control Module (ECM)

FUEL INJECTION (FUEL SYSTEMS)

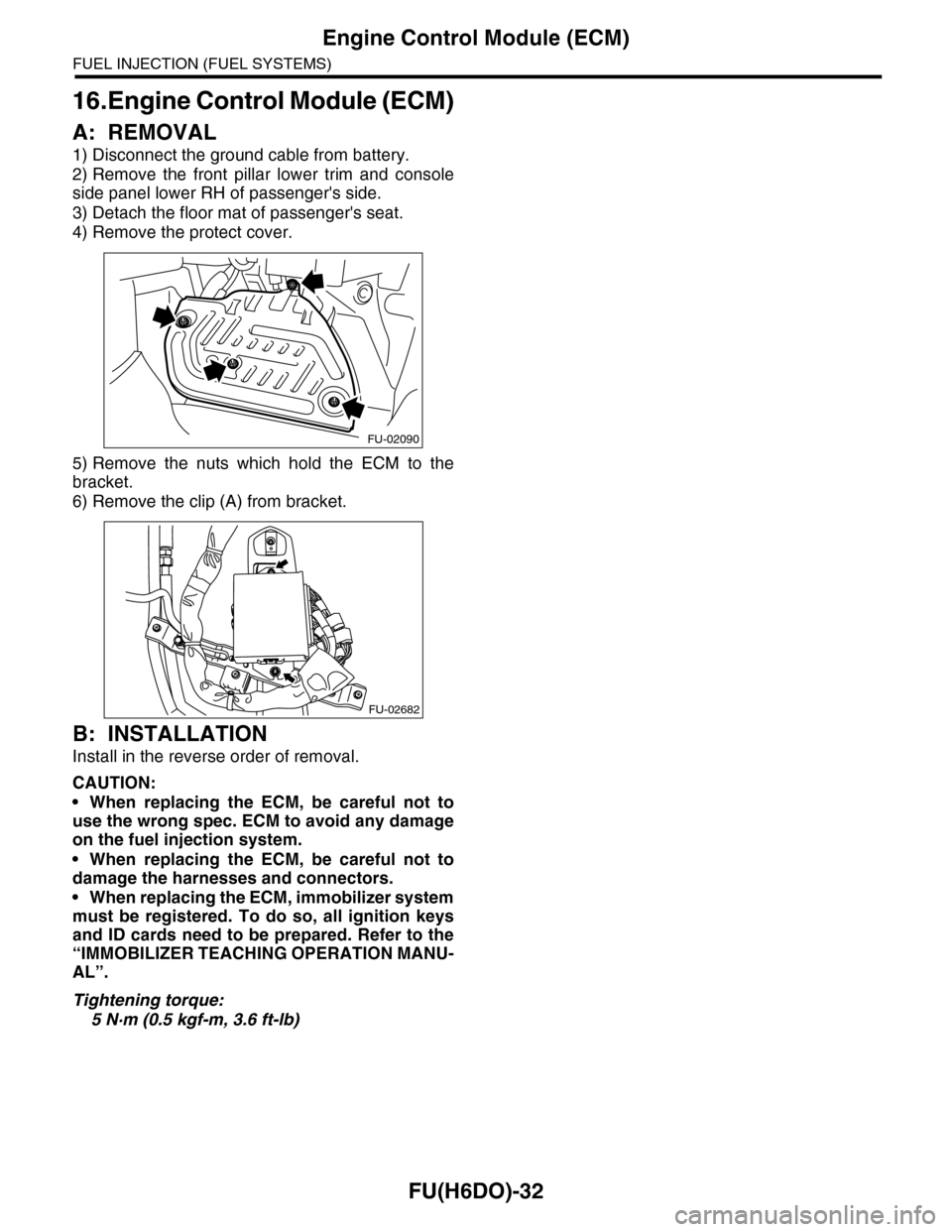

16.Engine Control Module (ECM)

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the front pillar lower trim and console

side panel lower RH of passenger's side.

3) Detach the floor mat of passenger's seat.

4) Remove the protect cover.

5) Remove the nuts which hold the ECM to the

bracket.

6) Remove the clip (A) from bracket.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

•When replacing the ECM, be careful not to

use the wrong spec. ECM to avoid any damage

on the fuel injection system.

•When replacing the ECM, be careful not to

damage the harnesses and connectors.

•When replacing the ECM, immobilizer system

must be registered. To do so, all ignition keys

and ID cards need to be prepared. Refer to the

“IMMOBILIZER TEACHING OPERATION MANU-

AL”.

Tightening torque:

5 N·m (0.5 kgf-m, 3.6 ft-lb)

FU-02090

FU-02682

Page 1594 of 2453

FU(H6DO)-33

Main Relay

FUEL INJECTION (FUEL SYSTEMS)

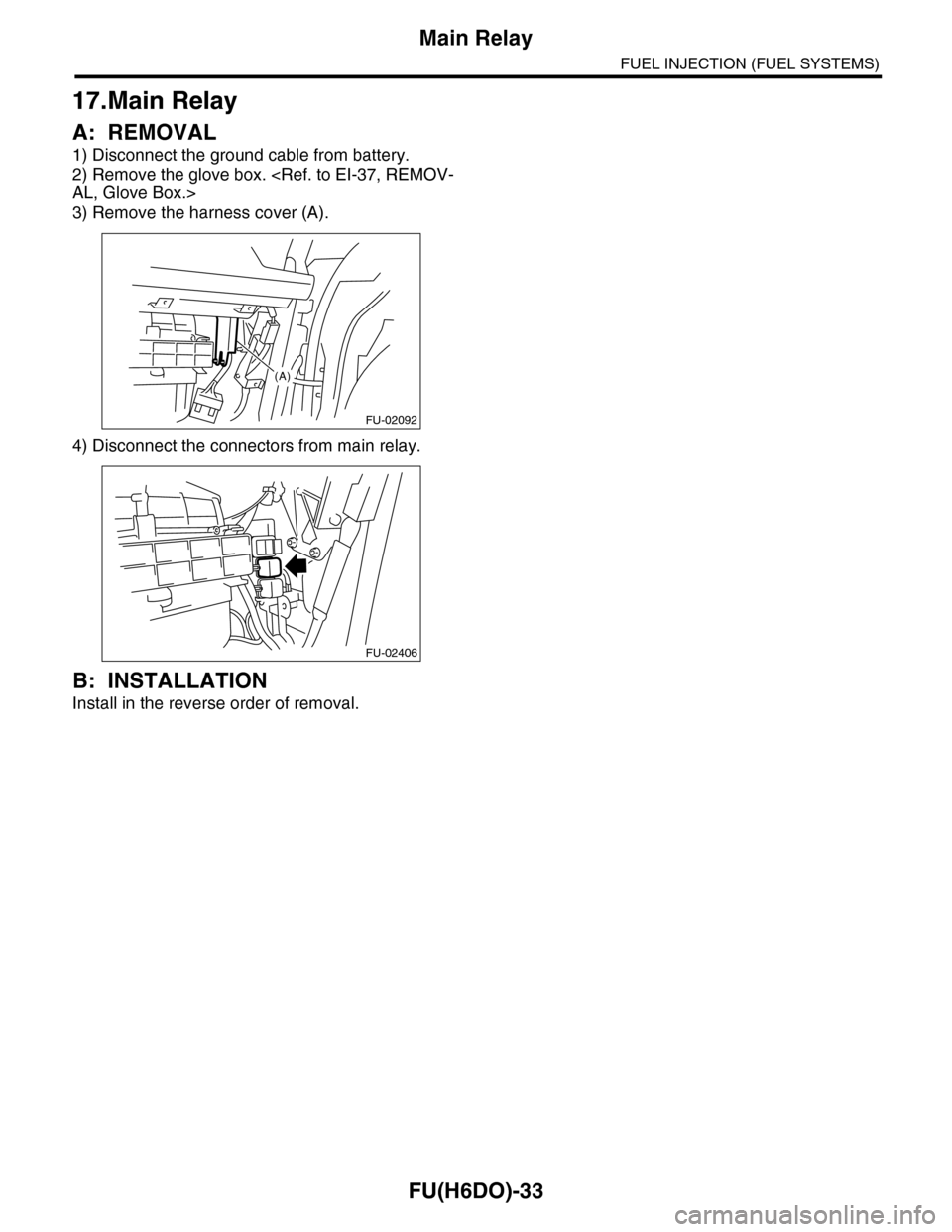

17.Main Relay

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the glove box.

AL, Glove Box.>

3) Remove the harness cover (A).

4) Disconnect the connectors from main relay.

B: INSTALLATION

Install in the reverse order of removal.

FU-02092

(A)

FU-02406