check engine SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1444 of 2453

EN(H6DO)(diag)-283

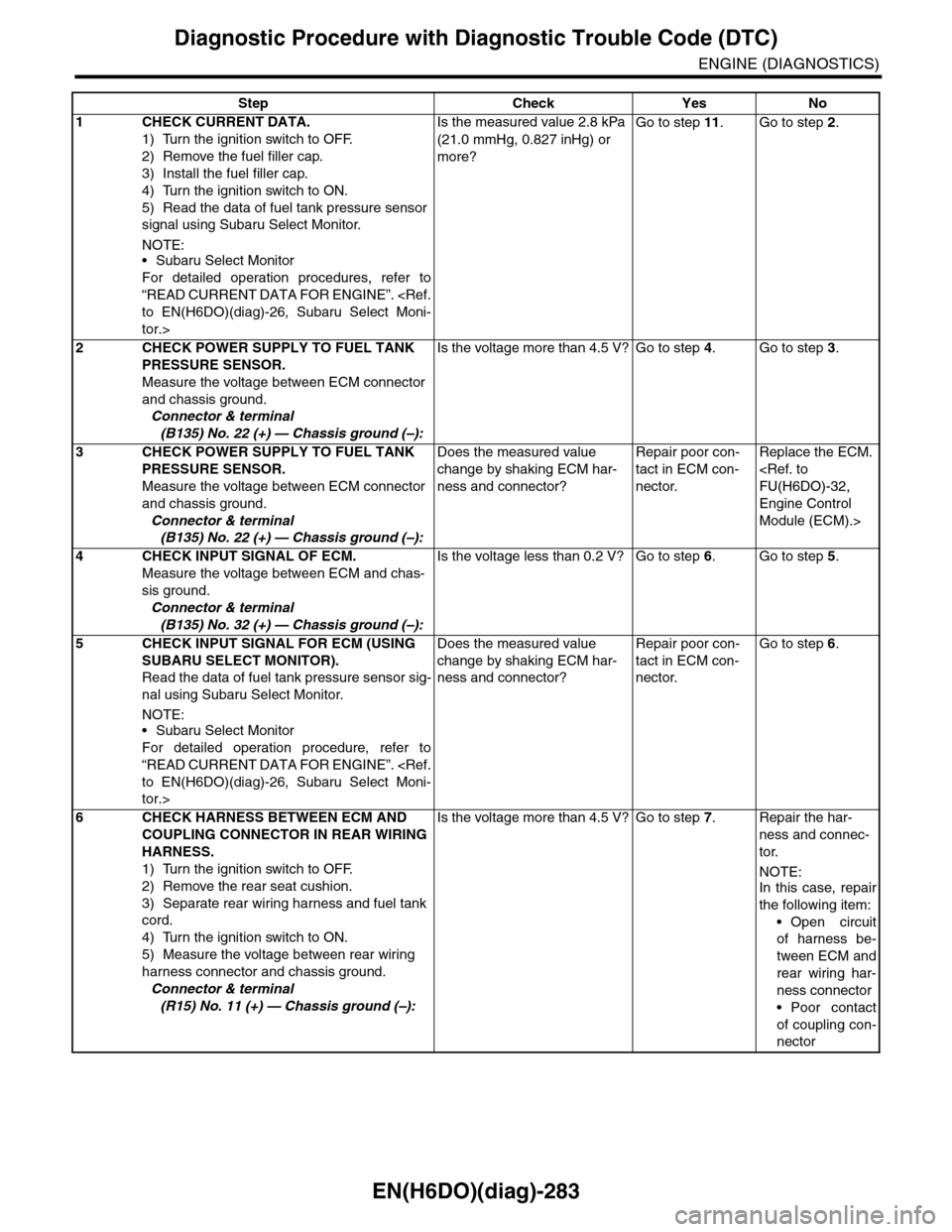

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK CURRENT DATA.

1) Turn the ignition switch to OFF.

2) Remove the fuel filler cap.

3) Install the fuel filler cap.

4) Turn the ignition switch to ON.

5) Read the data of fuel tank pressure sensor

signal using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the measured value 2.8 kPa

(21.0 mmHg, 0.827 inHg) or

more?

Go to step 11.Go to step 2.

2CHECK POWER SUPPLY TO FUEL TANK

PRESSURE SENSOR.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 22 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Go to step 4.Go to step 3.

3CHECK POWER SUPPLY TO FUEL TANK

PRESSURE SENSOR.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 22 (+) — Chassis ground (–):

Does the measured value

change by shaking ECM har-

ness and connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

4CHECK INPUT SIGNAL OF ECM.

Measure the voltage between ECM and chas-

sis ground.

Connector & terminal

(B135) No. 32 (+) — Chassis ground (–):

Is the voltage less than 0.2 V? Go to step 6.Go to step 5.

5CHECK INPUT SIGNAL FOR ECM (USING

SUBARU SELECT MONITOR).

Read the data of fuel tank pressure sensor sig-

nal using Subaru Select Monitor.

NOTE:

•Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Does the measured value

change by shaking ECM har-

ness and connector?

Repair poor con-

tact in ECM con-

nector.

Go to step 6.

6CHECK HARNESS BETWEEN ECM AND

COUPLING CONNECTOR IN REAR WIRING

HARNESS.

1) Turn the ignition switch to OFF.

2) Remove the rear seat cushion.

3) Separate rear wiring harness and fuel tank

cord.

4) Turn the ignition switch to ON.

5) Measure the voltage between rear wiring

harness connector and chassis ground.

Connector & terminal

(R15) No. 11 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Go to step 7.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

rear wiring har-

ness connector

•Poor contact

of coupling con-

nector

Page 1445 of 2453

EN(H6DO)(diag)-284

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

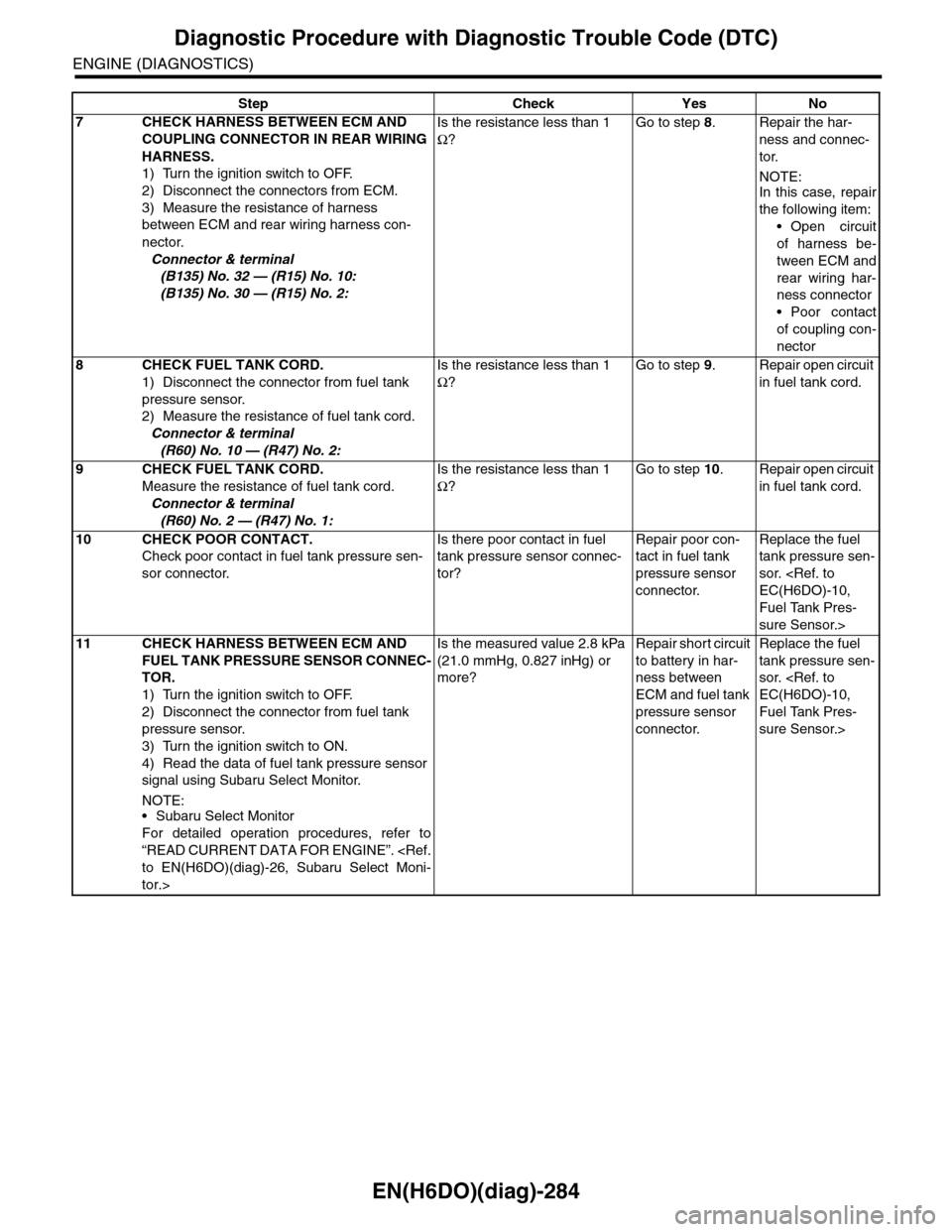

7CHECK HARNESS BETWEEN ECM AND

COUPLING CONNECTOR IN REAR WIRING

HARNESS.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM and rear wiring harness con-

nector.

Connector & terminal

(B135) No. 32 — (R15) No. 10:

(B135) No. 30 — (R15) No. 2:

Is the resistance less than 1

Ω?

Go to step 8.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

rear wiring har-

ness connector

•Poor contact

of coupling con-

nector

8CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel tank

pressure sensor.

2) Measure the resistance of fuel tank cord.

Connector & terminal

(R60) No. 10 — (R47) No. 2:

Is the resistance less than 1

Ω?

Go to step 9.Repair open circuit

in fuel tank cord.

9CHECK FUEL TANK CORD.

Measure the resistance of fuel tank cord.

Connector & terminal

(R60) No. 2 — (R47) No. 1:

Is the resistance less than 1

Ω?

Go to step 10.Repair open circuit

in fuel tank cord.

10 CHECK POOR CONTACT.

Check poor contact in fuel tank pressure sen-

sor connector.

Is there poor contact in fuel

tank pressure sensor connec-

tor?

Repair poor con-

tact in fuel tank

pressure sensor

connector.

Replace the fuel

tank pressure sen-

sor.

Fuel Tank Pres-

sure Sensor.>

11 CHECK HARNESS BETWEEN ECM AND

FUEL TANK PRESSURE SENSOR CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel tank

pressure sensor.

3) Turn the ignition switch to ON.

4) Read the data of fuel tank pressure sensor

signal using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the measured value 2.8 kPa

(21.0 mmHg, 0.827 inHg) or

more?

Repair short circuit

to battery in har-

ness between

ECM and fuel tank

pressure sensor

connector.

Replace the fuel

tank pressure sen-

sor.

Fuel Tank Pres-

sure Sensor.>

Step Check Yes No

Page 1446 of 2453

EN(H6DO)(diag)-285

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

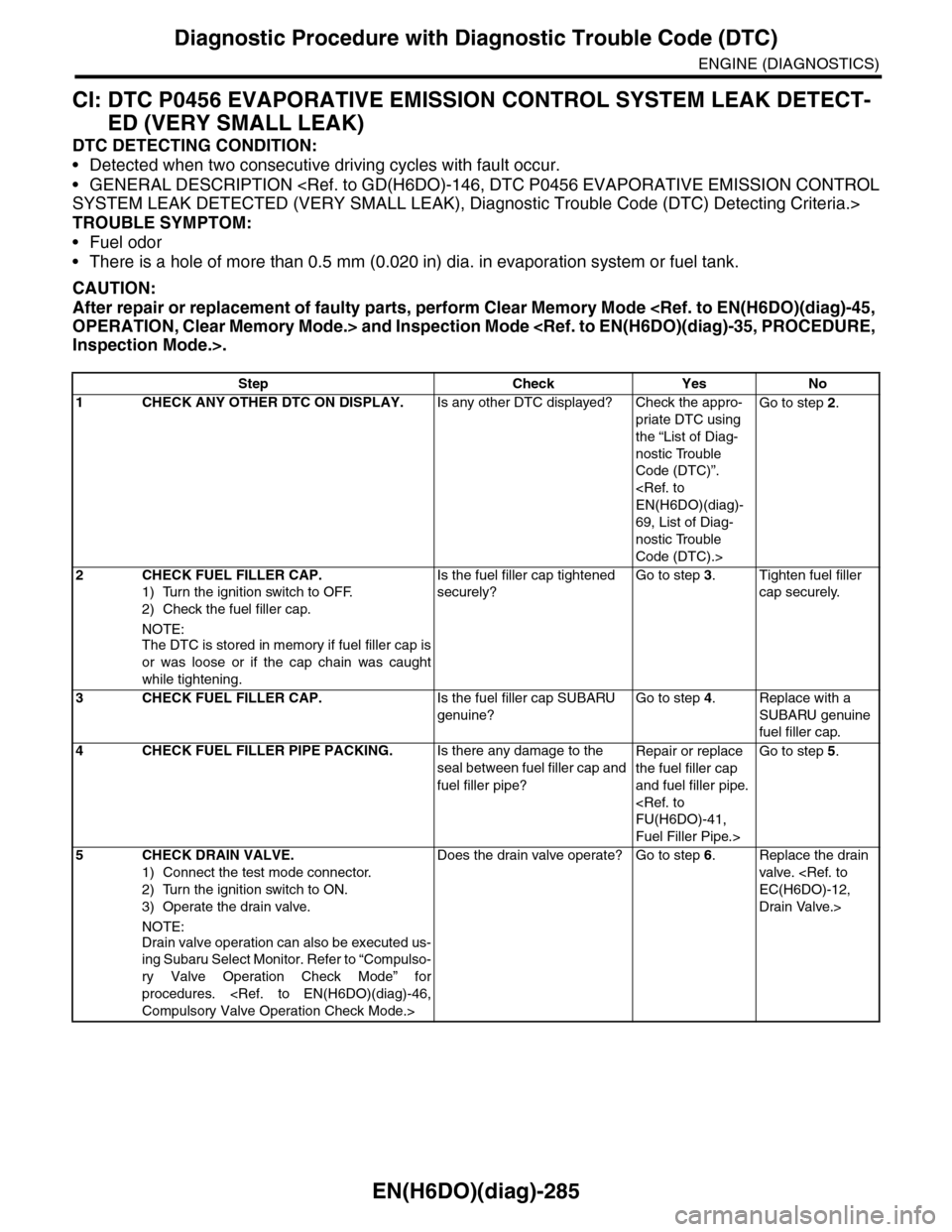

CI: DTC P0456 EVAPORATIVE EMISSION CONTROL SYSTEM LEAK DETECT-

ED (VERY SMALL LEAK)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Fuel odor

•There is a hole of more than 0.5 mm (0.020 in) dia. in evaporation system or fuel tank.

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK FUEL FILLER CAP.

1) Turn the ignition switch to OFF.

2) Check the fuel filler cap.

NOTE:

The DTC is stored in memory if fuel filler cap is

or was loose or if the cap chain was caught

while tightening.

Is the fuel filler cap tightened

securely?

Go to step 3.Tighten fuel filler

cap securely.

3CHECK FUEL FILLER CAP.Is the fuel filler cap SUBARU

genuine?

Go to step 4.Replace with a

SUBARU genuine

fuel filler cap.

4CHECK FUEL FILLER PIPE PACKING.Is there any damage to the

seal between fuel filler cap and

fuel filler pipe?

Repair or replace

the fuel filler cap

and fuel filler pipe.

Fuel Filler Pipe.>

Go to step 5.

5CHECK DRAIN VALVE.

1) Connect the test mode connector.

2) Turn the ignition switch to ON.

3) Operate the drain valve.

NOTE:

Drain valve operation can also be executed us-

ing Subaru Select Monitor. Refer to “Compulso-

ry Valve Operation Check Mode” for

procedures.

Does the drain valve operate? Go to step 6.Replace the drain

valve.

Drain Valve.>

Page 1447 of 2453

EN(H6DO)(diag)-286

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

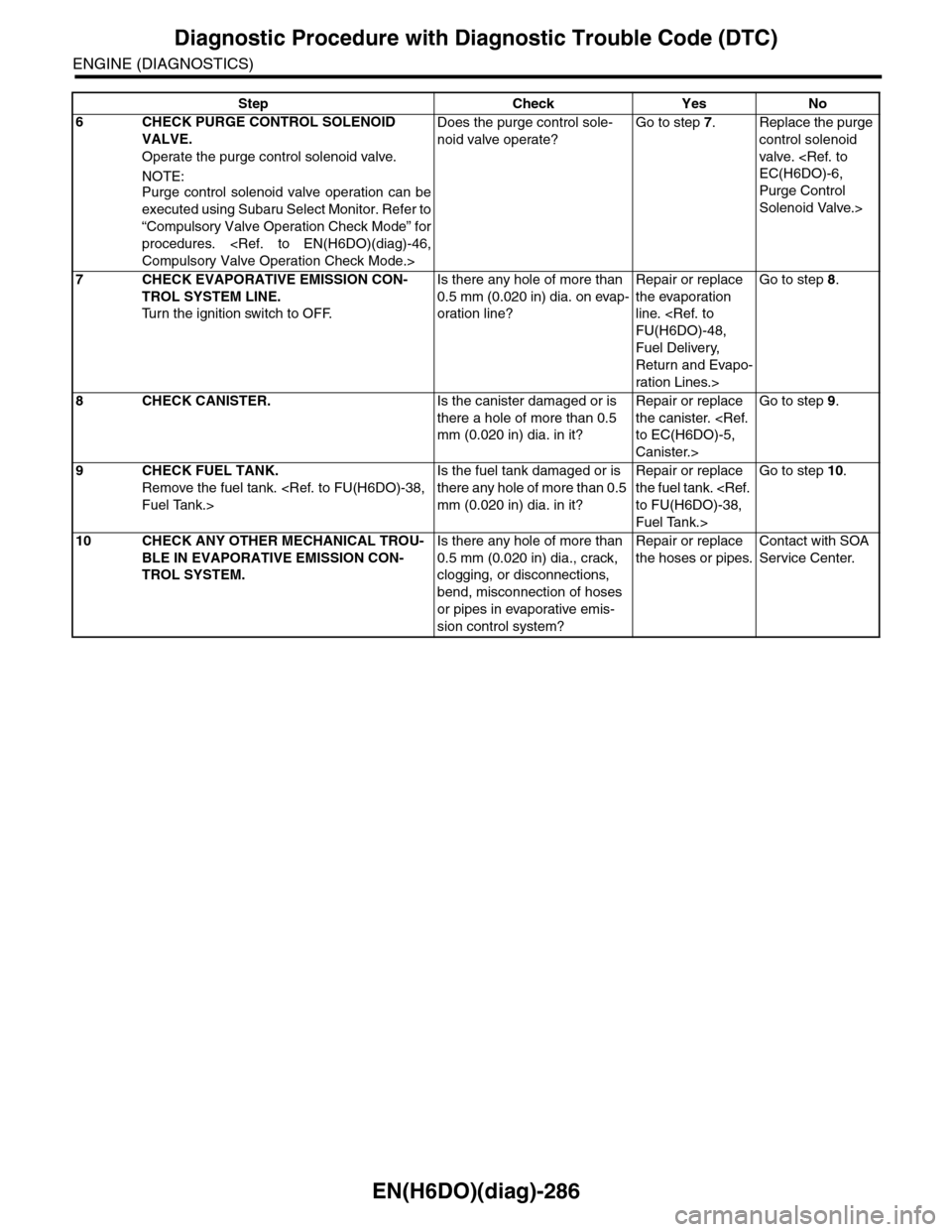

6CHECK PURGE CONTROL SOLENOID

VALVE.

Operate the purge control solenoid valve.

NOTE:Purge control solenoid valve operation can be

executed using Subaru Select Monitor. Refer to

“Compulsory Valve Operation Check Mode” for

procedures.

Does the purge control sole-

noid valve operate?

Go to step 7.Replace the purge

control solenoid

valve.

Purge Control

Solenoid Valve.>

7CHECK EVAPORATIVE EMISSION CON-

TROL SYSTEM LINE.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Is there any hole of more than

0.5 mm (0.020 in) dia. on evap-

oration line?

Repair or replace

the evaporation

line.

Fuel Delivery,

Return and Evapo-

ration Lines.>

Go to step 8.

8CHECK CANISTER.Is the canister damaged or is

there a hole of more than 0.5

mm (0.020 in) dia. in it?

Repair or replace

the canister.

Canister.>

Go to step 9.

9CHECK FUEL TANK.

Remove the fuel tank.

Is the fuel tank damaged or is

there any hole of more than 0.5

mm (0.020 in) dia. in it?

Repair or replace

the fuel tank.

Fuel Tank.>

Go to step 10.

10 CHECK ANY OTHER MECHANICAL TROU-

BLE IN EVAPORATIVE EMISSION CON-

TROL SYSTEM.

Is there any hole of more than

0.5 mm (0.020 in) dia., crack,

clogging, or disconnections,

bend, misconnection of hoses

or pipes in evaporative emis-

sion control system?

Repair or replace

the hoses or pipes.

Contact with SOA

Service Center.

Step Check Yes No

Page 1448 of 2453

EN(H6DO)(diag)-287

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

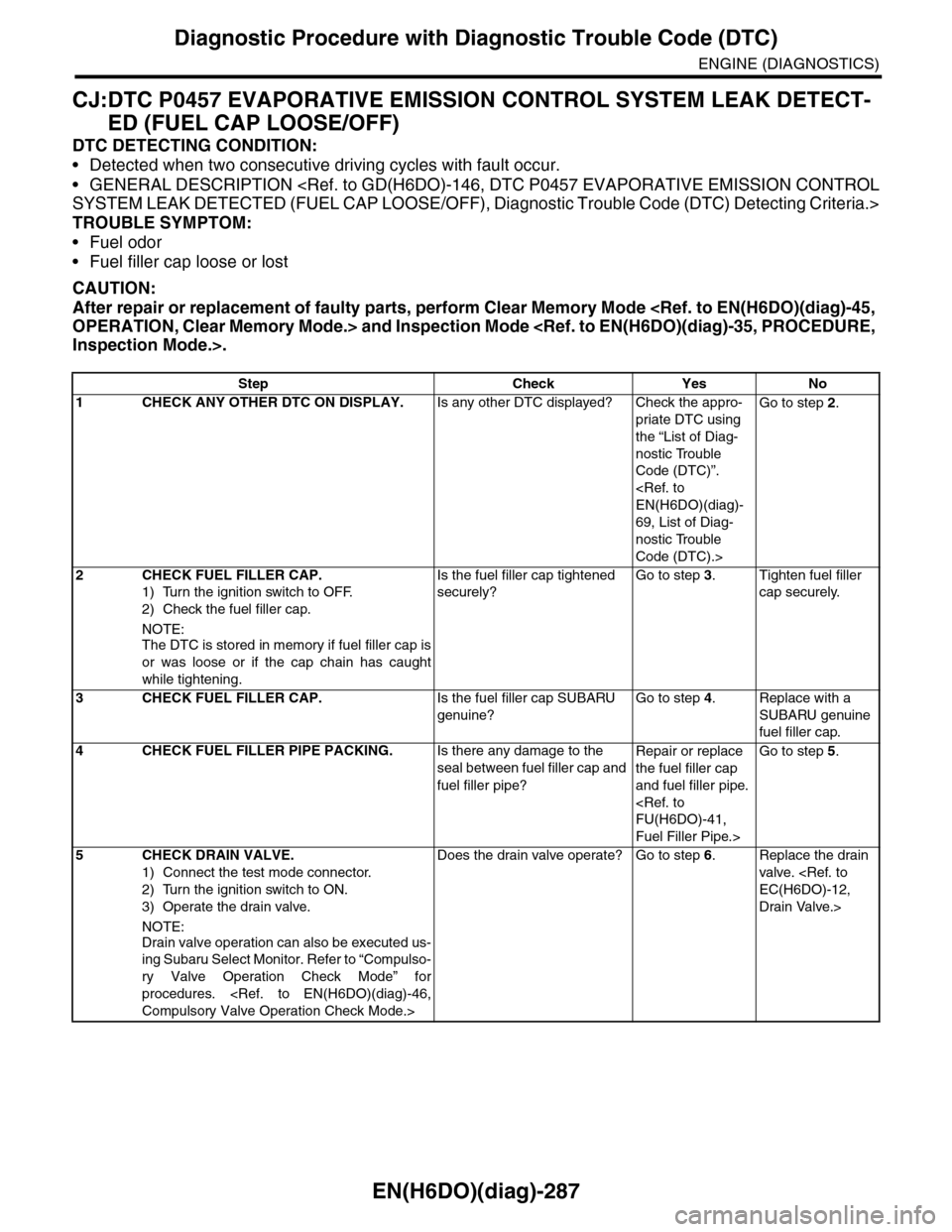

CJ:DTC P0457 EVAPORATIVE EMISSION CONTROL SYSTEM LEAK DETECT-

ED (FUEL CAP LOOSE/OFF)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Fuel odor

•Fuel filler cap loose or lost

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK FUEL FILLER CAP.

1) Turn the ignition switch to OFF.

2) Check the fuel filler cap.

NOTE:

The DTC is stored in memory if fuel filler cap is

or was loose or if the cap chain has caught

while tightening.

Is the fuel filler cap tightened

securely?

Go to step 3.Tighten fuel filler

cap securely.

3CHECK FUEL FILLER CAP.Is the fuel filler cap SUBARU

genuine?

Go to step 4.Replace with a

SUBARU genuine

fuel filler cap.

4CHECK FUEL FILLER PIPE PACKING.Is there any damage to the

seal between fuel filler cap and

fuel filler pipe?

Repair or replace

the fuel filler cap

and fuel filler pipe.

Fuel Filler Pipe.>

Go to step 5.

5CHECK DRAIN VALVE.

1) Connect the test mode connector.

2) Turn the ignition switch to ON.

3) Operate the drain valve.

NOTE:

Drain valve operation can also be executed us-

ing Subaru Select Monitor. Refer to “Compulso-

ry Valve Operation Check Mode” for

procedures.

Does the drain valve operate? Go to step 6.Replace the drain

valve.

Drain Valve.>

Page 1449 of 2453

EN(H6DO)(diag)-288

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

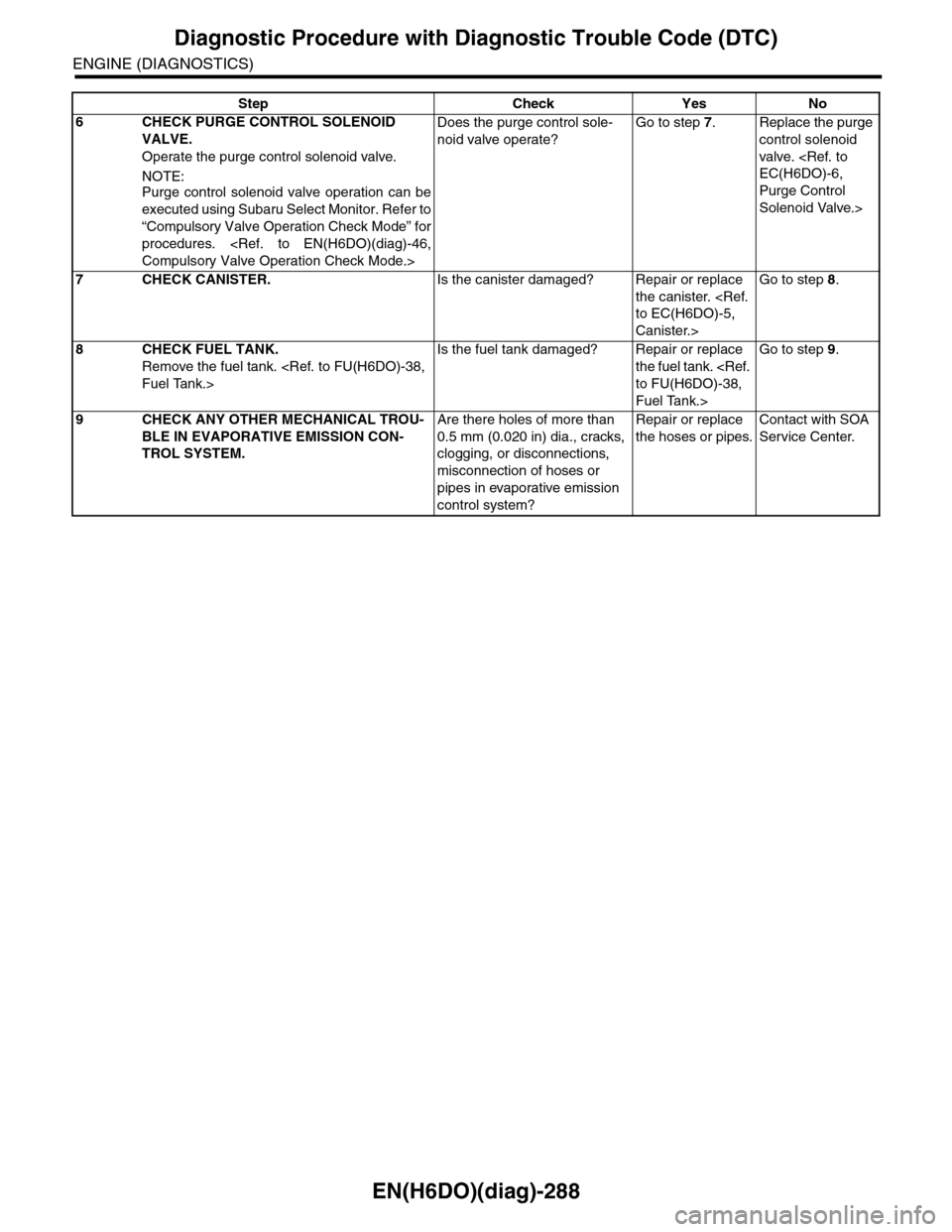

6CHECK PURGE CONTROL SOLENOID

VALVE.

Operate the purge control solenoid valve.

NOTE:Purge control solenoid valve operation can be

executed using Subaru Select Monitor. Refer to

“Compulsory Valve Operation Check Mode” for

procedures.

Does the purge control sole-

noid valve operate?

Go to step 7.Replace the purge

control solenoid

valve.

Purge Control

Solenoid Valve.>

7CHECK CANISTER.Is the canister damaged? Repair or replace

the canister.

Canister.>

Go to step 8.

8CHECK FUEL TANK.

Remove the fuel tank.

Is the fuel tank damaged? Repair or replace

the fuel tank.

Fuel Tank.>

Go to step 9.

9CHECK ANY OTHER MECHANICAL TROU-

BLE IN EVAPORATIVE EMISSION CON-

TROL SYSTEM.

Are there holes of more than

0.5 mm (0.020 in) dia., cracks,

clogging, or disconnections,

misconnection of hoses or

pipes in evaporative emission

control system?

Repair or replace

the hoses or pipes.

Contact with SOA

Service Center.

Step Check Yes No

Page 1451 of 2453

EN(H6DO)(diag)-290

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

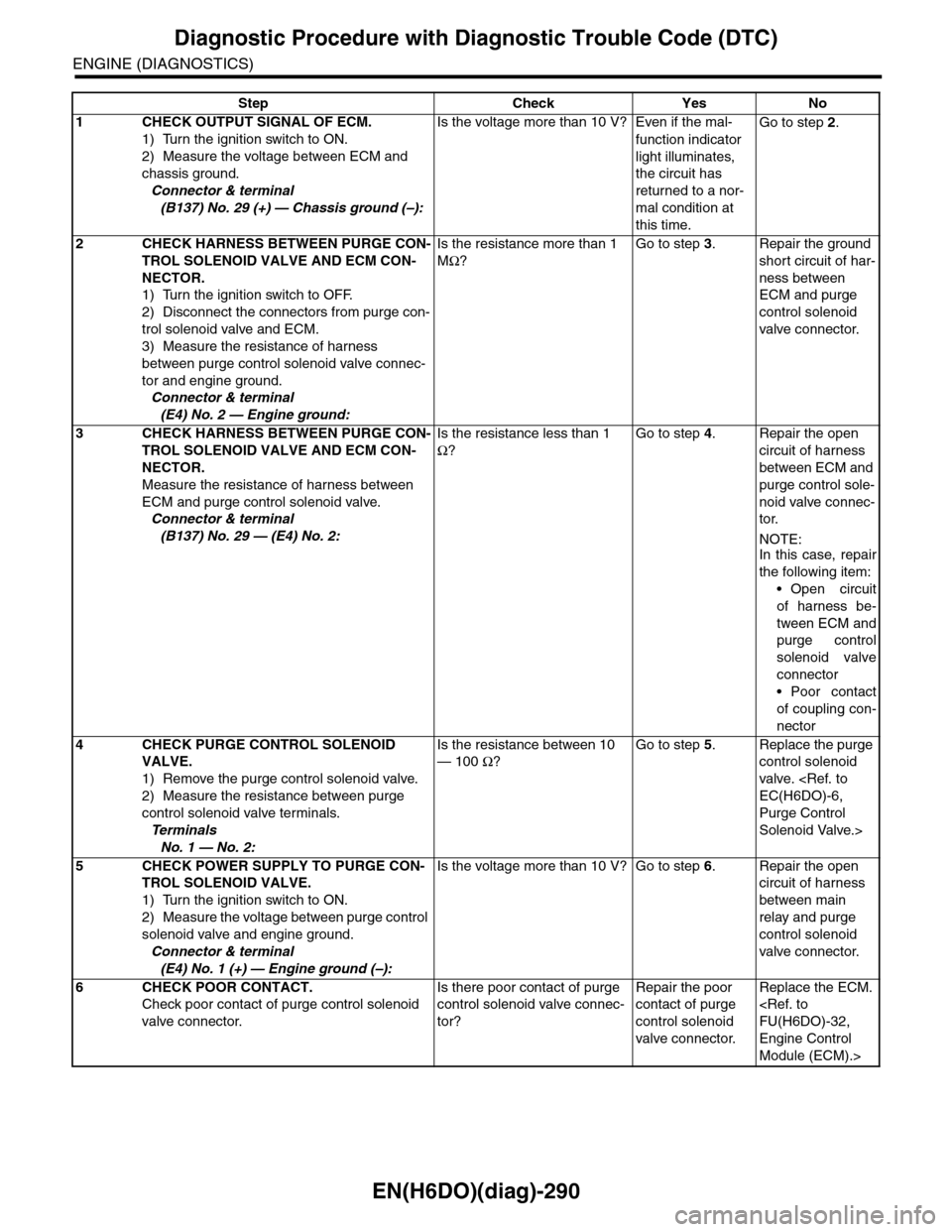

Step Check Yes No

1CHECK OUTPUT SIGNAL OF ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B137) No. 29 (+) — Chassis ground (–):

Is the voltage more than 10 V? Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.

Go to step 2.

2CHECK HARNESS BETWEEN PURGE CON-

TROL SOLENOID VALVE AND ECM CON-

NECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from purge con-

trol solenoid valve and ECM.

3) Measure the resistance of harness

between purge control solenoid valve connec-

tor and engine ground.

Connector & terminal

(E4) No. 2 — Engine ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the ground

short circuit of har-

ness between

ECM and purge

control solenoid

valve connector.

3CHECK HARNESS BETWEEN PURGE CON-

TROL SOLENOID VALVE AND ECM CON-

NECTOR.

Measure the resistance of harness between

ECM and purge control solenoid valve.

Connector & terminal

(B137) No. 29 — (E4) No. 2:

Is the resistance less than 1

Ω?

Go to step 4.Repair the open

circuit of harness

between ECM and

purge control sole-

noid valve connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

purge control

solenoid valve

connector

•Poor contact

of coupling con-

nector

4CHECK PURGE CONTROL SOLENOID

VALVE.

1) Remove the purge control solenoid valve.

2) Measure the resistance between purge

control solenoid valve terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance between 10

— 100 Ω?

Go to step 5.Replace the purge

control solenoid

valve.

Purge Control

Solenoid Valve.>

5CHECK POWER SUPPLY TO PURGE CON-

TROL SOLENOID VALVE.

1) Turn the ignition switch to ON.

2) Measure the voltage between purge control

solenoid valve and engine ground.

Connector & terminal

(E4) No. 1 (+) — Engine ground (–):

Is the voltage more than 10 V? Go to step 6.Repair the open

circuit of harness

between main

relay and purge

control solenoid

valve connector.

6CHECK POOR CONTACT.

Check poor contact of purge control solenoid

valve connector.

Is there poor contact of purge

control solenoid valve connec-

tor?

Repair the poor

contact of purge

control solenoid

valve connector.

Replace the ECM.

Engine Control

Module (ECM).>

Page 1453 of 2453

EN(H6DO)(diag)-292

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

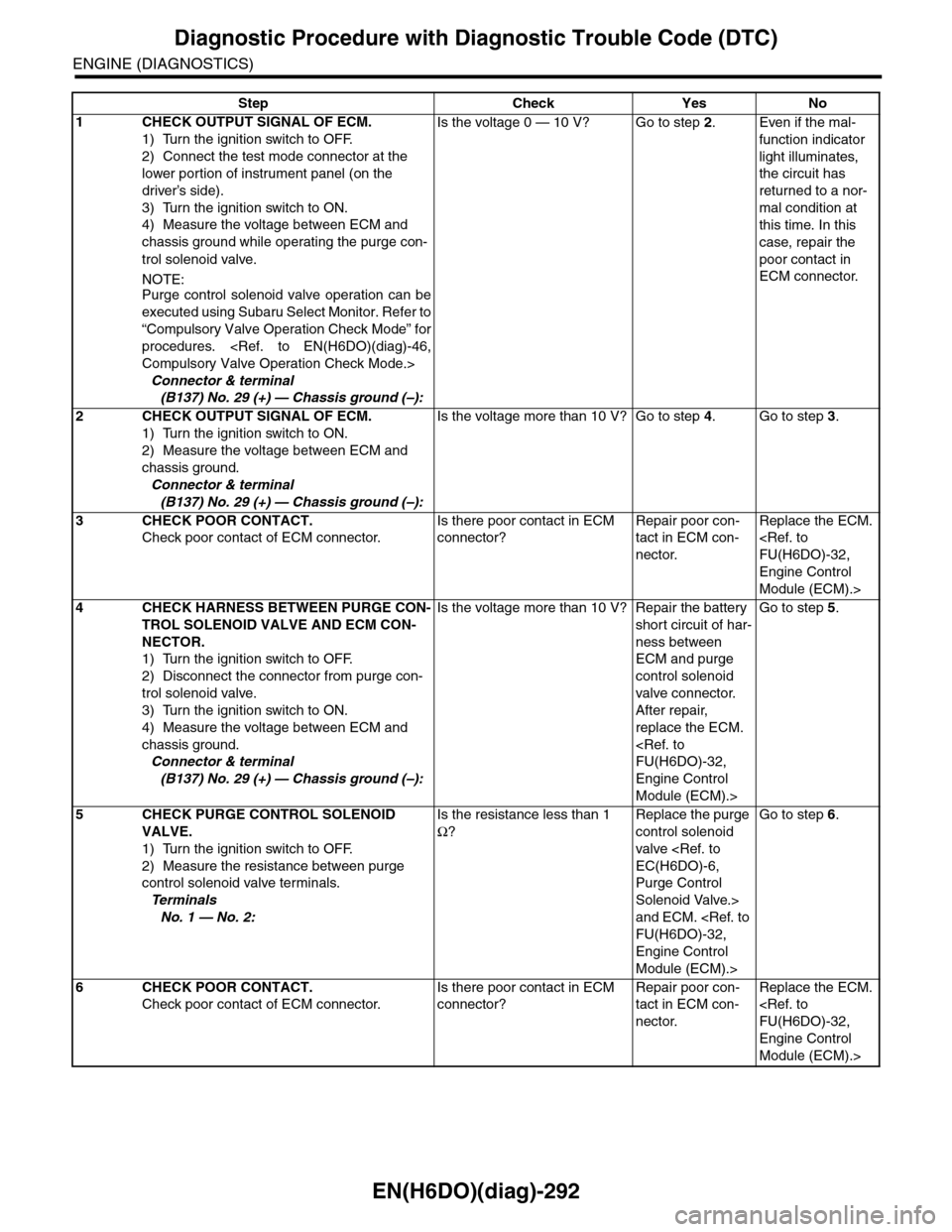

Step Check Yes No

1CHECK OUTPUT SIGNAL OF ECM.

1) Turn the ignition switch to OFF.

2) Connect the test mode connector at the

lower portion of instrument panel (on the

driver’s side).

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM and

chassis ground while operating the purge con-

trol solenoid valve.

NOTE:Purge control solenoid valve operation can be

executed using Subaru Select Monitor. Refer to

“Compulsory Valve Operation Check Mode” for

procedures.

Connector & terminal

(B137) No. 29 (+) — Chassis ground (–):

Is the voltage 0 — 10 V? Go to step 2.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time. In this

case, repair the

poor contact in

ECM connector.

2CHECK OUTPUT SIGNAL OF ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B137) No. 29 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Go to step 3.

3CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

4CHECK HARNESS BETWEEN PURGE CON-

TROL SOLENOID VALVE AND ECM CON-

NECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from purge con-

trol solenoid valve.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B137) No. 29 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and purge

control solenoid

valve connector.

After repair,

replace the ECM.

Engine Control

Module (ECM).>

Go to step 5.

5CHECK PURGE CONTROL SOLENOID

VALVE.

1) Turn the ignition switch to OFF.

2) Measure the resistance between purge

control solenoid valve terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance less than 1

Ω?

Replace the purge

control solenoid

valve

Purge Control

Solenoid Valve.>

and ECM.

Engine Control

Module (ECM).>

Go to step 6.

6CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

Page 1454 of 2453

EN(H6DO)(diag)-293

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

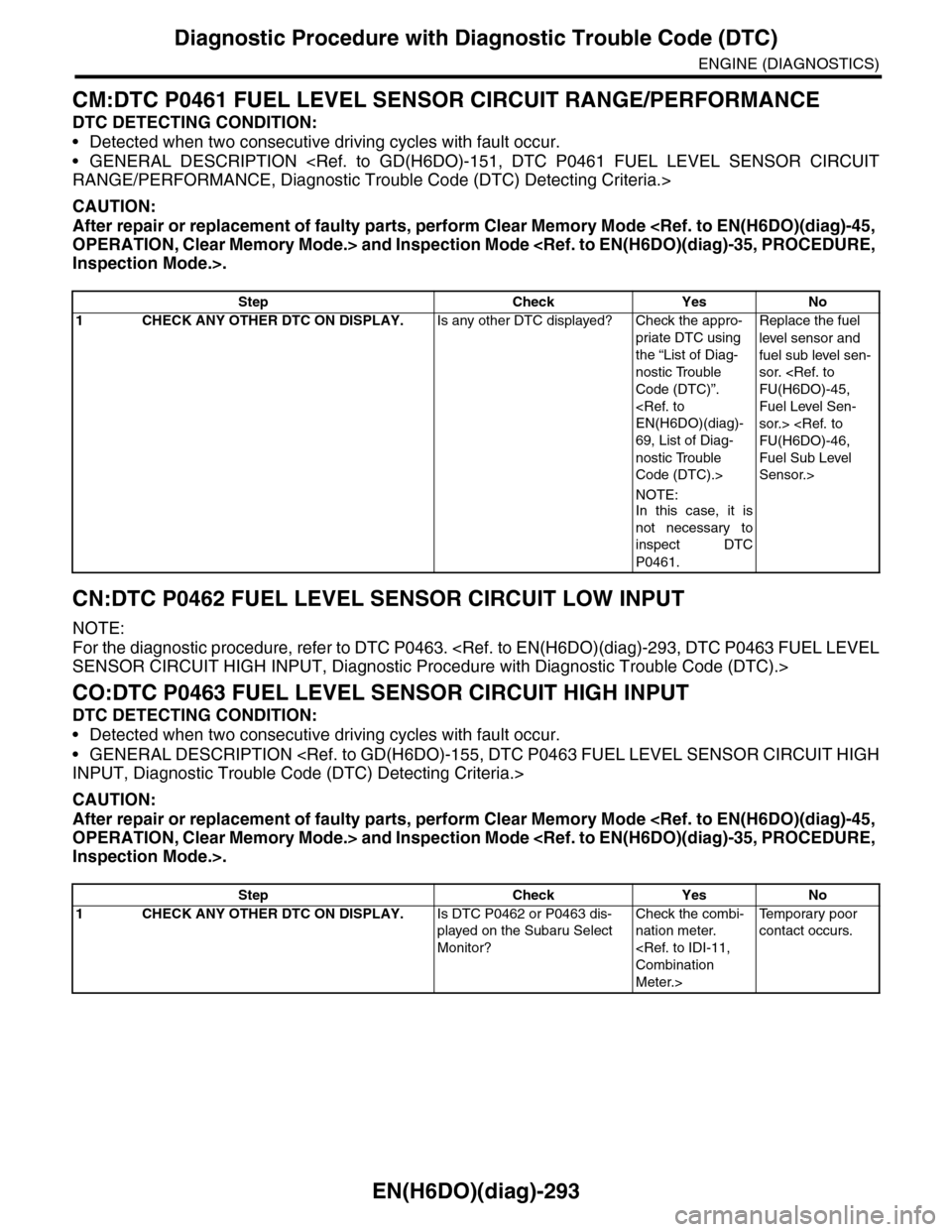

CM:DTC P0461 FUEL LEVEL SENSOR CIRCUIT RANGE/PERFORMANCE

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

CN:DTC P0462 FUEL LEVEL SENSOR CIRCUIT LOW INPUT

NOTE:

For the diagnostic procedure, refer to DTC P0463.

CO:DTC P0463 FUEL LEVEL SENSOR CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:In this case, it is

not necessary to

inspect DTC

P0461.

Replace the fuel

level sensor and

fuel sub level sen-

sor.

Fuel Level Sen-

sor.>

Fuel Sub Level

Sensor.>

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is DTC P0462 or P0463 dis-

played on the Subaru Select

Monitor?

Check the combi-

nation meter.

Meter.>

Te m p o r a r y p o o r

contact occurs.

Page 1455 of 2453

EN(H6DO)(diag)-294

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

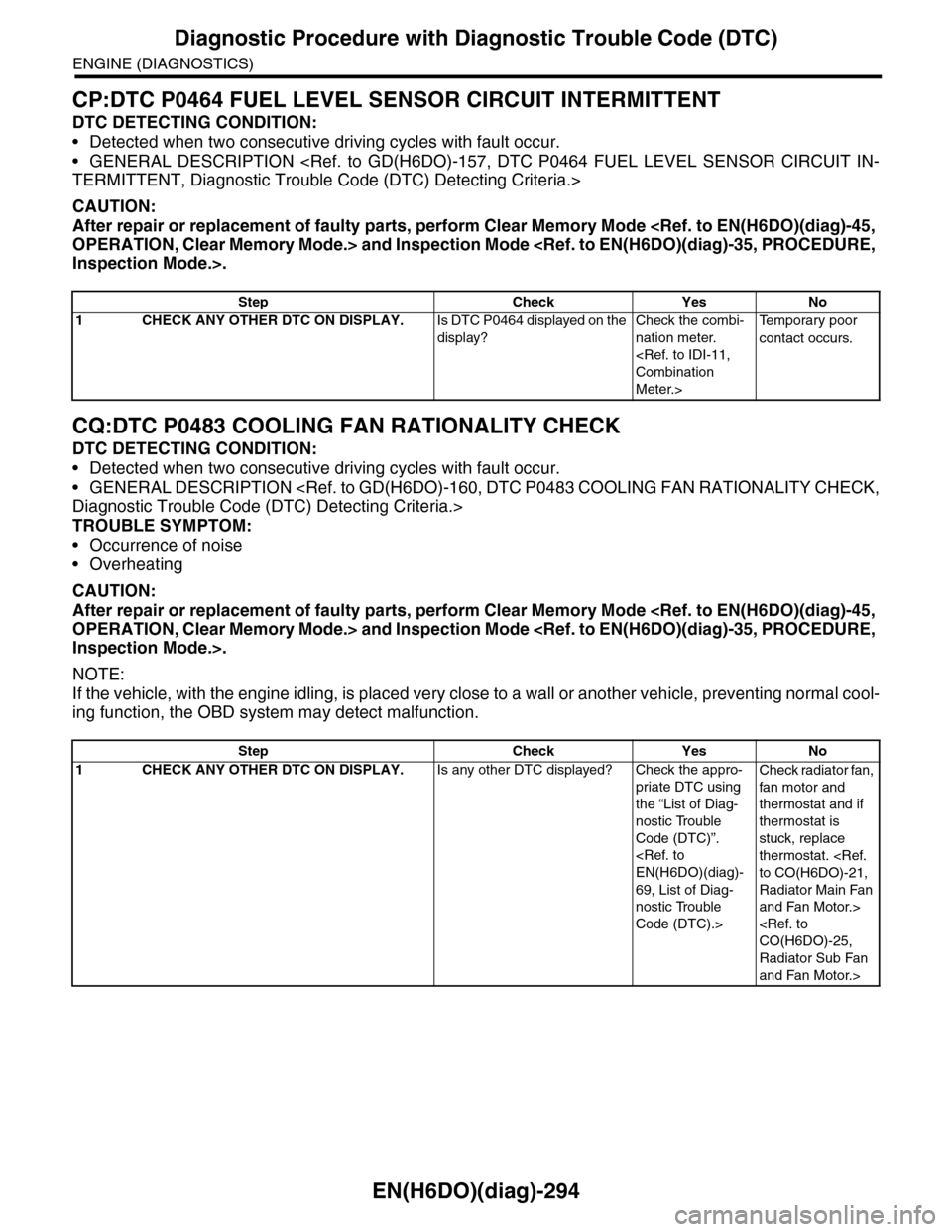

CP:DTC P0464 FUEL LEVEL SENSOR CIRCUIT INTERMITTENT

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

CQ:DTC P0483 COOLING FAN RATIONALITY CHECK

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Occurrence of noise

•Overheating

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

NOTE:

If the vehicle, with the engine idling, is placed very close to a wall or another vehicle, preventing normal cool-

ing function, the OBD system may detect malfunction.

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is DTC P0464 displayed on the

display?

Check the combi-

nation meter.

Meter.>

Te m p o r a r y p o o r

contact occurs.

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Check radiator fan,

fan motor and

thermostat and if

thermostat is

stuck, replace

thermostat.

Radiator Main Fan

and Fan Motor.>

Radiator Sub Fan

and Fan Motor.>