check engine SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1374 of 2453

EN(H6DO)(diag)-213

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

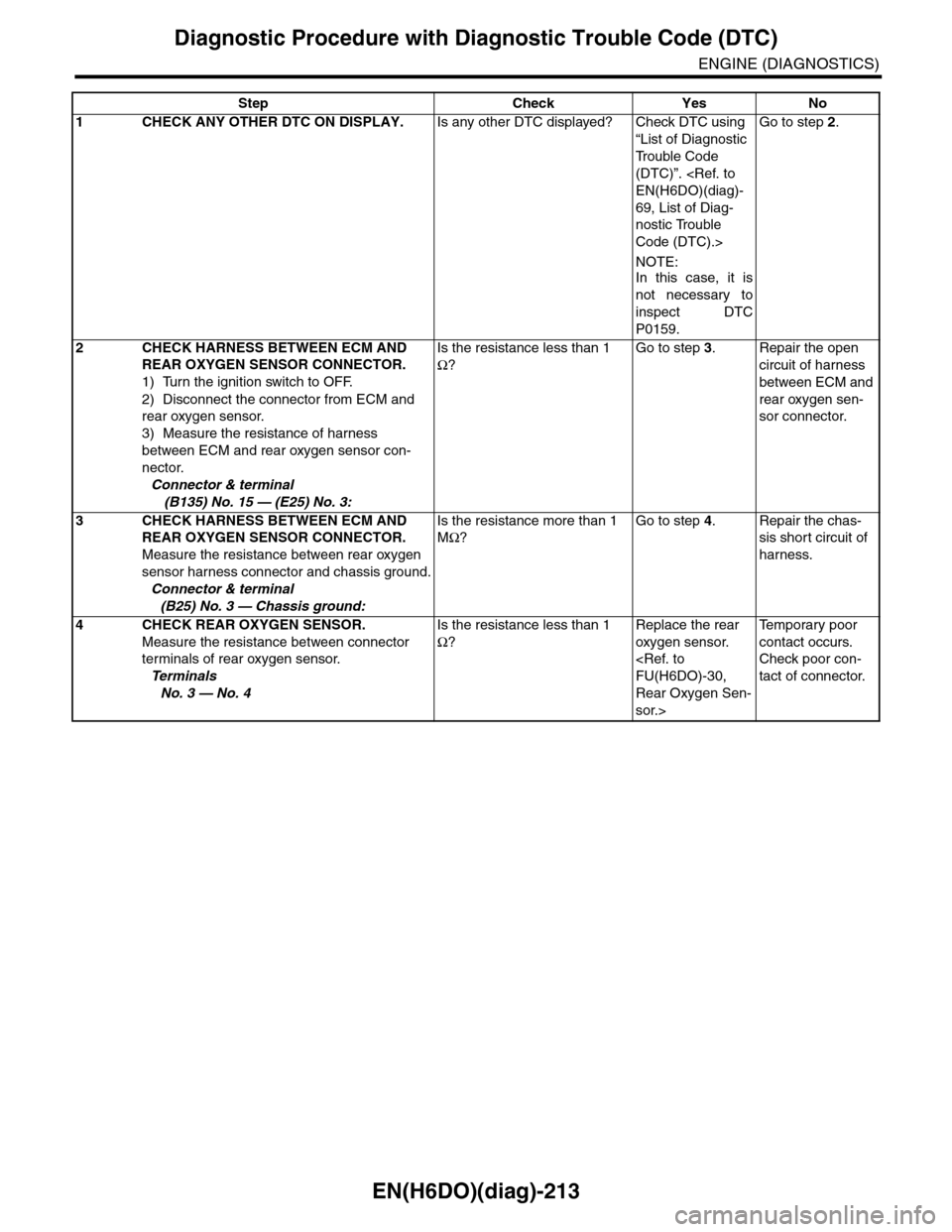

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:

In this case, it is

not necessary to

inspect DTC

P0159.

Go to step 2.

2CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

rear oxygen sensor.

3) Measure the resistance of harness

between ECM and rear oxygen sensor con-

nector.

Connector & terminal

(B135) No. 15 — (E25) No. 3:

Is the resistance less than 1

Ω?

Go to step 3.Repair the open

circuit of harness

between ECM and

rear oxygen sen-

sor connector.

3CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

Measure the resistance between rear oxygen

sensor harness connector and chassis ground.

Connector & terminal

(B25) No. 3 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 4.Repair the chas-

sis short circuit of

harness.

4CHECK REAR OXYGEN SENSOR.

Measure the resistance between connector

terminals of rear oxygen sensor.

Te r m i n a l s

No. 3 — No. 4

Is the resistance less than 1

Ω?

Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Te m p o r a r y p o o r

contact occurs.

Check poor con-

tact of connector.

Page 1377 of 2453

EN(H6DO)(diag)-216

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

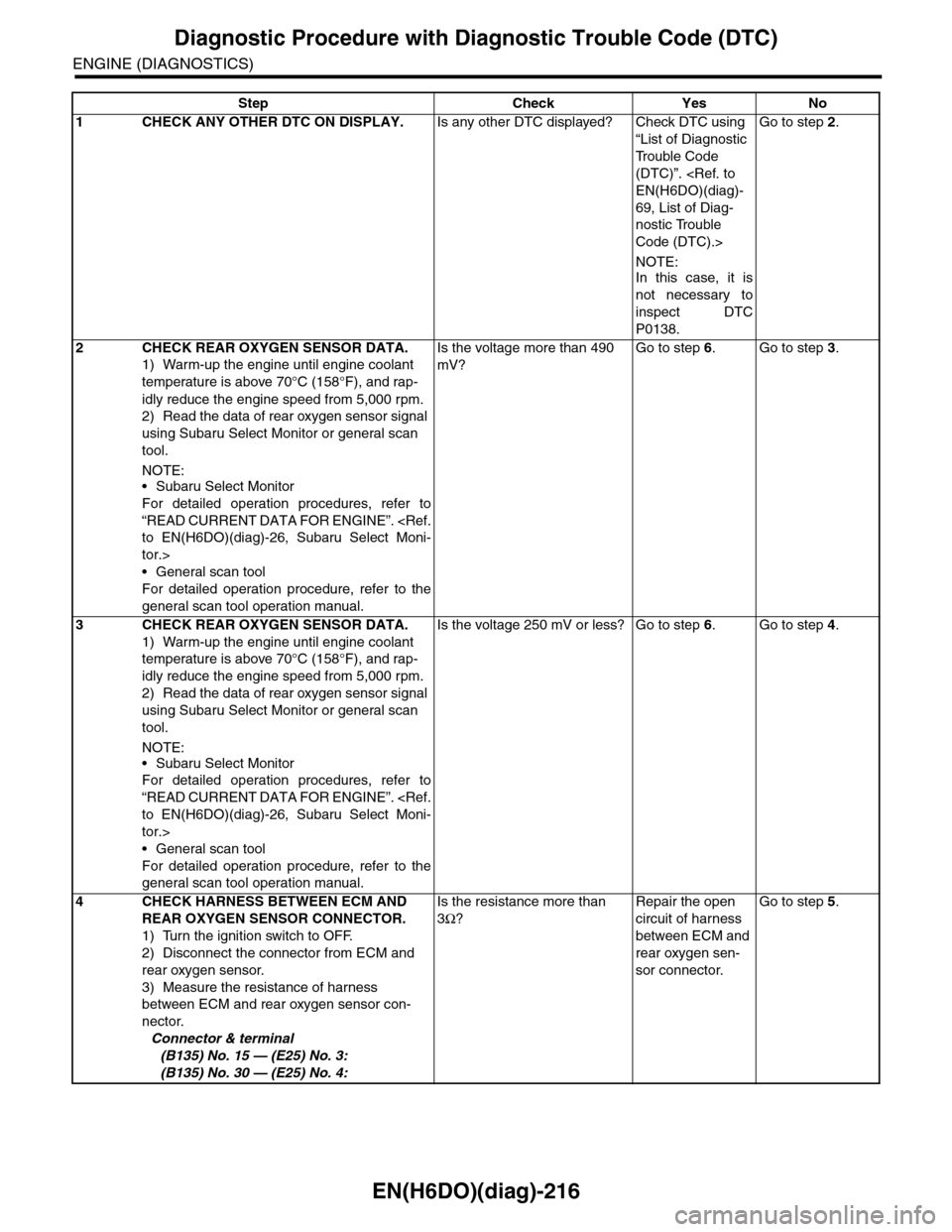

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:

In this case, it is

not necessary to

inspect DTC

P0138.

Go to step 2.

2CHECK REAR OXYGEN SENSOR DATA.

1) Warm-up the engine until engine coolant

temperature is above 70°C (158°F), and rap-

idly reduce the engine speed from 5,000 rpm.

2) Read the data of rear oxygen sensor signal

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the voltage more than 490

mV?

Go to step 6.Go to step 3.

3CHECK REAR OXYGEN SENSOR DATA.

1) Warm-up the engine until engine coolant

temperature is above 70°C (158°F), and rap-

idly reduce the engine speed from 5,000 rpm.

2) Read the data of rear oxygen sensor signal

using Subaru Select Monitor or general scan

tool.

NOTE:

•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the voltage 250 mV or less? Go to step 6.Go to step 4.

4CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

rear oxygen sensor.

3) Measure the resistance of harness

between ECM and rear oxygen sensor con-

nector.

Connector & terminal

(B135) No. 15 — (E25) No. 3:

(B135) No. 30 — (E25) No. 4:

Is the resistance more than

3Ω?

Repair the open

circuit of harness

between ECM and

rear oxygen sen-

sor connector.

Go to step 5.

Page 1378 of 2453

EN(H6DO)(diag)-217

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

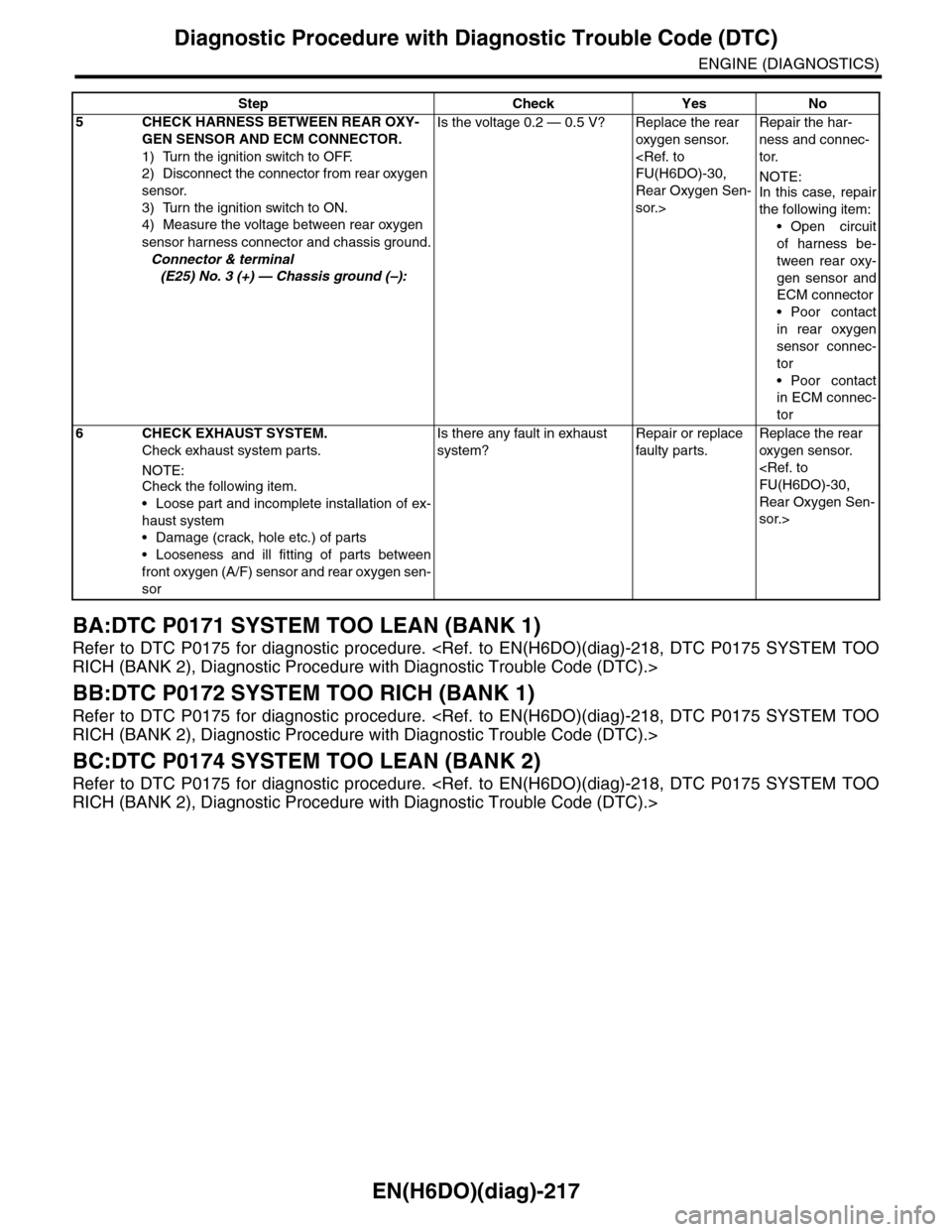

BA:DTC P0171 SYSTEM TOO LEAN (BANK 1)

Refer to DTC P0175 for diagnostic procedure.

BB:DTC P0172 SYSTEM TOO RICH (BANK 1)

Refer to DTC P0175 for diagnostic procedure.

BC:DTC P0174 SYSTEM TOO LEAN (BANK 2)

Refer to DTC P0175 for diagnostic procedure.

5CHECK HARNESS BETWEEN REAR OXY-

GEN SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor harness connector and chassis ground.

Connector & terminal

(E25) No. 3 (+) — Chassis ground (–):

Is the voltage 0.2 — 0.5 V? Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween rear oxy-

gen sensor and

ECM connector

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

in ECM connec-

tor

6 CHECK EXHAUST SYSTEM.

Check exhaust system parts.

NOTE:Check the following item.

•Loose part and incomplete installation of ex-

haust system

•Damage (crack, hole etc.) of parts

•Looseness and ill fitting of parts between

front oxygen (A/F) sensor and rear oxygen sen-

sor

Is there any fault in exhaust

system?

Repair or replace

faulty par ts.

Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Step Check Yes No

Page 1379 of 2453

EN(H6DO)(diag)-218

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

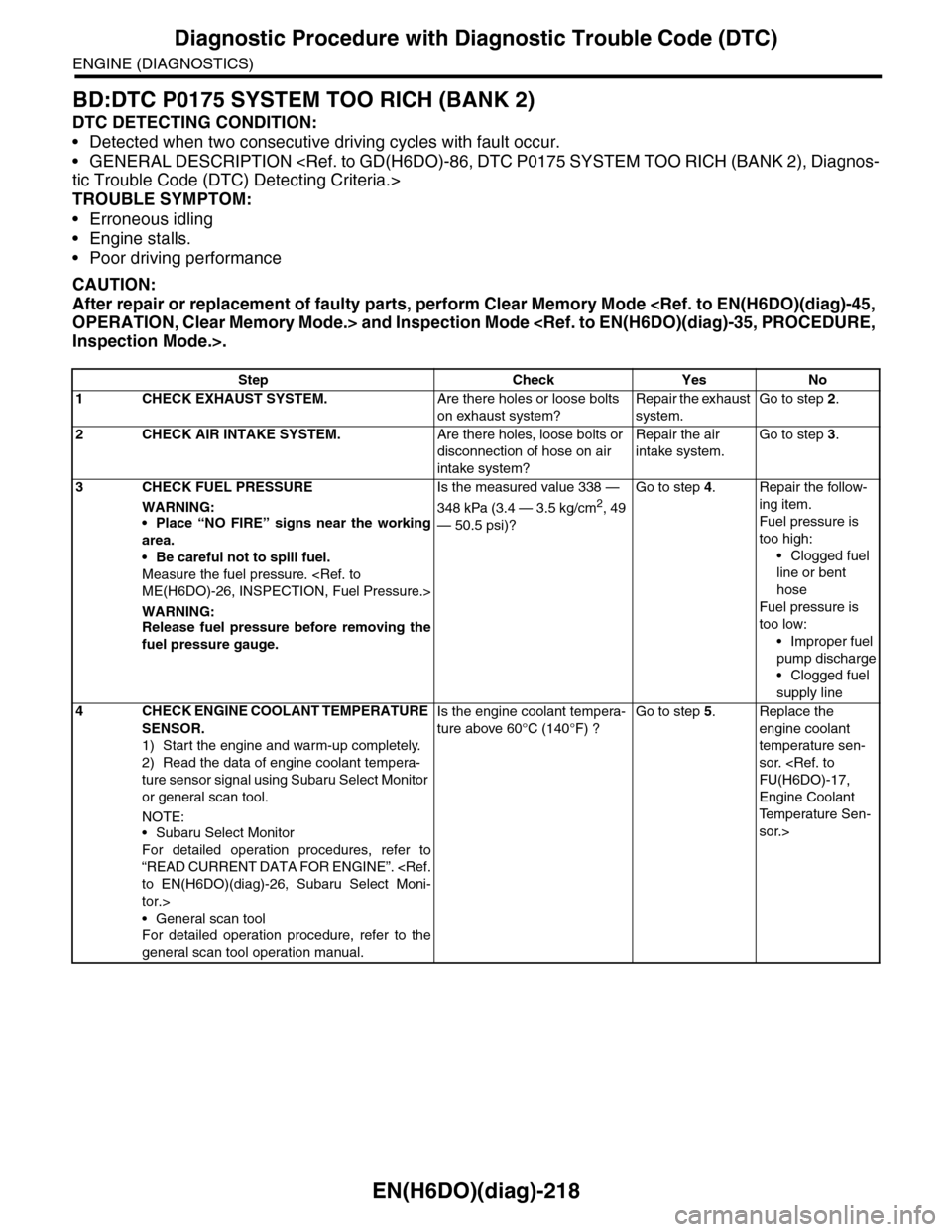

BD:DTC P0175 SYSTEM TOO RICH (BANK 2)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Erroneous idling

•Engine stalls.

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1 CHECK EXHAUST SYSTEM.Are there holes or loose bolts

on exhaust system?

Repair the exhaust

system.

Go to step 2.

2CHECK AIR INTAKE SYSTEM.Are there holes, loose bolts or

disconnection of hose on air

intake system?

Repair the air

intake system.

Go to step 3.

3CHECK FUEL PRESSURE

WARNING:

•Place “NO FIRE” signs near the working

area.

•Be careful not to spill fuel.

Measure the fuel pressure.

WARNING:Release fuel pressure before removing the

fuel pressure gauge.

Is the measured value 338 —

348 kPa (3.4 — 3.5 kg/cm2, 49

— 50.5 psi)?

Go to step 4.Repair the follow-

ing item.

Fuel pressure is

too high:

•Clogged fuel

line or bent

hose

Fuel pressure is

too low:

•Improper fuel

pump discharge

•Clogged fuel

supply line

4CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

1) Start the engine and warm-up completely.

2) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the engine coolant tempera-

ture above 60°C (140°F) ?

Go to step 5.Replace the

engine coolant

temperature sen-

sor.

Engine Coolant

Te m p e r a t u r e S e n -

sor.>

Page 1380 of 2453

EN(H6DO)(diag)-219

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

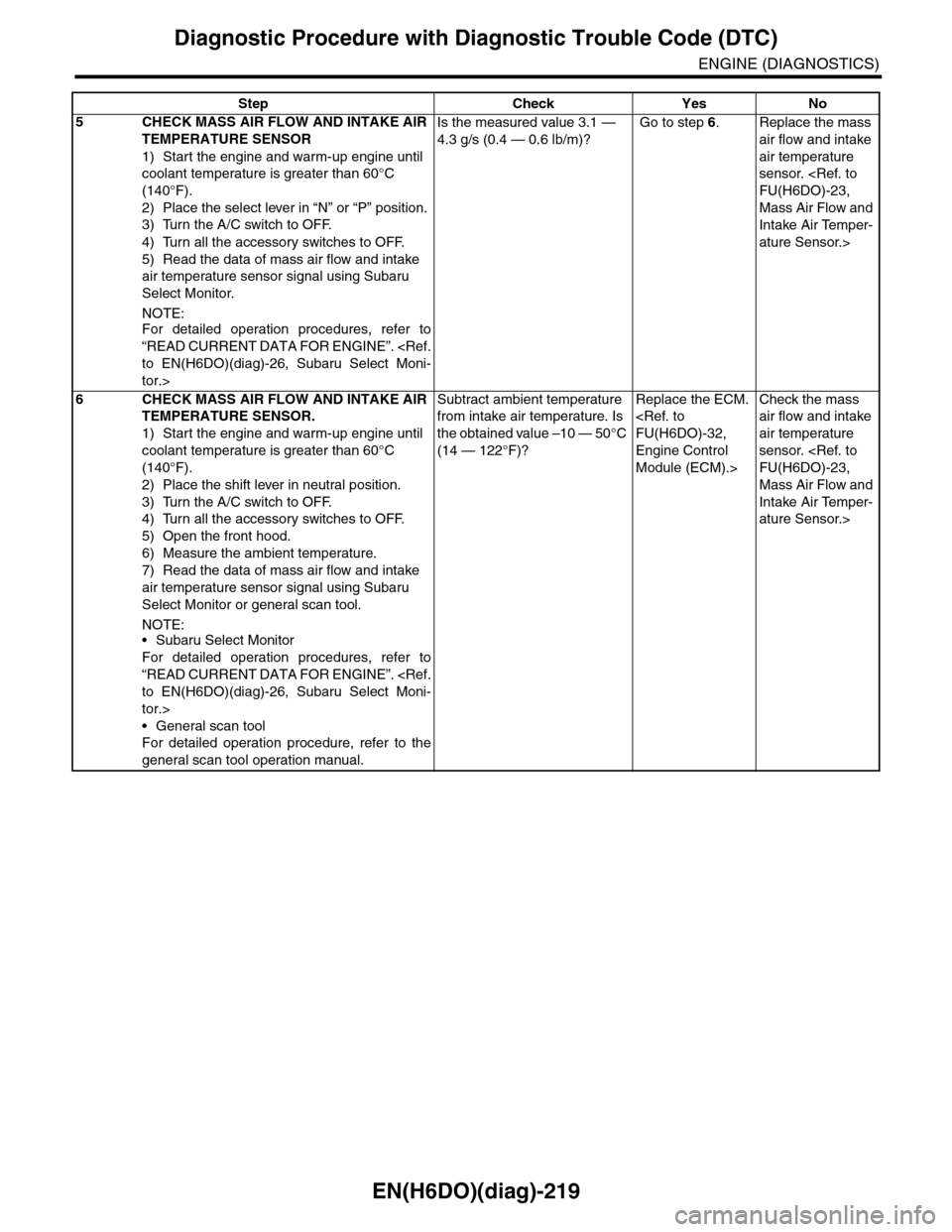

5CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR

1) Start the engine and warm-up engine until

coolant temperature is greater than 60°C

(140°F).

2) Place the select lever in “N” or “P” position.

3) Turn the A/C switch to OFF.

4) Turn all the accessory switches to OFF.

5) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor.

NOTE:

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the measured value 3.1 —

4.3 g/s (0.4 — 0.6 lb/m)?

Go to step 6.Replace the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

6CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR.

1) Start the engine and warm-up engine until

coolant temperature is greater than 60°C

(140°F).

2) Place the shift lever in neutral position.

3) Turn the A/C switch to OFF.

4) Turn all the accessory switches to OFF.

5) Open the front hood.

6) Measure the ambient temperature.

7) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor or general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Subtract ambient temperature

from intake air temperature. Is

the obtained value –10 — 50°C

(14 — 122°F)?

Replace the ECM.

Engine Control

Module (ECM).>

Check the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

Step Check Yes No

Page 1382 of 2453

EN(H6DO)(diag)-221

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

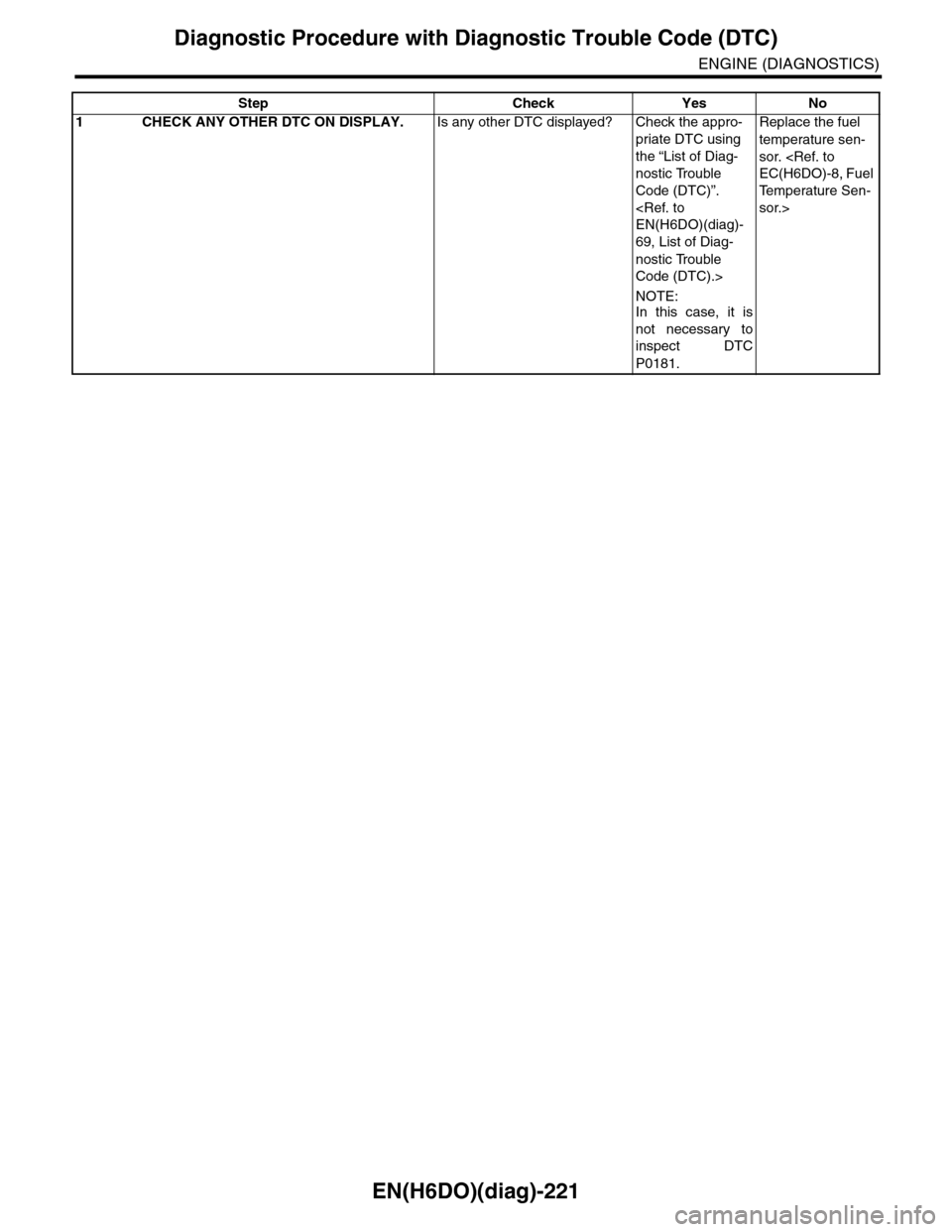

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:In this case, it is

not necessary to

inspect DTC

P0181.

Replace the fuel

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>

Page 1384 of 2453

EN(H6DO)(diag)-223

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

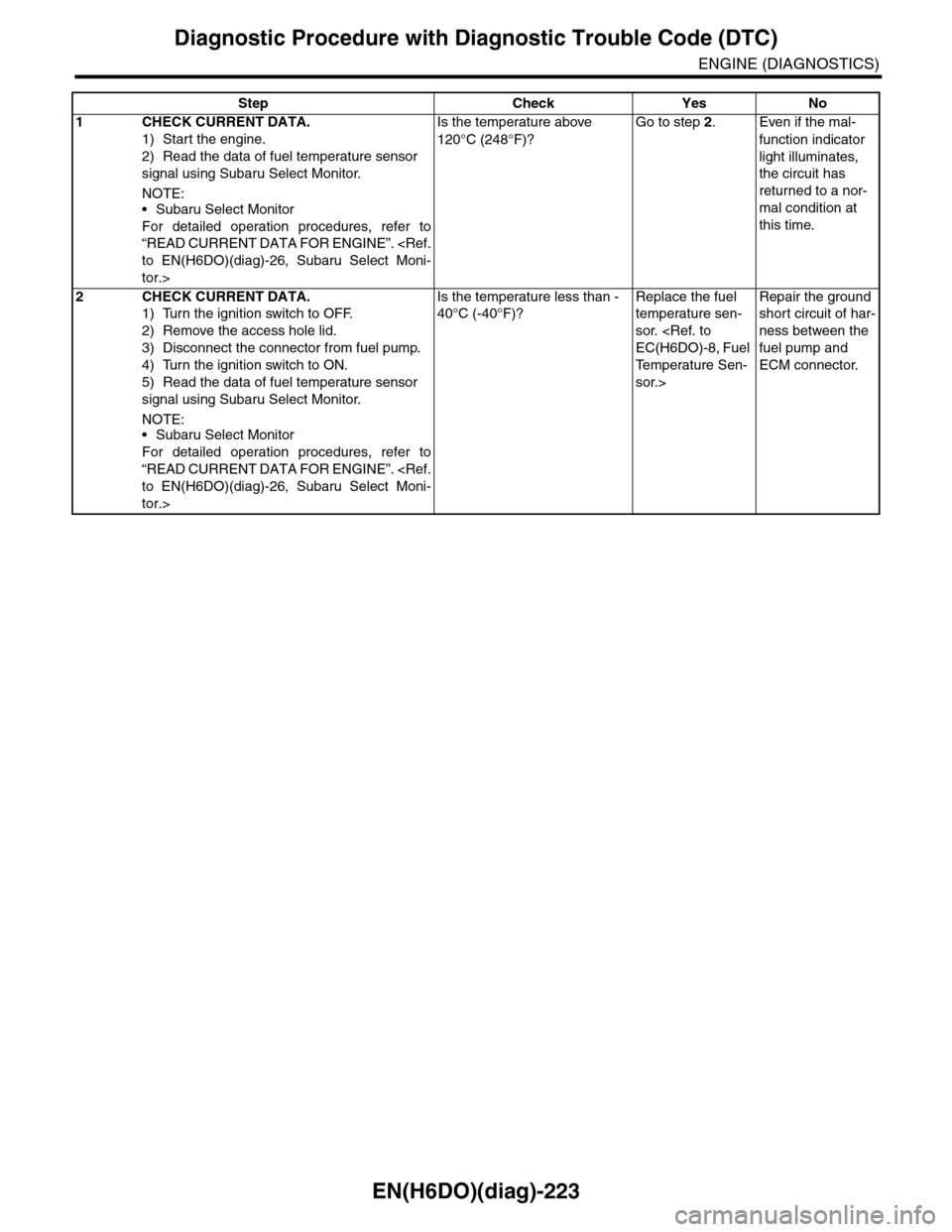

1CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of fuel temperature sensor

signal using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the temperature above

120°C (248°F)?

Go to step 2.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.

2CHECK CURRENT DATA.

1) Turn the ignition switch to OFF.

2) Remove the access hole lid.

3) Disconnect the connector from fuel pump.

4) Turn the ignition switch to ON.

5) Read the data of fuel temperature sensor

signal using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the temperature less than -

40°C (-40°F)?

Replace the fuel

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>

Repair the ground

short circuit of har-

ness between the

fuel pump and

ECM connector.

Page 1386 of 2453

EN(H6DO)(diag)-225

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

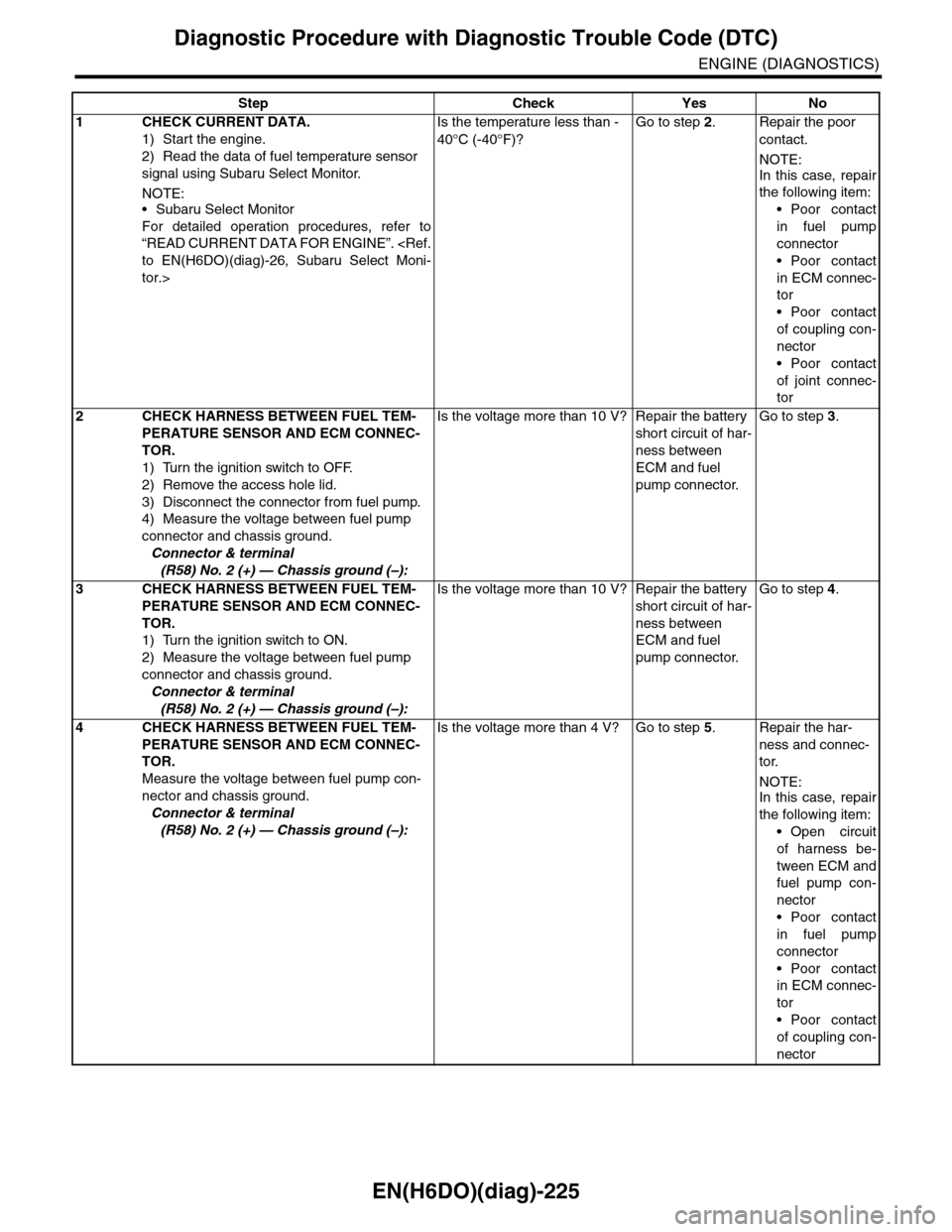

1CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of fuel temperature sensor

signal using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the temperature less than -

40°C (-40°F)?

Go to step 2.Repair the poor

contact.

NOTE:

In this case, repair

the following item:

•Poor contact

in fuel pump

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

of joint connec-

tor

2 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Remove the access hole lid.

3) Disconnect the connector from fuel pump.

4) Measure the voltage between fuel pump

connector and chassis ground.

Connector & terminal

(R58) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and fuel

pump connector.

Go to step 3.

3 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between fuel pump

connector and chassis ground.

Connector & terminal

(R58) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and fuel

pump connector.

Go to step 4.

4 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

Measure the voltage between fuel pump con-

nector and chassis ground.

Connector & terminal

(R58) No. 2 (+) — Chassis ground (–):

Is the voltage more than 4 V? Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

fuel pump con-

nector

•Poor contact

in fuel pump

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

Page 1387 of 2453

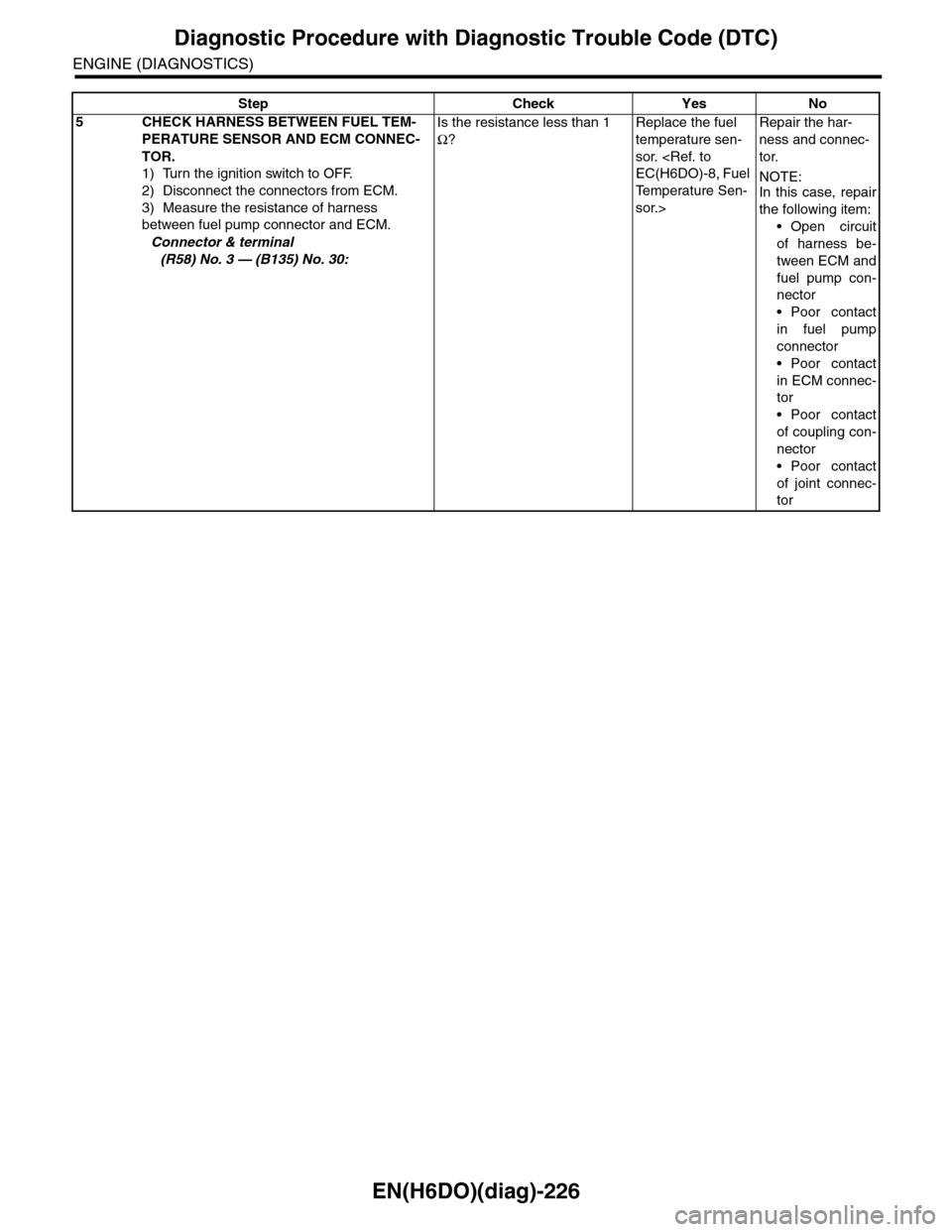

EN(H6DO)(diag)-226

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

5 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between fuel pump connector and ECM.

Connector & terminal

(R58) No. 3 — (B135) No. 30:

Is the resistance less than 1

Ω?

Replace the fuel

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

fuel pump con-

nector

•Poor contact

in fuel pump

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

of joint connec-

tor

Step Check Yes No

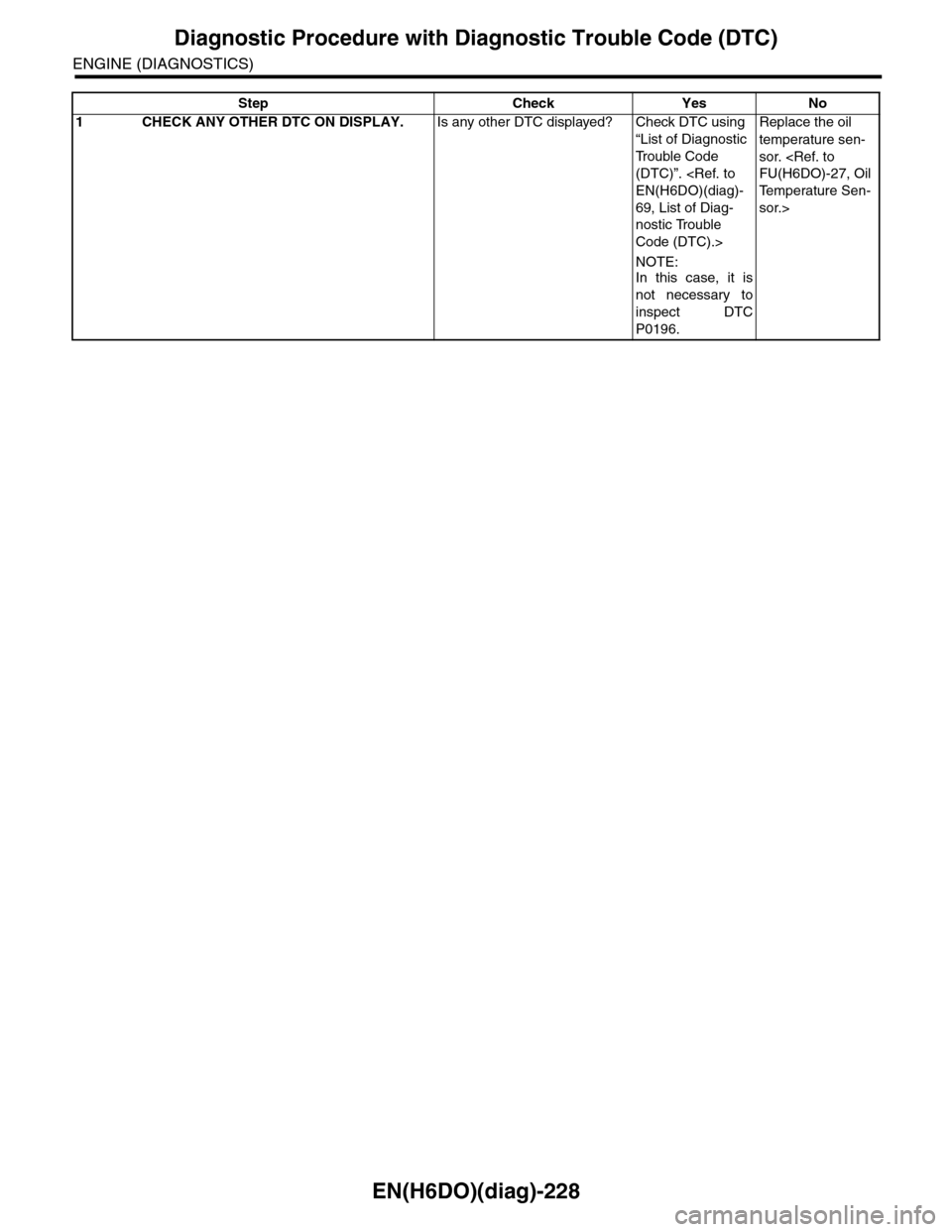

Page 1389 of 2453

EN(H6DO)(diag)-228

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:

In this case, it is

not necessary to

inspect DTC

P0196.

Replace the oil

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>