key SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 439 of 2453

IM (diag)-23

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

IMMOBILIZER (DIAGNOSTICS)

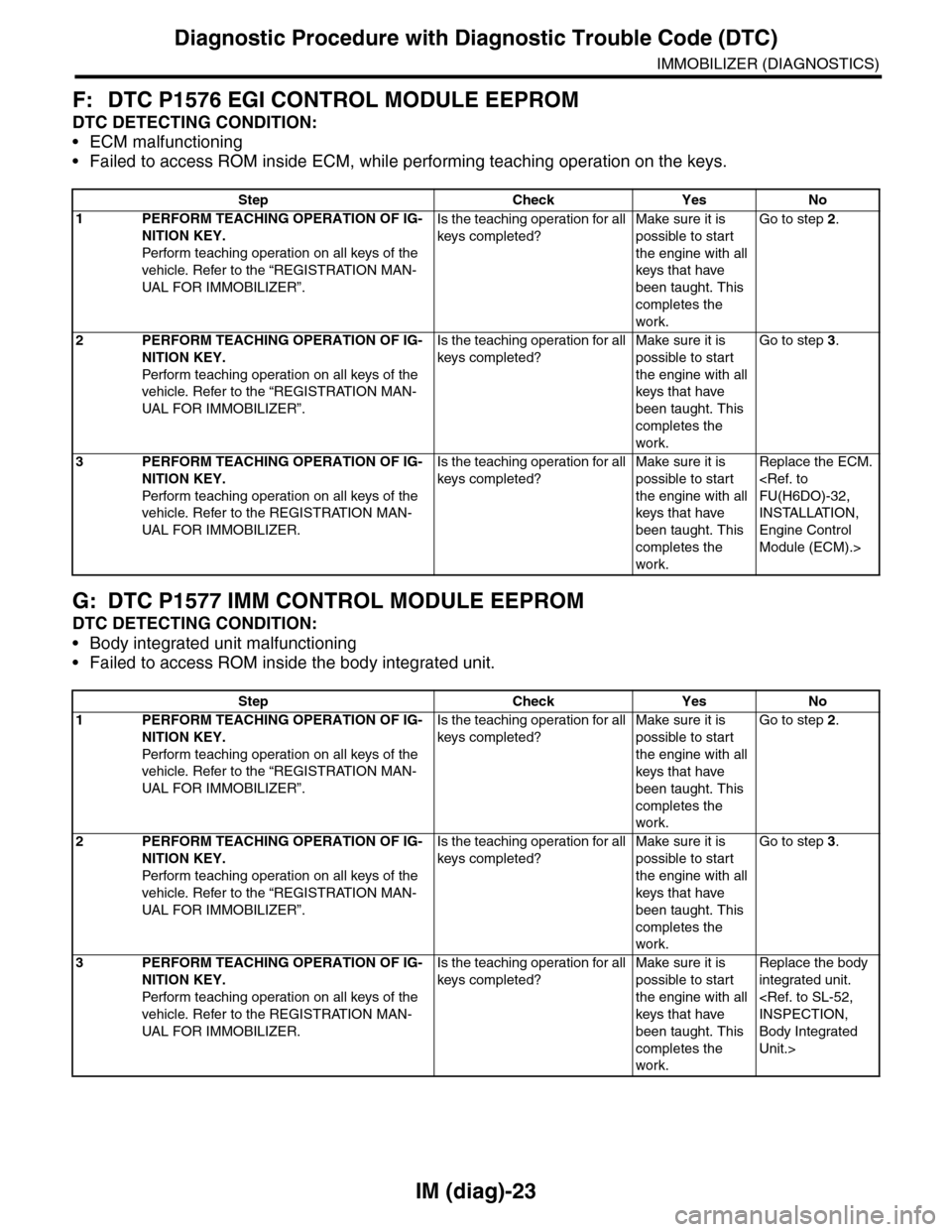

F: DTC P1576 EGI CONTROL MODULE EEPROM

DTC DETECTING CONDITION:

•ECM malfunctioning

•Failed to access ROM inside ECM, while performing teaching operation on the keys.

G: DTC P1577 IMM CONTROL MODULE EEPROM

DTC DETECTING CONDITION:

•Body integrated unit malfunctioning

•Failed to access ROM inside the body integrated unit.

Step Check Yes No

1PERFORM TEACHING OPERATION OF IG-

NITION KEY.

Perfor m teaching operation on all keys of the

vehicle. Refer to the “REGISTRATION MAN-

UAL FOR IMMO BILIZER”.

Is the teaching operation for all

keys completed?

Make sure it is

possible to start

the engine with all

keys that have

been taught. This

completes the

work.

Go to step 2.

2PERFORM TEACHING OPERATION OF IG-

NITION KEY.

Perfor m teaching operation on all keys of the

vehicle. Refer to the “REGISTRATION MAN-

UAL FOR IMMO BILIZER”.

Is the teaching operation for all

keys completed?

Make sure it is

possible to start

the engine with all

keys that have

been taught. This

completes the

work.

Go to step 3.

3PERFORM TEACHING OPERATION OF IG-

NITION KEY.

Perfor m teaching operation on all keys of the

vehicle. Refer to the REGISTRATION MAN-

UAL FOR IMMO BILIZER.

Is the teaching operation for all

keys completed?

Make sure it is

possible to start

the engine with all

keys that have

been taught. This

completes the

work.

Replace the ECM.

INSTALLATION,

Engine Control

Module (ECM).>

Step Check Yes No

1PERFORM TEACHING OPERATION OF IG-

NITION KEY.

Perfor m teaching operation on all keys of the

vehicle. Refer to the “REGISTRATION MAN-

UAL FOR IMMO BILIZER”.

Is the teaching operation for all

keys completed?

Make sure it is

possible to start

the engine with all

keys that have

been taught. This

completes the

work.

Go to step 2.

2PERFORM TEACHING OPERATION OF IG-

NITION KEY.

Perfor m teaching operation on all keys of the

vehicle. Refer to the “REGISTRATION MAN-

UAL FOR IMMO BILIZER”.

Is the teaching operation for all

keys completed?

Make sure it is

possible to start

the engine with all

keys that have

been taught. This

completes the

work.

Go to step 3.

3PERFORM TEACHING OPERATION OF IG-

NITION KEY.

Perfor m teaching operation on all keys of the

vehicle. Refer to the REGISTRATION MAN-

UAL FOR IMMO BILIZER.

Is the teaching operation for all

keys completed?

Make sure it is

possible to start

the engine with all

keys that have

been taught. This

completes the

work.

Replace the body

integrated unit.

Body Integrated

Unit.>

Page 459 of 2453

LAN(diag)-3

Check List for Interview

LAN SYSTEM (DIAGNOSTICS)

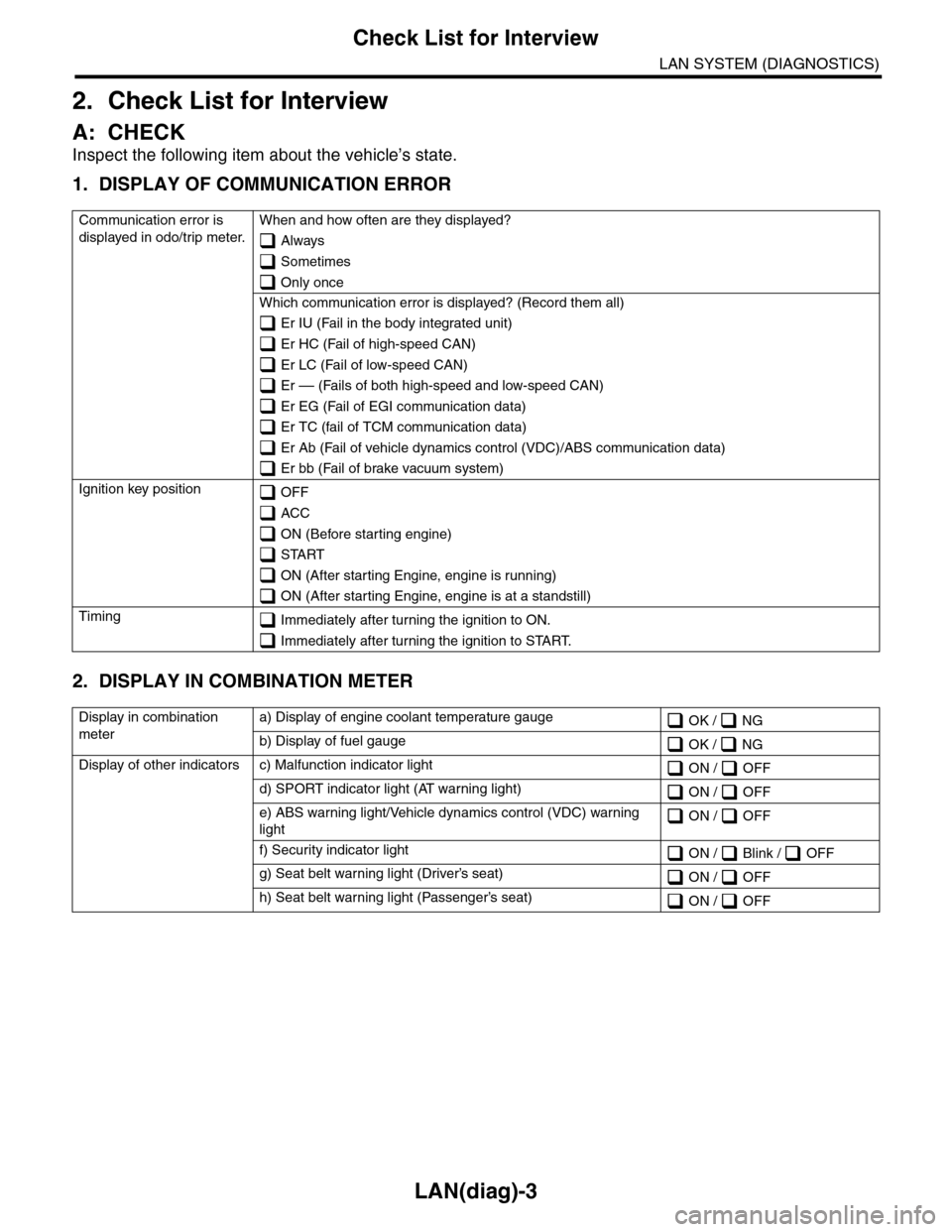

2. Check List for Interview

A: CHECK

Inspect the following item about the vehicle’s state.

1. DISPLAY OF COMMUNICATION ERROR

2. DISPLAY IN COMBINATION METER

Communication error is

displayed in odo/trip meter.

When and how often are they displayed?

Always

Sometimes

Only once

Which communication error is displayed? (Record them all)

Er IU (Fail in the body integrated unit)

Er HC (Fail of high-speed CAN)

Er LC (Fail of low-speed CAN)

Er –– (Fails of both high-speed and low-speed CAN)

Er EG (Fail of EGI communication data)

Er TC (fail of TCM communication data)

Er Ab (Fail of vehicle dynamics control (VDC)/ABS communication data)

Er bb (Fail of brake vacuum system)

Ignition key position OFF

ACC

ON (Before starting engine)

START

ON (After starting Engine, engine is running)

ON (After starting Engine, engine is at a standstill)

Timing Immediately after turning the ignition to ON.

Immediately after turning the ignition to START.

Display in combination

meter

a) Display of engine coolant temperature gauge OK / NG

b) Display of fuel gauge OK / NG

Display of other indicators c) Malfunction indicator light ON / OFF

d) SPORT indicator light (AT warning light) ON / OFF

e) ABS warning light/Vehicle dynamics control (VDC) warning

light ON / OFF

f) Security indicator light ON / Blink / OFF

g) Seat belt warning light (Driver’s seat) ON / OFF

h) Seat belt warning light (Passenger’s seat) ON / OFF

Page 460 of 2453

LAN(diag)-4

Check List for Interview

LAN SYSTEM (DIAGNOSTICS)

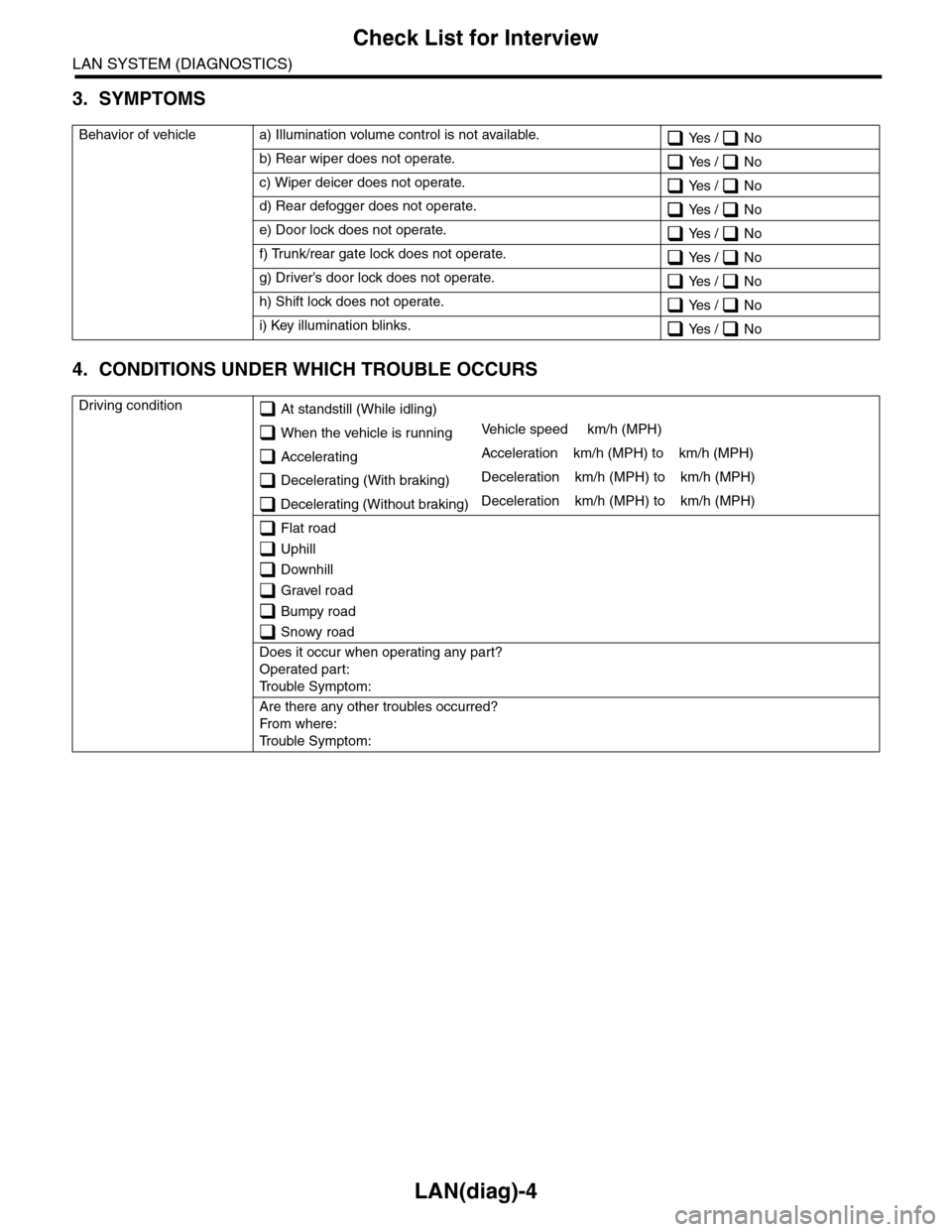

3. SYMPTOMS

4. CONDITIONS UNDER WHICH TROUBLE OCCURS

Behavior of vehicle a) Illumination volume control is not available. Yes / No

b) Rear wiper does not operate. Yes / No

c) Wiper deicer does not operate. Yes / No

d) Rear defogger does not operate. Yes / No

e) Door lock does not operate. Yes / No

f) Trunk/rear gate lock does not operate. Yes / No

g) Driver’s door lock does not operate. Yes / No

h) Shift lock does not operate. Yes / No

i) Key illumination blinks. Yes / No

Driving condition At standstill (While idling)

When the vehicle is runningVe h i c l e s p e e d k m / h ( M P H )

AcceleratingAcceleration km/h (MPH) to km/h (MPH)

Decelerating (With braking)Deceleration km/h (MPH) to km/h (MPH)

Decelerating (Without braking)Deceleration km/h (MPH) to km/h (MPH)

Flat road

Uphill

Downhill

Gravel road

Bumpy road

Snowy road

Does it occur when operating any part?

Operated part:

Tr o u b l e S y m p t o m :

Are there any other troubles occurred?

Fr o m wh er e :

Tr o u b l e S y m p t o m :

Page 461 of 2453

LAN(diag)-5

General Description

LAN SYSTEM (DIAGNOSTICS)

3. General Description

A: CAUTION

1. SRS AIRBAG SYSTEM

Airbag system wiring harness is routed near the

body integrated unit and twisted pair line.

CAUTION:

•All airbag system wiring harness and con-

nectors are colored yellow. Do not use the elec-

trical test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the body inte-

grated unit and LAN system.

•Refer to “Airbag System” when disconnect-

ing the air bag system connector.

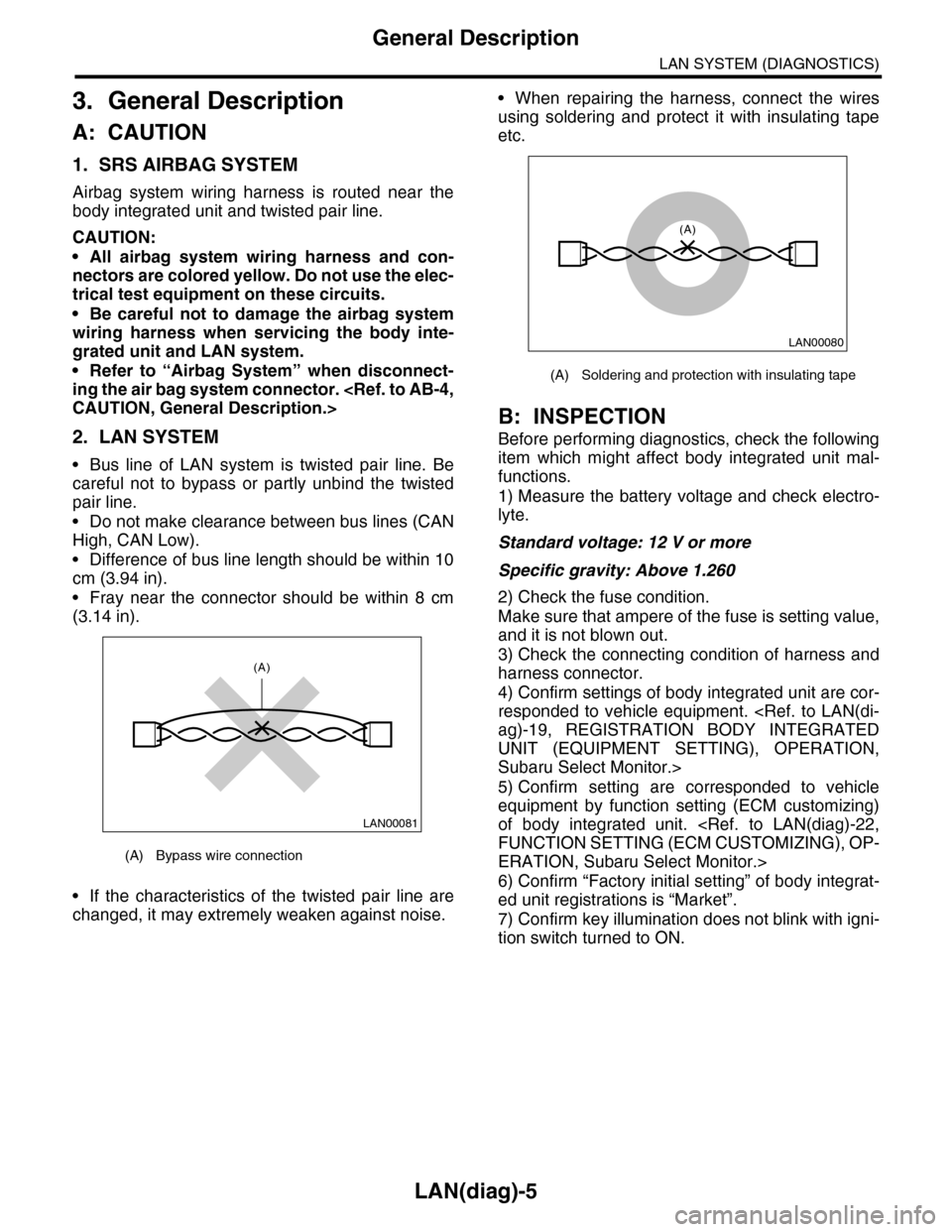

2. LAN SYSTEM

•Bus line of LAN system is twisted pair line. Be

careful not to bypass or partly unbind the twisted

pair line.

•Do not make clearance between bus lines (CAN

High, CAN Low).

•Difference of bus line length should be within 10

cm (3.94 in).

•Fray near the connector should be within 8 cm

(3.14 in).

•If the characteristics of the twisted pair line are

changed, it may extremely weaken against noise.

•When repairing the harness, connect the wires

using soldering and protect it with insulating tape

etc.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect body integrated unit mal-

functions.

1) Measure the battery voltage and check electro-

lyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

2) Check the fuse condition.

Make sure that ampere of the fuse is setting value,

and it is not blown out.

3) Check the connecting condition of harness and

harness connector.

4) Confirm settings of body integrated unit are cor-

responded to vehicle equipment.

UNIT (EQUIPMENT SETTING), OPERATION,

Subaru Select Monitor.>

5) Confirm setting are corresponded to vehicle

equipment by function setting (ECM customizing)

of body integrated unit.

ERATION, Subaru Select Monitor.>

6) Confirm “Factory initial setting” of body integrat-

ed unit registrations is “Market”.

7) Confirm key illumination does not blink with igni-

tion switch turned to ON.

(A) Bypass wire connection

LAN00081

(A)

(A) Soldering and protection with insulating tape

LAN00080

(A)

Page 463 of 2453

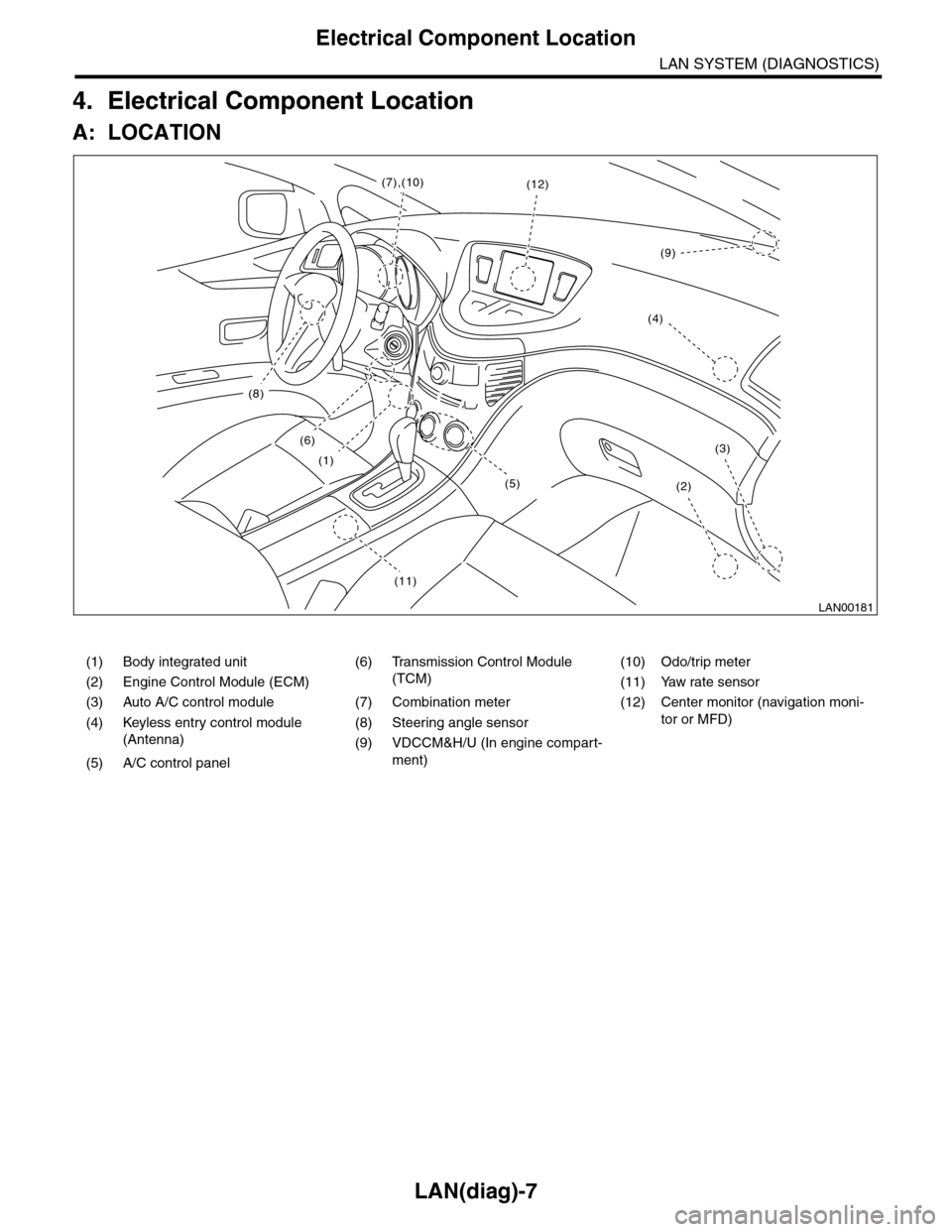

LAN(diag)-7

Electrical Component Location

LAN SYSTEM (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

(1) Body integrated unit (6) Transmission Control Module

(TCM)

(10) Odo/trip meter

(2) Engine Control Module (ECM) (11) Yaw rate sensor

(3) Auto A/C control module (7) Combination meter (12) Center monitor (navigation moni-

tor or MFD)(4) Keyless entry control module

(Antenna)

(8) Steering angle sensor

(9) VDCCM&H/U (In engine compart-

ment)(5) A/C control panel

LAN00181

(8)

(6)

(1)

(11)

(2)

(3)

(12)(7),(10)

(4)

(9)

(5)

Page 465 of 2453

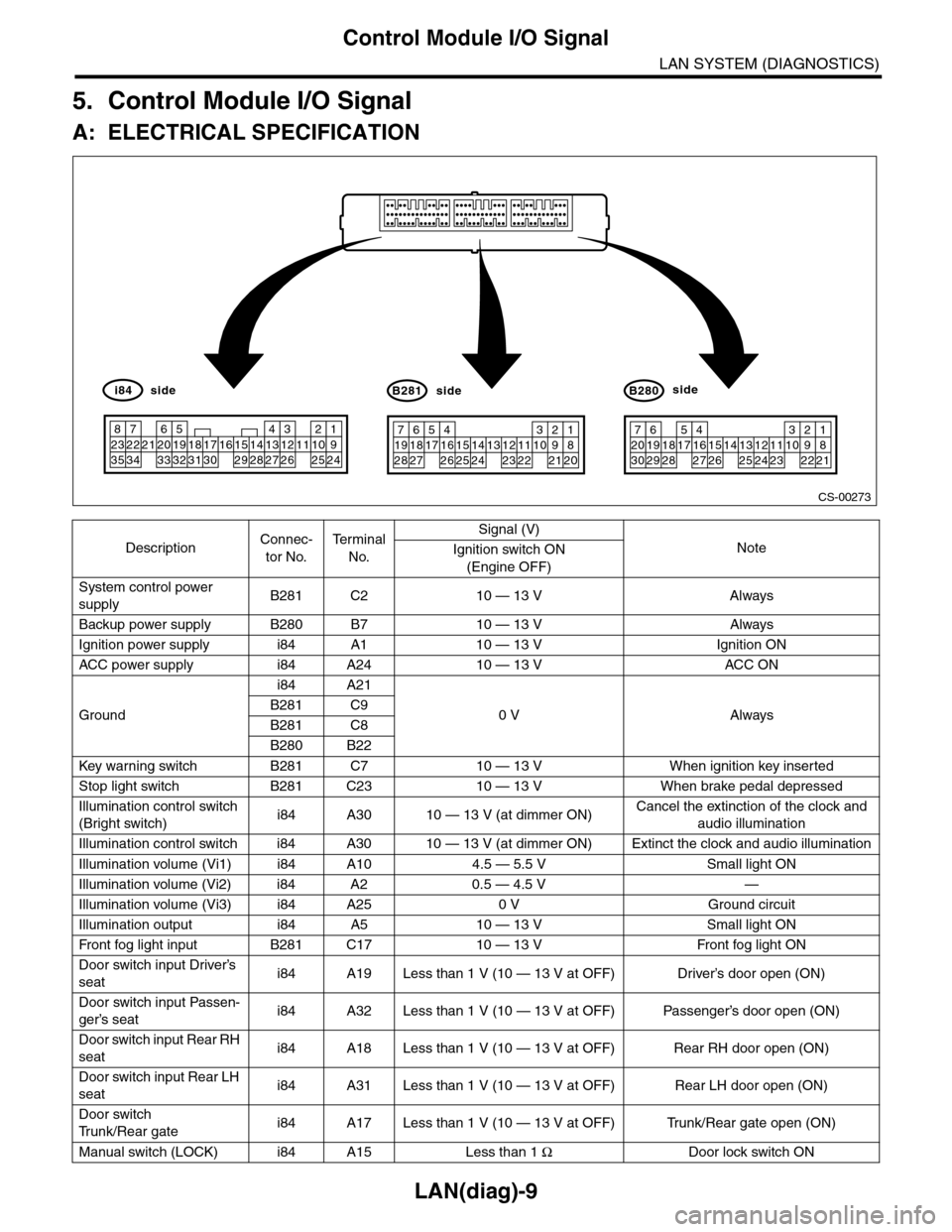

LAN(diag)-9

Control Module I/O Signal

LAN SYSTEM (DIAGNOSTICS)

5. Control Module I/O Signal

A: ELECTRICAL SPECIFICATION

DescriptionConnec-

tor No.

Te r m i n a l

No.

Signal (V)

NoteIgnition switch ON

(Engine OFF)

System control power

supplyB281 C2 10 — 13 V Always

Backup power supply B280 B7 10 — 13 V Always

Ignition power supply i84 A1 10 — 13 V Ignition ON

ACC power supply i84 A24 10 — 13 V AC C ON

Ground

i84 A21

0 V AlwaysB281 C9

B281 C8

B280 B22

Key war ning switch B281 C7 10 — 13 V When ignition key inser ted

Stop light switch B281 C23 10 — 13 V When brake pedal depressed

Illumination control switch

(Bright switch)i84 A30 10 — 13 V (at dimmer ON)Cancel the extinction of the clock and

audio illumination

Illumination control switch i84 A30 10 — 13 V (at dimmer ON) Extinct the clock and audio illumination

Illumination volume (Vi1) i84 A10 4.5 — 5.5 V Small light ON

Illumination volume (Vi2) i84 A2 0.5 — 4.5 V —

Illumination volume (Vi3) i84 A25 0 V Ground circuit

Illumination output i84 A5 10 — 13 V Small light ON

Fr o nt fog li g ht in p ut B 28 1 C1 7 1 0 — 1 3 V Fr o nt fo g l i gh t ON

Door switch input Driver’s

seati84 A19 Less than 1 V (10 — 13 V at OFF) Driver’s door open (ON)

Door switch input Passen-

ger’s seati84 A32 Less than 1 V (10 — 13 V at OFF) Passenger’s door open (ON)

Door switch input Rear RH

seati84 A18 Less than 1 V (10 — 13 V at OFF) Rear RH door open (ON)

Door switch input Rear LH

seati84 A31 Less than 1 V (10 — 13 V at OFF) Rear LH door open (ON)

Door switch

Tr u n k / R e a r g a t ei84 A17 Less than 1 V (10 — 13 V at OFF) Trunk/Rear gate open (ON)

Manual switch (LOCK) i84 A15 Less than 1 ΩDoor lock switch ON

CS-00273

71928

61827

51741626152514241312231122

3102921

1820

B281side

72030

619291828

51741627152614132512241123

3102922

1821

B280side

82335

722342162033

51932183117301615291428

41327

312261121025

1924

i84side

Page 466 of 2453

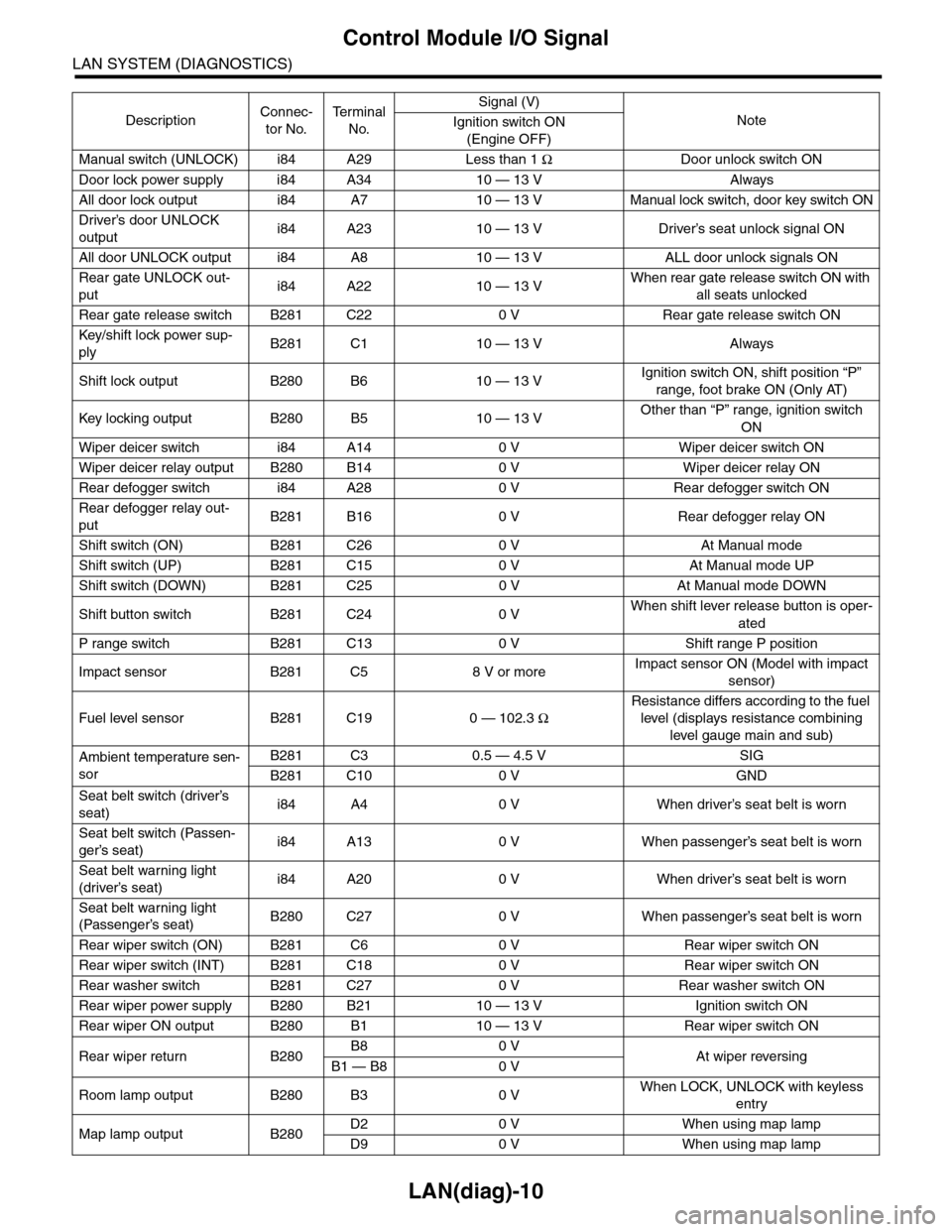

LAN(diag)-10

Control Module I/O Signal

LAN SYSTEM (DIAGNOSTICS)

Manual switch (UNLOCK) i84 A29 Less than 1 ΩDoor unlock switch ON

Door lock power supply i84 A34 10 — 13 V Always

All door lock output i84 A7 10 — 13 V Manual lock switch, door key switch ON

Driver’s door UNLOCK

outputi84 A23 10 — 13 V Driver’s seat unlock signal ON

All door UNLOCK output i84 A8 10 — 13 V ALL door unlock signals ON

Rear gate UNLOCK out-

puti84 A22 10 — 13 VWhen rear gate release switch ON with

all seats unlocked

Rear gate release switch B281 C22 0 V Rear gate release switch ON

Key/shift lock power sup-

plyB281 C1 10 — 13 V Always

Shift lock output B280 B6 10 — 13 VIgnition switch ON, shift position “P”

range, foot brake ON (Only AT)

Key locking output B280 B5 10 — 13 VOther than “P” range, ignition switch

ON

Wiper deicer switch i84 A14 0 V Wiper deicer switch ON

Wiper deicer relay output B280 B14 0 V Wiper deicer relay ON

Rear defogger switch i84 A28 0 V Rear defogger switch ON

Rear defogger relay out-

putB281 B16 0 V Rear defogger relay ON

Shift switch (ON) B281 C26 0 V At Manual mode

Shift switch (UP) B281 C15 0 V At Manual mode UP

Shift switch (DOWN) B281 C25 0 V At Manual mode DOWN

Shift button switch B281 C24 0 VWhen shift lever release button is oper-

ated

P range switch B281 C13 0 V Shift range P position

Impact sensor B281 C5 8 V or moreImpact sensor ON (Model with impact

sensor)

Fuel level sensor B281 C19 0 — 102.3 Ω

Resistance differs according to the fuel

level (displays resistance combining

level gauge main and sub)

Ambient temperature sen-

sor

B281 C3 0.5 — 4.5 V SIG

B281 C10 0 V GND

Seat belt switch (driver’s

seat)i84 A4 0 V When driver’s seat belt is worn

Seat belt switch (Passen-

ger’s seat)i84 A13 0 V When passenger’s seat belt is worn

Seat belt warning light

(driver’s seat)i84 A20 0 V When driver’s seat belt is worn

Seat belt warning light

(Passenger’s seat)B280 C27 0 V When passenger’s seat belt is worn

Rear wiper switch (ON) B281 C6 0 V Rear wiper switch ON

Rear wiper switch (INT) B281 C18 0 V Rear wiper switch ON

Rear washer switch B281 C27 0 V Rear washer switch ON

Rear wiper power supply B280 B21 10 — 13 V Ignition switch ON

Rear wiper ON output B280 B1 10 — 13 V Rear wiper switch ON

Rear wiper return B280B8 0 VAt wiper reversingB1 — B8 0 V

Room lamp output B280 B3 0 VWhen LOCK, UNLOCK with keyless

entry

Map lamp output B280D2 0 V When using map lamp

D9 0 V When using map lamp

DescriptionConnec-

tor No.

Te r m i n a l

No.

Signal (V)

NoteIgnition switch ON

(Engine OFF)

Page 467 of 2453

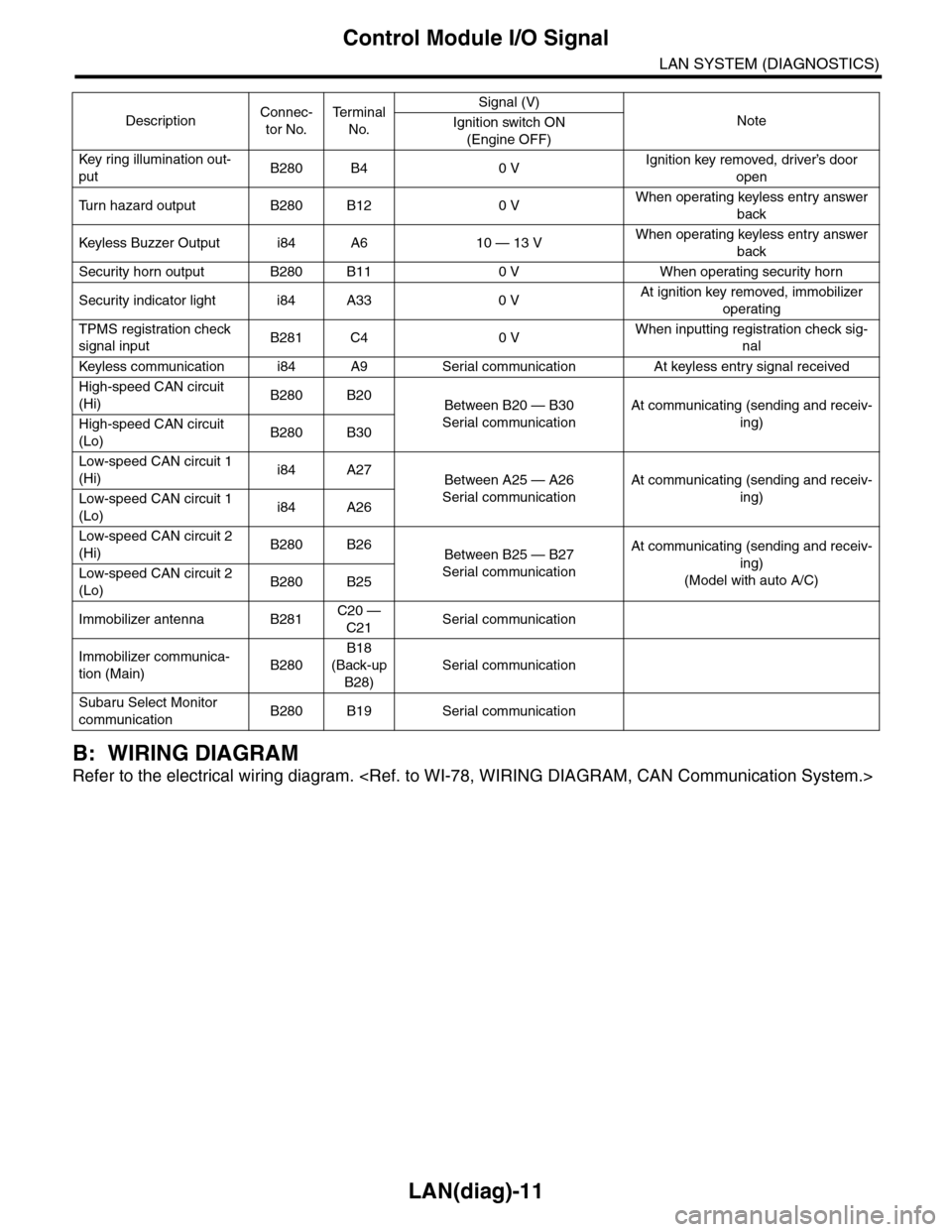

LAN(diag)-11

Control Module I/O Signal

LAN SYSTEM (DIAGNOSTICS)

B: WIRING DIAGRAM

Refer to the electrical wiring diagram.

Key r ing illumination out-

putB280 B4 0 VIgnition key removed, driver’s door

open

Tu r n h a z a r d o u t p u t B 2 8 0 B 1 2 0 VWhen operating keyless entry answer

back

Keyless Buzzer Output i84 A6 10 — 13 VWhen operating keyless entry answer

back

Security horn output B280 B11 0 V When operating security horn

Security indicator light i84 A33 0 VAt ignition key removed, immobilizer

operating

TPMS registration check

signal inputB281 C4 0 VWhen inputting registration check sig-

nal

Keyless communication i84 A9 Ser ial communication At keyless entr y signal received

High-speed CAN circuit

(Hi)B280 B20Between B20 — B30

Serial communication

At communicating (sending and receiv-

ing)High-speed CAN circuit

(Lo)B280 B30

Low-speed CAN circuit 1

(Hi)i84 A27Between A25 — A26

Serial communication

At communicating (sending and receiv-

ing)Low-speed CAN circuit 1

(Lo)i84 A26

Low-speed CAN circuit 2

(Hi)B280 B26Between B25 — B27

Serial communication

At communicating (sending and receiv-

ing)

(Model with auto A/C)Low-speed CAN circuit 2

(Lo)B280 B25

Immobilizer antenna B281C20 —

C21Serial communication

Immobilizer communica-

tion (Main)B280

B18

(Back-up

B28)

Serial communication

Subaru Select Monitor

communicationB280 B19 Serial communication

DescriptionConnec-

tor No.

Te r m i n a l

No.

Signal (V)

NoteIgnition switch ON

(Engine OFF)

Page 468 of 2453

LAN(diag)-12

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

6. Subaru Select Monitor

A: OPERATION

1. READ DIAGNOSTIC TROUBLE CODE

(DTC)

NOTE:

•DTC is displayed in the sequence of inputting.

(When inputting two DTCs or more simultaneously,

they are displayed in the sequence of priority.)

•When more than two DTCs are displayed, per-

form the diagnosis of top of them.

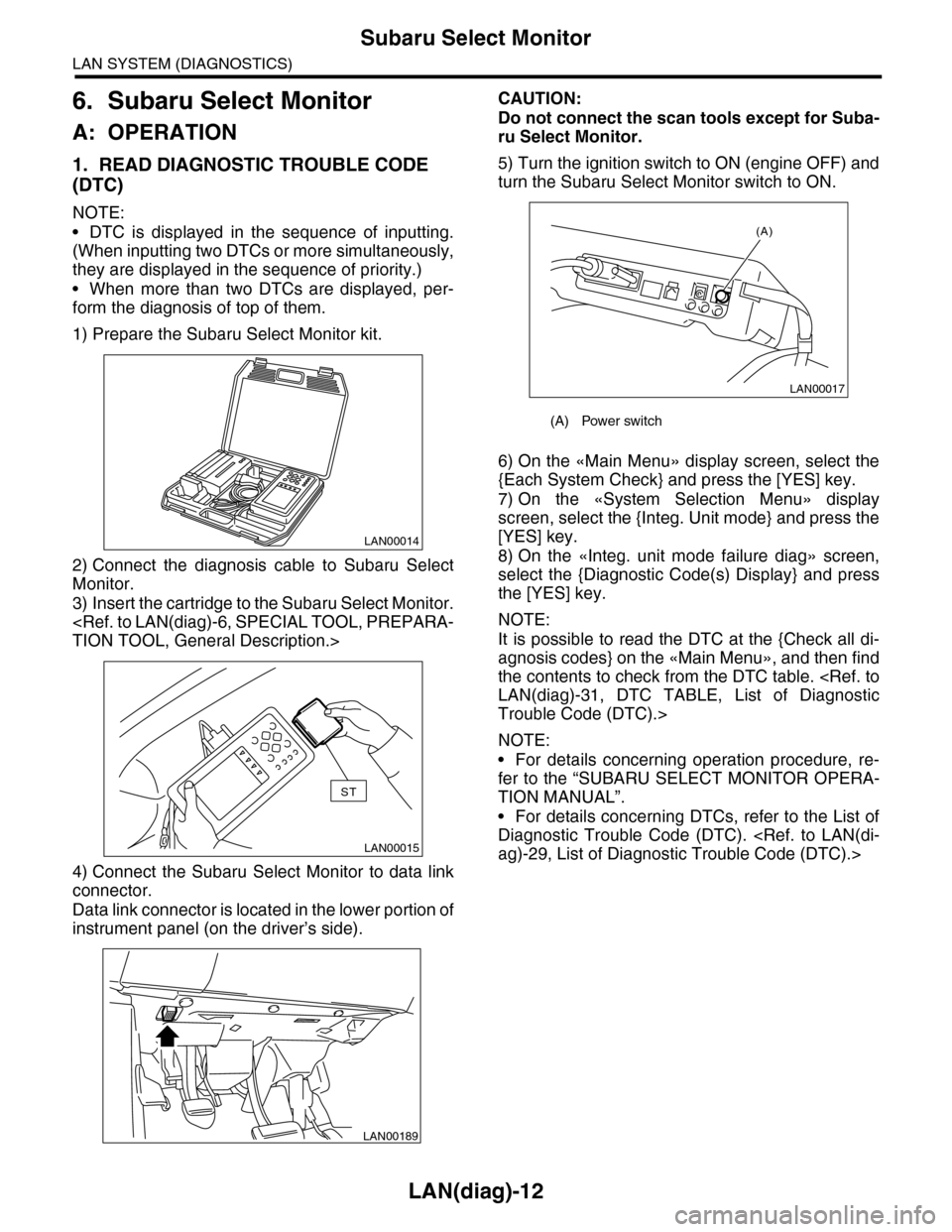

1) Prepare the Subaru Select Monitor kit.

2) Connect the diagnosis cable to Subaru Select

Monitor.

3) Insert the cartridge to the Subaru Select Monitor.

4) Connect the Subaru Select Monitor to data link

connector.

Data link connector is located in the lower portion of

instrument panel (on the driver’s side).

CAUTION:

Do not connect the scan tools except for Suba-

ru Select Monitor.

5) Turn the ignition switch to ON (engine OFF) and

turn the Subaru Select Monitor switch to ON.

6) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

7) On the «System Selection Menu» display

screen, select the {Integ. Unit mode} and press the

[YES] key.

8) On the «Integ. unit mode failure diag» screen,

select the {Diagnostic Code(s) Display} and press

the [YES] key.

NOTE:

It is possible to read the DTC at the {Check all di-

agnosis codes} on the «Main Menu», and then find

the contents to check from the DTC table.

Trouble Code (DTC).>

NOTE:

•For details concerning operation procedure, re-

fer to the “SUBARU SELECT MONITOR OPERA-

TION MANUAL”.

•For details concerning DTCs, refer to the List of

Diagnostic Trouble Code (DTC).

LAN00014

LAN00015

ST

LAN00189

(A) Power switch

LAN00017

(A)

Page 469 of 2453

![SUBARU TRIBECA 2009 1.G Service Owners Manual LAN(diag)-13

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sele SUBARU TRIBECA 2009 1.G Service Owners Manual LAN(diag)-13

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sele](/img/17/7322/w960_7322-468.png)

LAN(diag)-13

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Integ. Unit mode} and press the [YES] key.

3) On the «Integ. unit mode failure diag» display screen, select the {Current Data Display & Save} and press

the [YES] key.

4) On the «Current Data Display & Save» display screen, select the {12 Data Display} and press the [YES]

key.

5) Using the scroll key, scroll the display screen up or down until the desired data is shown.

•A support list contains both of analog and digital data, and they are shown in the following table.

3. DISPLAY OF ANALOG DATA

Items to be displayed Unit of measure Description Note

BATT Voltage (Control) 10 — 15 VBody integrated unit input

valueAlways

BATT Voltage (BACK UP) 10 — 15 VBody integrated unit input

valueAlways

IG power supply voltage 10 — 15 VBody integrated unit input

valueIgnition switch ON

ACC voltage 10 — 15 VBody integrated unit input

valueIgnition switch ACC

Illumination VR voltage 0 — 5 VBody integrated unit out-

put valueSmall light switch ON

Illumi. output d-ratio 0 — 100%Body integrated unit input

value

Small light ON

Illumination volume is other than bright.

Ambient temp sensor V 0 — 5 VBody integrated unit out-

put valueIgnition switch ON

Ambient temperature –40 — 87.5°CBody integrated unit out-

put valueIgnition switch ON

Fuel level voltage 0 — 8 VBody integrated unit input

valueIgnition switch ON

Fuel level resistance 0 — 102.3 ΩBody integrated unit input

valueIgnition switch ON

key-lock solenoid V 6 — 12 VBody integrated unit out-

put value

Other than parking range

Ignition ON

number of regist. 0 — 4 Key No. to register

Fr o nt W he e l S p ee d km / h C A N d a t a i np u t val u e R ec ep t io n f r o m V DC u ni t

VDC/ABS latest f-codeDTC display (Tempo-

rarily)CAN data input value

It is normal when DTC is not been input

even if this code is displayed.

Reception from VDC

Blower fan steps 0 — 2 levels CAN data input value0: OFF, 1: Low, 2: 2 levels or more

Reception from air conditioner ECM

Fuel level resistance2 0 — 102.3 ΩCAN data output value Reception from body integrated unit

Fuel consumption cc/s CAN data input valueReception from ECM and transmission to

center monitor

Coolant Temp. 40 — 130°C CAN data input value Reception from ECM

Ve h i c l e l a t e r a l Gm/s2CAN data input value Reception from VDC unit

SPORT Shift Stages 0 — 7 levels CAN data input value

(0: Light OFF; 1 — 5: Gear display; 6: Fail; 7:

AT F t e m p e r a t u r e H i g h / L o w )

Reception from TCM

Shift Position 0 — 7 levels CAN data input value

0: 1; 1: 2; 2: 3; 3: 4; 4: D; 5: N; 6: R; 7: P shift

position (There is no 8 input.)

Reception from TCM

Off delay timeOFF, Short, Normal,

Long

Body integrated unit set-

ting itemsCustomize setting

Auto lock time20, 30, 40, 50, 60 sec-

onds

Body integrated unit set-

ting itemsCustomize setting