Starter SUBARU TRIBECA 2009 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1971 of 2453

SC(H6DO)-13

Starter

STARTING/CHARGING SYSTEMS

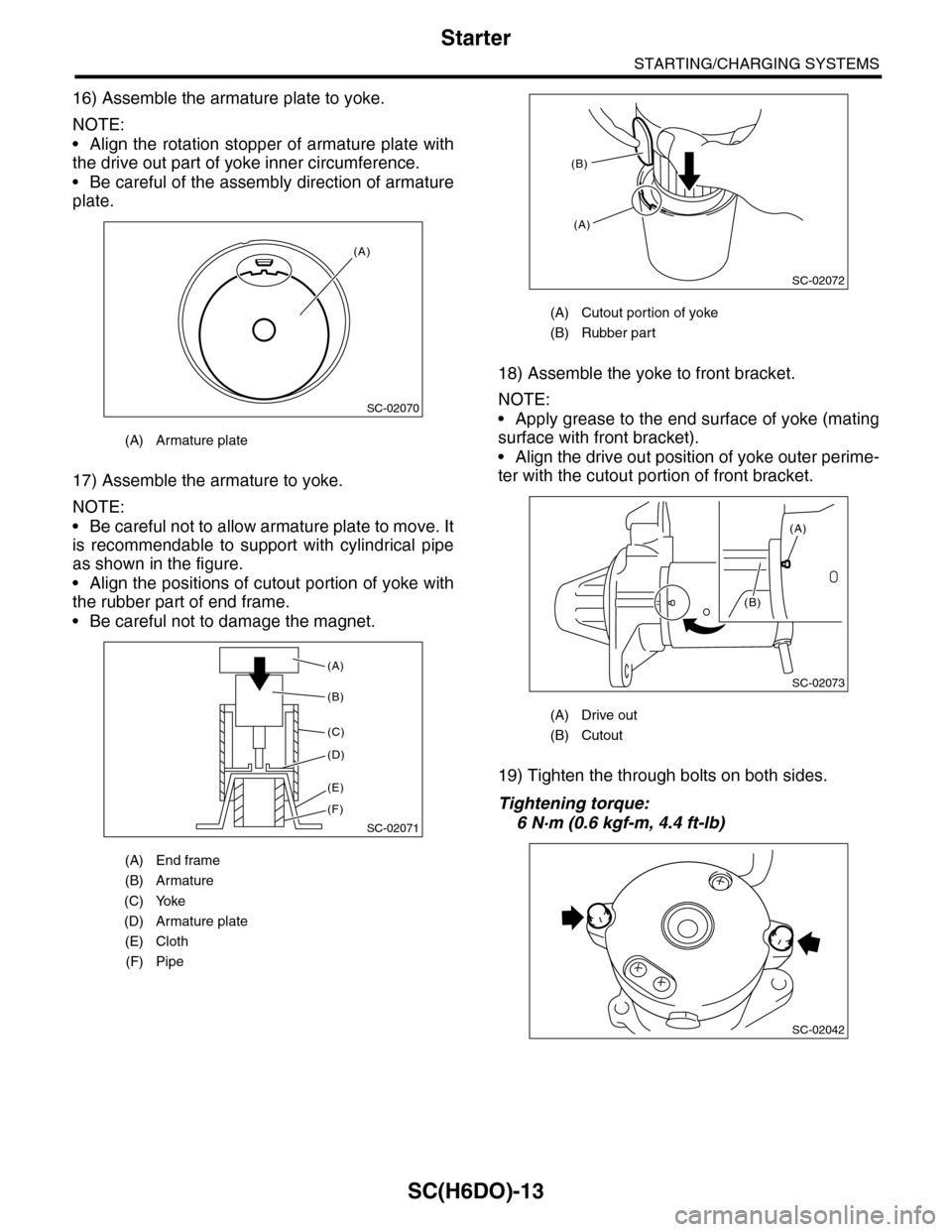

16) Assemble the armature plate to yoke.

NOTE:

•Align the rotation stopper of armature plate with

the drive out part of yoke inner circumference.

•Be careful of the assembly direction of armature

plate.

17) Assemble the armature to yoke.

NOTE:

•Be careful not to allow armature plate to move. It

is recommendable to support with cylindrical pipe

as shown in the figure.

•Align the positions of cutout portion of yoke with

the rubber part of end frame.

•Be careful not to damage the magnet.

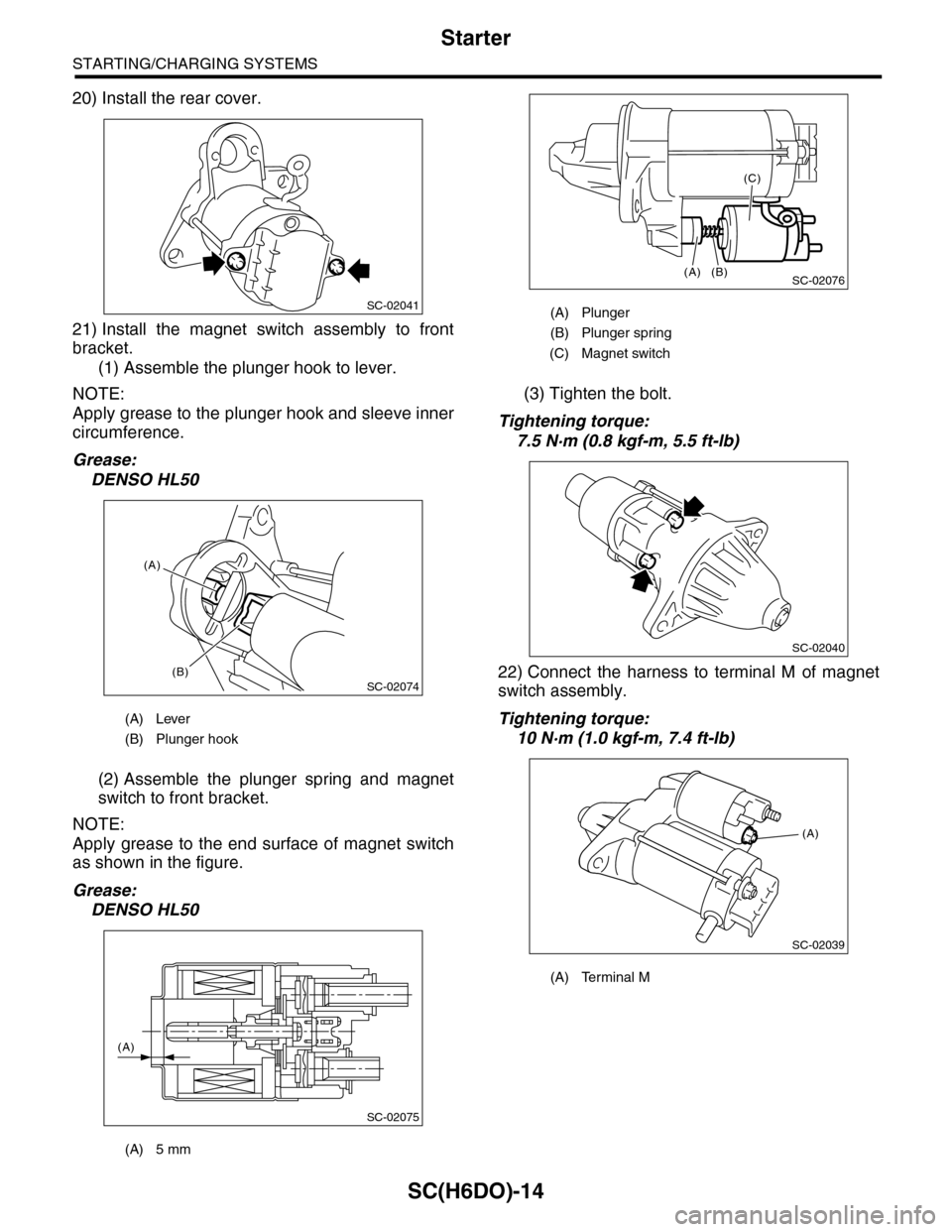

18) Assemble the yoke to front bracket.

NOTE:

•Apply grease to the end surface of yoke (mating

surface with front bracket).

•Align the drive out position of yoke outer perime-

ter with the cutout portion of front bracket.

19) Tighten the through bolts on both sides.

Tightening torque:

6 N·m (0.6 kgf-m, 4.4 ft-lb)

(A) Armature plate

(A) End frame

(B) Armature

(C) Yoke

(D) Armature plate

(E) Cloth

(F) Pipe

SC-02070

(A)

SC-02071

(A)

(B)

(C)

(D)

(E)

(F)

(A) Cutout portion of yoke

(B) Rubber part

(A) Drive out

(B) Cutout

SC-02072

(B)

(A)

SC-02073

(A)

(B)

SC-02042

Page 1972 of 2453

SC(H6DO)-14

Starter

STARTING/CHARGING SYSTEMS

20) Install the rear cover.

21) Install the magnet switch assembly to front

bracket.

(1) Assemble the plunger hook to lever.

NOTE:

Apply grease to the plunger hook and sleeve inner

circumference.

Grease:

DENSO HL50

(2) Assemble the plunger spring and magnet

switch to front bracket.

NOTE:

Apply grease to the end surface of magnet switch

as shown in the figure.

Grease:

DENSO HL50

(3) Tighten the bolt.

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

22) Connect the harness to terminal M of magnet

switch assembly.

Tightening torque:

10 N·m (1.0 kgf-m, 7.4 ft-lb)

(A) Lever

(B) Plunger hook

(A) 5 mm

SC-02041

SC-02074

(A)

(B)

SC-02075

(A)

(A) Plunger

(B) Plunger spring

(C) Magnet switch

(A) Terminal M

SC-02076

(C)

(B)(A)

SC-02040

(A)

SC-02039

Page 1973 of 2453

SC(H6DO)-15

Starter

STARTING/CHARGING SYSTEMS

E: INSPECTION

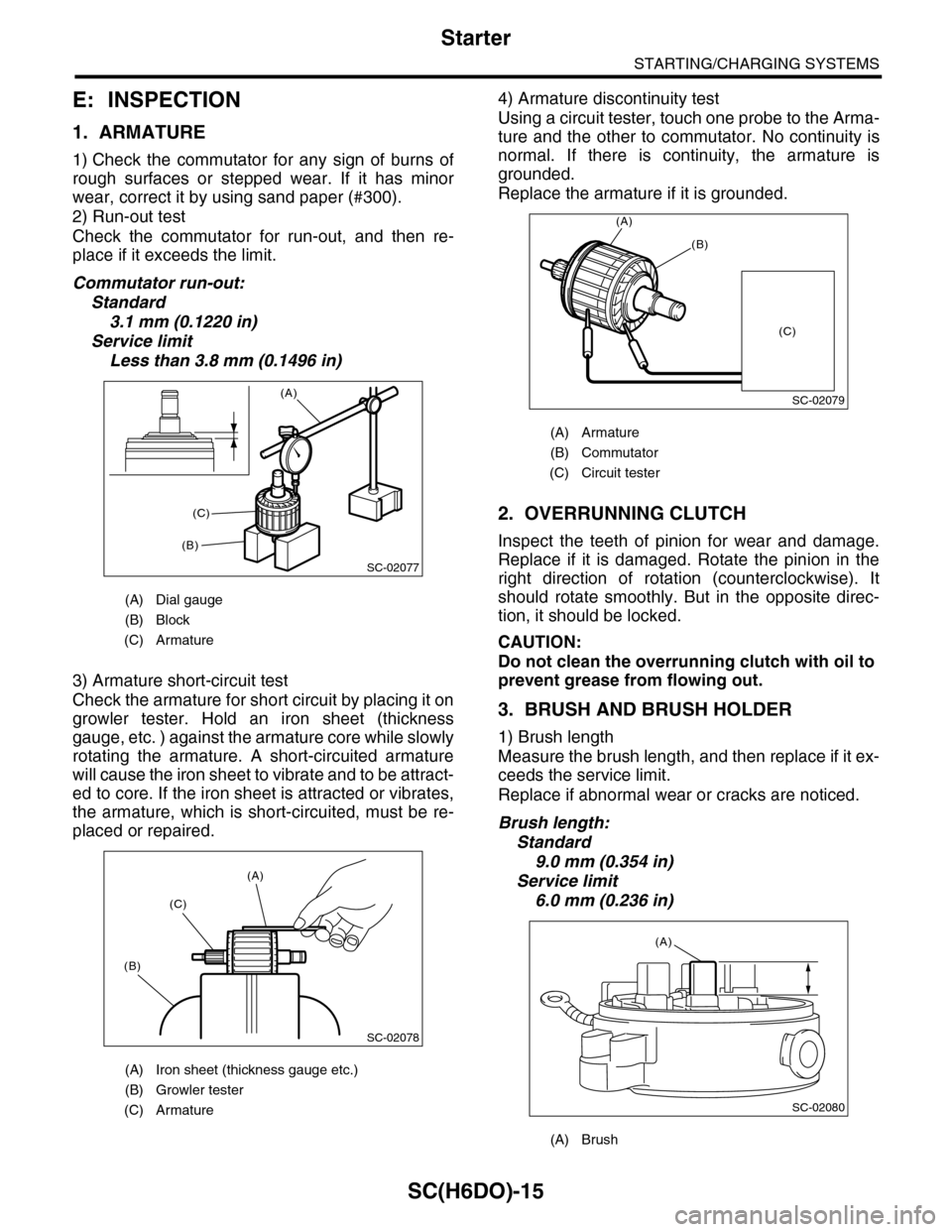

1. ARMATURE

1) Check the commutator for any sign of burns of

rough surfaces or stepped wear. If it has minor

wear, correct it by using sand paper (#300).

2) Run-out test

Check the commutator for run-out, and then re-

place if it exceeds the limit.

Commutator run-out:

Standard

3.1 mm (0.1220 in)

Service limit

Less than 3.8 mm (0.1496 in)

3) Armature short-circuit test

Check the armature for short circuit by placing it on

growler tester. Hold an iron sheet (thickness

gauge, etc. ) against the armature core while slowly

rotating the armature. A short-circuited armature

will cause the iron sheet to vibrate and to be attract-

ed to core. If the iron sheet is attracted or vibrates,

the armature, which is short-circuited, must be re-

placed or repaired.

4) Armature discontinuity test

Using a circuit tester, touch one probe to the Arma-

ture and the other to commutator. No continuity is

normal. If there is continuity, the armature is

grounded.

Replace the armature if it is grounded.

2. OVERRUNNING CLUTCH

Inspect the teeth of pinion for wear and damage.

Replace if it is damaged. Rotate the pinion in the

right direction of rotation (counterclockwise). It

should rotate smoothly. But in the opposite direc-

tion, it should be locked.

CAUTION:

Do not clean the overrunning clutch with oil to

prevent grease from flowing out.

3. BRUSH AND BRUSH HOLDER

1) Brush length

Measure the brush length, and then replace if it ex-

ceeds the service limit.

Replace if abnormal wear or cracks are noticed.

Brush length:

Standard

9.0 mm (0.354 in)

Service limit

6.0 mm (0.236 in)

(A) Dial gauge

(B) Block

(C) Armature

(A) Iron sheet (thickness gauge etc.)

(B) Growler tester

(C) Armature

SC-02077

(A)

(B)

(C)

SC-02078

(A)

(C)

(B)

(A) Armature

(B) Commutator

(C) Circuit tester

(A) Brush

SC-02079

(A)

(B)

(C)

SC-02080

(A)

Page 1974 of 2453

SC(H6DO)-16

Starter

STARTING/CHARGING SYSTEMS

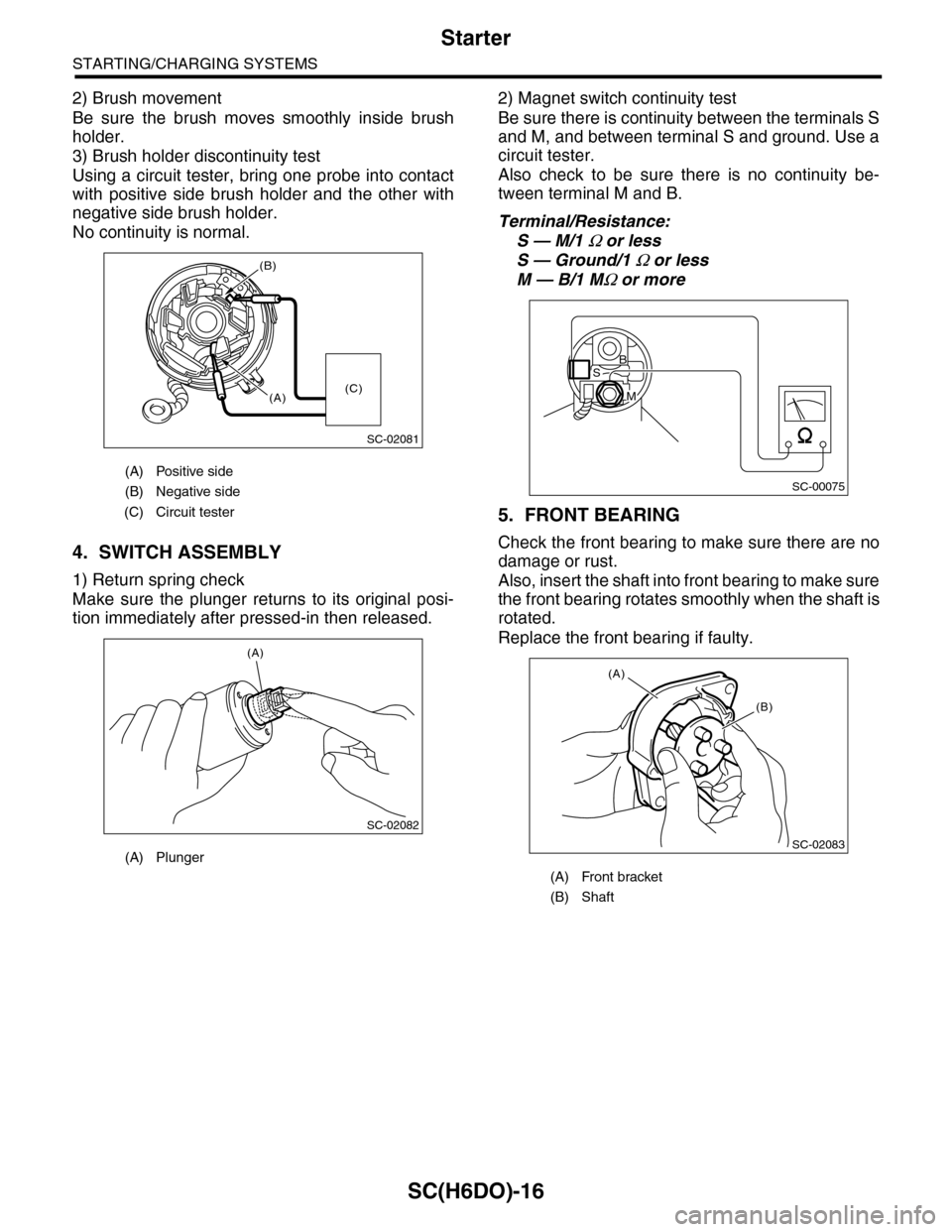

2) Brush movement

Be sure the brush moves smoothly inside brush

holder.

3) Brush holder discontinuity test

Using a circuit tester, bring one probe into contact

with positive side brush holder and the other with

negative side brush holder.

No continuity is normal.

4. SWITCH ASSEMBLY

1) Return spring check

Make sure the plunger returns to its original posi-

tion immediately after pressed-in then released.

2) Magnet switch continuity test

Be sure there is continuity between the terminals S

and M, and between terminal S and ground. Use a

circuit tester.

Also check to be sure there is no continuity be-

tween terminal M and B.

Terminal/Resistance:

S — M/1 Ω or less

S — Ground/1 Ω or less

M — B/1 MΩ or more

5. FRONT BEARING

Check the front bearing to make sure there are no

damage or rust.

Also, insert the shaft into front bearing to make sure

the front bearing rotates smoothly when the shaft is

rotated.

Replace the front bearing if faulty.

(A) Positive side

(B) Negative side

(C) Circuit tester

(A) Plunger

SC-02081

(B)

(A)(C)

SC-02082

(A)

(A) Front bracket

(B) Shaft

SC-00075

B

M

S

SC-02083

(A)

(B)

Page 1975 of 2453

SC(H6DO)-17

Starter

STARTING/CHARGING SYSTEMS

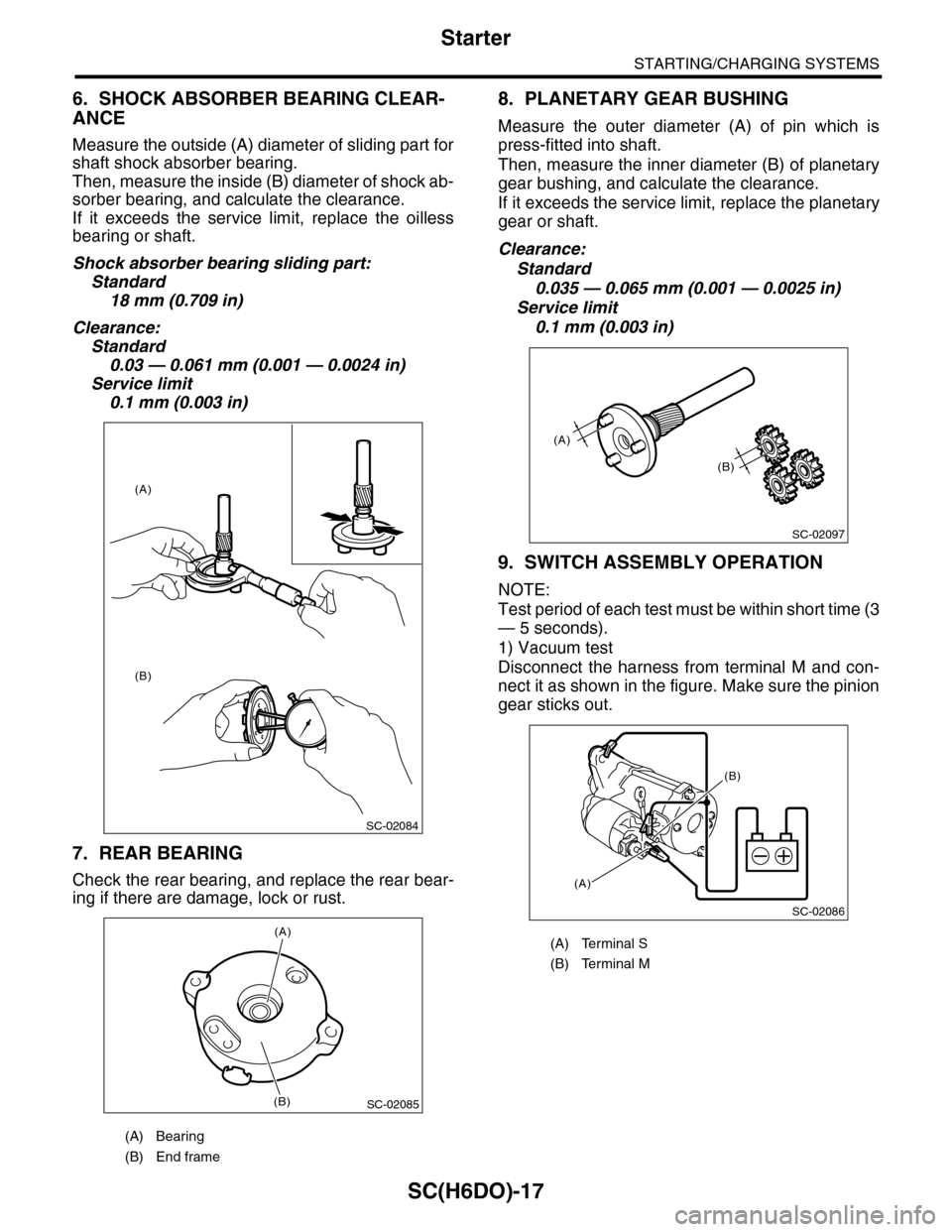

6. SHOCK ABSORBER BEARING CLEAR-

ANCE

Measure the outside (A) diameter of sliding part for

shaft shock absorber bearing.

Then, measure the inside (B) diameter of shock ab-

sorber bearing, and calculate the clearance.

If it exceeds the service limit, replace the oilless

bearing or shaft.

Shock absorber bearing sliding part:

Standard

18 mm (0.709 in)

Clearance:

Standard

0.03 — 0.061 mm (0.001 — 0.0024 in)

Service limit

0.1 mm (0.003 in)

7. REAR BEARING

Check the rear bearing, and replace the rear bear-

ing if there are damage, lock or rust.

8. PLANETARY GEAR BUSHING

Measure the outer diameter (A) of pin which is

press-fitted into shaft.

Then, measure the inner diameter (B) of planetary

gear bushing, and calculate the clearance.

If it exceeds the service limit, replace the planetary

gear or shaft.

Clearance:

Standard

0.035 — 0.065 mm (0.001 — 0.0025 in)

Service limit

0.1 mm (0.003 in)

9. SWITCH ASSEMBLY OPERATION

NOTE:

Test period of each test must be within short time (3

— 5 seconds).

1) Vacuum test

Disconnect the harness from terminal M and con-

nect it as shown in the figure. Make sure the pinion

gear sticks out.

(A) Bearing

(B) End frame

SC-02084

(A)

(B)

SC-02085

(A)

(B)

(A) Terminal S

(B) Terminal M

SC-02097

(A)

(B)

SC-02086

(A)

(B)

Page 1976 of 2453

SC(H6DO)-18

Starter

STARTING/CHARGING SYSTEMS

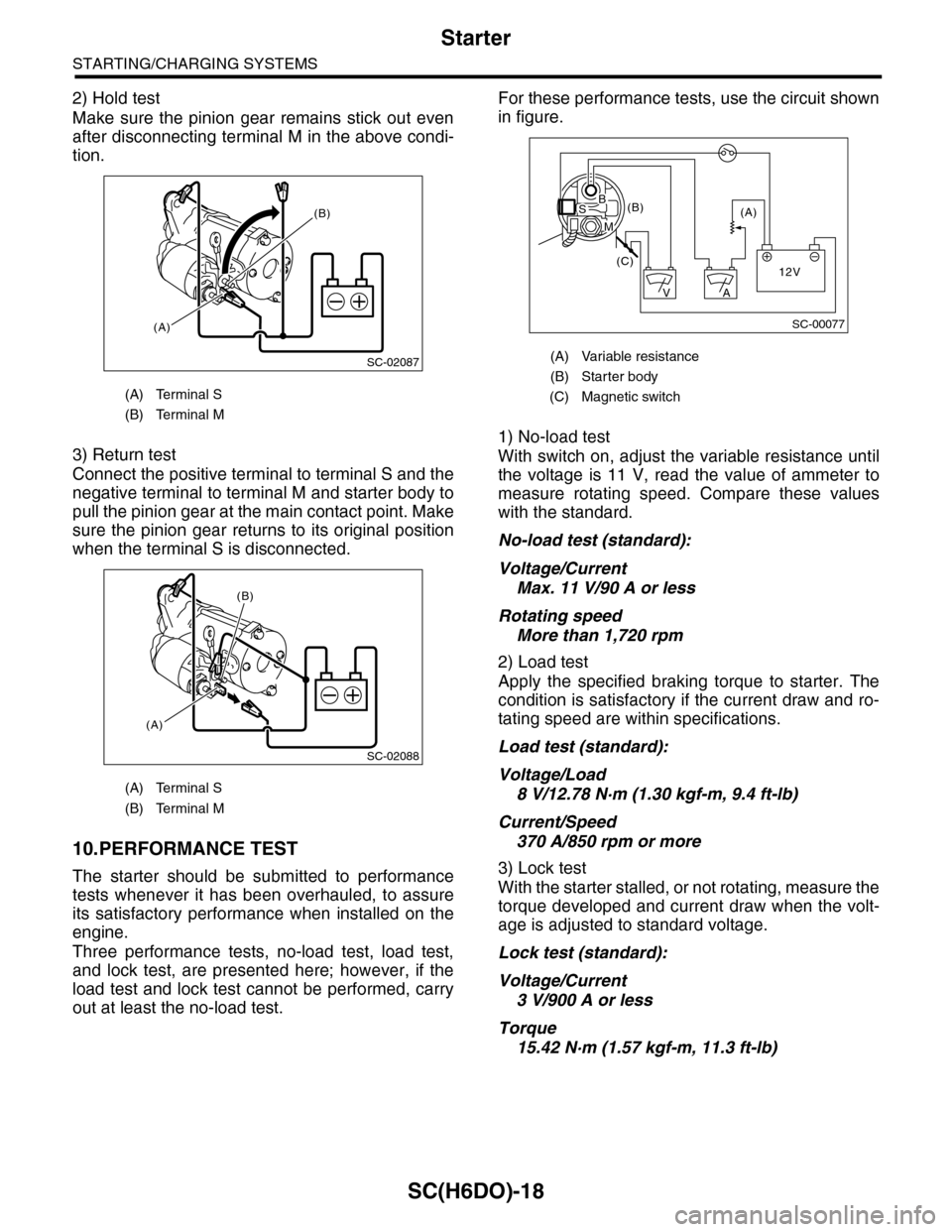

2) Hold test

Make sure the pinion gear remains stick out even

after disconnecting terminal M in the above condi-

tion.

3) Return test

Connect the positive terminal to terminal S and the

negative terminal to terminal M and starter body to

pull the pinion gear at the main contact point. Make

sure the pinion gear returns to its original position

when the terminal S is disconnected.

10.PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

1) No-load test

With switch on, adjust the variable resistance until

the voltage is 11 V, read the value of ammeter to

measure rotating speed. Compare these values

with the standard.

No-load test (standard):

Voltage/Current

Max. 11 V/90 A or less

Rotating speed

More than 1,720 rpm

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and ro-

tating speed are within specifications.

Load test (standard):

Voltage/Load

8 V/12.78 N·m (1.30 kgf-m, 9.4 ft-lb)

Current/Speed

370 A/850 rpm or more

3) Lock test

With the starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to standard voltage.

Lock test (standard):

Voltage/Current

3 V/900 A or less

Torque

15.42 N·m (1.57 kgf-m, 11.3 ft-lb)

(A) Terminal S

(B) Terminal M

(A) Terminal S

(B) Terminal M

SC-02087

(B)

(A)

SC-02088

(A)

(B)

(A) Variable resistance

(B) Starter body

(C) Magnetic switch

SC-00077

(A)(B)

(C)12V

+

AV

BS

M

Page 2050 of 2453

5AT-34

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

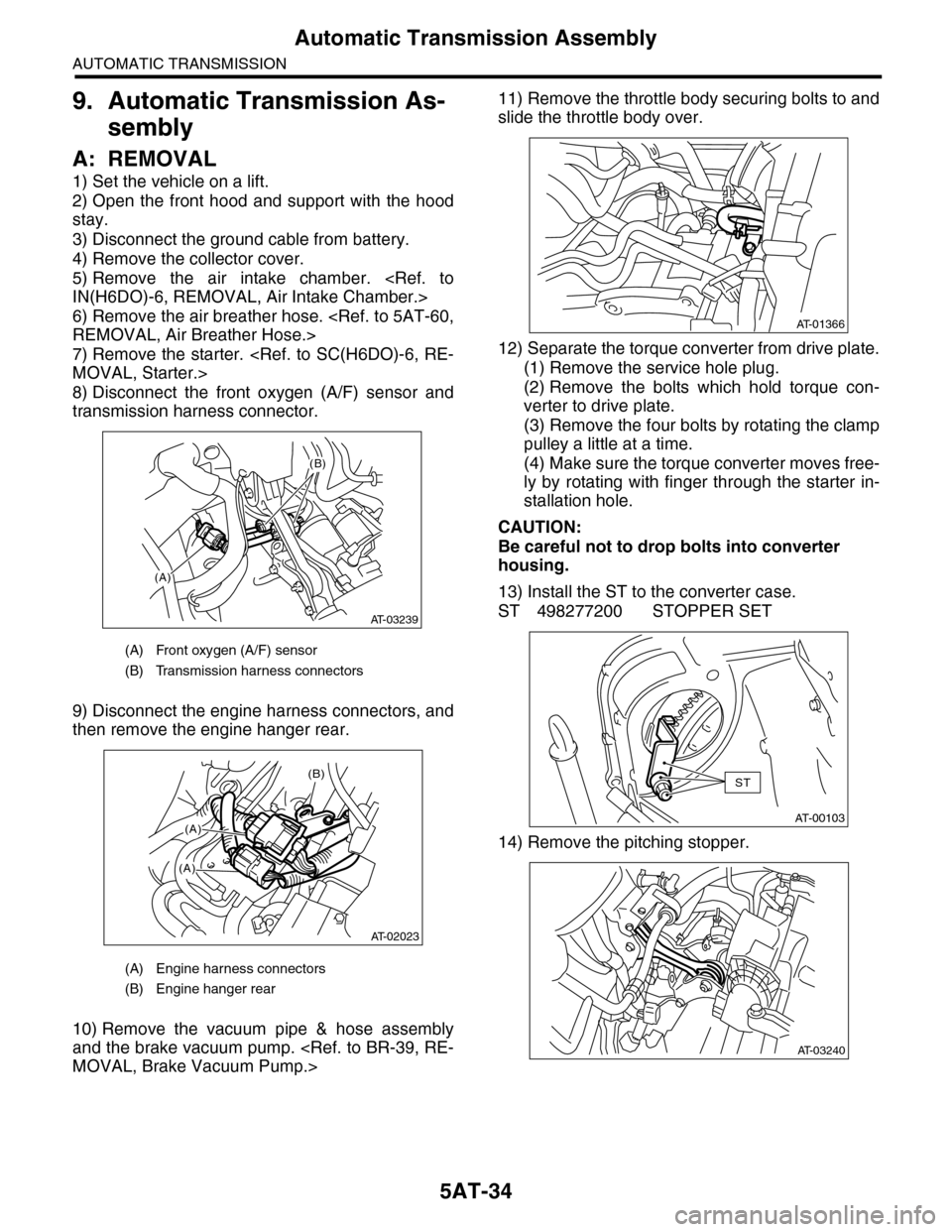

9. Automatic Transmission As-

sembly

A: REMOVAL

1) Set the vehicle on a lift.

2) Open the front hood and support with the hood

stay.

3) Disconnect the ground cable from battery.

4) Remove the collector cover.

5) Remove the air intake chamber.

6) Remove the air breather hose.

7) Remove the starter.

8) Disconnect the front oxygen (A/F) sensor and

transmission harness connector.

9) Disconnect the engine harness connectors, and

then remove the engine hanger rear.

10) Remove the vacuum pipe & hose assembly

and the brake vacuum pump.

11) Remove the throttle body securing bolts to and

slide the throttle body over.

12) Separate the torque converter from drive plate.

(1) Remove the service hole plug.

(2) Remove the bolts which hold torque con-

verter to drive plate.

(3) Remove the four bolts by rotating the clamp

pulley a little at a time.

(4) Make sure the torque converter moves free-

ly by rotating with finger through the starter in-

stallation hole.

CAUTION:

Be careful not to drop bolts into converter

housing.

13) Install the ST to the converter case.

ST 498277200 STOPPER SET

14) Remove the pitching stopper.

(A) Front oxygen (A/F) sensor

(B) Transmission harness connectors

(A) Engine harness connectors

(B) Engine hanger rear

(A)

(B)

AT-03239

(B)

(A)

(A)

AT-02023

AT-01366

AT-00103

ST

AT-03240

Page 2053 of 2453

5AT-37

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

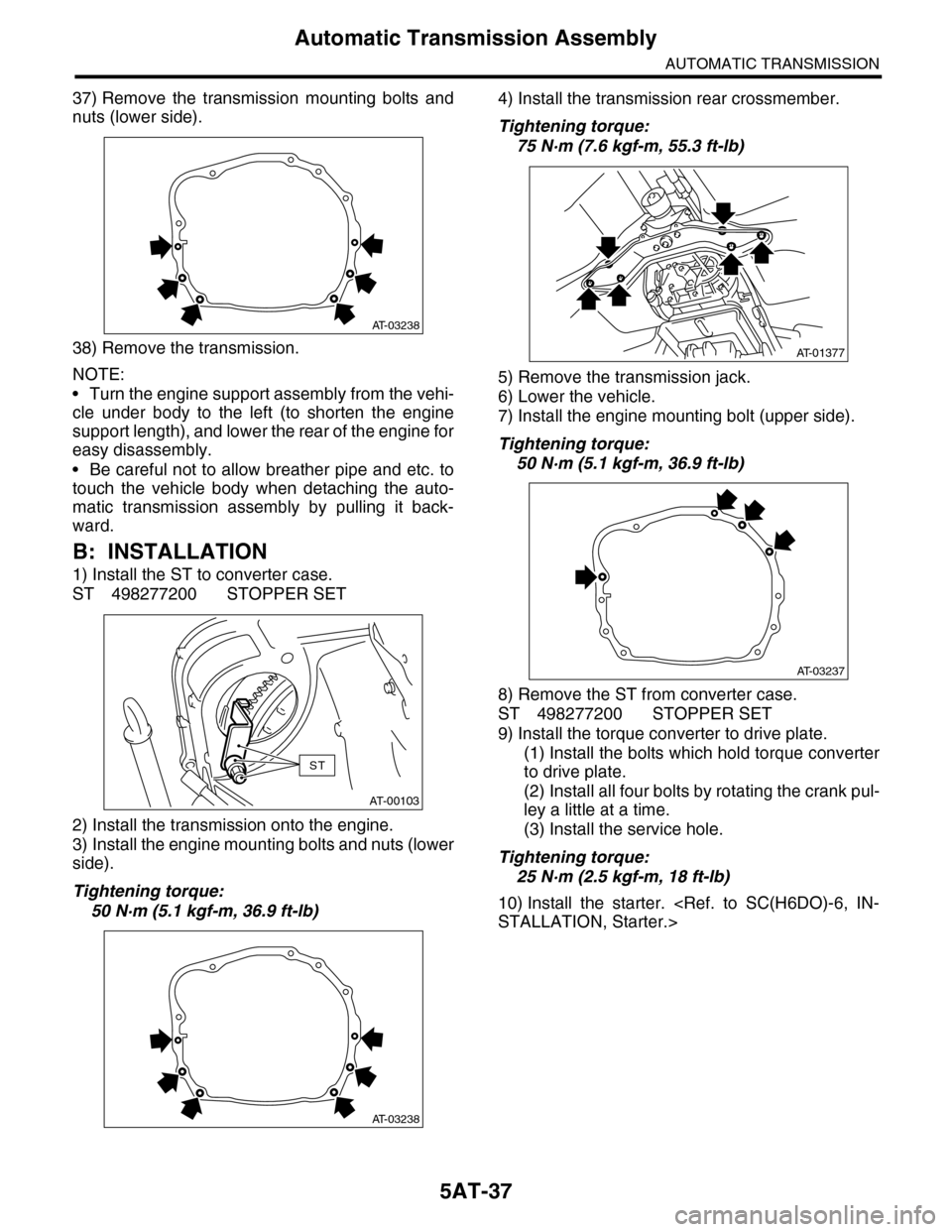

37) Remove the transmission mounting bolts and

nuts (lower side).

38) Remove the transmission.

NOTE:

•Turn the engine support assembly from the vehi-

cle under body to the left (to shorten the engine

support length), and lower the rear of the engine for

easy disassembly.

•Be careful not to allow breather pipe and etc. to

touch the vehicle body when detaching the auto-

matic transmission assembly by pulling it back-

ward.

B: INSTALLATION

1) Install the ST to converter case.

ST 498277200 STOPPER SET

2) Install the transmission onto the engine.

3) Install the engine mounting bolts and nuts (lower

side).

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

4) Install the transmission rear crossmember.

Tightening torque:

75 N·m (7.6 kgf-m, 55.3 ft-lb)

5) Remove the transmission jack.

6) Lower the vehicle.

7) Install the engine mounting bolt (upper side).

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

8) Remove the ST from converter case.

ST 498277200 STOPPER SET

9) Install the torque converter to drive plate.

(1) Install the bolts which hold torque converter

to drive plate.

(2) Install all four bolts by rotating the crank pul-

ley a little at a time.

(3) Install the service hole.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

10) Install the starter.

AT-03238

AT-00103

ST

AT-03238

AT-01377

AT-03237

Page 2146 of 2453

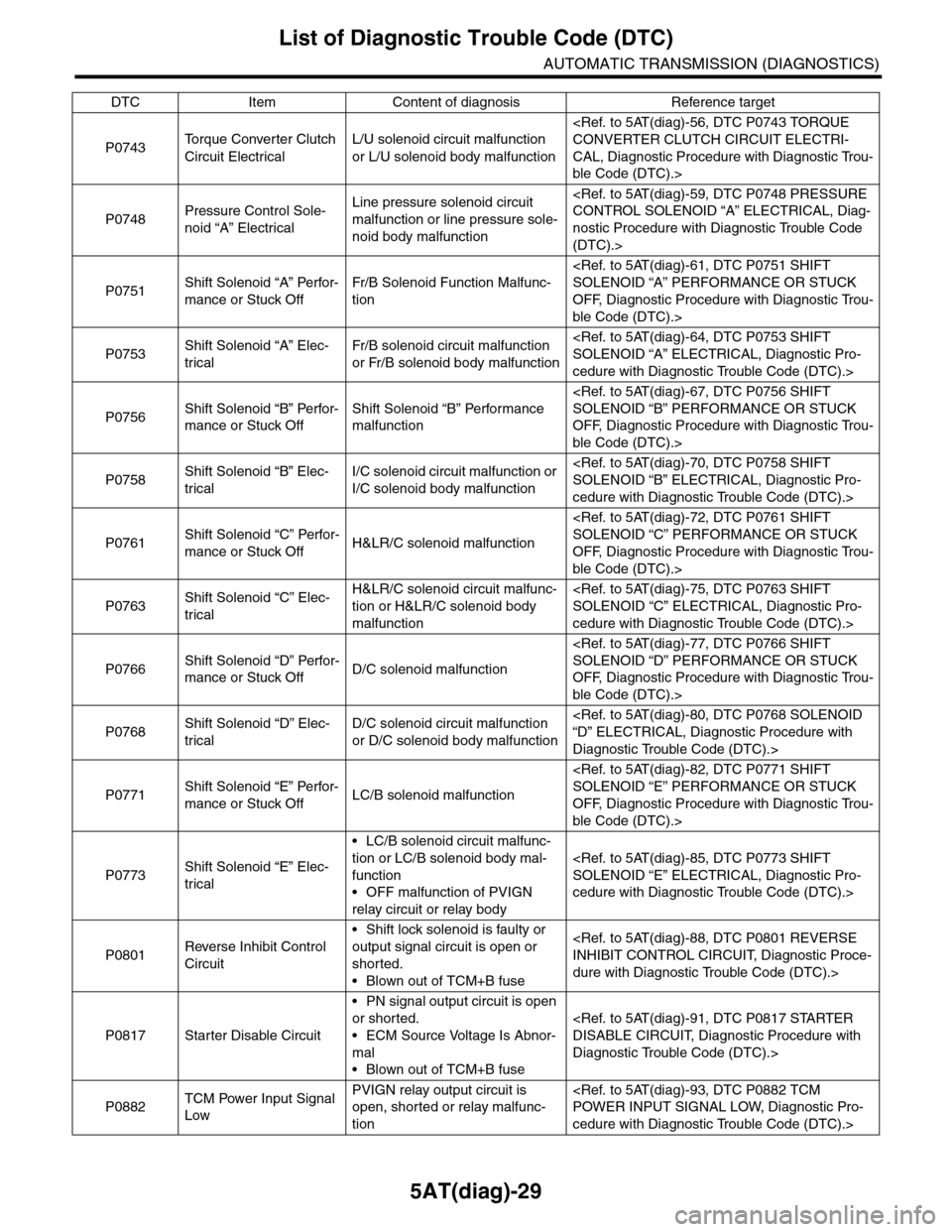

5AT(diag)-29

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

P0743To r q u e C o n v e r t e r C l u t c h

Circuit Electrical

L/U solenoid circuit malfunction

or L/U solenoid body malfunction

CAL, Diagnostic Procedure with Diagnostic Trou-

ble Code (DTC).>

P0748Pressure Control Sole-

noid “A” Electrical

Line pressure solenoid circuit

malfunction or line pressure sole-

noid body malfunction

nostic Procedure with Diagnostic Trouble Code

(DTC).>

P0751Shift Solenoid “A” Perfor-

mance or Stuck Off

Fr/B Solenoid Function Malfunc-

tion

OFF, Diagnostic Procedure with Diagnostic Trou-

ble Code (DTC).>

P0753Shift Solenoid “A” Elec-

trical

Fr/B solenoid circuit malfunction

or Fr/B solenoid body malfunction

cedure with Diagnostic Trouble Code (DTC).>

P0756Shift Solenoid “B” Perfor-

mance or Stuck Off

Shift Solenoid “B” Performance

malfunction

OFF, Diagnostic Procedure with Diagnostic Trou-

ble Code (DTC).>

P0758Shift Solenoid “B” Elec-

trical

I/C solenoid circuit malfunction or

I/C solenoid body malfunction

cedure with Diagnostic Trouble Code (DTC).>

P0761Shift Solenoid “C” Perfor-

mance or Stuck OffH&LR/C solenoid malfunction

OFF, Diagnostic Procedure with Diagnostic Trou-

ble Code (DTC).>

P0763Shift Solenoid “C” Elec-

trical

H&LR/C solenoid circuit malfunc-

tion or H&LR/C solenoid body

malfunction

cedure with Diagnostic Trouble Code (DTC).>

P0766Shift Solenoid “D” Perfor-

mance or Stuck OffD/C solenoid malfunction

OFF, Diagnostic Procedure with Diagnostic Trou-

ble Code (DTC).>

P0768Shift Solenoid “D” Elec-

trical

D/C solenoid circuit malfunction

or D/C solenoid body malfunction

Diagnostic Trouble Code (DTC).>

P0771Shift Solenoid “E” Perfor-

mance or Stuck OffLC/B solenoid malfunction

OFF, Diagnostic Procedure with Diagnostic Trou-

ble Code (DTC).>

P0773Shift Solenoid “E” Elec-

trical

•LC/B solenoid circuit malfunc-

tion or LC/B solenoid body mal-

function

•OFF malfunction of PVIGN

relay circuit or relay body

cedure with Diagnostic Trouble Code (DTC).>

P0801Reverse Inhibit Control

Circuit

•Shift lock solenoid is faulty or

output signal circuit is open or

shorted.

•Blown out of TCM+B fuse

dure with Diagnostic Trouble Code (DTC).>

P0817 Starter Disable Circuit

•PN signal output circuit is open

or shorted.

•ECM Source Voltage Is Abnor-

mal

•Blown out of TCM+B fuse

Diagnostic Trouble Code (DTC).>

P0882TCM Power Input Signal

Low

PVIGN relay output circuit is

open, shorted or relay malfunc-

tion

cedure with Diagnostic Trouble Code (DTC).>

DTC Item Content of diagnosis Reference target

Page 2208 of 2453

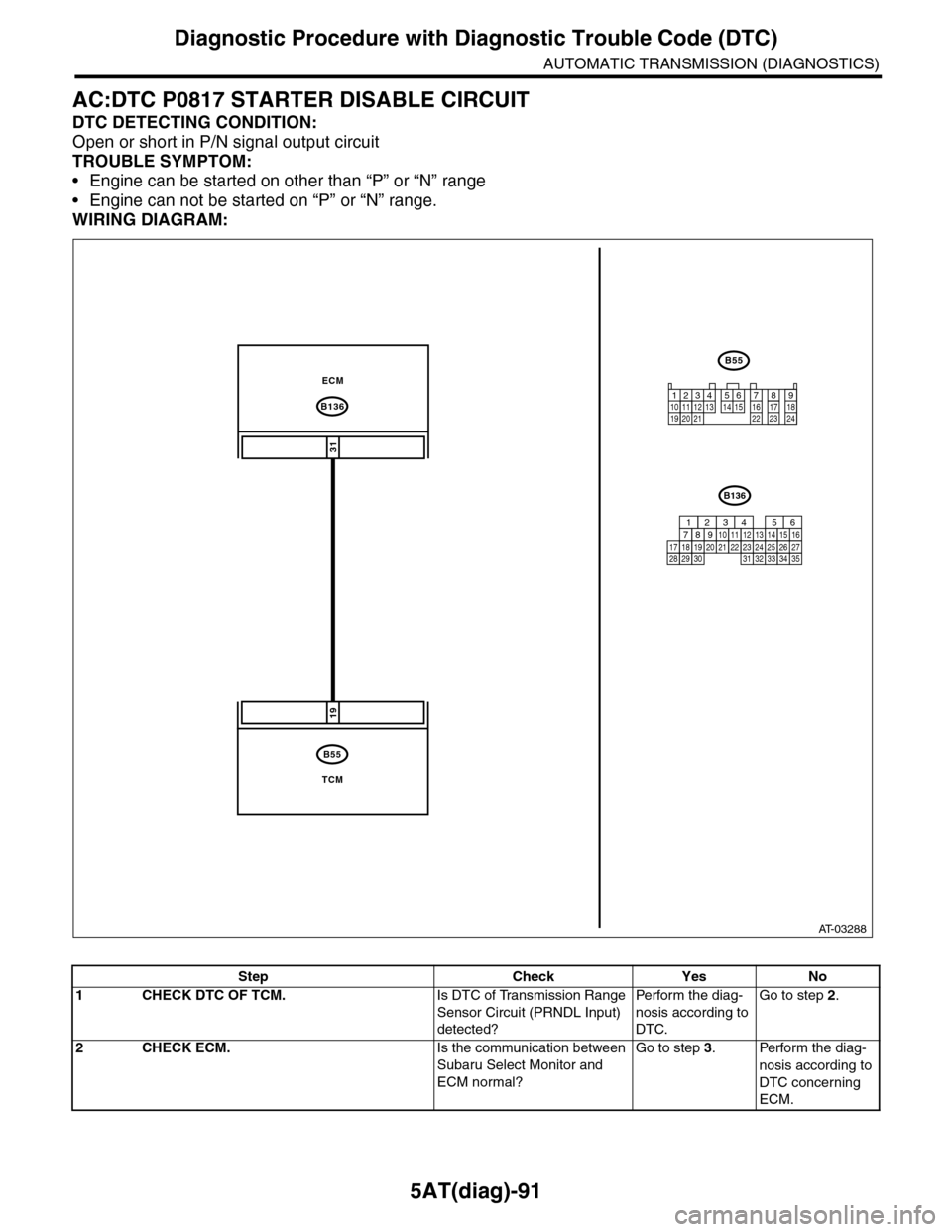

5AT(diag)-91

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

AC:DTC P0817 STARTER DISABLE CIRCUIT

DTC DETECTING CONDITION:

Open or short in P/N signal output circuit

TROUBLE SYMPTOM:

•Engine can be started on other than “P” or “N” range

•Engine can not be started on “P” or “N” range.

WIRING DIAGRAM:

AT-03288

B136

B55

31

19

ECM

TCM

B55

12341011 121920 21135614 1578916 17 1822 23 24

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

Step Check Yes No

1CHECK DTC OF TCM.Is DTC of Transmission Range

Sensor Circuit (PRNDL Input)

detected?

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK ECM.Is the communication between

Subaru Select Monitor and

ECM normal?

Go to step 3.Perform the diag-

nosis according to

DTC concerning

ECM.