compression ratio SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1089 of 2453

VDC-8

VDC Control Module & Hydraulic Control Unit (VDCCM&H/U)

VEHICLE DYNAMICS CONTROL (VDC)

4) Connect the VDCCM&H/U connectors.

NOTE:

•Be sure to remove all foreign matter from inside

the connector before connecting.

•Make sure the VDCCM&H/U connector is se-

curely locked.

5) Bleed air from the brake system.

C: INSPECTION

1) Check the condition of connection and settle-

ment of connector.

2) Check the mark used for VDCCM&H/U identifi-

cation.

Refer to “SPECIFICATION” for the identification

mark.

1. CHECKING THE HYDRAULIC UNIT ABS

OPERATION BY PRESSURE GAUGE

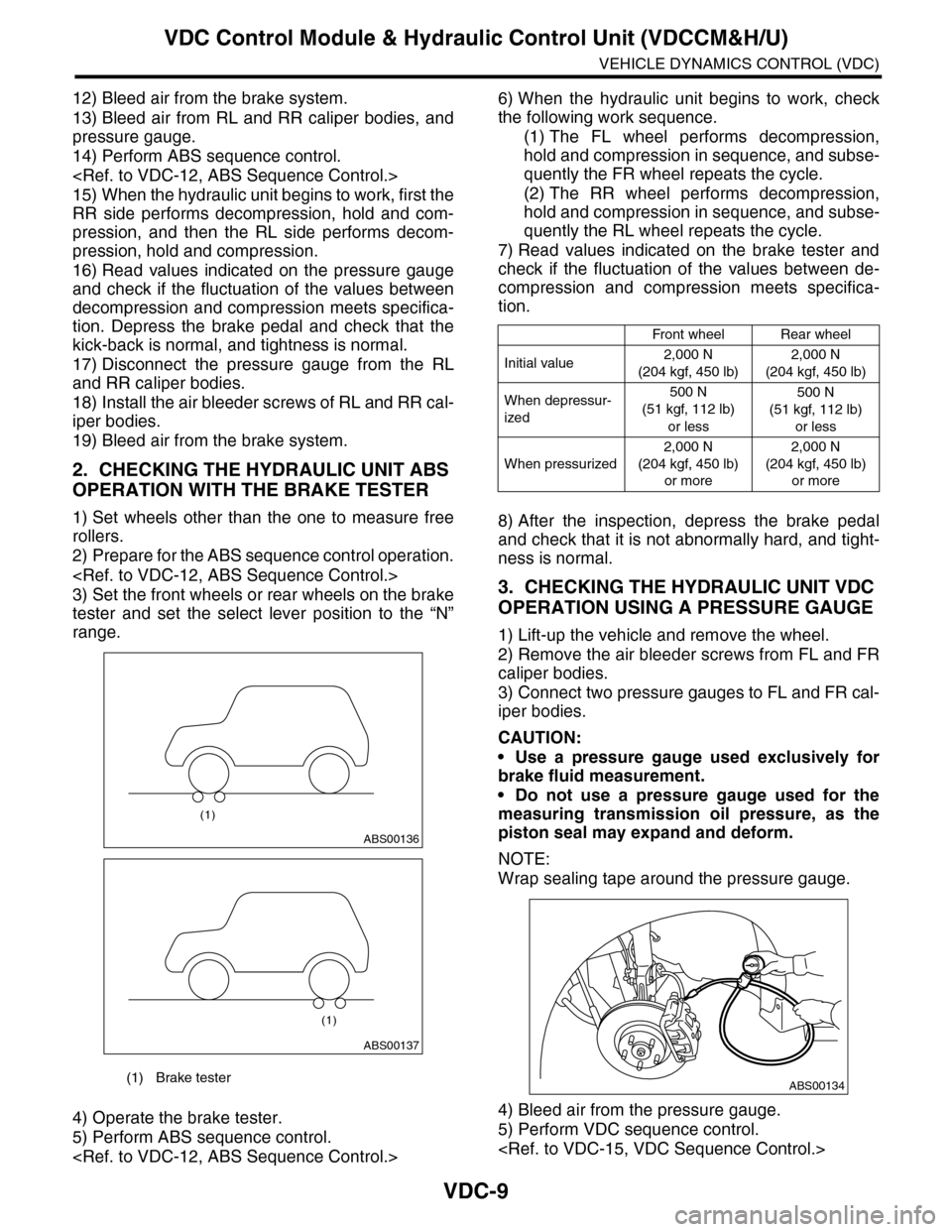

1) Lift-up the vehicle and remove the wheel.

2) Remove the air bleeder screws from FL and FR

caliper bodies.

3) Connect two pressure gauges to FL and FR cal-

iper bodies.

CAUTION:

•Use a pressure gauge used exclusively for

brake fluid measurement.

•Do not use the pressure gauge used for the

measurement of transmission oil. Doing so will

cause the piston seal to expand and deform.

NOTE:

Wrap sealing tape around the pressure gauge.

4) Bleed air from the pressure gauges and the FL

and FR caliper bodies.

5) Perform ABS sequence control.

6) When the hydraulic unit begins to work, first the

FL side performs decompression, hold and com-

pression, and then the FR side performs decom-

pression, hold and compression.

7) Read values indicated on the pressure gauge

and check if the fluctuation of the values between

decompression and compression meets the stan-

dard values. Depress the brake pedal and check

that the kick-back is normal, and tightness is nor-

mal.

8) Disconnect the pressure gauges from FL and FR

caliper bodies.

9) Install the air bleeder screws of FL and FR cali-

per bodies.

10) Remove the air bleeder screws from RL and

RR caliper bodies.

11) Connect two pressure gauges to RL and RR

caliper bodies.

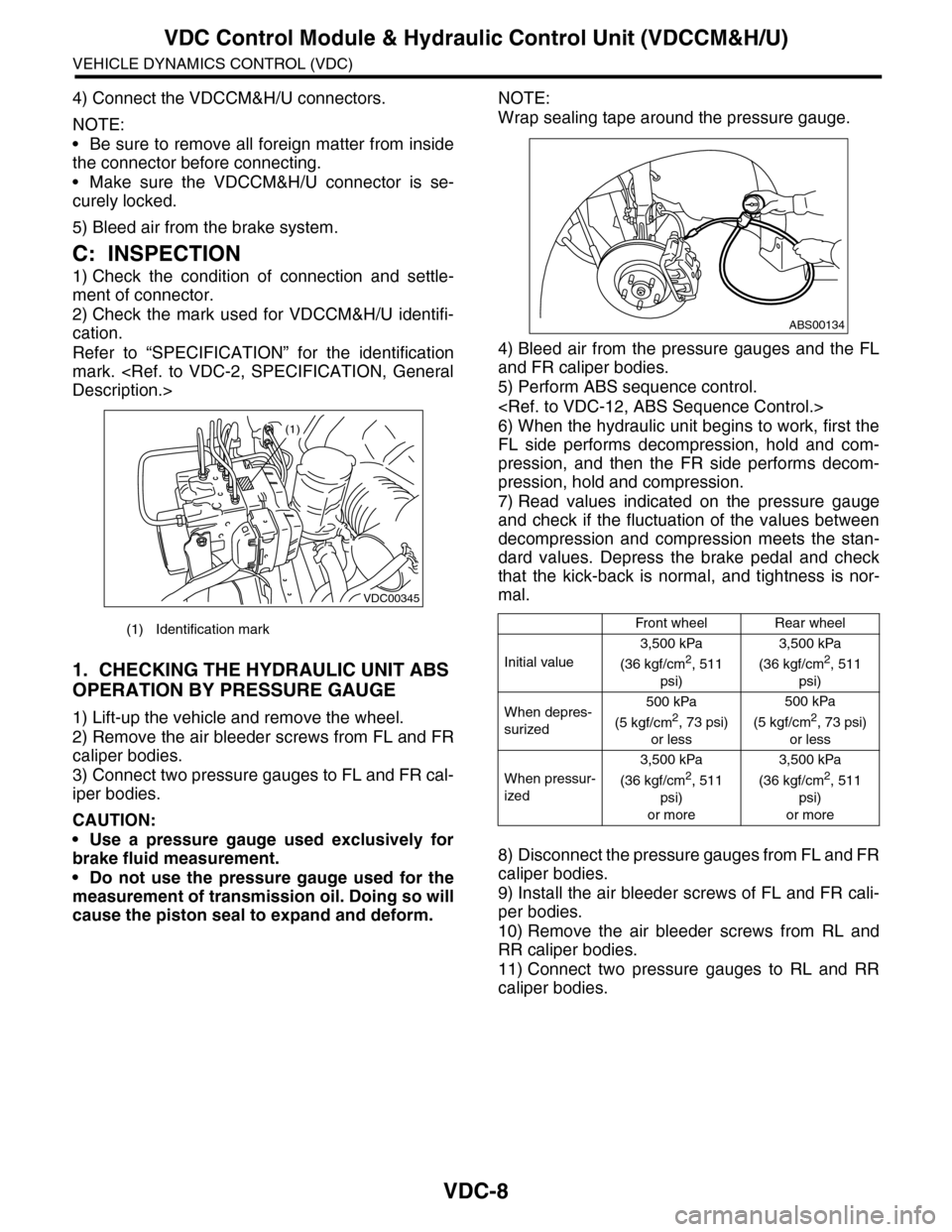

(1) Identification mark

VDC00345

(1)

Front wheelRear wheel

Initial value

3,500 kPa

(36 kgf/cm2, 511

psi)

3,500 kPa

(36 kgf/cm2, 511

psi)

When depres-

surized

500 kPa

(5 kgf/cm2, 73 psi)

or less

500 kPa

(5 kgf/cm2, 73 psi)

or less

When pressur-

ized

3,500 kPa

(36 kgf/cm2, 511

psi)

or more

3,500 kPa

(36 kgf/cm2, 511

psi)

or more

ABS00134

Page 1090 of 2453

VDC-9

VDC Control Module & Hydraulic Control Unit (VDCCM&H/U)

VEHICLE DYNAMICS CONTROL (VDC)

12) Bleed air from the brake system.

13) Bleed air from RL and RR caliper bodies, and

pressure gauge.

14) Perform ABS sequence control.

15) When the hydraulic unit begins to work, first the

RR side performs decompression, hold and com-

pression, and then the RL side performs decom-

pression, hold and compression.

16) Read values indicated on the pressure gauge

and check if the fluctuation of the values between

decompression and compression meets specifica-

tion. Depress the brake pedal and check that the

kick-back is normal, and tightness is normal.

17) Disconnect the pressure gauge from the RL

and RR caliper bodies.

18) Install the air bleeder screws of RL and RR cal-

iper bodies.

19) Bleed air from the brake system.

2. CHECKING THE HYDRAULIC UNIT ABS

OPERATION WITH THE BRAKE TESTER

1) Set wheels other than the one to measure free

rollers.

2) Prepare for the ABS sequence control operation.

3) Set the front wheels or rear wheels on the brake

tester and set the select lever position to the “N”

range.

4) Operate the brake tester.

5) Perform ABS sequence control.

6) When the hydraulic unit begins to work, check

the following work sequence.

(1) The FL wheel performs decompression,

hold and compression in sequence, and subse-

quently the FR wheel repeats the cycle.

(2) The RR wheel performs decompression,

hold and compression in sequence, and subse-

quently the RL wheel repeats the cycle.

7) Read values indicated on the brake tester and

check if the fluctuation of the values between de-

compression and compression meets specifica-

tion.

8) After the inspection, depress the brake pedal

and check that it is not abnormally hard, and tight-

ness is normal.

3. CHECKING THE HYDRAULIC UNIT VDC

OPERATION USING A PRESSURE GAUGE

1) Lift-up the vehicle and remove the wheel.

2) Remove the air bleeder screws from FL and FR

caliper bodies.

3) Connect two pressure gauges to FL and FR cal-

iper bodies.

CAUTION:

•Use a pressure gauge used exclusively for

brake fluid measurement.

•Do not use a pressure gauge used for the

measuring transmission oil pressure, as the

piston seal may expand and deform.

NOTE:

Wrap sealing tape around the pressure gauge.

4) Bleed air from the pressure gauge.

5) Perform VDC sequence control.

(1) Brake tester

ABS00136

(1)

ABS00137

(1)

Front wheelRear wheel

Initial value2,000 N

(204 kgf, 450 lb)

2,000 N

(204 kgf, 450 lb)

When depressur-

ized

500 N

(51 kgf, 112 lb)

or less

500 N

(51 kgf, 112 lb)

or less

When pressurized

2,000 N

(204 kgf, 450 lb)

or more

2,000 N

(204 kgf, 450 lb)

or more

ABS00134

Page 1095 of 2453

VDC-14

ABS Sequence Control

VEHICLE DYNAMICS CONTROL (VDC)

NOTE:

The control operation starts from point A.

B: SPECIFICATION

1. ABS SEQUENCE CONTROL COMPLETE

CONDITION

When the following conditions develop, the ABS

sequence control stops and ABS operation is re-

turned to the normal control mode.

1) When the speed of at least one wheel reaches

10 km/h (6 MPH).

2) When the brake pedal is released during ABS

sequence control and the stop lamp switch is be-

comes OFF.

3) After completion of ABS sequence control.

4) When a malfunction is detected.

(1) All wheel speed (10) RR decompression valve (18) 1.0 seconds

(2) Ignition key (11) RR hold valve (19) 1.4 seconds

(3) ABS warning light (12) RL decompression valve (20) 0.6 seconds

(4) Stop light switch (13) RL hold valve (21) 0.4 seconds

(5) Valve relay (14) Pump motor (22) Point A

(6) FL decompression valve (15) 1.5 seconds (23) Reset

(7) FL hold valve (16) Light OFF (24) Linear valve 1

(8) FR decompression valve (17) Light ON (25) Linear valve 2

(9) FR hold valve

Page 1098 of 2453

VDC-17

VDC Sequence Control

VEHICLE DYNAMICS CONTROL (VDC)

NOTE:

The control operation starts from point A.

B: SPECIFICATION

1. CONDITIONS FOR COMPLETION OF

VDC SEQUENCE CONTROL

When the following conditions develop, the VDC

sequence control stops and VDC operation is re-

turned to the normal control mode.

1) When the speed of at least one wheel reaches

10 km/h (6 MPH).

2) When the brake pedal is pressed during se-

quence control and the stop light switch is set to

ON.

3) After completion of VDC sequence control.

4) When a malfunction is detected.

(1) All wheel speed (11) FR compression valve (21) Light OFF

(2) Ignition key (12) RR decompression valve (22) Light ON

(3) ABS warning light (13) RR compression valve (23) 3.4 seconds

(4) VDC warning light (14) RL decompression valve (24) 1 second

(5) VDC operation lamp (CAN output) (15) RL compression valve (25) 1.6 seconds

(6) Stop light switch (16) Pump motor (26) Point A

(7) Valve relay (17) Linear valve 1 (27) Reset

(8) FL decompression valve (18) Linear valve 2 (28) 0.8 seconds

(9) FL compression valve (19) 1.5 seconds (29) 1.2 seconds

(10) FR decompression valve (20) Approx. 3 sec. (30) 0.4 seconds

Page 1409 of 2453

EN(H6DO)(diag)-248

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

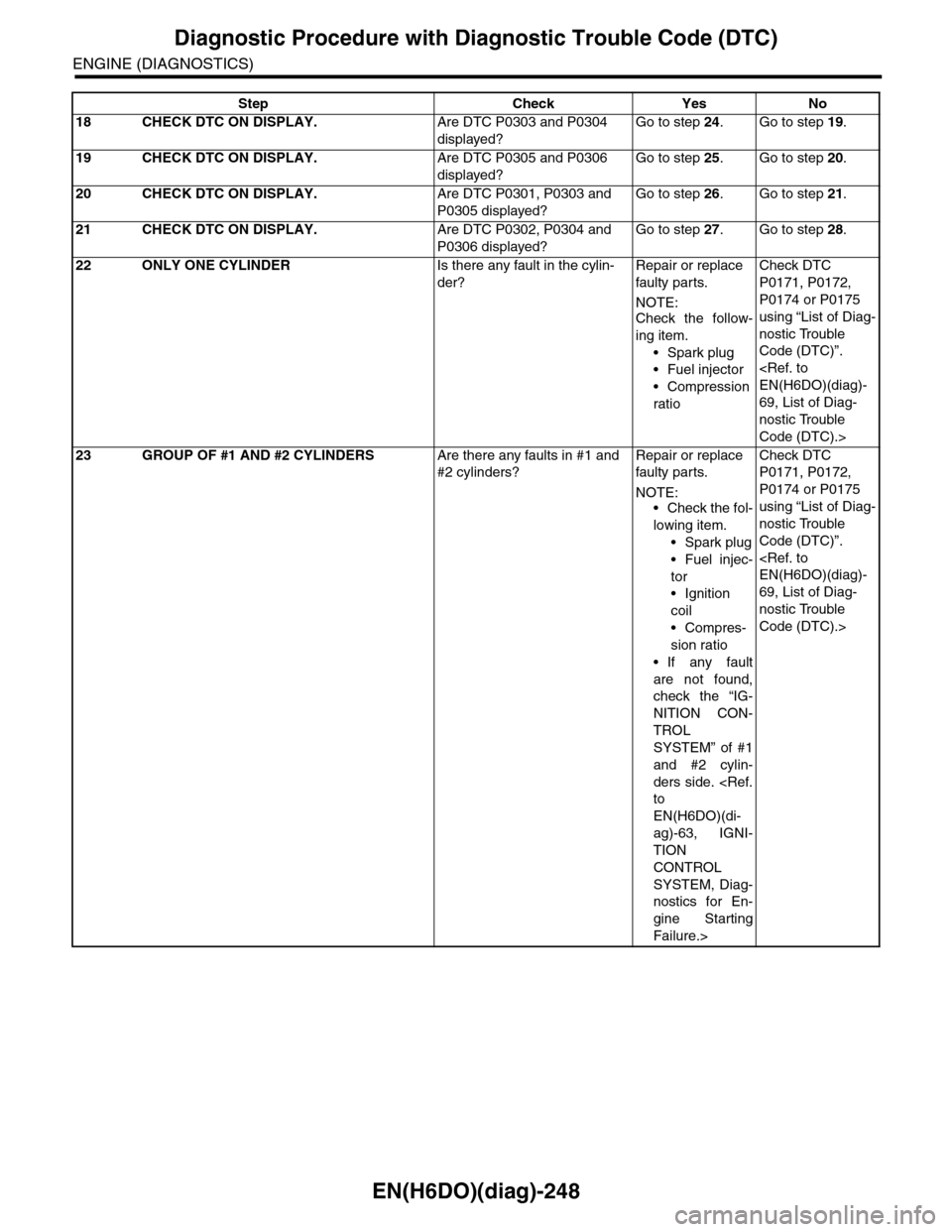

18 CHECK DTC ON DISPLAY.Are DTC P0303 and P0304

displayed?

Go to step 24.Go to step 19.

19 CHECK DTC ON DISPLAY.Are DTC P0305 and P0306

displayed?

Go to step 25.Go to step 20.

20 CHECK DTC ON DISPLAY.Are DTC P0301, P0303 and

P0305 displayed?

Go to step 26.Go to step 21.

21 CHECK DTC ON DISPLAY.Are DTC P0302, P0304 and

P0306 displayed?

Go to step 27.Go to step 28.

22 ONLY ONE CYLINDERIs there any fault in the cylin-

der?

Repair or replace

faulty par ts.

NOTE:Check the follow-

ing item.

•Spark plug

•Fuel injector

•Compression

ratio

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

23 GROUP OF #1 AND #2 CYLINDERSAre there any faults in #1 and

#2 cylinders?

Repair or replace

faulty par ts.

NOTE:•Check the fol-

lowing item.

•Spark plug

•Fuel injec-

tor

•Ignition

coil

•Compres-

sion ratio

•If any fault

are not found,

check the “IG-

NITION CON-

TROL

SYSTEM” of #1

and #2 cylin-

ders side.

EN(H6DO)(di-

ag)-63, IGNI-

TION

CONTROL

SYSTEM, Diag-

nostics for En-

gine Starting

Failure.>

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Step Check Yes No

Page 1411 of 2453

EN(H6DO)(diag)-250

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

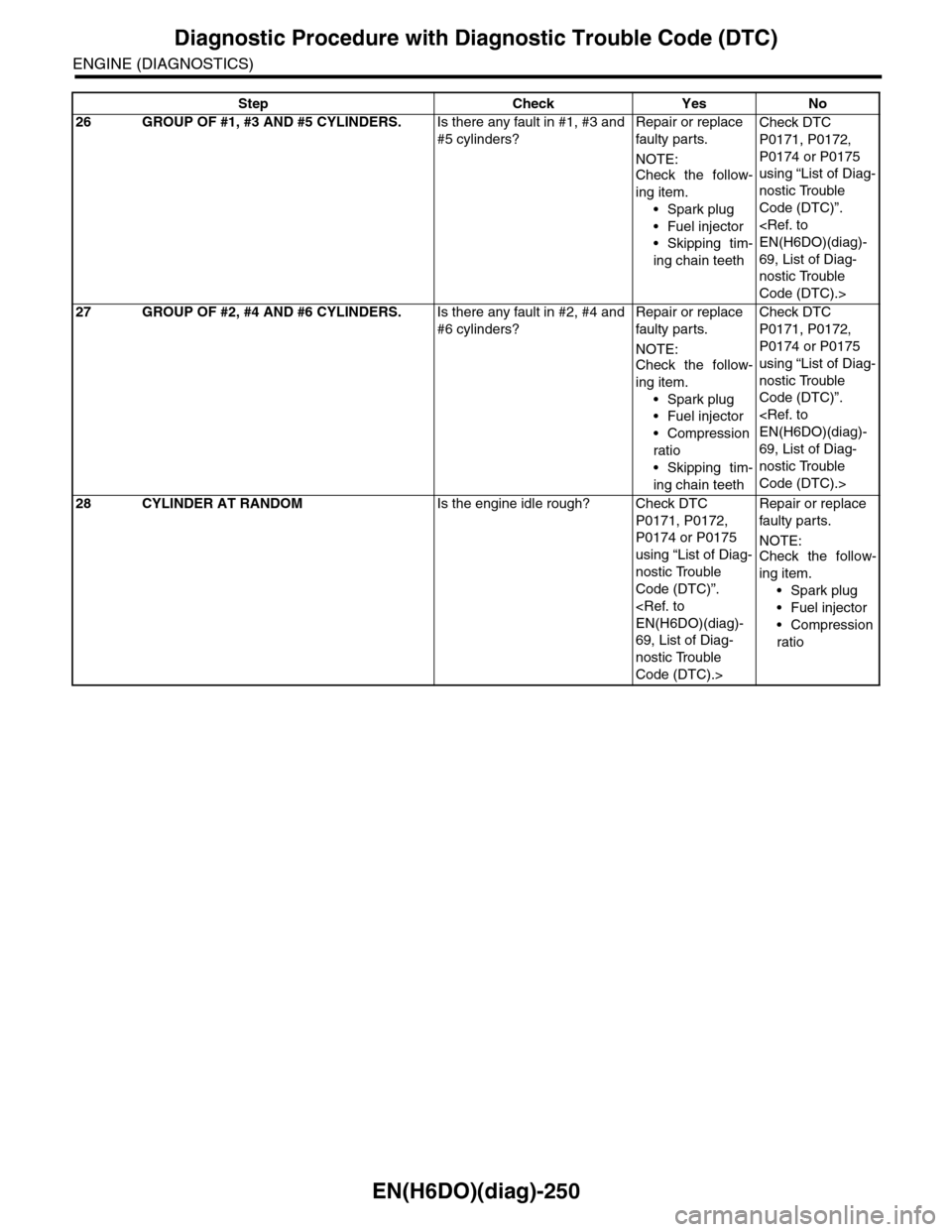

26 GROUP OF #1, #3 AND #5 CYLINDERS.Is there any fault in #1, #3 and

#5 cylinders?

Repair or replace

faulty par ts.

NOTE:

Check the follow-

ing item.

•Spark plug

•Fuel injector

•Skipping tim-

ing chain teeth

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

27 GROUP OF #2, #4 AND #6 CYLINDERS.Is there any fault in #2, #4 and

#6 cylinders?

Repair or replace

faulty par ts.

NOTE:Check the follow-

ing item.

•Spark plug

•Fuel injector

•Compression

ratio

•Skipping tim-

ing chain teeth

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

28 CYLINDER AT RANDOMIs the engine idle rough? Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Repair or replace

faulty par ts.

NOTE:Check the follow-

ing item.

•Spark plug

•Fuel injector

•Compression

ratio

Step Check Yes No

Page 1868 of 2453

ME(H6DO)-2

General Description

MECHANICAL

1. General Description

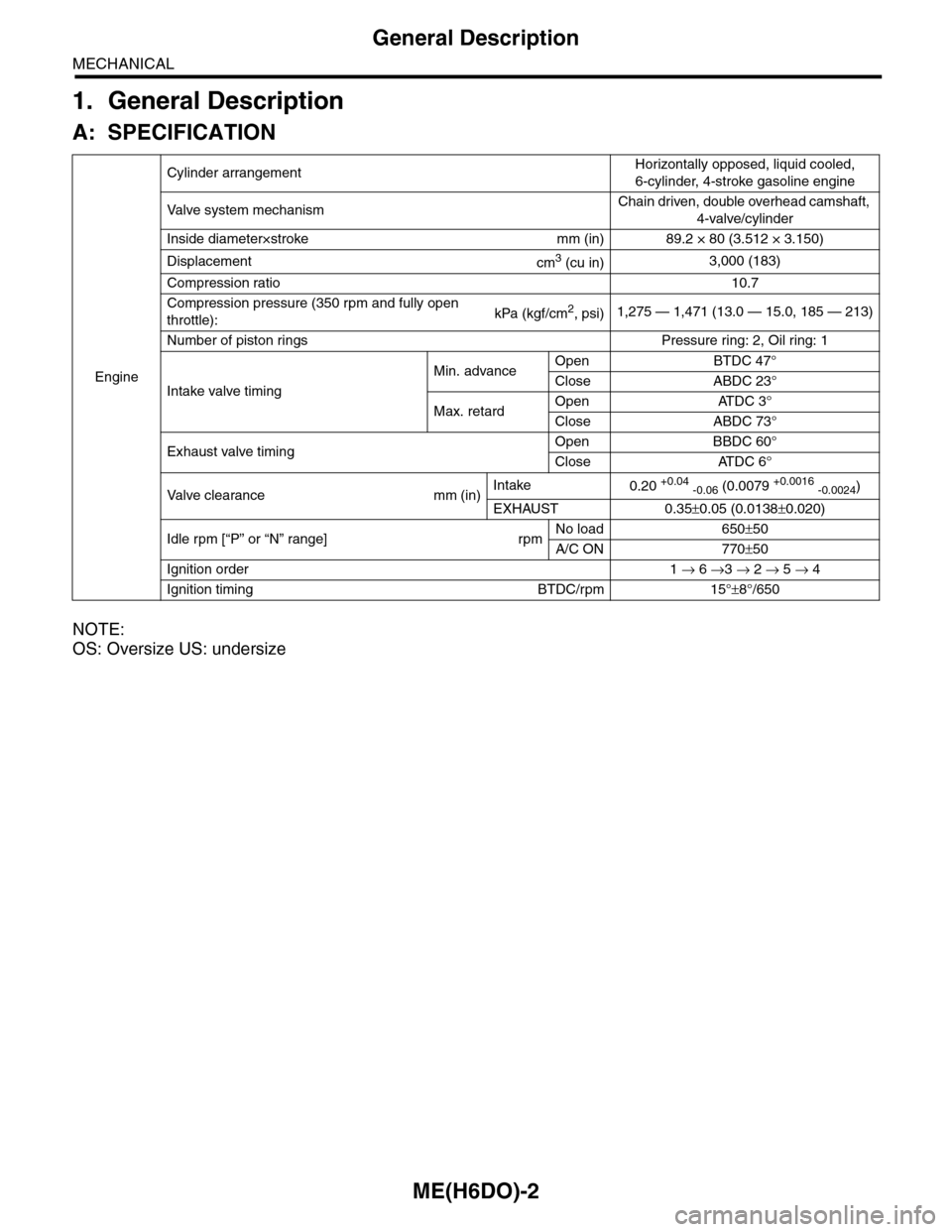

A: SPECIFICATION

NOTE:

OS: Oversize US: undersize

Engine

Cylinder arrangementHorizontally opposed, liquid cooled,

6-cylinder, 4-stroke gasoline engine

Va l ve s y s t e m m e c h a n i s mChain driven, double overhead camshaft,

4-valve/cylinder

Inside diameter×stroke mm (in) 89.2 × 80 (3.512 × 3.150)

Displacementcm3 (cu in)3,000 (183)

Compression ratio10.7

Compression pressure (350 rpm and fully open

throttle):kPa (kgf/cm2, psi)1,275 — 1,471 (13.0 — 15.0, 185 — 213)

Number of piston rings Pressure ring: 2, Oil ring: 1

Intake valve timing

Min. advanceOpen BTDC 47°

Close ABDC 23°

Max. retardOpen ATDC 3°

Close ABDC 73°

Exhaust valve timingOpen BBDC 60°

Close ATDC 6°

Va l ve c l e a r a n c e m m ( i n )Intake0.20 +0.04 -0.06 (0.0079 +0.0016 -0.0024)

EXHAUST 0.35±0.05 (0.0138±0.020)

Idle rpm [“P” or “N” range] rpmNo load 650±50

A/C ON 770±50

Ignition order 1 → 6 →3 → 2 → 5 → 4

Ignition timing BTDC/rpm 15°±8°/650

Page 1886 of 2453

ME(H6DO)-20

General Description

MECHANICAL

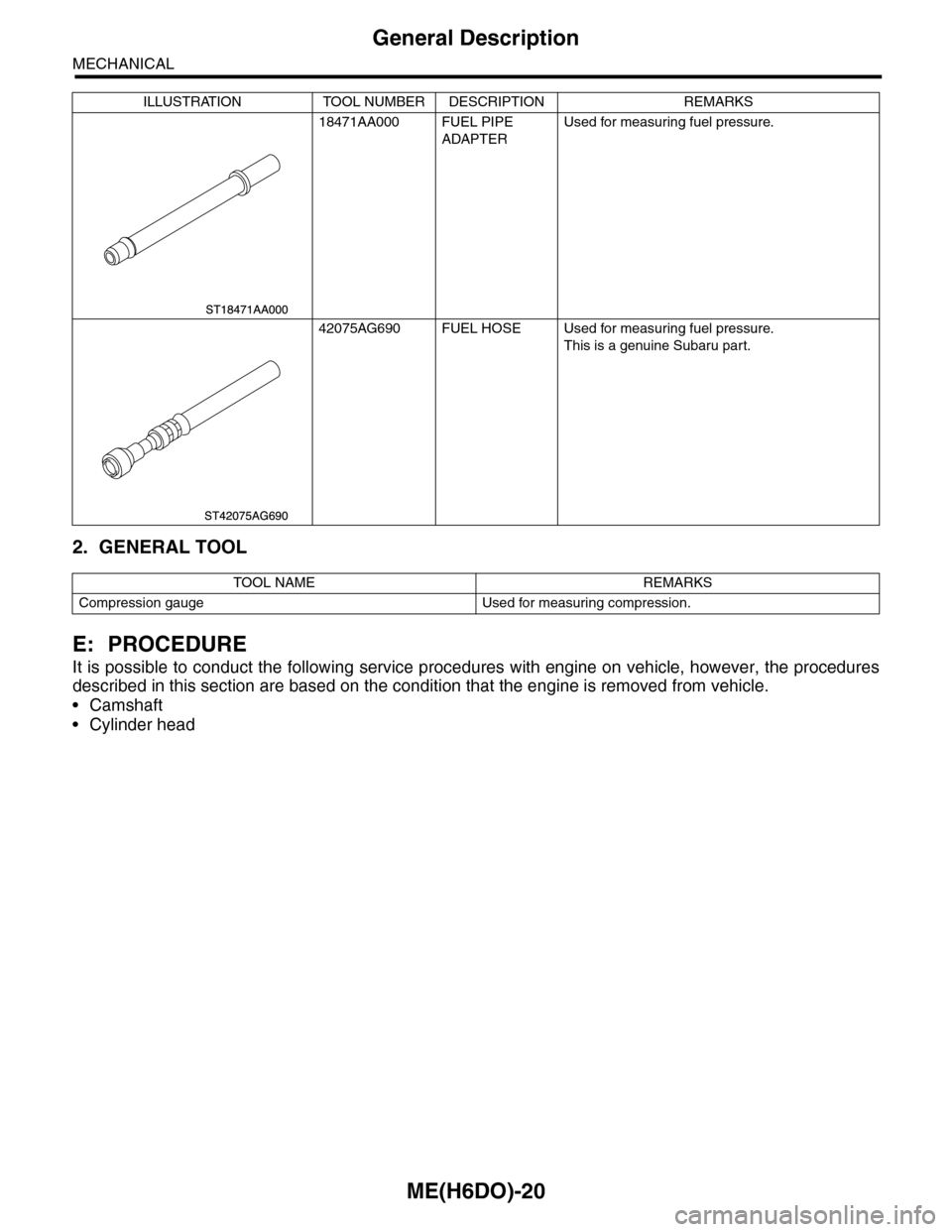

2. GENERAL TOOL

E: PROCEDURE

It is possible to conduct the following service procedures with engine on vehicle, however, the procedures

described in this section are based on the condition that the engine is removed from vehicle.

•Camshaft

•Cylinder head

18471AA000 FUEL PIPE

ADAPTER

Used for measuring fuel pressure.

42075AG690 FUEL HOSE Used for measuring fuel pressure.

This is a genuine Subaru part.

TOOL NAME REMARKS

Compression gauge Used for measuring compression.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

Page 1887 of 2453

ME(H6DO)-21

Compression

MECHANICAL

2. Compression

A: INSPECTION

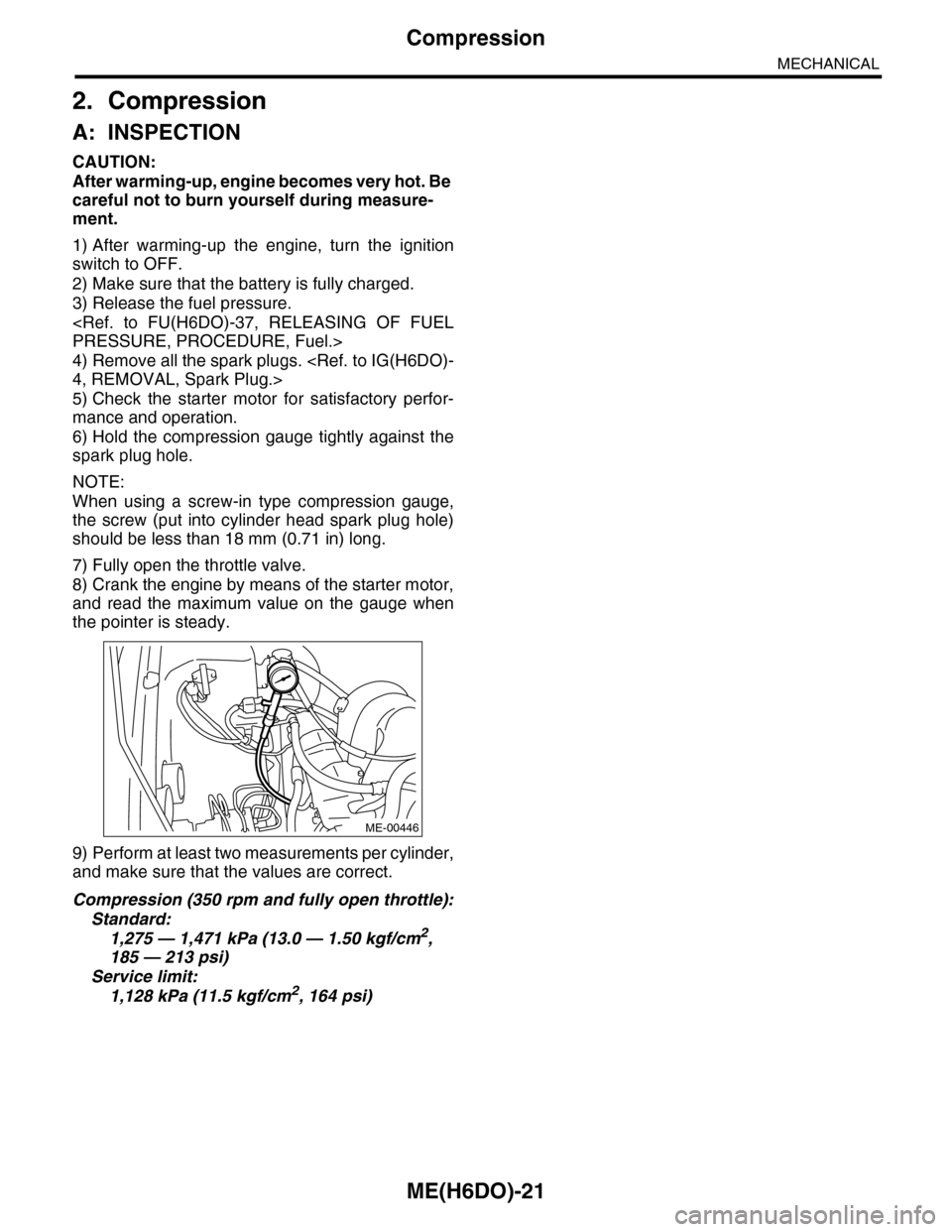

CAUTION:

After warming-up, engine becomes very hot. Be

careful not to burn yourself during measure-

ment.

1) After warming-up the engine, turn the ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Release the fuel pressure.

4) Remove all the spark plugs.

5) Check the starter motor for satisfactory perfor-

mance and operation.

6) Hold the compression gauge tightly against the

spark plug hole.

NOTE:

When using a screw-in type compression gauge,

the screw (put into cylinder head spark plug hole)

should be less than 18 mm (0.71 in) long.

7) Fully open the throttle valve.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

9) Perform at least two measurements per cylinder,

and make sure that the values are correct.

Compression (350 rpm and fully open throttle):

Standard:

1,275 — 1,471 kPa (13.0 — 1.50 kgf/cm2,

185 — 213 psi)

Service limit:

1,128 kPa (11.5 kgf/cm2, 164 psi)

ME-00446

Page 1952 of 2453

ME(H6DO)-86

Engine Trouble in General

MECHANICAL

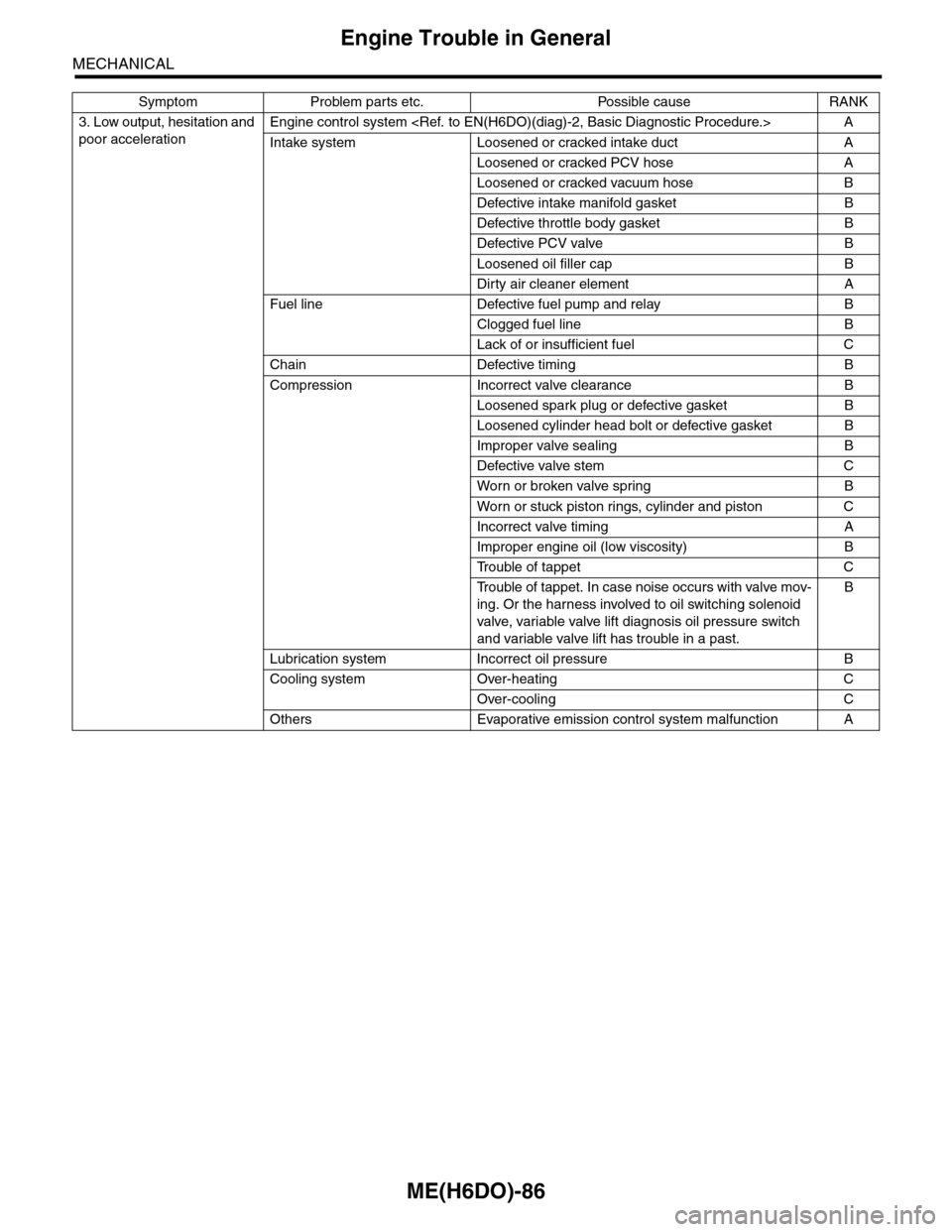

3. Low output, hesitation and

poor acceleration

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Cooling system Over-heating C

Over-cooling C

Others Evaporative emission control system malfunction A

Symptom Problem parts etc. Possible cause RANK