coolant temperature sensor SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1643 of 2453

GD(H6DO)-31

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

V: DTC P0101 MASS OR VOLUME AIR FLOW CIRCUIT RANGE/PERFOR-

MANCE

1. OUTLINE OF DIAGNOSIS

Detect for abnormalities in the air flow sensor output properties.

Judge as a low side NG when the air flow voltage indicates a small value regardless of running in a state

where the air flow voltage increases. Judge as a high side NG when the air flow voltage indicates a large val-

ue regardless of running in a state where the air flow voltage decreases. Judge air flow sensor property NG

when the Low side or High side becomes NG.

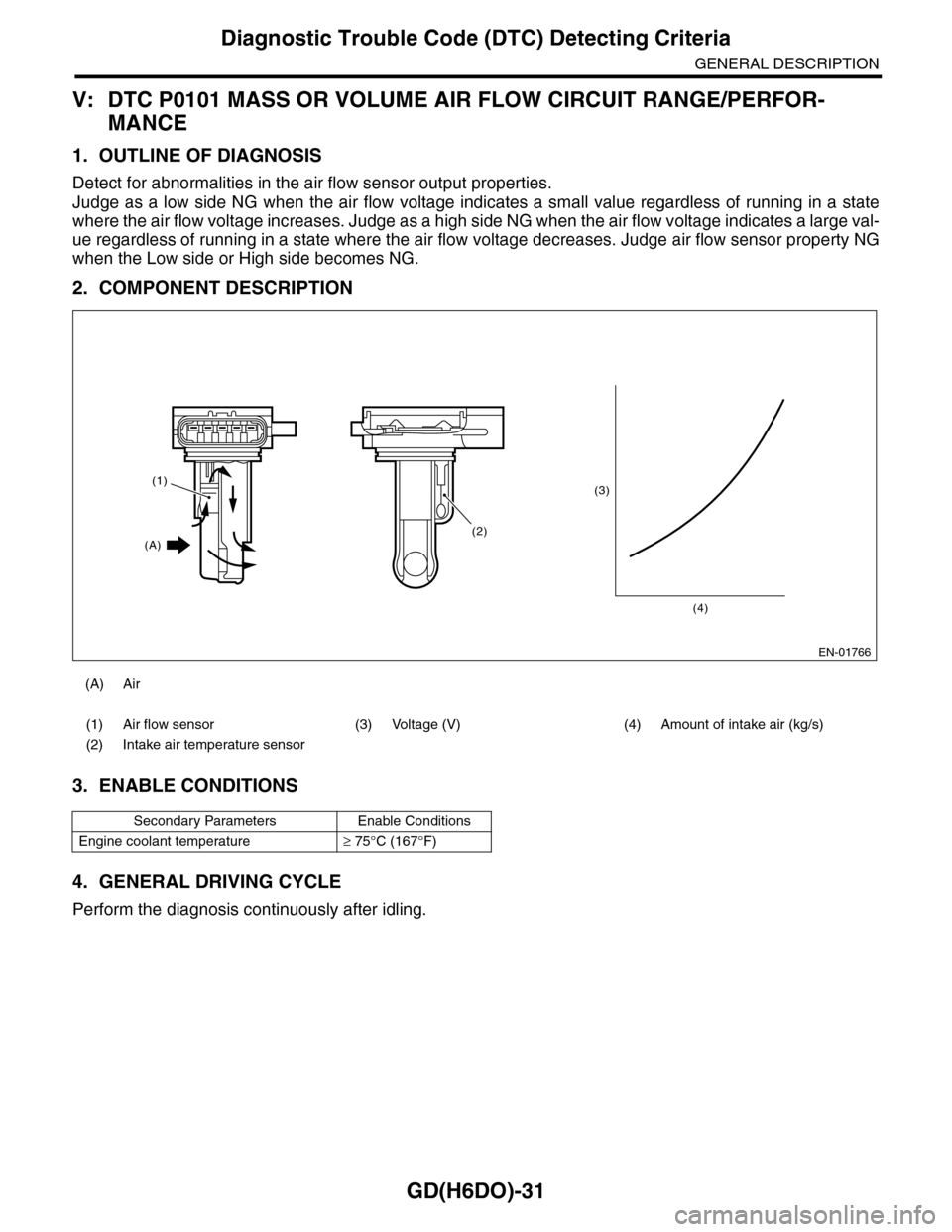

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously after idling.

(A) Air

(1) Air flow sensor (3) Voltage (V) (4) Amount of intake air (kg/s)

(2) Intake air temperature sensor

Secondary Parameters Enable Conditions

Engine coolant temperature≥ 75°C (167°F)

EN-01766

(3)

(4)

(2)

(1)

(A)

Page 1654 of 2453

GD(H6DO)-42

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

AA:DTC P0111 INTAKE AIR TEMPERATURE CIRCUIT RANGE/PERFORMANCE

1. OUTLINE OF DIAGNOSIS

Detect the malfunction of intake air temperature sensor output property.

Judge as NG when the intake air temperature is not varied whereas it seemed to be varied from the viewpoint

of engine condition.

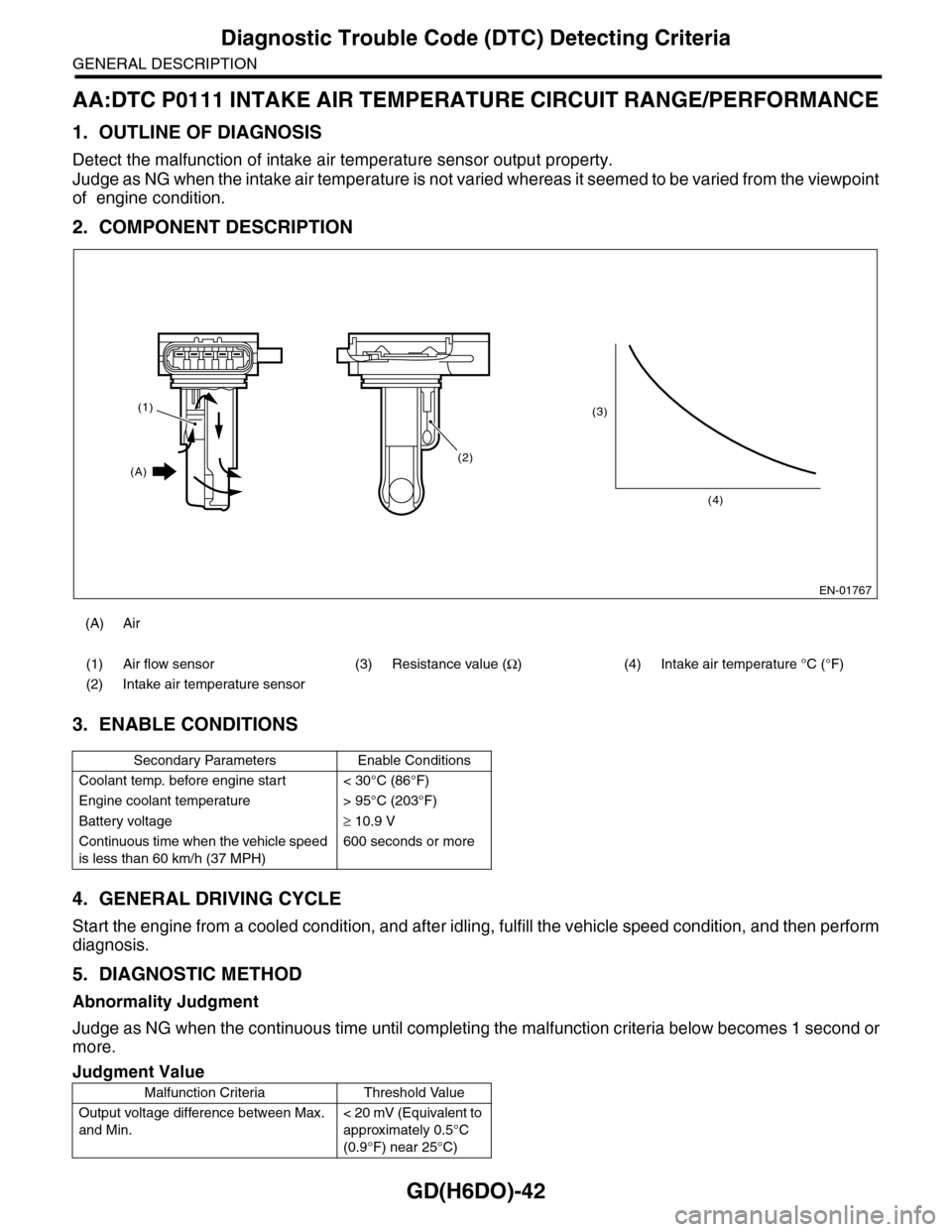

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Start the engine from a cooled condition, and after idling, fulfill the vehicle speed condition, and then perform

diagnosis.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

(A) Air

(1) Air flow sensor (3) Resistance value (Ω)(4)Intake air temperature °C (°F)

(2) Intake air temperature sensor

Secondary Parameters Enable Conditions

Coolant temp. before engine start < 30°C (86°F)

Engine coolant temperature > 95°C (203°F)

Battery voltage≥ 10.9 V

Continuous time when the vehicle speed

is less than 60 km/h (37 MPH)

600 seconds or more

Judgment Value

Malfunction Criteria Threshold Value

Output voltage difference between Max.

and Min.

< 20 mV (Equivalent to

approximately 0.5°C

(0.9°F) near 25°C)

EN-01767

(3)

(4)

(2)

(1)

(A)

Page 1660 of 2453

GD(H6DO)-48

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

AD:DTC P0117 ENGINE COOLANT TEMPERATURE CIRCUIT LOW INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the engine coolant temperature sensor.

Judge as NG if it is out of specification.

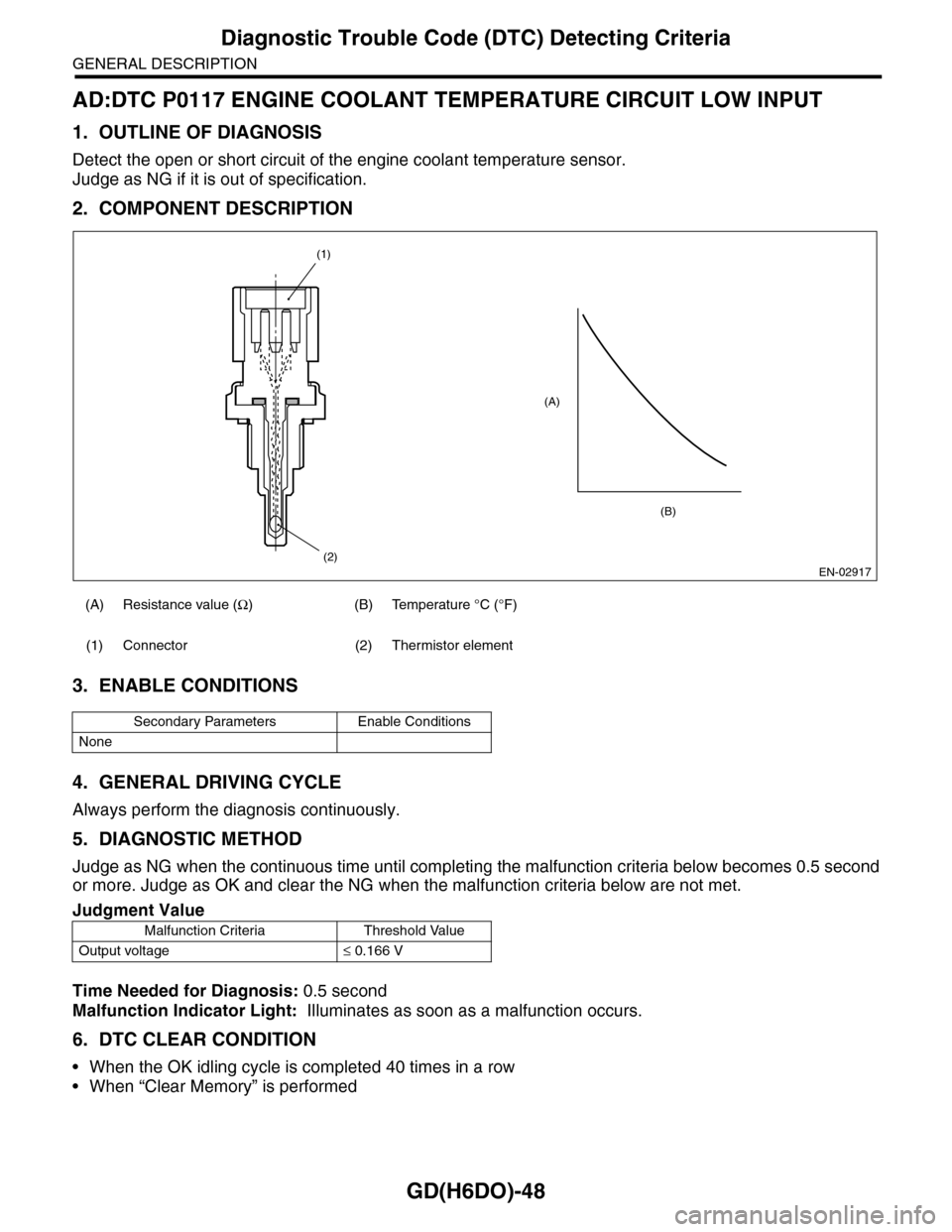

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time until completing the malfunction criteria below becomes 0.5 second

or more. Judge as OK and clear the NG when the malfunction criteria below are not met.

Time Needed for Diagnosis: 0.5 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

(A) Resistance value (Ω) (B) Temperature °C (°F)

(1) Connector (2) Thermistor element

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage≤ 0.166 V

EN-02917

(A)

(2)

(1)

(B)

Page 1661 of 2453

GD(H6DO)-49

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Engine coolant temperature sensor process: Engine coolant temperature is fixed at 70°C (158°F).

•ISC Feedback: Calculate target engine RPM as engine coolant temperature 70°C (158°F).

•ISC learning: Not allowed to learn.

•Air conditioner control: Not allowed to turn the air conditioner to ON.

•Radiator fan control: Send the duty signal 50% to the controller.

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Page 1662 of 2453

GD(H6DO)-50

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

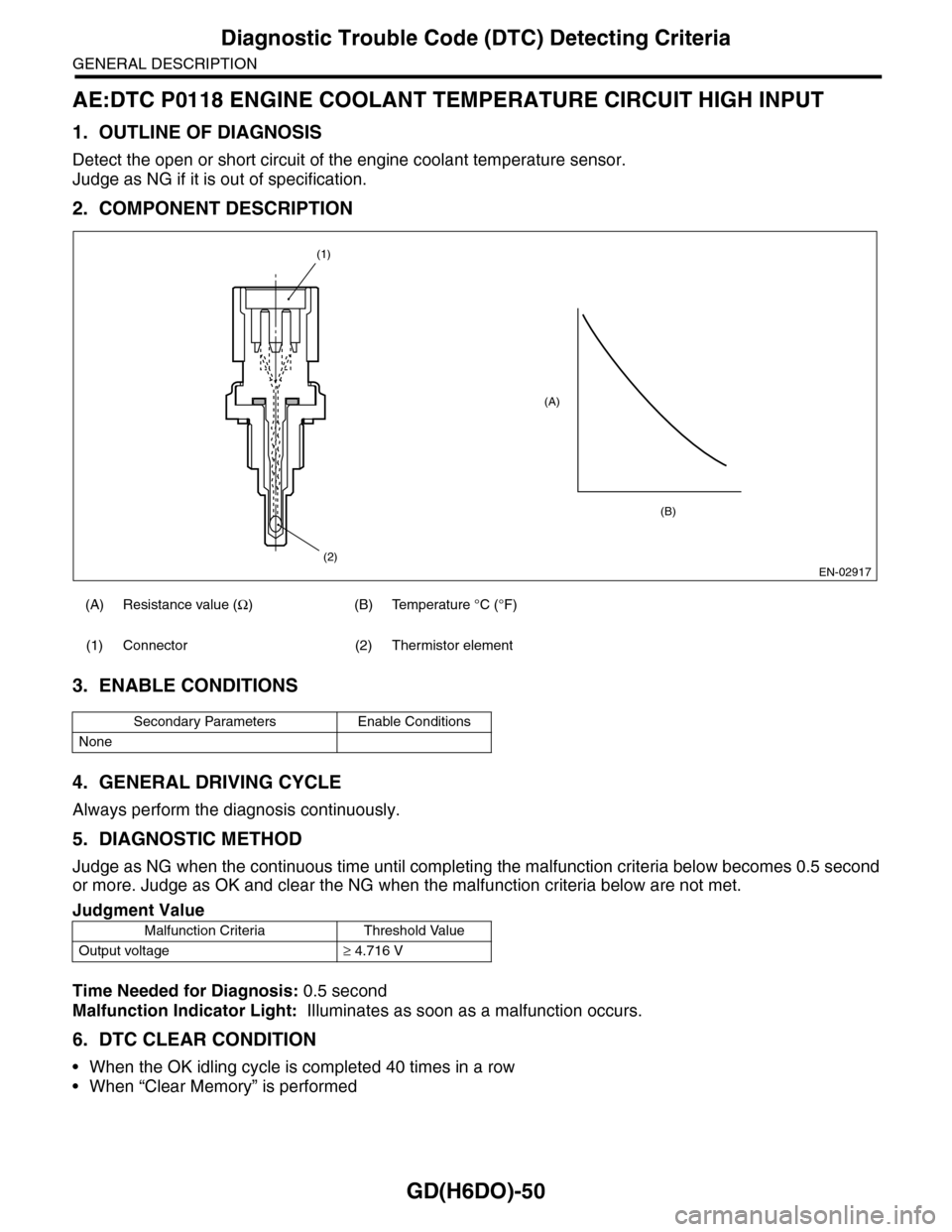

AE:DTC P0118 ENGINE COOLANT TEMPERATURE CIRCUIT HIGH INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the engine coolant temperature sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time until completing the malfunction criteria below becomes 0.5 second

or more. Judge as OK and clear the NG when the malfunction criteria below are not met.

Time Needed for Diagnosis: 0.5 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

(A) Resistance value (Ω) (B) Temperature °C (°F)

(1) Connector (2) Thermistor element

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage≥ 4.716 V

EN-02917

(A)

(2)

(1)

(B)

Page 1663 of 2453

GD(H6DO)-51

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

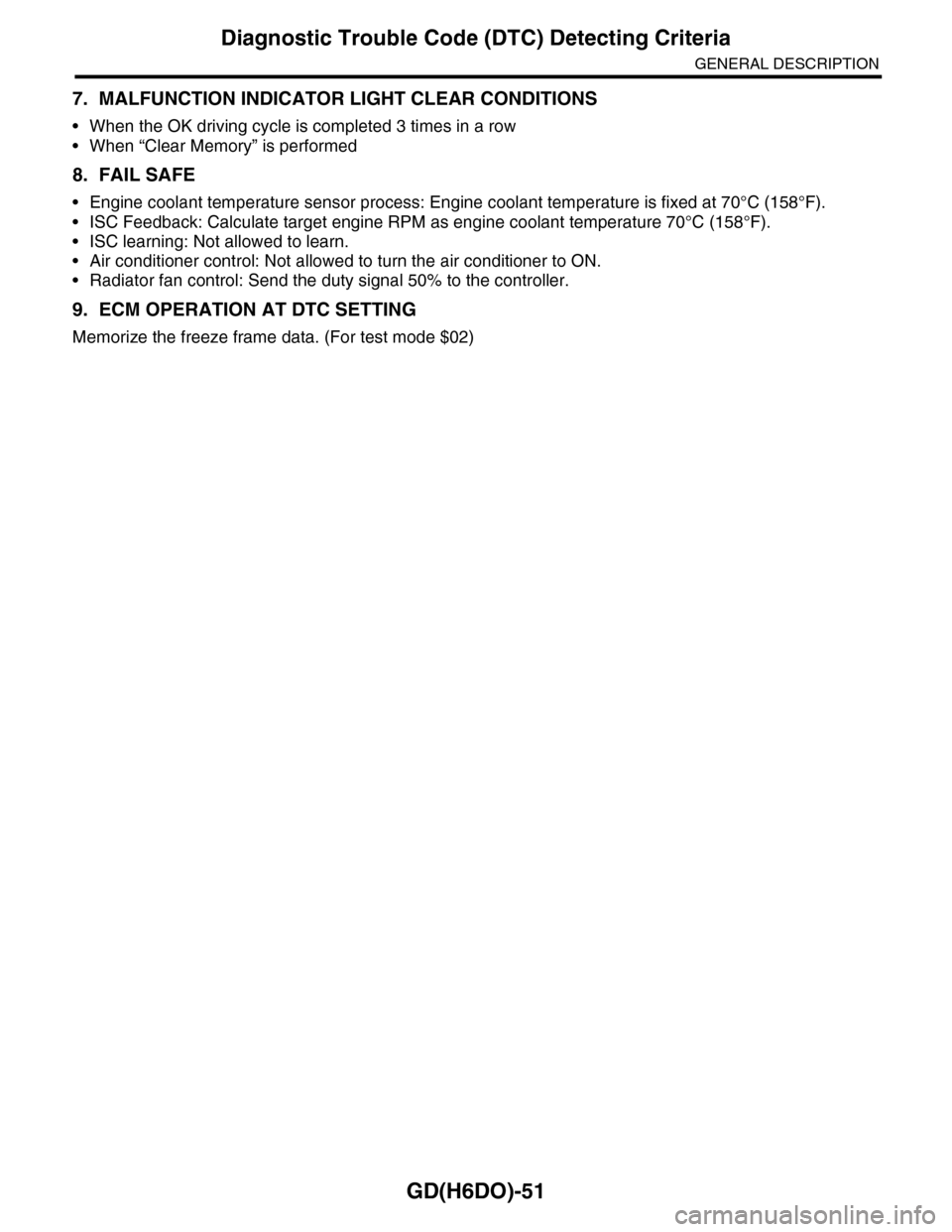

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Engine coolant temperature sensor process: Engine coolant temperature is fixed at 70°C (158°F).

•ISC Feedback: Calculate target engine RPM as engine coolant temperature 70°C (158°F).

•ISC learning: Not allowed to learn.

•Air conditioner control: Not allowed to turn the air conditioner to ON.

•Radiator fan control: Send the duty signal 50% to the controller.

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Page 1669 of 2453

GD(H6DO)-57

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

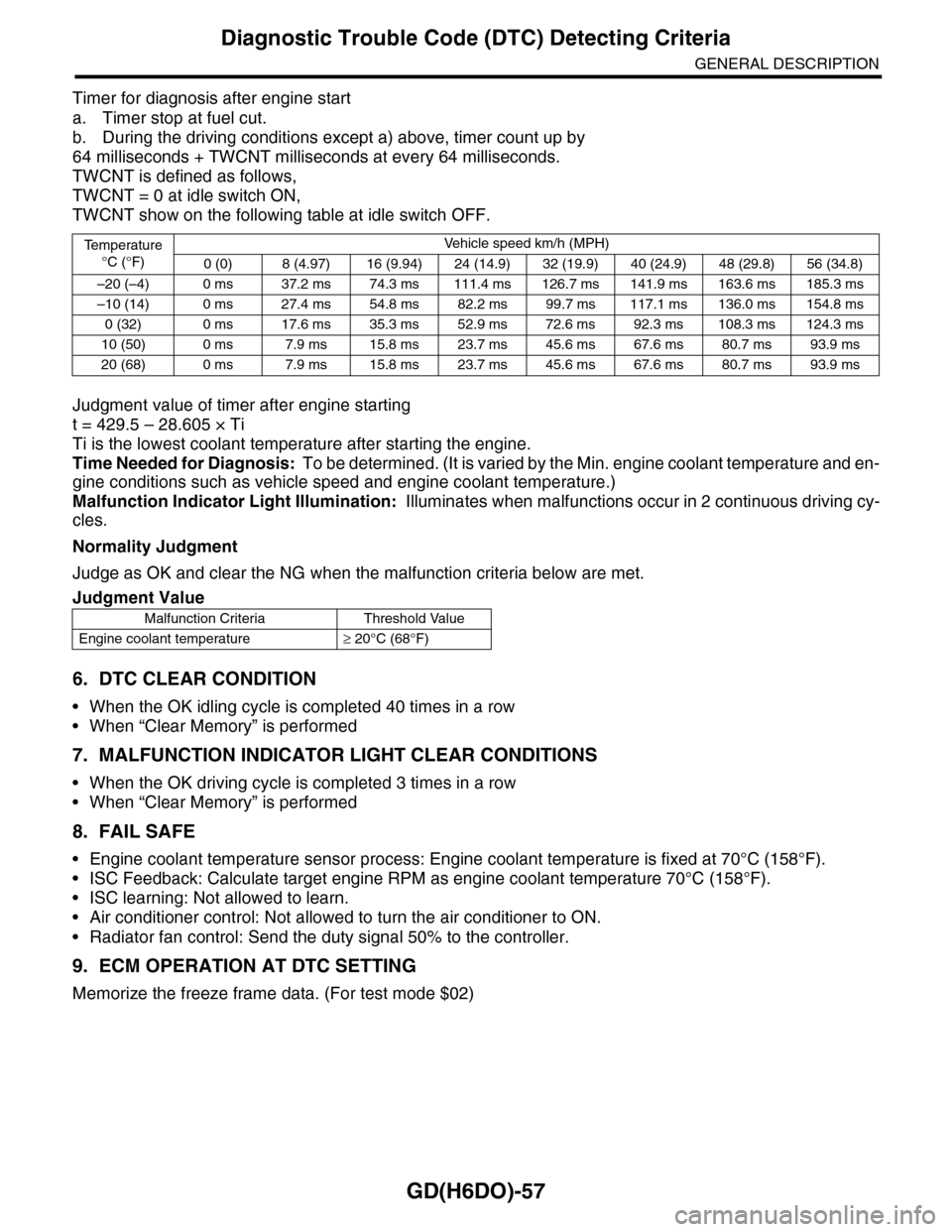

Timer for diagnosis after engine start

a. Timer stop at fuel cut.

b. During the driving conditions except a) above, timer count up by

64 milliseconds + TWCNT milliseconds at every 64 milliseconds.

TWCNT is defined as follows,

TWCNT = 0 at idle switch ON,

TWCNT show on the following table at idle switch OFF.

Judgment value of timer after engine starting

t = 429.5 – 28.605 × Ti

Ti is the lowest coolant temperature after starting the engine.

Time Needed for Diagnosis: To be determined. (It is varied by the Min. engine coolant temperature and en-

gine conditions such as vehicle speed and engine coolant temperature.)

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Engine coolant temperature sensor process: Engine coolant temperature is fixed at 70°C (158°F).

•ISC Feedback: Calculate target engine RPM as engine coolant temperature 70°C (158°F).

•ISC learning: Not allowed to learn.

•Air conditioner control: Not allowed to turn the air conditioner to ON.

•Radiator fan control: Send the duty signal 50% to the controller.

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Te m p e r a t u r e

°C (°F)

Ve h i c l e s p e e d k m / h ( M P H )

0 (0) 8 (4.97) 16 (9.94) 24 (14.9) 32 (19.9) 40 (24.9) 48 (29.8) 56 (34.8)

–20 (–4) 0 ms 37.2 ms 74.3 ms 111.4 ms 126.7 ms 141.9 ms 163.6 ms 185.3 ms

–10 (14) 0 ms 27.4 ms 54.8 ms 82.2 ms 99.7 ms 117.1 ms 136.0 ms 154.8 ms

0 (32) 0 ms 17.6 ms 35.3 ms 52.9 ms 72.6 ms 92.3 ms 108.3 ms 124.3 ms

10 (50) 0 ms 7.9 ms 15.8 ms 23.7 ms 45.6 ms 67.6 ms 80.7 ms 93.9 ms

20 (68) 0 ms 7.9 ms 15.8 ms 23.7 ms 45.6 ms 67.6 ms 80.7 ms 93.9 ms

Judgment Value

Malfunction Criteria Threshold Value

Engine coolant temperature≥ 20°C (68°F)

Page 1670 of 2453

GD(H6DO)-58

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

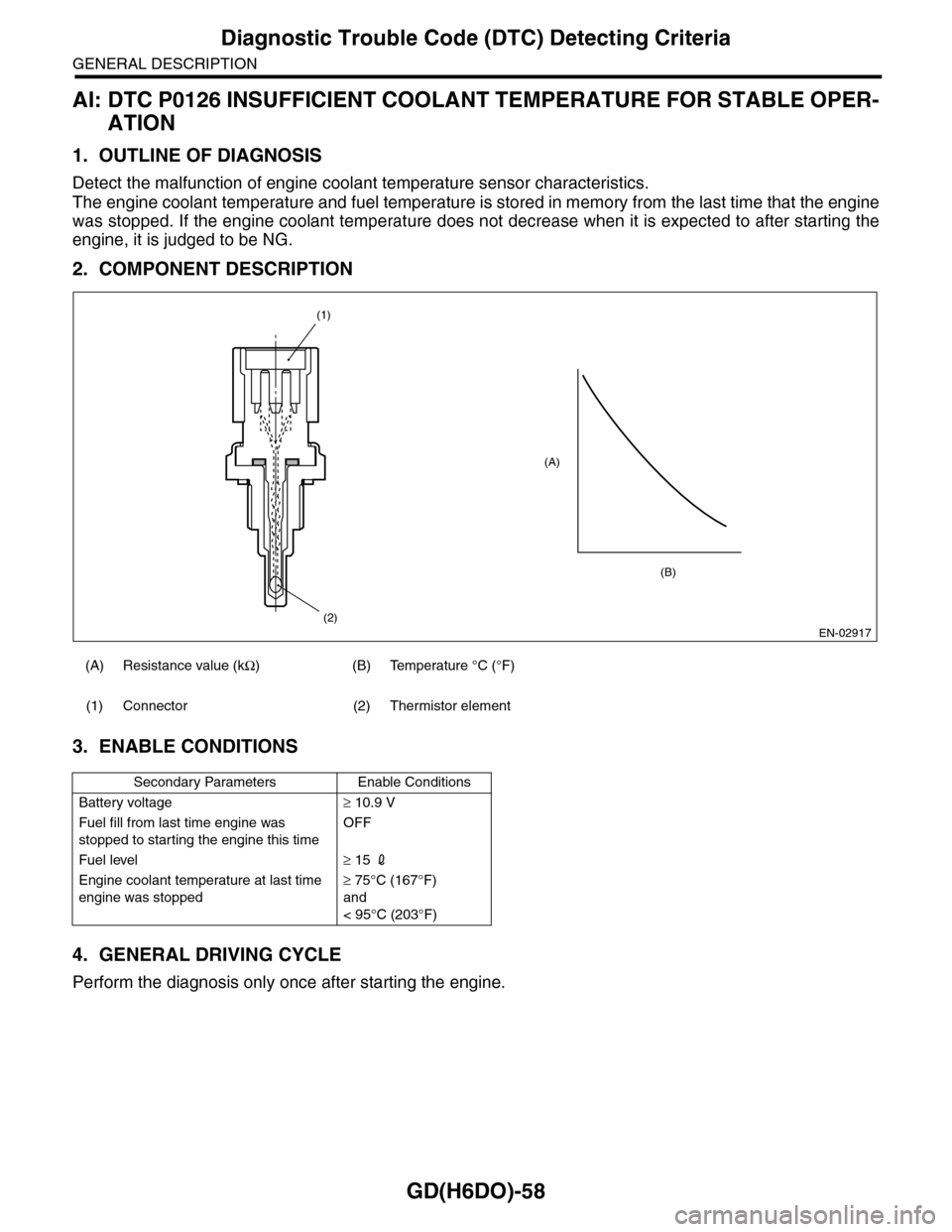

AI: DTC P0126 INSUFFICIENT COOLANT TEMPERATURE FOR STABLE OPER-

ATION

1. OUTLINE OF DIAGNOSIS

Detect the malfunction of engine coolant temperature sensor characteristics.

The engine coolant temperature and fuel temperature is stored in memory from the last time that the engine

was stopped. If the engine coolant temperature does not decrease when it is expected to after starting the

engine, it is judged to be NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once after starting the engine.

(A) Resistance value (kΩ)(B)Temperature °C (°F)

(1) Connector (2) Thermistor element

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Fuel fill from last time engine was

stopped to starting the engine this time

OFF

Fuel level≥ 15 2

Engine coolant temperature at last time

engine was stopped

≥ 75°C (167°F)

and

< 95°C (203°F)

EN-02917

(A)

(2)

(1)

(B)

Page 1692 of 2453

GD(H6DO)-80

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

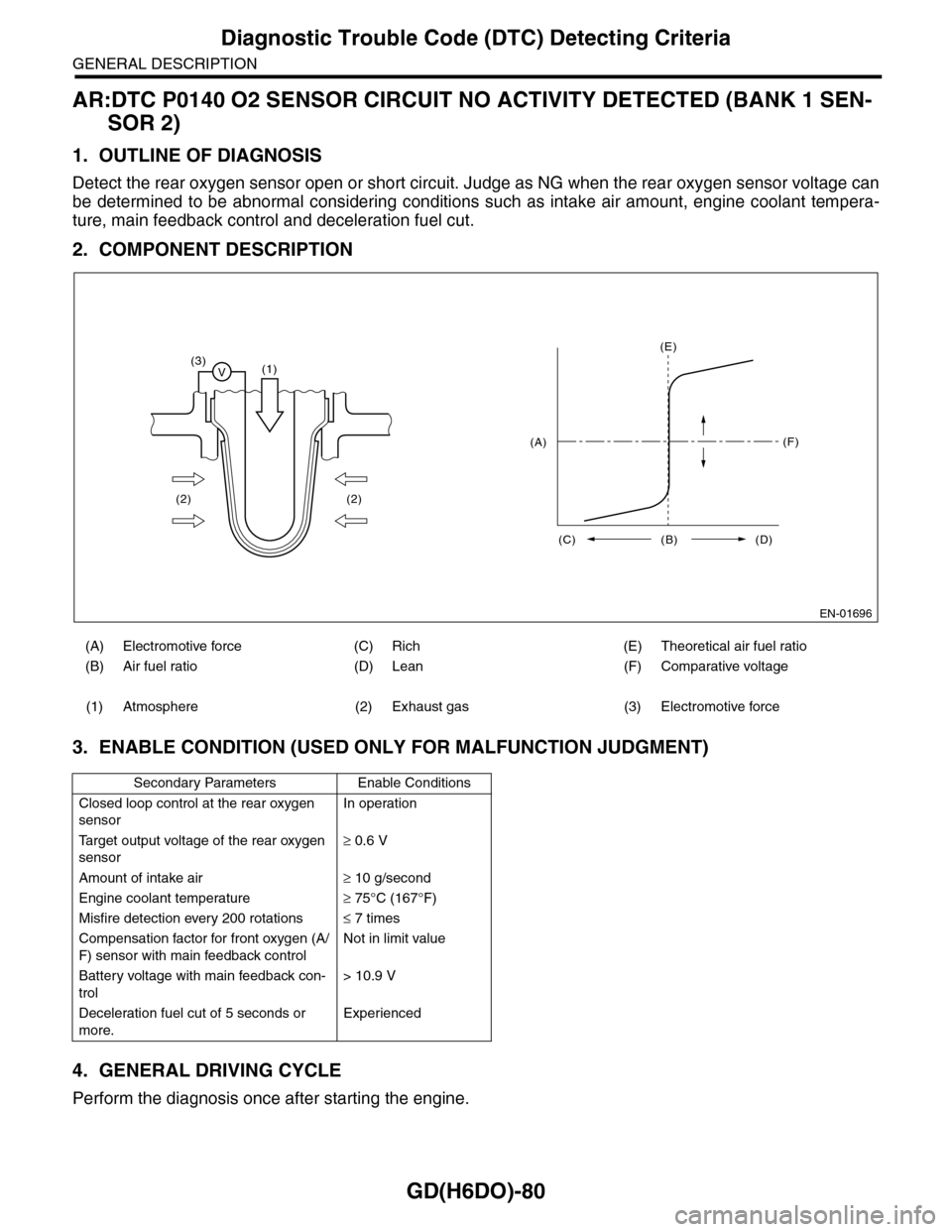

AR:DTC P0140 O2 SENSOR CIRCUIT NO ACTIVITY DETECTED (BANK 1 SEN-

SOR 2)

1. OUTLINE OF DIAGNOSIS

Detect the rear oxygen sensor open or short circuit. Judge as NG when the rear oxygen sensor voltage can

be determined to be abnormal considering conditions such as intake air amount, engine coolant tempera-

ture, main feedback control and deceleration fuel cut.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITION (USED ONLY FOR MALFUNCTION JUDGMENT)

4. GENERAL DRIVING CYCLE

Perform the diagnosis once after starting the engine.

(A) Electromotive force (C) Rich (E) Theoretical air fuel ratio

(B) Air fuel ratio (D) Lean (F) Comparative voltage

(1) Atmosphere (2) Exhaust gas (3) Electromotive force

Secondary Parameters Enable Conditions

Closed loop control at the rear oxygen

sensor

In operation

Ta r g e t o u t p u t v o l t a g e o f t h e r e a r o x y g e n

sensor

≥ 0.6 V

Amount of intake air≥ 10 g/second

Engine coolant temperature≥ 75°C (167°F)

Misfire detection every 200 rotations≤ 7 times

Compensation factor for front oxygen (A/

F) sensor with main feedback control

Not in limit value

Battery voltage with main feedback con-

trol

> 10.9 V

Deceleration fuel cut of 5 seconds or

more.

Experienced

EN-01696

(3)V(1)

(2) (2)

(E)

(F)

(C) (B) (D)

(A)

Page 1695 of 2453

GD(H6DO)-83

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

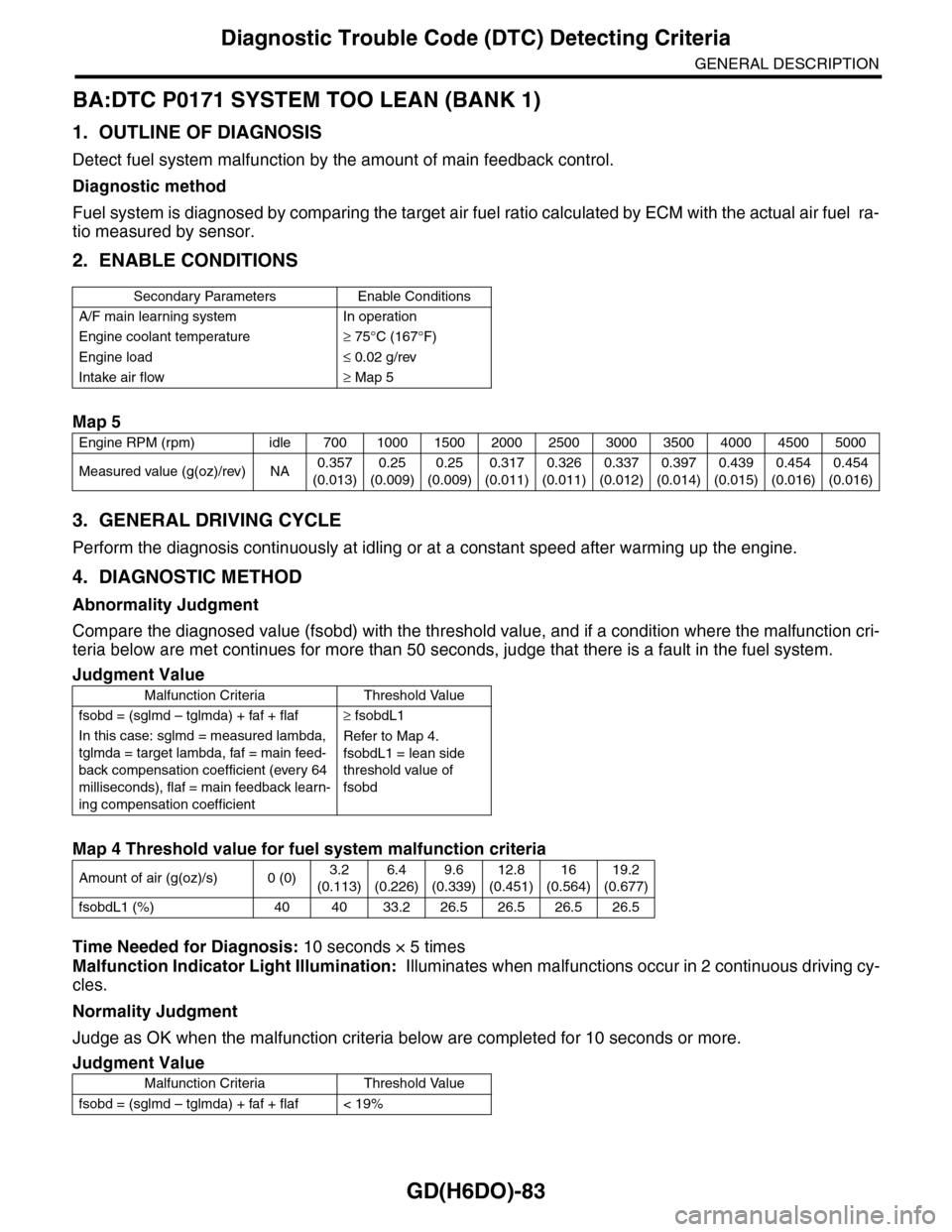

BA:DTC P0171 SYSTEM TOO LEAN (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect fuel system malfunction by the amount of main feedback control.

Diagnostic method

Fuel system is diagnosed by comparing the target air fuel ratio calculated by ECM with the actual air fuel ra-

tio measured by sensor.

2. ENABLE CONDITIONS

3. GENERAL DRIVING CYCLE

Perform the diagnosis continuously at idling or at a constant speed after warming up the engine.

4. DIAGNOSTIC METHOD

Abnormality Judgment

Compare the diagnosed value (fsobd) with the threshold value, and if a condition where the malfunction cri-

teria below are met continues for more than 50 seconds, judge that there is a fault in the fuel system.

Time Needed for Diagnosis: 10 seconds × 5 times

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK when the malfunction criteria below are completed for 10 seconds or more.

Secondary Parameters Enable Conditions

A/F main learning system In operation

Engine coolant temperature≥ 75°C (167°F)

Engine load≤ 0.02 g/rev

Intake air flow≥ Map 5

Map 5

Engine RPM (rpm) idle 700 1000 1500 2000 2500 3000 3500 4000 4500 5000

Measured value (g(oz)/rev) NA0.357

(0.013)

0.25

(0.009)

0.25

(0.009)

0.317

(0.011)

0.326

(0.011)

0.337

(0.012)

0.397

(0.014)

0.439

(0.015)

0.454

(0.016)

0.454

(0.016)

Judgment Value

Malfunction Criteria Threshold Value

fsobd = (sglmd – tglmda) + faf + flaf≥ fsobdL1

In this case: sglmd = measured lambda,

tglmda = target lambda, faf = main feed-

back compensation coefficient (every 64

milliseconds), flaf = main feedback learn-

ing compensation coefficient

Refer to Map 4.

fsobdL1 = lean side

threshold value of

fsobd

Map 4 Threshold value for fuel system malfunction criteria

Amount of air (g(oz)/s) 0 (0)3.2

(0.113)

6.4

(0.226)

9.6

(0.339)

12.8

(0.451)

16

(0.564)

19.2

(0.677)

fsobdL1 (%) 40 40 33.2 26.5 26.5 26.5 26.5

Judgment Value

Malfunction Criteria Threshold Value

fsobd = (sglmd – tglmda) + faf + flaf < 19%