coolant temperature sensor SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1516 of 2453

EN(H6DO)(diag)-355

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

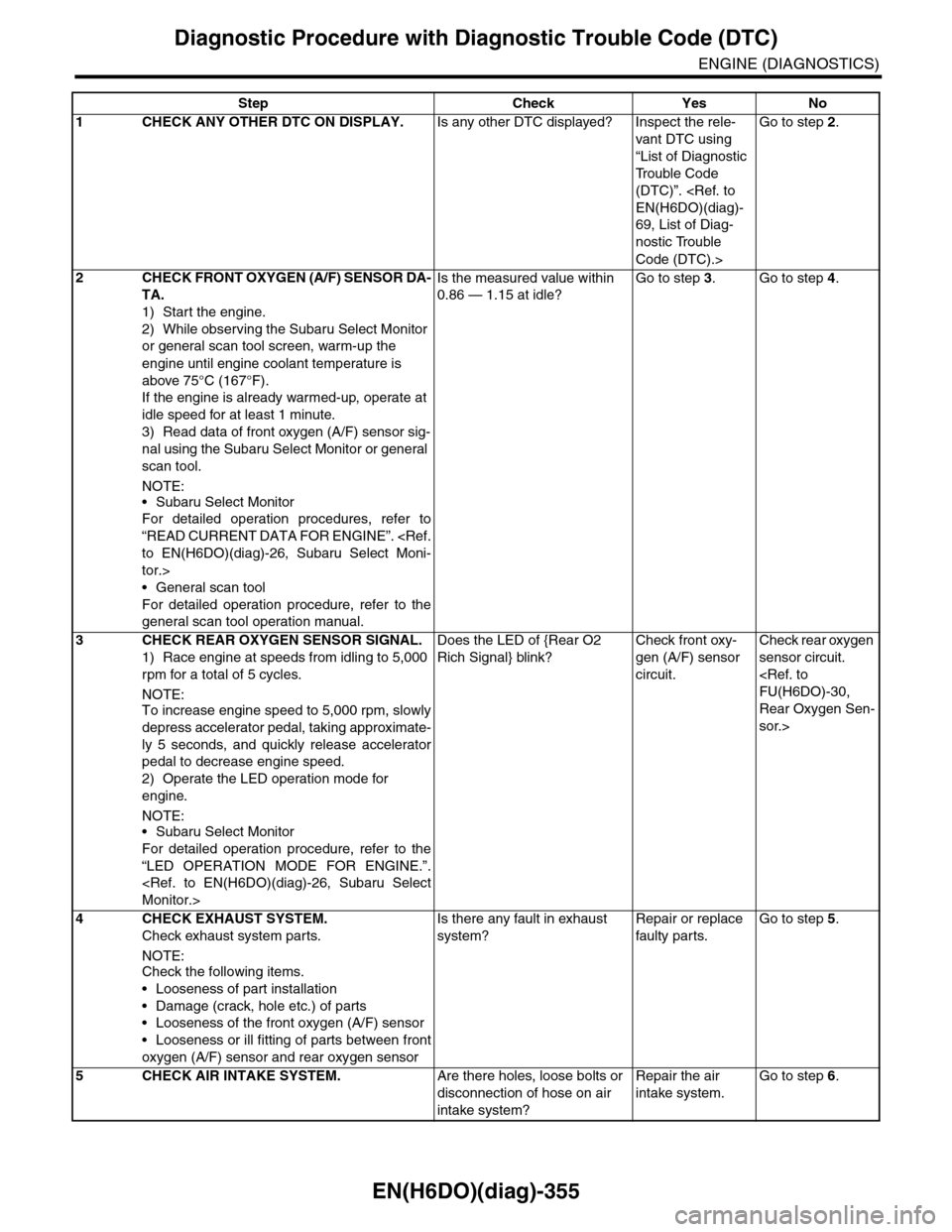

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK FRONT OXYGEN (A/F) SENSOR DA-

TA.

1) Start the engine.

2) While observing the Subaru Select Monitor

or general scan tool screen, warm-up the

engine until engine coolant temperature is

above 75°C (167°F).

If the engine is already warmed-up, operate at

idle speed for at least 1 minute.

3) Read data of front oxygen (A/F) sensor sig-

nal using the Subaru Select Monitor or general

scan tool.

NOTE:

•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the measured value within

0.86 — 1.15 at idle?

Go to step 3.Go to step 4.

3CHECK REAR OXYGEN SENSOR SIGNAL.

1) Race engine at speeds from idling to 5,000

rpm for a total of 5 cycles.

NOTE:To increase engine speed to 5,000 rpm, slowly

depress accelerator pedal, taking approximate-

ly 5 seconds, and quickly release accelerator

pedal to decrease engine speed.

2) Operate the LED operation mode for

engine.

NOTE:•Subaru Select Monitor

For detailed operation procedure, refer to the

“LED OPERATION MODE FOR ENGINE.”.

Does the LED of {Rear O2

Rich Signal} blink?

Check front oxy-

gen (A/F) sensor

circuit.

Check rear oxygen

sensor circuit.

Rear Oxygen Sen-

sor.>

4 CHECK EXHAUST SYSTEM.

Check exhaust system parts.

NOTE:Check the following items.

•Looseness of part installation

•Damage (crack, hole etc.) of parts

•Looseness of the front oxygen (A/F) sensor

•Looseness or ill fitting of parts between front

oxygen (A/F) sensor and rear oxygen sensor

Is there any fault in exhaust

system?

Repair or replace

faulty par ts.

Go to step 5.

5CHECK AIR INTAKE SYSTEM.Are there holes, loose bolts or

disconnection of hose on air

intake system?

Repair the air

intake system.

Go to step 6.

Page 1517 of 2453

EN(H6DO)(diag)-356

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

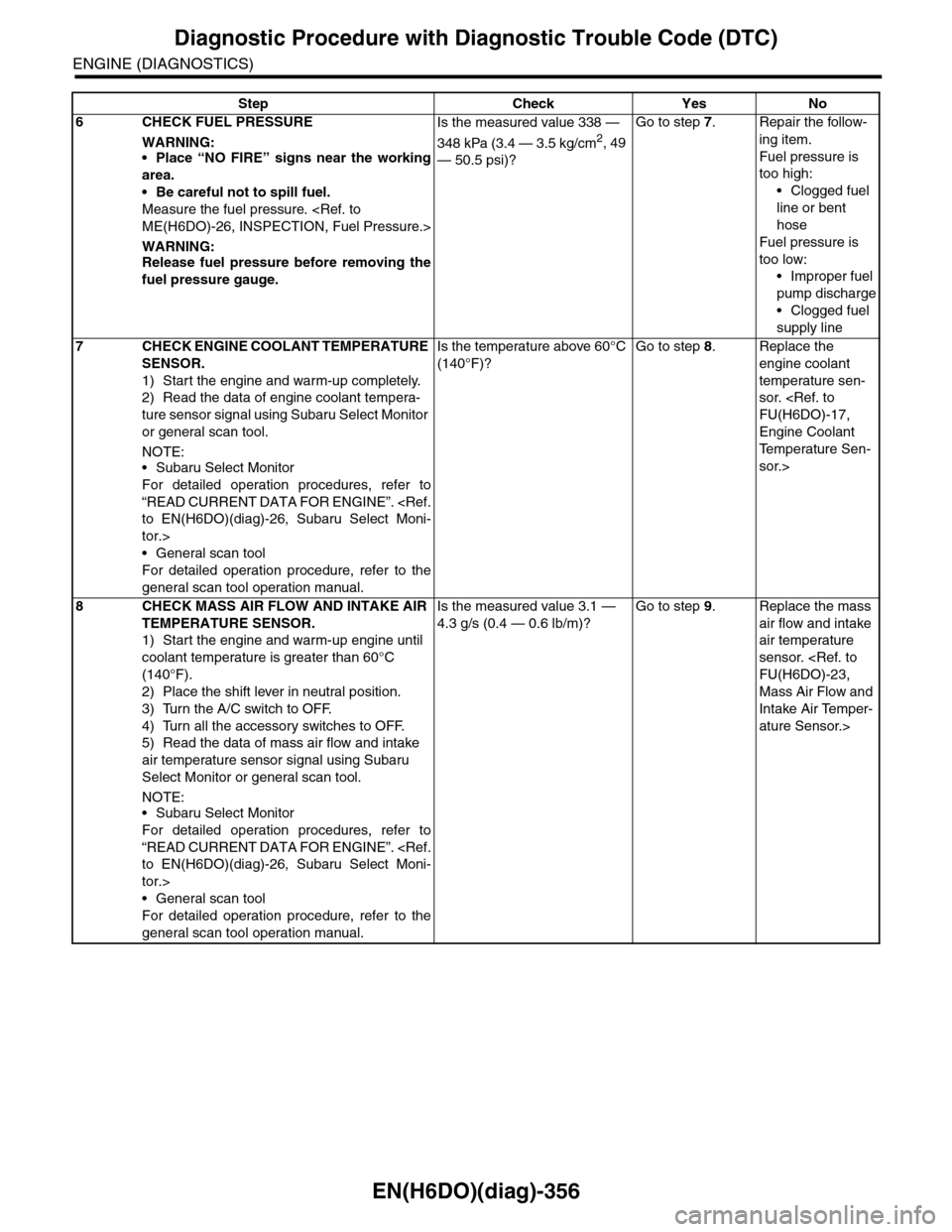

6CHECK FUEL PRESSURE

WARNING:•Place “NO FIRE” signs near the working

area.

•Be careful not to spill fuel.

Measure the fuel pressure.

WARNING:Release fuel pressure before removing the

fuel pressure gauge.

Is the measured value 338 —

348 kPa (3.4 — 3.5 kg/cm2, 49

— 50.5 psi)?

Go to step 7.Repair the follow-

ing item.

Fuel pressure is

too high:

•Clogged fuel

line or bent

hose

Fuel pressure is

too low:

•Improper fuel

pump discharge

•Clogged fuel

supply line

7CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

1) Start the engine and warm-up completely.

2) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the temperature above 60°C

(140°F)?

Go to step 8.Replace the

engine coolant

temperature sen-

sor.

Engine Coolant

Te m p e r a t u r e S e n -

sor.>

8CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR.

1) Start the engine and warm-up engine until

coolant temperature is greater than 60°C

(140°F).

2) Place the shift lever in neutral position.

3) Turn the A/C switch to OFF.

4) Turn all the accessory switches to OFF.

5) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor or general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the measured value 3.1 —

4.3 g/s (0.4 — 0.6 lb/m)?

Go to step 9.Replace the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

Step Check Yes No

Page 1518 of 2453

EN(H6DO)(diag)-357

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

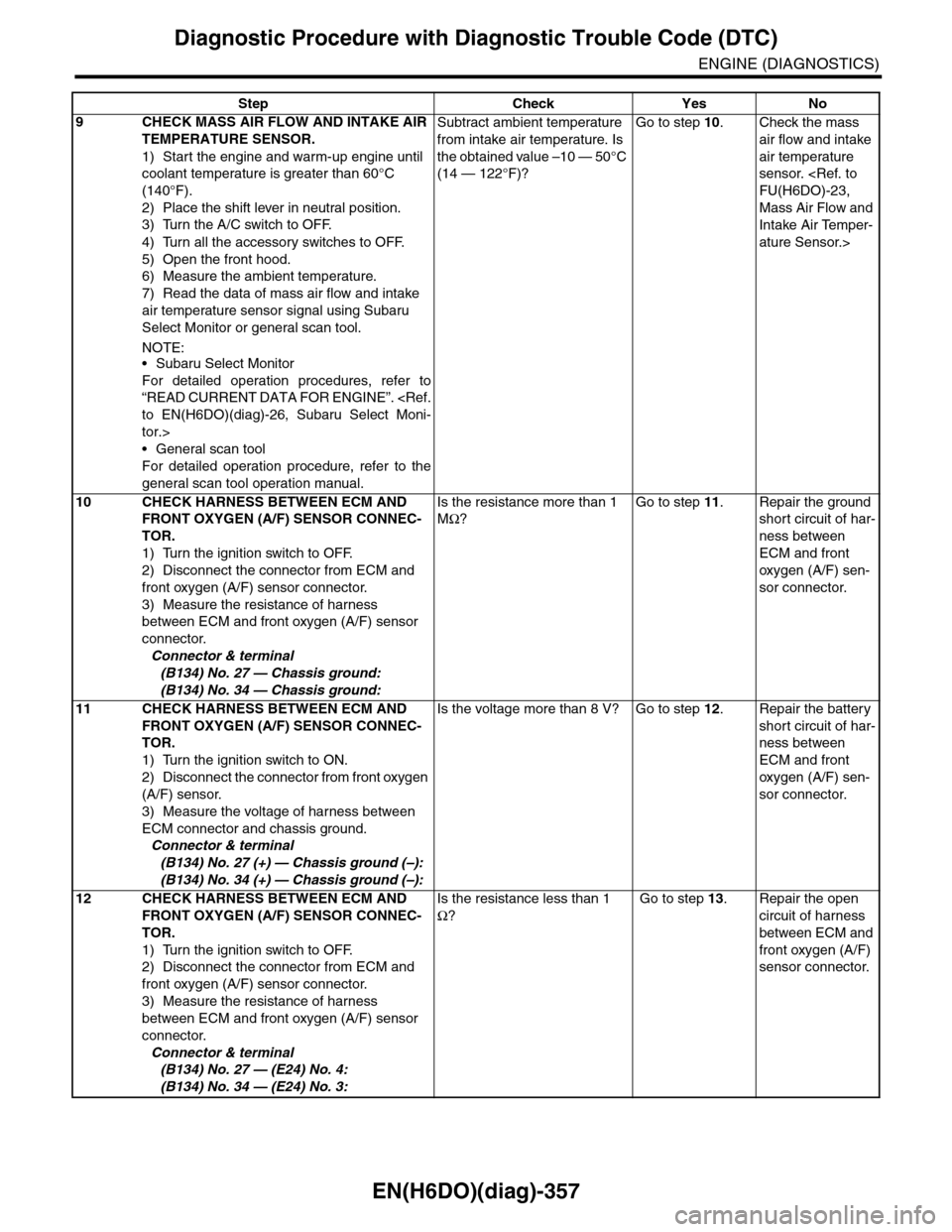

9CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR.

1) Start the engine and warm-up engine until

coolant temperature is greater than 60°C

(140°F).

2) Place the shift lever in neutral position.

3) Turn the A/C switch to OFF.

4) Turn all the accessory switches to OFF.

5) Open the front hood.

6) Measure the ambient temperature.

7) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor or general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Subtract ambient temperature

from intake air temperature. Is

the obtained value –10 — 50°C

(14 — 122°F)?

Go to step 10.Check the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

10 CHECK HARNESS BETWEEN ECM AND

FRONT OXYGEN (A/F) SENSOR CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

front oxygen (A/F) sensor connector.

3) Measure the resistance of harness

between ECM and front oxygen (A/F) sensor

connector.

Connector & terminal

(B134) No. 27 — Chassis ground:

(B134) No. 34 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 11.Repair the ground

short circuit of har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.

11 CHECK HARNESS BETWEEN ECM AND

FRONT OXYGEN (A/F) SENSOR CONNEC-

TOR.

1) Turn the ignition switch to ON.

2) Disconnect the connector from front oxygen

(A/F) sensor.

3) Measure the voltage of harness between

ECM connector and chassis ground.

Connector & terminal

(B134) No. 27 (+) — Chassis ground (–):

(B134) No. 34 (+) — Chassis ground (–):

Is the voltage more than 8 V? Go to step 12.Repair the battery

short circuit of har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.

12 CHECK HARNESS BETWEEN ECM AND

FRONT OXYGEN (A/F) SENSOR CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

front oxygen (A/F) sensor connector.

3) Measure the resistance of harness

between ECM and front oxygen (A/F) sensor

connector.

Connector & terminal

(B134) No. 27 — (E24) No. 4:

(B134) No. 34 — (E24) No. 3:

Is the resistance less than 1

Ω?

Go to step 13.Repair the open

circuit of harness

between ECM and

front oxygen (A/F)

sensor connector.

Step Check Yes No

Page 1519 of 2453

EN(H6DO)(diag)-358

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

13 CHECK REAR OXYGEN SENSOR DATA.

1) Warm-up the engine until engine coolant

temperature is above 70°C (158°F), and keep

the engine speed at 5,000 rpm.

2) Read the data of rear oxygen sensor signal

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the voltage more than 490

mV?

Go to step 16.Go to step 14.

14 CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

rear oxygen sensor.

3) Measure the resistance of harness

between ECM and rear oxygen sensor con-

nector.

Connector & terminal

(B137) No. 25 — (E61) No. 3:

(B136) No. 35 — (E61) No. 4:

Is the resistance more than

3Ω?

Repair the open

circuit of harness

between ECM and

rear oxygen sen-

sor connector.

Go to step 15.

15 CHECK HARNESS BETWEEN REAR OXY-

GEN SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor harness connector and chassis ground.

Connector & terminal

(E25) No. 3 (+) — Chassis ground (–):

Is the voltage 0.2 — 0.5 V? Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween rear oxy-

gen sensor and

ECM connector

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

in ECM connec-

tor

Step Check Yes No

Page 1520 of 2453

EN(H6DO)(diag)-359

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

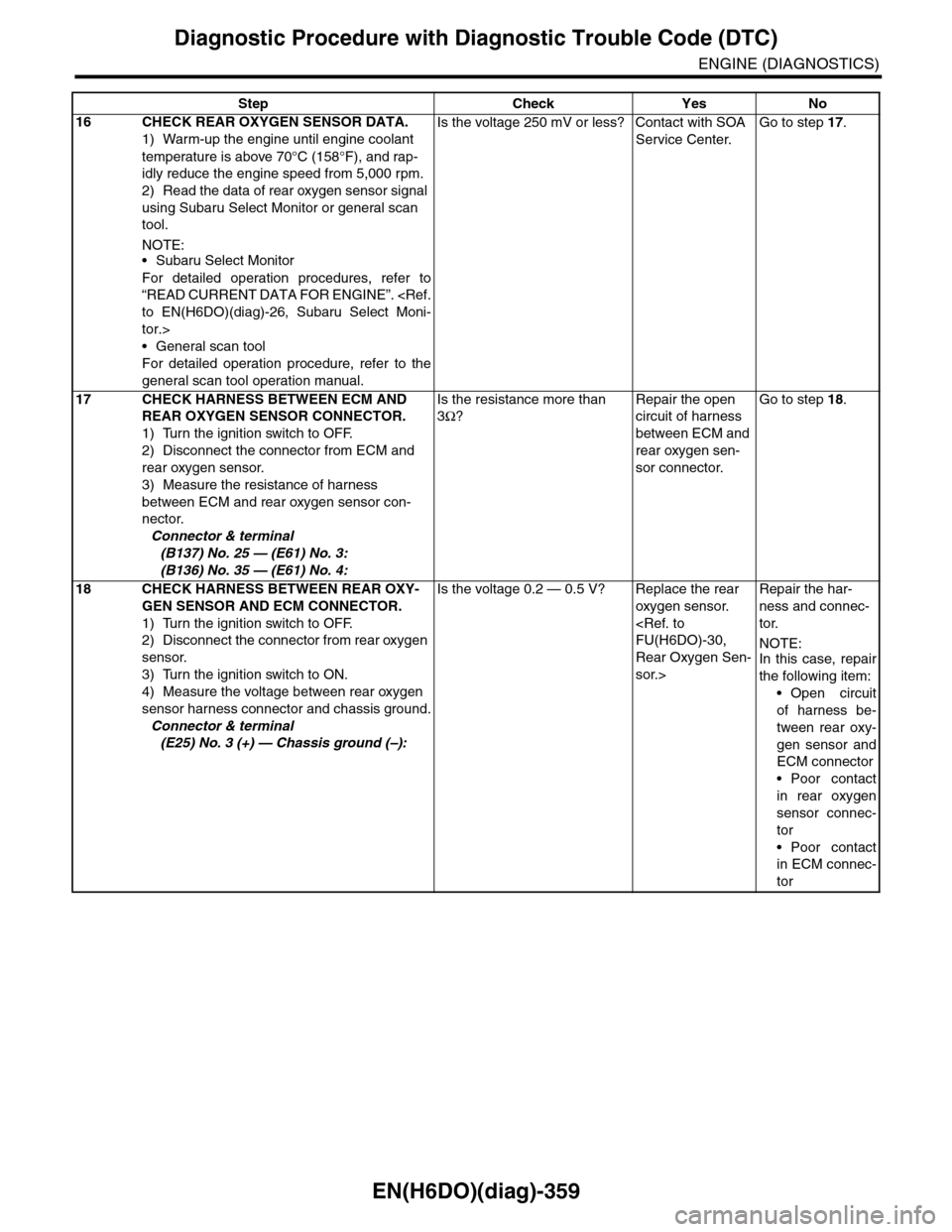

16 CHECK REAR OXYGEN SENSOR DATA.

1) Warm-up the engine until engine coolant

temperature is above 70°C (158°F), and rap-

idly reduce the engine speed from 5,000 rpm.

2) Read the data of rear oxygen sensor signal

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the voltage 250 mV or less? Contact with SOA

Service Center.

Go to step 17.

17 CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

rear oxygen sensor.

3) Measure the resistance of harness

between ECM and rear oxygen sensor con-

nector.

Connector & terminal

(B137) No. 25 — (E61) No. 3:

(B136) No. 35 — (E61) No. 4:

Is the resistance more than

3Ω?

Repair the open

circuit of harness

between ECM and

rear oxygen sen-

sor connector.

Go to step 18.

18 CHECK HARNESS BETWEEN REAR OXY-

GEN SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor harness connector and chassis ground.

Connector & terminal

(E25) No. 3 (+) — Chassis ground (–):

Is the voltage 0.2 — 0.5 V? Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween rear oxy-

gen sensor and

ECM connector

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

in ECM connec-

tor

Step Check Yes No

Page 1553 of 2453

EN(H6DO)(diag)-392

General Diagnostic Table

ENGINE (DIAGNOSTICS)

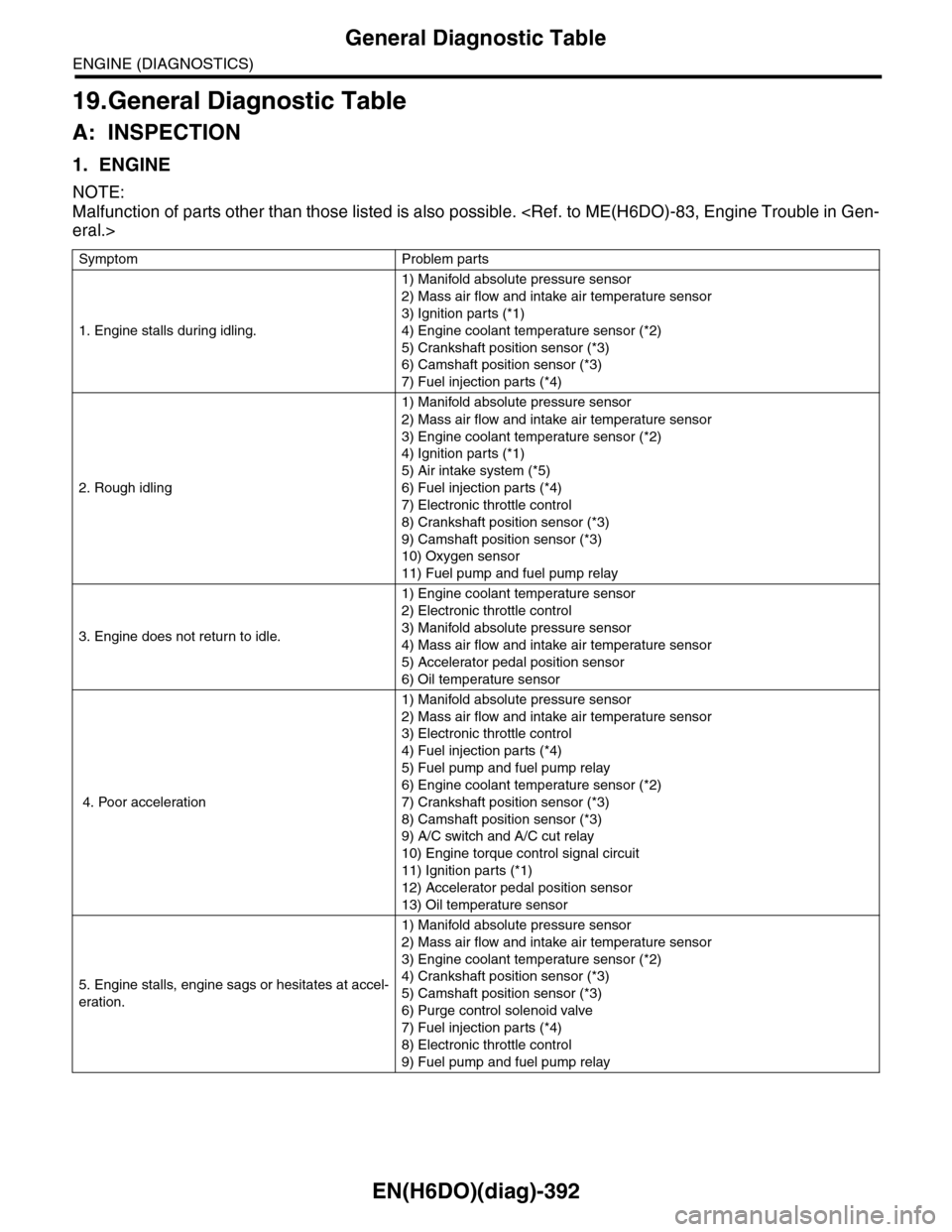

19.General Diagnostic Table

A: INSPECTION

1. ENGINE

NOTE:

Malfunction of parts other than those listed is also possible.

Symptom Problem parts

1. Engine stalls during idling.

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Ignition parts (*1)

4) Engine coolant temperature sensor (*2)

5) Crankshaft position sensor (*3)

6) Camshaft position sensor (*3)

7) Fuel injection parts (*4)

2. Rough idling

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Ignition parts (*1)

5) Air intake system (*5)

6) Fuel injection parts (*4)

7) Electronic throttle control

8) Crankshaft position sensor (*3)

9) Camshaft position sensor (*3)

10) Oxygen sensor

11) Fuel pump and fuel pump relay

3. Engine does not return to idle.

1) Engine coolant temperature sensor

2) Electronic throttle control

3) Manifold absolute pressure sensor

4) Mass air flow and intake air temperature sensor

5) Accelerator pedal position sensor

6) Oil temperature sensor

4. Poor acceleration

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Electronic throttle control

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

6) Engine coolant temperature sensor (*2)

7) Crankshaft position sensor (*3)

8) Camshaft position sensor (*3)

9) A/C switch and A/C cut relay

10) Engine torque control signal circuit

11) Ignition parts (*1)

12) Accelerator pedal position sensor

13) Oil temperature sensor

5. Engine stalls, engine sags or hesitates at accel-

eration.

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Purge control solenoid valve

7) Fuel injection parts (*4)

8) Electronic throttle control

9) Fuel pump and fuel pump relay

Page 1554 of 2453

EN(H6DO)(diag)-393

General Diagnostic Table

ENGINE (DIAGNOSTICS)

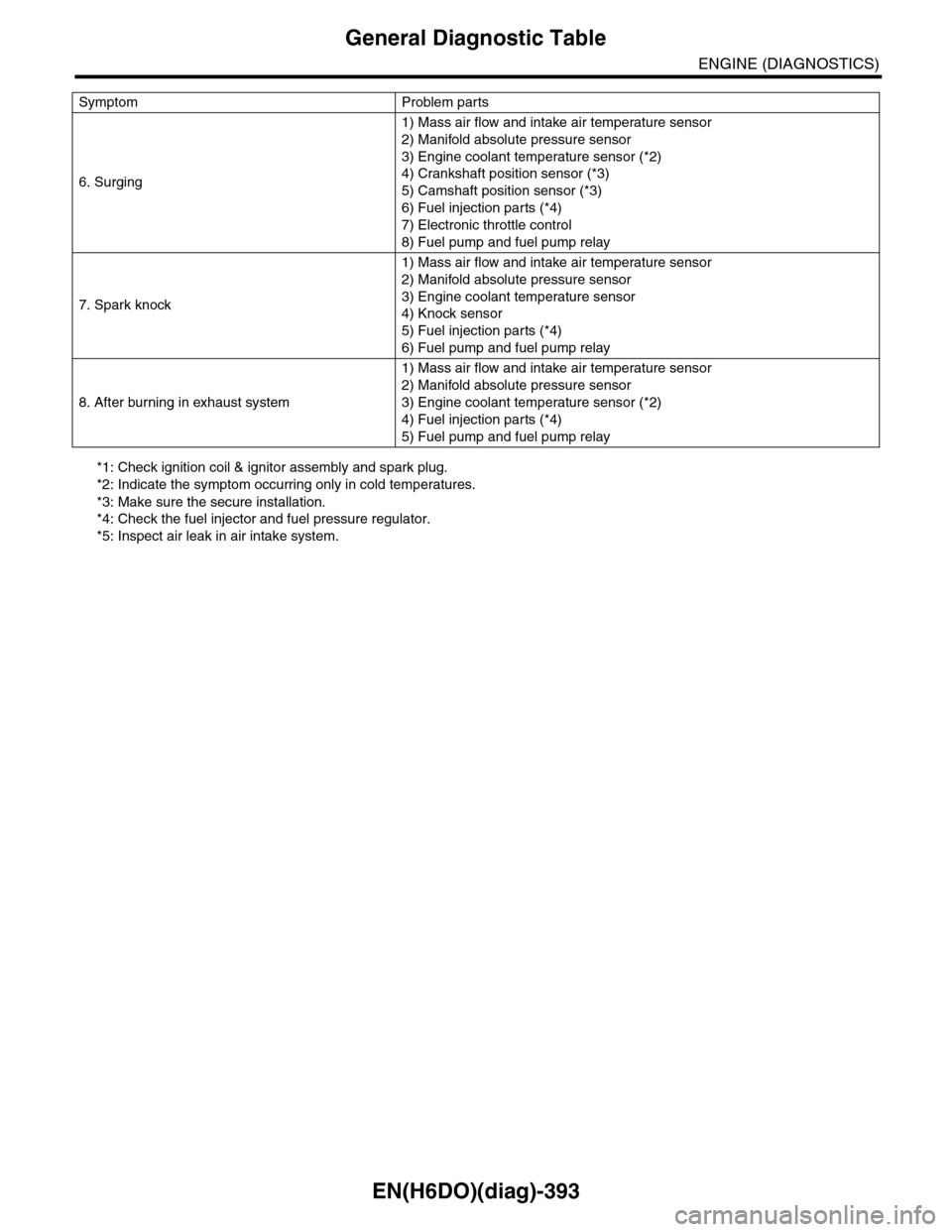

*1: Check ignition coil & ignitor assembly and spark plug.

*2: Indicate the symptom occurring only in cold temperatures.

*3: Make sure the secure installation.

*4: Check the fuel injector and fuel pressure regulator.

*5: Inspect air leak in air intake system.

6. Surging

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Electronic throttle control

8) Fuel pump and fuel pump relay

7. Spark knock

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor

4) Knock sensor

5) Fuel injection parts (*4)

6) Fuel pump and fuel pump relay

8. After burning in exhaust system

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

Symptom Problem parts

Page 1578 of 2453

FU(H6DO)-17

Engine Coolant Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

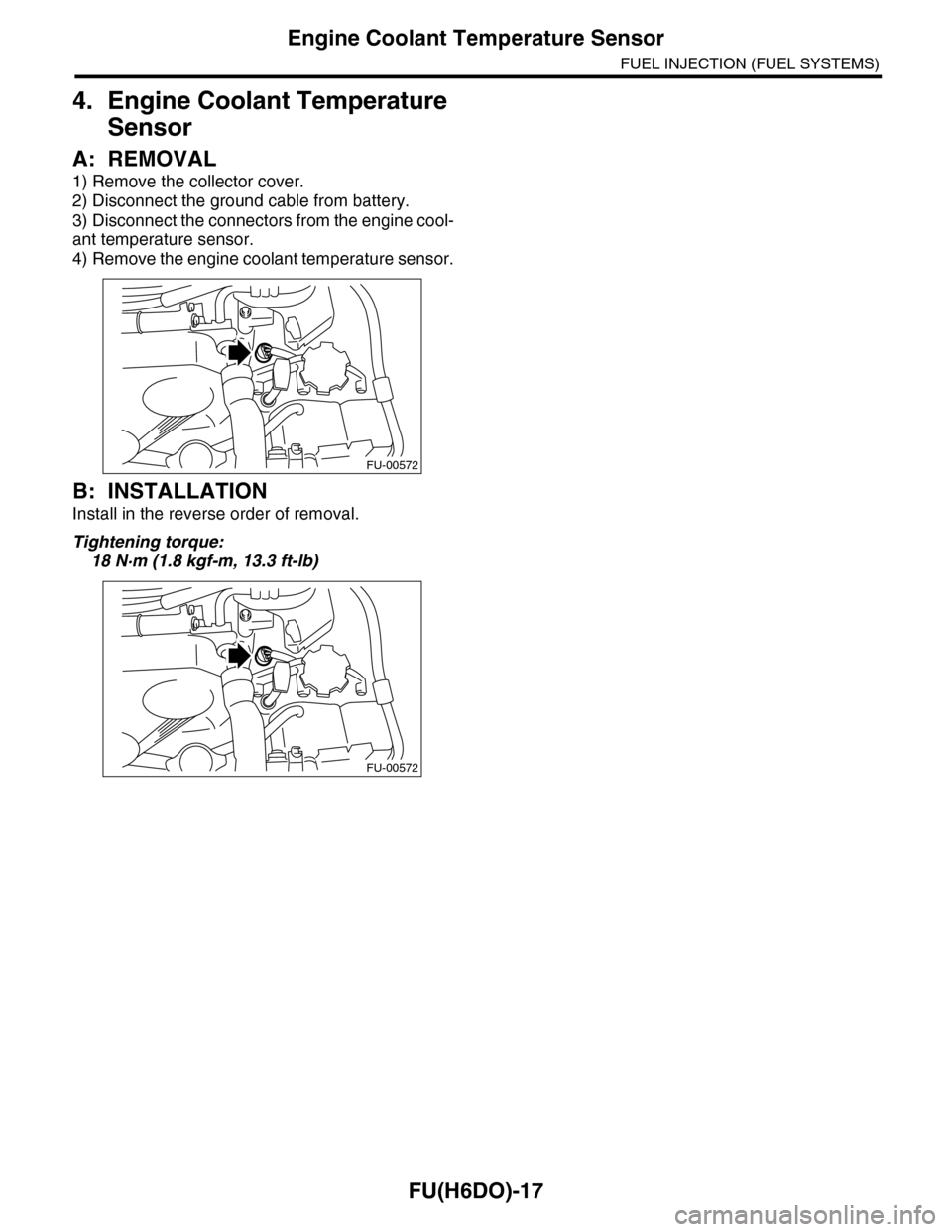

4. Engine Coolant Temperature

Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Disconnect the connectors from the engine cool-

ant temperature sensor.

4) Remove the engine coolant temperature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

FU-00572

FU-00572

Page 1615 of 2453

GD(H6DO)-3

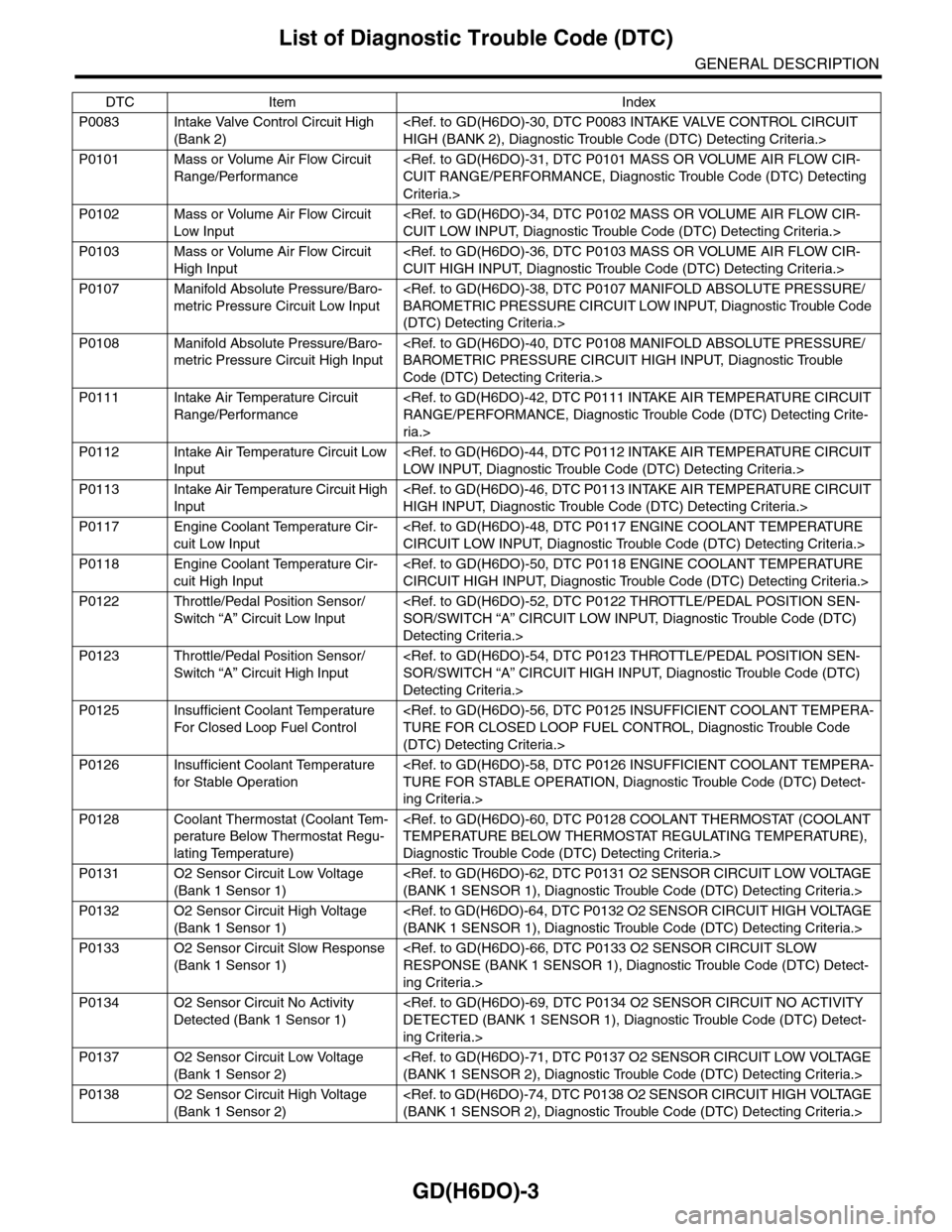

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

P0083 Intake Valve Control Circuit High

(Bank 2)

P0101 Mass or Volume Air Flow Circuit

Range/Performance

Criteria.>

P0102 Mass or Volume Air Flow Circuit

Low Input

P0103 Mass or Volume Air Flow Circuit

High Input

P0107 Manifold Absolute Pressure/Baro-

metric Pressure Circuit Low Input

(DTC) Detecting Criteria.>

P0108 Manifold Absolute Pressure/Baro-

metric Pressure Circuit High Input

Code (DTC) Detecting Criteria.>

P0111 Intake Air Temperature Circuit

Range/Performance

ria.>

P0112 Intake Air Temperature Circuit Low

Input

P0113 Intake Air Temperature Circuit High

Input

P0117 Engine Coolant Temperature Cir-

cuit Low Input

P0118 Engine Coolant Temperature Cir-

cuit High Input

P0122 Throttle/Pedal Position Sensor/

Switch “A” Circuit Low Input

Detecting Criteria.>

P0123 Throttle/Pedal Position Sensor/

Switch “A” Circuit High Input

Detecting Criteria.>

P0125 Insufficient Coolant Temperature

For Closed Loop Fuel Control

(DTC) Detecting Criteria.>

P0126 Insufficient Coolant Temperature

for Stable Operation

ing Criteria.>

P0128 Coolant Thermostat (Coolant Tem-

perature Below Thermostat Regu-

lating Temperature)

Diagnostic Trouble Code (DTC) Detecting Criteria.>

P0131 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 1)

P0132 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 1)

P0133 O2 Sensor Circuit Slow Response

(Bank 1 Sensor 1)

ing Criteria.>

P0134 O2 Sensor Circuit No Activity

Detected (Bank 1 Sensor 1)

ing Criteria.>

P0137 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 2)

P0138 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 2)

DTC Item Index

Page 1638 of 2453

GD(H6DO)-26

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

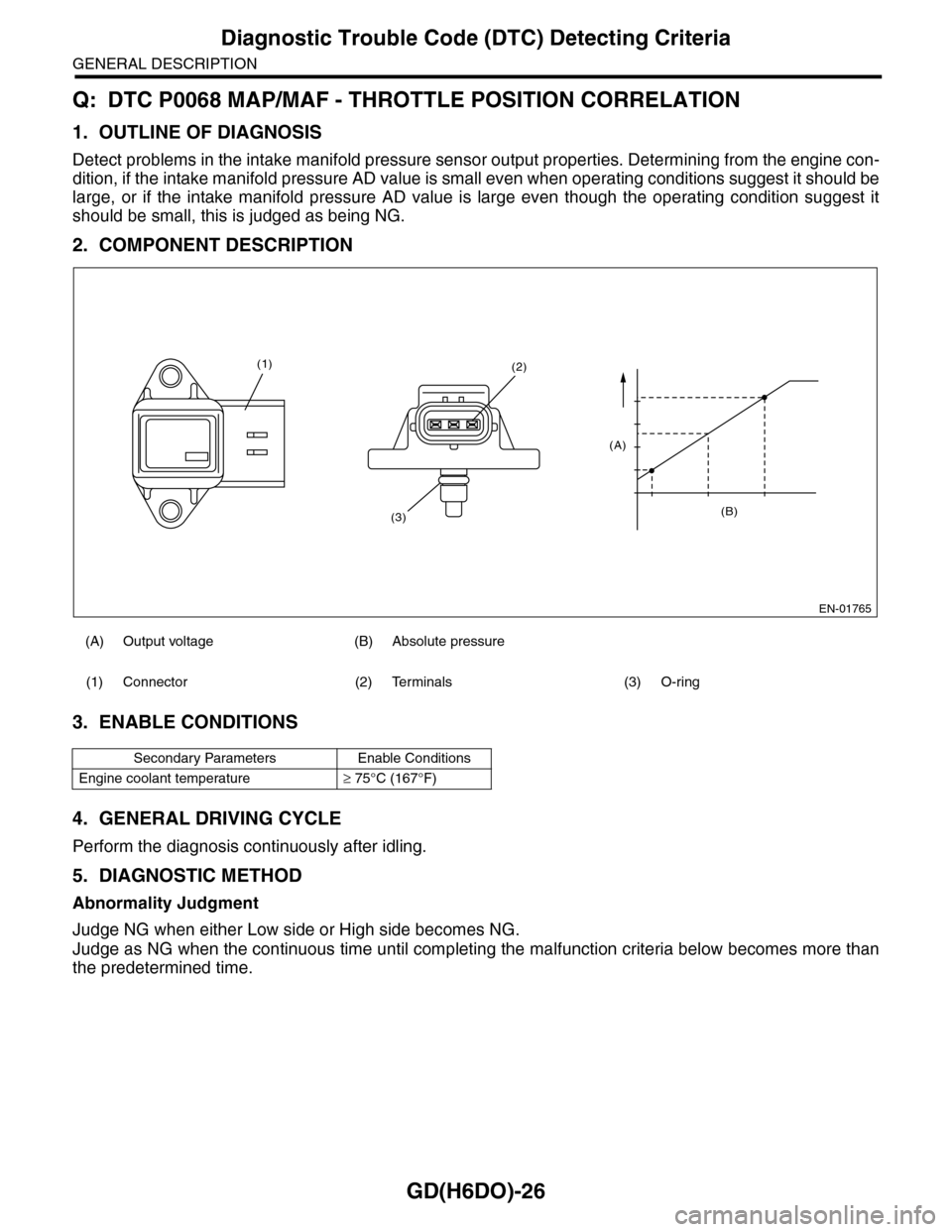

Q: DTC P0068 MAP/MAF - THROTTLE POSITION CORRELATION

1. OUTLINE OF DIAGNOSIS

Detect problems in the intake manifold pressure sensor output properties. Determining from the engine con-

dition, if the intake manifold pressure AD value is small even when operating conditions suggest it should be

large, or if the intake manifold pressure AD value is large even though the operating condition suggest it

should be small, this is judged as being NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously after idling.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge NG when either Low side or High side becomes NG.

Judge as NG when the continuous time until completing the malfunction criteria below becomes more than

the predetermined time.

(A) Output voltage (B) Absolute pressure

(1) Connector (2) Terminals (3) O-ring

Secondary Parameters Enable Conditions

Engine coolant temperature≥ 75°C (167°F)

EN-01765

(B)

(A)

(2)

(3)

(1)