sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2215 of 2453

5AT(diag)-98

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

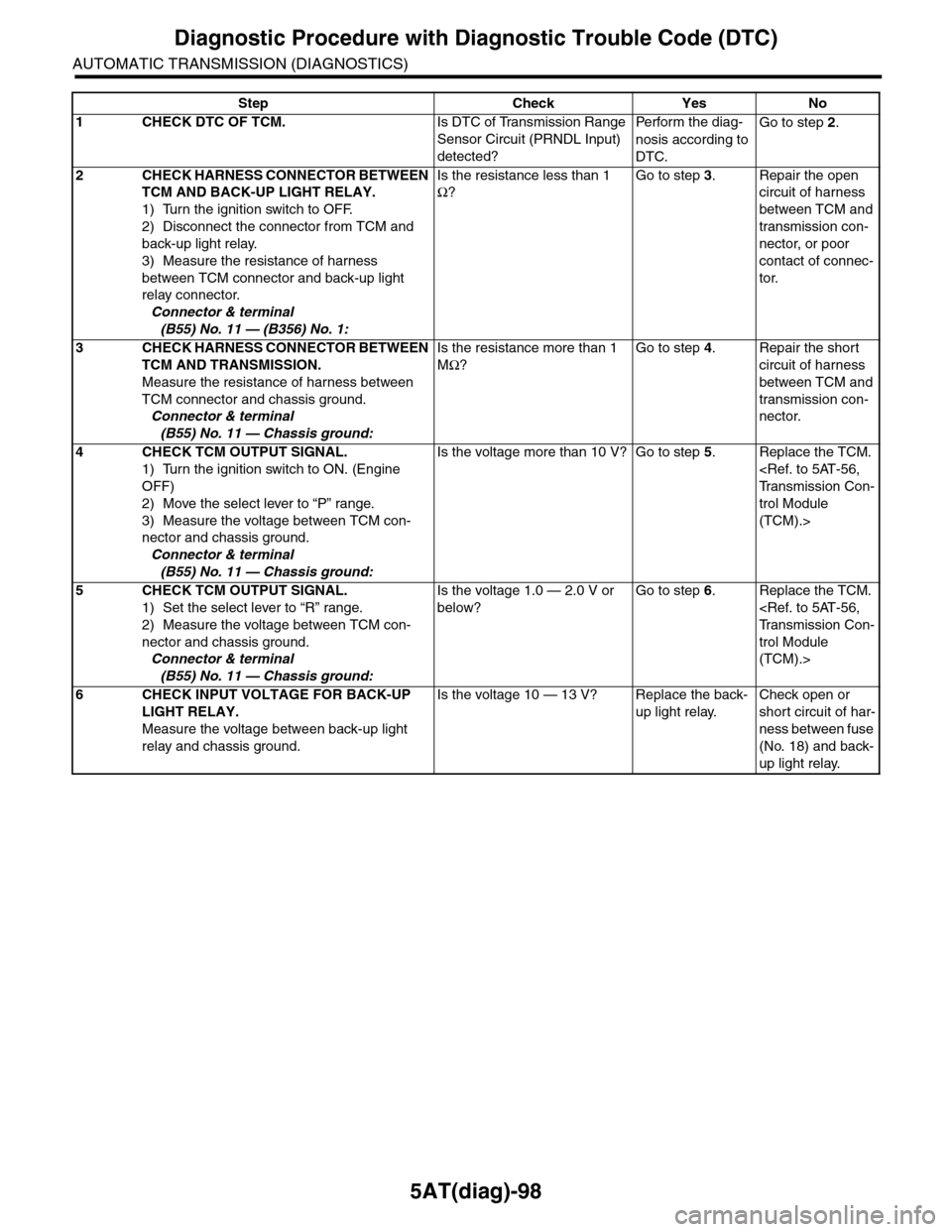

Step Check Yes No

1CHECK DTC OF TCM.Is DTC of Transmission Range

Sensor Circuit (PRNDL Input)

detected?

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND BACK-UP LIGHT RELAY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM and

back-up light relay.

3) Measure the resistance of harness

between TCM connector and back-up light

relay connector.

Connector & terminal

(B55) No. 11 — (B356) No. 1:

Is the resistance less than 1

Ω?

Go to step 3.Repair the open

circuit of harness

between TCM and

transmission con-

nector, or poor

contact of connec-

tor.

3CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 4.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

4CHECK TCM OUTPUT SIGNAL.

1) Turn the ignition switch to ON. (Engine

OFF)

2) Move the select lever to “P” range.

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the voltage more than 10 V? Go to step 5.Replace the TCM.

trol Module

(TCM).>

5CHECK TCM OUTPUT SIGNAL.

1) Set the select lever to “R” range.

2) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the voltage 1.0 — 2.0 V or

below?

Go to step 6.Replace the TCM.

trol Module

(TCM).>

6CHECK INPUT VOLTAGE FOR BACK-UP

LIGHT RELAY.

Measure the voltage between back-up light

relay and chassis ground.

Is the voltage 10 — 13 V? Replace the back-

up light relay.

Check open or

short circuit of har-

ness between fuse

(No. 18) and back-

up light relay.

Page 2218 of 2453

5AT(diag)-101

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

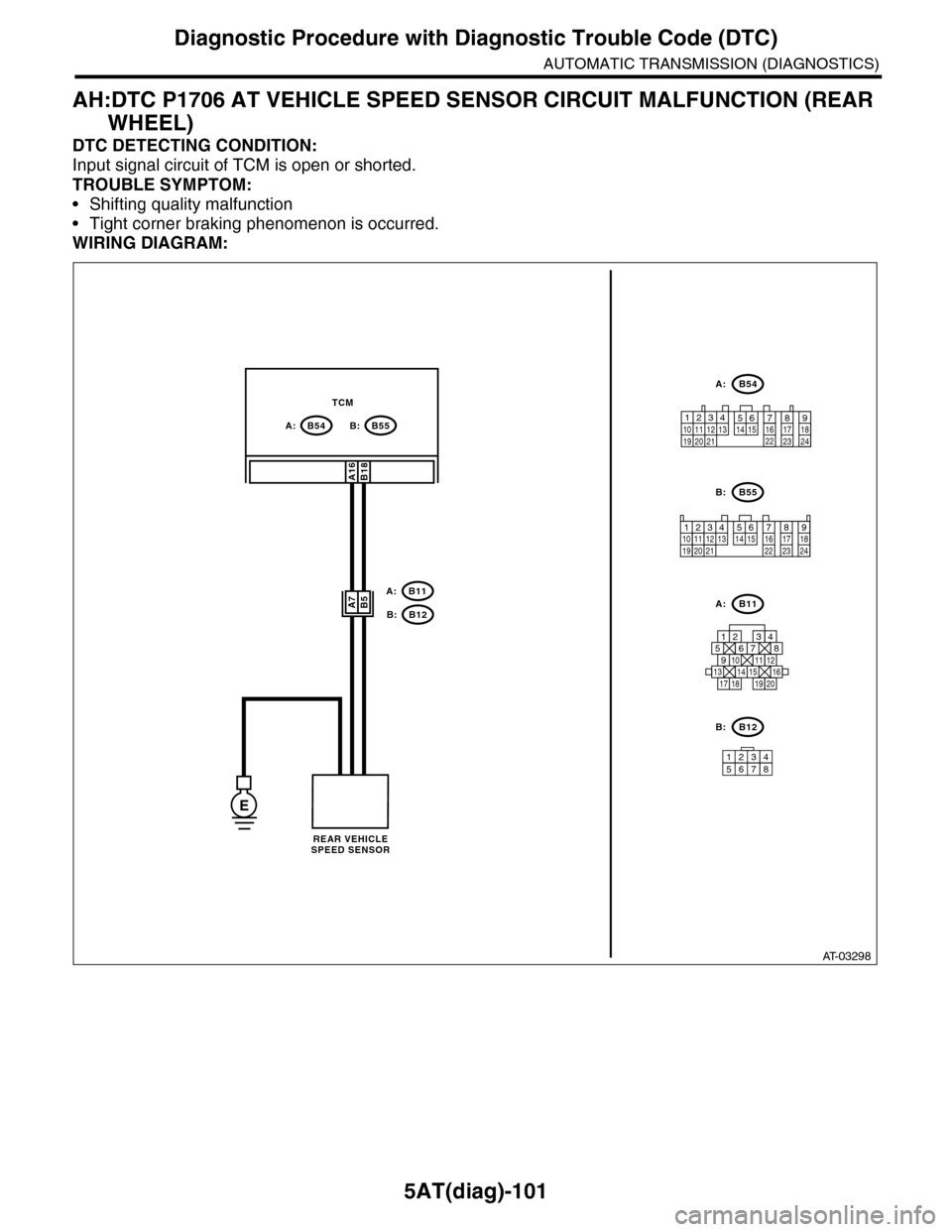

AH:DTC P1706 AT VEHICLE SPEED SENSOR CIRCUIT MALFUNCTION (REAR

WHEEL)

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

•Shifting quality malfunction

•Tight corner braking phenomenon is occurred.

WIRING DIAGRAM:

AT-03298

12341011 121920 21135614 1578916 17 1822 23 24

B54B55B:A:

A:

B:A:

B:

A:

B:

12345678

A16

A7B11

B12

TCM

B54

B55

12789563410 11 1219 20 2113 14 15 16 17 18222324

B11

B12

B18

B5

125678

131415169101112

34

17181920

E

REAR VEHICLESPEED SENSOR

Page 2219 of 2453

5AT(diag)-102

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

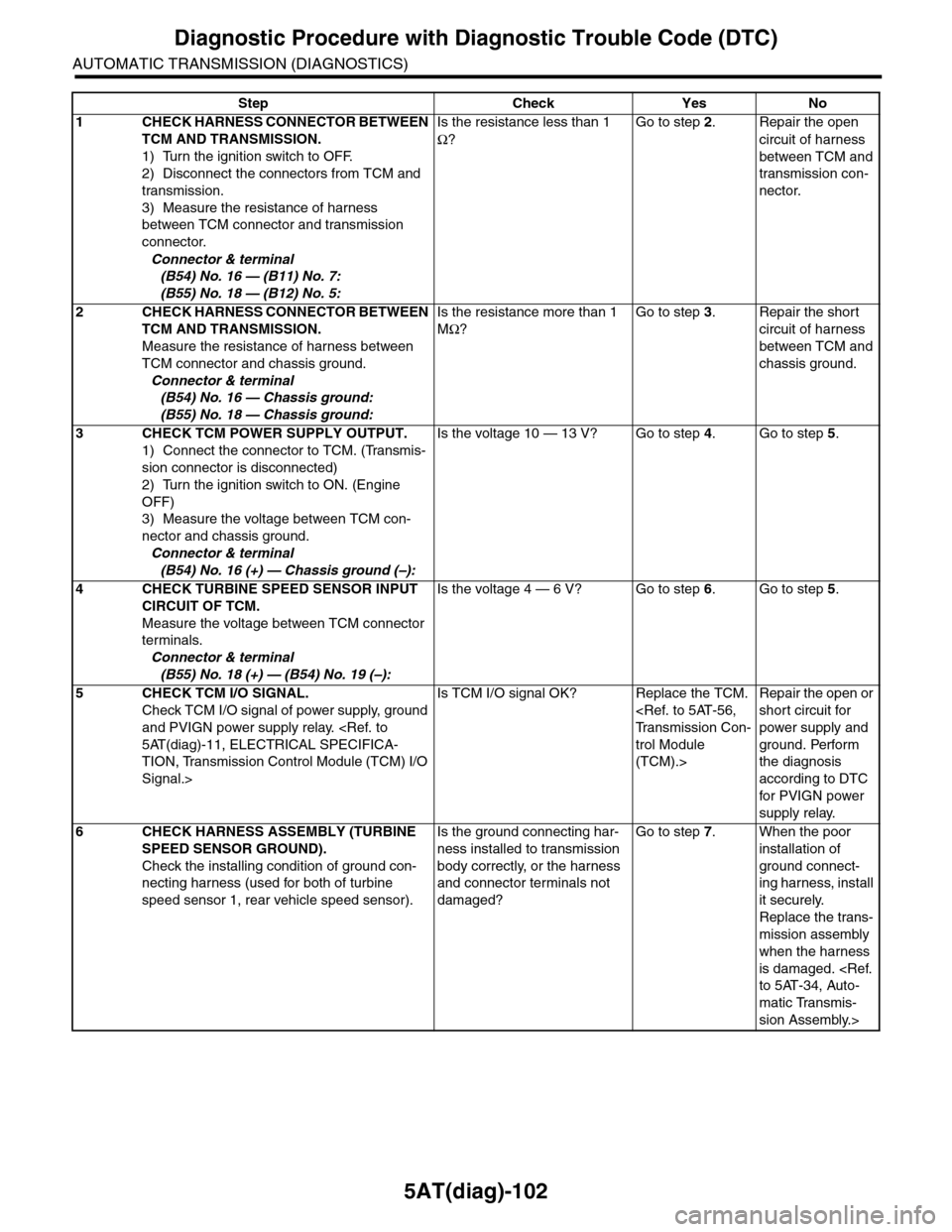

Step Check Yes No

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM connector and transmission

connector.

Connector & terminal

(B54) No. 16 — (B11) No. 7:

(B55) No. 18 — (B12) No. 5:

Is the resistance less than 1

Ω?

Go to step 2.Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B54) No. 16 — Chassis ground:

(B55) No. 18 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the short

circuit of harness

between TCM and

chassis ground.

3CHECK TCM POWER SUPPLY OUTPUT.

1) Connect the connector to TCM. (Transmis-

sion connector is disconnected)

2) Turn the ignition switch to ON. (Engine

OFF)

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 16 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 4.Go to step 5.

4CHECK TURBINE SPEED SENSOR INPUT

CIRCUIT OF TCM.

Measure the voltage between TCM connector

terminals.

Connector & terminal

(B55) No. 18 (+) — (B54) No. 19 (–):

Is the voltage 4 — 6 V? Go to step 6.Go to step 5.

5CHECK TCM I/O SIGNAL.

Check TCM I/O signal of power supply, ground

and PVIGN power supply relay.

TION, Transmission Control Module (TCM) I/O

Signal.>

Is TCM I/O signal OK? Replace the TCM.

trol Module

(TCM).>

Repair the open or

short circuit for

power supply and

ground. Perform

the diagnosis

according to DTC

for PVIGN power

supply relay.

6CHECK HARNESS ASSEMBLY (TURBINE

SPEED SENSOR GROUND).

Check the installing condition of ground con-

necting harness (used for both of turbine

speed sensor 1, rear vehicle speed sensor).

Is the ground connecting har-

ness installed to transmission

body correctly, or the harness

and connector terminals not

damaged?

Go to step 7.When the poor

installation of

ground connect-

ing harness, install

it securely.

Replace the trans-

mission assembly

when the harness

is damaged.

matic Transmis-

sion Assembly.>

Page 2220 of 2453

5AT(diag)-103

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

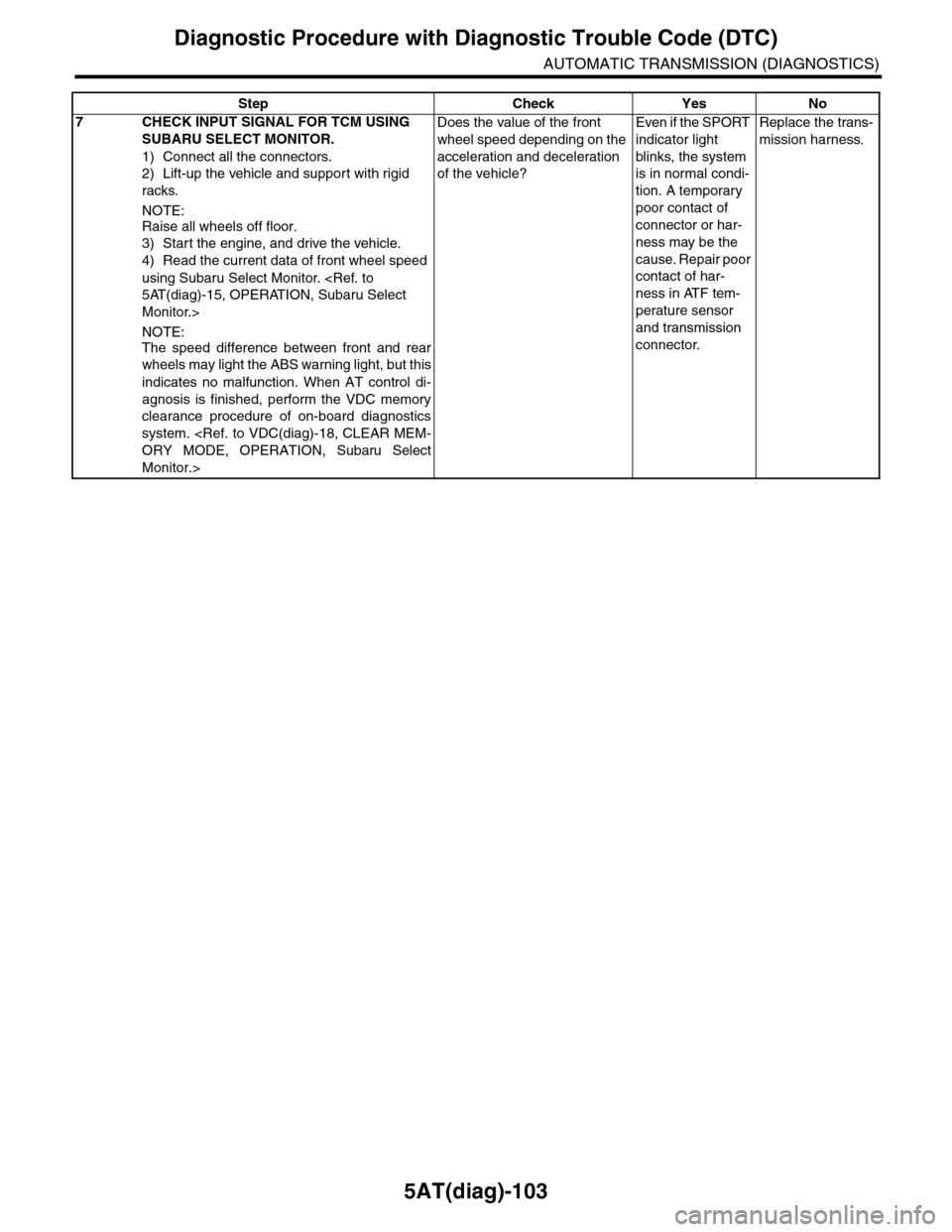

7CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:

Raise all wheels off floor.

3) Start the engine, and drive the vehicle.

4) Read the current data of front wheel speed

using Subaru Select Monitor.

Monitor.>

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the value of the front

wheel speed depending on the

acceleration and deceleration

of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair poor

contact of har-

ness in ATF tem-

perature sensor

and transmission

connector.

Replace the trans-

mission harness.

Step Check Yes No

Page 2224 of 2453

5AT(diag)-107

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

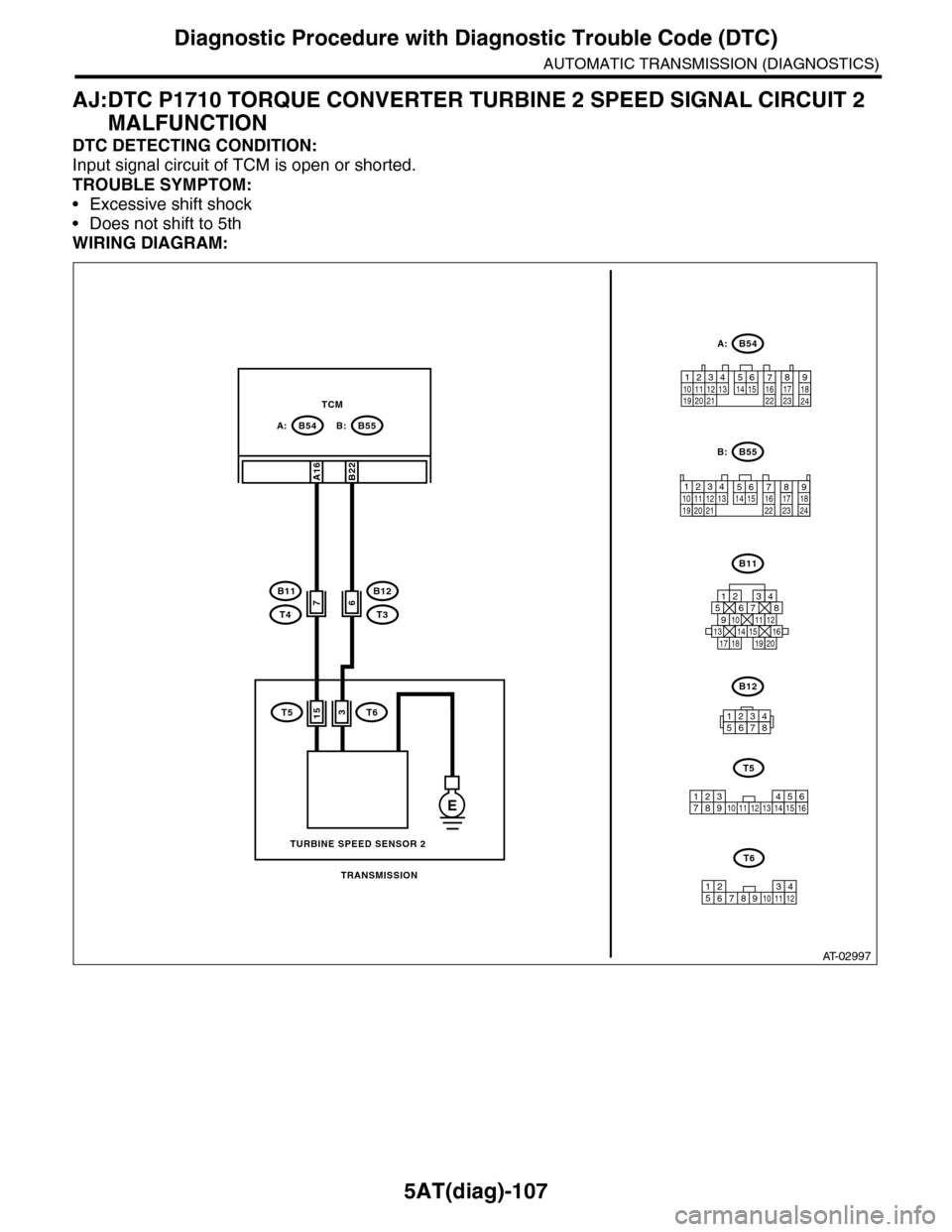

AJ:DTC P1710 TORQUE CONVERTER TURBINE 2 SPEED SIGNAL CIRCUIT 2

MALFUNCTION

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

•Excessive shift shock

•Does not shift to 5th

WIRING DIAGRAM:

AT-02997

12341011 121920 21135614 1578916 17 1822 23 24

12345678

B54

B55

12789563410 11 1219 20 2113 14 15 16 17 18222324

B11

B12

125678

131415169101112

34

17181920

B54A:B55B:

A16

7B11

T4

B12

T3

TCM

TURBINE SPEED SENSOR 2

TRANSMISSION

B22

6

E

B:

A:

T5T6

123 68910 11 12 13 14451516

T5

7

12586910 113412

T6

7

315

Page 2225 of 2453

5AT(diag)-108

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM connector and transmission

connector.

Connector & terminal

(B55) No. 22 — (B12) No. 6:

(B54) No. 16 — (B11) No. 7:

Is the resistance less than 1

Ω?

Go to step 2.Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 22 — Chassis ground:

(B54) No. 16 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

3CHECK TCM POWER SUPPLY OUTPUT.

1) Connect the connector to TCM. (Transmis-

sion connector is disconnected)

2) Turn the ignition switch to ON. (Engine

OFF)

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 16 (+) — (B54) No. 19 (–):

Is the voltage 10 — 13 V? Go to step 4.Go to step 5.

4CHECK TURBINE SPEED SENSOR INPUT

CIRCUIT OF TCM.

Measure the voltage between TCM connector

terminals.

Connector & terminal

(B55) No. 22 (+) — (B54) No. 19 (–):

Is the voltage 4 — 6 V? Go to step 6.Go to step 5.

5CHECK TCM I/O SIGNAL.

Check TCM I/O signal of power supply, ground

and PVIGN power supply relay.

TION, Transmission Control Module (TCM) I/O

Signal.>

Is I/O signal OK? Replace the TCM.

trol Module

(TCM).>

Repair the open or

short circuit for

power supply and

ground. Perform

the diagnosis

according to DTC

for PVIGN power

supply relay.

Page 2226 of 2453

5AT(diag)-109

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

6CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:

Raise all wheels off floor.

3) Start the engine, and set the vehicle in 1st

speed driving condition of manual mode.

4) Read the current data of torque converter

turbine speed 2 using Subaru Select Monitor.

NOTE:The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the value of the turbine

speed sensor 2 change

depending on the acceleration,

deceleration and shifting gear

of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness of turbine

speed sensor 2

and transmission

connector.

Go to step 7.

7CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:

Raise all wheels off floor.

5) Drain the ATF.

CAUTION:Do not drain ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmis-

sion connector and control valve body connec-

tor.

Connector & terminal

(T3) No. 6 — (T6) No. 3:

(T4) No. 7 — (T5) No. 15:

Is the resistance less than 1

Ω?

Go to step 8.Repair the open

circuit of harness

between transmis-

sion connector

and control valve

body connector.

8CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

Measure the resistance between transmission

ground and control valve body connector.

Connector & terminal

(T6) No. 3 — Transmission ground:

(T5) No. 15 — Transmission ground:

Is the resistance more than 1

MΩ?

Replace the con-

trol valve body.

Body.>

Repair the short

circuit of harness

between transmis-

sion connector

and transmission

ground.

Step Check Yes No

Page 2227 of 2453

5AT(diag)-110

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

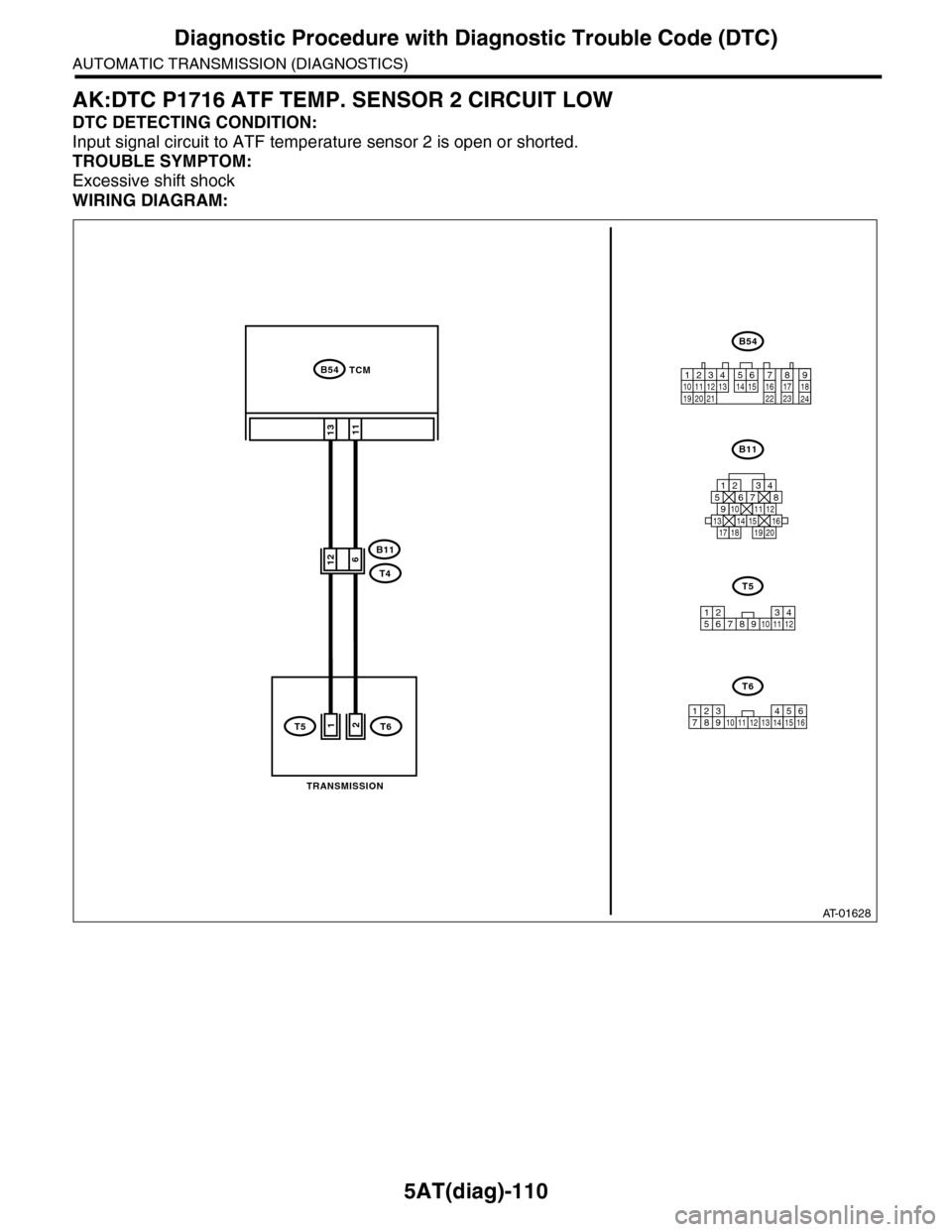

AK:DTC P1716 ATF TEMP. SENSOR 2 CIRCUIT LOW

DTC DETECTING CONDITION:

Input signal circuit to ATF temperature sensor 2 is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock

WIRING DIAGRAM:

AT-01628

11

B54

B11

T4

TCM

13

B54

B11

12789563410 11 1219 20 2113 14 15 16 17 18222324

TRANSMISSION

125678

131415169101112

34

17181920

612

T5T621123 68910 11 12 13 14451516

T6

7

12586910 113412

T5

7

Page 2228 of 2453

5AT(diag)-111

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

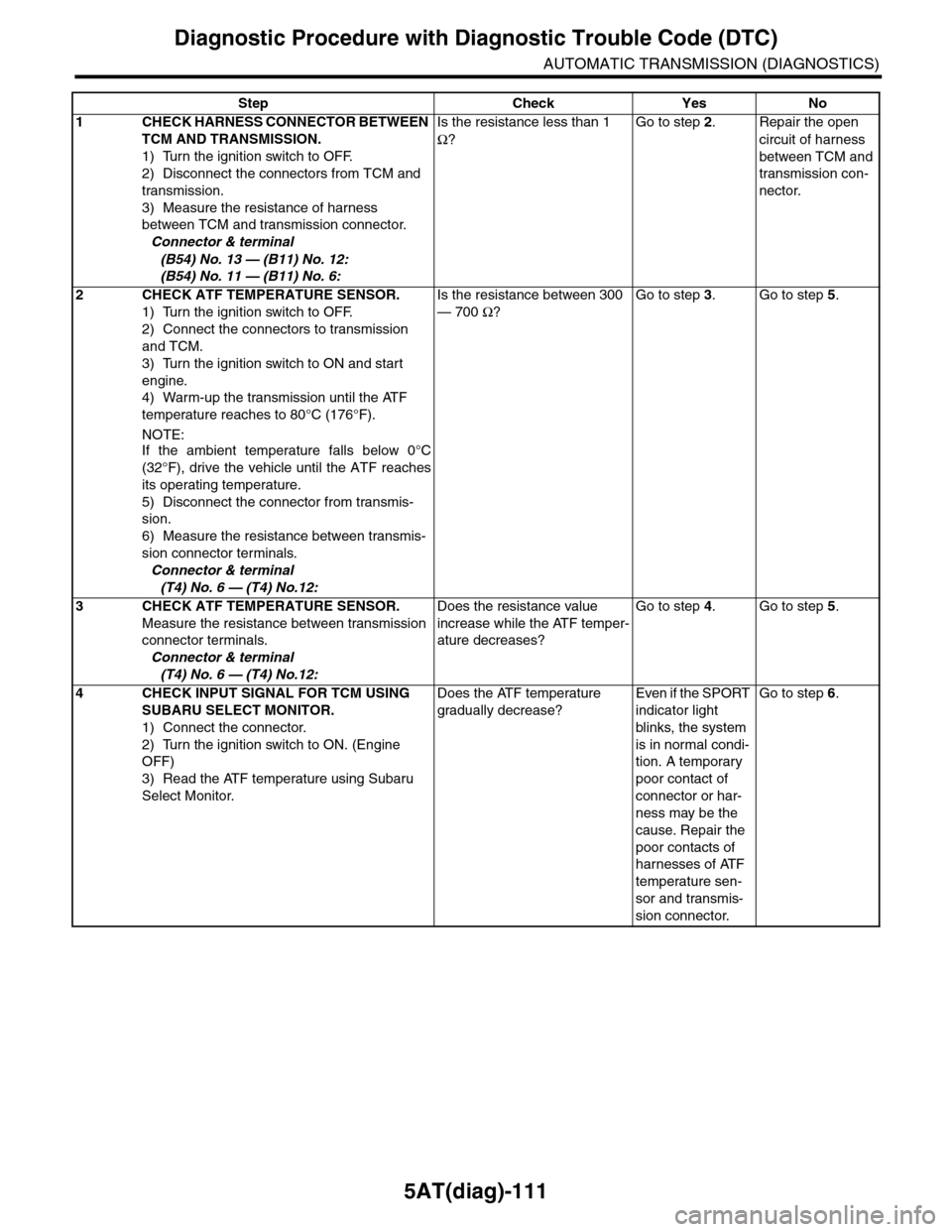

Step Check Yes No

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B54) No. 13 — (B11) No. 12:

(B54) No. 11 — (B11) No. 6:

Is the resistance less than 1

Ω?

Go to step 2.Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2CHECK ATF TEMPERATURE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the connectors to transmission

and TCM.

3) Turn the ignition switch to ON and start

engine.

4) Warm-up the transmission until the ATF

temperature reaches to 80°C (176°F).

NOTE:

If the ambient temperature falls below 0°C

(32°F), drive the vehicle until the ATF reaches

its operating temperature.

5) Disconnect the connector from transmis-

sion.

6) Measure the resistance between transmis-

sion connector terminals.

Connector & terminal

(T4) No. 6 — (T4) No.12:

Is the resistance between 300

— 700 Ω?

Go to step 3.Go to step 5.

3CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission

connector terminals.

Connector & terminal

(T4) No. 6 — (T4) No.12:

Does the resistance value

increase while the ATF temper-

ature decreases?

Go to step 4.Go to step 5.

4CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connector.

2) Turn the ignition switch to ON. (Engine

OFF)

3) Read the ATF temperature using Subaru

Select Monitor.

Does the ATF temperature

gradually decrease?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contacts of

harnesses of ATF

temperature sen-

sor and transmis-

sion connector.

Go to step 6.

Page 2229 of 2453

5AT(diag)-112

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

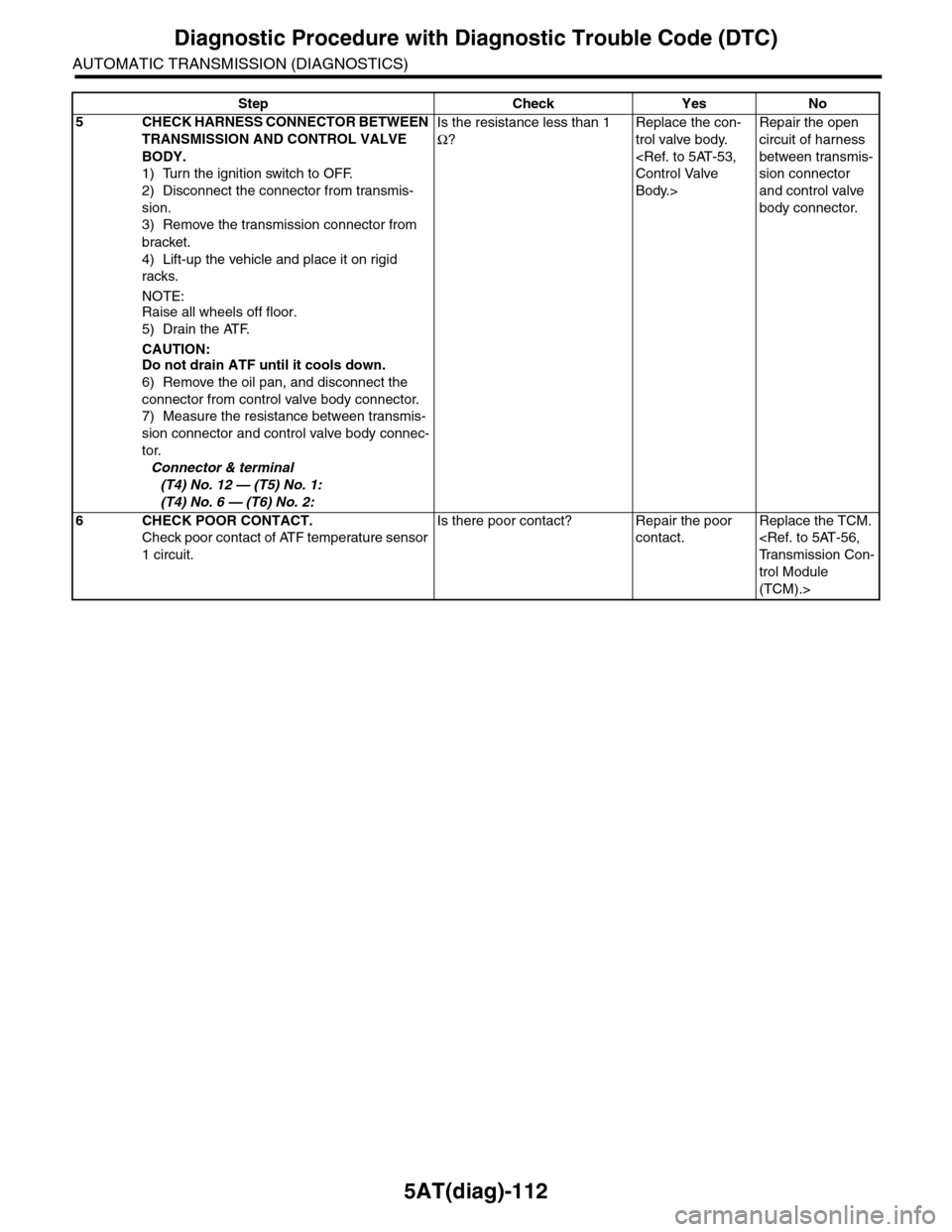

5CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:Raise all wheels off floor.

5) Drain the ATF.

CAUTION:Do not drain ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmis-

sion connector and control valve body connec-

tor.

Connector & terminal

(T4) No. 12 — (T5) No. 1:

(T4) No. 6 — (T6) No. 2:

Is the resistance less than 1

Ω?

Replace the con-

trol valve body.

Body.>

Repair the open

circuit of harness

between transmis-

sion connector

and control valve

body connector.

6CHECK POOR CONTACT.

Check poor contact of ATF temperature sensor

1 circuit.

Is there poor contact? Repair the poor

contact.

Replace the TCM.

trol Module

(TCM).>

Step Check Yes No