engine SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1998 of 2453

PM-15

Engine Coolant

PERIODIC MAINTENANCE SERVICES

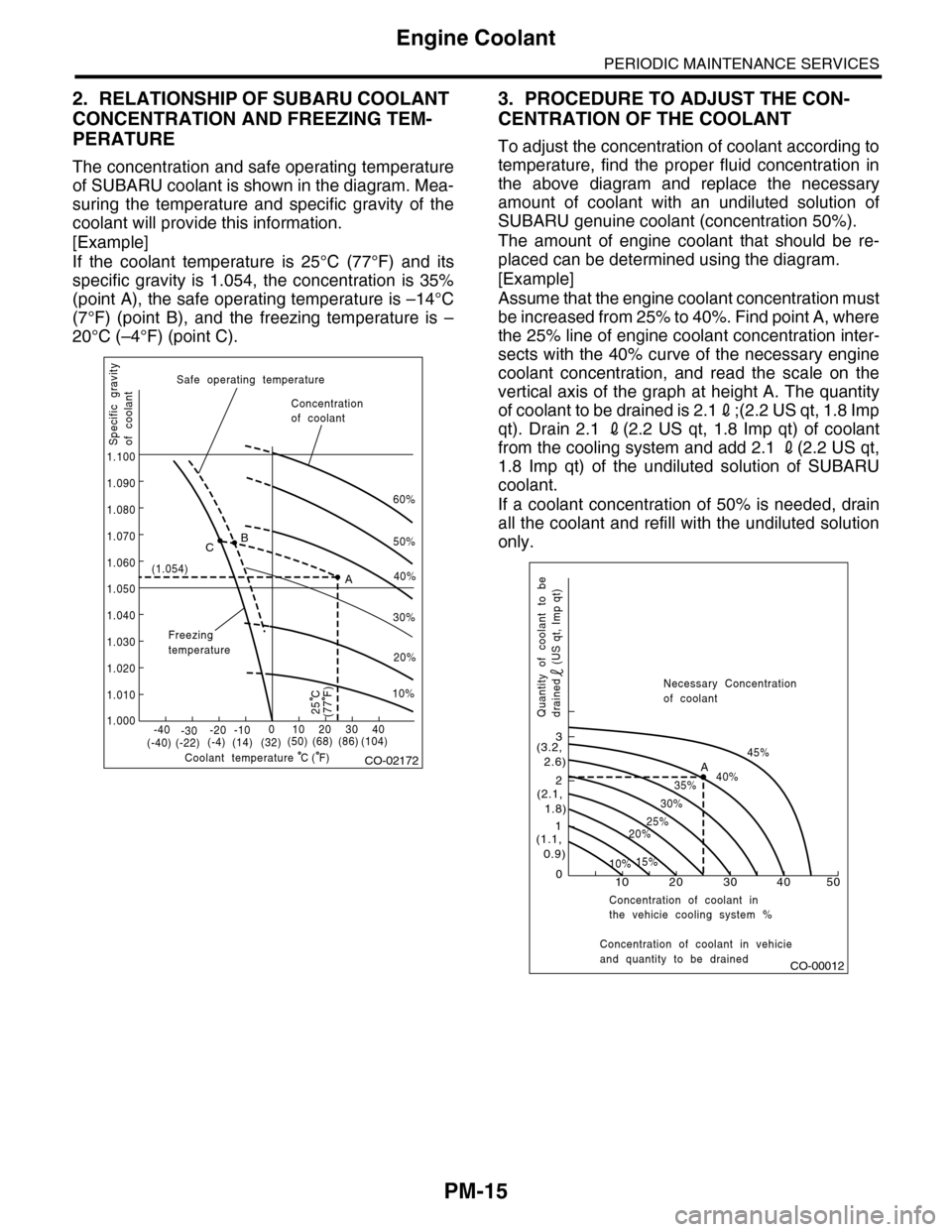

2. RELATIONSHIP OF SUBARU COOLANT

CONCENTRATION AND FREEZING TEM-

PERATURE

The concentration and safe operating temperature

of SUBARU coolant is shown in the diagram. Mea-

suring the temperature and specific gravity of the

coolant will provide this information.

[Example]

If the coolant temperature is 25°C (77°F) and its

specific gravity is 1.054, the concentration is 35%

(point A), the safe operating temperature is –14°C

(7°F) (point B), and the freezing temperature is –

20°C (–4°F) (point C).

3. PROCEDURE TO ADJUST THE CON-

CENTRATION OF THE COOLANT

To adjust the concentration of coolant according to

temperature, find the proper fluid concentration in

the above diagram and replace the necessary

amount of coolant with an undiluted solution of

SUBARU genuine coolant (concentration 50%).

The amount of engine coolant that should be re-

placed can be determined using the diagram.

[Example]

Assume that the engine coolant concentration must

be increased from 25% to 40%. Find point A, where

the 25% line of engine coolant concentration inter-

sects with the 40% curve of the necessary engine

coolant concentration, and read the scale on the

vertical axis of the graph at height A. The quantity

of coolant to be drained is 2.12;(2.2 US qt, 1.8 Imp

qt). Drain 2.1 2(2.2 US qt, 1.8 Imp qt) of coolant

from the cooling system and add 2.1 2(2.2 US qt,

1.8 Imp qt) of the undiluted solution of SUBARU

coolant.

If a coolant concentration of 50% is needed, drain

all the coolant and refill with the undiluted solution

only.

CO-02172

60%

(1.054)

1.000

1.010

1.020

1.030

1.040

1.050

1.060

1.070

1.080

1.090

1.100

Safe operating temperature

Freezingtemperature

Concentrationof coolant

Specific gravityof coolant

Coolant temperature

B

A

C

-40(-40) (-22)(-4)(14)(32)(50) (68) (86)

( F)

(104)-30-20 -10010203040

(77 F)

50%

40%

30%

20%

25 C

10%

C

CO-00012

100

1

2

3

(1.1, 0.9)

(2.1, 1.8)

(3.2, 2.6)

10%15%

25%20%

30%

35%40%

45%A

20 30 40 50

Concentration of coolant in vehicieand quantity to be drained

Quantity of coolant to bedrained (US qt, Imp qt)

Necessary Concentrationof coolant

Concentration of coolant inthe vehicie cooling system %

Page 1999 of 2453

PM-16

Automatic Transmission Fluid

PERIODIC MAINTENANCE SERVICES

11. Automatic Transmission Fluid

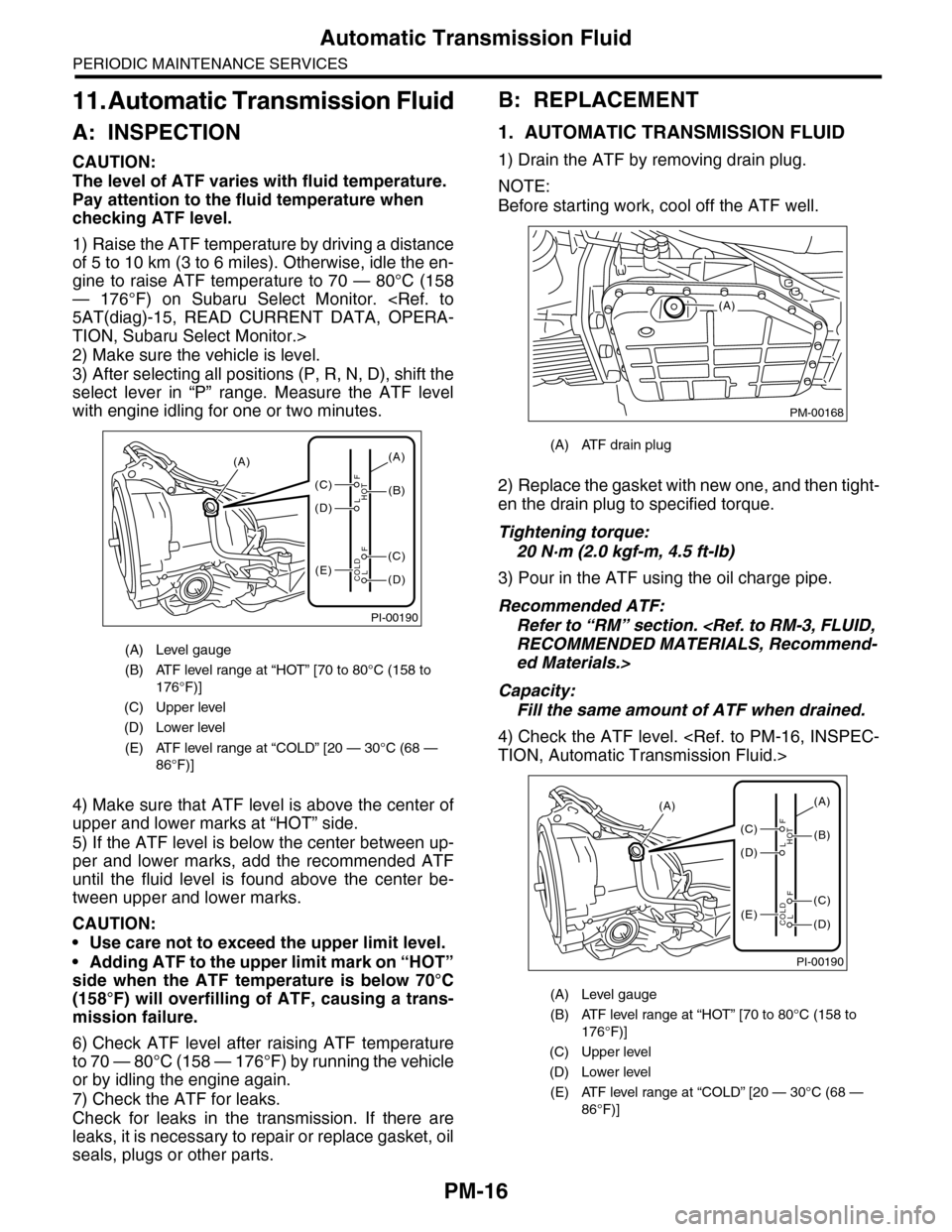

A: INSPECTION

CAUTION:

The level of ATF varies with fluid temperature.

Pay attention to the fluid temperature when

checking ATF level.

1) Raise the ATF temperature by driving a distance

of 5 to 10 km (3 to 6 miles). Otherwise, idle the en-

gine to raise ATF temperature to 70 — 80°C (158

— 176°F) on Subaru Select Monitor.

TION, Subaru Select Monitor.>

2) Make sure the vehicle is level.

3) After selecting all positions (P, R, N, D), shift the

select lever in “P” range. Measure the ATF level

with engine idling for one or two minutes.

4) Make sure that ATF level is above the center of

upper and lower marks at “HOT” side.

5) If the ATF level is below the center between up-

per and lower marks, add the recommended ATF

until the fluid level is found above the center be-

tween upper and lower marks.

CAUTION:

•Use care not to exceed the upper limit level.

•Adding ATF to the upper limit mark on “HOT”

side when the ATF temperature is below 70°C

(158°F) will overfilling of ATF, causing a trans-

mission failure.

6) Check ATF level after raising ATF temperature

to 70 — 80°C (158 — 176°F) by running the vehicle

or by idling the engine again.

7) Check the ATF for leaks.

Check for leaks in the transmission. If there are

leaks, it is necessary to repair or replace gasket, oil

seals, plugs or other parts.

B: REPLACEMENT

1. AUTOMATIC TRANSMISSION FLUID

1) Drain the ATF by removing drain plug.

NOTE:

Before starting work, cool off the ATF well.

2) Replace the gasket with new one, and then tight-

en the drain plug to specified torque.

Tightening torque:

20 N·m (2.0 kgf-m, 4.5 ft-lb)

3) Pour in the ATF using the oil charge pipe.

Recommended ATF:

Refer to “RM” section.

ed Materials.>

Capacity:

Fill the same amount of ATF when drained.

4) Check the ATF level.

(A) Level gauge

(B) ATF level range at “HOT” [70 to 80°C (158 to

176°F)]

(C) Upper level

(D) Lower level

(E) ATF level range at “COLD” [20 — 30°C (68 —

86°F)]

PI-00190

(A)

(C)

(D)

(E)(D)

(C)

(B)

(A)

F

L

F

HOT

LCOLD

(A) ATF drain plug

(A) Level gauge

(B) ATF level range at “HOT” [70 to 80°C (158 to

176°F)]

(C) Upper level

(D) Lower level

(E) ATF level range at “COLD” [20 — 30°C (68 —

86°F)]

PM-00168

(A)

PI-00190

(A)

(C)

(D)

(E)(D)

(C)

(B)

(A)

F

L

F

HOT

LCOLD

Page 2002 of 2453

PM-19

Brake Line

PERIODIC MAINTENANCE SERVICES

13.Brake Line

A: INSPECTION

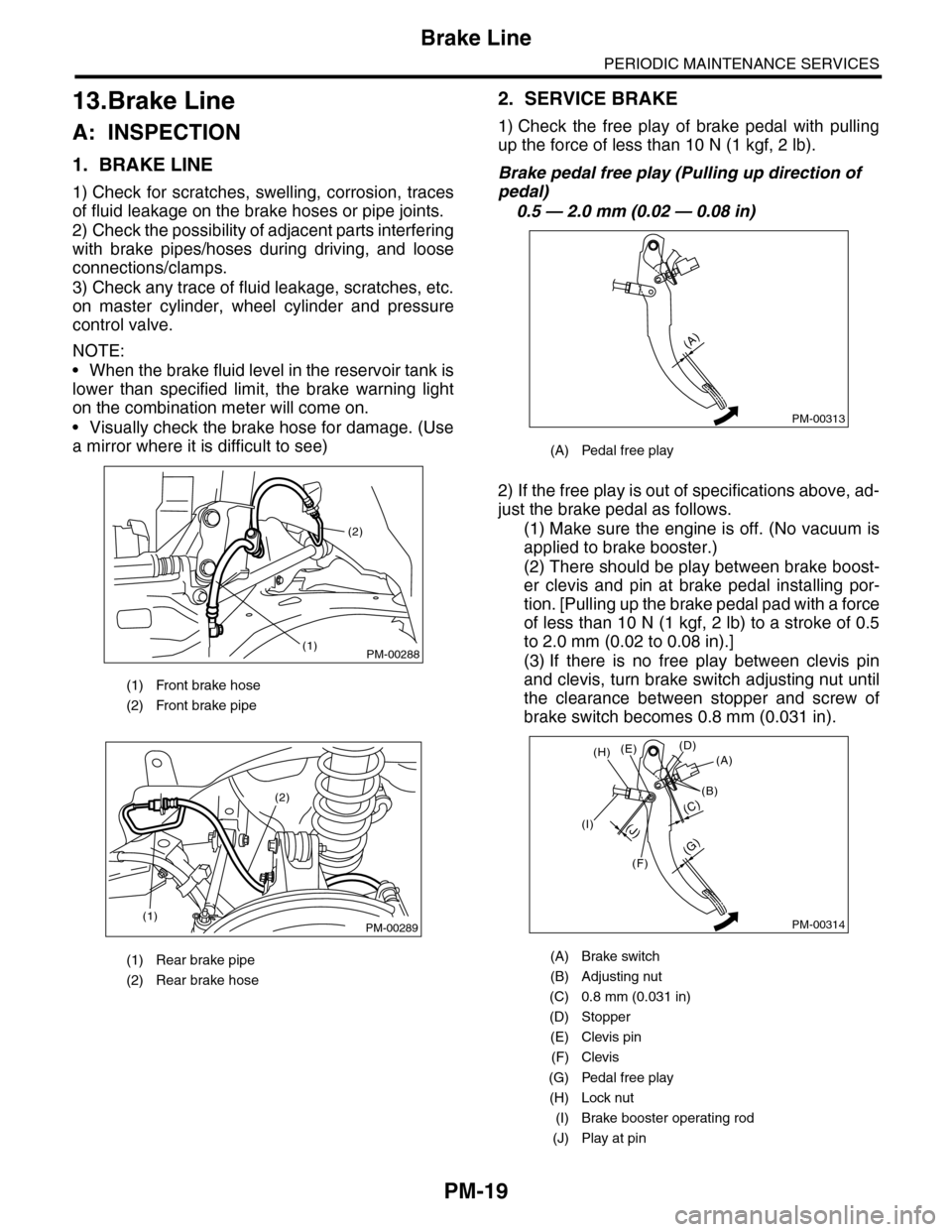

1. BRAKE LINE

1) Check for scratches, swelling, corrosion, traces

of fluid leakage on the brake hoses or pipe joints.

2) Check the possibility of adjacent parts interfering

with brake pipes/hoses during driving, and loose

connections/clamps.

3) Check any trace of fluid leakage, scratches, etc.

on master cylinder, wheel cylinder and pressure

control valve.

NOTE:

•When the brake fluid level in the reservoir tank is

lower than specified limit, the brake warning light

on the combination meter will come on.

•Visually check the brake hose for damage. (Use

a mirror where it is difficult to see)

2. SERVICE BRAKE

1) Check the free play of brake pedal with pulling

up the force of less than 10 N (1 kgf, 2 lb).

Brake pedal free play (Pulling up direction of

pedal)

0.5 — 2.0 mm (0.02 — 0.08 in)

2) If the free play is out of specifications above, ad-

just the brake pedal as follows.

(1) Make sure the engine is off. (No vacuum is

applied to brake booster.)

(2) There should be play between brake boost-

er clevis and pin at brake pedal installing por-

tion. [Pulling up the brake pedal pad with a force

of less than 10 N (1 kgf, 2 lb) to a stroke of 0.5

to 2.0 mm (0.02 to 0.08 in).]

(3) If there is no free play between clevis pin

and clevis, turn brake switch adjusting nut until

the clearance between stopper and screw of

brake switch becomes 0.8 mm (0.031 in).

(1) Front brake hose

(2) Front brake pipe

(1) Rear brake pipe

(2) Rear brake hose

PM-00288

(2)

(1)

PM-00289(1)

(2)

(A) Pedal free play

(A) Brake switch

(B) Adjusting nut

(C) 0.8 mm (0.031 in)

(D) Stopper

(E) Clevis pin

(F) Clevis

(G) Pedal free play

(H) Lock nut

(I) Brake booster operating rod

(J) Play at pin

PM-00313

(A)

PM-00314

(G)

(A)(D)(E)

(B)

(C)

(F)

(J)(I)

(H)

Page 2003 of 2453

PM-20

Brake Line

PERIODIC MAINTENANCE SERVICES

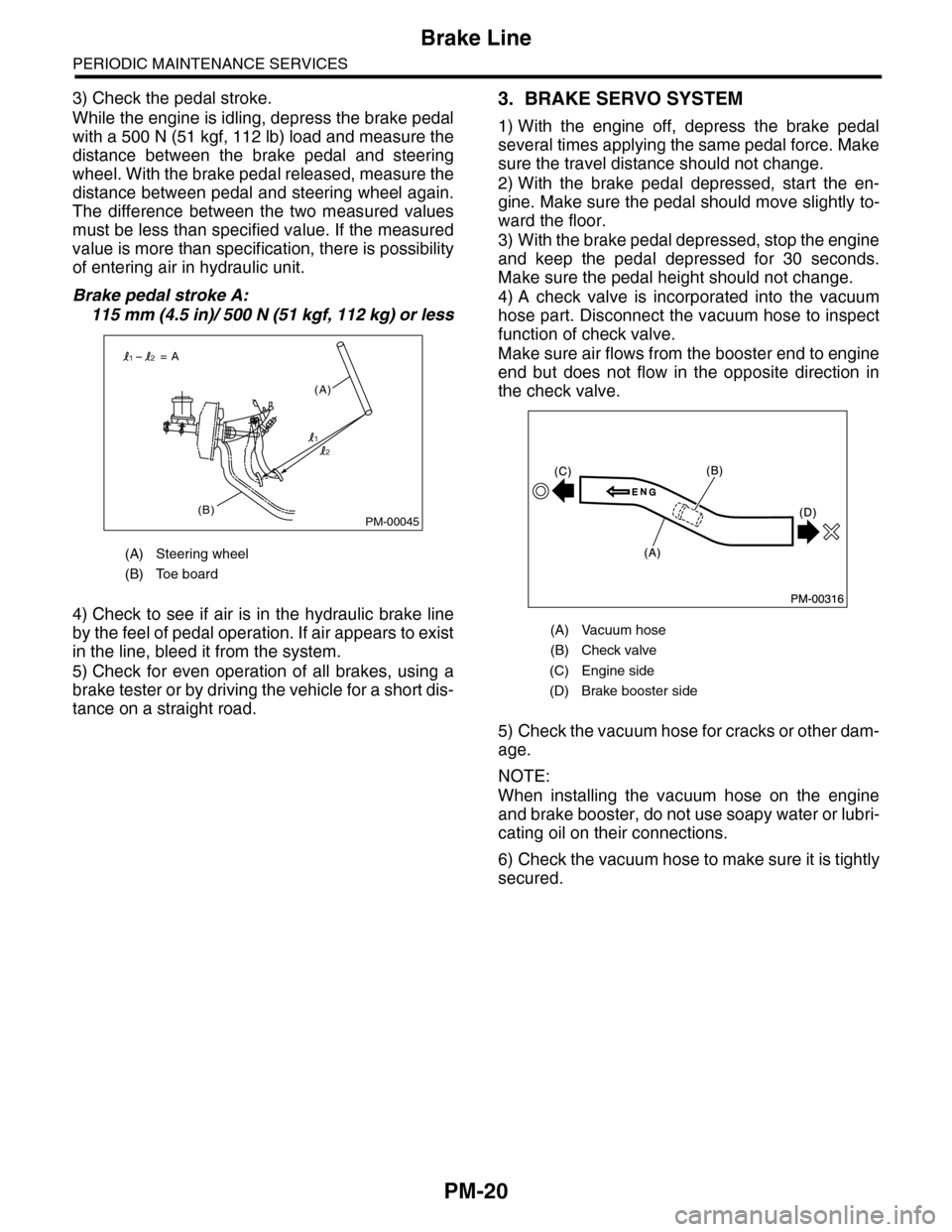

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 500 N (51 kgf, 112 lb) load and measure the

distance between the brake pedal and steering

wheel. With the brake pedal released, measure the

distance between pedal and steering wheel again.

The difference between the two measured values

must be less than specified value. If the measured

value is more than specification, there is possibility

of entering air in hydraulic unit.

Brake pedal stroke A:

115 mm (4.5 in)/ 500 N (51 kgf, 112 kg) or less

4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

3. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force. Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine. Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds.

Make sure the pedal height should not change.

4) A check valve is incorporated into the vacuum

hose part. Disconnect the vacuum hose to inspect

function of check valve.

Make sure air flows from the booster end to engine

end but does not flow in the opposite direction in

the check valve.

5) Check the vacuum hose for cracks or other dam-

age.

NOTE:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or lubri-

cating oil on their connections.

6) Check the vacuum hose to make sure it is tightly

secured.

(A) Steering wheel

(B) Toe board

PM-00045(B)

(A)

= A

1

12

2

(A) Vacuum hose

(B) Check valve

(C) Engine side

(D) Brake booster side

Page 2013 of 2453

PM-30

Steering System (Power Steering)

PERIODIC MAINTENANCE SERVICES

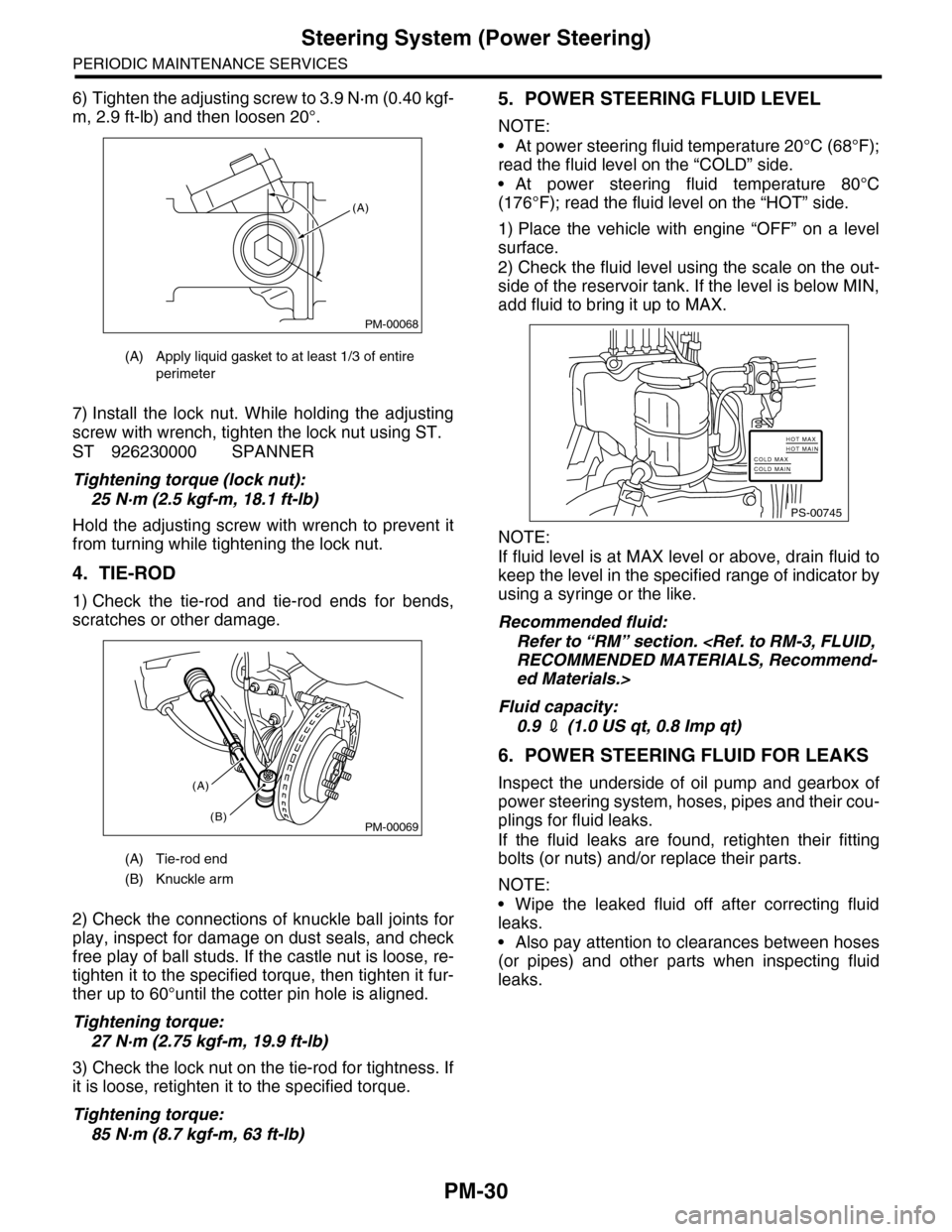

6) Tighten the adjusting screw to 3.9 N·m (0.40 kgf-

m, 2.9 ft-lb) and then loosen 20°.

7) Install the lock nut. While holding the adjusting

screw with wrench, tighten the lock nut using ST.

ST 926230000 SPANNER

Tightening torque (lock nut):

25 N·m (2.5 kgf-m, 18.1 ft-lb)

Hold the adjusting screw with wrench to prevent it

from turning while tightening the lock nut.

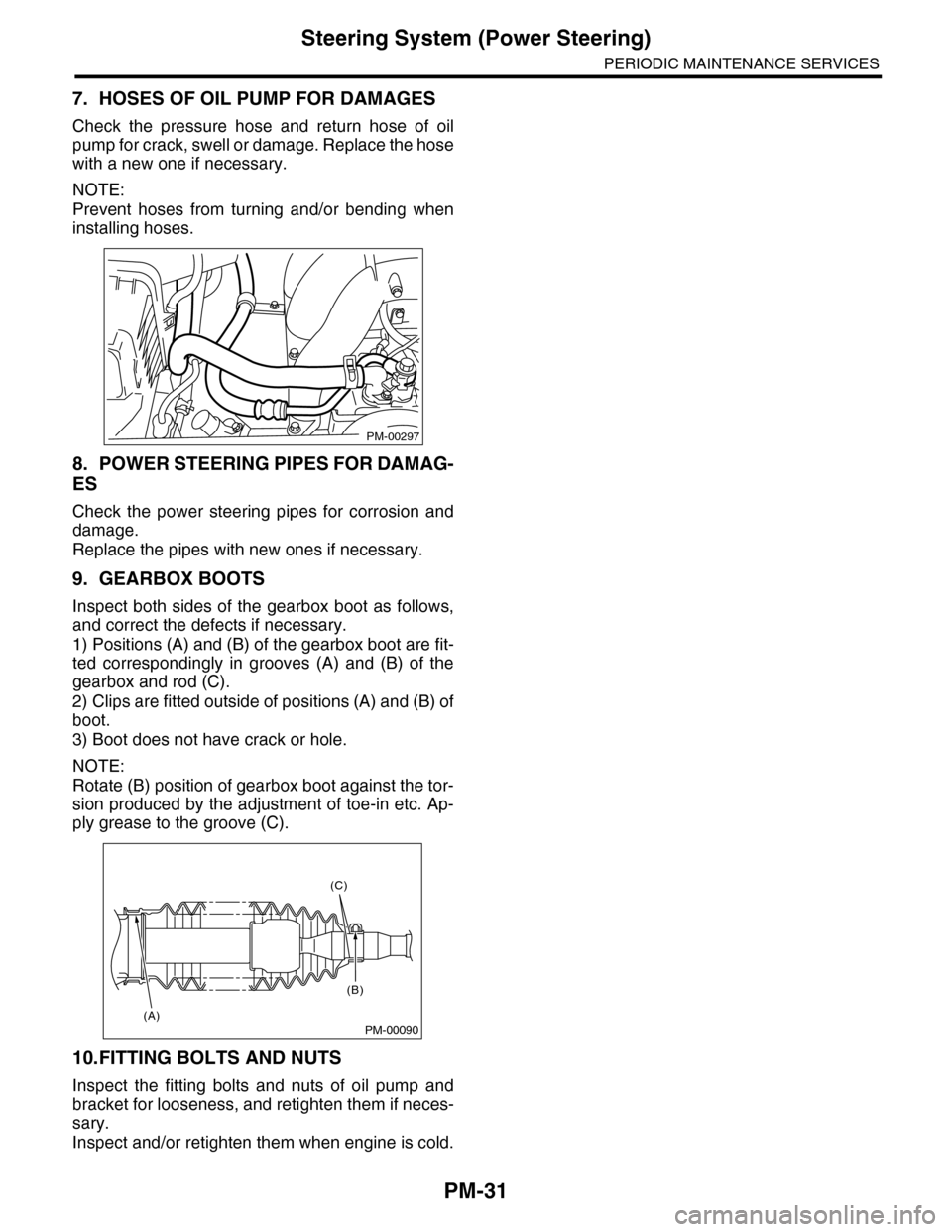

4. TIE-ROD

1) Check the tie-rod and tie-rod ends for bends,

scratches or other damage.

2) Check the connections of knuckle ball joints for

play, inspect for damage on dust seals, and check

free play of ball studs. If the castle nut is loose, re-

tighten it to the specified torque, then tighten it fur-

ther up to 60°until the cotter pin hole is aligned.

Tightening torque:

27 N·m (2.75 kgf-m, 19.9 ft-lb)

3) Check the lock nut on the tie-rod for tightness. If

it is loose, retighten it to the specified torque.

Tightening torque:

85 N·m (8.7 kgf-m, 63 ft-lb)

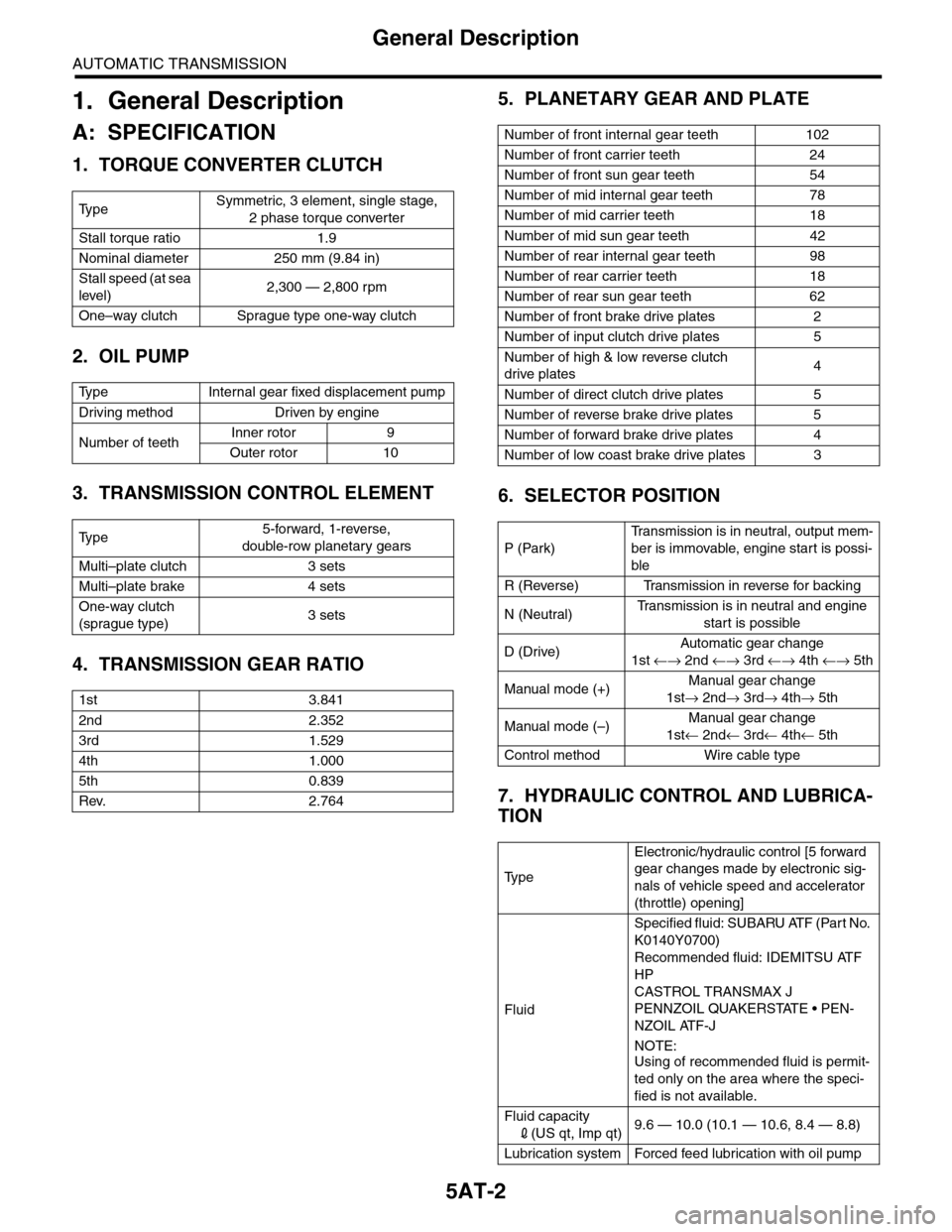

5. POWER STEERING FLUID LEVEL

NOTE:

•At power steering fluid temperature 20°C (68°F);

read the fluid level on the “COLD” side.

•At power steering fluid temperature 80°C

(176°F); read the fluid level on the “HOT” side.

1) Place the vehicle with engine “OFF” on a level

surface.

2) Check the fluid level using the scale on the out-

side of the reservoir tank. If the level is below MIN,

add fluid to bring it up to MAX.

NOTE:

If fluid level is at MAX level or above, drain fluid to

keep the level in the specified range of indicator by

using a syringe or the like.

Recommended fluid:

Refer to “RM” section.

ed Materials.>

Fluid capacity:

0.9 2 (1.0 US qt, 0.8 Imp qt)

6. POWER STEERING FLUID FOR LEAKS

Inspect the underside of oil pump and gearbox of

power steering system, hoses, pipes and their cou-

plings for fluid leaks.

If the fluid leaks are found, retighten their fitting

bolts (or nuts) and/or replace their parts.

NOTE:

•Wipe the leaked fluid off after correcting fluid

leaks.

•Also pay attention to clearances between hoses

(or pipes) and other parts when inspecting fluid

leaks.

(A) Apply liquid gasket to at least 1/3 of entire

perimeter

(A) Tie-rod end

(B) Knuckle arm

PM-00068

(A)

PM-00069

(A)

(B)

PS-00745

HOT MAXHOT MAINCOLD MAXCOLD MAIN

Page 2014 of 2453

PM-31

Steering System (Power Steering)

PERIODIC MAINTENANCE SERVICES

7. HOSES OF OIL PUMP FOR DAMAGES

Check the pressure hose and return hose of oil

pump for crack, swell or damage. Replace the hose

with a new one if necessary.

NOTE:

Prevent hoses from turning and/or bending when

installing hoses.

8. POWER STEERING PIPES FOR DAMAG-

ES

Check the power steering pipes for corrosion and

damage.

Replace the pipes with new ones if necessary.

9. GEARBOX BOOTS

Inspect both sides of the gearbox boot as follows,

and correct the defects if necessary.

1) Positions (A) and (B) of the gearbox boot are fit-

ted correspondingly in grooves (A) and (B) of the

gearbox and rod (C).

2) Clips are fitted outside of positions (A) and (B) of

boot.

3) Boot does not have crack or hole.

NOTE:

Rotate (B) position of gearbox boot against the tor-

sion produced by the adjustment of toe-in etc. Ap-

ply grease to the groove (C).

10.FITTING BOLTS AND NUTS

Inspect the fitting bolts and nuts of oil pump and

bracket for looseness, and retighten them if neces-

sary.

Inspect and/or retighten them when engine is cold.

PM-00297

PM-00090

(C)

(B)

(A)

Page 2018 of 2453

5AT-2

General Description

AUTOMATIC TRANSMISSION

1. General Description

A: SPECIFICATION

1. TORQUE CONVERTER CLUTCH

2. OIL PUMP

3. TRANSMISSION CONTROL ELEMENT

4. TRANSMISSION GEAR RATIO

5. PLANETARY GEAR AND PLATE

6. SELECTOR POSITION

7. HYDRAULIC CONTROL AND LUBRICA-

TION

Ty p eSymmetric, 3 element, single stage,

2 phase torque converter

Stall torque ratio 1.9

Nominal diameter 250 mm (9.84 in)

Stall speed (at sea

level)2,300 — 2,800 rpm

One–way clutch Sprague type one-way clutch

Ty p e I n t e r n a l g e a r f i x e d d i s p l a c e m e n t p u m p

Driving method Driven by engine

Number of teethInner rotor 9

Outer rotor 10

Ty p e5-forward, 1-reverse,

double-row planetary gears

Multi–plate clutch 3 sets

Multi–plate brake 4 sets

One-way clutch

(sprague type)3 sets

1st 3.841

2nd 2.352

3rd 1.529

4th 1.000

5th 0.839

Rev. 2.764

Number of front internal gear teeth 102

Number of front carrier teeth 24

Number of front sun gear teeth 54

Number of mid internal gear teeth 78

Number of mid carrier teeth 18

Number of mid sun gear teeth 42

Number of rear internal gear teeth 98

Number of rear carrier teeth 18

Number of rear sun gear teeth 62

Number of front brake drive plates 2

Number of input clutch drive plates 5

Number of high & low reverse clutch

drive plates4

Number of direct clutch drive plates 5

Number of reverse brake drive plates 5

Number of forward brake drive plates 4

Number of low coast brake drive plates 3

P (Park)

Tr a n s m i s s i o n i s i n n e u t r a l , o u t p u t m e m -

ber is immovable, engine start is possi-

ble

R (Reverse) Transmission in reverse for backing

N (Neutral)Tr a n s m i s s i o n i s i n n e u t r a l a n d e n g i n e

start is possible

D (Drive)Automatic gear change

1st ←→ 2nd ←→ 3rd ←→ 4th ←→ 5th

Manual mode (+)Manual gear change

1st→ 2nd→ 3rd→ 4th→ 5th

Manual mode (–)Manual gear change

1st← 2nd← 3rd← 4th← 5th

Control method Wire cable type

Ty p e

Electronic/hydraulic control [5 forward

gear changes made by electronic sig-

nals of vehicle speed and accelerator

(throttle) opening]

Fluid

Specified fluid: SUBARU ATF (Part No.

K0140Y0700)

Recommended fluid: IDEMITSU ATF

HP

CASTROL TRANSMAX J

PENNZOIL QUAKERSTATE • PEN-

NZOIL ATF-J

NOTE:

Using of recommended fluid is permit-

ted only on the area where the speci-

fied is not available.

Fluid capacity

2(US qt, Imp qt)9.6 — 10.0 (10.1 — 10.6, 8.4 — 8.8)

Lubrication system Forced feed lubrication with oil pump

Page 2034 of 2453

5AT-18

General Description

AUTOMATIC TRANSMISSION

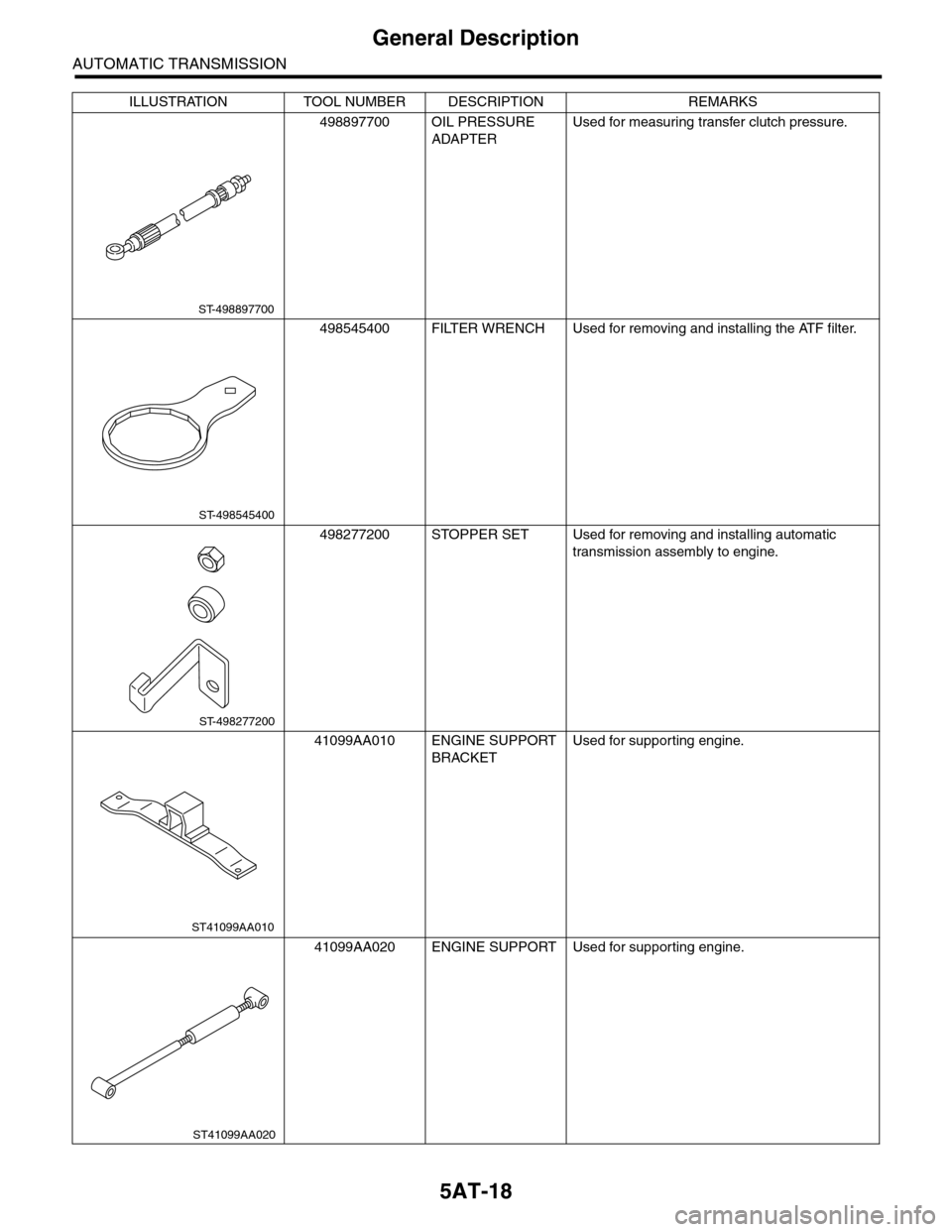

498897700 OIL PRESSURE

ADAPTER

Used for measuring transfer clutch pressure.

498545400 FILTER WRENCH Used for removing and installing the ATF filter.

498277200 STOPPER SET Used for removing and installing automatic

transmission assembly to engine.

41099AA010 ENGINE SUPPORT

BRACKET

Used for supporting engine.

41099AA020 ENGINE SUPPORT Used for supporting engine.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-498897700

ST-498545400

ST-498277200

ST41099AA010

ST41099AA020

Page 2042 of 2453

5AT-26

Automatic Transmission Fluid

AUTOMATIC TRANSMISSION

2. Automatic Transmission Fluid

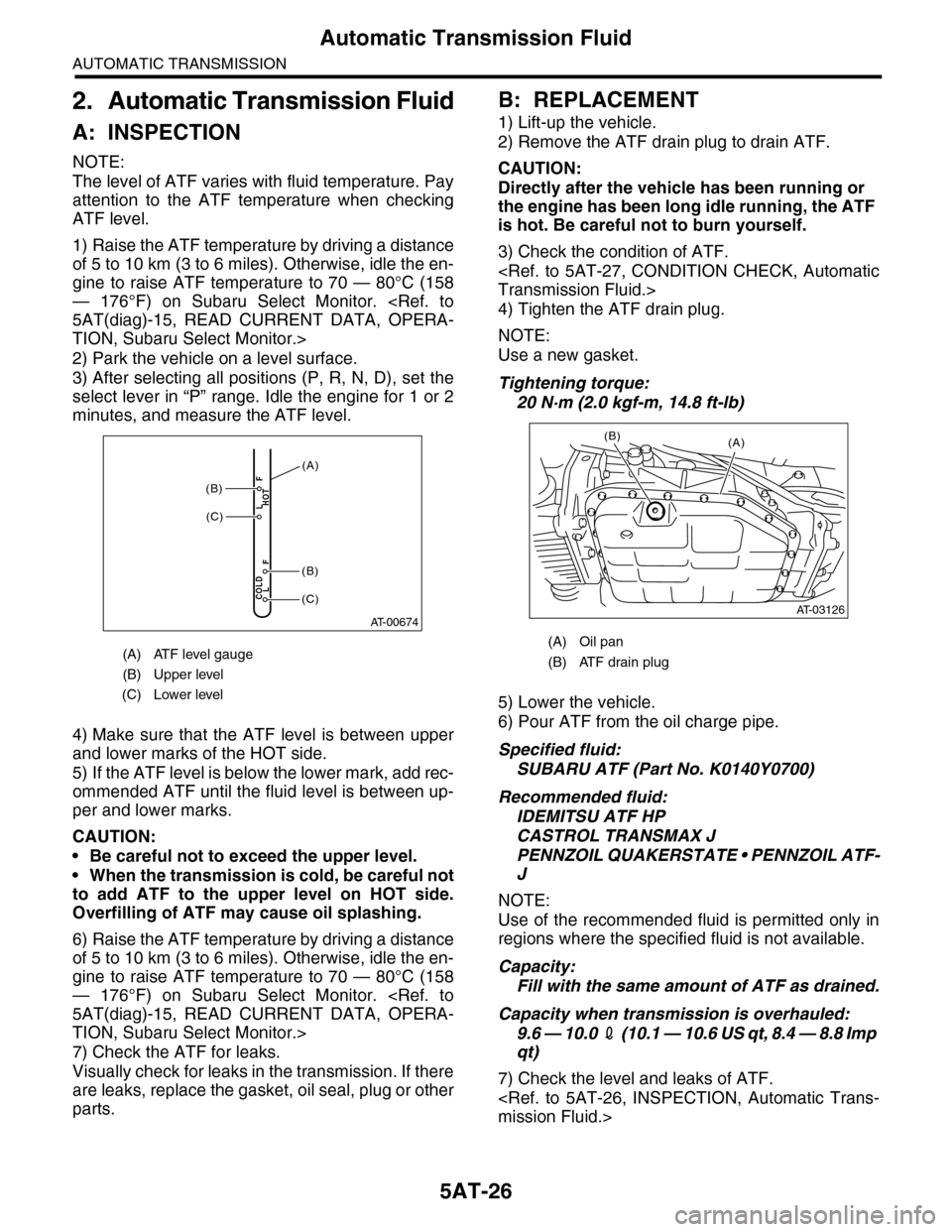

A: INSPECTION

NOTE:

The level of ATF varies with fluid temperature. Pay

attention to the ATF temperature when checking

ATF level.

1) Raise the ATF temperature by driving a distance

of 5 to 10 km (3 to 6 miles). Otherwise, idle the en-

gine to raise ATF temperature to 70 — 80°C (158

— 176°F) on Subaru Select Monitor.

TION, Subaru Select Monitor.>

2) Park the vehicle on a level surface.

3) After selecting all positions (P, R, N, D), set the

select lever in “P” range. Idle the engine for 1 or 2

minutes, and measure the ATF level.

4) Make sure that the ATF level is between upper

and lower marks of the HOT side.

5) If the ATF level is below the lower mark, add rec-

ommended ATF until the fluid level is between up-

per and lower marks.

CAUTION:

•Be careful not to exceed the upper level.

•When the transmission is cold, be careful not

to add ATF to the upper level on HOT side.

Overfilling of ATF may cause oil splashing.

6) Raise the ATF temperature by driving a distance

of 5 to 10 km (3 to 6 miles). Otherwise, idle the en-

gine to raise ATF temperature to 70 — 80°C (158

— 176°F) on Subaru Select Monitor.

TION, Subaru Select Monitor.>

7) Check the ATF for leaks.

Visually check for leaks in the transmission. If there

are leaks, replace the gasket, oil seal, plug or other

parts.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the ATF drain plug to drain ATF.

CAUTION:

Directly after the vehicle has been running or

the engine has been long idle running, the ATF

is hot. Be careful not to burn yourself.

3) Check the condition of ATF.

4) Tighten the ATF drain plug.

NOTE:

Use a new gasket.

Tightening torque:

20 N·m (2.0 kgf-m, 14.8 ft-lb)

5) Lower the vehicle.

6) Pour ATF from the oil charge pipe.

Specified fluid:

SUBARU ATF (Part No. K0140Y0700)

Recommended fluid:

IDEMITSU ATF HP

CASTROL TRANSMAX J

PENNZOIL QUAKERSTATE • PENNZOIL ATF-

J

NOTE:

Use of the recommended fluid is permitted only in

regions where the specified fluid is not available.

Capacity:

Fill with the same amount of ATF as drained.

Capacity when transmission is overhauled:

9.6 — 10.0 2 ( 1 0 . 1 — 1 0 . 6 U S q t , 8 . 4 — 8 . 8 I m p

qt)

7) Check the level and leaks of ATF.

(A) ATF level gauge

(B) Upper level

(C) Lower level

AT-00674

COLDLF

HOTLF(C)

(C)

(B)

(B)

(A)

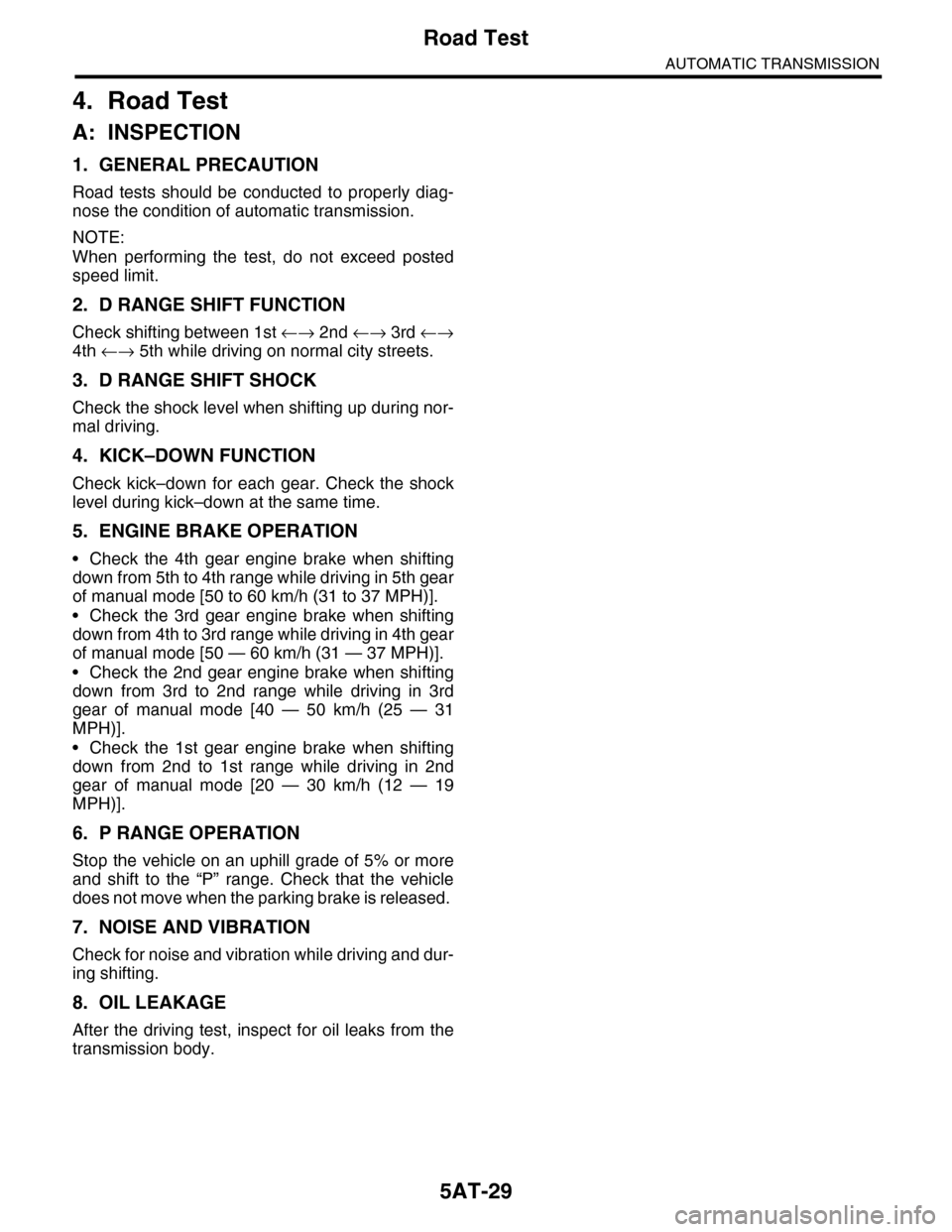

(A) Oil pan

(B) ATF drain plug

(A)

AT-03126

(B)

Page 2045 of 2453

5AT-29

Road Test

AUTOMATIC TRANSMISSION

4. Road Test

A: INSPECTION

1. GENERAL PRECAUTION

Road tests should be conducted to properly diag-

nose the condition of automatic transmission.

NOTE:

When performing the test, do not exceed posted

speed limit.

2. D RANGE SHIFT FUNCTION

Check shifting between 1st ←→ 2nd ←→ 3rd ←→

4th ←→ 5th while driving on normal city streets.

3. D RANGE SHIFT SHOCK

Check the shock level when shifting up during nor-

mal driving.

4. KICK–DOWN FUNCTION

Check kick–down for each gear. Check the shock

level during kick–down at the same time.

5. ENGINE BRAKE OPERATION

•Check the 4th gear engine brake when shifting

down from 5th to 4th range while driving in 5th gear

of manual mode [50 to 60 km/h (31 to 37 MPH)].

•Check the 3rd gear engine brake when shifting

down from 4th to 3rd range while driving in 4th gear

of manual mode [50 — 60 km/h (31 — 37 MPH)].

•Check the 2nd gear engine brake when shifting

down from 3rd to 2nd range while driving in 3rd

gear of manual mode [40 — 50 km/h (25 — 31

MPH)].

•Check the 1st gear engine brake when shifting

down from 2nd to 1st range while driving in 2nd

gear of manual mode [20 — 30 km/h (12 — 19

MPH)].

6. P RANGE OPERATION

Stop the vehicle on an uphill grade of 5% or more

and shift to the “P” range. Check that the vehicle

does not move when the parking brake is released.

7. NOISE AND VIBRATION

Check for noise and vibration while driving and dur-

ing shifting.

8. OIL LEAKAGE

After the driving test, inspect for oil leaks from the

transmission body.