engine SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2144 of 2453

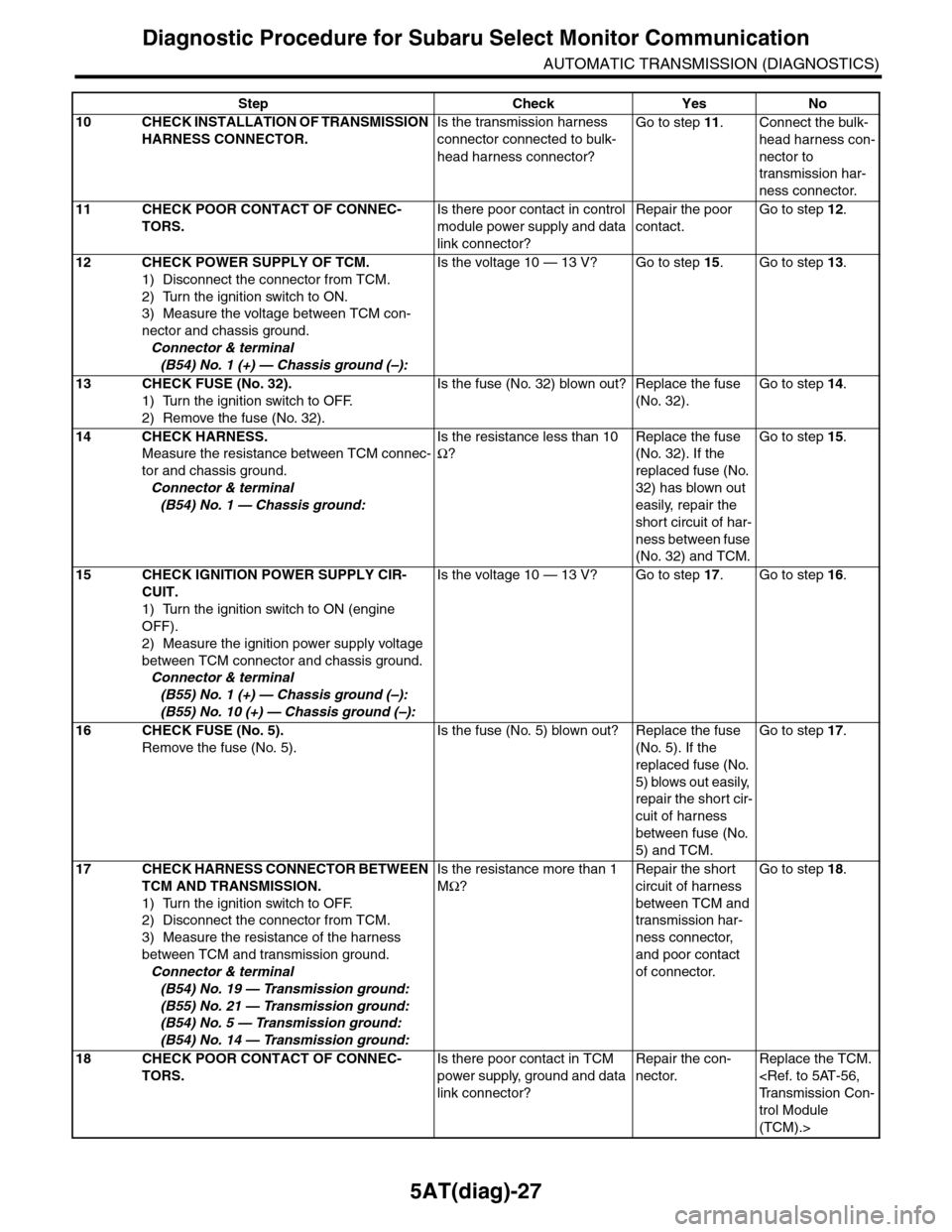

5AT(diag)-27

Diagnostic Procedure for Subaru Select Monitor Communication

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

10 CHECK INSTALLATION OF TRANSMISSION

HARNESS CONNECTOR.

Is the transmission harness

connector connected to bulk-

head harness connector?

Go to step 11.Connect the bulk-

head harness con-

nector to

transmission har-

ness connector.

11 CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in control

module power supply and data

link connector?

Repair the poor

contact.

Go to step 12.

12 CHECK POWER SUPPLY OF TCM.

1) Disconnect the connector from TCM.

2) Turn the ignition switch to ON.

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 1 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 15.Go to step 13.

13 CHECK FUSE (No. 32).

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 32).

Is the fuse (No. 32) blown out? Replace the fuse

(No. 32).

Go to step 14.

14 CHECK HARNESS.

Measure the resistance between TCM connec-

tor and chassis ground.

Connector & terminal

(B54) No. 1 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the fuse

(No. 32). If the

replaced fuse (No.

32) has blown out

easily, repair the

short circuit of har-

ness between fuse

(No. 32) and TCM.

Go to step 15.

15 CHECK IGNITION POWER SUPPLY CIR-

CUIT.

1) Turn the ignition switch to ON (engine

OFF).

2) Measure the ignition power supply voltage

between TCM connector and chassis ground.

Connector & terminal

(B55) No. 1 (+) — Chassis ground (–):

(B55) No. 10 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 17.Go to step 16.

16 CHECK FUSE (No. 5).

Remove the fuse (No. 5).

Is the fuse (No. 5) blown out? Replace the fuse

(No. 5). If the

replaced fuse (No.

5) blows out easily,

repair the short cir-

cuit of harness

between fuse (No.

5) and TCM.

Go to step 17.

17 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM.

3) Measure the resistance of the harness

between TCM and transmission ground.

Connector & terminal

(B54) No. 19 — Transmission ground:

(B55) No. 21 — Transmission ground:

(B54) No. 5 — Transmission ground:

(B54) No. 14 — Transmission ground:

Is the resistance more than 1

MΩ?

Repair the short

circuit of harness

between TCM and

transmission har-

ness connector,

and poor contact

of connector.

Go to step 18.

18 CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in TCM

power supply, ground and data

link connector?

Repair the con-

nector.

Replace the TCM.

trol Module

(TCM).>

Step Check Yes No

Page 2145 of 2453

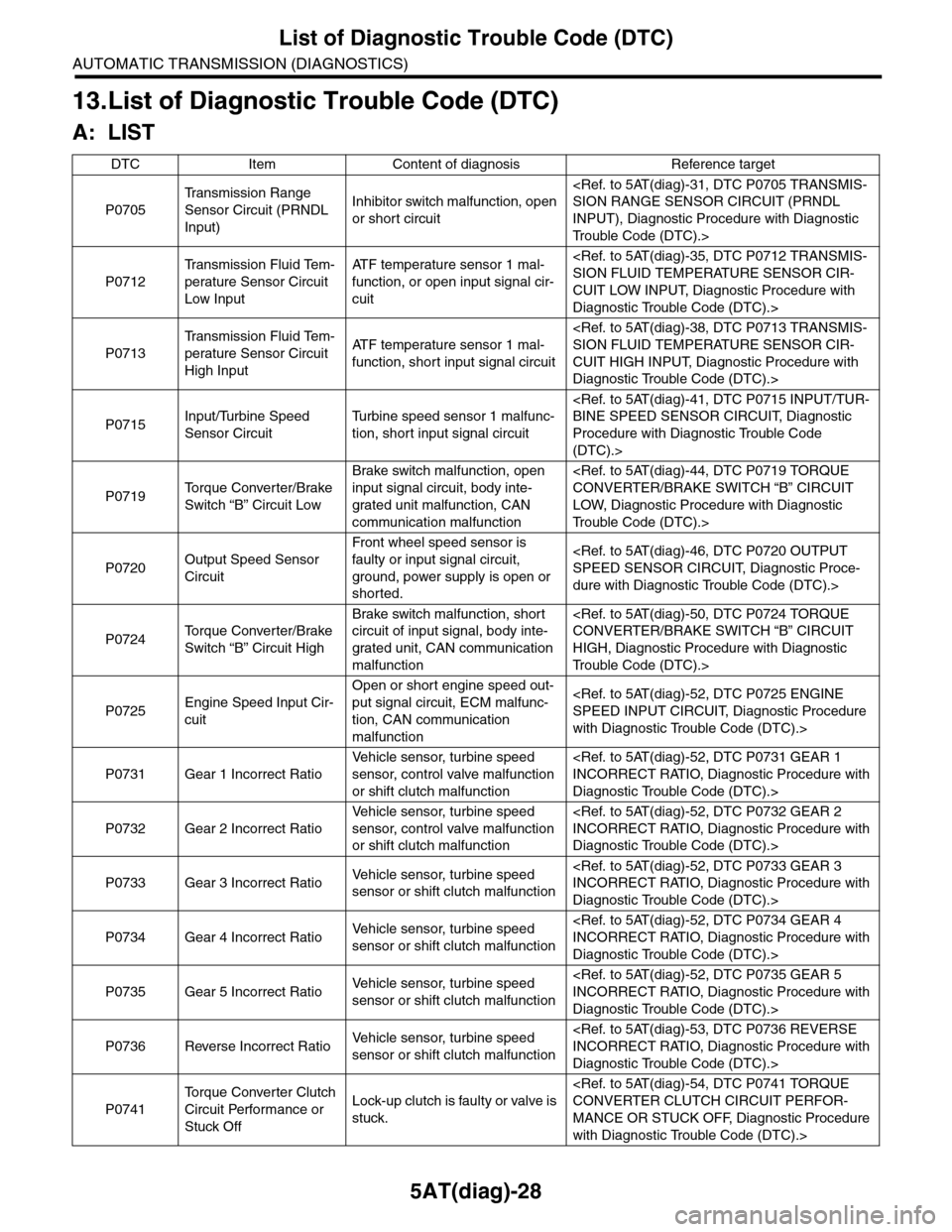

5AT(diag)-28

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

13.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Content of diagnosis Reference target

P0705

Tr a n s m i s s i o n R a n g e

Sensor Circuit (PRNDL

Input)

Inhibitor switch malfunction, open

or short circuit

INPUT), Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0712

Tr a n s m i s s i o n F l u i d Te m -

perature Sensor Circuit

Low Input

AT F t e m p e r a t u r e s e n s o r 1 m a l -

function, or open input signal cir-

cuit

CUIT LOW INPUT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0713

Tr a n s m i s s i o n F l u i d Te m -

perature Sensor Circuit

High Input

AT F t e m p e r a t u r e s e n s o r 1 m a l -

function, short input signal circuit

CUIT HIGH INPUT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0715Input/Turbine Speed

Sensor Circuit

Tu r b i n e s p e e d s e n s o r 1 m a l f u n c -

tion, short input signal circuit

Procedure with Diagnostic Trouble Code

(DTC).>

P0719To r q u e C o n v e r t e r / B r a k e

Switch “B” Circuit Low

Brake switch malfunction, open

input signal circuit, body inte-

grated unit malfunction, CAN

communication malfunction

LOW, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0720Output Speed Sensor

Circuit

Front wheel speed sensor is

faulty or input signal circuit,

ground, power supply is open or

shorted.

dure with Diagnostic Trouble Code (DTC).>

P0724To r q u e C o n v e r t e r / B r a k e

Switch “B” Circuit High

Brake switch malfunction, short

circuit of input signal, body inte-

grated unit, CAN communication

malfunction

HIGH, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0725Engine Speed Input Cir-

cuit

Open or short engine speed out-

put signal circuit, ECM malfunc-

tion, CAN communication

malfunction

with Diagnostic Trouble Code (DTC).>

P0731 Gear 1 Incorrect Ratio

Ve h i c l e s e n s o r, t u r b i n e s p e e d

sensor, control valve malfunction

or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0732 Gear 2 Incorrect Ratio

Ve h i c l e s e n s o r, t u r b i n e s p e e d

sensor, control valve malfunction

or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0733 Gear 3 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0734 Gear 4 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0735 Gear 5 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0736 Reverse Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0741

To r q u e C o n v e r t e r C l u t c h

Circuit Performance or

Stuck Off

Lock-up clutch is faulty or valve is

stuck.

MANCE OR STUCK OFF, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

Page 2147 of 2453

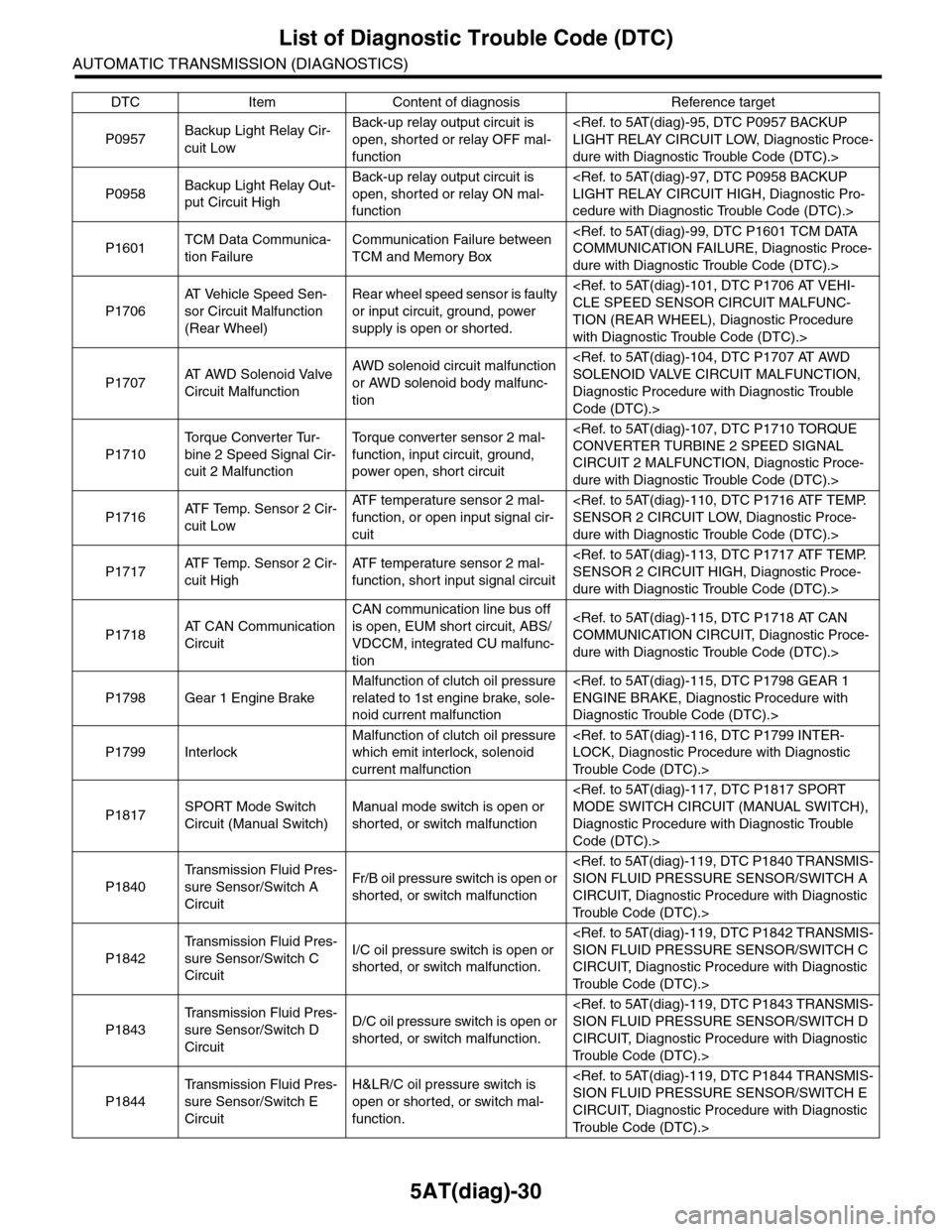

5AT(diag)-30

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

P0957Backup Light Relay Cir-

cuit Low

Back-up relay output circuit is

open, shorted or relay OFF mal-

function

dure with Diagnostic Trouble Code (DTC).>

P0958Backup Light Relay Out-

put Circuit High

Back-up relay output circuit is

open, shorted or relay ON mal-

function

cedure with Diagnostic Trouble Code (DTC).>

P1601TCM Data Communica-

tion Failure

Communication Failure between

TCM and Memory Box

dure with Diagnostic Trouble Code (DTC).>

P1706

AT Ve h i c l e S p e e d S e n -

sor Circuit Malfunction

(Rear Wheel)

Rear wheel speed sensor is faulty

or input circuit, ground, power

supply is open or shorted.

TION (REAR WHEEL), Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1707AT A W D S o l e n o i d V a l v e

Circuit Malfunction

AWD solenoid circuit malfunction

or AWD solenoid body malfunc-

tion

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1710

To r q u e C o n v e r t e r Tu r -

bine 2 Speed Signal Cir-

cuit 2 Malfunction

To r q u e c o n v e r t e r s e n s o r 2 m a l -

function, input circuit, ground,

power open, short circuit

CIRCUIT 2 MALFUNCTION, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P1716AT F Te m p . S e n s o r 2 C i r -

cuit Low

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, or open input signal cir-

cuit

dure with Diagnostic Trouble Code (DTC).>

P1717AT F Te m p . S e n s o r 2 C i r -

cuit High

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, short input signal circuit

dure with Diagnostic Trouble Code (DTC).>

P1718AT C A N C o m m u n i c a t i o n

Circuit

CAN communication line bus off

is open, EUM short circuit, ABS/

VDCCM, integrated CU malfunc-

tion

dure with Diagnostic Trouble Code (DTC).>

P1798 Gear 1 Engine Brake

Malfunction of clutch oil pressure

related to 1st engine brake, sole-

noid current malfunction

Diagnostic Trouble Code (DTC).>

P1799 Interlock

Malfunction of clutch oil pressure

which emit interlock, solenoid

current malfunction

Tr o u b l e C o d e ( D T C ) . >

P1817SPORT Mode Switch

Circuit (Manual Switch)

Manual mode switch is open or

shorted, or switch malfunction

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1840

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch A

Circuit

Fr/B oil pressure switch is open or

shorted, or switch malfunction

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1842

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch C

Circuit

I/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1843

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch D

Circuit

D/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1844

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch E

Circuit

H&LR/C oil pressure switch is

open or shorted, or switch mal-

function.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

DTC Item Content of diagnosis Reference target

Page 2153 of 2453

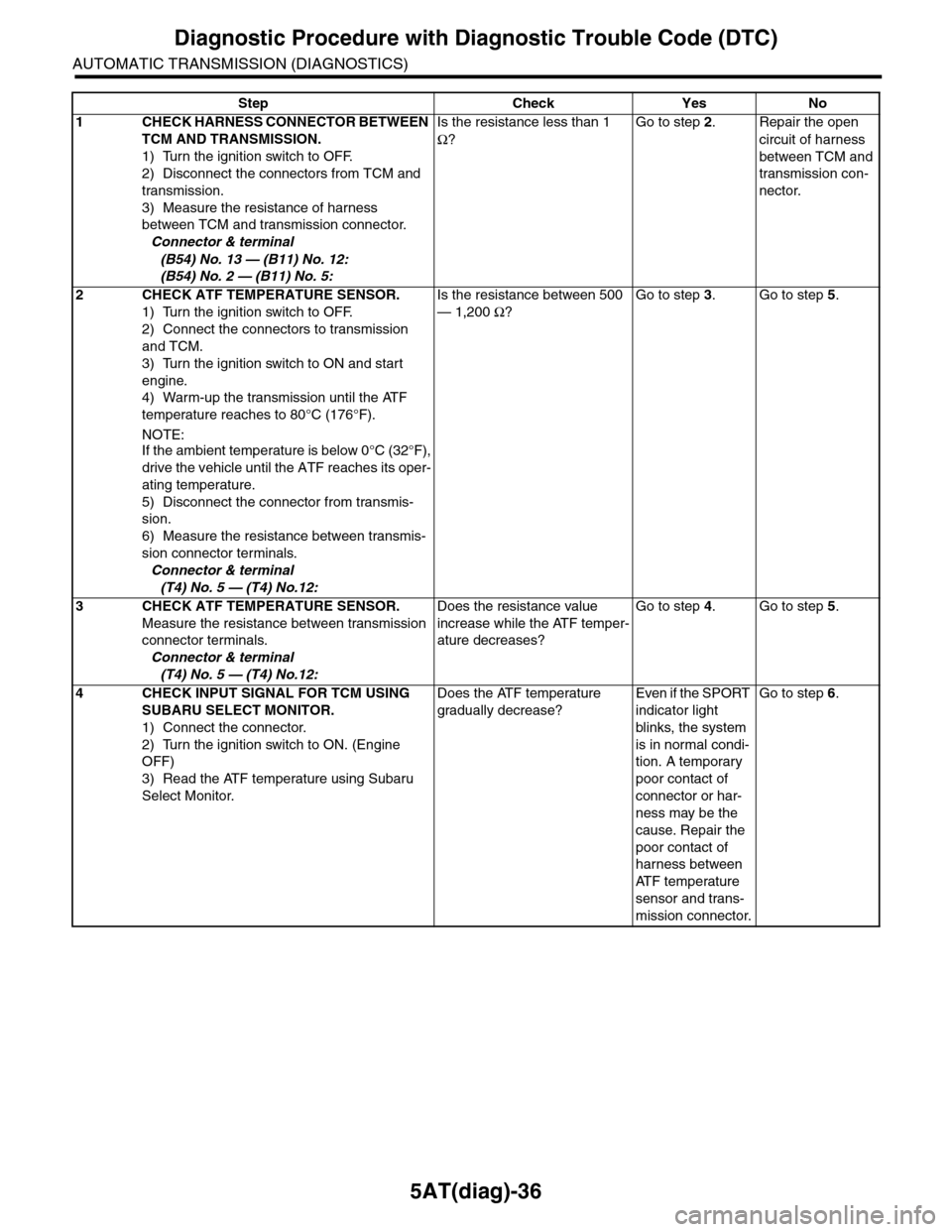

5AT(diag)-36

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

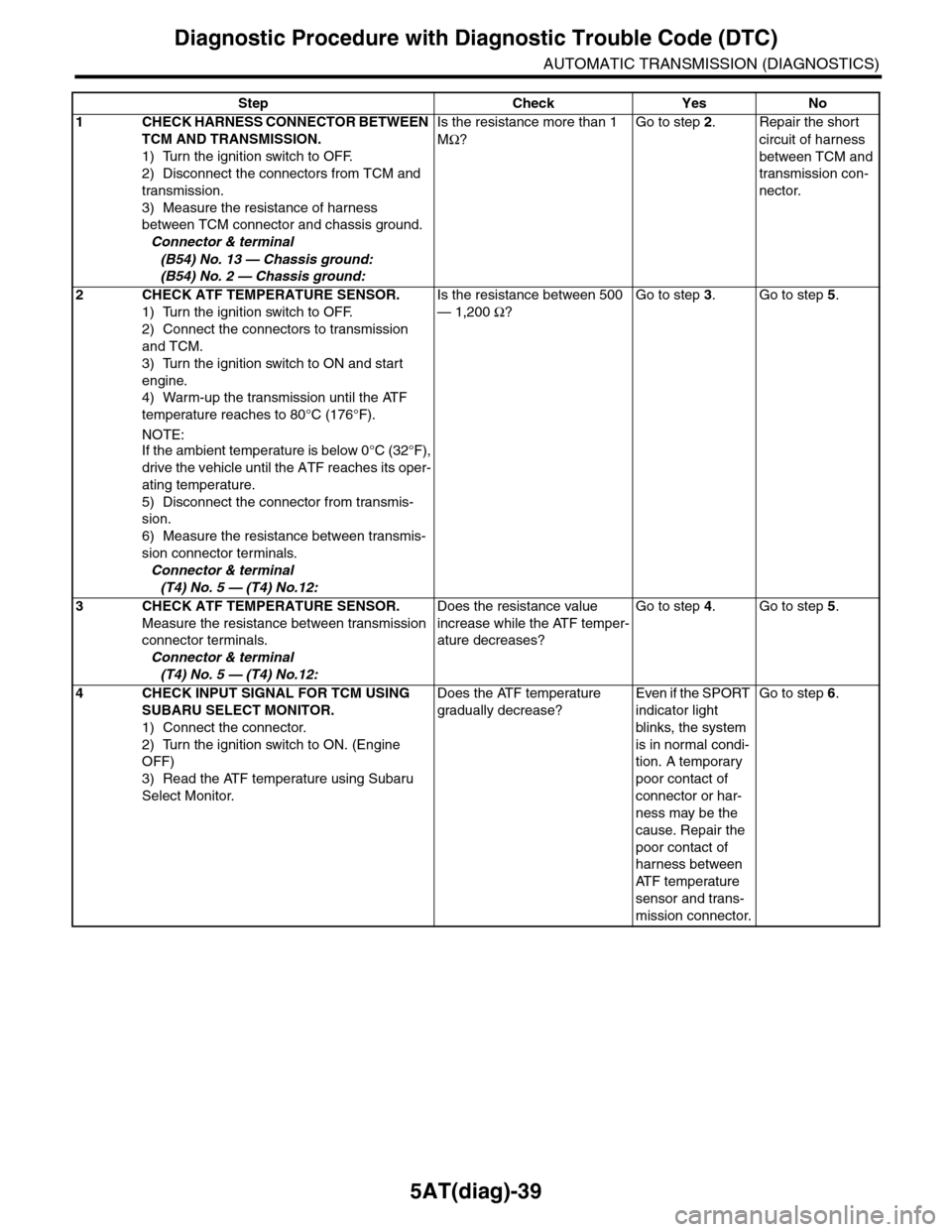

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B54) No. 13 — (B11) No. 12:

(B54) No. 2 — (B11) No. 5:

Is the resistance less than 1

Ω?

Go to step 2.Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2CHECK ATF TEMPERATURE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the connectors to transmission

and TCM.

3) Turn the ignition switch to ON and start

engine.

4) Warm-up the transmission until the ATF

temperature reaches to 80°C (176°F).

NOTE:

If the ambient temperature is below 0°C (32°F),

drive the vehicle until the ATF reaches its oper-

ating temperature.

5) Disconnect the connector from transmis-

sion.

6) Measure the resistance between transmis-

sion connector terminals.

Connector & terminal

(T4) No. 5 — (T4) No.12:

Is the resistance between 500

— 1,200 Ω?

Go to step 3.Go to step 5.

3CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission

connector terminals.

Connector & terminal

(T4) No. 5 — (T4) No.12:

Does the resistance value

increase while the ATF temper-

ature decreases?

Go to step 4.Go to step 5.

4CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connector.

2) Turn the ignition switch to ON. (Engine

OFF)

3) Read the ATF temperature using Subaru

Select Monitor.

Does the ATF temperature

gradually decrease?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness between

AT F t e m p e r a t u r e

sensor and trans-

mission connector.

Go to step 6.

Page 2156 of 2453

5AT(diag)-39

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM connector and chassis ground.

Connector & terminal

(B54) No. 13 — Chassis ground:

(B54) No. 2 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 2.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

2CHECK ATF TEMPERATURE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the connectors to transmission

and TCM.

3) Turn the ignition switch to ON and start

engine.

4) Warm-up the transmission until the ATF

temperature reaches to 80°C (176°F).

NOTE:

If the ambient temperature is below 0°C (32°F),

drive the vehicle until the ATF reaches its oper-

ating temperature.

5) Disconnect the connector from transmis-

sion.

6) Measure the resistance between transmis-

sion connector terminals.

Connector & terminal

(T4) No. 5 — (T4) No.12:

Is the resistance between 500

— 1,200 Ω?

Go to step 3.Go to step 5.

3CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission

connector terminals.

Connector & terminal

(T4) No. 5 — (T4) No.12:

Does the resistance value

increase while the ATF temper-

ature decreases?

Go to step 4.Go to step 5.

4CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connector.

2) Turn the ignition switch to ON. (Engine

OFF)

3) Read the ATF temperature using Subaru

Select Monitor.

Does the ATF temperature

gradually decrease?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness between

AT F t e m p e r a t u r e

sensor and trans-

mission connector.

Go to step 6.

Page 2159 of 2453

5AT(diag)-42

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

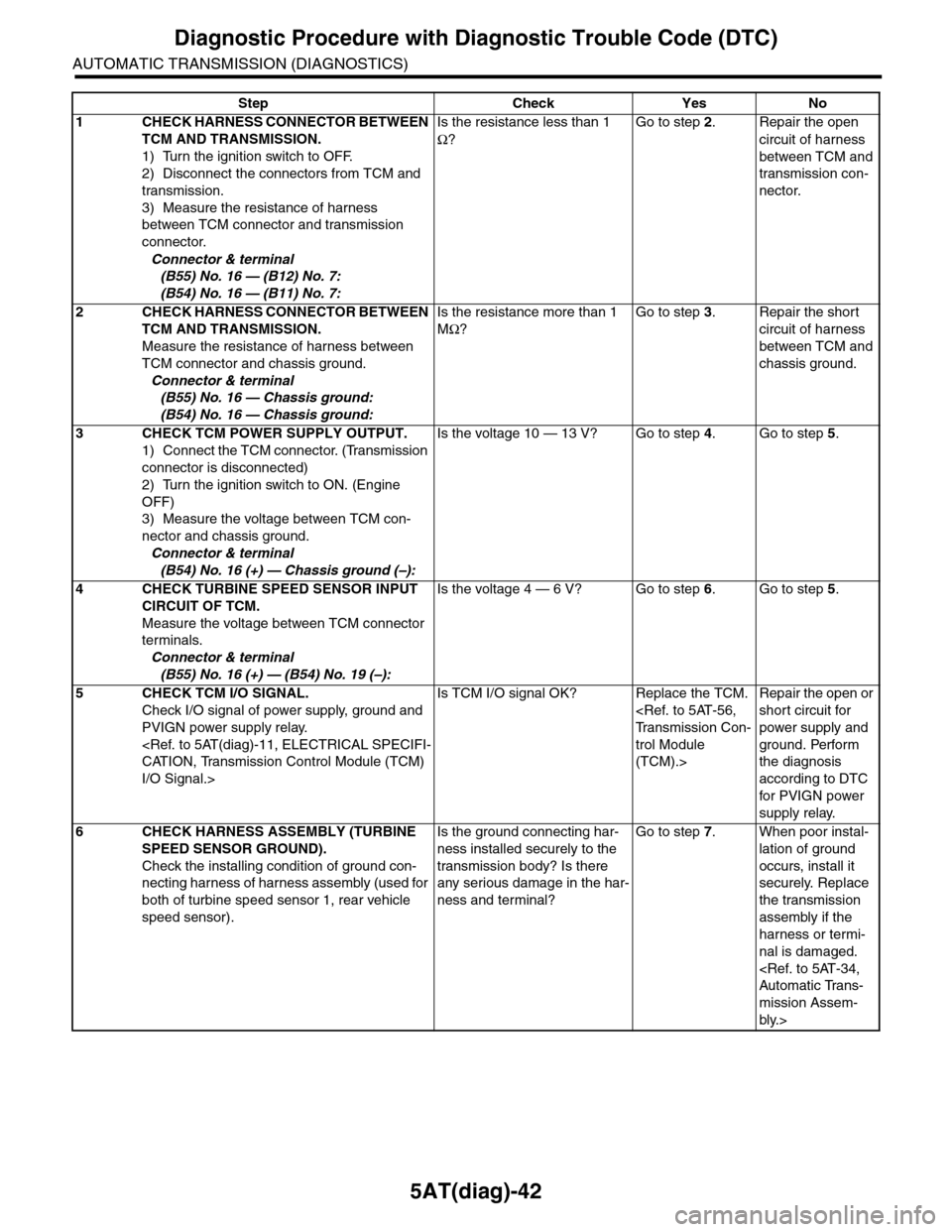

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM connector and transmission

connector.

Connector & terminal

(B55) No. 16 — (B12) No. 7:

(B54) No. 16 — (B11) No. 7:

Is the resistance less than 1

Ω?

Go to step 2.Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 16 — Chassis ground:

(B54) No. 16 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the short

circuit of harness

between TCM and

chassis ground.

3CHECK TCM POWER SUPPLY OUTPUT.

1) Connect the TCM connector. (Transmission

connector is disconnected)

2) Turn the ignition switch to ON. (Engine

OFF)

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 16 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 4.Go to step 5.

4CHECK TURBINE SPEED SENSOR INPUT

CIRCUIT OF TCM.

Measure the voltage between TCM connector

terminals.

Connector & terminal

(B55) No. 16 (+) — (B54) No. 19 (–):

Is the voltage 4 — 6 V? Go to step 6.Go to step 5.

5CHECK TCM I/O SIGNAL.

Check I/O signal of power supply, ground and

PVIGN power supply relay.

I/O Signal.>

Is TCM I/O signal OK? Replace the TCM.

trol Module

(TCM).>

Repair the open or

short circuit for

power supply and

ground. Perform

the diagnosis

according to DTC

for PVIGN power

supply relay.

6CHECK HARNESS ASSEMBLY (TURBINE

SPEED SENSOR GROUND).

Check the installing condition of ground con-

necting harness of harness assembly (used for

both of turbine speed sensor 1, rear vehicle

speed sensor).

Is the ground connecting har-

ness installed securely to the

transmission body? Is there

any serious damage in the har-

ness and terminal?

Go to step 7.When poor instal-

lation of ground

occurs, install it

securely. Replace

the transmission

assembly if the

harness or termi-

nal is damaged.

mission Assem-

bly.>

Page 2160 of 2453

5AT(diag)-43

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

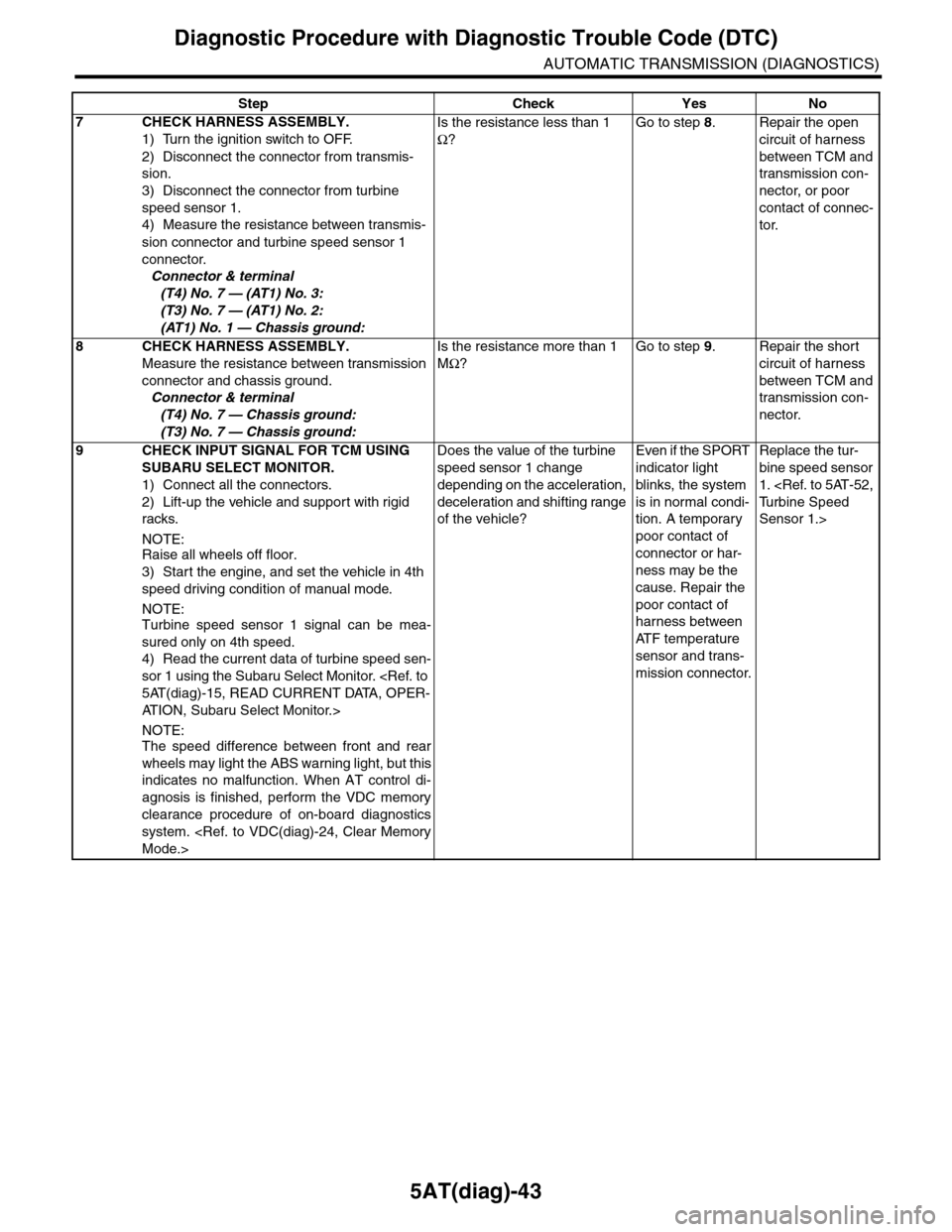

7CHECK HARNESS ASSEMBLY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Disconnect the connector from turbine

speed sensor 1.

4) Measure the resistance between transmis-

sion connector and turbine speed sensor 1

connector.

Connector & terminal

(T4) No. 7 — (AT1) No. 3:

(T3) No. 7 — (AT1) No. 2:

(AT1) No. 1 — Chassis ground:

Is the resistance less than 1

Ω?

Go to step 8.Repair the open

circuit of harness

between TCM and

transmission con-

nector, or poor

contact of connec-

tor.

8CHECK HARNESS ASSEMBLY.

Measure the resistance between transmission

connector and chassis ground.

Connector & terminal

(T4) No. 7 — Chassis ground:

(T3) No. 7 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 9.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

9CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:Raise all wheels off floor.

3) Start the engine, and set the vehicle in 4th

speed driving condition of manual mode.

NOTE:Turbine speed sensor 1 signal can be mea-

sured only on 4th speed.

4) Read the current data of turbine speed sen-

sor 1 using the Subaru Select Monitor.

AT I O N , S u b a r u S e l e c t M o n i t o r . >

NOTE:The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Does the value of the turbine

speed sensor 1 change

depending on the acceleration,

deceleration and shifting range

of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness between

AT F t e m p e r a t u r e

sensor and trans-

mission connector.

Replace the tur-

bine speed sensor

1.

Sensor 1.>

Step Check Yes No

Page 2162 of 2453

5AT(diag)-45

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

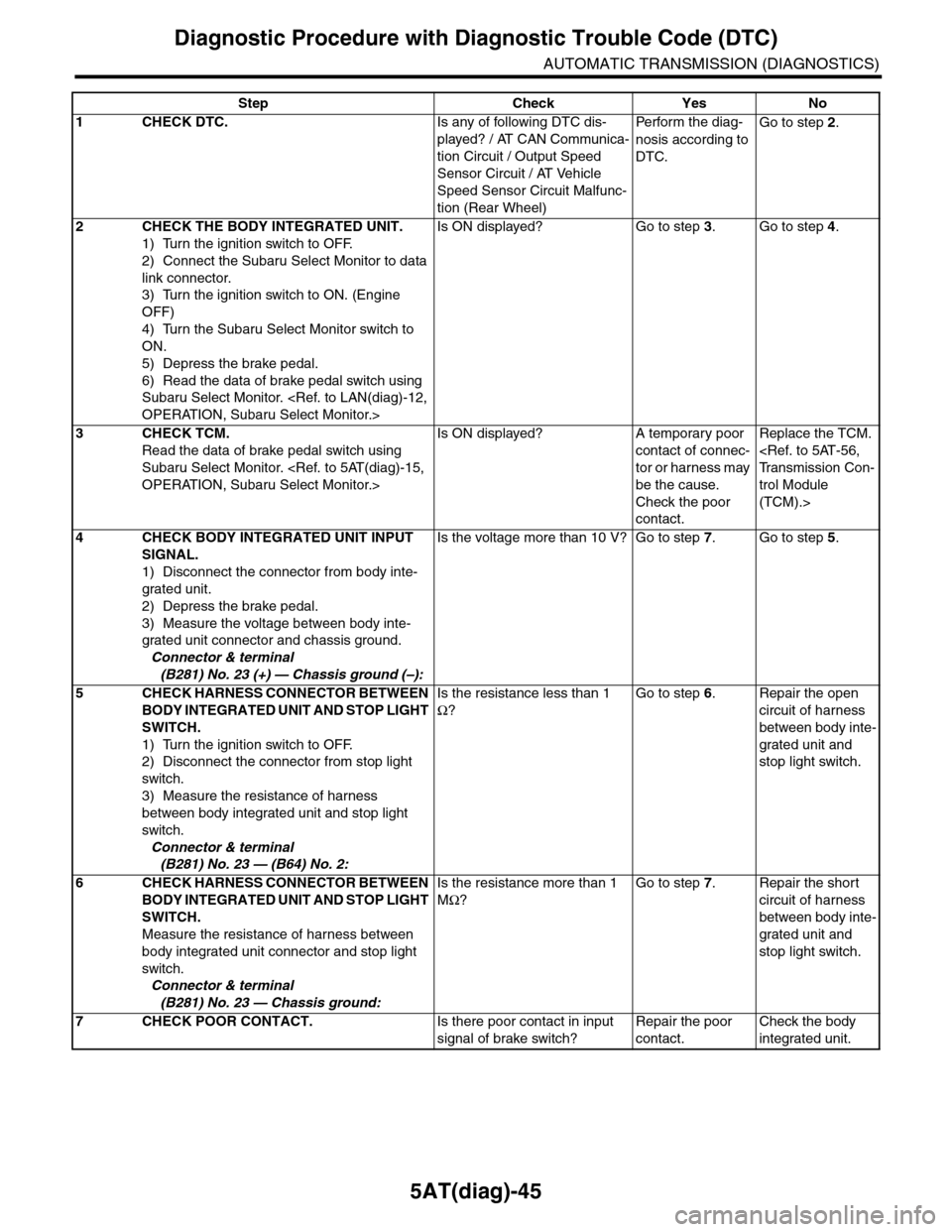

1CHECK DTC.Is any of following DTC dis-

played? / AT CAN Communica-

tion Circuit / Output Speed

Sensor Circuit / AT Vehicle

Speed Sensor Circuit Malfunc-

tion (Rear Wheel)

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK THE BODY INTEGRATED UNIT.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON. (Engine

OFF)

4) Turn the Subaru Select Monitor switch to

ON.

5) Depress the brake pedal.

6) Read the data of brake pedal switch using

Subaru Select Monitor.

Is ON displayed? Go to step 3.Go to step 4.

3CHECK TCM.

Read the data of brake pedal switch using

Subaru Select Monitor.

Is ON displayed? A temporary poor

contact of connec-

tor or harness may

be the cause.

Check the poor

contact.

Replace the TCM.

trol Module

(TCM).>

4CHECK BODY INTEGRATED UNIT INPUT

SIGNAL.

1) Disconnect the connector from body inte-

grated unit.

2) Depress the brake pedal.

3) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(B281) No. 23 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 7.Go to step 5.

5CHECK HARNESS CONNECTOR BETWEEN

BODY INTEGRATED UNIT AND STOP LIGHT

SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from stop light

switch.

3) Measure the resistance of harness

between body integrated unit and stop light

switch.

Connector & terminal

(B281) No. 23 — (B64) No. 2:

Is the resistance less than 1

Ω?

Go to step 6.Repair the open

circuit of harness

between body inte-

grated unit and

stop light switch.

6CHECK HARNESS CONNECTOR BETWEEN

BODY INTEGRATED UNIT AND STOP LIGHT

SWITCH.

Measure the resistance of harness between

body integrated unit connector and stop light

switch.

Connector & terminal

(B281) No. 23 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the short

circuit of harness

between body inte-

grated unit and

stop light switch.

7CHECK POOR CONTACT.Is there poor contact in input

signal of brake switch?

Repair the poor

contact.

Check the body

integrated unit.

Page 2164 of 2453

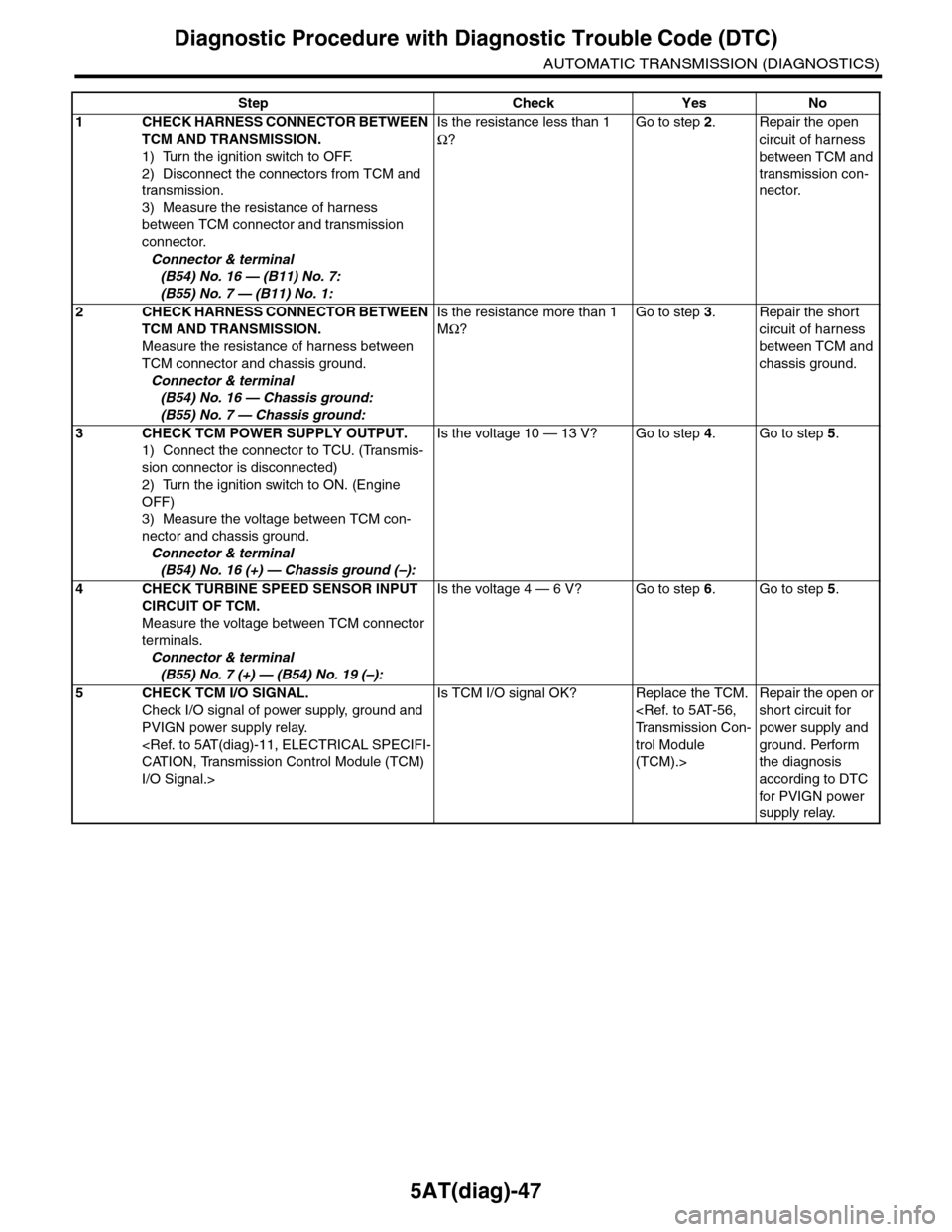

5AT(diag)-47

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

1CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM connector and transmission

connector.

Connector & terminal

(B54) No. 16 — (B11) No. 7:

(B55) No. 7 — (B11) No. 1:

Is the resistance less than 1

Ω?

Go to step 2.Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B54) No. 16 — Chassis ground:

(B55) No. 7 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the short

circuit of harness

between TCM and

chassis ground.

3CHECK TCM POWER SUPPLY OUTPUT.

1) Connect the connector to TCU. (Transmis-

sion connector is disconnected)

2) Turn the ignition switch to ON. (Engine

OFF)

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 16 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 4.Go to step 5.

4CHECK TURBINE SPEED SENSOR INPUT

CIRCUIT OF TCM.

Measure the voltage between TCM connector

terminals.

Connector & terminal

(B55) No. 7 (+) — (B54) No. 19 (–):

Is the voltage 4 — 6 V? Go to step 6.Go to step 5.

5CHECK TCM I/O SIGNAL.

Check I/O signal of power supply, ground and

PVIGN power supply relay.

I/O Signal.>

Is TCM I/O signal OK? Replace the TCM.

trol Module

(TCM).>

Repair the open or

short circuit for

power supply and

ground. Perform

the diagnosis

according to DTC

for PVIGN power

supply relay.

Page 2165 of 2453

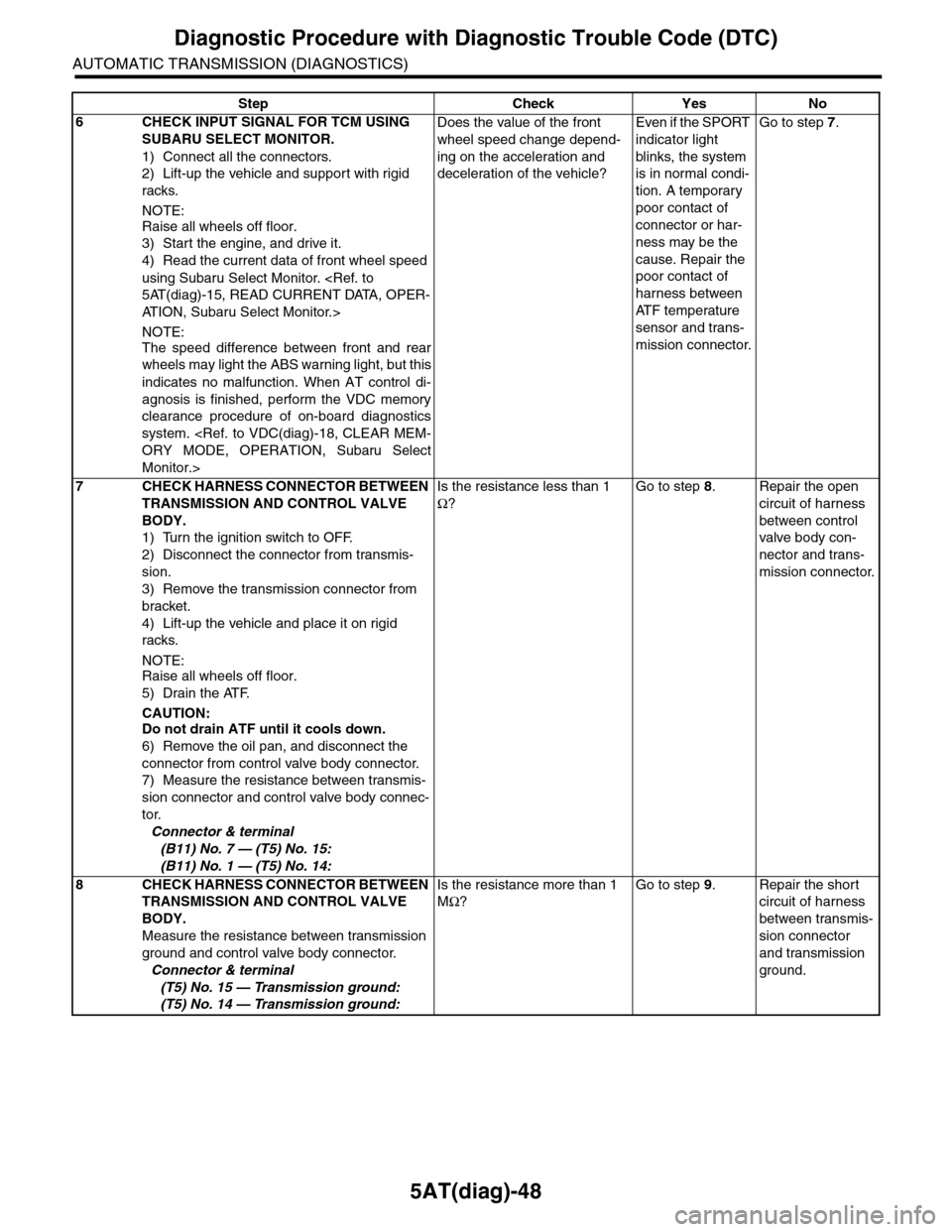

5AT(diag)-48

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

6CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:

Raise all wheels off floor.

3) Start the engine, and drive it.

4) Read the current data of front wheel speed

using Subaru Select Monitor.

AT I O N , S u b a r u S e l e c t M o n i t o r . >

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the value of the front

wheel speed change depend-

ing on the acceleration and

deceleration of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness between

AT F t e m p e r a t u r e

sensor and trans-

mission connector.

Go to step 7.

7CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:Raise all wheels off floor.

5) Drain the ATF.

CAUTION:Do not drain ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmis-

sion connector and control valve body connec-

tor.

Connector & terminal

(B11) No. 7 — (T5) No. 15:

(B11) No. 1 — (T5) No. 14:

Is the resistance less than 1

Ω?

Go to step 8.Repair the open

circuit of harness

between control

valve body con-

nector and trans-

mission connector.

8CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

Measure the resistance between transmission

ground and control valve body connector.

Connector & terminal

(T5) No. 15 — Transmission ground:

(T5) No. 14 — Transmission ground:

Is the resistance more than 1

MΩ?

Go to step 9.Repair the short

circuit of harness

between transmis-

sion connector

and transmission

ground.

Step Check Yes No