Heat SUBARU TRIBECA 2009 1.G Service Manual Online

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 827 of 2453

DS-10

Propeller Shaft

DRIVE SHAFT SYSTEM

2. Propeller Shaft

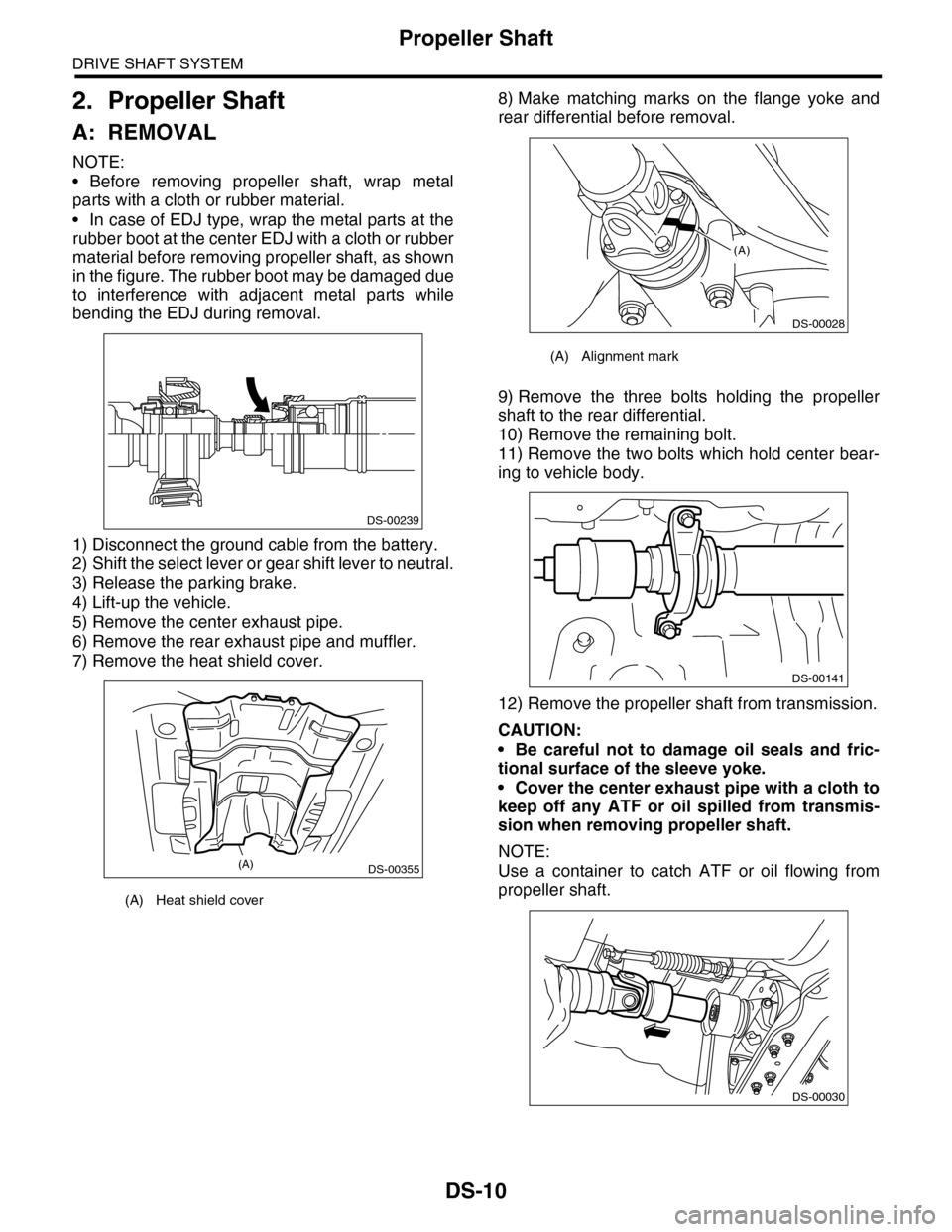

A: REMOVAL

NOTE:

•Before removing propeller shaft, wrap metal

parts with a cloth or rubber material.

•In case of EDJ type, wrap the metal parts at the

rubber boot at the center EDJ with a cloth or rubber

material before removing propeller shaft, as shown

in the figure. The rubber boot may be damaged due

to interference with adjacent metal parts while

bending the EDJ during removal.

1) Disconnect the ground cable from the battery.

2) Shift the select lever or gear shift lever to neutral.

3) Release the parking brake.

4) Lift-up the vehicle.

5) Remove the center exhaust pipe.

6) Remove the rear exhaust pipe and muffler.

7) Remove the heat shield cover.

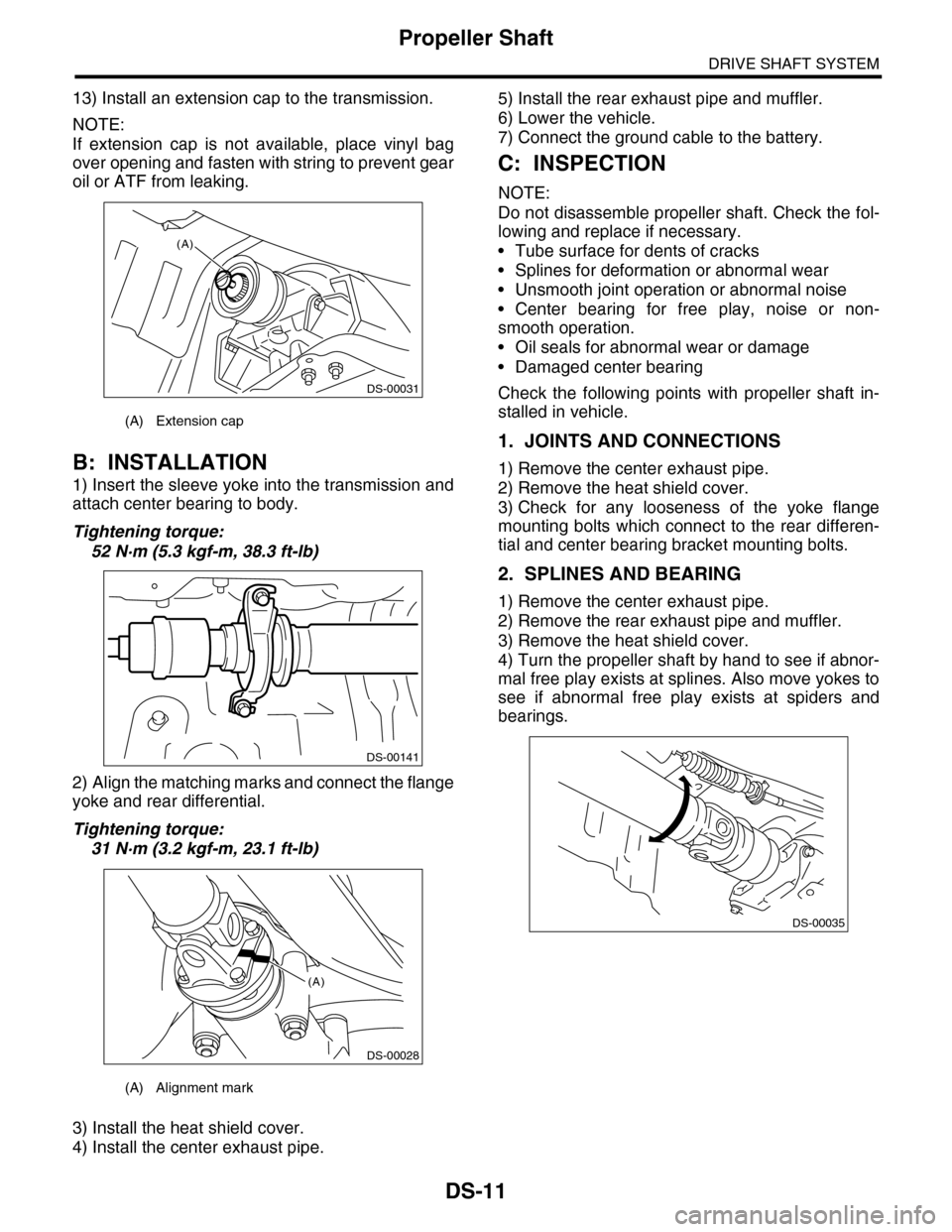

8) Make matching marks on the flange yoke and

rear differential before removal.

9) Remove the three bolts holding the propeller

shaft to the rear differential.

10) Remove the remaining bolt.

11) Remove the two bolts which hold center bear-

ing to vehicle body.

12) Remove the propeller shaft from transmission.

CAUTION:

•Be careful not to damage oil seals and fric-

tional surface of the sleeve yoke.

•Cover the center exhaust pipe with a cloth to

keep off any ATF or oil spilled from transmis-

sion when removing propeller shaft.

NOTE:

Use a container to catch ATF or oil flowing from

propeller shaft.(A) Heat shield cover

DS-00239

DS-00355(A)

(A) Alignment mark

DS-00028

(A)

DS-00141

DS-00030

Page 828 of 2453

DS-11

Propeller Shaft

DRIVE SHAFT SYSTEM

13) Install an extension cap to the transmission.

NOTE:

If extension cap is not available, place vinyl bag

over opening and fasten with string to prevent gear

oil or ATF from leaking.

B: INSTALLATION

1) Insert the sleeve yoke into the transmission and

attach center bearing to body.

Tightening torque:

52 N·m (5.3 kgf-m, 38.3 ft-lb)

2) Align the matching marks and connect the flange

yoke and rear differential.

Tightening torque:

31 N·m (3.2 kgf-m, 23.1 ft-lb)

3) Install the heat shield cover.

4) Install the center exhaust pipe.

5) Install the rear exhaust pipe and muffler.

6) Lower the vehicle.

7) Connect the ground cable to the battery.

C: INSPECTION

NOTE:

Do not disassemble propeller shaft. Check the fol-

lowing and replace if necessary.

•Tube surface for dents of cracks

•Splines for deformation or abnormal wear

•Unsmooth joint operation or abnormal noise

•Center bearing for free play, noise or non-

smooth operation.

•Oil seals for abnormal wear or damage

•Damaged center bearing

Check the following points with propeller shaft in-

stalled in vehicle.

1. JOINTS AND CONNECTIONS

1) Remove the center exhaust pipe.

2) Remove the heat shield cover.

3) Check for any looseness of the yoke flange

mounting bolts which connect to the rear differen-

tial and center bearing bracket mounting bolts.

2. SPLINES AND BEARING

1) Remove the center exhaust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Turn the propeller shaft by hand to see if abnor-

mal free play exists at splines. Also move yokes to

see if abnormal free play exists at spiders and

bearings.

(A) Extension cap

(A) Alignment mark

DS-00031

(A)

DS-00141

DS-00028

(A)

DS-00035

Page 829 of 2453

DS-12

Propeller Shaft

DRIVE SHAFT SYSTEM

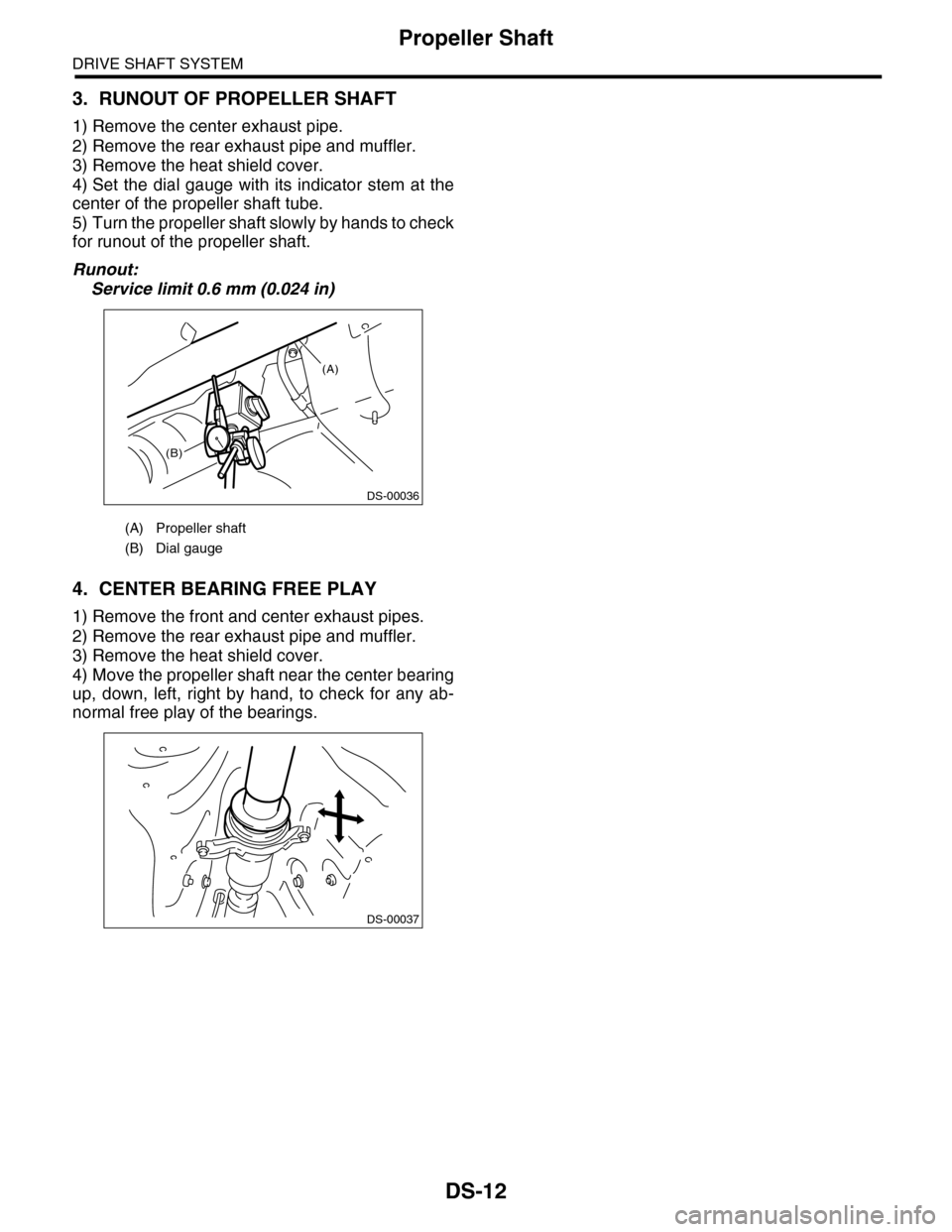

3. RUNOUT OF PROPELLER SHAFT

1) Remove the center exhaust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Set the dial gauge with its indicator stem at the

center of the propeller shaft tube.

5) Turn the propeller shaft slowly by hands to check

for runout of the propeller shaft.

Runout:

Service limit 0.6 mm (0.024 in)

4. CENTER BEARING FREE PLAY

1) Remove the front and center exhaust pipes.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Move the propeller shaft near the center bearing

up, down, left, right by hand, to check for any ab-

normal free play of the bearings.

(A) Propeller shaft

(B) Dial gauge

DS-00036

(B)

(A)

DS-00037

Page 919 of 2453

PS-39

Pipe Assembly

POWER ASSISTED SYSTEM (POWER STEERING)

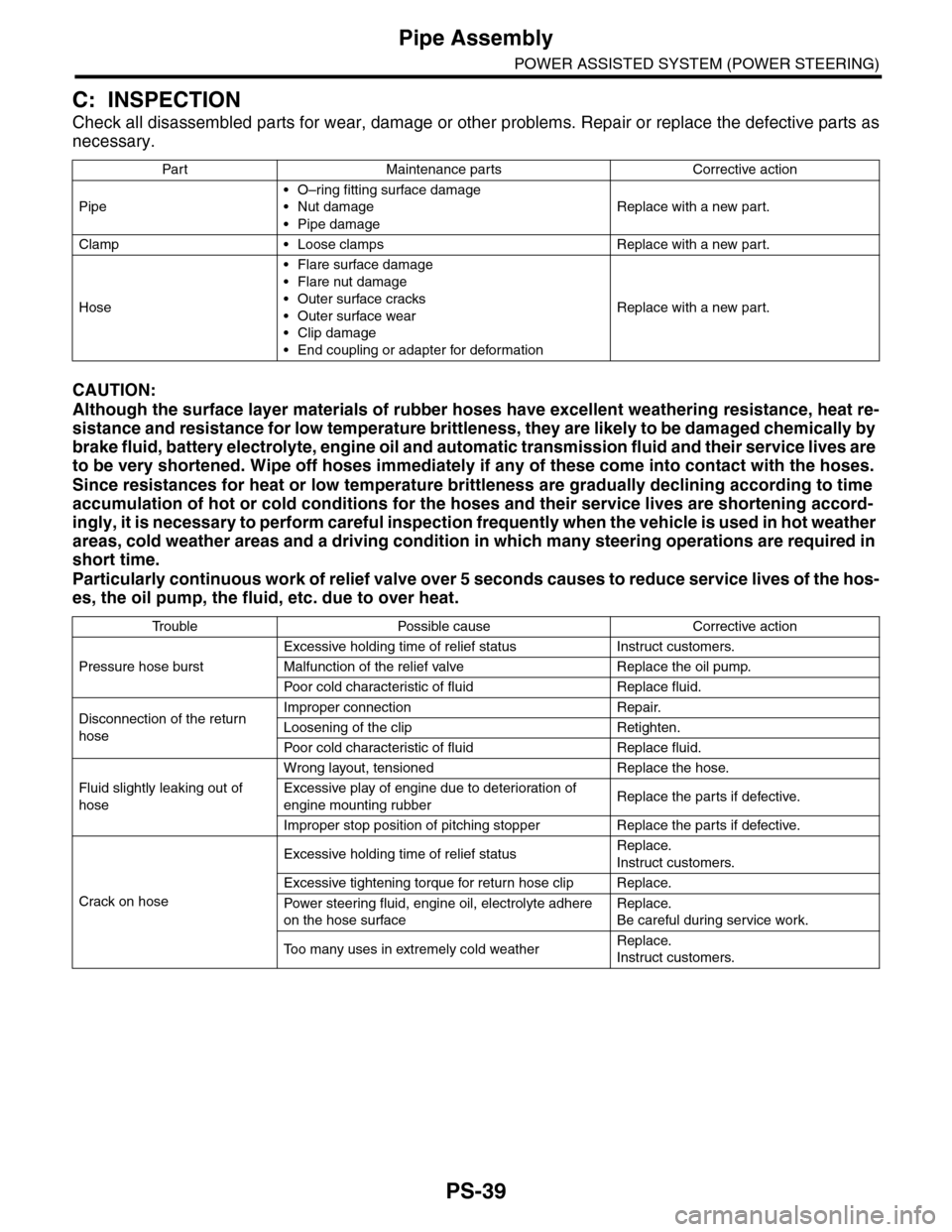

C: INSPECTION

Check all disassembled parts for wear, damage or other problems. Repair or replace the defective parts as

necessary.

CAUTION:

Although the surface layer materials of rubber hoses have excellent weathering resistance, heat re-

sistance and resistance for low temperature brittleness, they are likely to be damaged chemically by

brake fluid, battery electrolyte, engine oil and automatic transmission fluid and their service lives are

to be very shortened. Wipe off hoses immediately if any of these come into contact with the hoses.

Since resistances for heat or low temperature brittleness are gradually declining according to time

accumulation of hot or cold conditions for the hoses and their service lives are shortening accord-

ingly, it is necessary to perform careful inspection frequently when the vehicle is used in hot weather

areas, cold weather areas and a driving condition in which many steering operations are required in

short time.

Particularly continuous work of relief valve over 5 seconds causes to reduce service lives of the hos-

es, the oil pump, the fluid, etc. due to over heat.

Par t Maintenance par ts Corrective action

Pipe

•O–ring fitting surface damage

•Nut damage

•Pipe damage

Replace with a new part.

Clamp • Loose clamps Replace with a new part.

Hose

•Flare surface damage

•Flare nut damage

•Outer surface cracks

•Outer surface wear

•Clip damage

•End coupling or adapter for deformation

Replace with a new part.

Tr o u b l e P o s s i b l e c a u s e C o r r e c t i v e a c t i o n

Pressure hose burst

Excessive holding time of relief status Instruct customers.

Malfunction of the relief valve Replace the oil pump.

Poor cold character istic of fluid R eplace fluid.

Disconnection of the return

hose

Improper connection Repair.

Loosening of the clip Retighten.

Poor cold character istic of fluid R eplace fluid.

Fluid slightly leaking out of

hose

Wrong layout, tensioned Replace the hose.

Excessive play of engine due to deterioration of

engine mounting rubberReplace the parts if defective.

Improper stop position of pitching stopper Replace the parts if defective.

Crack on hose

Excessive holding time of relief statusReplace.

Instruct customers.

Excessive tightening torque for return hose clip Replace.

Power steer ing fluid, engine oil, electrolyte adhere

on the hose surface

Replace.

Be careful during service work.

To o m a n y u s e s i n e x t r e m e l y c o l d w e a t h e rReplace.

Instruct customers.

Page 1129 of 2453

CO(H6DO)-10

Engine Coolant

COOLING

3. Engine Coolant

A: REPLACEMENT

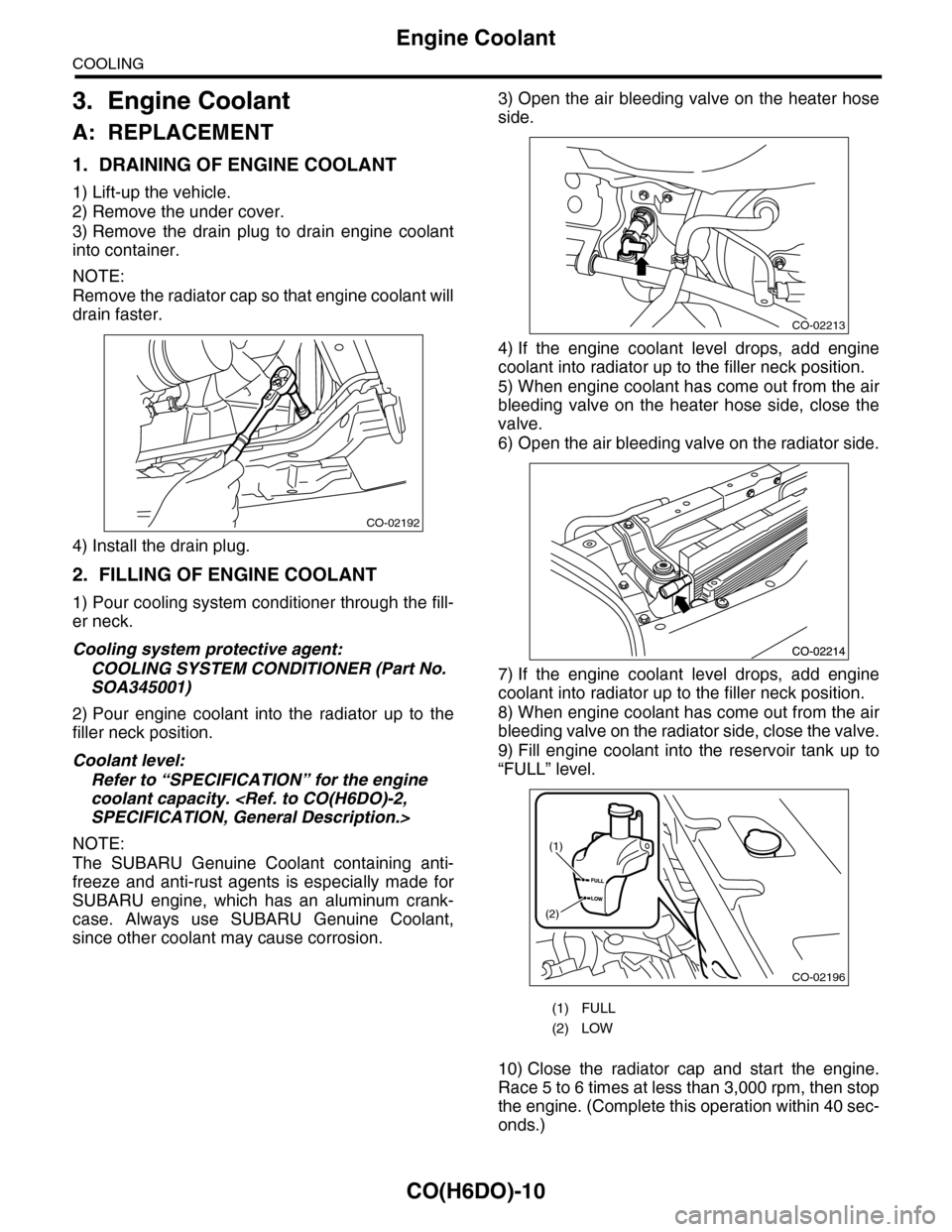

1. DRAINING OF ENGINE COOLANT

1) Lift-up the vehicle.

2) Remove the under cover.

3) Remove the drain plug to drain engine coolant

into container.

NOTE:

Remove the radiator cap so that engine coolant will

drain faster.

4) Install the drain plug.

2. FILLING OF ENGINE COOLANT

1) Pour cooling system conditioner through the fill-

er neck.

Cooling system protective agent:

COOLING SYSTEM CONDITIONER (Part No.

SOA345001)

2) Pour engine coolant into the radiator up to the

filler neck position.

Coolant level:

Refer to “SPECIFICATION” for the engine

coolant capacity.

NOTE:

The SUBARU Genuine Coolant containing anti-

freeze and anti-rust agents is especially made for

SUBARU engine, which has an aluminum crank-

case. Always use SUBARU Genuine Coolant,

since other coolant may cause corrosion.

3) Open the air bleeding valve on the heater hose

side.

4) If the engine coolant level drops, add engine

coolant into radiator up to the filler neck position.

5) When engine coolant has come out from the air

bleeding valve on the heater hose side, close the

valve.

6) Open the air bleeding valve on the radiator side.

7) If the engine coolant level drops, add engine

coolant into radiator up to the filler neck position.

8) When engine coolant has come out from the air

bleeding valve on the radiator side, close the valve.

9) Fill engine coolant into the reservoir tank up to

“FULL” level.

10) Close the radiator cap and start the engine.

Race 5 to 6 times at less than 3,000 rpm, then stop

the engine. (Complete this operation within 40 sec-

onds.)

CO-02192

(1) FULL

(2) LOW

CO-02213

CO-02196

(1)

(2)

Page 1130 of 2453

CO(H6DO)-11

Engine Coolant

COOLING

11) Wait for one minute after the engine stops,

open the radiator cap. If the engine coolant level

drops, add engine coolant into radiator up to the fill-

er neck position.

12) Perform the procedures 10) and 11) again.

13) Attach the radiator cap and reservoir tank cap

properly.

14) Start the engine and operate the heater at max-

imum hot position and the blower speed setting to

“LO.”

15) Run the engine at 2,000 rpm or less until radia-

tor fan starts and stops.

NOTE:

•Be careful with the engine coolant temperature

gauge to prevent overheating.

•If the radiator hose becomes harden with the

pressure of engine coolant, air bleeding operation

seems to be almost completed.

16) Stop the engine and wait until the engine cool-

ant temperature lowers to 30°C (86°F).

17) Open the radiator cap. If the engine coolant lev-

el drops, add engine coolant into radiator up to the

filler neck position and reservoir tank to the “FULL”

level.

18) Attach the radiator cap and reservoir tank cap

properly.

19) Set the heater setting to maximum hot position

and the blower speed setting to “LO” and start the

engine. Perform racing at less than 3,000 rpm. If

the flowing sound is heard at this time, perform the

procedures from 15) again.

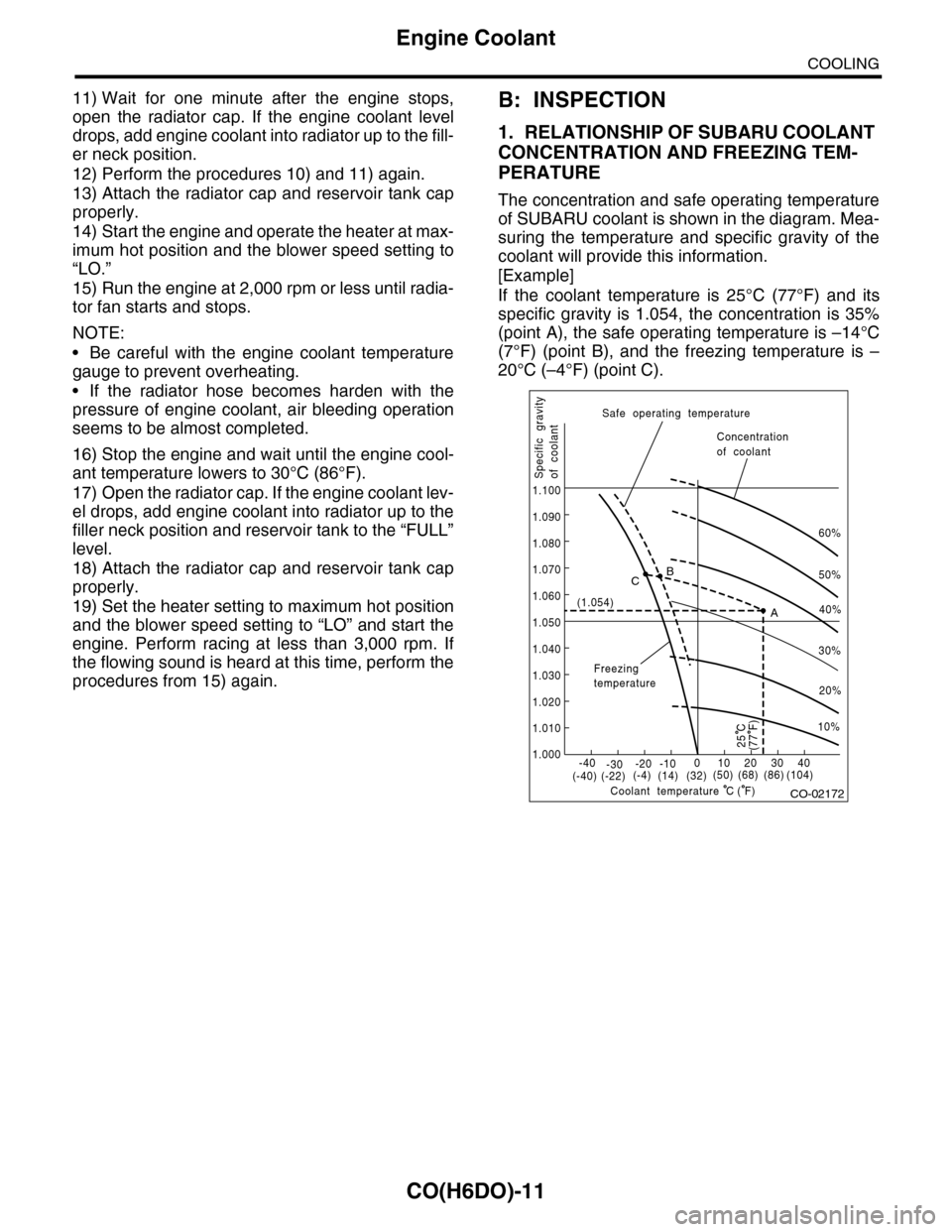

B: INSPECTION

1. RELATIONSHIP OF SUBARU COOLANT

CONCENTRATION AND FREEZING TEM-

PERATURE

The concentration and safe operating temperature

of SUBARU coolant is shown in the diagram. Mea-

suring the temperature and specific gravity of the

coolant will provide this information.

[Example]

If the coolant temperature is 25°C (77°F) and its

specific gravity is 1.054, the concentration is 35%

(point A), the safe operating temperature is –14°C

(7°F) (point B), and the freezing temperature is –

20°C (–4°F) (point C).

CO-02172

60%

(1.054)

1.000

1.010

1.020

1.030

1.040

1.050

1.060

1.070

1.080

1.090

1.100

Safe operating temperature

Freezingtemperature

Concentrationof coolant

Specific gravityof coolant

Coolant temperature

B

A

C

-40(-40) (-22)(-4)(14)(32)(50) (68) (86)

( F)

(104)-30-20 -10010203040

(77 F)

50%

40%

30%

20%

25 C

10%

C

Page 1149 of 2453

CO(H6DO)-30

Engine Cooling System Trouble in General

COOLING

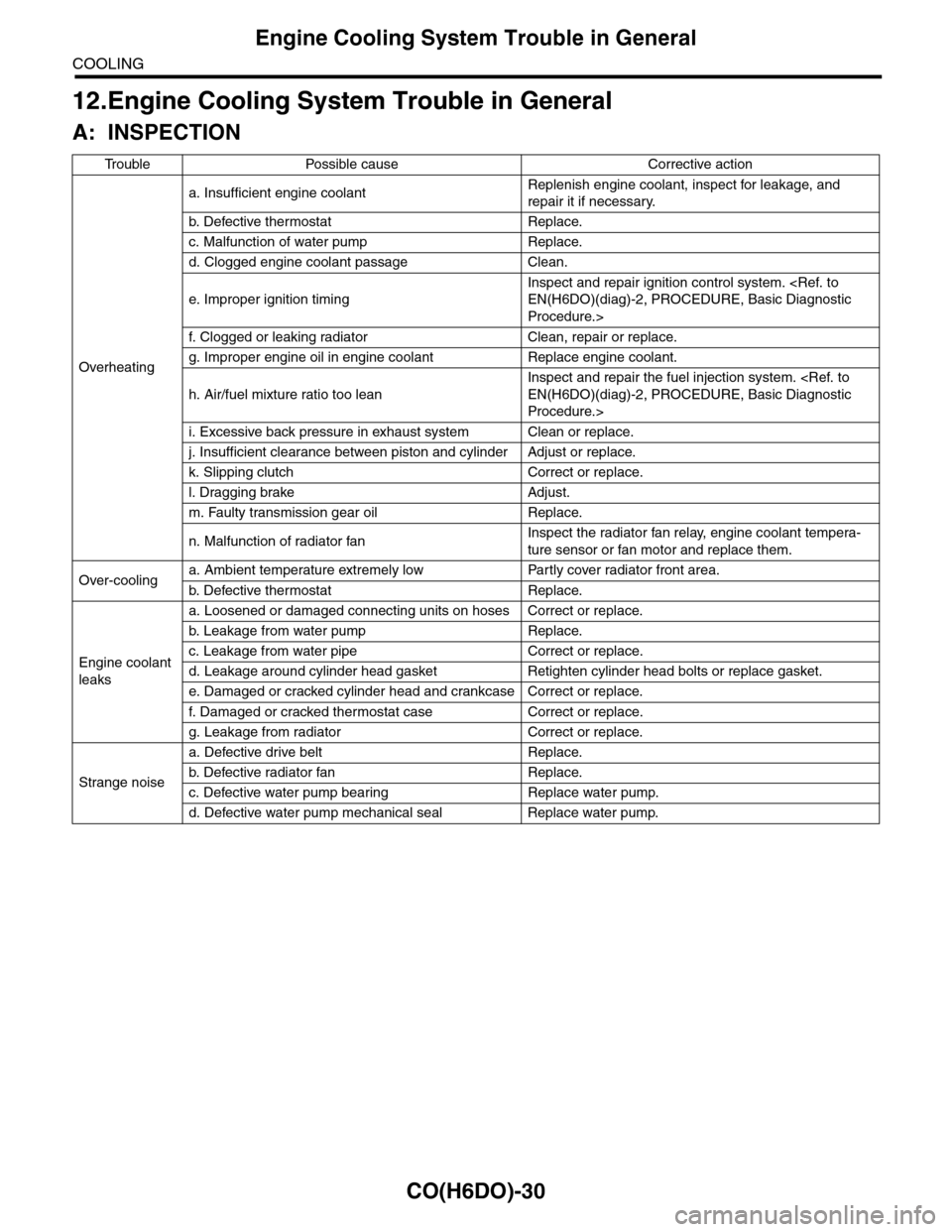

12.Engine Cooling System Trouble in General

A: INSPECTION

Tr o u b l e P o s s i b l e c a u s e C o r r e c t i v e a c t i o n

Overheating

a. Insufficient engine coolantReplenish engine coolant, inspect for leakage, and

repair it if necessary.

b. De fe c ti ve t he r mo st a t Rep la c e.

c. Malfunction of water pump Replace.

d. Clogged engine coolant passage Clean.

e. Improper ignition timing

Inspect and repair ignition control system.

Procedure.>

f. Clogged or leaking radiator Clean, repair or replace.

g. Improper engine oil in engine coolant Replace engine coolant.

h. Air/fuel mixture ratio too lean

Inspect and repair the fuel injection system.

Procedure.>

i. Excessive back pressure in exhaust system Clean or replace.

j. Insufficient clearance between piston and cylinder Adjust or replace.

k. Slipping clutch Correct or replace.

l. Dragging brake Adjust.

m. Faulty transmission gear oil Replace.

n. Malfunction of radiator fanInspect the radiator fan relay, engine coolant tempera-

ture sensor or fan motor and replace them.

Over-coolinga. Ambient temperature extremely low Partly cover radiator front area.

b. De fe c ti ve t he r mo st a t Rep la c e.

Engine coolant

leaks

a. Loosened or damaged connecting units on hoses Correct or replace.

b. L ea k ag e f r o m wat e r pu mp Rep la c e.

c. Leakage from water pipe Correct or replace.

d. Leakage around cylinder head gasket Retighten cylinder head bolts or replace gasket.

e. Damaged or cracked cylinder head and crankcase Correct or replace.

f. Damaged or cracked ther mostat case Correct or replace.

g. Leakage from radiator Correct or replace.

Strange noise

a. Defective drive belt Replace.

b. De fe c ti ve ra di a t or fan Rep la c e.

c. Defective water pump bearing Replace water pump.

d. Defective water pump mechanical seal Replace water pump.

Page 1179 of 2453

EN(H6DO)(diag)-18

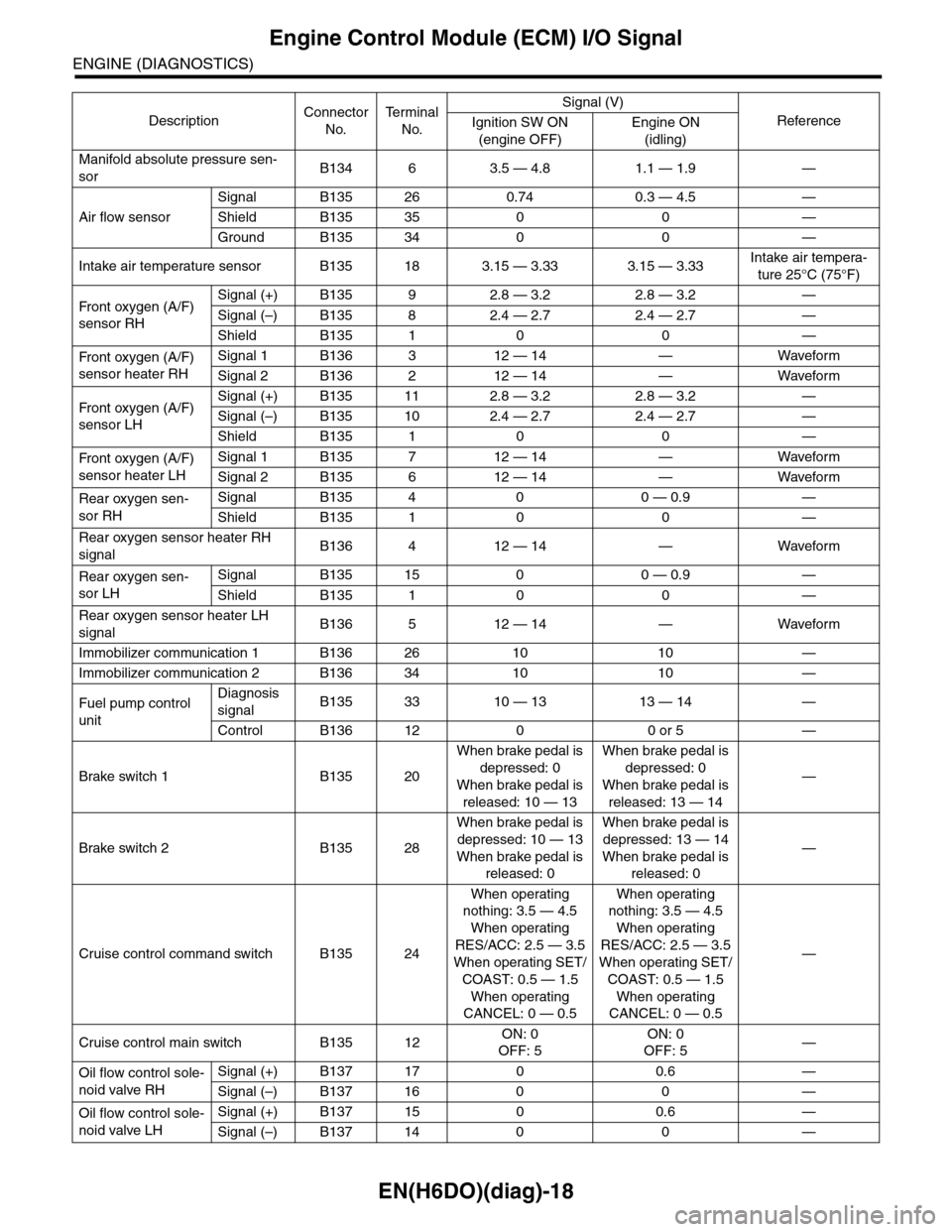

Engine Control Module (ECM) I/O Signal

ENGINE (DIAGNOSTICS)

Manifold absolute pressure sen-

sorB134 6 3.5 — 4.8 1.1 — 1.9 —

Air flow sensor

Signal B135 26 0.74 0.3 — 4.5 —

Shield B135 35 0 0 —

Ground B135 34 0 0 —

Intake air temperature sensor B135 18 3.15 — 3.33 3.15 — 3.33Intake air tempera-

ture 25°C (75°F)

Fr o nt ox yg e n ( A / F)

sensor RH

Signal (+) B135 9 2.8 — 3.2 2.8 — 3.2 —

Signal (–) B135 8 2.4 — 2.7 2.4 — 2.7 —

Shield B135 1 0 0 —

Fr o nt ox yg e n ( A / F)

sensor heater RH

Signal 1 B136 3 12 — 14 — Waveform

Signal 2 B136 2 12 — 14 — Waveform

Fr o nt ox yg e n ( A / F)

sensor LH

Signal (+) B135 11 2.8 — 3.2 2.8 — 3.2 —

Signal (–) B135 10 2.4 — 2.7 2.4 — 2.7 —

Shield B135 1 0 0 —

Fr o nt ox yg e n ( A / F)

sensor heater LH

Signal 1 B135 7 12 — 14 — Waveform

Signal 2 B135 6 12 — 14 — Waveform

Rear oxygen sen-

sor RH

Signal B135 4 0 0 — 0.9 —

Shield B135 1 0 0 —

Rear oxygen sensor heater RH

signalB136 4 12 — 14 — Waveform

Rear oxygen sen-

sor LH

Signal B135 15 0 0 — 0.9 —

Shield B135 1 0 0 —

Rear oxygen sensor heater LH

signalB136 5 12 — 14 — Waveform

Immobilizer communication 1 B136 26 10 10 —

Immobilizer communication 2 B136 34 10 10 —

Fuel pump control

unit

Diagnosis

signalB135 33 10 — 13 13 — 14 —

Control B136 12 0 0 or 5 —

Brake switch 1 B135 20

When brake pedal is

depressed: 0

When brake pedal is

released: 10 — 13

When brake pedal is

depressed: 0

When brake pedal is

released: 13 — 14

—

Brake switch 2 B135 28

When brake pedal is

depressed: 10 — 13

When brake pedal is

released: 0

When brake pedal is

depressed: 13 — 14

When brake pedal is

released: 0

—

Cruise control command switch B135 24

When operating

nothing: 3.5 — 4.5

When operating

RES/ACC: 2.5 — 3.5

When operating SET/

COAST: 0.5 — 1.5

When operating

CANCEL: 0 — 0.5

When operating

nothing: 3.5 — 4.5

When operating

RES/ACC: 2.5 — 3.5

When operating SET/

COAST: 0.5 — 1.5

When operating

CANCEL: 0 — 0.5

—

Cruise control main switch B135 12ON: 0

OFF: 5

ON: 0

OFF: 5—

Oil flow control sole-

noid valve RH

Signal (+) B137 17 0 0.6 —

Signal (–) B137 16 0 0 —

Oil flow control sole-

noid valve LH

Signal (+) B137 15 0 0.6 —

Signal (–) B137 14 0 0 —

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

ReferenceIgnition SW ON

(engine OFF)

Engine ON

(idling)

Page 1196 of 2453

EN(H6DO)(diag)-35

Inspection Mode

ENGINE (DIAGNOSTICS)

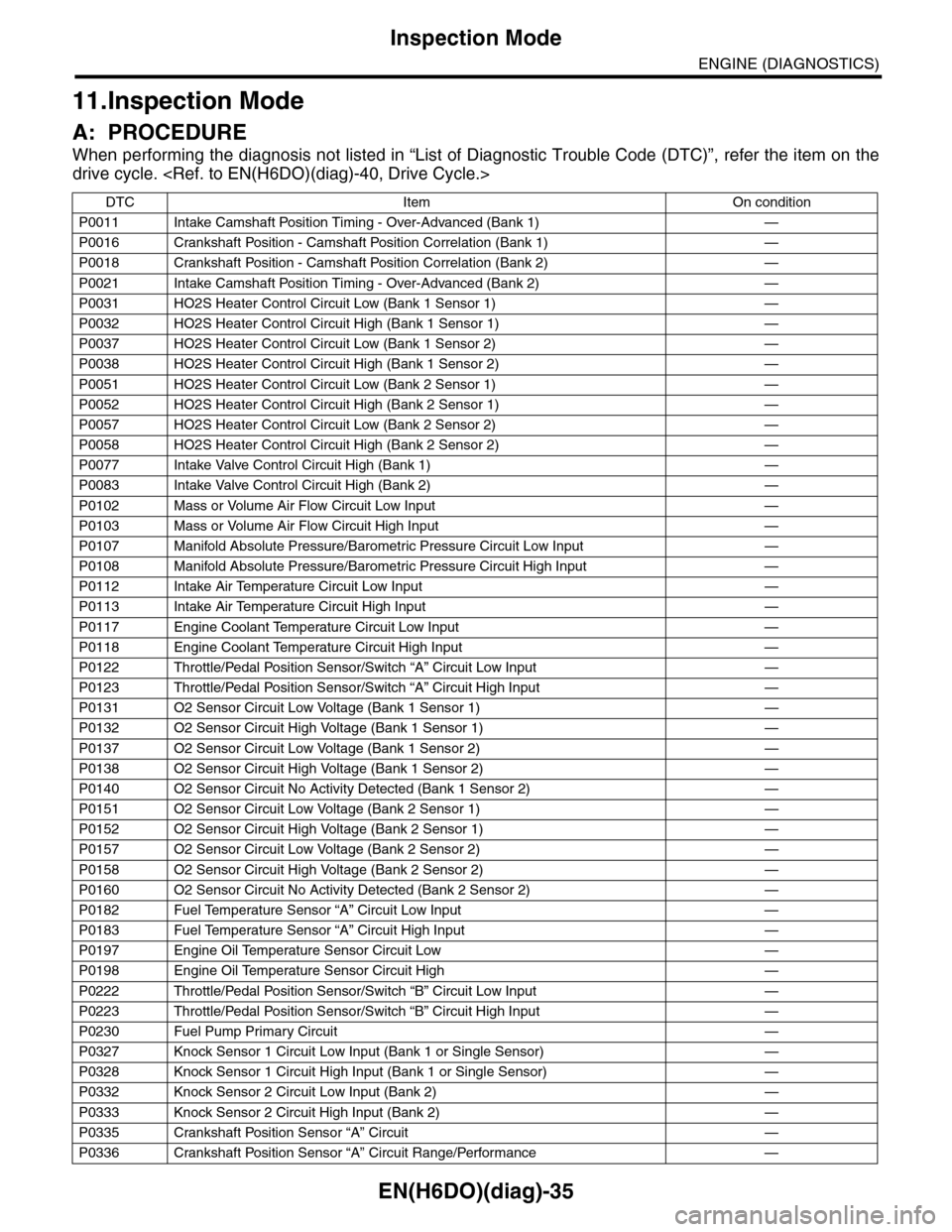

11.Inspection Mode

A: PROCEDURE

When performing the diagnosis not listed in “List of Diagnostic Trouble Code (DTC)”, refer the item on the

drive cycle.

DTC Item On condition

P0011 Intake Camshaft Position Timing - Over-Advanced (Bank 1) —

P0016 Crankshaft Position - Camshaft Position Correlation (Bank 1) —

P0018 Crankshaft Position - Camshaft Position Correlation (Bank 2) —

P0021 Intake Camshaft Position Timing - Over-Advanced (Bank 2) —

P0031 HO2S Heater Control Circuit Low (Bank 1 Sensor 1) —

P0032 HO2S Heater Control Circuit High (Bank 1 Sensor 1) —

P0037 HO2S Heater Control Circuit Low (Bank 1 Sensor 2) —

P0038 HO2S Heater Control Circuit High (Bank 1 Sensor 2) —

P0051 HO2S Heater Control Circuit Low (Bank 2 Sensor 1) —

P0052 HO2S Heater Control Circuit High (Bank 2 Sensor 1) —

P0057 HO2S Heater Control Circuit Low (Bank 2 Sensor 2) —

P0058 HO2S Heater Control Circuit High (Bank 2 Sensor 2) —

P0077 Intake Valve Control Circuit High (Bank 1) —

P0083 Intake Valve Control Circuit High (Bank 2) —

P0102 Mass or Volume Air Flow Circuit Low Input —

P0103 Mass or Volume Air Flow Circuit High Input —

P0107 Manifold Absolute Pressure/Barometric Pressure Circuit Low Input —

P0108 Manifold Absolute Pressure/Barometric Pressure Circuit High Input —

P0112 Intake Air Temperature Circuit Low Input —

P0113 Intake Air Temperature Circuit High Input —

P0117 Engine Coolant Temperature Circuit Low Input —

P0118 Engine Coolant Temperature Circuit High Input —

P0122 Throttle/Pedal Position Sensor/Switch “A” Circuit Low Input —

P0123 Throttle/Pedal Position Sensor/Switch “A” Circuit High Input —

P0131 O2 Sensor Circuit Low Voltage (Bank 1 Sensor 1) —

P0132 O2 Sensor Circuit High Voltage (Bank 1 Sensor 1) —

P0137 O2 Sensor Circuit Low Voltage (Bank 1 Sensor 2) —

P0138 O2 Sensor Circuit High Voltage (Bank 1 Sensor 2) —

P0140 O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 2) —

P0151 O2 Sensor Circuit Low Voltage (Bank 2 Sensor 1) —

P0152 O2 Sensor Circuit High Voltage (Bank 2 Sensor 1) —

P0157 O2 Sensor Circuit Low Voltage (Bank 2 Sensor 2) —

P0158 O2 Sensor Circuit High Voltage (Bank 2 Sensor 2) —

P0160 O2 Sensor Circuit No Activity Detected (Bank 2 Sensor 2) —

P0182 Fuel Temperature Sensor “A” Circuit Low Input —

P0183 Fuel Temperature Sensor “A” Circuit High Input —

P0197 Engine Oil Temperature Sensor Circuit Low —

P0198 Engine Oil Temperature Sensor Circuit High —

P0222 Throttle/Pedal Position Sensor/Switch “B” Circuit Low Input —

P0223 Throttle/Pedal Position Sensor/Switch “B” Circuit High Input —

P0230 Fuel Pump Primary Circuit —

P0327 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor) —

P0328 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor) —

P0332 Knock Sensor 2 Circuit Low Input (Bank 2) —

P0333 Knock Sensor 2 Circuit High Input (Bank 2) —

P0335 Crankshaft Position Sensor “A” Circuit —

P0336 Crankshaft Position Sensor “A” Circuit Range/Performance —

Page 1204 of 2453

EN(H6DO)(diag)-43

Drive Cycle

ENGINE (DIAGNOSTICS)

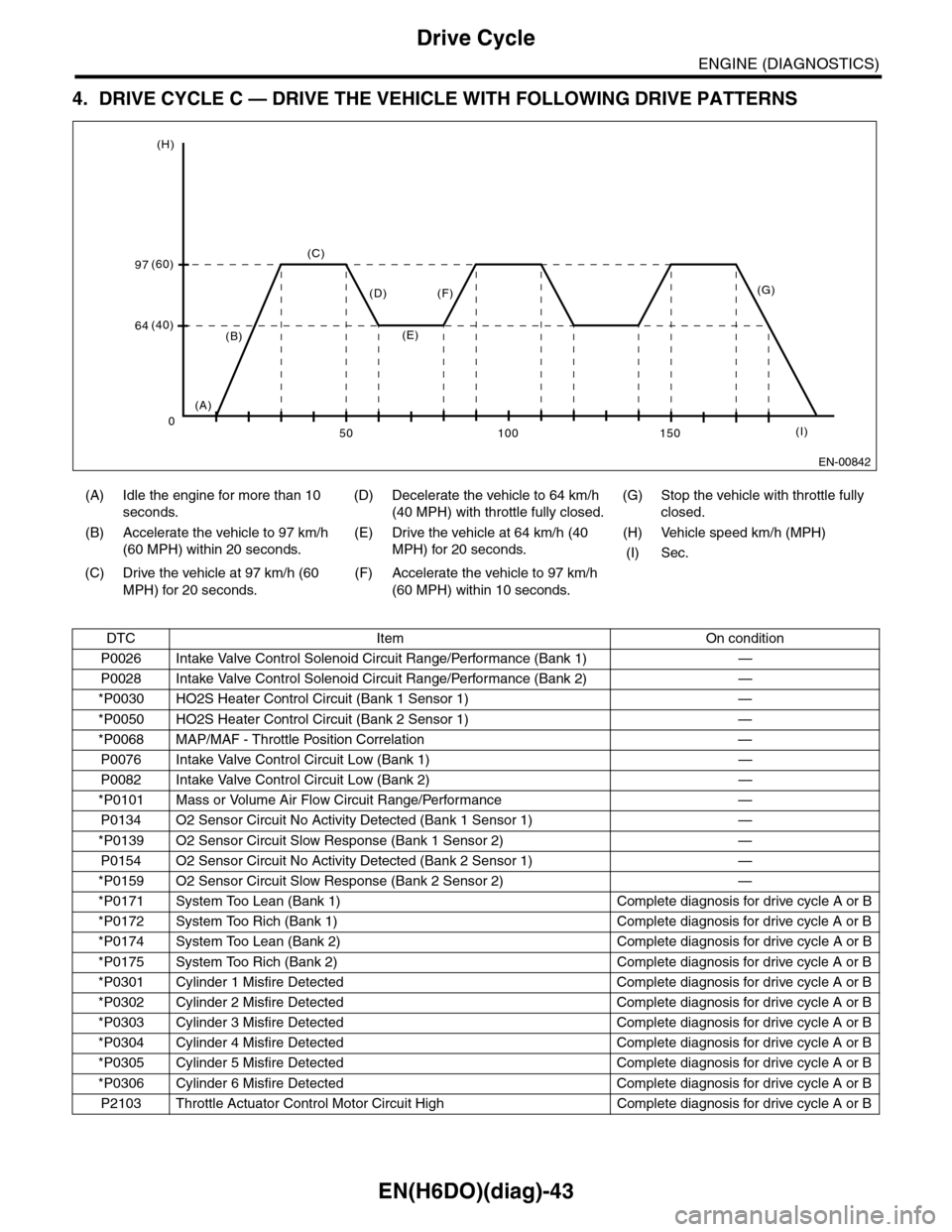

4. DRIVE CYCLE C — DRIVE THE VEHICLE WITH FOLLOWING DRIVE PATTERNS

(A) Idle the engine for more than 10

seconds.

(D) Decelerate the vehicle to 64 km/h

(40 MPH) with throttle fully closed.

(G) Stop the vehicle with throttle fully

closed.

(B) Accelerate the vehicle to 97 km/h

(60 MPH) within 20 seconds.

(E) Drive the vehicle at 64 km/h (40

MPH) for 20 seconds.

(H) Vehicle speed km/h (MPH)

(I) Sec.

(C) Drive the vehicle at 97 km/h (60

MPH) for 20 seconds.

(F) Accelerate the vehicle to 97 km/h

(60 MPH) within 10 seconds.

DTC Item On condition

P0026 Intake Valve Control Solenoid Circuit Range/Performance (Bank 1) —

P0028 Intake Valve Control Solenoid Circuit Range/Performance (Bank 2) —

*P0030 HO2S Heater Control Circuit (Bank 1 Sensor 1) —

*P0050 HO2S Heater Control Circuit (Bank 2 Sensor 1) —

*P0068 MAP/MAF - Throttle Position Correlation —

P0076 Intake Valve Control Circuit Low (Bank 1) —

P0082 Intake Valve Control Circuit Low (Bank 2) —

*P0101 Mass or Volume Air Flow Circuit Range/Performance —

P0134 O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 1) —

*P0139 O2 Sensor Circuit Slow Response (Bank 1 Sensor 2) —

P0154 O2 Sensor Circuit No Activity Detected (Bank 2 Sensor 1) —

*P0159 O2 Sensor Circuit Slow Response (Bank 2 Sensor 2) —

*P0171 System Too Lean (Bank 1) Complete diagnosis for drive cycle A or B

*P0172 System Too Rich (Bank 1) Complete diagnosis for drive cycle A or B

*P0174 System Too Lean (Bank 2) Complete diagnosis for drive cycle A or B

*P0175 System Too Rich (Bank 2) Complete diagnosis for drive cycle A or B

*P0301 Cylinder 1 Misfire Detected Complete diagnosis for drive cycle A or B

*P0302 Cylinder 2 Misfire Detected Complete diagnosis for drive cycle A or B

*P0303 Cylinder 3 Misfire Detected Complete diagnosis for drive cycle A or B

*P0304 Cylinder 4 Misfire Detected Complete diagnosis for drive cycle A or B

*P0305 Cylinder 5 Misfire Detected Complete diagnosis for drive cycle A or B

*P0306 Cylinder 6 Misfire Detected Complete diagnosis for drive cycle A or B

P2103 Throttle Actuator Control Motor Circuit High Complete diagnosis for drive cycle A or B

EN-00842

(C)

(H)

(I)

(60)97

64(40)(B)

(A)

(F)(D)

(E)

150100500

(G)