Variable SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1242 of 2453

EN(H6DO)(diag)-81

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

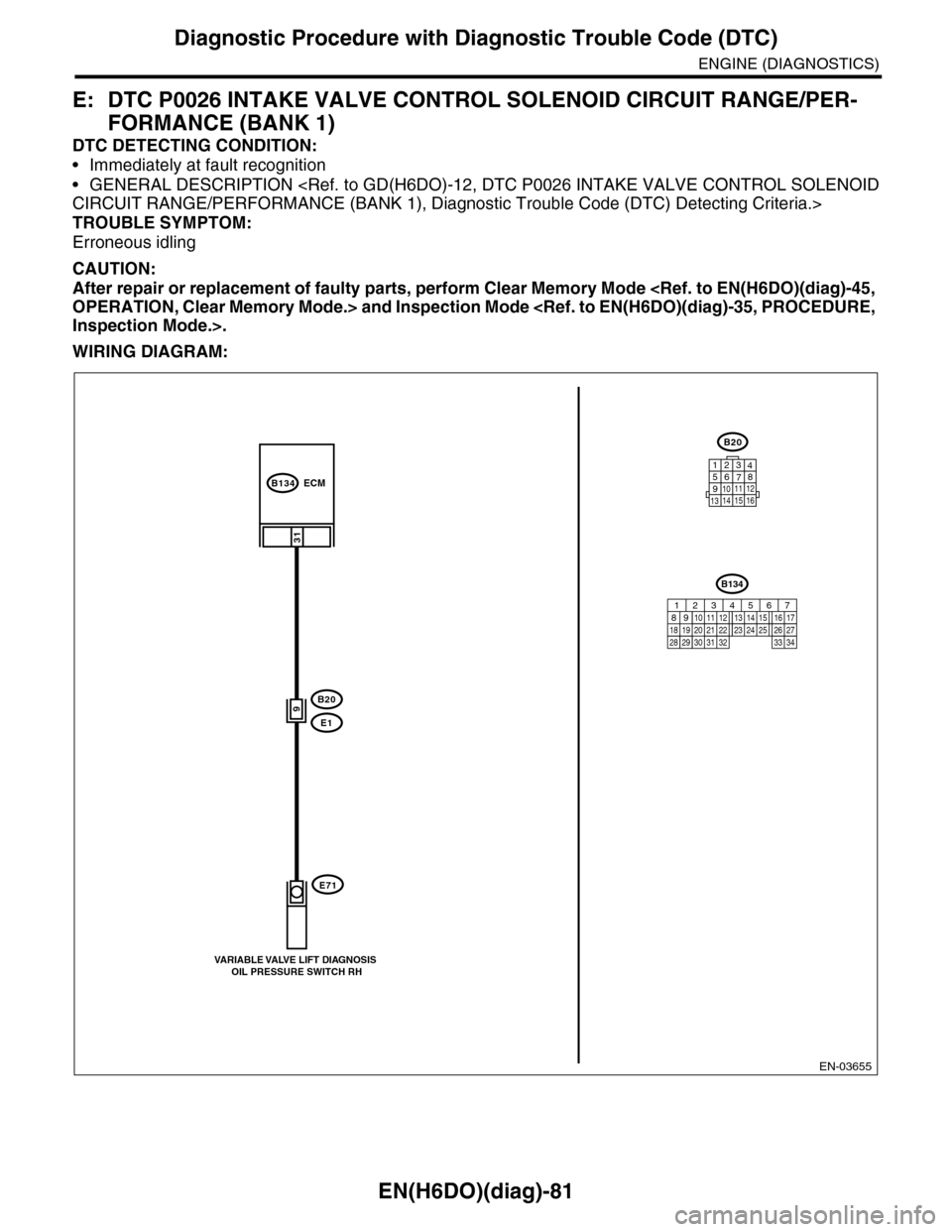

E: DTC P0026 INTAKE VALVE CONTROL SOLENOID CIRCUIT RANGE/PER-

FORMANCE (BANK 1)

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

Erroneous idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03655

B134

31

B20

E19

ECM

B20

1234567891011 121314 15 16

1

VARIABLE VALVE LIFT DIAGNOSIS OIL PRESSURE SWITCH RH

E71

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1243 of 2453

EN(H6DO)(diag)-82

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

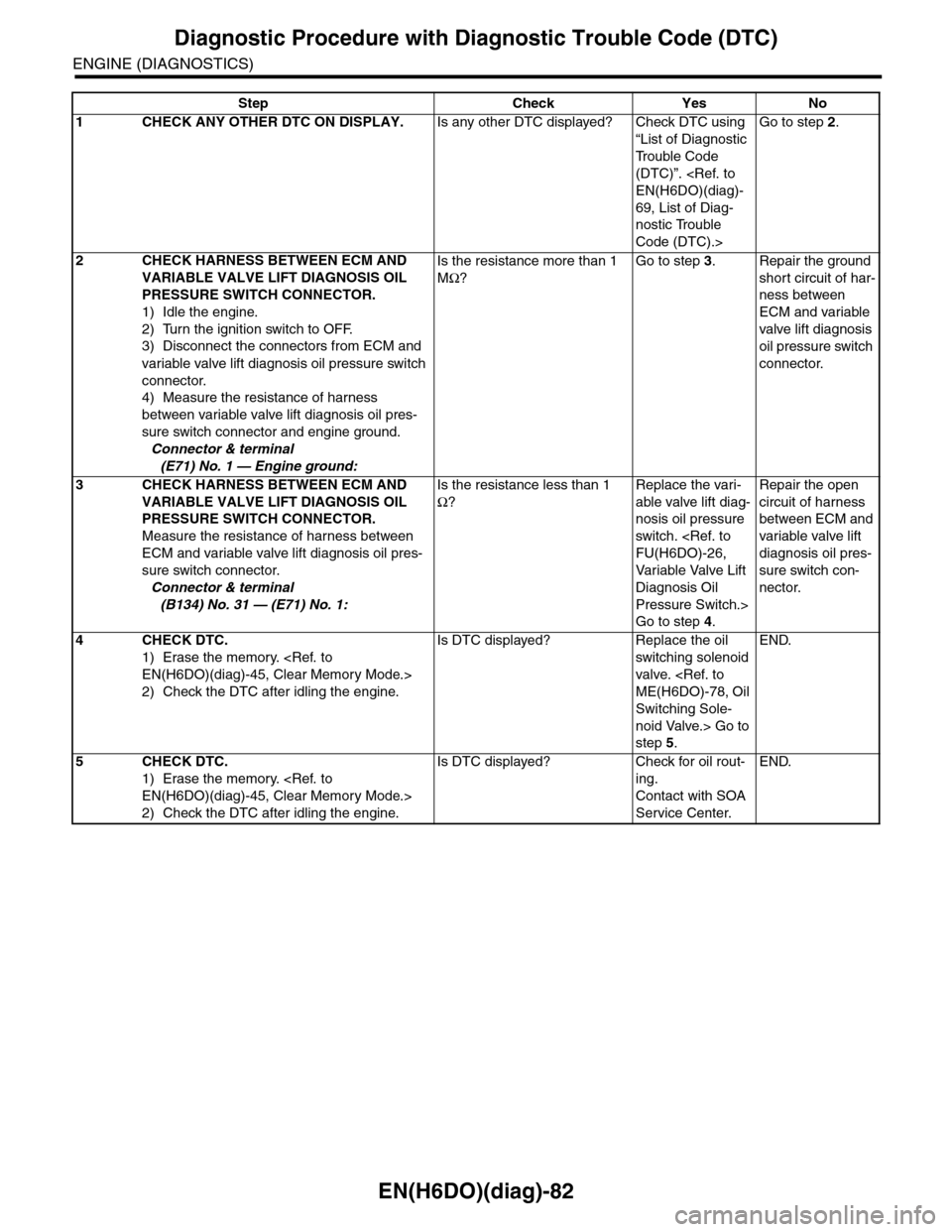

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK HARNESS BETWEEN ECM AND

VARIABLE VALVE LIFT DIAGNOSIS OIL

PRESSURE SWITCH CONNECTOR.

1) Idle the engine.

2) Turn the ignition switch to OFF.

3) Disconnect the connectors from ECM and

variable valve lift diagnosis oil pressure switch

connector.

4) Measure the resistance of harness

between variable valve lift diagnosis oil pres-

sure switch connector and engine ground.

Connector & terminal

(E71) No. 1 — Engine ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the ground

short circuit of har-

ness between

ECM and variable

valve lift diagnosis

oil pressure switch

connector.

3CHECK HARNESS BETWEEN ECM AND

VARIABLE VALVE LIFT DIAGNOSIS OIL

PRESSURE SWITCH CONNECTOR.

Measure the resistance of harness between

ECM and variable valve lift diagnosis oil pres-

sure switch connector.

Connector & terminal

(B134) No. 31 — (E71) No. 1:

Is the resistance less than 1

Ω?

Replace the vari-

able valve lift diag-

nosis oil pressure

switch.

Va r i a bl e Va l ve L i f t

Diagnosis Oil

Pressure Switch.>

Go to step 4.

Repair the open

circuit of harness

between ECM and

variable valve lift

diagnosis oil pres-

sure switch con-

nector.

4CHECK DTC.

1) Erase the memory.

2) Check the DTC after idling the engine.

Is DTC displayed? Replace the oil

switching solenoid

valve.

Switching Sole-

noid Valve.> Go to

step 5.

END.

5CHECK DTC.

1) Erase the memory.

2) Check the DTC after idling the engine.

Is DTC displayed? Check for oil rout-

ing.

Contact with SOA

Service Center.

END.

Page 1244 of 2453

EN(H6DO)(diag)-83

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

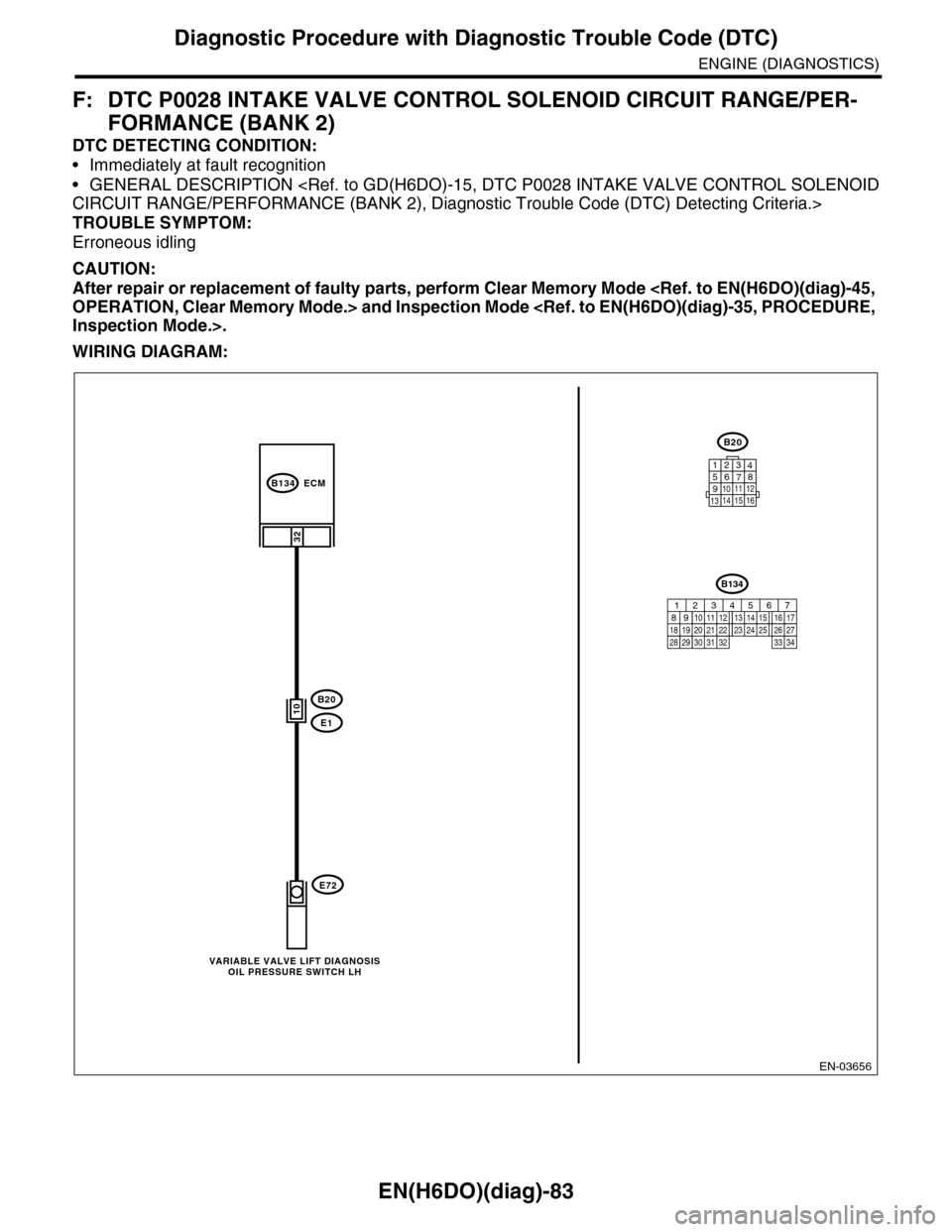

F: DTC P0028 INTAKE VALVE CONTROL SOLENOID CIRCUIT RANGE/PER-

FORMANCE (BANK 2)

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

Erroneous idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03656

B134

32

B20

E110

ECM

B20

1234567891011 121314 15 16

VARIABLE VALVE LIFT DIAGNOSISOIL PRESSURE SWITCH LH

E72

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1245 of 2453

EN(H6DO)(diag)-84

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

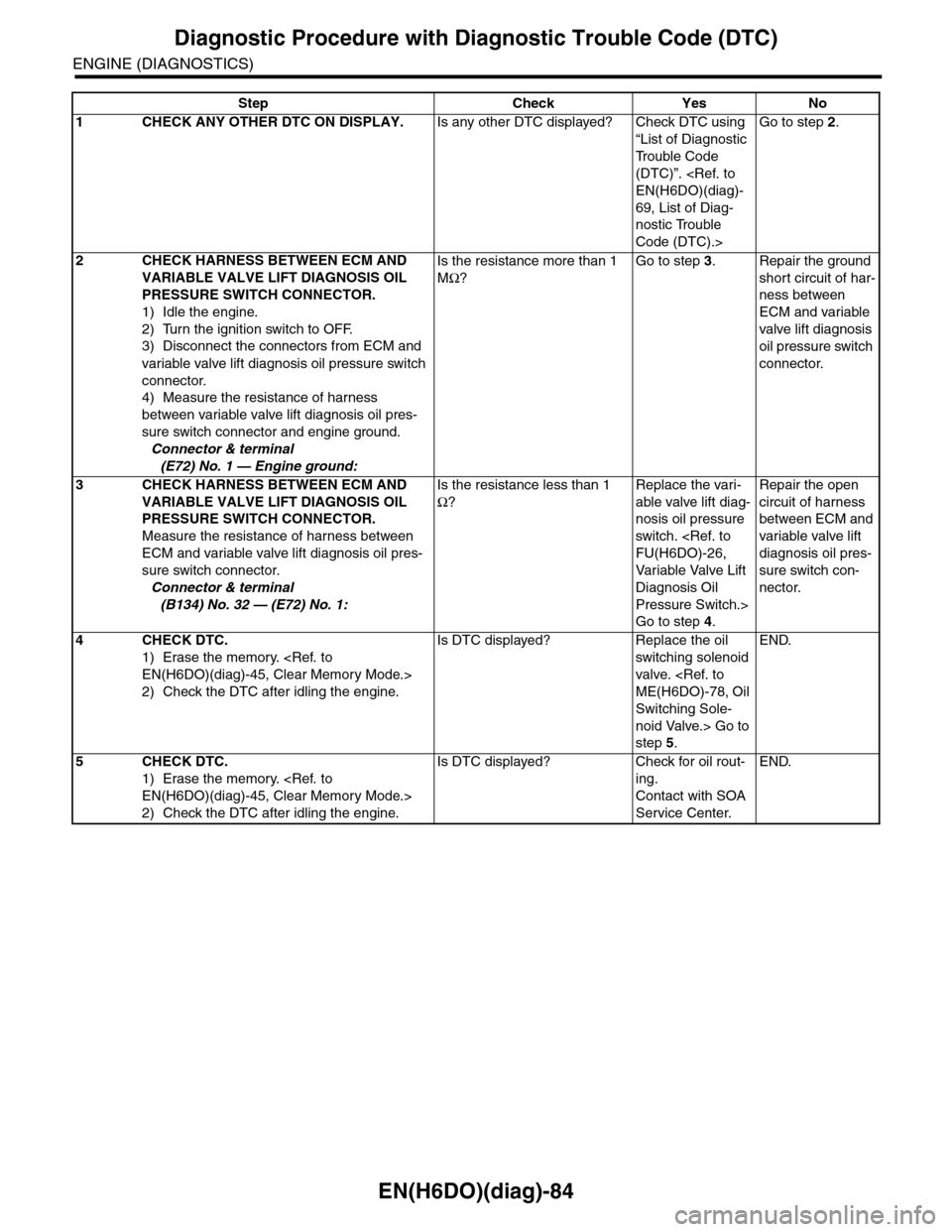

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK HARNESS BETWEEN ECM AND

VARIABLE VALVE LIFT DIAGNOSIS OIL

PRESSURE SWITCH CONNECTOR.

1) Idle the engine.

2) Turn the ignition switch to OFF.

3) Disconnect the connectors from ECM and

variable valve lift diagnosis oil pressure switch

connector.

4) Measure the resistance of harness

between variable valve lift diagnosis oil pres-

sure switch connector and engine ground.

Connector & terminal

(E72) No. 1 — Engine ground:

Is the resistance more than 1

MΩ?

Go to step 3.Repair the ground

short circuit of har-

ness between

ECM and variable

valve lift diagnosis

oil pressure switch

connector.

3CHECK HARNESS BETWEEN ECM AND

VARIABLE VALVE LIFT DIAGNOSIS OIL

PRESSURE SWITCH CONNECTOR.

Measure the resistance of harness between

ECM and variable valve lift diagnosis oil pres-

sure switch connector.

Connector & terminal

(B134) No. 32 — (E72) No. 1:

Is the resistance less than 1

Ω?

Replace the vari-

able valve lift diag-

nosis oil pressure

switch.

Va r i a bl e Va l ve L i f t

Diagnosis Oil

Pressure Switch.>

Go to step 4.

Repair the open

circuit of harness

between ECM and

variable valve lift

diagnosis oil pres-

sure switch con-

nector.

4CHECK DTC.

1) Erase the memory.

2) Check the DTC after idling the engine.

Is DTC displayed? Replace the oil

switching solenoid

valve.

Switching Sole-

noid Valve.> Go to

step 5.

END.

5CHECK DTC.

1) Erase the memory.

2) Check the DTC after idling the engine.

Is DTC displayed? Check for oil rout-

ing.

Contact with SOA

Service Center.

END.

Page 1567 of 2453

FU(H6DO)-6

General Description

FUEL INJECTION (FUEL SYSTEMS)

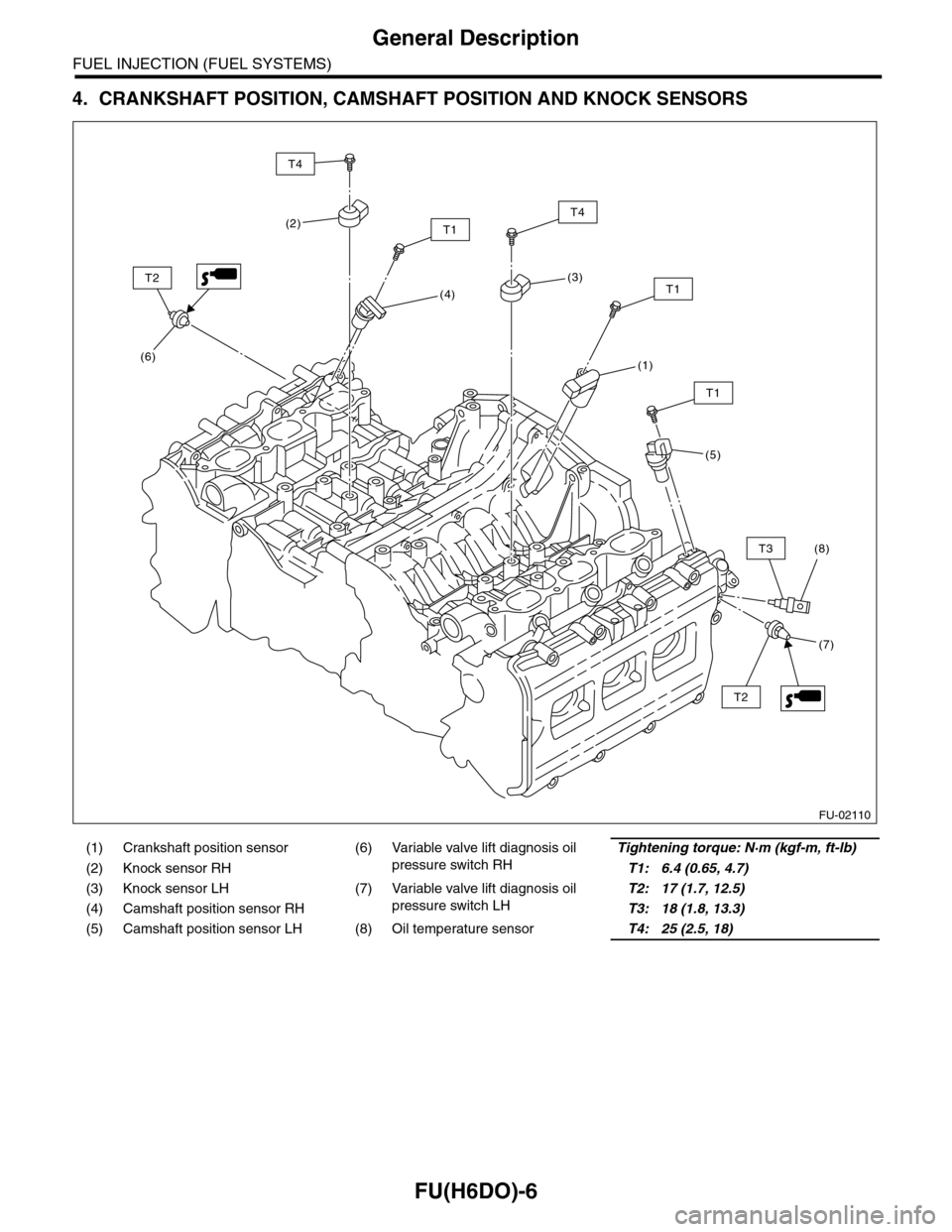

4. CRANKSHAFT POSITION, CAMSHAFT POSITION AND KNOCK SENSORS

(1) Crankshaft position sensor (6) Variable valve lift diagnosis oil

pressure switch RH

Tightening torque: N·m (kgf-m, ft-lb)

(2) Knock sensor RHT1: 6.4 (0.65, 4.7)

(3) Knock sensor LH (7) Variable valve lift diagnosis oil

pressure switch LH

T2: 17 (1.7, 12.5)

(4) Camshaft position sensor RHT3: 18 (1.8, 13.3)

(5) Camshaft position sensor LH (8) Oil temperature sensorT4: 25 (2.5, 18)

FU-02110

(6)

(4)

T2

T1

(3)

T4

(1)

(8)

T1

T3

(5)

T1

(2)

T4

(7)

T2

Page 1587 of 2453

FU(H6DO)-26

Variable Valve Lift Diagnosis Oil Pressure Switch

FUEL INJECTION (FUEL SYSTEMS)

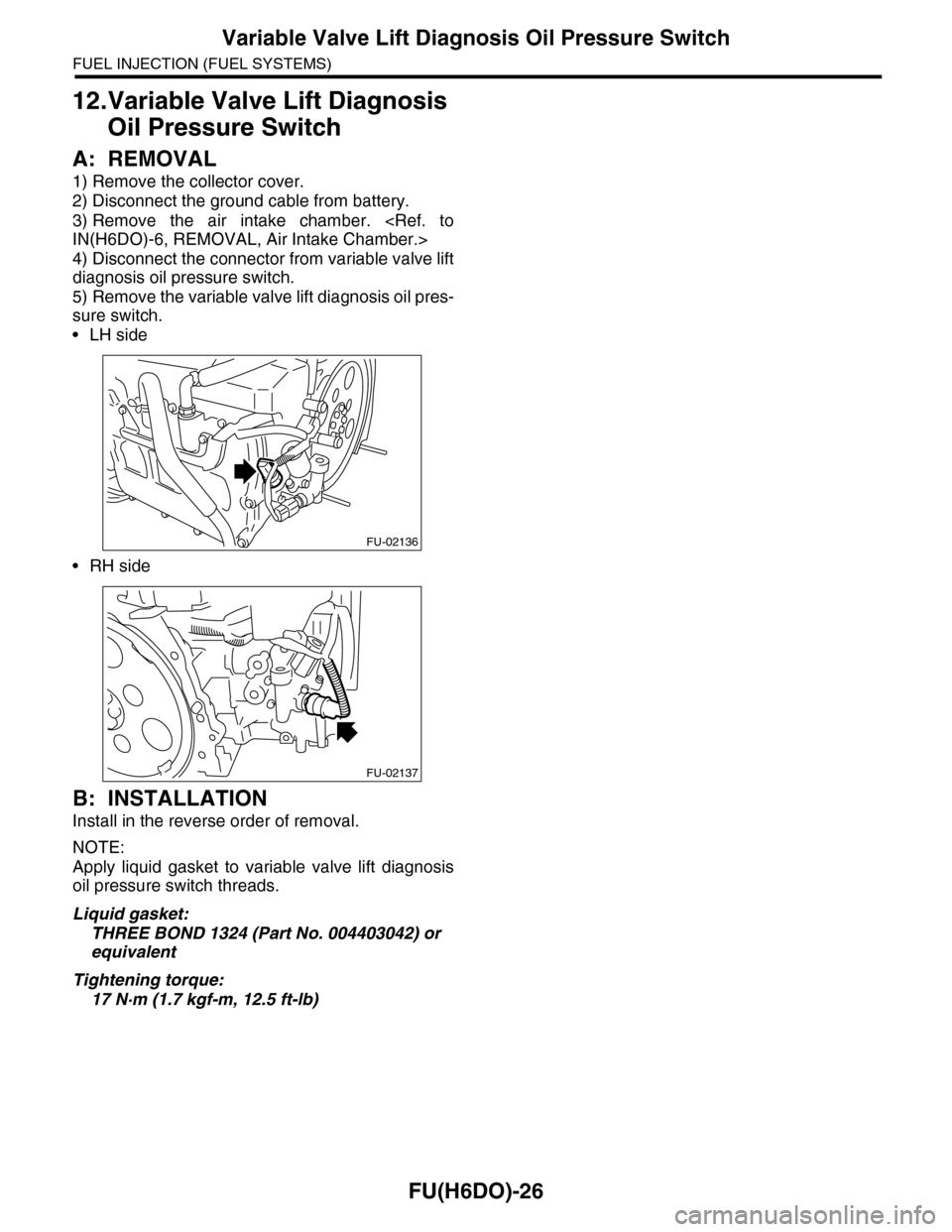

12.Variable Valve Lift Diagnosis

Oil Pressure Switch

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

4) Disconnect the connector from variable valve lift

diagnosis oil pressure switch.

5) Remove the variable valve lift diagnosis oil pres-

sure switch.

•LH side

•RH side

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Apply liquid gasket to variable valve lift diagnosis

oil pressure switch threads.

Liquid gasket:

THREE BOND 1324 (Part No. 004403042) or

equivalent

Tightening torque:

17 N·m (1.7 kgf-m, 12.5 ft-lb)

FU-02136

FU-02137

Page 1624 of 2453

GD(H6DO)-12

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

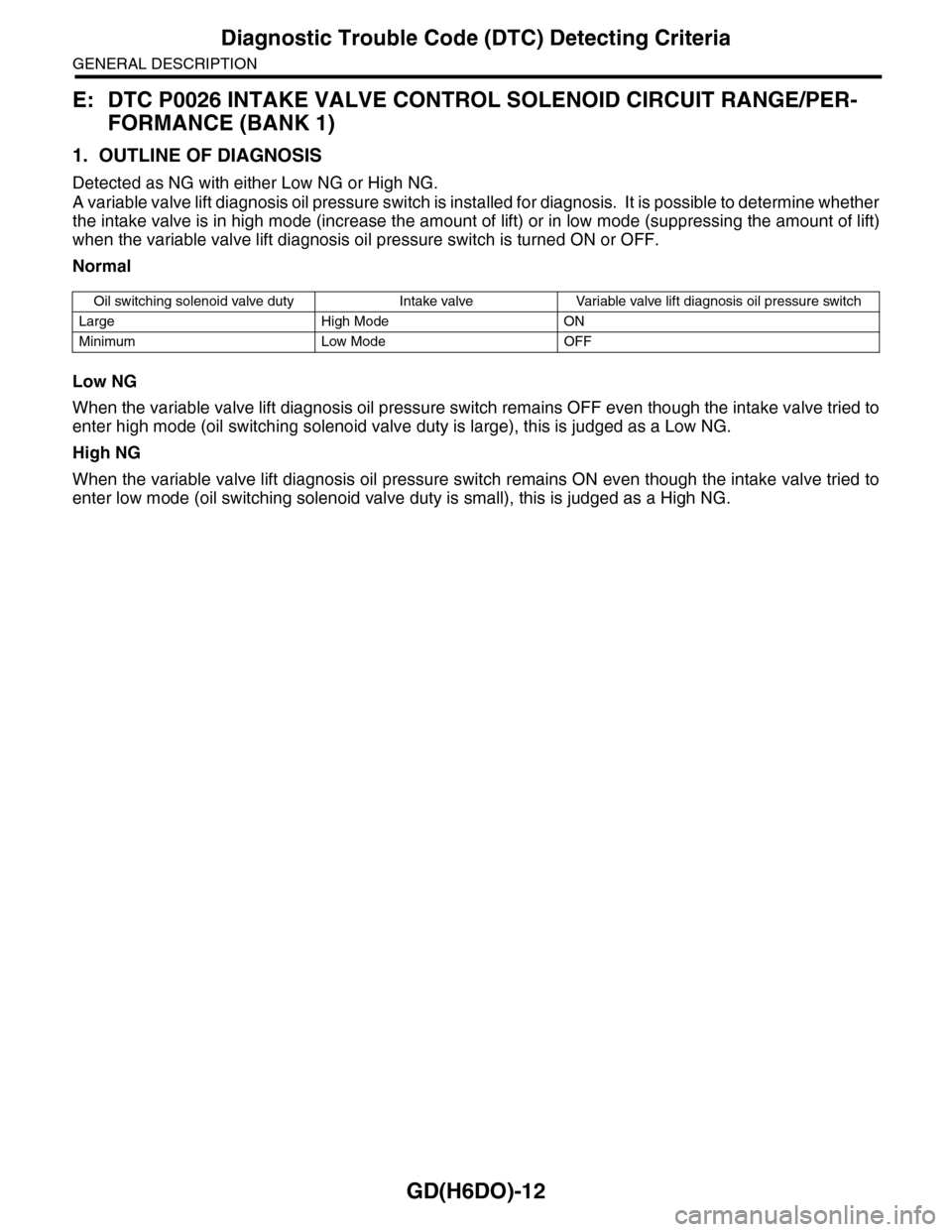

E: DTC P0026 INTAKE VALVE CONTROL SOLENOID CIRCUIT RANGE/PER-

FORMANCE (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detected as NG with either Low NG or High NG.

A variable valve lift diagnosis oil pressure switch is installed for diagnosis. It is possible to determine whether

the intake valve is in high mode (increase the amount of lift) or in low mode (suppressing the amount of lift)

when the variable valve lift diagnosis oil pressure switch is turned ON or OFF.

Normal

Low NG

When the variable valve lift diagnosis oil pressure switch remains OFF even though the intake valve tried to

enter high mode (oil switching solenoid valve duty is large), this is judged as a Low NG.

High NG

When the variable valve lift diagnosis oil pressure switch remains ON even though the intake valve tried to

enter low mode (oil switching solenoid valve duty is small), this is judged as a High NG.

Oil switching solenoid valve duty Intake valve Variable valve lift diagnosis oil pressure switch

Large High Mode ON

Minimum Low Mode OFF

Page 1625 of 2453

GD(H6DO)-13

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

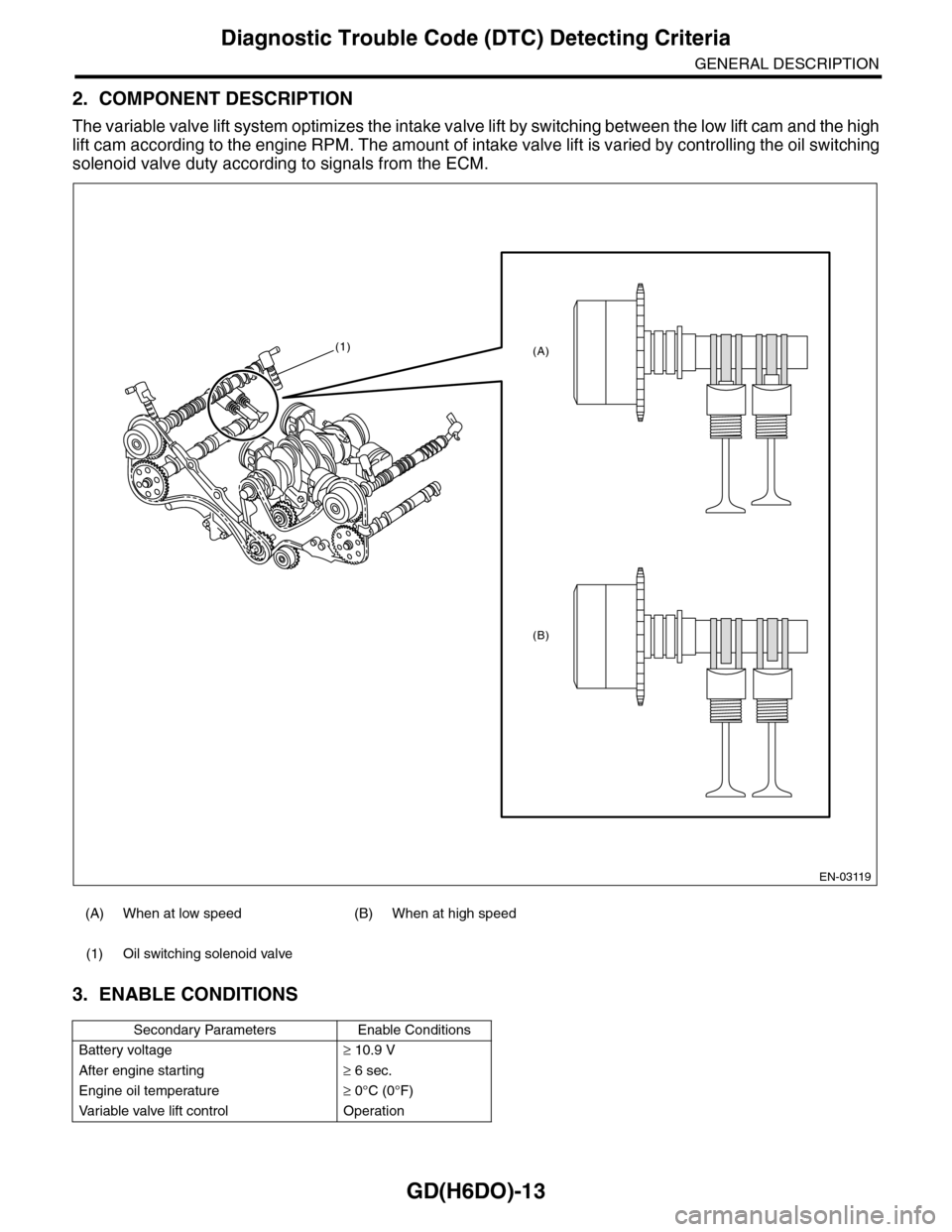

2. COMPONENT DESCRIPTION

The variable valve lift system optimizes the intake valve lift by switching between the low lift cam and the high

lift cam according to the engine RPM. The amount of intake valve lift is varied by controlling the oil switching

solenoid valve duty according to signals from the ECM.

3. ENABLE CONDITIONS

(A) When at low speed (B) When at high speed

(1) Oil switching solenoid valve

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

After engine starting≥ 6 sec.

Engine oil temperature≥ 0°C (0°F)

Va r i a b l e va l v e l i f t c o n t r o l O p e r a t i o n

EN-03119

(1)

(B)

(A)

Page 1626 of 2453

GD(H6DO)-14

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

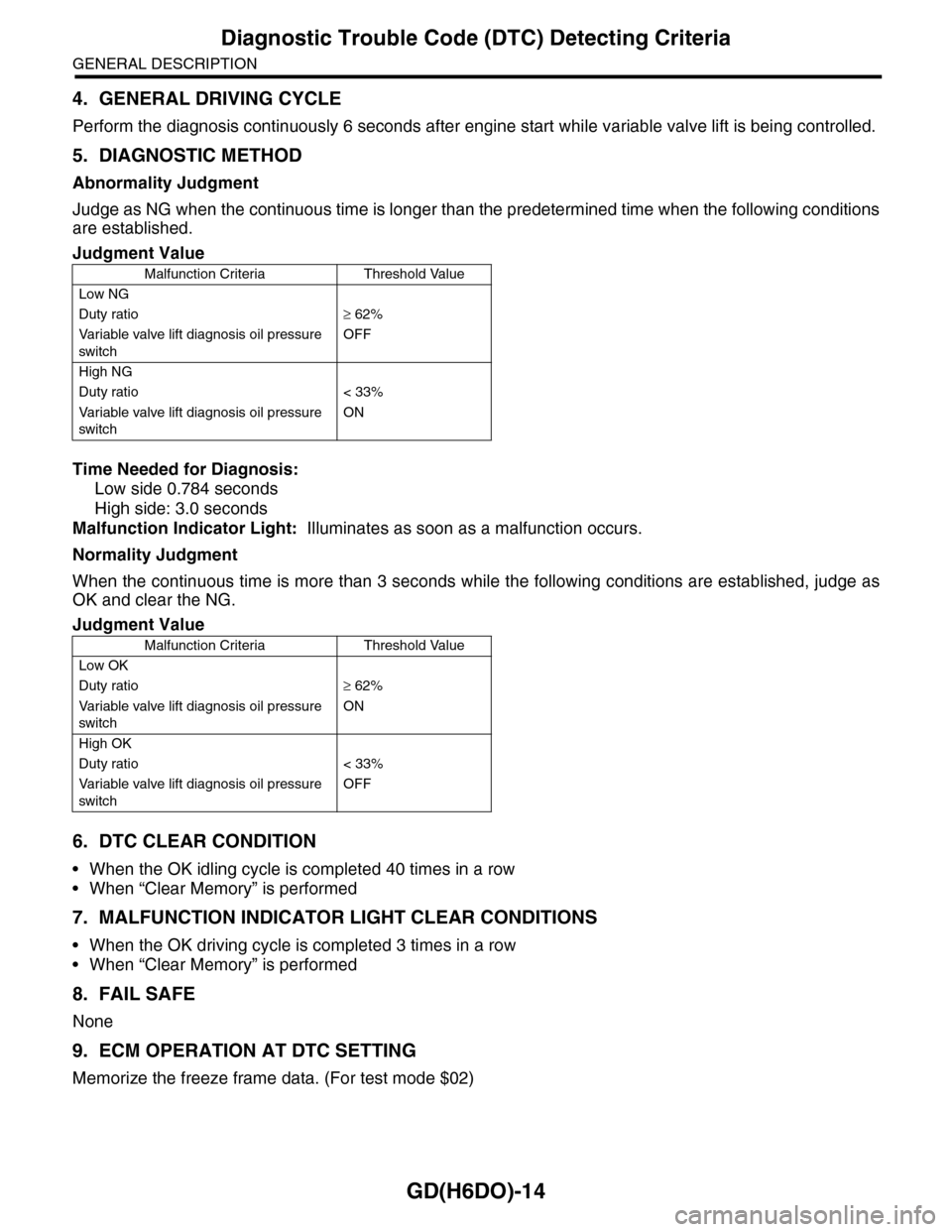

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously 6 seconds after engine start while variable valve lift is being controlled.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time is longer than the predetermined time when the following conditions

are established.

Time Needed for Diagnosis:

Low side 0.784 seconds

High side: 3.0 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

When the continuous time is more than 3 seconds while the following conditions are established, judge as

OK and clear the NG.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

None

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Judgment Value

Malfunction Criteria Threshold Value

Low NG

Duty ratio≥ 62%

Va r i a b l e va l v e l i f t d i a g n o s i s o i l p r e s s u r e

switch

OFF

High NG

Duty ratio < 33%

Va r i a b l e va l v e l i f t d i a g n o s i s o i l p r e s s u r e

switch

ON

Judgment Value

Malfunction Criteria Threshold Value

Low OK

Duty ratio≥ 62%

Va r i a b l e va l v e l i f t d i a g n o s i s o i l p r e s s u r e

switch

ON

High OK

Duty ratio < 33%

Va r i a b l e va l v e l i f t d i a g n o s i s o i l p r e s s u r e

switch

OFF

Page 1944 of 2453

ME(H6DO)-78

Oil Switching Solenoid Valve

MECHANICAL

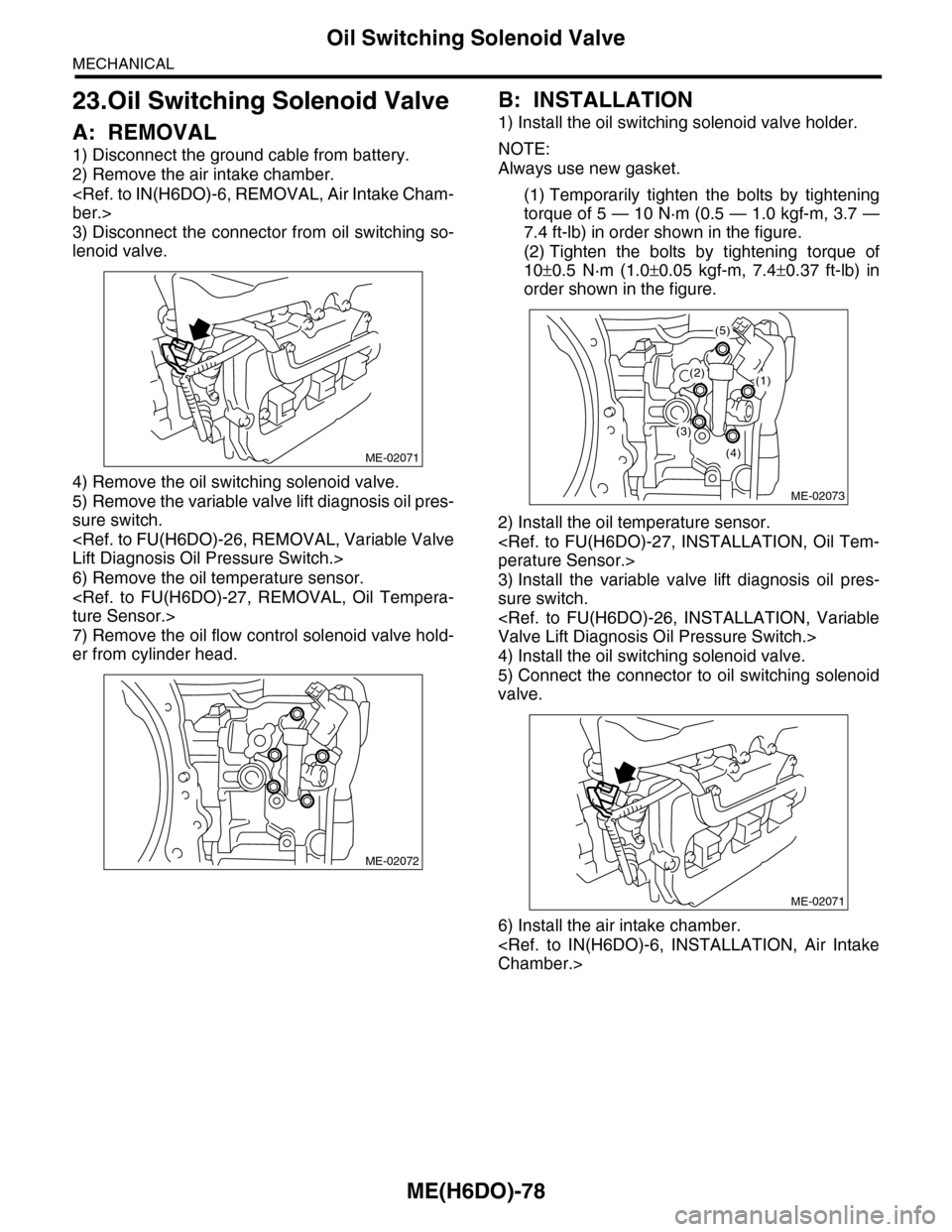

23.Oil Switching Solenoid Valve

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake chamber.

3) Disconnect the connector from oil switching so-

lenoid valve.

4) Remove the oil switching solenoid valve.

5) Remove the variable valve lift diagnosis oil pres-

sure switch.

6) Remove the oil temperature sensor.

7) Remove the oil flow control solenoid valve hold-

er from cylinder head.

B: INSTALLATION

1) Install the oil switching solenoid valve holder.

NOTE:

Always use new gasket.

(1) Temporarily tighten the bolts by tightening

torque of 5 — 10 N·m (0.5 — 1.0 kgf-m, 3.7 —

7.4 ft-lb) in order shown in the figure.

(2) Tighten the bolts by tightening torque of

10±0.5 N·m (1.0±0.05 kgf-m, 7.4±0.37 ft-lb) in

order shown in the figure.

2) Install the oil temperature sensor.

3) Install the variable valve lift diagnosis oil pres-

sure switch.

4) Install the oil switching solenoid valve.

5) Connect the connector to oil switching solenoid

valve.

6) Install the air intake chamber.

ME-02071

ME-02072

ME-02073

(2)(1)

(5)

(4)

(3)

ME-02071