Variable SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1949 of 2453

ME(H6DO)-83

Engine Trouble in General

MECHANICAL

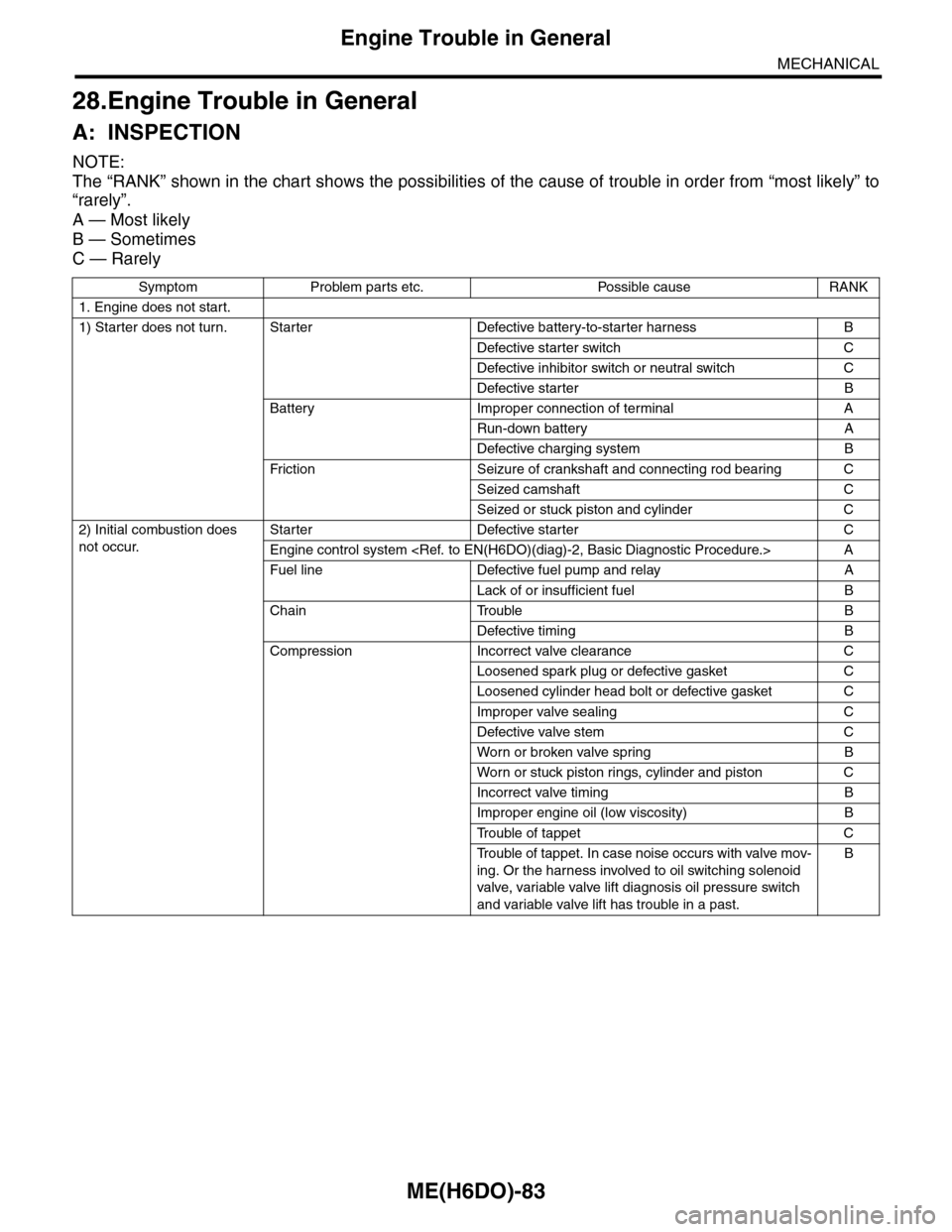

28.Engine Trouble in General

A: INSPECTION

NOTE:

The “RANK” shown in the chart shows the possibilities of the cause of trouble in order from “most likely” to

“rarely”.

A — Most likely

B — Sometimes

C — Rarely

Symptom Problem parts etc. Possible cause RANK

1. Engine does not start.

1) Starter does not turn. Starter Defective battery-to-starter harness B

Defective starter switch C

Defective inhibitor switch or neutral switch C

Defective starter B

Battery Improper connection of terminal A

Run-down battery A

Defective charging system B

Fr iction Seizure of crankshaft and connecting rod bear ing C

Seized camshaft C

Seized or stuck piston and cylinder C

2) Initial combustion does

not occur.

Starter Defective starter C

Engine control system

Fuel line Defective fuel pump and relay A

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Page 1950 of 2453

ME(H6DO)-84

Engine Trouble in General

MECHANICAL

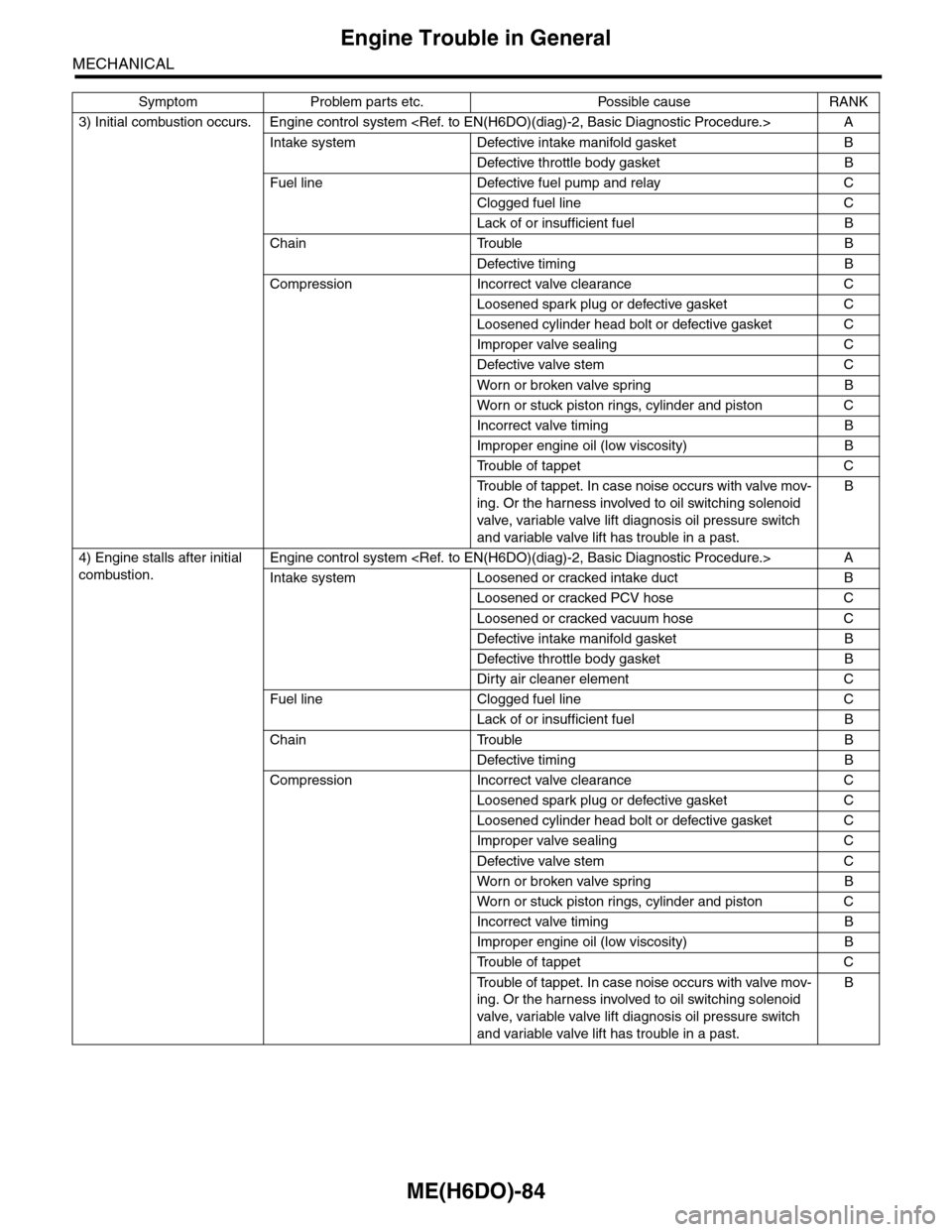

3) Initial combustion occurs. Engine control system

Intake system Defective intake manifold gasket B

Defective throttle body gasket B

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

4) Engine stalls after initial

combustion.

Engine control system

Intake system Loosened or cracked intake duct B

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose C

Defective intake manifold gasket B

Defective throttle body gasket B

Dirty air cleaner element C

Fuel line Clogged fuel line C

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Symptom Problem parts etc. Possible cause RANK

Page 1951 of 2453

ME(H6DO)-85

Engine Trouble in General

MECHANICAL

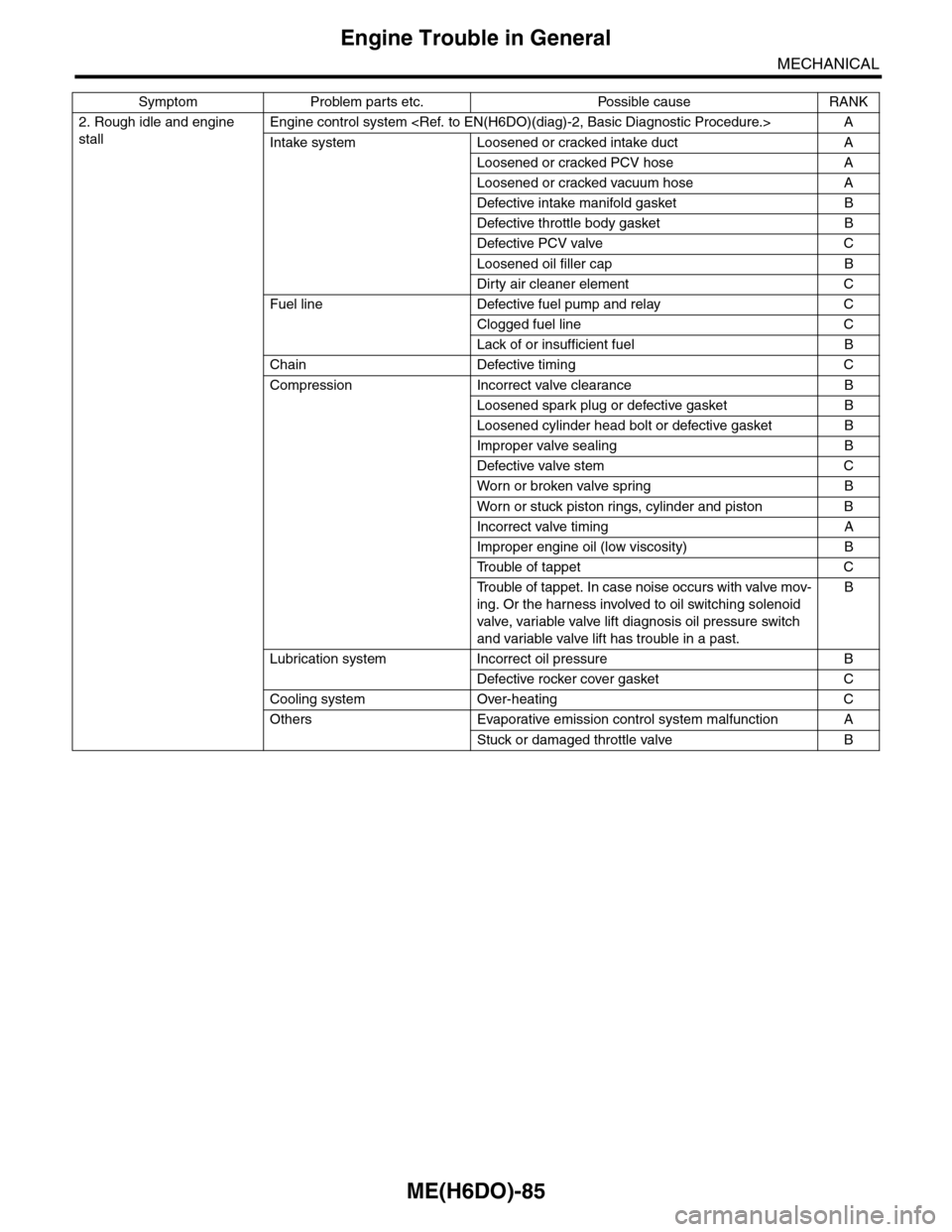

2. Rough idle and engine

stall

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve C

Loosened oil filler cap B

Dirty air cleaner element C

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Defective timing C

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston B

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Defective rocker cover gasket C

Cooling system Over-heating C

Others Evaporative emission control system malfunction A

Stuck or damaged throttle valve B

Symptom Problem parts etc. Possible cause RANK

Page 1952 of 2453

ME(H6DO)-86

Engine Trouble in General

MECHANICAL

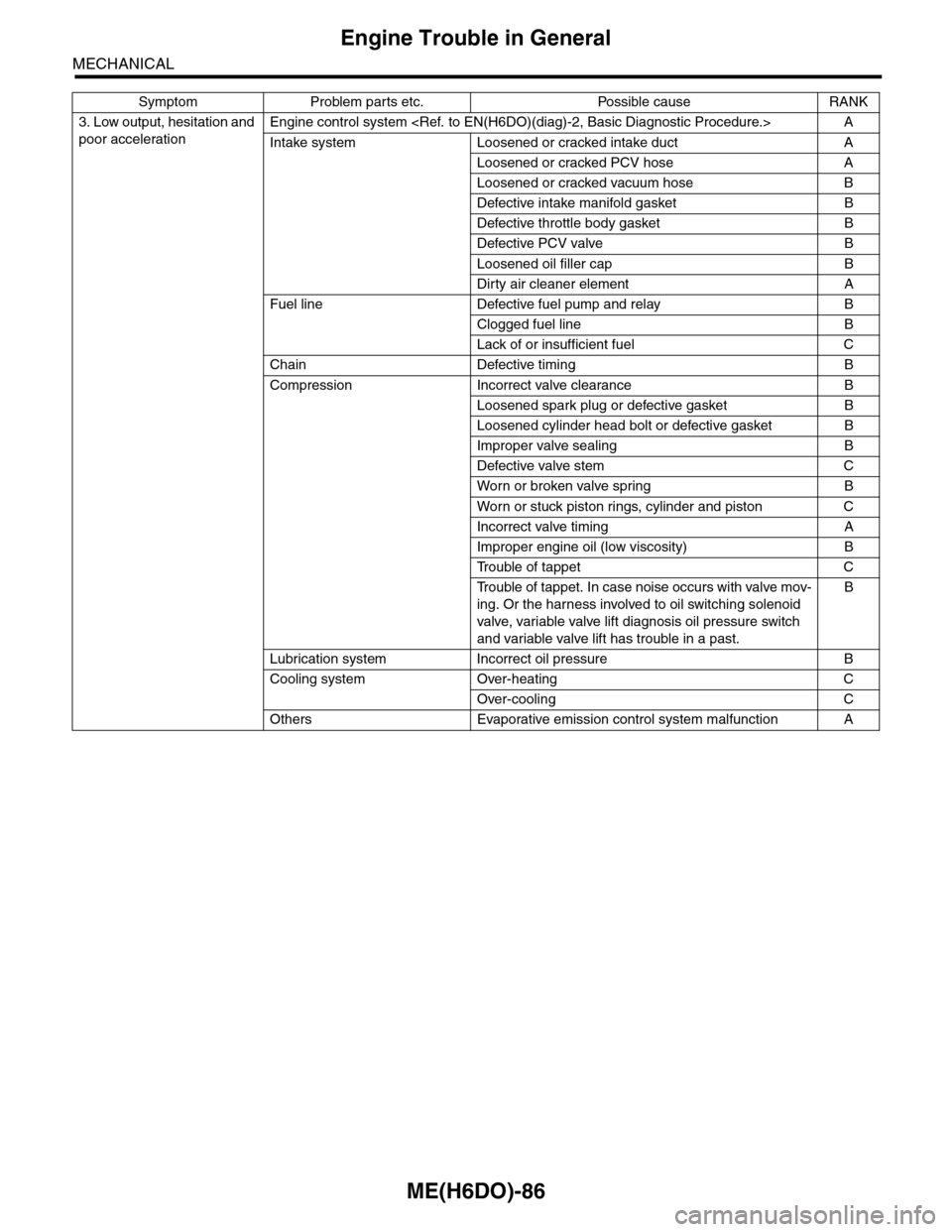

3. Low output, hesitation and

poor acceleration

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Cooling system Over-heating C

Over-cooling C

Others Evaporative emission control system malfunction A

Symptom Problem parts etc. Possible cause RANK

Page 1953 of 2453

ME(H6DO)-87

Engine Trouble in General

MECHANICAL

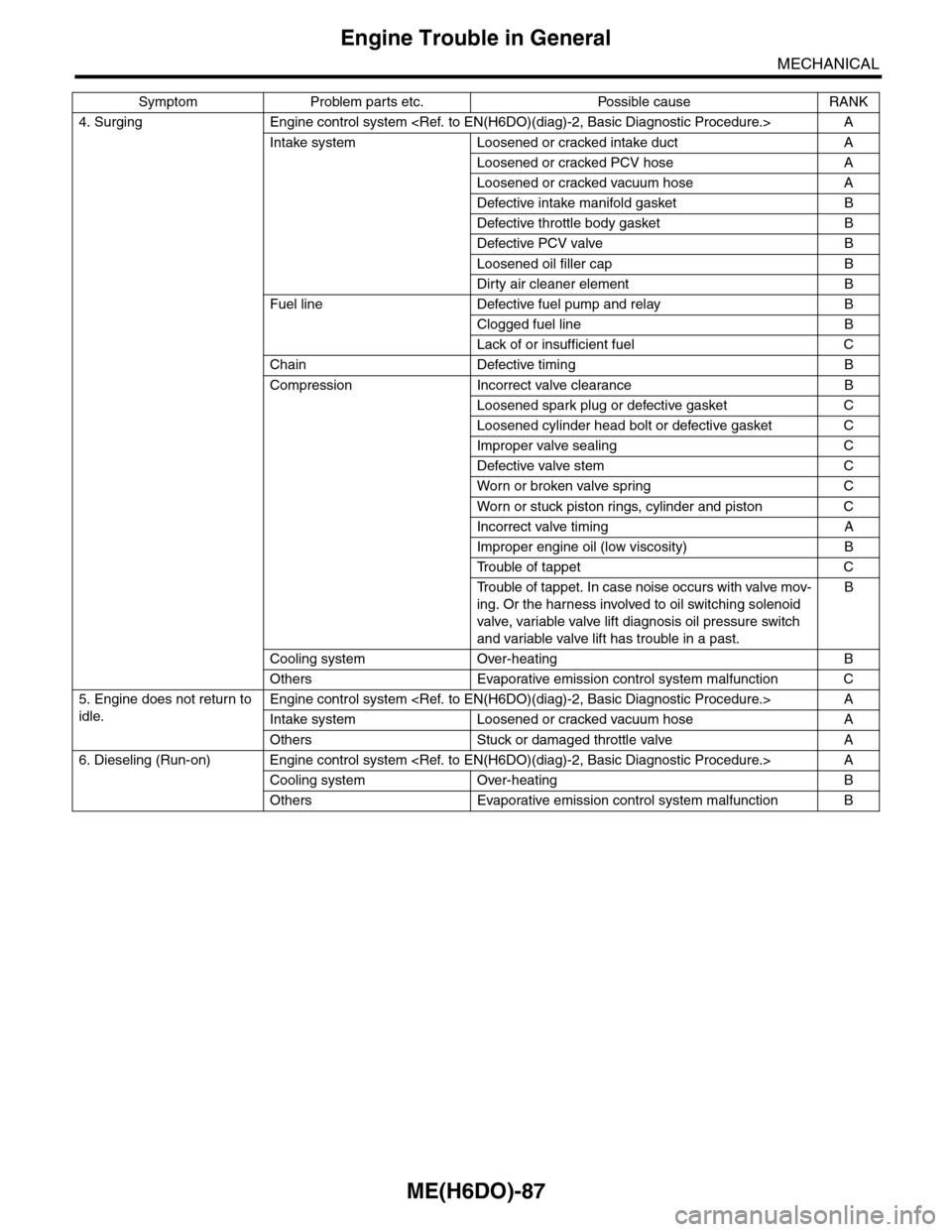

4. Surging Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element B

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating B

Others Evaporative emission control system malfunction C

5. Engine does not return to

idle.

Engine control system

Intake system Loosened or cracked vacuum hose A

Others Stuck or damaged throttle valve A

6. Dieseling (Run-on) Engine control system

Cooling system Over-heating B

Others Evaporative emission control system malfunction B

Symptom Problem parts etc. Possible cause RANK

Page 1954 of 2453

ME(H6DO)-88

Engine Trouble in General

MECHANICAL

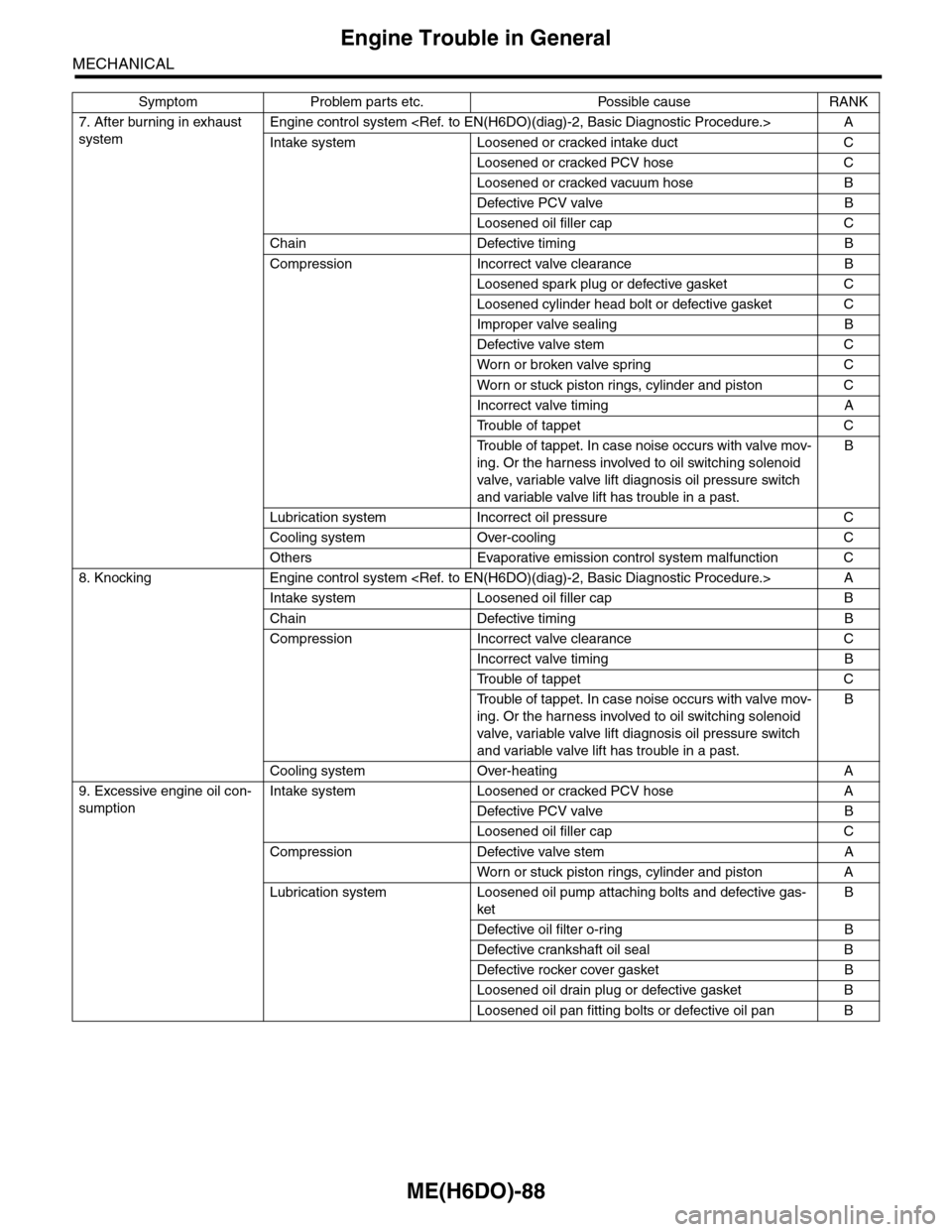

7. After burning in exhaust

system

Engine control system

Intake system Loosened or cracked intake duct C

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose B

Defective PCV valve B

Loosened oil filler cap C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure C

Cooling system Over-cooling C

Others Evaporative emission control system malfunction C

8. Knocking Engine control system

Intake system Loosened oil filler cap B

Chain Defective timing B

Compression Incorrect valve clearance C

Incorrect valve timing B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating A

9. Excessive engine oil con-

sumption

Intake system Loosened or cracked PCV hose A

Defective PCV valve B

Loosened oil filler cap C

Compression Defective valve stem A

Wor n or stuck piston r ings, cylinder and piston A

Lubrication system Loosened oil pump attaching bolts and defective gas-

ket

B

Defective oil filter o-ring B

Defective crankshaft oil seal B

Defective rocker cover gasket B

Loosened oil drain plug or defective gasket B

Loosened oil pan fitting bolts or defective oil pan B

Symptom Problem parts etc. Possible cause RANK

Page 1955 of 2453

ME(H6DO)-89

Engine Trouble in General

MECHANICAL

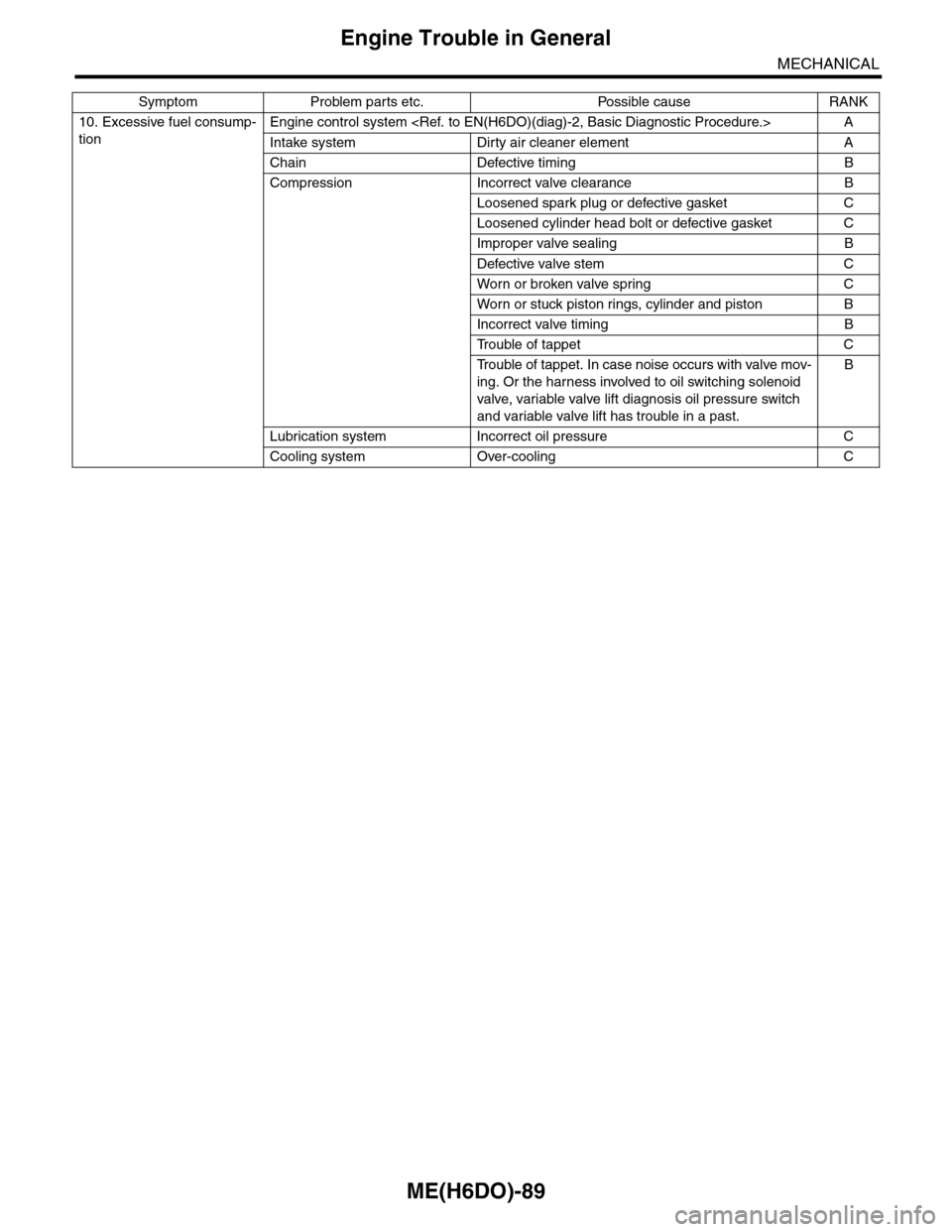

10. Excessive fuel consump-

tion

Engine control system

Intake system Dirty air cleaner element A

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston B

Incorrect valve timing B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure C

Cooling system Over-cooling C

Symptom Problem parts etc. Possible cause RANK

Page 1976 of 2453

SC(H6DO)-18

Starter

STARTING/CHARGING SYSTEMS

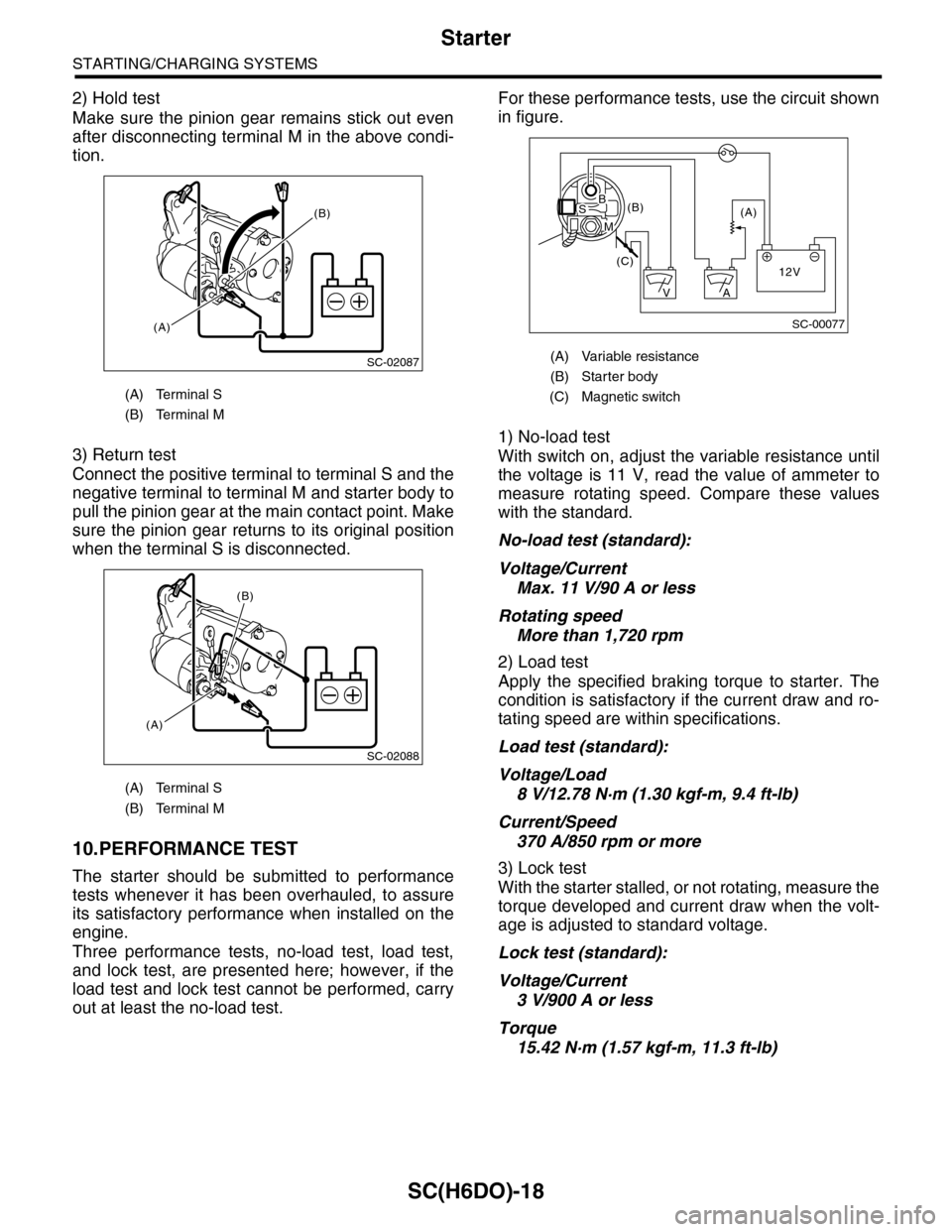

2) Hold test

Make sure the pinion gear remains stick out even

after disconnecting terminal M in the above condi-

tion.

3) Return test

Connect the positive terminal to terminal S and the

negative terminal to terminal M and starter body to

pull the pinion gear at the main contact point. Make

sure the pinion gear returns to its original position

when the terminal S is disconnected.

10.PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

1) No-load test

With switch on, adjust the variable resistance until

the voltage is 11 V, read the value of ammeter to

measure rotating speed. Compare these values

with the standard.

No-load test (standard):

Voltage/Current

Max. 11 V/90 A or less

Rotating speed

More than 1,720 rpm

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and ro-

tating speed are within specifications.

Load test (standard):

Voltage/Load

8 V/12.78 N·m (1.30 kgf-m, 9.4 ft-lb)

Current/Speed

370 A/850 rpm or more

3) Lock test

With the starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to standard voltage.

Lock test (standard):

Voltage/Current

3 V/900 A or less

Torque

15.42 N·m (1.57 kgf-m, 11.3 ft-lb)

(A) Terminal S

(B) Terminal M

(A) Terminal S

(B) Terminal M

SC-02087

(B)

(A)

SC-02088

(A)

(B)

(A) Variable resistance

(B) Starter body

(C) Magnetic switch

SC-00077

(A)(B)

(C)12V

+

AV

BS

M

Page 2297 of 2453

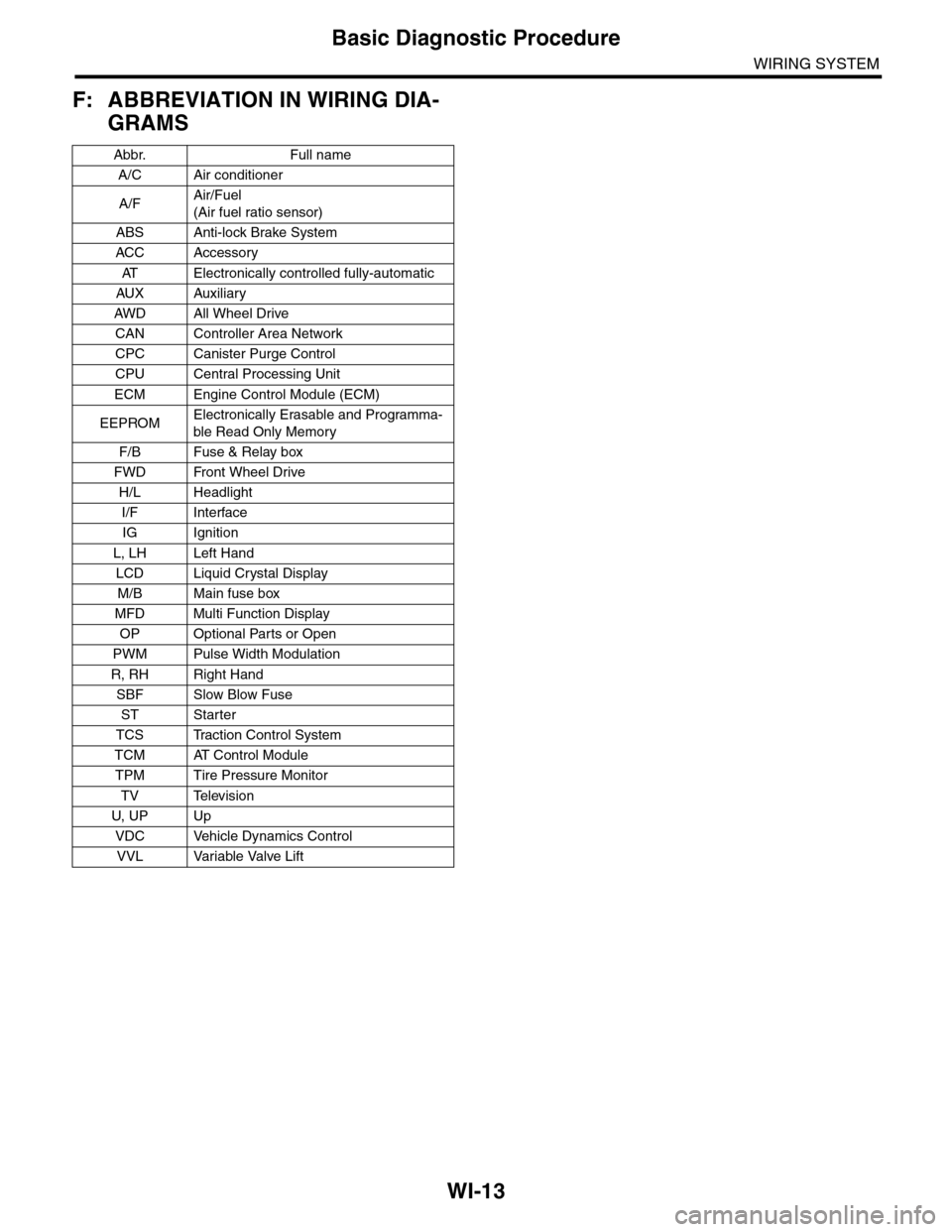

WI-13

Basic Diagnostic Procedure

WIRING SYSTEM

F: ABBREVIATION IN WIRING DIA-

GRAMS

Abbr. Full name

A/C Air conditioner

A/FAir/Fuel

(Air fuel ratio sensor)

ABS Anti-lock Brake System

ACC Accessor y

AT E l e c t r o n i c a l l y c o n t r o l l e d f u l l y - a u t o m a t i c

AUX Auxiliar y

AW D A ll W he e l D r i ve

CAN Controller Area Network

CPC Canister Purge Control

CPU Central Processing Unit

ECM Engine Control Module (ECM)

EEPROMElectronically Erasable and Programma-

ble Read Only Memory

F/B Fuse & Relay box

FWD Front Wheel Drive

H/L Headlight

I/F Interface

IG Ignition

L, LH Left Hand

LCD Liquid Crystal Display

M/B Main fuse box

MFD Multi Function Display

OP Optional Parts or Open

PWM Pulse Width Modulation

R, RH Right Hand

SBF Slow Blow Fuse

ST Starter

TCS Traction Control System

TCM AT Control Module

TPM Tire Pressure Monitor

TV Television

U, UP Up

VDC Vehicle Dynamics Control

VVL Variable Valve Lift

Page 2441 of 2453

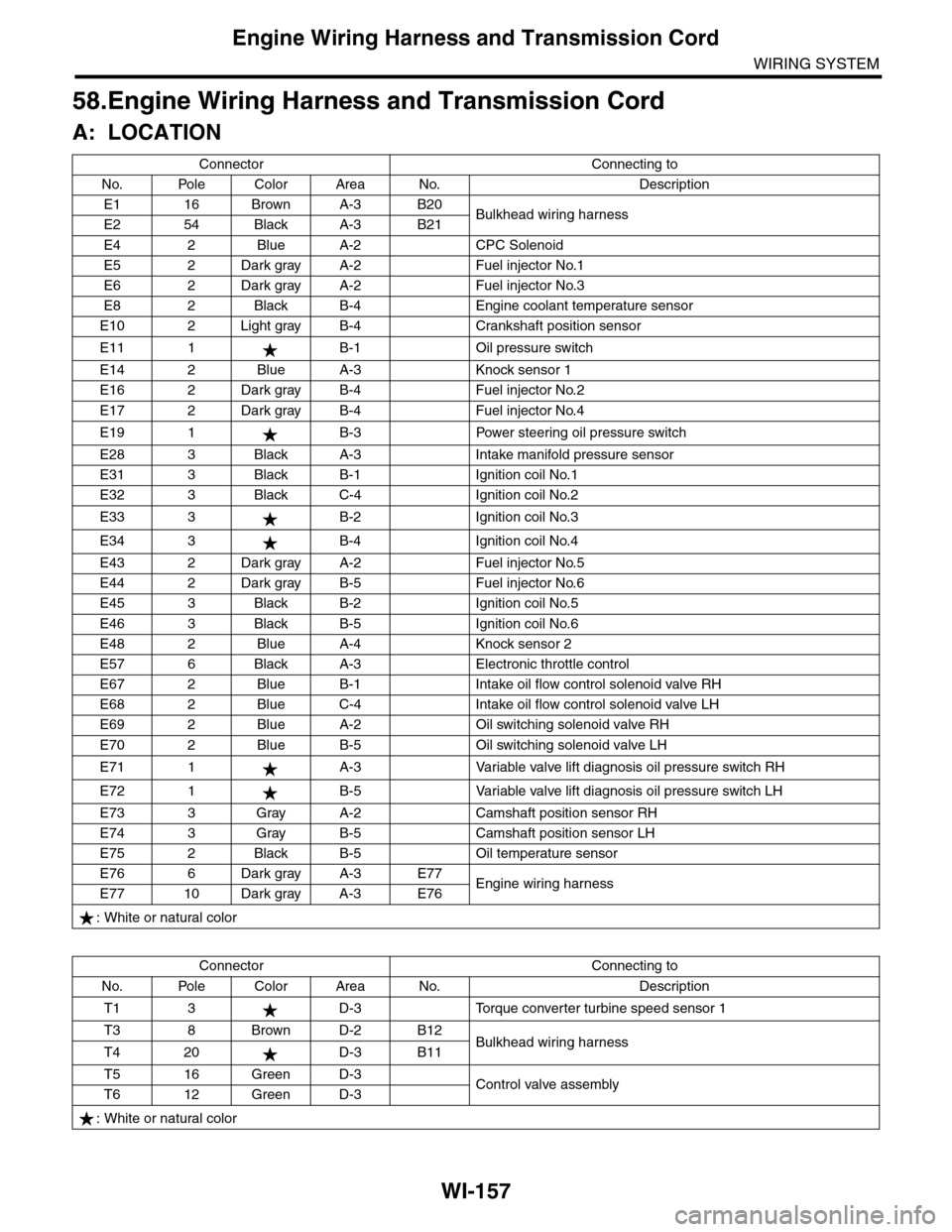

WI-157

Engine Wiring Harness and Transmission Cord

WIRING SYSTEM

58.Engine Wiring Harness and Transmission Cord

A: LOCATION

Connector Connecting to

No. Pole Color Area No. Description

E1 16 Brown A-3 B20Bulkhead wiring harnessE2 54 Black A-3 B21

E4 2 Blue A-2 CPC Solenoid

E5 2 Dark gray A-2 Fuel injector No.1

E6 2 Dark gray A-2 Fuel injector No.3

E8 2 Black B-4 Engine coolant temperature sensor

E10 2 Light gray B-4 Crankshaft position sensor

E11 1 B-1 Oil pressure switch

E14 2 Blue A-3 Knock sensor 1

E16 2 Dark gray B-4 Fuel injector No.2

E17 2 Dark gray B-4 Fuel injector No.4

E19 1 B-3 Power steering oil pressure switch

E28 3 Black A-3 Intake manifold pressure sensor

E31 3 Black B-1 Ignition coil No.1

E32 3 Black C-4 Ignition coil No.2

E33 3 B-2 Ignition coil No.3

E34 3 B-4 Ignition coil No.4

E43 2 Dark gray A-2 Fuel injector No.5

E44 2 Dark gray B-5 Fuel injector No.6

E45 3 Black B-2 Ignition coil No.5

E46 3 Black B-5 Ignition coil No.6

E48 2 Blue A-4 Knock sensor 2

E57 6 Black A-3 Electronic throttle control

E67 2 Blue B-1 Intake oil flow control solenoid valve RH

E68 2 Blue C-4 Intake oil flow control solenoid valve LH

E69 2 Blue A-2 Oil switching solenoid valve RH

E70 2 Blue B-5 Oil switching solenoid valve LH

E71 1 A-3 Variable valve lift diagnosis oil pressure switch RH

E72 1 B-5 Variable valve lift diagnosis oil pressure switch LH

E73 3 Gray A-2 Camshaft position sensor RH

E74 3 Gray B-5 Camshaft position sensor LH

E75 2 Black B-5 Oil temperature sensor

E76 6 Dark gray A-3 E77Engine wiring harnessE77 10 Dark gray A-3 E76

: White or natural color

Connector Connecting to

No. Pole Color Area No. Description

T1 3 D-3 Torque converter turbine speed sensor 1

T3 8 Brown D-2 B12Bulkhead wiring harnessT4 20 D-3 B11

T5 16 Green D-3Control valve assemblyT6 12 Green D-3

: White or natural color