SUZUKI ERTIGA 2013 1.G Owners Manual

Manufacturer: SUZUKI, Model Year: 2013, Model line: ERTIGA, Model: SUZUKI ERTIGA 2013 1.GPages: 207, PDF Size: 5.14 MB

Page 151 of 207

Downloaded from www.Manualslib.com manuals search engine 7-6

INSPECTION AND MAINTENANCE

60MK0-14E

NOTE:

I – Inspect, clean, adjust, lubricate or replace as necessary

R – Replace or change

T – Tighten to the specified torque

*1 Inspect or replace more frequently if necessary.Severe

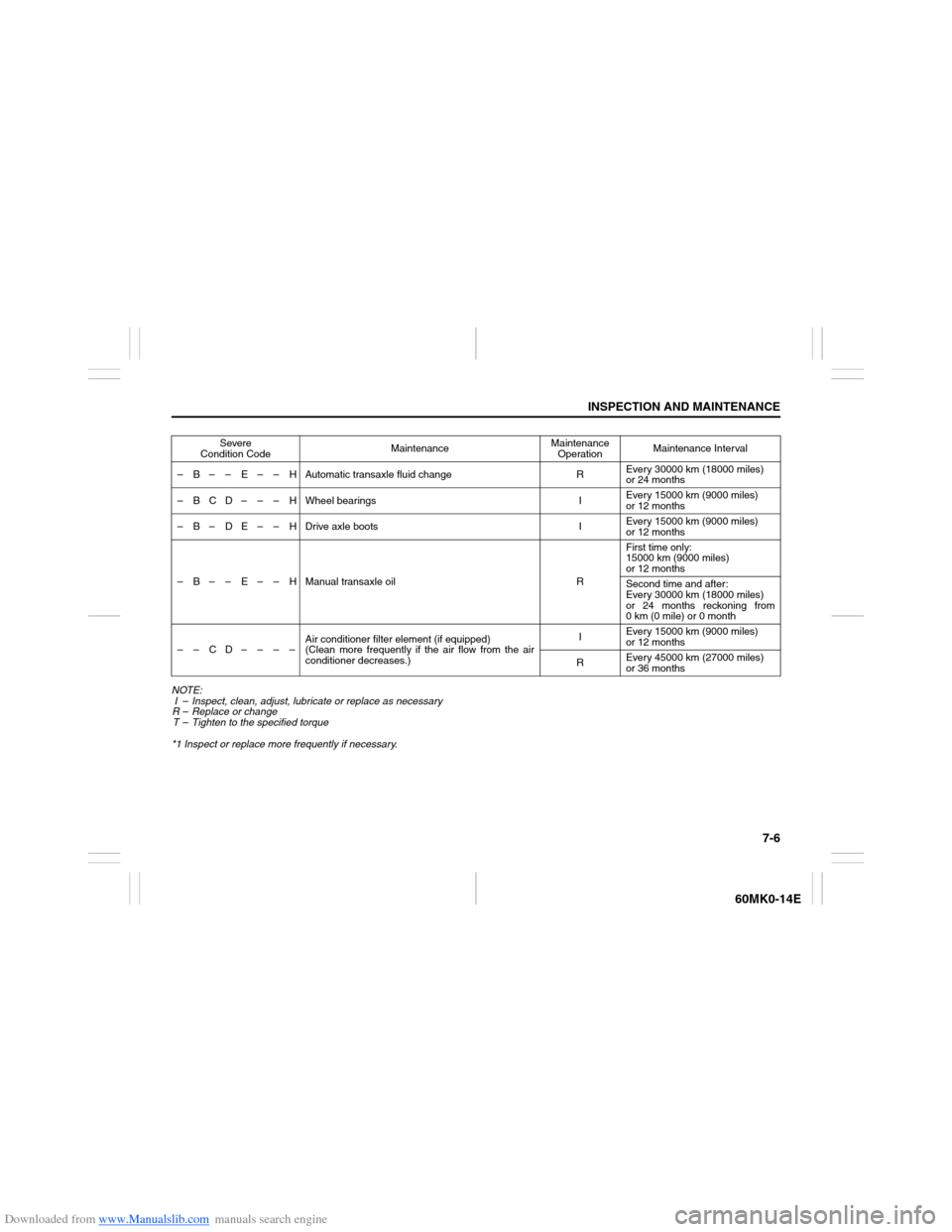

Condition CodeMaintenanceMaintenance

OperationMaintenance Interval

– B – – E – – H Automatic transaxle fluid change REvery 30000 km (18000 miles)

or 24 months

– B C D – – – H Wheel bearings IEvery 15000 km (9000 miles)

or 12 months

– B – D E – – H Drive axle boots IEvery 15000 km (9000 miles)

or 12 months

– B – – E – – H Manual transaxle oil RFirst time only:

15000 km (9000 miles)

or 12 months

Second time and after:

Every 30000 km (18000 miles)

or 24 months reckoning from

0 km (0 mile) or 0 month

– – CD– – – –Air conditioner filter element (if equipped)

(Clean more frequently if the air flow from the air

conditioner decreases.)IEvery 15000 km (9000 miles)

or 12 months

REvery 45000 km (27000 miles)

or 36 months

Page 152 of 207

Downloaded from www.Manualslib.com manuals search engine 7-7INSPECTION AND MAINTENANCE

60MK0-14E

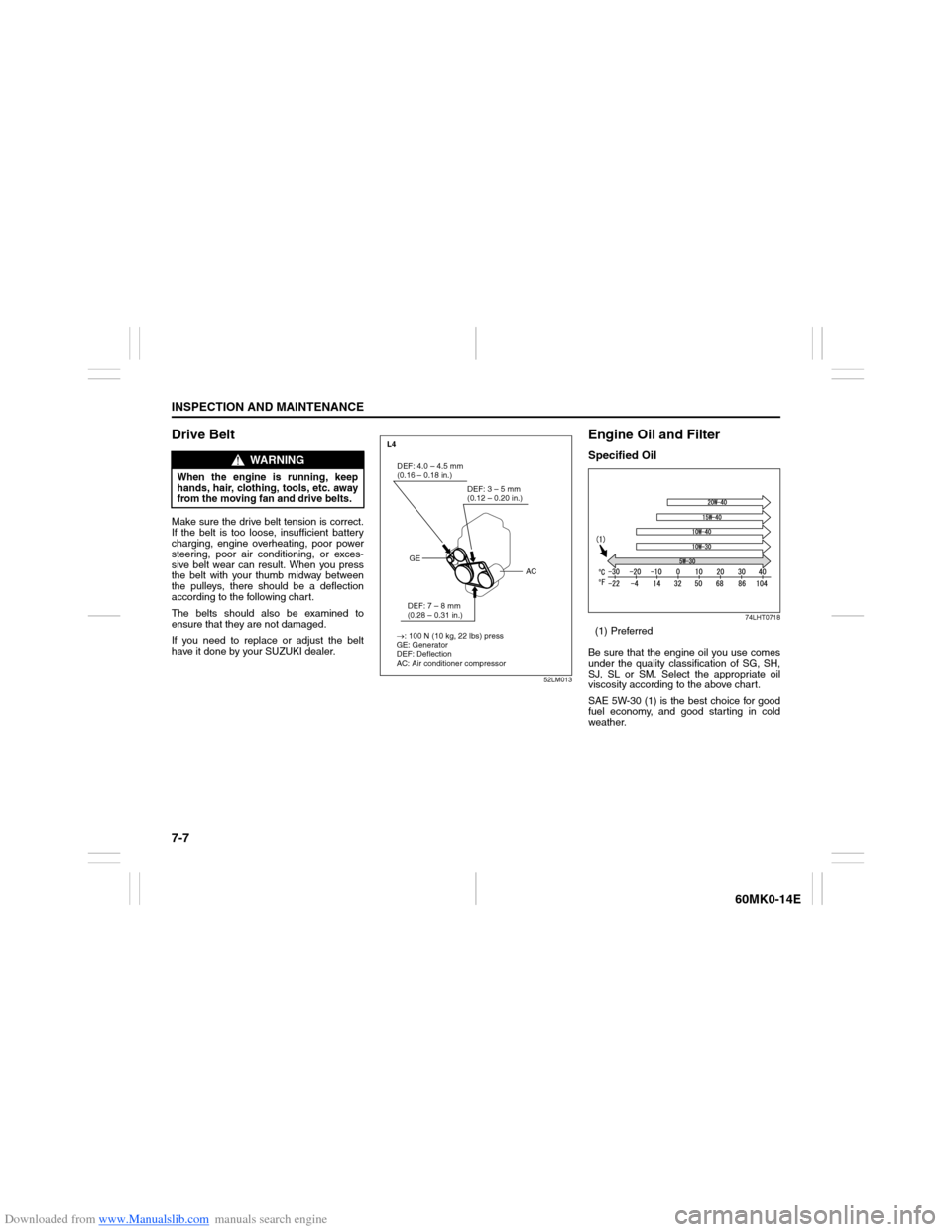

Drive BeltMake sure the drive belt tension is correct.

If the belt is too loose, insufficient battery

charging, engine overheating, poor power

steering, poor air conditioning, or exces-

sive belt wear can result. When you press

the belt with your thumb midway between

the pulleys, there should be a deflection

according to the following chart.

The belts should also be examined to

ensure that they are not damaged.

If you need to replace or adjust the belt

have it done by your SUZUKI dealer.

52LM013

Engine Oil and FilterSpecified Oil

74LHT0718

(1) Preferred

Be sure that the engine oil you use comes

under the quality classification of SG, SH,

SJ, SL or SM. Select the appropriate oil

viscosity according to the above chart.

SAE 5W-30 (1) is the best choice for good

fuel economy, and good starting in cold

weather.

WARNING

When the engine is running, keep

hands, hair, clothing, tools, etc. away

from the moving fan and drive belts.

→: 100 N (10 kg, 22 lbs) press

GE: Generator

DEF: Deflection

AC: Air conditioner compressorDEF: 4.0 – 4.5 mm

(0.16 – 0.18 in.)

DEF: 3 – 5 mm

(0.12 – 0.20 in.)

GE

ACDEF: 7 – 8 mm

(0.28 – 0.31 in.)

L4

Page 153 of 207

Downloaded from www.Manualslib.com manuals search engine 7-8

INSPECTION AND MAINTENANCE

60MK0-14E

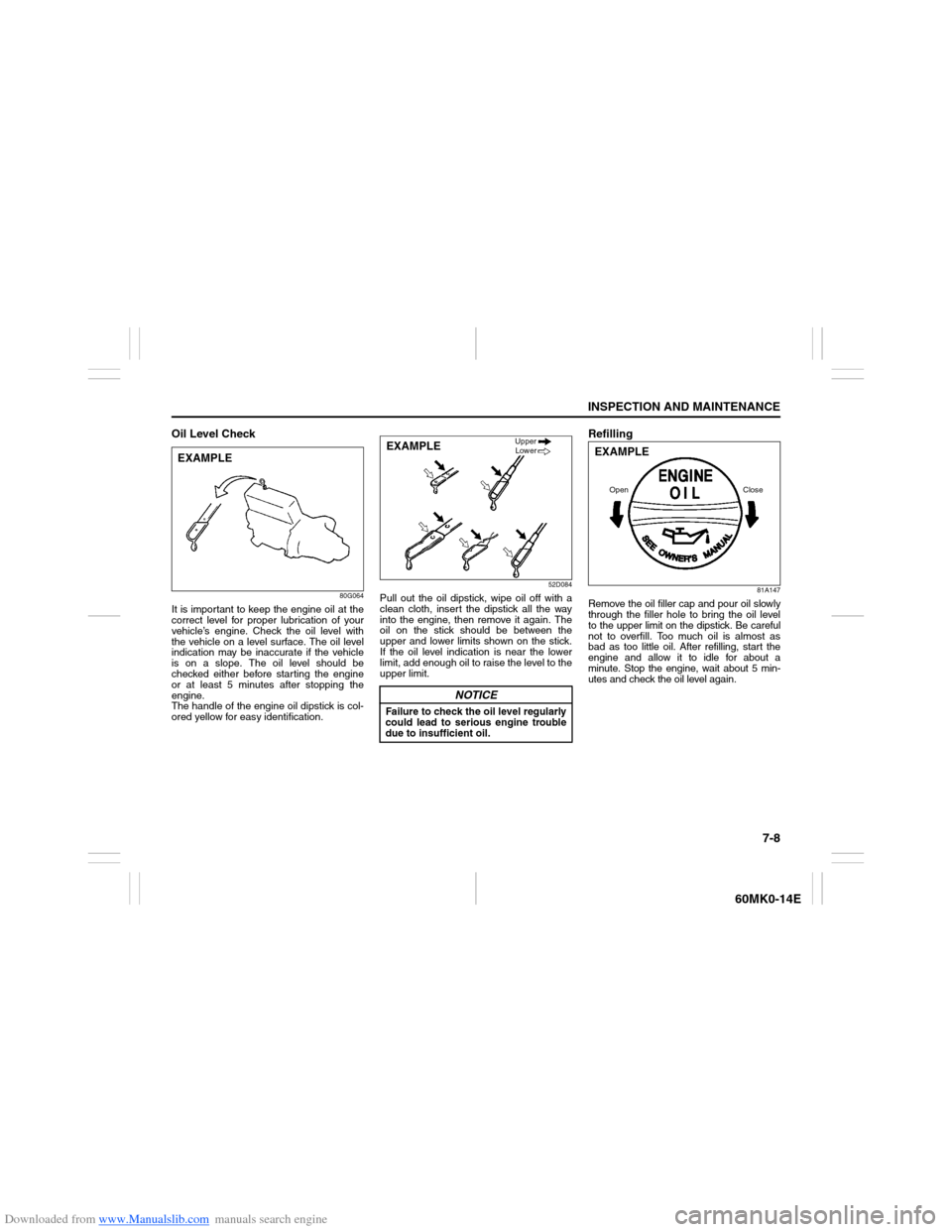

Oil Level Check

80G064

It is important to keep the engine oil at the

correct level for proper lubrication of your

vehicle’s engine. Check the oil level with

the vehicle on a level surface. The oil level

indication may be inaccurate if the vehicle

is on a slope. The oil level should be

checked either before starting the engine

or at least 5 minutes after stopping the

engine.

The handle of the engine oil dipstick is col-

ored yellow for easy identification.

52D084

Pull out the oil dipstick, wipe oil off with a

clean cloth, insert the dipstick all the way

into the engine, then remove it again. The

oil on the stick should be between the

upper and lower limits shown on the stick.

If the oil level indication is near the lower

limit, add enough oil to raise the level to the

upper limit.

Refilling

81A147

Remove the oil filler cap and pour oil slowly

through the filler hole to bring the oil level

to the upper limit on the dipstick. Be careful

not to overfill. Too much oil is almost as

bad as too little oil. After refilling, start the

engine and allow it to idle for about a

minute. Stop the engine, wait about 5 min-

utes and check the oil level again.

EXAMPLE

NOTICE

Failure to check the oil level regularly

could lead to serious engine trouble

due to insufficient oil.EXAMPLE

Upper

Lower

Close Open

EXAMPLE

Page 154 of 207

Downloaded from www.Manualslib.com manuals search engine 7-9INSPECTION AND MAINTENANCE

60MK0-14E

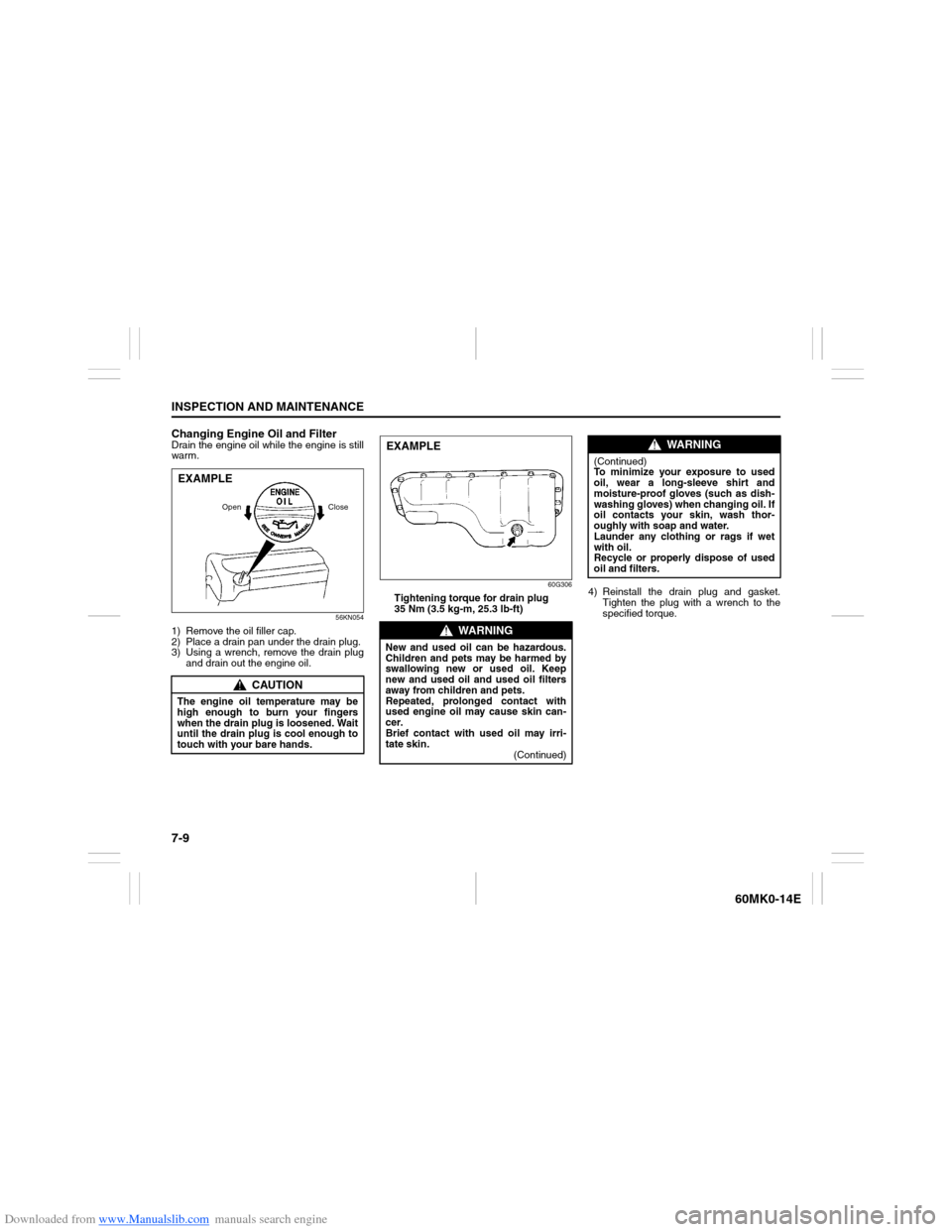

Changing Engine Oil and FilterDrain the engine oil while the engine is still

warm.

56KN054

1) Remove the oil filler cap.

2) Place a drain pan under the drain plug.

3) Using a wrench, remove the drain plug

and drain out the engine oil.

60G306

Tightening torque for drain plug

35 Nm (3.5 kg-m, 25.3 lb-ft)4) Reinstall the drain plug and gasket.

Tighten the plug with a wrench to the

specified torque.

CAUTION

The engine oil temperature may be

high enough to burn your fingers

when the drain plug is loosened. Wait

until the drain plug is cool enough to

touch with your bare hands.

Open Close

EXAMPLE

WARNING

New and used oil can be hazardous.

Children and pets may be harmed by

swallowing new or used oil. Keep

new and used oil and used oil filters

away from children and pets.

Repeated, prolonged contact with

used engine oil may cause skin can-

cer.

Brief contact with used oil may irri-

tate skin.

(Continued)EXAMPLE

WARNING

(Continued)

To minimize your exposure to used

oil, wear a long-sleeve shirt and

moisture-proof gloves (such as dish-

washing gloves) when changing oil. If

oil contacts your skin, wash thor-

oughly with soap and water.

Launder any clothing or rags if wet

with oil.

Recycle or properly dispose of used

oil and filters.

Page 155 of 207

Downloaded from www.Manualslib.com manuals search engine 7-10

INSPECTION AND MAINTENANCE

60MK0-14E

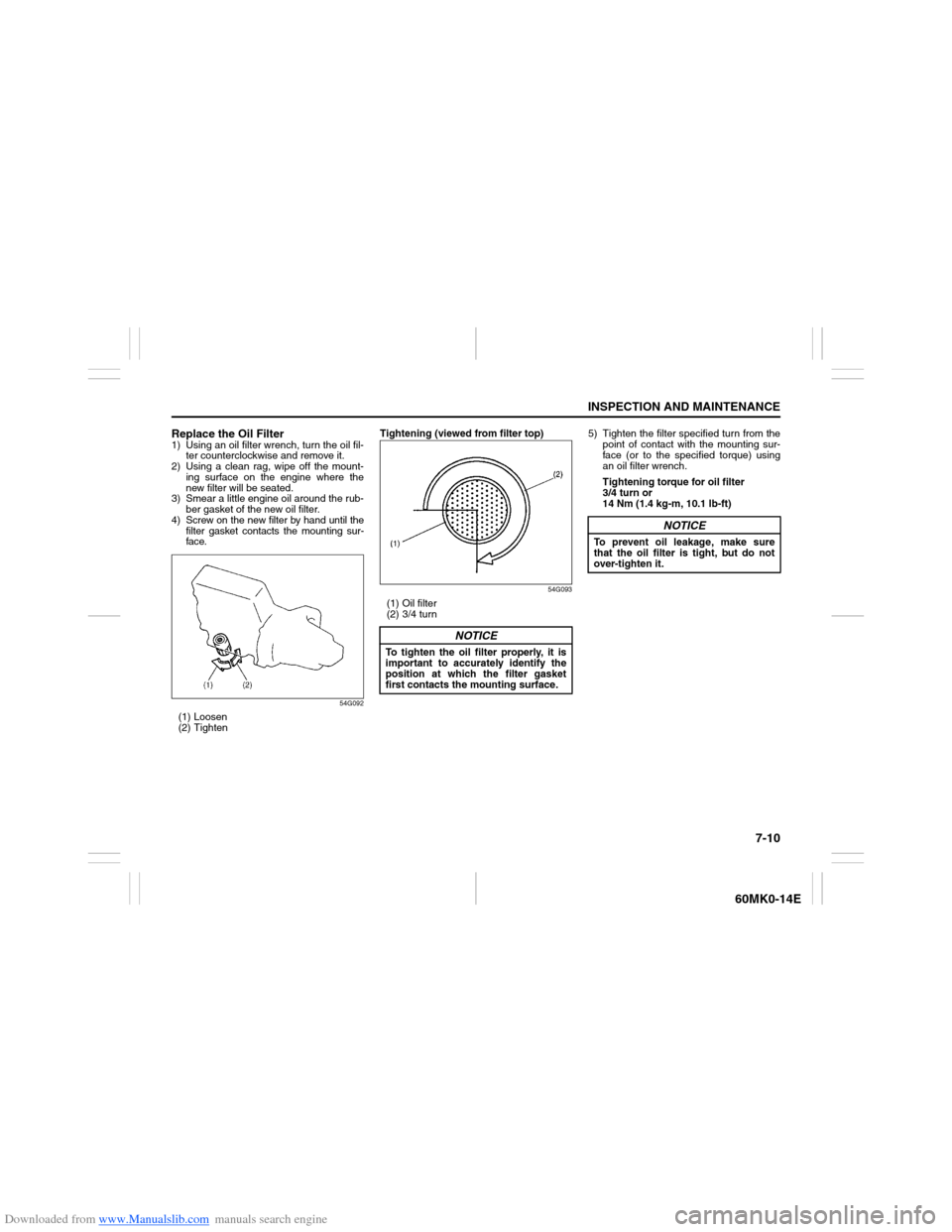

Replace the Oil Filter1) Using an oil filter wrench, turn the oil fil-

ter counterclockwise and remove it.

2) Using a clean rag, wipe off the mount-

ing surface on the engine where the

new filter will be seated.

3) Smear a little engine oil around the rub-

ber gasket of the new oil filter.

4) Screw on the new filter by hand until the

filter gasket contacts the mounting sur-

face.

54G092

(1) Loosen

(2) TightenTightening (viewed from filter top)

54G093

(1) Oil filter

(2) 3/4 turn5) Tighten the filter specified turn from the

point of contact with the mounting sur-

face (or to the specified torque) using

an oil filter wrench.

Tightening torque for oil filter

3/4 turn or

14 Nm (1.4 kg-m, 10.1 lb-ft)

NOTICE

To tighten the oil filter properly, it is

important to accurately identify the

position at which the filter gasket

first contacts the mounting surface.

NOTICE

To prevent oil leakage, make sure

that the oil filter is tight, but do not

over-tighten it.

Page 156 of 207

Downloaded from www.Manualslib.com manuals search engine 7-11INSPECTION AND MAINTENANCE

60MK0-14E

Refill with Oil and Check for Leaks1) Pour oil through the filler hole and

install the filler cap.

For the approximate capacity of the oil,

refer to the “Capacities” item in the

“SPECIFICATIONS” section.

2) Start the engine and look carefully for

leaks at the oil filter and drain plug. Run

the engine at various speeds for at least

5 minutes.

3) Stop the engine and wait about 5 min-

utes. Check the oil level again and add

oil if necessary. Check for leaks again.

Engine CoolantSelection of CoolantTo maintain optimum performance and

durability of your engine, use SUZUKI

Genuine Coolant or equivalent.

This type of coolant is best for your cooling

system as it:

Helps maintain proper engine tempera-

ture.

Gives proper protection against freezing

and boiling.

Gives proper protection against corro-

sion and rust.Failure to use the proper coolant can dam-

age your cooling system. Your authorized

SUZUKI dealer can help you select the

proper coolant.

NOTICE

When replacing the oil filter, it is

recommended that you use a genu-

ine SUZUKI replacement filter. If

you use an aftermarket filter, make

sure it is of equivalent quality and

follow the manufacturer’s instruc-

tions.

Oil leaks from around the oil filter

or drain plug indicate incorrect

installation or gasket damage. If

you find any leaks or are not sure

that the filter has been properly

tightened, have the vehicle

inspected by your SUZUKI dealer.

NOTICE

To avoid damaging your cooling sys-

tem:

Always use a high quality ethylene

glycol base non-silicate type cool-

ant diluted with distilled water at

the correct mixture concentration.

Make sure that the proper mix is 50/

50 coolant to distilled water and in

no case higher than 70/30. Concen-

trations greater than 70/30 coolant

to distilled water will cause over-

heating conditions.

Do not use straight coolant nor

plain water.

Do not add extra inhibitors or addi-

tives. They may not be compatible

with your cooling system.

Do not mix different types of base

coolants. Doing so may result in

accelerated seal wear and/or the

possibility of severe overheating

and extensive engine/automatic

transaxle damage.

Page 157 of 207

Downloaded from www.Manualslib.com manuals search engine 7-12

INSPECTION AND MAINTENANCE

60MK0-14E

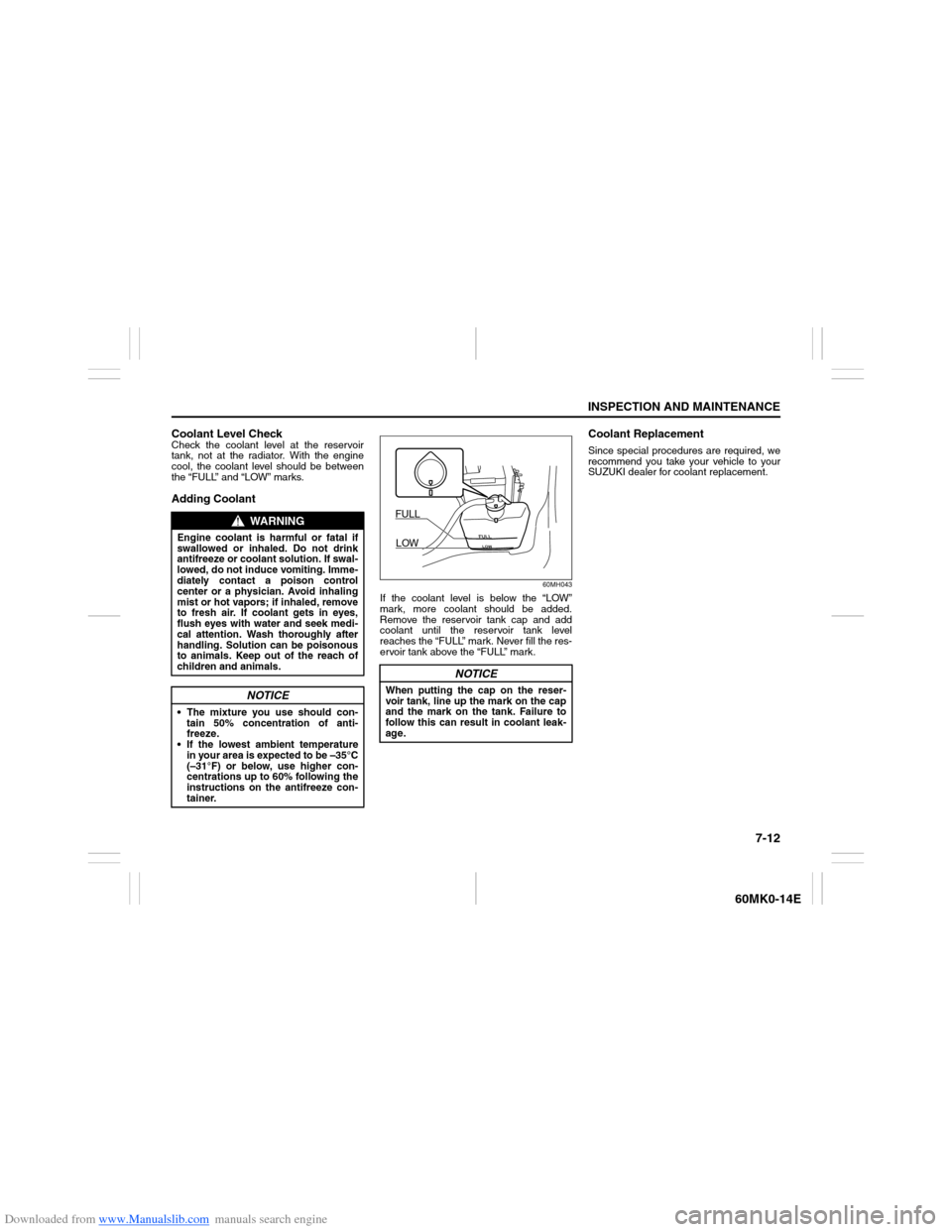

Coolant Level CheckCheck the coolant level at the reservoir

tank, not at the radiator. With the engine

cool, the coolant level should be between

the “FULL” and “LOW” marks.Adding Coolant

60MH043

If the coolant level is below the “LOW”

mark, more coolant should be added.

Remove the reservoir tank cap and add

coolant until the reservoir tank level

reaches the “FULL” mark. Never fill the res-

ervoir tank above the “FULL” mark.

Coolant ReplacementSince special procedures are required, we

recommend you take your vehicle to your

SUZUKI dealer for coolant replacement.

WARNING

Engine coolant is harmful or fatal if

swallowed or inhaled. Do not drink

antifreeze or coolant solution. If swal-

lowed, do not induce vomiting. Imme-

diately contact a poison control

center or a physician. Avoid inhaling

mist or hot vapors; if inhaled, remove

to fresh air. If coolant gets in eyes,

flush eyes with water and seek medi-

cal attention. Wash thoroughly after

handling. Solution can be poisonous

to animals. Keep out of the reach of

children and animals.

NOTICE

The mixture you use should con-

tain 50% concentration of anti-

freeze.

If the lowest ambient temperature

in your area is expected to be –35°C

(–31°F) or below, use higher con-

centrations up to 60% following the

instructions on the antifreeze con-

tainer.

NOTICE

When putting the cap on the reser-

voir tank, line up the mark on the cap

and the mark on the tank. Failure to

follow this can result in coolant leak-

age.FULL

LOW

Page 158 of 207

Downloaded from www.Manualslib.com manuals search engine 7-13INSPECTION AND MAINTENANCE

60MK0-14E

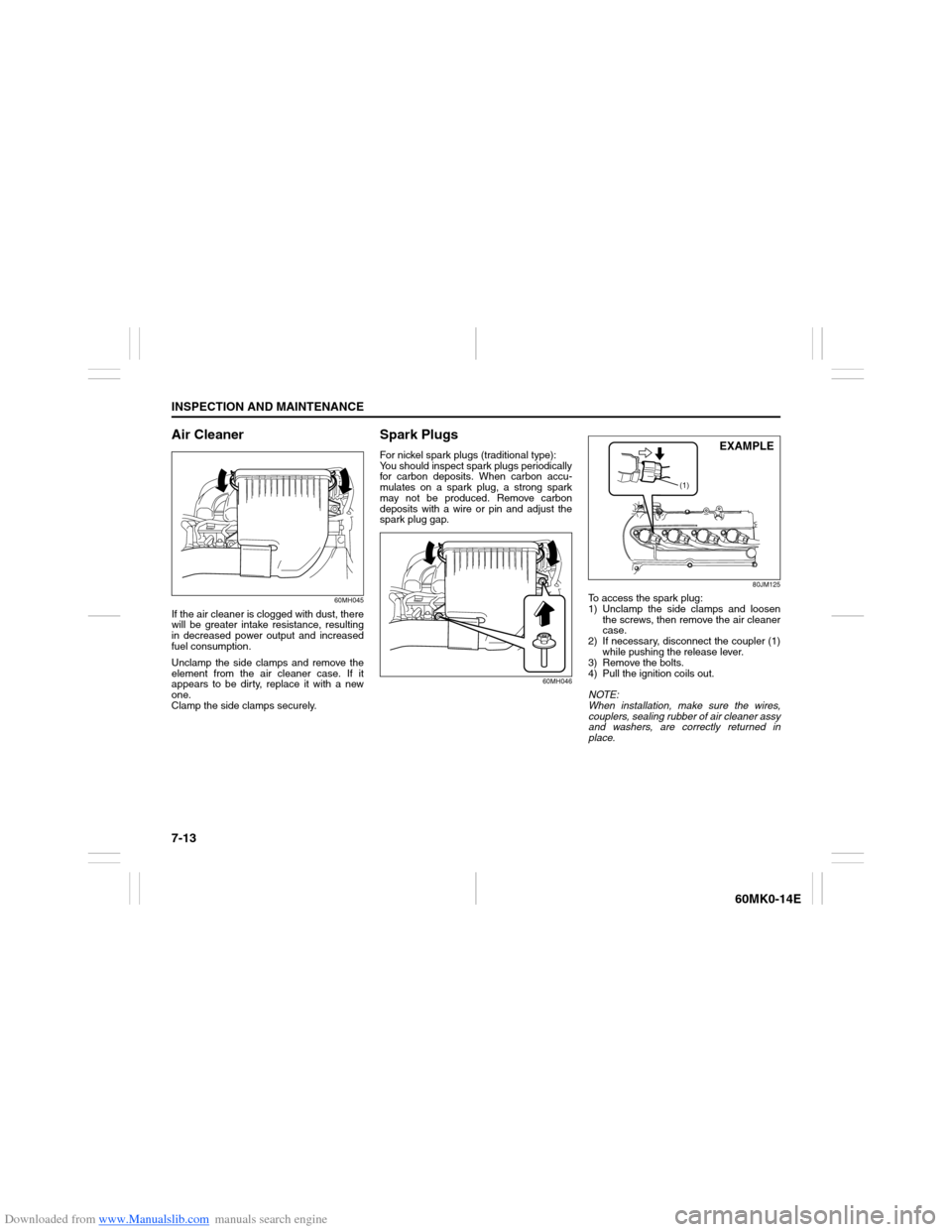

Air Cleaner

60MH045

If the air cleaner is clogged with dust, there

will be greater intake resistance, resulting

in decreased power output and increased

fuel consumption.

Unclamp the side clamps and remove the

element from the air cleaner case. If it

appears to be dirty, replace it with a new

one.

Clamp the side clamps securely.

Spark PlugsFor nickel spark plugs (traditional type):

You should inspect spark plugs periodically

for carbon deposits. When carbon accu-

mulates on a spark plug, a strong spark

may not be produced. Remove carbon

deposits with a wire or pin and adjust the

spark plug gap.

60MH04680JM125

To access the spark plug:

1) Unclamp the side clamps and loosen

the screws, then remove the air cleaner

case.

2) If necessary, disconnect the coupler (1)

while pushing the release lever.

3) Remove the bolts.

4) Pull the ignition coils out.

NOTE:

When installation, make sure the wires,

couplers, sealing rubber of air cleaner assy

and washers, are correctly returned in

place.

(1)

EXAMPLE

Page 159 of 207

Downloaded from www.Manualslib.com manuals search engine 7-14

INSPECTION AND MAINTENANCE

60MK0-14E

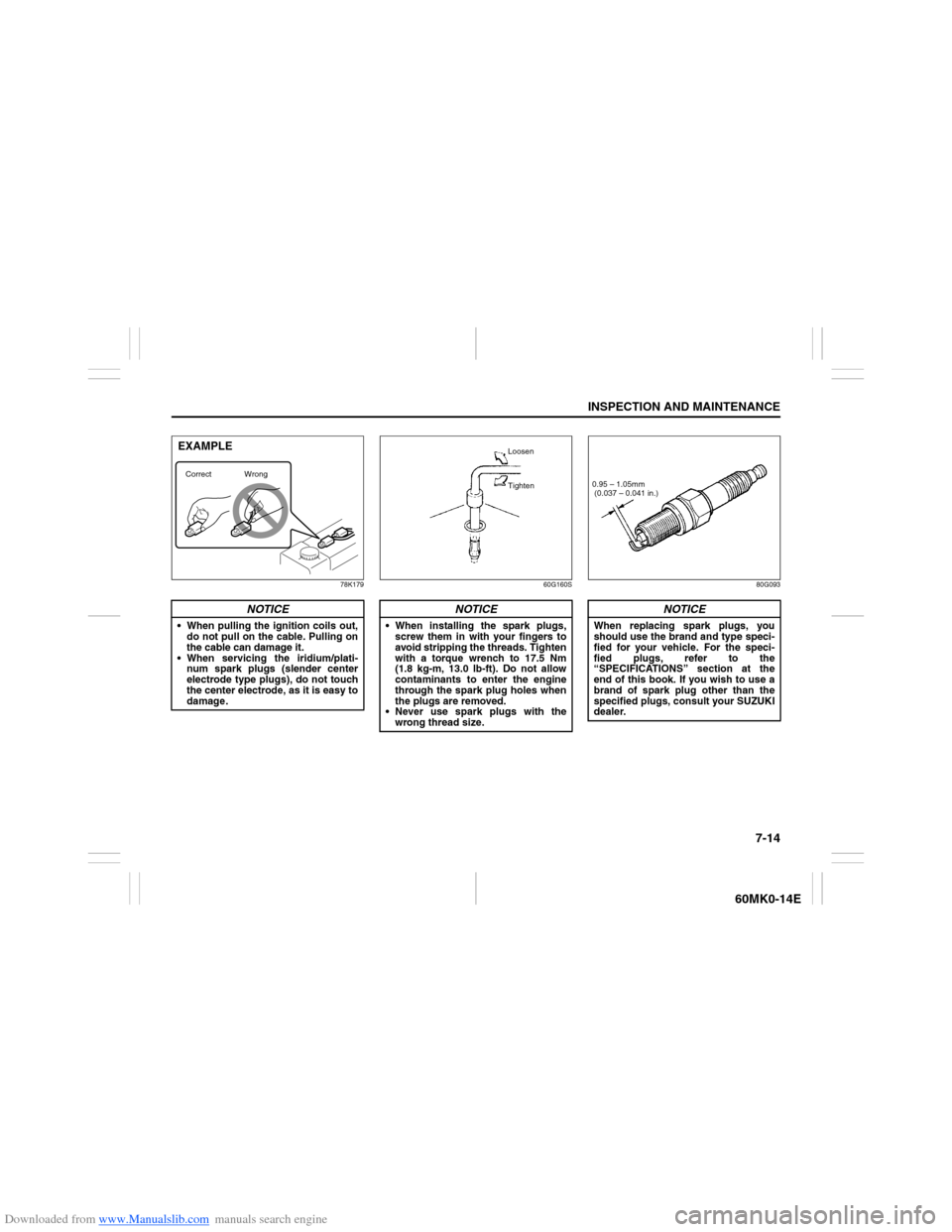

78K179 60G160S 80G093

NOTICE

When pulling the ignition coils out,

do not pull on the cable. Pulling on

the cable can damage it.

When servicing the iridium/plati-

num spark plugs (slender center

electrode type plugs), do not touch

the center electrode, as it is easy to

damage.Correct WrongEXAMPLE

NOTICE

When installing the spark plugs,

screw them in with your fingers to

avoid stripping the threads. Tighten

with a torque wrench to 17.5 Nm

(1.8 kg-m, 13.0 lb-ft). Do not allow

contaminants to enter the engine

through the spark plug holes when

the plugs are removed.

Never use spark plugs with the

wrong thread size.

Loosen

Tighten

NOTICE

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the speci-

fied plugs, refer to the

“SPECIFICATIONS” section at the

end of this book. If you wish to use a

brand of spark plug other than the

specified plugs, consult your SUZUKI

dealer.0.95 – 1.05mm

(0.037 – 0.041 in.)

Page 160 of 207

Downloaded from www.Manualslib.com manuals search engine 7-15INSPECTION AND MAINTENANCE

60MK0-14E

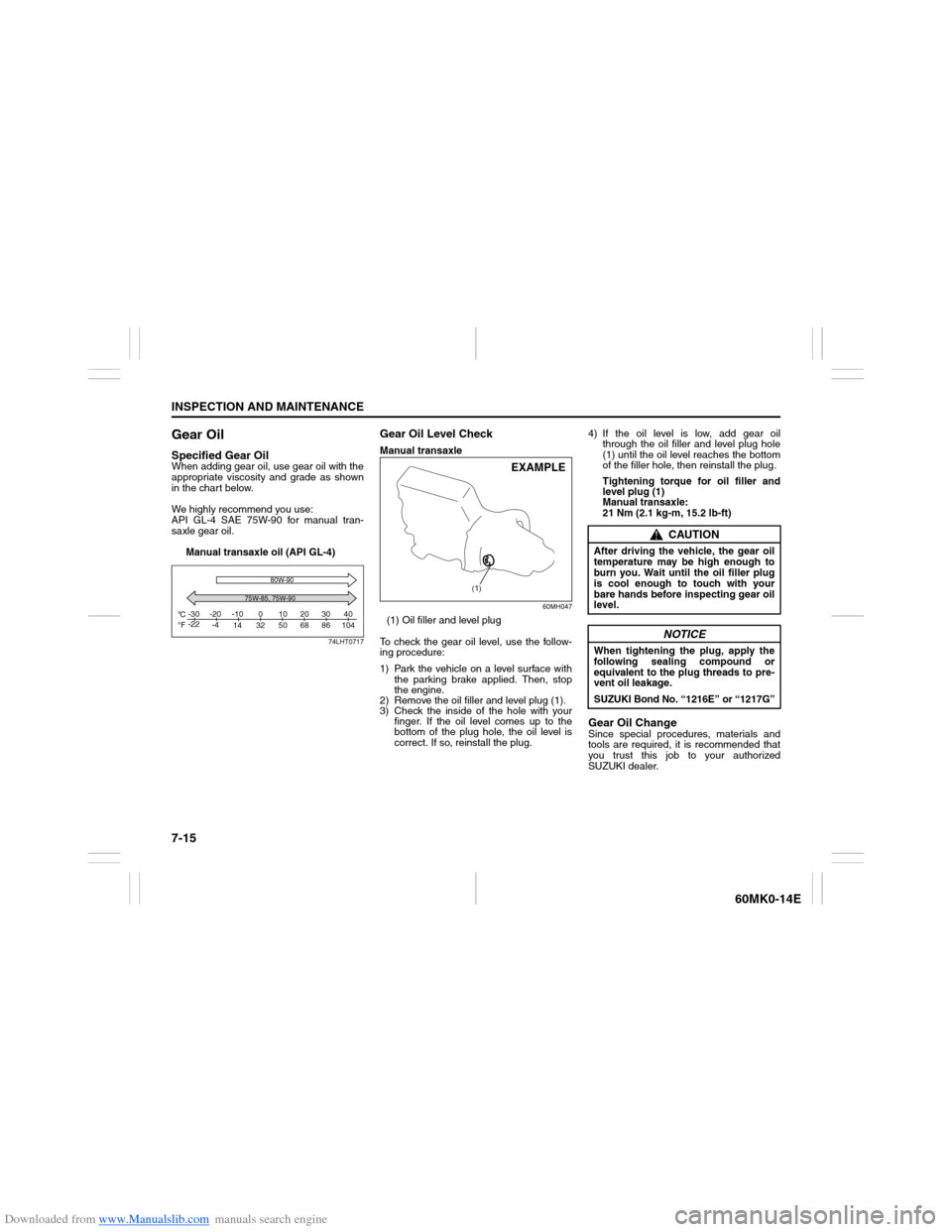

Gear OilSpecified Gear OilWhen adding gear oil, use gear oil with the

appropriate viscosity and grade as shown

in the chart below.

We highly recommend you use:

API GL-4 SAE 75W-90 for manual tran-

saxle gear oil.

Manual transaxle oil (API GL-4)

74LHT0717

Gear Oil Level CheckManual transaxle

60MH047

(1) Oil filler and level plug

To check the gear oil level, use the follow-

ing procedure:

1) Park the vehicle on a level surface with

the parking brake applied. Then, stop

the engine.

2) Remove the oil filler and level plug (1).

3) Check the inside of the hole with your

finger. If the oil level comes up to the

bottom of the plug hole, the oil level is

correct. If so, reinstall the plug.4) If the oil level is low, add gear oil

through the oil filler and level plug hole

(1) until the oil level reaches the bottom

of the filler hole, then reinstall the plug.

Tightening torque for oil filler and

level plug (1)

Manual transaxle:

21 Nm (2.1 kg-m, 15.2 lb-ft)

Gear Oil ChangeSince special procedures, materials and

tools are required, it is recommended that

you trust this job to your authorized

SUZUKI dealer.

C

Fo o-30

-22-20

-4-10

14 32 50 68 86 104010203040

75W-85, 75W-9080W-90

(1)

EXAMPLE

CAUTION

After driving the vehicle, the gear oil

temperature may be high enough to

burn you. Wait until the oil filler plug

is cool enough to touch with your

bare hands before inspecting gear oil

level.

NOTICE

When tightening the plug, apply the

following sealing compound or

equivalent to the plug threads to pre-

vent oil leakage.

SUZUKI Bond No. “1216E” or “1217G”