SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 141 of 962

With vacuum pump gauge set at Black side of

VTV, when pump is operated, pointer moves

considerably but moves back to zero position as

soon as pump operation is stopped.

Brown side

(Actuator side) Black side

Fig. 4-l-60

1. VTV

2. Vacuum pump gauge

install VTV. Refer to Fig. 4-l -2 for installation.

[ VSV (Vacuum Switching Valve)]

1) Disconnect VSV vacuum hoses from 3 way

joint and secondary actuator and while

blowing either hose, check that air doesn’t

come out of the other hose.

2) Turn on ignition switch and depress accelera-

tor pedal fully. 5 or 6 seconds later, while

blowing either vacuum hose, check that air

comes out of the other hose.

J5

Fig. 4- l-61

1I

1. vsv4. WOTS

2. Ignition switch5. ECM

3. Battery6. Blow air

If check results in steps 1) and 2)are not satisfac-

tory, either replace VSV or check WOTS and its

circuit referring to SECTION5 “EMISSION

CONTROL SYSTEM”.

Idle Speed Adjustment

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

Before idle speed check and adjustment, make

sure of the following.

l Lead wires and hoses of engine emission

control systems are connected securely.

l Accelerator cable has some play, that is, it is

not tight.

l All vacuum hoses are connected securely.

l Fuel level should be within round mark at the

center of level gauge.

l Valve lash is checked and adjusted according

to the maintenance schedule.

l Air cleaner has been properly installed and is

in good condition.

l All accessories (wipers, heater, lights, etc) are

out of service.

l Ignition timing is within specification.

l Idle up actuator is not operating when engine

is running at idle speed.

NOTE:

In areas above 4,00Ofeet( 1,220m) elevation

(high altitude), idle up system will be normally

in operation. Do not attempt to adjust the idle

speed.

After above items are all confirmed, adjust idle

speed as follows.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust by turning idle speed adjusting screw.

If idle speed can not be adjusted to the speci-

fication by turning the adjusting screw, it can

be due to faulty return of throttle valve or

some other reason. Determine cause and

repair, and then adjust idle speed to specifica-

tion.

4-26

Page 142 of 962

1. Idle speed adjusting screw

Fig. 4- l-62 Idle speed adjusting screw

4) After idle speed adjustment, check idle-up for

operation with lights (small light, tail light,

side marker light and license light), heater fan

and rear defogger (if equipped) turned “ON”,

only one at a time. Refer to item “Idle Up

Adjustment”. (p. 4-20).

5) Stop engine and check to ensure that accelera-

tor cable play is within the specification as

previously outlined. If play is out of specifica-

tion, adjust it.

Idle Mixture Inspection and Adjustment

[Inspection]

1) Warm up engine to normal operating tem-

perature.

2) Remove seal rubber of duty check coupler

and connect positive terminal of duty meter

to “Blue/Red” wire and negative terminal to

“Black/Green” wire.

1

1. Duty check

3) Set tachometer.

4) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

5) Check duty at specified idle speed. If it is out

of specification, adjust it to specification ac-

cording to following adjustment procedure.

Specified DutyIO-50

at 750 - 850 r/min.

After inspection, install seal rubber to duty

check coupler.

[Idle Mixture Adjustment]

The carburetor has been calibrated at the facto-

ry and. should not normally need adjustment in

the field. For this reason, the mixture adjust-

ment should never be changed from the original

factory setting. However, if during diagnosis, the

check indicates the carburetor to be the cause of

a driver performance complaint or emission

failure, or the carburetor is overhauled or

replaced, the idle mixture can be adjusted using

the following procedure.

After adjustment, mixture adjusting screw pin

must be installed.

Idle mixture adjustment procedure is as follows:

1) Remove carburetor from intake manifold

following normal service procedure to gain

access to mixture adjusting screw pin covering

mixture adjusting screw.

2) Drive out mixture adjusting screw pin using

about 4.5 mm (0.18 in) thick iron rod as

shown below.

1. Mixture adjusting screw pin2. Rod

Fig. 4- l-64 Mixture adjusting screw pin

2. Air intake case

Fig. 4- l-63

4-27

Page 143 of 962

3) Reinstall carburetor following normal service

procedures.

Connect emission control system hoses and

lead wires. Make specified play on accelerator

cable and refill cooling system.

4) Place transaxle gear shift lever in “Neutral”,

set parking brake and block drive wheels.

5) Start engine, and warm it up to normal

operating temperature, stop engine.

6) Be sure to check the following before idle

mixture adjustment.

l Fuel level is within round mark at the

center of level gauge.

l Valve lash is checked and adjusted accord-

ing to the maintenance schedule.

l Air cleaner has been properly installed

and is in good condition.

l All accessories (wipers, heater, lights etc)

are out of service.

l Ignition timing is within specification.

l Choke valve opens fully.

l Idle-up actuator does not operate.

7) Check and adjust idle speed to specification

if necessary.

8) Remove seal rubber of duty check coupler

and connect positive terminal of duty

meter to“Blue/Red” wire and negative

terminal to “Black/Green” wire.

9) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

10) With engine running at idle speed, adjust idle

mixture adjusting screw slowly in small incre-

ment allowing time for duty to stabilize after

turning screw to obtain duty of 10 - 50.

If duty is too low, back screw out; if too

high, screw it in. After obtaining duty of

10 - 50, recheck idle speed, and adjust if

necessary.

NOTE:

If adjustment can’t be made because duty meter

indicator does not deflect, check feed back

system according to the checking procedure of

system described in section of Emission Control

System.

11) After adjustment, install seal rubber to duty

check coupler and drive in idle mixture

adjusting screw pin.

4-28

Page 144 of 962

4-2. AIR CLEANER

GENERAL DESCRIPTION

In the air cleaner case, a dry-type air cleaner element is provided for filtering.out dirt and dust from air

being drawn into the engine for combustion.

A damaged element must be replaced with a new one, since it allows dust particles to enter the engine if

used as it is. Such dust particles could cause wear to the engine inner parts and this further results in

decreased output.

Also, the element must be cleaned periodically. Dusty and dirty element causes decrease in output and

increase in fuel consumption. The dusty element even after cleaning should be replaced with a new one.

Fig. 4-2-l

1. Air cleaner case

2. Air cleaner case cap

3. Air cleaner element4. Air cleaner inlet hose

5. Air cleaner outlet hose

6. Warm air hose

7. Carburetor air intake case

8. Check valve

9. Therm0 sensor (valve)10. Air control actuator

MAINTENANCE SERVICES

Air Cleaner Element

[Cleaning]

1) Remove air cleaner outlet hose and case cap.

Fig. 4-2-21. Air cleaner outlet hose2. Air cleaner case cap3. Clamp

4-29

Page 145 of 962

2) Take out air cleaner element from air cleaner

case and blow off dust with compressed air’

from inside of element.

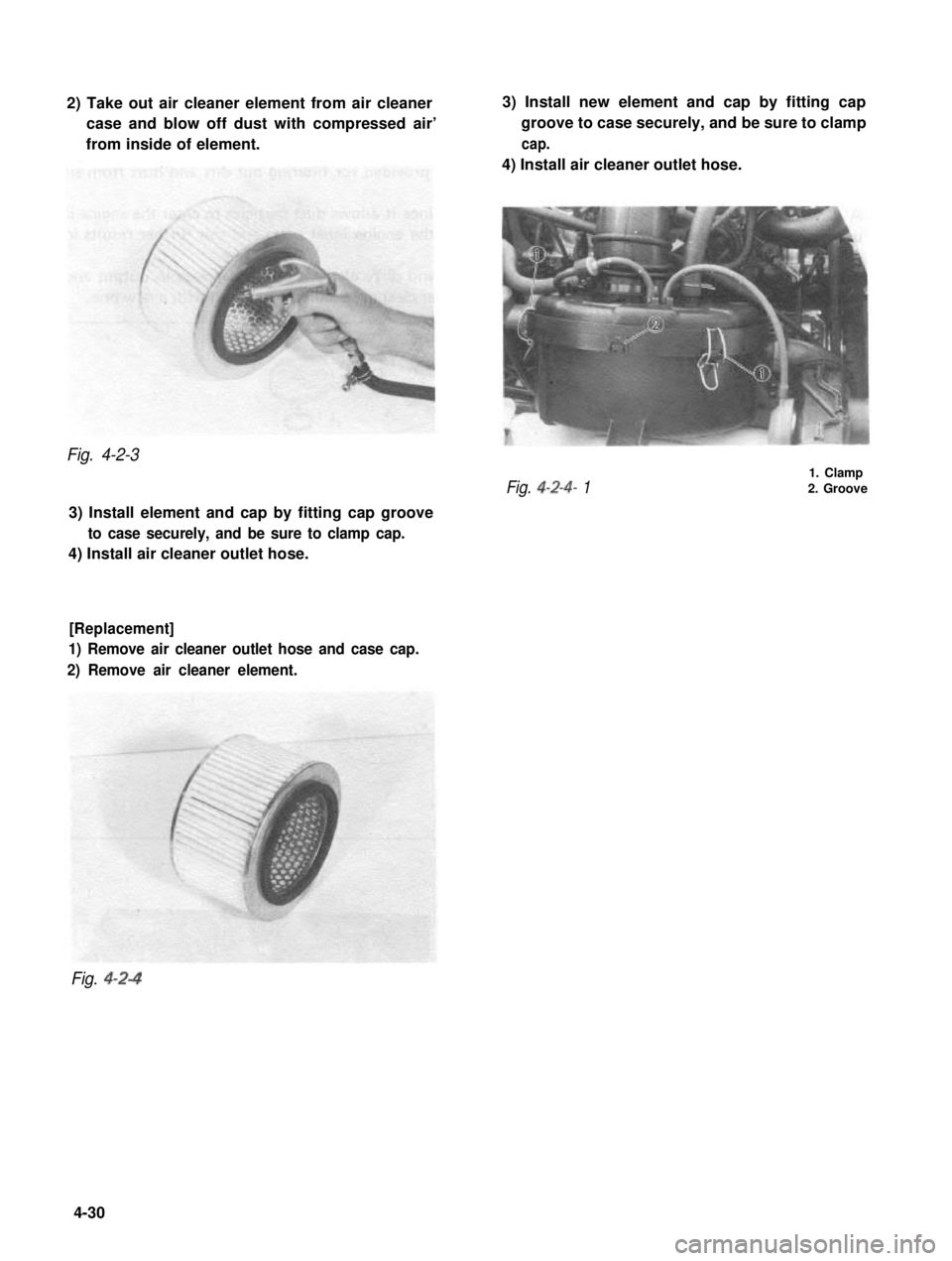

3) Install new element and cap by fitting cap

groove to case securely, and be sure to clamp

cap.

4) Install air cleaner outlet hose.

Fig. 4-2-3

Fig. 4-2-4- 1

1. Clamp2. Groove

3) Install element and cap by fitting cap groove

to case securely, and be sure to clamp cap.

4) Install air cleaner outlet hose.

[Replacement]

1) Remove air cleaner outlet hose and case cap.

2) Remove air cleaner element.

Fig. 4-2-4

4-30

Page 146 of 962

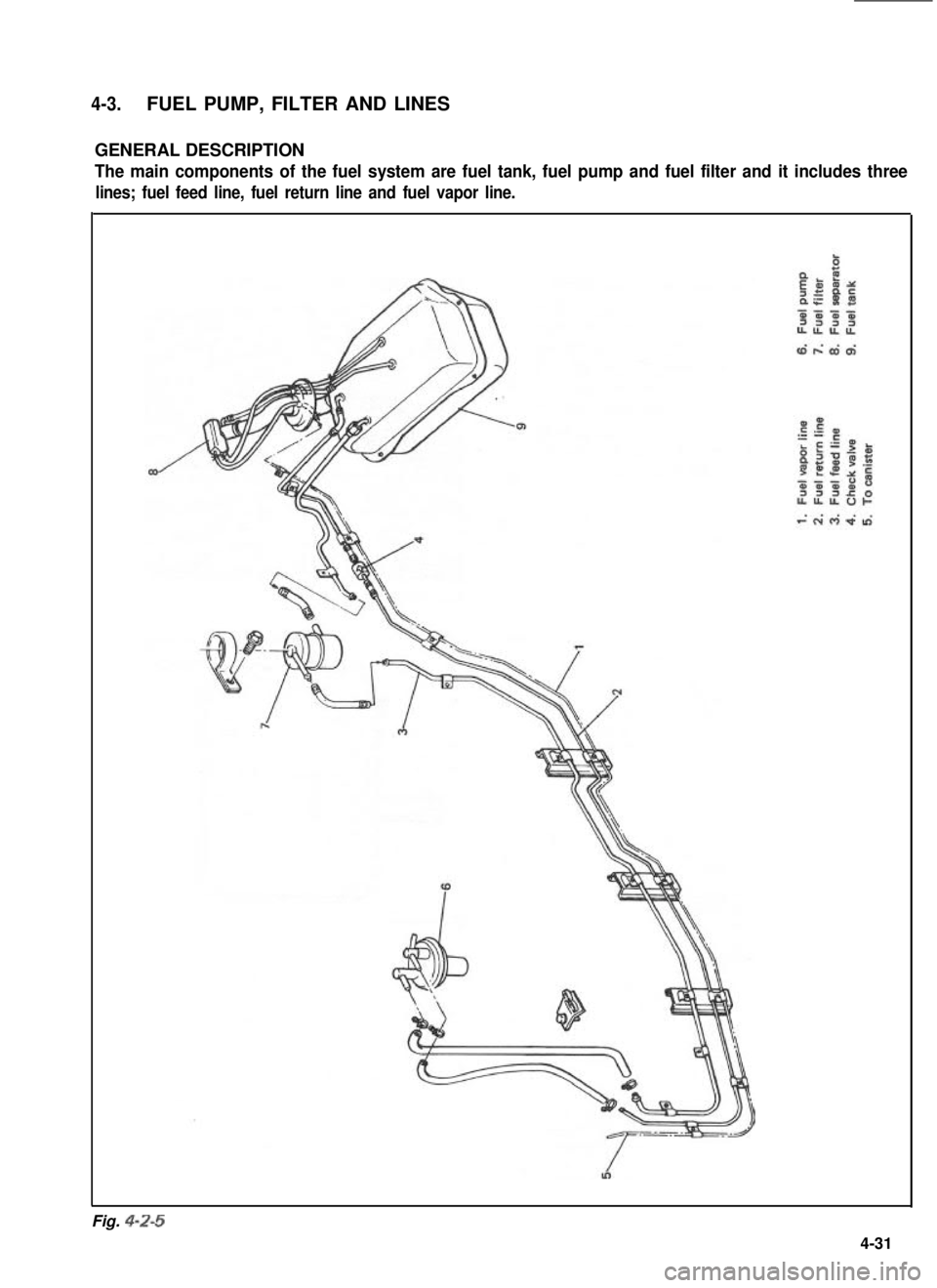

4-3.FUEL PUMP, FILTER AND LINES

GENERAL DESCRIPTION

The main components of the fuel system are fuel tank, fuel pump and fuel filter and it includes three

lines; fuel feed line, fuel return line and fuel vapor line.

Fig. 4-Z-5

4-31

Page 147 of 962

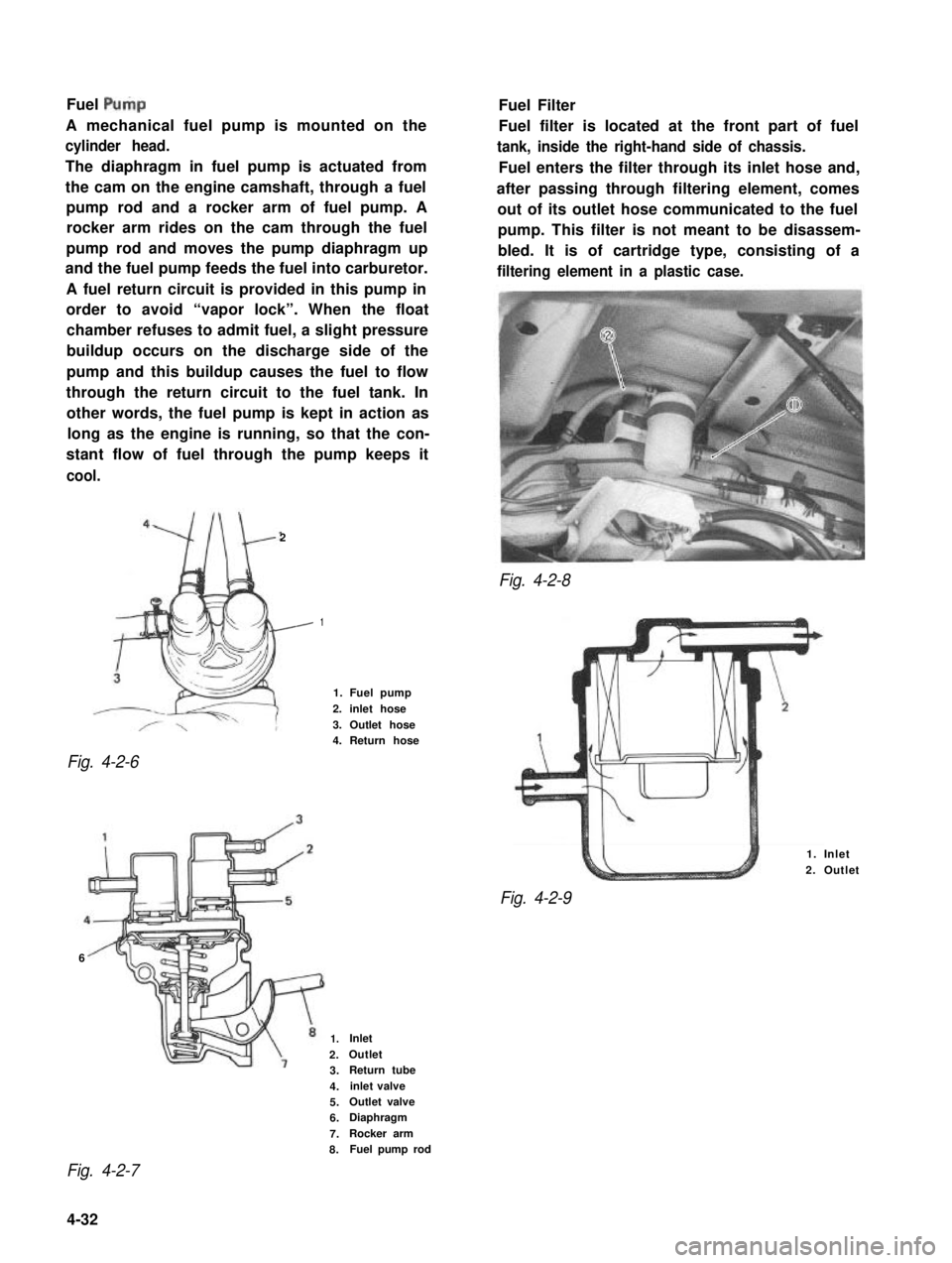

Fuel Pulp

A mechanical fuel pump is mounted on the

cylinder head.

The diaphragm in fuel pump is actuated from

the cam on the engine camshaft, through a fuel

pump rod and a rocker arm of fuel pump. A

rocker arm rides on the cam through the fuel

pump rod and moves the pump diaphragm up

and the fuel pump feeds the fuel into carburetor.

A fuel return circuit is provided in this pump in

order to avoid “vapor lock”. When the float

chamber refuses to admit fuel, a slight pressure

buildup occurs on the discharge side of the

pump and this buildup causes the fuel to flow

through the return circuit to the fuel tank. In

other words, the fuel pump is kept in action as

long as the engine is running, so that the con-

stant flow of fuel through the pump keeps it

cool.

2

Fig. 4-2-8

Fig. 4-2-6

Fuel Filter

Fuel filter is located at the front part of fuel

tank, inside the right-hand side of chassis.

Fuel enters the filter through its inlet hose and,

after passing through filtering element, comes

out of its outlet hose communicated to the fuel

pump. This filter is not meant to be disassem-

bled. It is of cartridge type, consisting of a

filtering element in a plastic case.

1

1. Fuel pump

2. inlet hose

3. Outlet hose4. Return hose

6

1. Inlet

2. Outlet

Fig. 4-2-9

1.Inlet

2.Outlet

3.Return tube

4.inlet valve

5.Outlet valve

6.Diaphragm

7.Rocker arm

8.Fuel pump rod

Fig. 4-2-7

4-32

Page 148 of 962

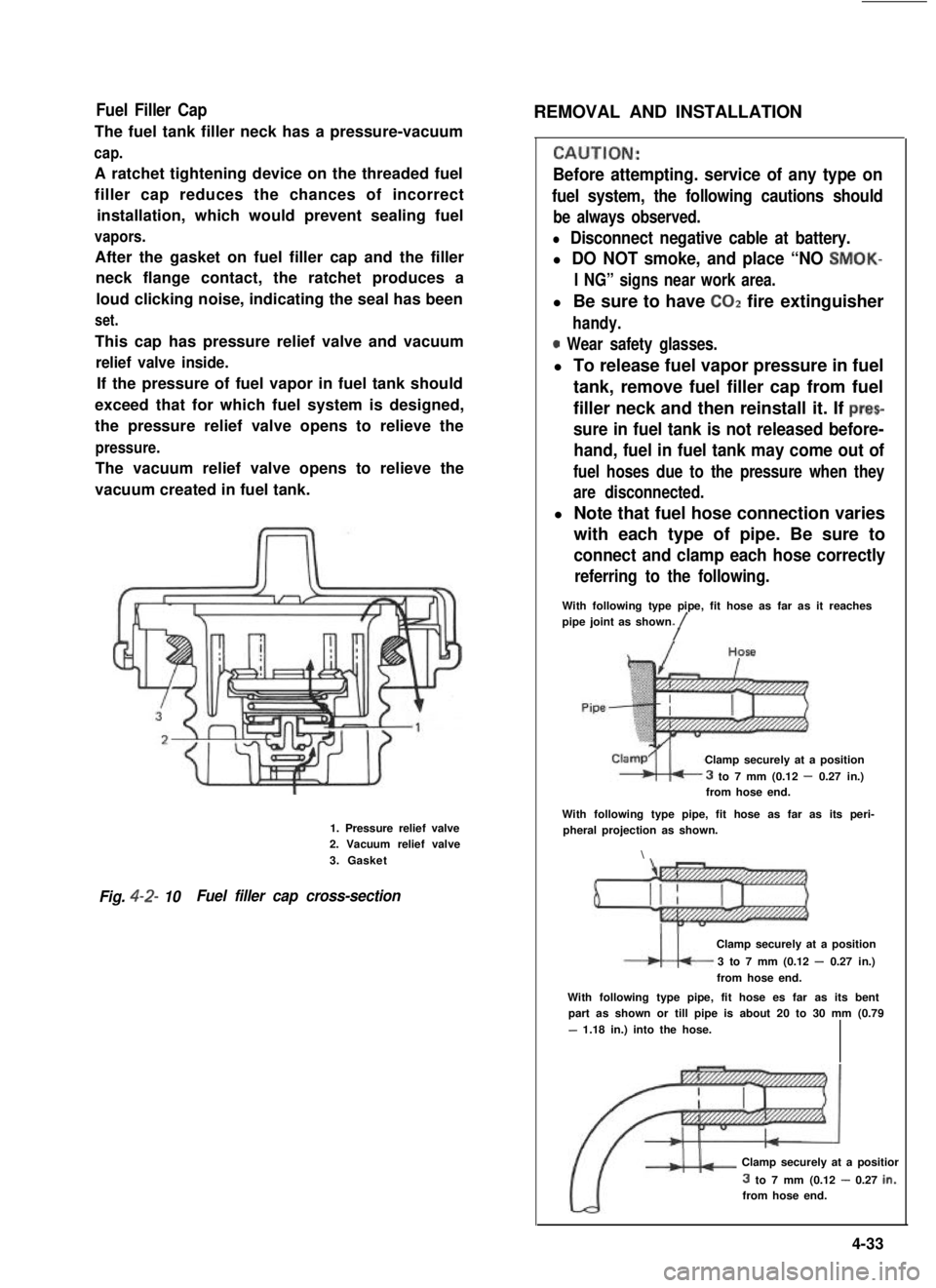

Fuel Filler Cap

The fuel tank filler neck has a pressure-vacuum

cap.

A ratchet tightening device on the threaded fuel

filler cap reduces the chances of incorrect

installation, which would prevent sealing fuel

vapors.

After the gasket on fuel filler cap and the filler

neck flange contact, the ratchet produces a

loud clicking noise, indicating the seal has been

set.

This cap has pressure relief valve and vacuum

relief valve inside.

If the pressure of fuel vapor in fuel tank should

exceed that for which fuel system is designed,

the pressure relief valve opens to relieve the

pressure.

The vacuum relief valve opens to relieve the

vacuum created in fuel tank.

1. Pressure relief valve2. Vacuum relief valve

3. Gasket

Fig. 4-2- 10Fuel filler cap cross-section

REMOVAL AND INSTALLATION

CALJTION:

Before attempting. service of any type on

fuel system, the following cautions should

be always observed.

l Disconnect negative cable at battery.

l DO NOT smoke, and place “NO SMOK-

I NG” signs near work area.

l Be sure to have COZ fire extinguisher

handy.

0 Wear safety glasses.

l To release fuel vapor pressure in fuel

tank, remove fuel filler cap from fuel

filler neck and then reinstall it. If prec

sure in fuel tank is not released before-

hand, fuel in fuel tank may come out of

fuel hoses due to the pressure when they

are disconnected.

l Note that fuel hose connection varies

with each type of pipe. Be sure to

connect and clamp each hose correctly

referring to the following.

With following type pipe, fit hose as far as it reachespipe joint as shown./

Clamp securely at a position

3 to 7 mm (0.12 - 0.27 in.)from hose end.

With following type pipe, fit hose as far as its peri-pheral projection as shown.

\

Clamp securely at a position

3 to 7 mm (0.12 - 0.27 in.)

from hose end.

With following type pipe, fit hose es far as its bentpart as shown or till pipe is about 20 to 30 mm (0.79

- 1.18 in.) into the hose.

Clamp securely at a positior

3 to 7 mm (0.12 - 0.27 in.:from hose end.

4-33

Page 149 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual ,Fuel Pump

[ Rem’oval]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap from fuel filler neck to

release fuel vapor pressure in fuel tank. After

releasing, reinstall the cap.

3) SUZUKI GRAND VITARA 1987 Service Repair Manual ,Fuel Pump

[ Rem’oval]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap from fuel filler neck to

release fuel vapor pressure in fuel tank. After

releasing, reinstall the cap.

3)](/img/20/57437/w960_57437-148.png)

,Fuel Pump

[ Rem’oval]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap from fuel filler neck to

release fuel vapor pressure in fuel tank. After

releasing, reinstall the cap.

3) Disconnect fuel inlet, outlet and return hoses

from fuel pump.

Fuel Filter

[Removal]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap to release fuel vapor

pressure in fuel tank. After releasing, reinstall

the cap.

3) Disconnect inlet and outlet hoses from fuel

filter.

4) Remove fuel filter with clamp.

[Installation]

1) Install filter and clamp, and connect inlet

and outlet hoses to fuel filter.

NOTE:.

The top connection is for outlet hose, the

lower one for inlet hose.

1. Fuel pump

2. Inlet hose3. Outlet hose

4. Return hose

Fig. 4-2-l 1

4) Remove fuel pump from cylinder head.

5) Remove fuel pump rod from cylinder head.

2

1. Fuel pump rod

2. Cylinder head

[Installation]

Reverse removal procedure for installation

using care for the following.

l After oiling it,install fuel pump rod to

cylinder head.

0 Use new fuel pump gasket.

l Make sure for proper hose connection.

0 Upon completion of installation, start engine

and check fuel hose or its joints for leaks.

1.Fuel filter3.From fueltank

2.To fuel pump4.Clamp

Fig.4-2-13

2) Connect negative cable to battery.

3) After installation, start engine and check it

for leaks.

Fuel Tank

[Removal]

1) Disconnect negative cable from battery.

2) Disconnect fuel level gauge lead wire.

3) To release the pressure in fuel tank, remove

fuel filler cap and then, reinstall it.

4) Raise car on hoist.

5) Drain fuel by removing drain plug.

6) Remove filler hose protector.

7) Disconnect filler hose from fuel tank.

.8) Disconnect fuel hosesand pipe from fuel tank.

9) Remove fuel tank.

4-34

Page 150 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal i SUZUKI GRAND VITARA 1987 Service Repair Manual [Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal i](/img/20/57437/w960_57437-149.png)

[Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal injury

cou Id occur.J

The following procedure is used for purging the

fuel tank.

1) After removing fuel tank, remove all hoses,

fuel level gauge from fuel tank.

2) Drain all remaining fuel from tank.

3) Move tank to flushing area.

4) Fill tank with warm water or tap water, and

agitate vigorously and drain. Repeat this

washing until inside of tank is clean.

Replace tank if inside is rusty.

5) Completely flush out remaining water after

washing.

[ Installation]

Reverse removal procedure for installation using

care for the following.

Tightening torque30-45 Nm

for fuel tank(3.0- 4.5 kg-m)

drain plug(22.0 - 32.5 lb-ft)

Refer to Fig. 4-2-5 for piping and clamp posi-

tions.

l Make sure for correct hose-to-pipe connec-

tion.

l Clamp hoses securely.

l Upon completion of installation, start engine

and check hose joints for leaks.

MAINTENANCE SERVICES

Fuel Lines

Visually inspect fuel lines and connections for

evidence of fuel leakage, hose cracking, and

damage. Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being crack-

ed.

Fig. 4-2-14

Fuel Filler (tank) Cap

Visually inspect gasket of fuel filler cap.

If it is damaged or deteriorated, replace filler cap

with new one.

NOTE:

If cap requires replacement, only a cap with

the same features should be used. Failure to

use correct cap can result in a serious malfunc-

tion of the system.

Fig. 4-2-15

1. Fuel filler cap

2. Fuel filler capgasket

Fuel Filter

As said before, this filter does not permit dis-

assembly: it is to be replaced with a new one

periodically.

Replace fuel filter referring to previous item of

“Fuel Filter Removal and Installation”.

This servicing must be performed in a well

ventilated area and away from any open

flames (such as gas hot water heaters).

4-35