SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 171 of 962

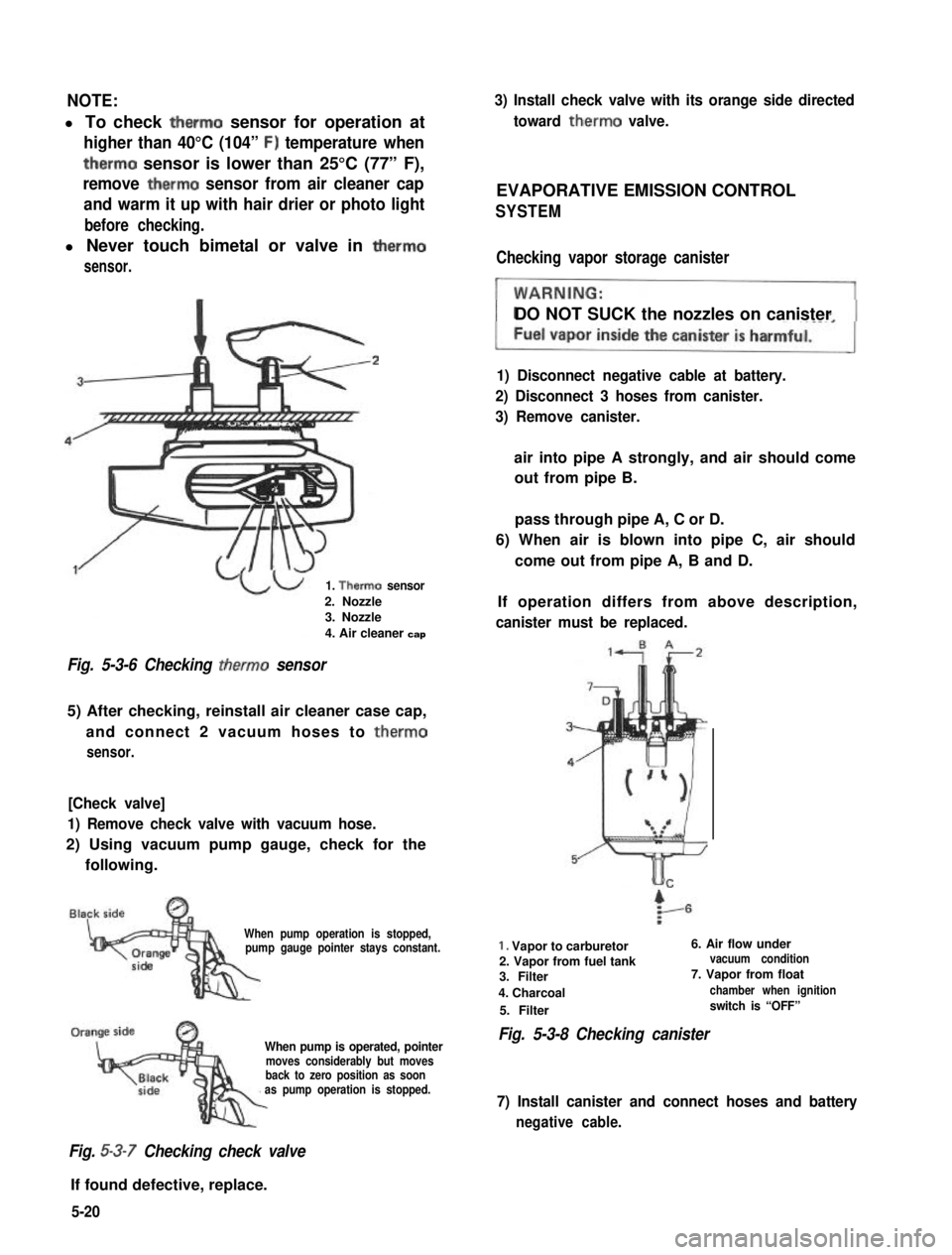

NOTE:

l To check therm0 sensor for operation at

higher than 40°C (104” F) temperature when

therm0 sensor is lower than 25°C (77” F),

remove therm0 sensor from air cleaner cap

and warm it up with hair drier or photo light

before checking.

l Never touch bimetal or valve in therm0

sensor.

1. Therm0 sensor

2. Nozzle3. Nozzle

4. Air cleaner cap

Fig. 5-3-6 Checking therm0 sensor

5) After checking, reinstall air cleaner case cap,

and connect 2 vacuum hoses to therm0

sensor.

[Check valve]

1) Remove check valve with vacuum hose.

2) Using vacuum pump gauge, check for the

following.

When pump operation is stopped,pump gauge pointer stays constant.

When pump is operated, pointermoves considerably but movesback to zero position as soonas pump operation is stopped.

Fig. 5-3-7 Checking check valve

If found defective, replace.

3) Install check valve with its orange side directed

toward therm0 valve.

EVAPORATIVE EMISSION CONTROL

SYSTEM

Checking vapor storage canister

DO NOT SUCK the nozzles on canister

1) Disconnect negative cable at battery.

2) Disconnect 3 hoses from canister.

3) Remove canister.

air into pipe A strongly, and air should come

out from pipe B.

pass through pipe A, C or D.

6) When air is blown into pipe C, air should

come out from pipe A, B and D.

If operation differs from above description,

canister must be replaced.

1. Vapor to carburetor6. Air flow under

2. Vapor from fuel tankvacuum condition

3. Filter7. Vapor from float

4. Charcoalchamber when ignition

5. Filterswitch is “OFF”

Fig. 5-3-8 Checking canister

7) Install canister and connect hoses and battery

negative cable.

5-20

Page 172 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Hoses]

Visually inspect hoses and pipe for cracks,

damage, or excessive bends, and hose connec-

tion for tightness.

Fig. 5-3-9

HOT IDLE COMPENSATOR (HIC)

Checking Hot Idle Compensator

1) Remove air i SUZUKI GRAND VITARA 1987 Service Repair Manual [Hoses]

Visually inspect hoses and pipe for cracks,

damage, or excessive bends, and hose connec-

tion for tightness.

Fig. 5-3-9

HOT IDLE COMPENSATOR (HIC)

Checking Hot Idle Compensator

1) Remove air i](/img/20/57437/w960_57437-171.png)

[Hoses]

Visually inspect hoses and pipe for cracks,

damage, or excessive bends, and hose connec-

tion for tightness.

Fig. 5-3-9

HOT IDLE COMPENSATOR (HIC)

Checking Hot Idle Compensator

1) Remove air intake case with hose.

2) Check temperature around HIC with thermo-

meter.

3) If temperature is below 45°C (113” F), air

should not come out of HIC when air is

blown into hose. If temperature is above

65°C (149” F), air comes out of HIC.

Replace H IC if defective.

4) After checking, install air intake case and

connect hose to intake manifold.

NOTE:

l To check HIC for operation at higher than

65°C (149°F) temperature when HIC (bi-

metal) temperature is lower than 45°C

(113”F), warm it up with hair drier or photo

light before checking.

l Never touch bimetal or valve in HIC.

1

Below 45°C (113’F)Above 65’C (149’F)

Fig.5-i- 10

DECELERATION MIXTURE CONTROL

SYSTEM

Checking

[Hoses]

Inspect each hose for pinholes, cracks or damage.

Also check to ensure that each joint is securely

connected. Any part found defective must be

corrected or replaced.

.

Fig. 5-3- 11

[Mixture control valve (MCV)]

1) Warm up the engine to normal operating

temperature.

2) Disconnect hose @ and reconnect it. At this

time, check that air is drawn into MCV.

NOTE:

At this time, the engine will idle rough or die,

but this is normal.

A piece of paper

If the above checks show anything wrong,

replace it.

5-21

Page 173 of 962

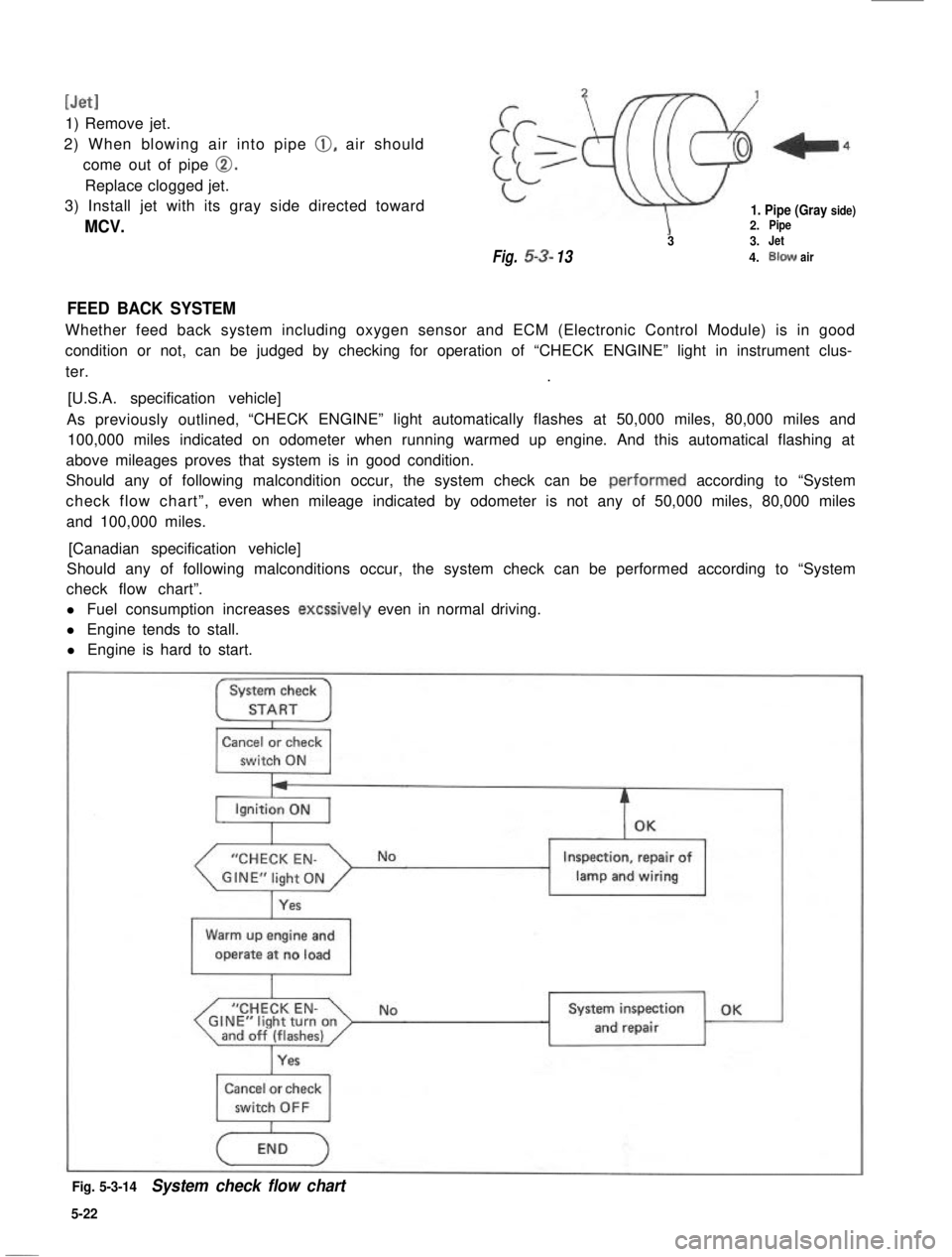

[Jet1

1) Remove jet.

2) When blowing air into pipe 0, air should

come out of pipe 0.

Replace clogged jet.

3) Install jet with its gray side directed toward

MCV.

1. Pipe (Gray side)2.Pipe

33.Jet

Fig.53-134.Blowair

FEED BACK SYSTEM

Whether feed back system including oxygen sensor and ECM (Electronic Control Module) is in good

condition or not, can be judged by checking for operation of “CHECK ENGINE” light in instrument clus-

ter..

[U.S.A. specification vehicle]

As previously outlined,“CHECK ENGINE” light automatically flashes at 50,000 miles, 80,000 miles and

100,000 miles indicated on odometer when running warmed up engine. And this automatical flashing at

above mileages proves that system is in good condition.

Should any of following malcondition occur, the system check can be .performed according to “System

check flow chart”,even when mileage indicated by odometer is not any of 50,000 miles, 80,000 miles

and 100,000 miles.

[Canadian specification vehicle]

Should any of following malconditions occur, the system check can be performed according to “System

check flow chart”.

l Fuel consumption increases excssively even in normal driving.

l Engine tends to stall.

l Engine is hard to start.

System check

STARTI

Cancel or check

switch ON

“CHECK EN-

Yes

Inspection, repair of

lamp and wiring1

Warm up engine and

operate at no load

I

“CHECK EN-GINE”light turnonand off (flashes)I

NoSystem inspection OK

and repair

Cancel or check

Fig. 5-3-14System check flow chart

5-22

Page 174 of 962

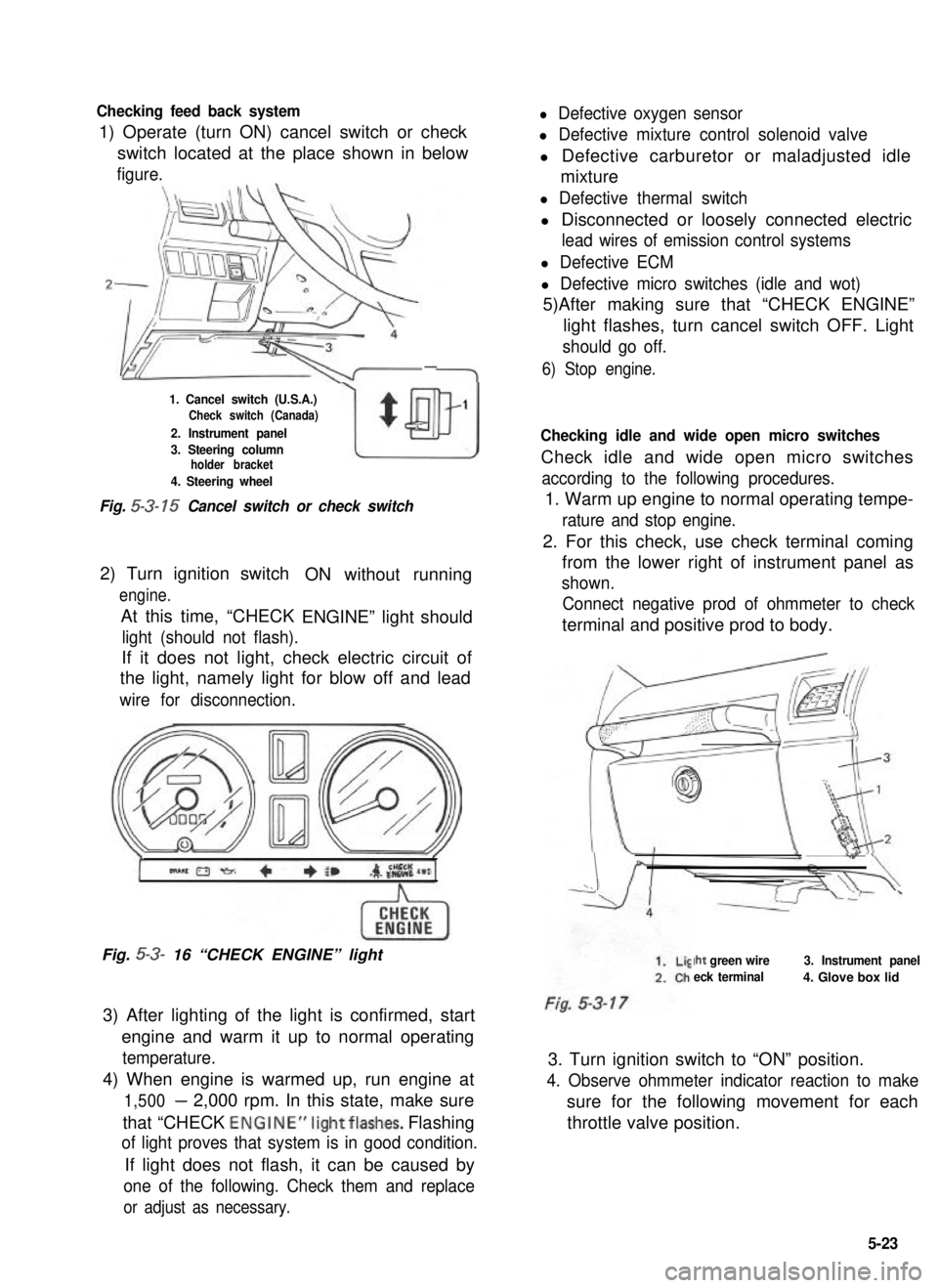

Checking feed back system

1) Operate (turn ON) cancel switch or check

l Defective oxygen sensor

l Defective mixture control solenoid valve

switch located at the place shown in belowl Defective carburetor or maladjusted idle

figure.mixture

-

1. Cancel switch (U.S.A.)Check switch (Canada)

2. Instrument panel

w

$

1

3. Steering columnholder bracket

4. Steering wheel

Fig. 5-3- 15 Cancel switch or check switch

2) Turn ignition switch

engine.

At this time, “CHECK

ON without running

ENGINE” light should

light (should not flash).

If it does not light, check electric circuit of

the light, namely light for blow off and lead

wire for disconnection.

Fig. 5-3- 16 “CHECK ENGINE” light

3) After lighting of the light is confirmed, start

engine and warm it up to normal operating

temperature.

4) When engine is warmed up, run engine at

1,500- 2,000 rpm. In this state, make sure

that “CHECK ENGINE”lightflashes. Flashing

of light proves that system is in good condition.

If light does not flash, it can be caused by

one of the following. Check them and replace

or adjust as necessary.

l Defective thermal switch

l Disconnected or loosely connected electric

lead wires of emission control systems

l Defective ECM

l Defective micro switches (idle and wot)

5)After making sure that “CHECK ENGINE”

light flashes, turn cancel switch OFF. Light

should go off.

6) Stop engine.

Checking idle and wide open micro switches

Check idle and wide open micro switches

according to the following procedures.

1. Warm up engine to normal operating tempe-

rature and stop engine.

2. For this check, use check terminal coming

from the lower right of instrument panel as

shown.

Connect negative prod of ohmmeter to check

terminal and positive prod to body.

Iht green wire

eck terminal

3. Instrument panel

4. Glove box lid

3. Turn ignition switch to “ON” position.

4. Observe ohmmeter indicator reaction to make

sure for the following movement for each

throttle valve position.

5-23

Page 175 of 962

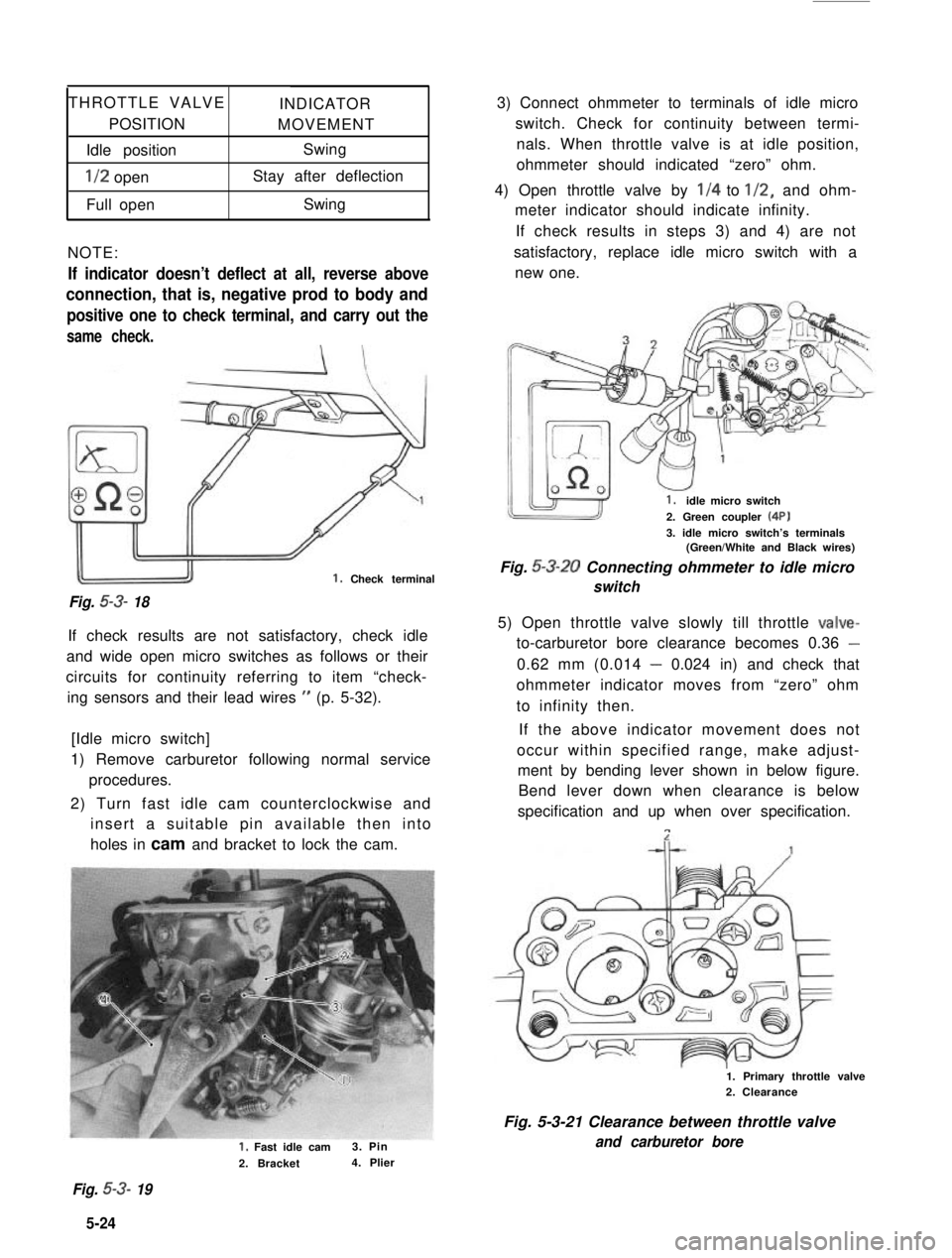

THROTTLE VALVEINDICATOR

POSITIONMOVEMENT

Idle positionSwing

l/2 openStay after deflection

Full openSwing

NOTE:

If indicator doesn’t deflect at all, reverse above

connection, that is, negative prod to body and

positive one to check terminal, and carry out the

same check.

Fig. 53- 18

1. Check terminal

If check results are not satisfactory, check idle

and wide open micro switches as follows or their

circuits for continuity referring to item “check-

ing sensors and their lead wires ” (p. 5-32).

[Idle micro switch]

1) Remove carburetor following normal service

procedures.

2) Turn fast idle cam counterclockwise and

insert a suitable pin available then into

holes in cam and bracket to lock the cam.

1, Fast idle cam3. Pin

2. Bracket4. Plier

3) Connect ohmmeter to terminals of idle micro

switch. Check for continuity between termi-

nals. When throttle valve is at idle position,

ohmmeter should indicated “zero” ohm.

4) Open throttle valve by l/4 to l/2, and ohm-

meter indicator should indicate infinity.

If check results in steps 3) and 4) are not

satisfactory, replace idle micro switch with a

new one.

1.idle micro switch

2. Green coupler (4P)

3. idle micro switch’s terminals(Green/White and Black wires)

Fig. 5-3-20 Connecting ohmmeter to idle micro

switch

5) Open throttle valve slowly till throttle valve-

to-carburetor bore clearance becomes 0.36 -

0.62 mm (0.014 - 0.024 in) and check that

ohmmeter indicator moves from “zero” ohm

to infinity then.

If the above indicator movement does not

occur within specified range, make adjust-

ment by bending lever shown in below figure.

Bend lever down when clearance is below

specification and up when over specification.

n

1. Primary throttle valve2. Clearance

Fig. 5-3-21 Clearance between throttle valve

and carburetor bore

Fig. 5-3- 19

5-24 4

Page 176 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 5-3-22 Lever

1. Lever

.

[Wide open micro switch]

1) Connect ohmmeter to wide open micro

switch as indicated in below figure.

At this time, ohmmeter indicator should

indicate “zero” ohm.

2) Wh SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 5-3-22 Lever

1. Lever

.

[Wide open micro switch]

1) Connect ohmmeter to wide open micro

switch as indicated in below figure.

At this time, ohmmeter indicator should

indicate “zero” ohm.

2) Wh](/img/20/57437/w960_57437-175.png)

Fig. 5-3-22 Lever

1. Lever

.

[Wide open micro switch]

1) Connect ohmmeter to wide open micro

switch as indicated in below figure.

At this time, ohmmeter indicator should

indicate “zero” ohm.

2) When throttle valve is fully opened, ohmmeter

should indicate infinity.

If any defect, replace.

1. Wide open micro switch

2. Yellow coupler

3. Green coupler (4P)4. Wide open micro switch’sterminals(Green and Black/Yellow wires)

Fig. 5-3-23 Checking wide open micro switch

3) Open throttle valve gradually until the ohm-

meter indicates infinity. Then, using a vernier,

measure the clearance between throttle valve

and carburetor bore as shown in below figure.

The clearance should be within 6.0 - 7.2 mm

(0.24- 0.28 in). If the clearance is out of

specified range, make adjustment by bending

the lever in below figure.

1. Primary throttle valve2. Clearance

Fig. 5-3-24 Clearance between throttle valve

and carburetor bore

1. Wide open micro switch lever

Fig. 5-3-25 Wide open micro switch lever

Upon completion of checks, install carburetor

following normal service procedures.

Checking mixture control solenoid valve

1) Check to make sure that ignition switch is at

“OFF” position.

2) Disconnect couplers from ECM, TWSVs and

vsv.

3) Disconnect mixture control solenoid valve

lead wires at the coupler (5P).

Fig. 5-3-26

1. Green coupler (BP)

5-25

Page 177 of 962

4) Using couplers of the same shape as that

mentioned in step 3) or 1P couplers, connect

only mixture control solenoid valve wire

terminals (Yellow/Black terminal of coupler

@ and Black/White terminal of coupler 0,

White terminal of coupler @ and Blue/Red

terminal of coupler 0.

NOTE:

l Couplers must be used to connect each

terminal.

l Use special care when connecting terminals

as wrong connection may cause damage to

other parts.

9

1. Coupler of MCSV side7. 1 p coupler2. Coupler of wire harness side8. 5p coupler (when using this3. Yellow/Black wire terminalcoupler, leave positions

4. Black/White wire terminalindicated as 9 in figure

,5. White wire terminalblank).

6. Blue/Red wire terminal9. Blank

Fig. 5-3-27

5) Remove cap of duty check coupler located

on dash panel and connect terminals with a

lead wire to short them.

6) Turn ignition switch “ON” and “OFF”

repeatedly (without starting engine) and

check if MCSV. operating sound is heard as

ignition switch is operated.

Operating sounds prove its proper operation.

Fig. 5-3-29

7) Upon completion of checks, re-connect

disconnected couplers to original positions

securely.

Checking thermal switch

NOTE:

For the rough check of the operation, thermal

switch can be checked by warming up (above

46.5”C, 116°F) or cooling down (below 3O”C,

86°F) the engine without being removed from

the intake manifold.

The check procedure is the same as the follow-

ing except item 11, 21, 5) and 6).

1) Drain cooling system.

2) Remove thermal switch from intake mani-

fold.

3) Cool switch to below 30°C (86” F), and using

an ohmmeter, check that there is continuity

between terminals.

Fig. 5-3-28

1. Duty check coupler2. Lead wire

5-26

Page 178 of 962

1

1. Thermal switch

2. Cool water

3. Thermometer

1. Thermal engine room switch

Fig. 5-3-30 Checking thermal switch in coolFig. 5-3-32 Checking thermal engine room

waterswitch

4) Heat switch to above 46.5”C (116”F), and

check that there is no continuity between

terminals.t

Ll

%I

Rio 0II

I \\1. Hot waterII/2. Heater

Fig. 5-3-31 Checking switch in hot water

5) Reinstall switch to intake manifold. Before

installing, wind sealing tape on its thread.

6) Refill cooling system.

Checking thermal engine room switch

1) Disconnect connector of switch and connect

ohmmeter between terminals on switch side.

2) Make sure that switch is “ON” (ohmmeter

indicates “Zero”ohm) when atmospheric

temperature is below 7°C (44” F) and “OFF”

(ohmmeter. indicates infinity) when above

19.5”C (67” F).

Checking high altitude compensator

Check the compensator as follows:

1) Disconnect the coupler of compensator and

connect an ohmmeter to the compensator.

2) Check to be sure that;

* If the altitude of the place where this check is

performed is above 1,220 m (4,000 ft), the

ohmmetershould indicate“Zero” ohm

(compensator is ON).

0 If the altitude is below 1,220 m (4,000 ft),

the ohmmeter should indicate infinity ohm

(compensator is OFF).

3) After checking, connect the coupler.

1. High altitude compensator

Fig. 5-3-33 Checking high altitude compensator

5-27

Page 179 of 962

Checking oxygen sensor

1) Warm up the engine to normal operating

temperature.

2) Disconnect the connector of the oxygen

sensor.

Fig. 5-3-34 Connector of oxygen sensor

3) Connect the voltmeter between the oxygen

sensor side terminal of the disconnected

connector and the ground as shown in below

figure.

NOTE:

Be sure to use a voltmeter whose inner resis-

tance is more than some MS!Z per IV or a

digital type voltmeter. Any other voltmeter

should not be used because accurate measure-

ments are not obtained.

NEVER apply voltage to the oxygen sensor as

it may cause damage to the sensor.

NEVER connect ohmmeter to the oxygen

sensor as it may cause damage to the sensor.

i

1. Oxygen sertsor side terminal

2. Ground

3. Left side fender

4) While keeping the engine running at 1,500 -

2,000 rpm, turn the wide open micro switch

“OFF” by moving the lever with the finger as

shown in below figure. Then take the reading

of the voltmeter to make sure it is about 0.8V.

I, Lever

2. Wide open micro switch

Fig. 5-3-36 Moving lever3. Carburetor

5) With the engine running at 1,000 - 1,500

rpm, disconnect the vacuum hose at the in-

take manifold as shown in below figure. At

this time, check to ensure that the voltmeter

indicator is below 0.2V.

1. Vacuum hose

2. Intake manifold3. MCV

Fig. 5-3-37 Disconnecting vacuum hose

6) After checking, reconnect the vacuum hose to

the intake manifold and the connector of

oxygen sensor.

Fig. 5-3-35 Connec ring voltmeter

5-28

Page 180 of 962

Checking feed back system circuits

When the feed back system does not seem to operate properly even after each of its components has been

checked and proved normal, it is necessary to check each circuit of the feed back system. The checking

procedure of each circuit is described here.

[Checking ECM ground circuits]

The ECM is grounded both at the dash panel and

the intake manifold. If either grounding is not

made securely, the feed back system will not

operate. Therefore, check if the ECM is properly

grounded at these two points according to the

following procedure.

1) Turn OFF the ignition switch.

2) Disconnect the coupler from the ECM.

3) Connect an ohmmeter between the terminal

@ of the disconnected coupler (on the

wiring harness side) and the body (ground)

as shown in below figure, and measure the

resistance. Then repeat the same with the

terminal 0.1. ECM (Electronic Control2. CouplerModule)3. Instrument main panel

Fig. 5-3-38 ECM and coupler

1. Coupler (Viewed from wire harness side)

2. “B” (Black) leed wire

3. “B/G” (Black/Green) lead wire

4. Body ground

5. Engine ground

Fig. 5-3-39Checking ECM ground circuit

5-29