SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 101 of 962

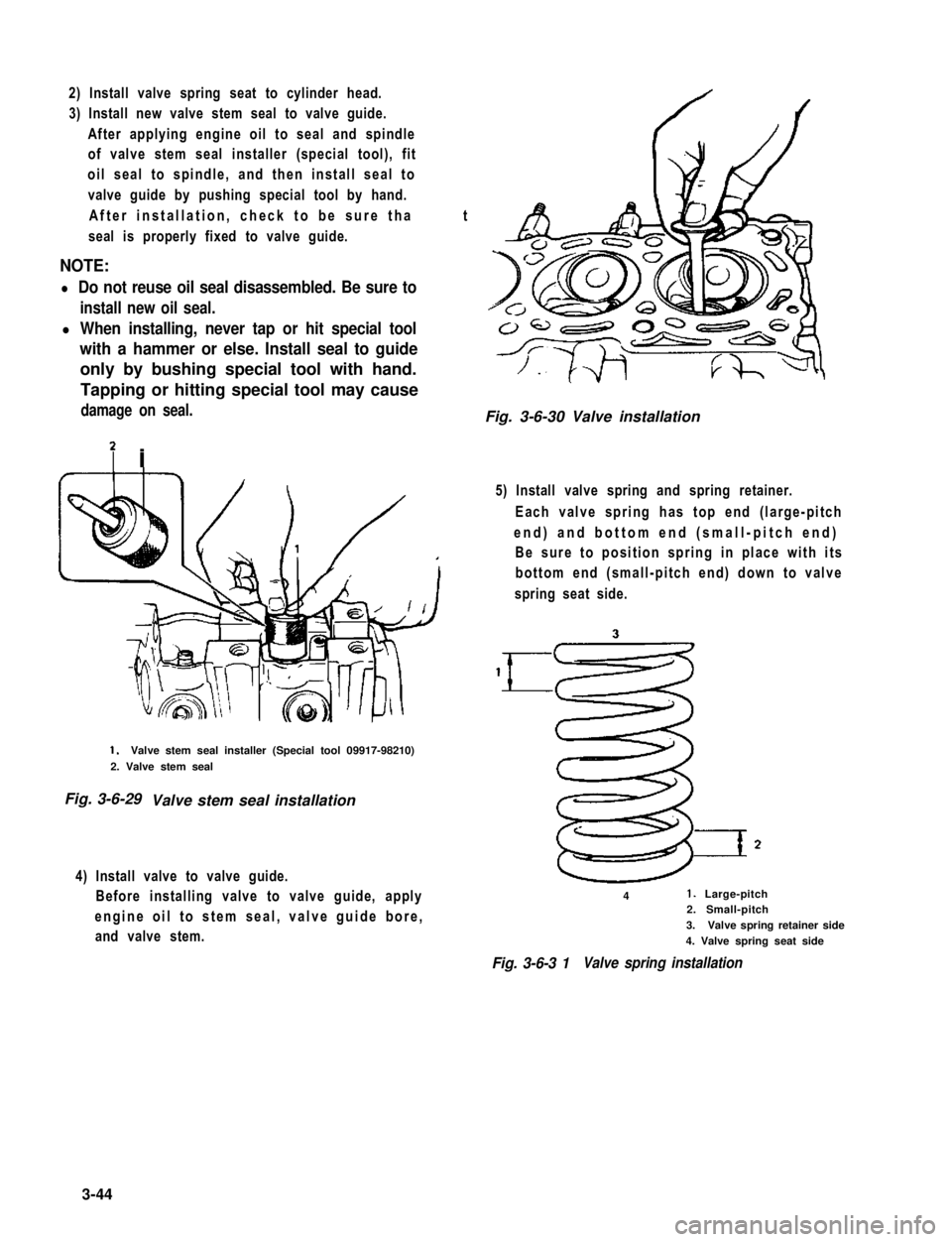

2) Install valve spring seat to cylinder head.

3) Install new valve stem seal to valve guide.

After applying engine oil to seal and spindle

of valve stem seal installer (special tool), fit

oil seal to spindle, and then install seal to

valve guide by pushing special tool by hand.

After installation, check to be sure that

seal is properly fixed to valve guide.

NOTE:

l Do not reuse oil seal disassembled. Be sure to

install new oil seal.

l When installing, never tap or hit special tool

with a hammer or else. Install seal to guide

only by bushing special tool with hand.

Tapping or hitting special tool may cause

damage on seal.

7 i

1.Valve stem seal installer (Special tool 09917-98210)

2. Valve stem seal

Fig. 3-6-29 Valve stem seal installation

4) Install valve to valve guide.

Before installing valve to valve guide, apply

engine oil to stem seal, valve guide bore,

and valve stem.

Fig. 3-6-30 Valve installation

5) Install valve spring and spring retainer.

Each valve spring has top end (large-pitch

end) and bottom end (small-pitch end)

Be sure to position spring in place with its

bottom end (small-pitch end) down to valve

spring seat side.

41. Large-pitch2. Small-pitch

3.Valve spring retainer side

4. Valve spring seat side

Fig. 3-6-3 1Valve spring installation

3-44

Page 102 of 962

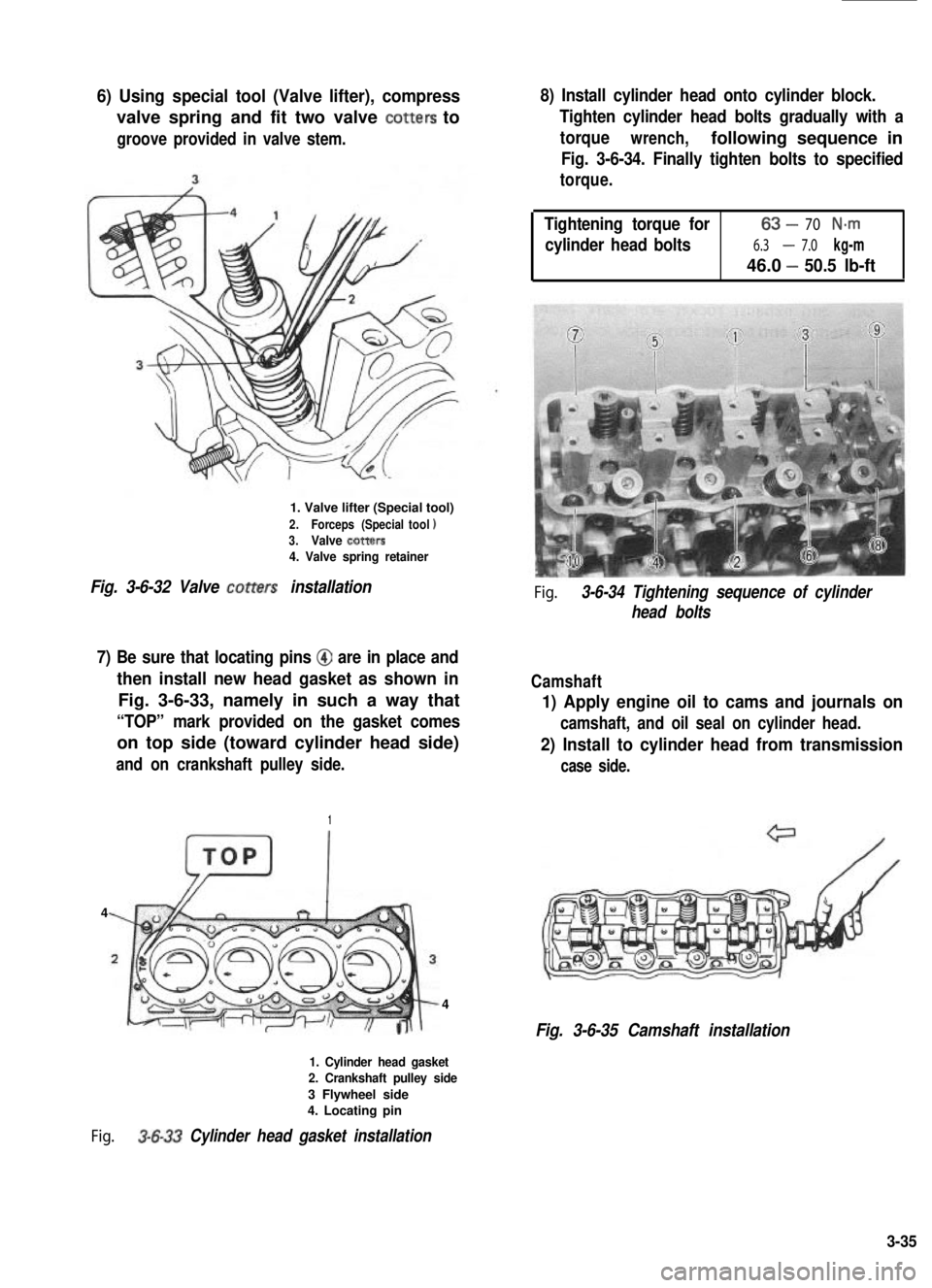

6) Using special tool (Valve lifter), compress

valve spring and fit two valve totters to

groove provided in valve stem.

1. Valve lifter (Special tool)

2.Forceps (Specialtool13.Valve totters4. Valve spring retainer

Fig. 3-6-32 Valve totters installation

7) Be sure that locating pins @ are in place and

then install new head gasket as shown in

Fig. 3-6-33, namely in such a way that

“TOP” mark provided on the gasket comes

on top side (toward cylinder head side)

and on crankshaft pulley side.

1

4

4

1. Cylinder head gasket2. Crankshaft pulley side

3 Flywheel side4. Locating pin

Fig. 3-6-33 Cylinder head gasket installation

8) Install cylinder head onto cylinder block.

Tighten cylinder head bolts gradually with a

torquewrench,following sequence in

Fig. 3-6-34. Finally tighten bolts to specified

torque.

Tightening torque for63-70 N-m

cylinder head bolts6.3-7.0 kg-m

46.0 -50.5 lb-ft

Fig. 3-6-34 Tightening sequence of cylinder

head bolts

Camshaft

1) Apply engine oil to cams and journals on

camshaft, and oil seal on cylinder head.

2) Install to cylinder head from transmission

case side.

Fig. 3-6-35 Camshaft installation

3-35

Page 103 of 962

Rocker-Arm Shafts

1) Apply engine oil to rocker arms and rocker

arm shafts.

2) install rocker arms, springs and rocker arm

shafts.

The two rocker arm shafts are not identical.

To distinguish between the two, dimensions

of their stepped ends differ as shown in

Fig. 36-36. Install intake rocker arm shaft,

facing its stepped end to camshaft pulley

side, and exhaust rocker arm shaft, facing

its stepped end to distributor side (rear side).

56

b01000

/3

I

3

I

o-

“7

1. Intake rocker arm shaft

2.14 mm (0.55 in)

3. Exhaust rocker arm shaft

4.15 mm (0.59 in)

5. Camshaft pulley side

6.Distributor side

Fig. 3-6-36 Rocker arm shafts installation

3) After installing rocker arms, springs, and

rocker arm shafts as shown in Fig. 3-6-37,

tighten rocker arm shaft screws to specified

torque.

Tightening torque9 -12 N.m

for rocker arm shaft0.9 -1.2 kg-m

screws7.0 -8.5 lb-ft

NOTE:

Valve clearance is adjusted after all parts are

assembled. So it is not adjusted at this point

Leave rocker arm adjusting screw as loose as

can be.

1. Intake side

2. Exhaust side

Fig. 3-6-37

Water Inlet Pipe

Install water inlet pipe to cylinder block.

Make sure to fit seal ring @(O-ring) to inlet

pipe before installation.

Fig. 3-6-38

Intake Manifold and Carburetor

1) Install intake manifold gasket to cylinder

head. Use new gasket.

NOTE:

Clean cylinder head mating surface with gasket

before installation.

2) Install intake manifold with carburetor to

cylinder head.

3) Tighten manifold bolts and nuts to specified

torque.

Tightening torque ~.mkg-mlb-ftfor manifold bolts

and nuts18 - 281.8 - 2.8 13.5-20.0

3-46

Page 104 of 962

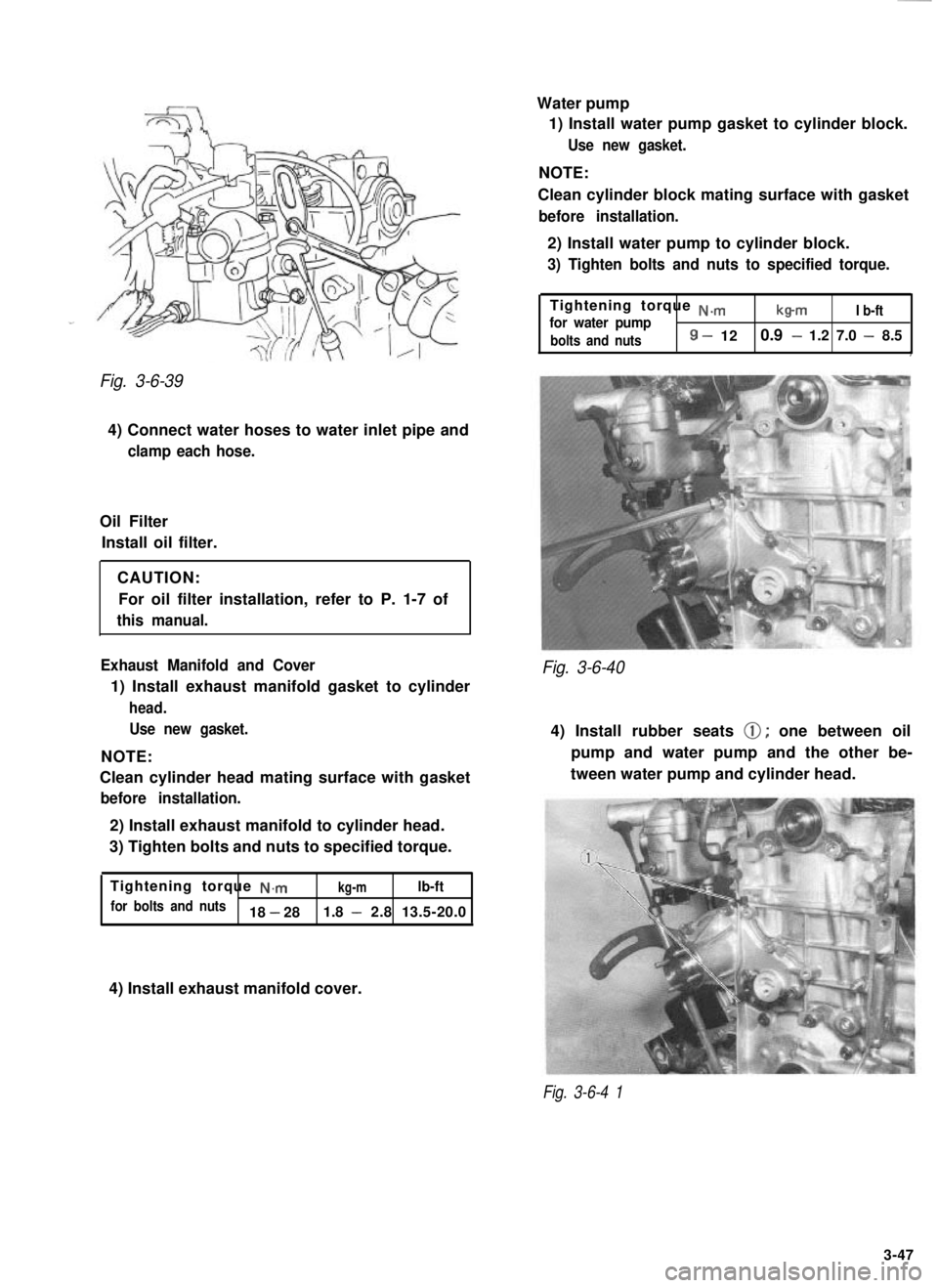

Fig. 3-6-39

4) Connect water hoses to water inlet pipe and

clamp each hose.

Oil FilterInstall oil filter.

CAUTION:For oil filter installation, refer to P. 1-7 of

this manual.

Exhaust Manifold and Cover

1) Install exhaust manifold gasket to cylinder

head. Use new gasket.

NOTE:

Clean cylinder head mating surface with gasket

before installation.

2) Install exhaust manifold to cylinder head.

3) Tighten bolts and nuts to specified torque.

Tightening torque

N.mkg-mlb-ft

for bolts and nuts18 - 28 1.8 - 2.8 13.5-20.0 Water pump

1) Install water pump gasket to cylinder block.

Use new gasket.

NOTE:

Clean cylinder block mating surface with gasket

before installation.

2) Install water pump to cylinder block.

3) Tighten bolts and nuts to specified torque.

Tightening torque N.m

for water pumpb-mI b-ft

bolts and nuts

8 - 12 0.9 - 1.2 7.0 - 8.5,

Fig. 3-6-40

4) Install rubber seats 0; one between oil

pump and water pump and the other be-

tween water pump and cylinder head.

4) Install exhaust manifold cover.

Fig. 3-6-4 1

3-47

Page 105 of 962

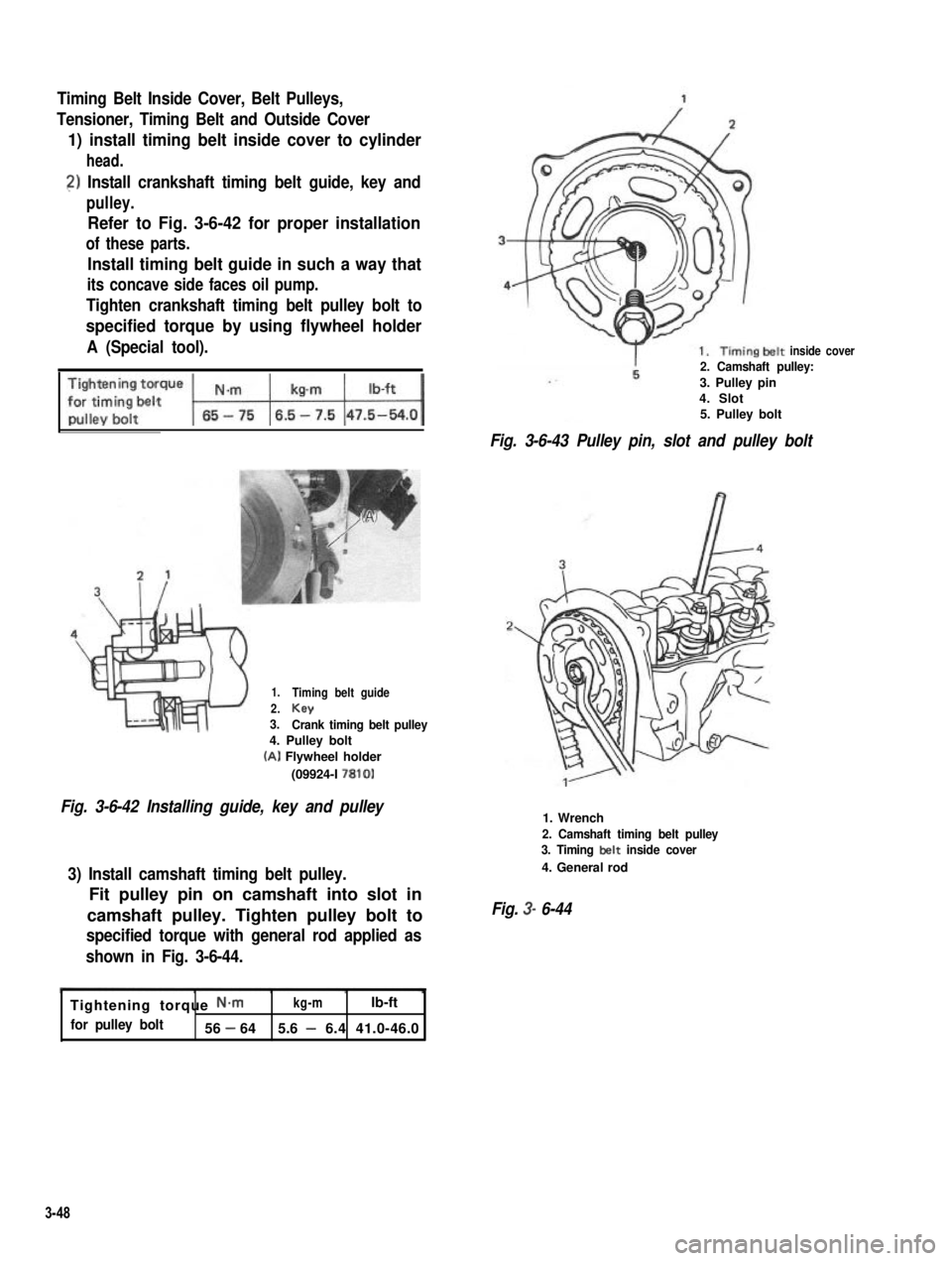

Timing Belt Inside Cover, Belt Pulleys,

Tensioner, Timing Belt and Outside Cover

1) install timing belt inside cover to cylinder

head.

2) Install crankshaft timing belt guide, key and

pulley.

Refer to Fig. 3-6-42 for proper installation

of these parts.

Install timing belt guide in such a way that

its concave side faces oil pump.

Tighten crankshaft timing belt pulley bolt to

specified torque by using flywheel holder

A (Special tool).

1.

2.3.

Timing belt guide

KeyCrank timing belt pulley4. Pulley bolt

(A) Flywheel holder

(09924-I 7810)

Fig. 3-6-42 Installing guide, key and pulley

3) Install camshaft timing belt pulley.

Fit pulley pin on camshaft into slot in

camshaft pulley. Tighten pulley bolt to

specified torque with general rod applied as

shown in Fig. 3-6-44.

inside cover2. Camshaft pulley:

3. Pulley pin4. Slot5. Pulley bolt

Fig. 3-6-43 Pulley pin, slot and pulley bolt

1. Wrench

2. Camshaft timing belt pulley3. Timing belt inside cover

4. General rod

Fig. 3- 6-44

Tightening torque N-mkg-mlb-ft

for pulley bolt56 - 645.6 - 6.4 41.0-46.0

3-48

Page 106 of 962

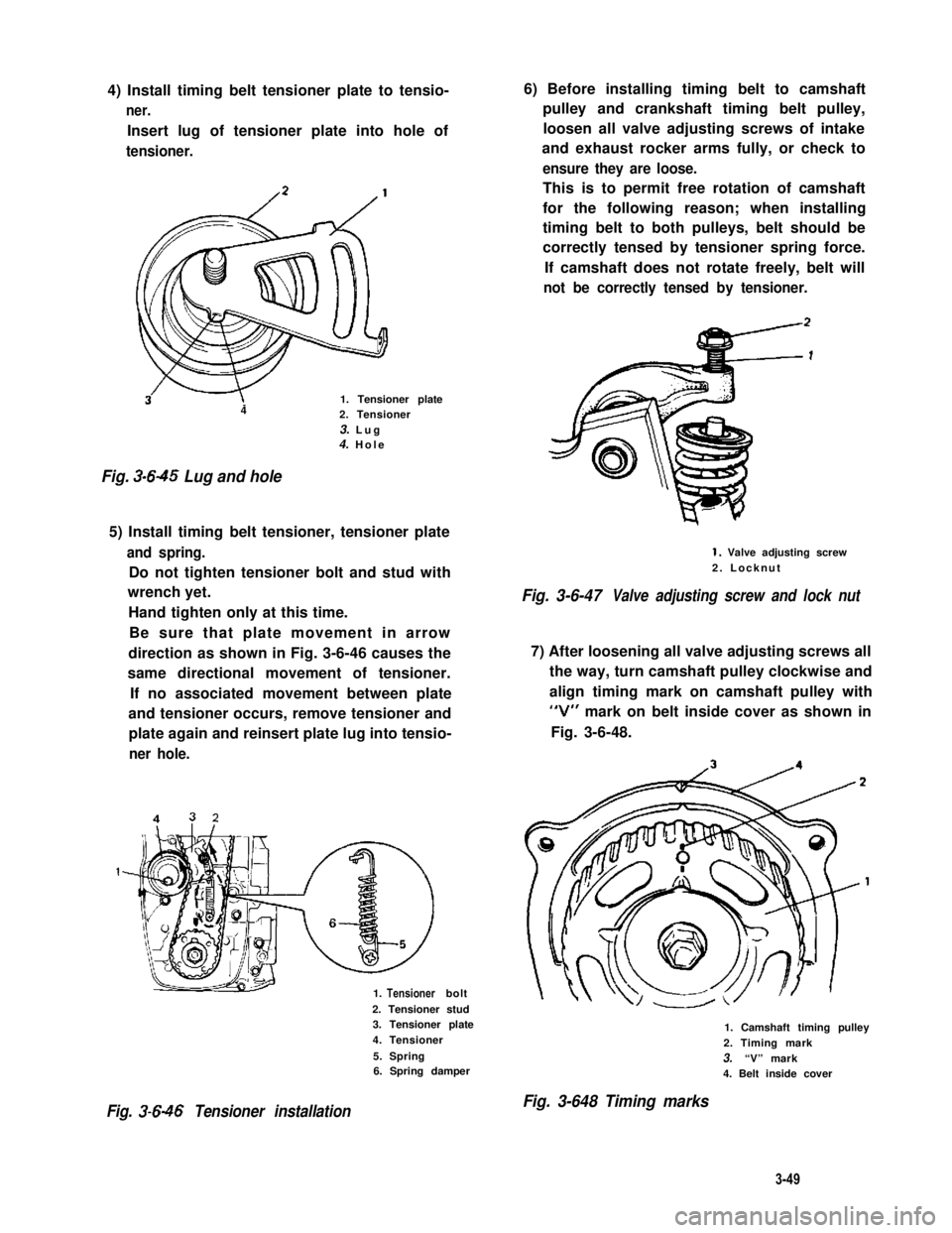

4) Install timing belt tensioner plate to tensio-

ner.

Insert lug of tensioner plate into hole of

tensioner.

3w1. Tensioner plate42. Tensioner

3. Lug4. Hole

Fig. 3-645 Lug and hole

5) Install timing belt tensioner, tensioner plate

and spring.

Do not tighten tensioner bolt and stud with

wrench yet.

Hand tighten only at this time.

Be sure that plate movement in arrow

direction as shown in Fig. 3-6-46 causes the

same directional movement of tensioner.

If no associated movement between plate

and tensioner occurs, remove tensioner and

plate again and reinsert plate lug into tensio-

ner hole.

1. bolt

2. Tensioner stud3. Tensioner plate

4. Tensioner

5. Spring6. Spring damper

Fig. 3-646 Tensioner installation

6) Before installing timing belt to camshaft

pulley and crankshaft timing belt pulley,

loosen all valve adjusting screws of intake

and exhaust rocker arms fully, or check to

ensure they are loose.

This is to permit free rotation of camshaft

for the following reason; when installing

timing belt to both pulleys, belt should be

correctly tensed by tensioner spring force.

If camshaft does not rotate freely, belt will

not be correctly tensed by tensioner.

1. Valve adjusting screw

2. Locknut

Fig. 3-6-47Valve adjusting screw and lock nut

7) After loosening all valve adjusting screws all

the way, turn camshaft pulley clockwise and

align timing mark on camshaft pulley with

“V” mark on belt inside cover as shown in

Fig. 3-6-48.

1. Camshaft timing pulley

2. Timing mark

3.“V” mark4. Belt inside cover

Fig. 3-648 Timing marks

3-49

Tensioner

Page 107 of 962

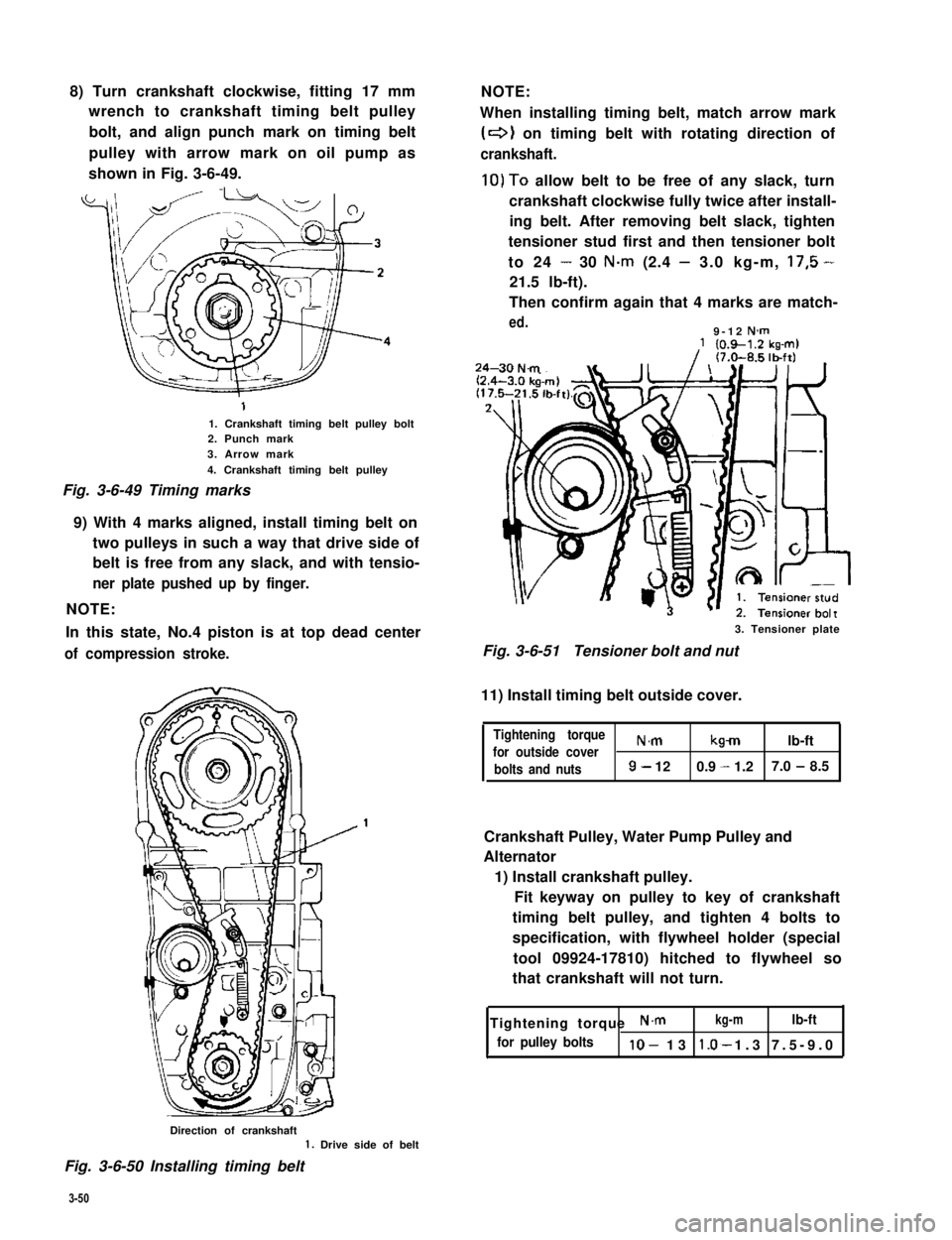

8) Turn crankshaft clockwise, fitting 17 mm

wrench to crankshaft timing belt pulley

bolt, and align punch mark on timing belt

pulley with arrow mark on oil pump as

shown in Fig. 3-6-49.

1. Crankshaft timing belt pulley bolt2. Punch mark3. Arrow mark

4. Crankshaft timing belt pulley

Fig. 3-6-49 Timing marks

9) With 4 marks aligned, install timing belt on

two pulleys in such a way that drive side of

belt is free from any slack, and with tensio-

ner plate pushed up by finger.

NOTE:

In this state, No.4 piston is at top dead center

of compression stroke.

NOTE:

When installing timing belt, match arrow mark

(+I on timing belt with rotating direction of

crankshaft.

10)To allow belt to be free of any slack, turn

crankshaft clockwise fully twice after install-

ing belt. After removing belt slack, tighten

tensioner stud first and then tensioner bolt

to 24 - 30 N.m (2.4 - 3.0 kg-m, 17,5 -

21.5 lb-ft).

Then confirm again that 4 marks are match-

ed.9-12 N-m

3. Tensioner plate

Fig. 3-6-51Tensioner bolt and nut

11) Install timing belt outside cover.

Tightening torque

for outside coverN.mkmlb-ft

bolts and nuts9- 120.9 - 1.27.0 - 8.5

Crankshaft Pulley, Water Pump Pulley and

Alternator

1) Install crankshaft pulley.

Fit keyway on pulley to key of crankshaft

timing belt pulley, and tighten 4 bolts to

specification, with flywheel holder (special

tool 09924-17810) hitched to flywheel so

that crankshaft will not turn.

Tightening torque N.mkg-mlb-ft

for pulley boltslo- 13 1.3 7.5-9.0*

Direction of crankshaft1. Drive side of belt

Fig. 3-6-50 Installing timing belt

3-50

Page 108 of 962

-1. Key

‘32. Crankshaft pulley3. Pulley bolt

Fig. 3-6-52 Installing crankshaft pulley

2) Install alternator assembly.

Tighten alternator ass’y securing bolts (3pcs)

only to the extent to allow alternator to be

moved by hand. Don’t torque them tight.

NOTE:

Adjust water pump belt tension to specification

upon completion of installing engine ass’y to

body and then cooling fan and water pump

pulley. Make sure to refer to p. 1-5 of this

manual for adjusting procedure.

Distributor Case

1) Install distributor case O-ring to cylinder

head.

2) Install distributor case.

3) Tighten bolts to specified torque.

Tightening torque N.mkg-mlb-ft

forcasebolts8-120.8-1.26.0-8.5

Fig. 3-6-53

Fuel Pump

Install fuel pump rod, gasket and fuel pump to

cylinder head.

Apply engine oil to rod @ before installation.

Use new gasket.

Fig. 3-6-54 Fuel pump rod installation

case with about 3Occ (1.02/1.05 US/Imp

3-51

Page 109 of 962

Clutch Disc and Cover?

Install clutch disc and cover.

For installation, refer to p. 11-7 of SECTION 11

CLUTCH in this manual and torque each bolt to

specification.

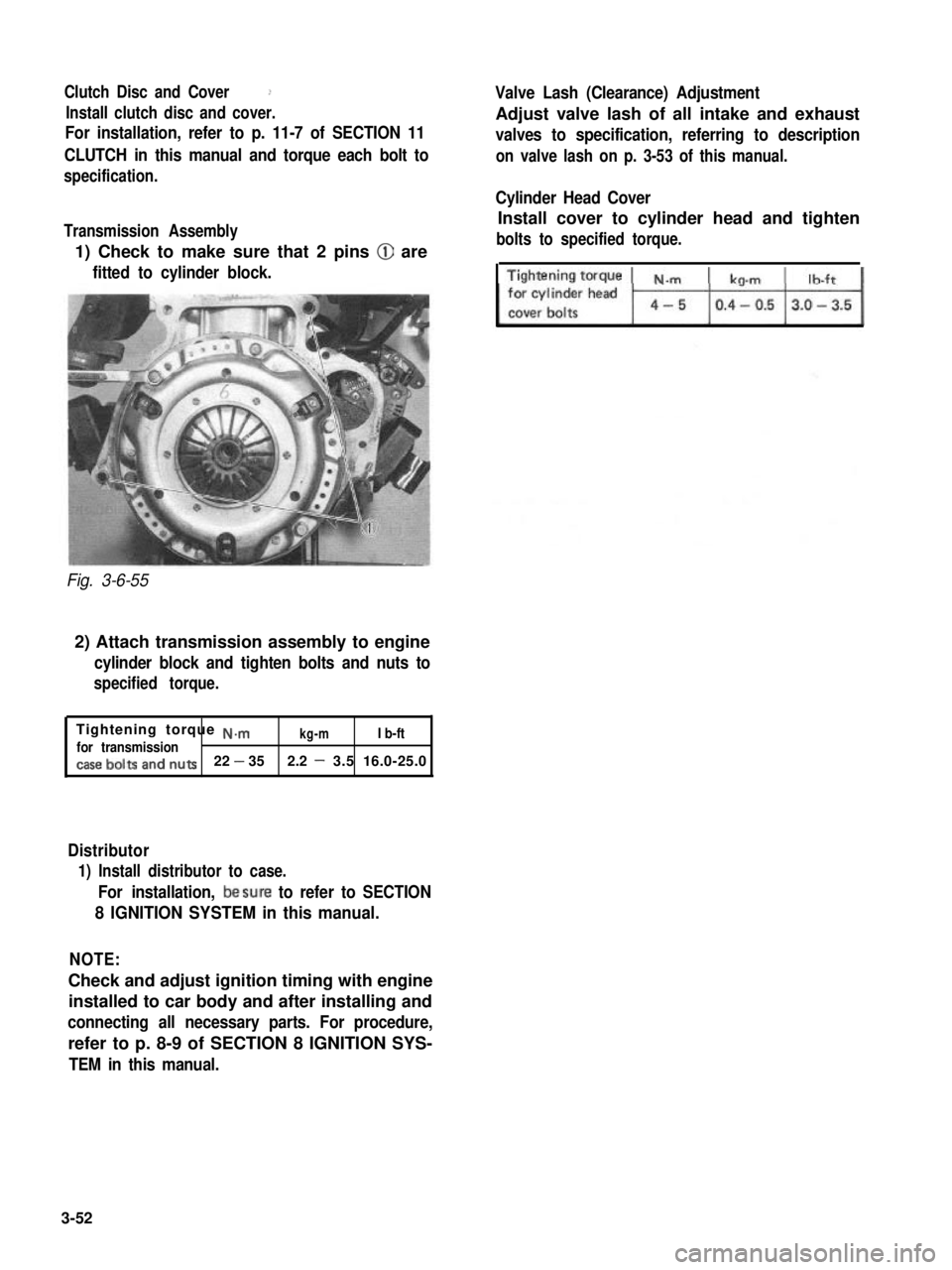

Transmission Assembly

1) Check to make sure that 2 pins @ are

fitted to cylinder block.

Fig. 3-6-55

2) Attach transmission assembly to engine

cylinder block and tighten bolts and nuts to

specified torque.

Tightening torque ~.mkg-mI b-ftfor transmission,.aSe bolts an,-j nutS22 - 352.2 - 3.5 16.0-25.0

Distributor

1) Install distributor to case.

For installation, besure to refer to SECTION

8 IGNITION SYSTEM in this manual.

Valve Lash (Clearance) Adjustment

Adjust valve lash of all intake and exhaust

valves to specification, referring to description

on valve lash on p. 3-53 of this manual.

Cylinder Head Cover

Install cover to cylinder head and tighten

bolts to specified torque.

NOTE:

Check and adjust ignition timing with engine

installed to car body and after installing and

connecting all necessary parts. For procedure,

refer to p. 8-9 of SECTION 8 IGNITION SYS-

TEM in this manual.

3-52

Page 110 of 962

3-7. ENGINE INSTALLATION

1) Lower engine with transmission into vehicle,

but do not remove lifting device.

2) Tighten engine mounting bracket bolts

(right and left) and transmission mounting

bolts to specification. Refer to p. 3-58.

3) Remove lifting device.

4) Reverse removal procedures for installation

of remainder.

5) Adjust accelerator cable play and clutch

cable play.

6) Connect vacuum hoses securely. Refer to

section 5 “EMISSION CONTROL SYSTEM”

for correct connection.

7) Connect wire harnesses and couplers secure-

IY.

8) Tighten bolts and nuts to specified torque.

For individual specification, refer to each

section.

9) Fill specified amount of specified trans-

mission oil and engine oil. For the detail,

refer to SECTION 1 PERIODIC MAINTE-

NANCE SERVICE of this manual.

10) After adjusting water pump belt tension to

specification, fill specified amount of engine

cooling water.

11) Before starting engine, check again to ensure

that all parts once disassembled or discon-

nected are back in place securely.

12)Start engine and check ignition timing. If

it is not to specified timing, adjust it, referr-

ing to SECTION 8 of this manual.

13) After engine is started, check for oil leak,

abnormal noise and other malcondition.

Also, check each part for operation.

3-8. ENGINE MAINTENANCE SERVICE

Fan Belt

Adjust belt tension as outlined in SECTION 6

ENGINE COOLING SYSTEM (p. 6-10).

Ignition Timing

Refer to IGNITION TIMING, Page 8-9.

Carburetor

fidjustments to be made are detailed in SEC-

TION 4 (p. 4-19).

Valve Lash (Clearance)

Valve lash specifications:

Valve lash refers to gap between rocker arm

adjusting screw and valve stem. Use a thickness

gauge to measure this gap @.

When coldWhen hot(Coolant tempe-(Coolant tempa-

Valve lashrature is 15 - 25%rature is 60 - 66’C

(gap A)or 69 - 77’F)or 140 - 154’F)

specif i-0.13 - 0.17 mm0.23 - 0.27 mmcationIntake(0.0051 - 0.0067 in) (0.009 - 0.011 in)

Exhaust0.16 -0.20 mm0.26 - 0.30 mm(0.0063 - 0.0079 in) (0.0102 - 0.0116 in)

Screw lock nut 15 - 19 N.m(1.5 - 1.9 kg-m, 11 .O - 13.5 lb-ft)

Adjusting screw

8

Valve stem

Fig. 3-8-l

Checking and adjusting procedures:

NOTE:

l Refer to Fig. 3-3-11 of SECTION 3 for

cylinder numbers (No. 1, No. 2, No. 3 and

No. 4) mentioned in this section.

l When adjustment becomes necessary in step

4), loosen adjusting screw lock nut and then

make adjustment by turning adjusting screw.

After adjustment, tighten lock nut to specifi-

ed torque while holding adjusting screw

stationary with straight headed screwdriver,

and then make sure again that gap @ is

within specification.

3-53