SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 131 of 962

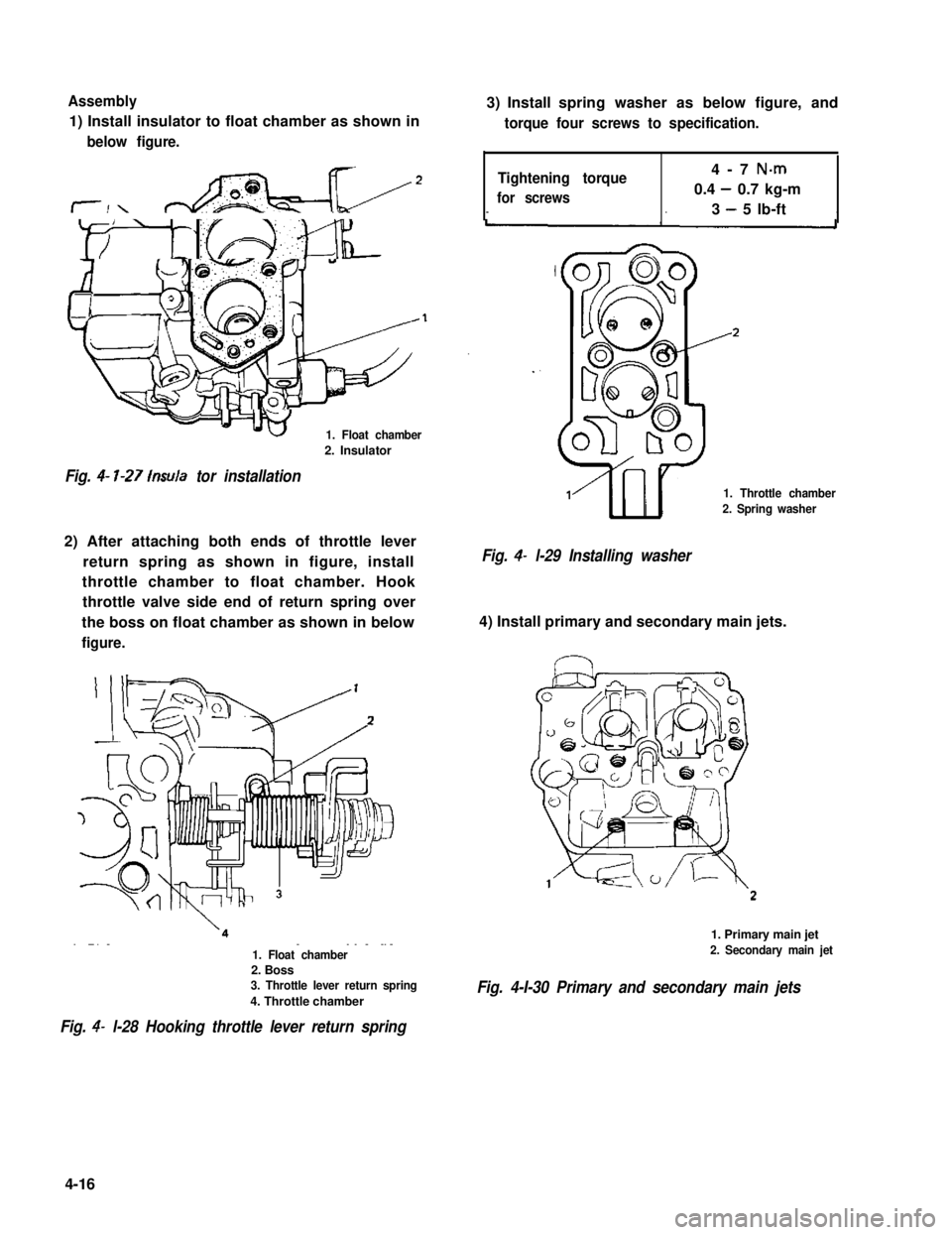

Assembly

1) Install insulator to float chamber as shown in

below figure.

1. Float chamber

2. Insulator

Fig. 4- l-27 lnsula tor installation

2) After attaching both ends of throttle lever

return spring as shown in figure, install

throttle chamber to float chamber. Hook

throttle valve side end of return spring over

the boss on float chamber as shown in below

figure.

3) Install spring washer as below figure, and

torque four screws to specification.

Tightening torque

for screws

4-7 N-m

0.4 - 0.7 kg-m

3 - 5 lb-ft

1. Throttle chamber

2. Spring washer

Fig. 4- l-29 Installing washer

4) Install primary and secondary main jets.

1. Float chamber2. Boss3. Throttle lever return spring

4. Throttle chamber

Fig. 4- l-28 Hooking throttle lever return spring

1. Primary main jet

2. Secondary main jet

Fig. 4-I-30 Primary and secondary main jets

4-16

Page 132 of 962

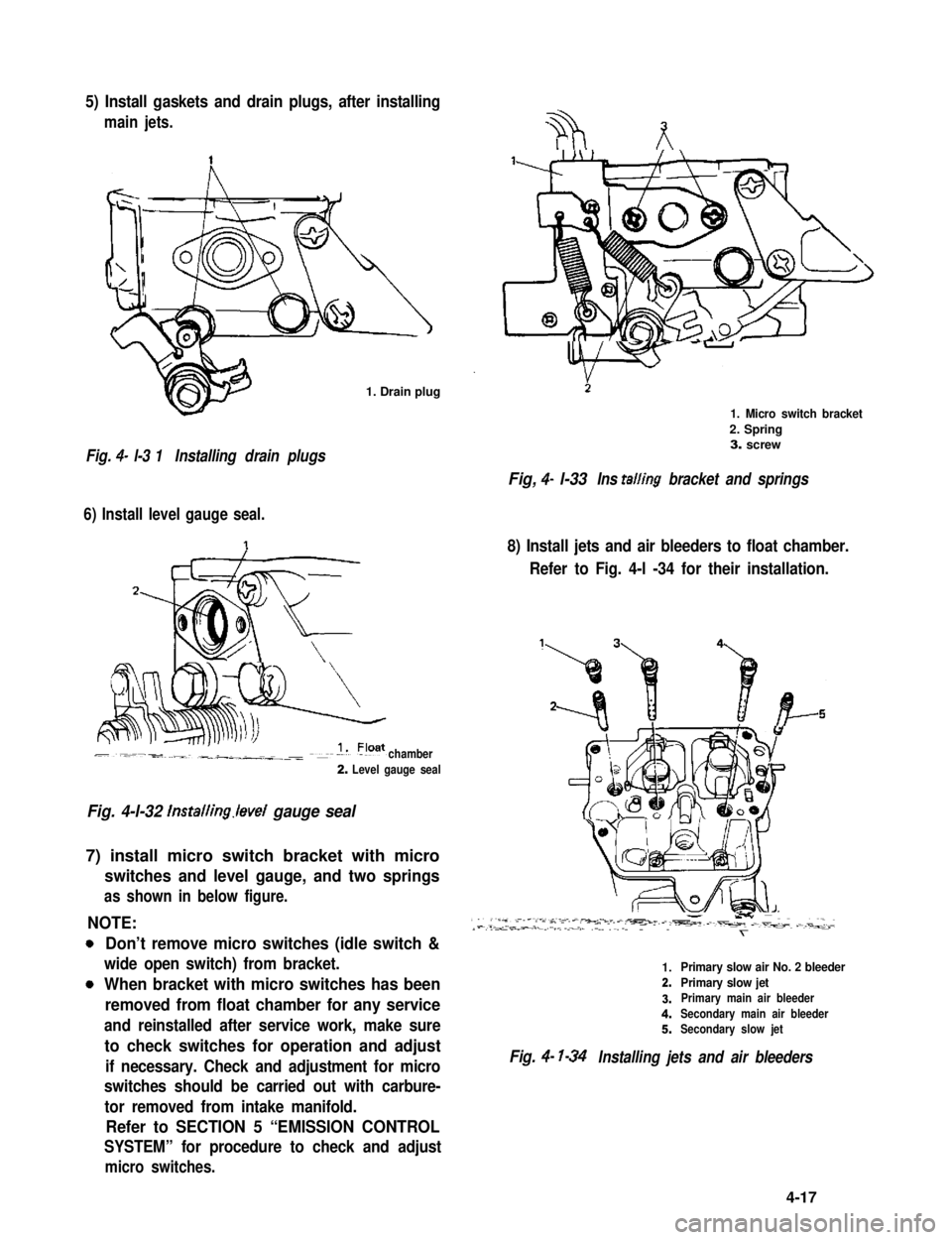

5) Install gaskets and drain plugs, after installing

main jets.

1. Drain plug

Fig. 4- l-3 1Installing drain plugs

6) Install level gauge seal.

chamber

2. Level gauge seal

Fig. 4-l-32 lnstalling.level gauge seal

7) install micro switch bracket with micro

switches and level gauge, and two springs

as shown in below figure.

NOTE:

0

0

Don’t remove micro switches (idle switch &

wide open switch) from bracket.

When bracket with micro switches has been

removed from float chamber for any service

and reinstalled after service work, make sure

to check switches for operation and adjust

if necessary. Check and adjustment for micro

switches should be carried out with carbure-

tor removed from intake manifold.

Refer to SECTION 5 “EMISSION CONTROL

SYSTEM” for procedure to check and adjust

micro switches.

1. Micro switch bracket

2. Spring3. screw

Fig, 4- l-33Ins tailing bracket and springs

8) Install jets and air bleeders to float chamber.

Refer to Fig. 4-l -34 for their installation.

1.Primary slow air No. 2 bleeder

2.Primary slow jet

3.Primary main air bleeder

4.Secondary main air bleeder

5.Secondary slow jet

Fig. 4- l-34Installing jets and air bleeders

4-17

Page 133 of 962

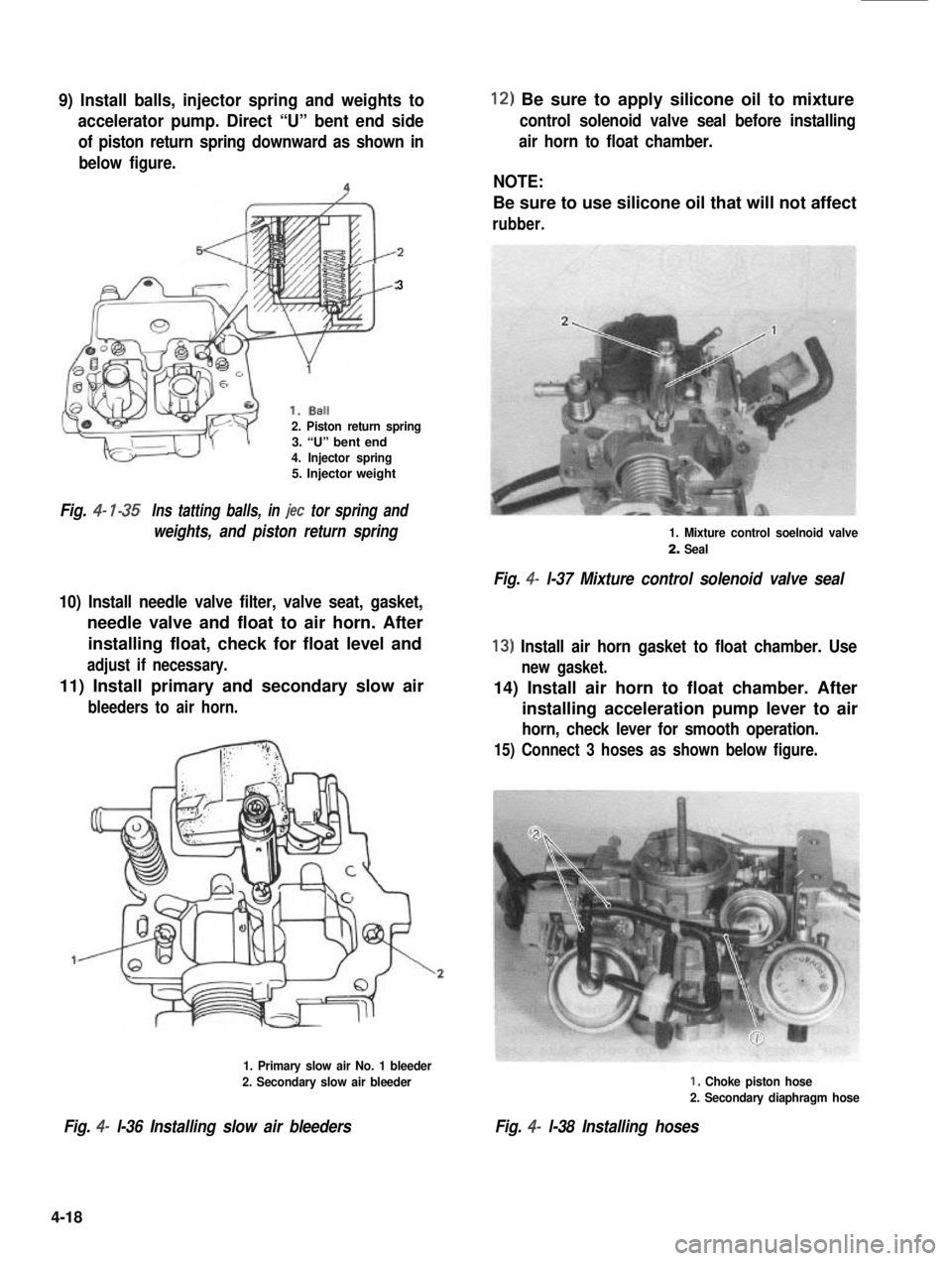

9) Install balls, injector spring and weights to

accelerator pump. Direct “U” bent end side

of piston return spring downward as shown in

below figure.

3

2. Piston return spring3. “U” bent end4. Injector spring5. Injector weight

Fig. 4- l-35Ins tatting balls, in jet tor spring and

weights, and piston return spring

10) Install needle valve filter, valve seat, gasket,

needle valve and float to air horn. After

installing float, check for float level and

adjust if necessary.

11) Install primary and secondary slow air

bleeders to air horn.

1. Primary slow air No. 1 bleeder

2. Secondary slow air bleeder

Fig. 4- l-36 Installing slow air bleeders

12) Be sure to apply silicone oil to mixture

control solenoid valve seal before installing

air horn to float chamber.

NOTE:

Be sure to use silicone oil that will not affect

rubber.

1. Mixture control soelnoid valve

2. Seal

Fig. 4- l-37 Mixture control solenoid valve seal

13) Install air horn gasket to float chamber. Use

new gasket.

14) Install air horn to float chamber. After

installing acceleration pump lever to air

horn, check lever for smooth operation.

15) Connect 3 hoses as shown below figure.

I, Choke piston hose

2. Secondary diaphragm hose

Fig. 4- l-38 Installing hoses

4-18

Page 134 of 962

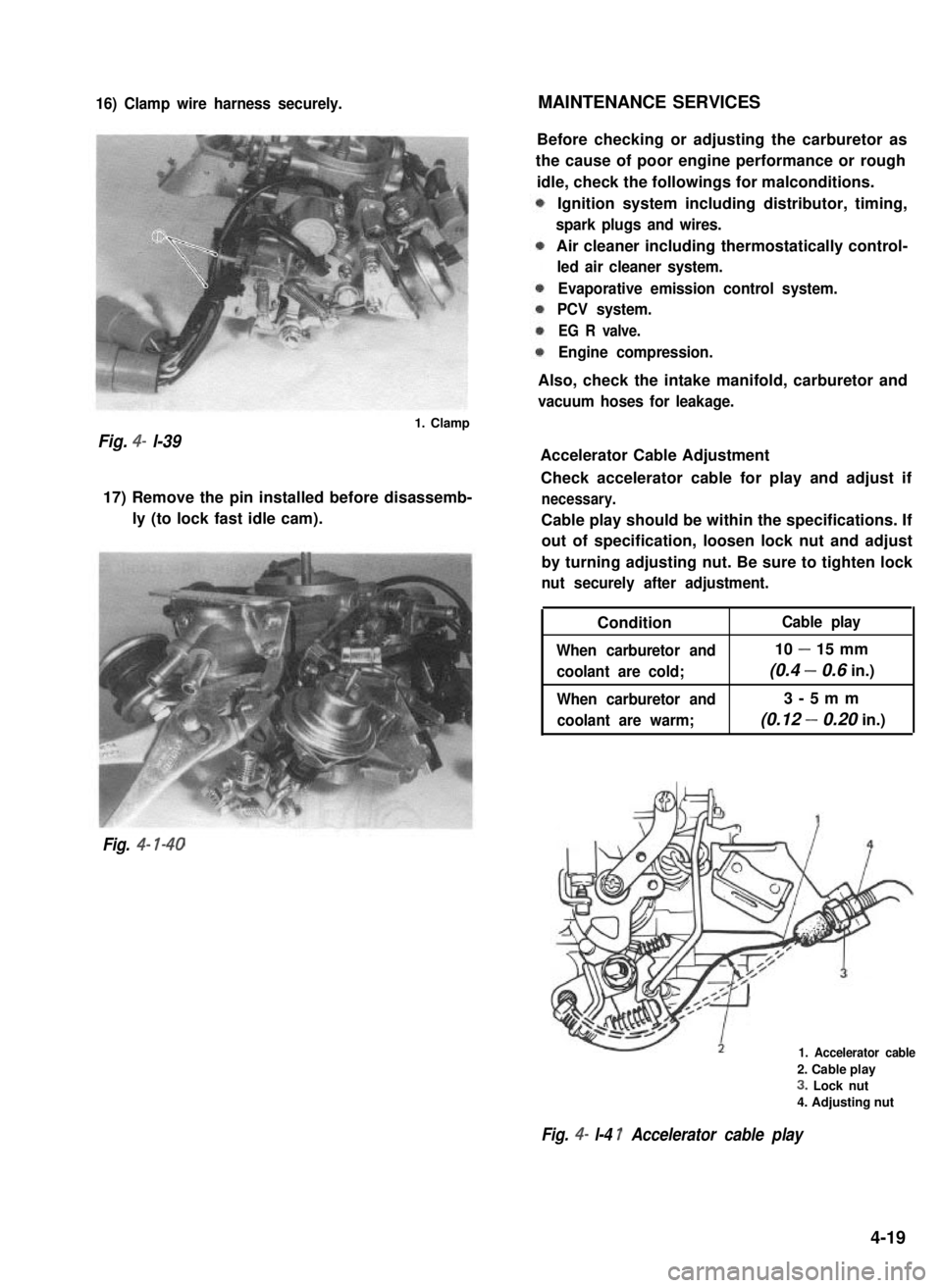

16) Clamp wire harness securely.MAINTENANCE SERVICES

Fig. 4- l-39

1. Clamp

17) Remove the pin installed before disassemb-

ly (to lock fast idle cam).

Fig. 4- l-40

Before checking or adjusting the carburetor as

the cause of poor engine performance or rough

idle, check the followings for malconditions.

Ignition system including distributor, timing,

spark plugs and wires.

Air cleaner including thermostatically control-

led air cleaner system.

Evaporative emission control system.

PCV system.

EG R valve.

Engine compression.

Also, check the intake manifold, carburetor and

vacuum hoses for leakage.

Accelerator Cable Adjustment

Check accelerator cable for play and adjust if

necessary.

Cable play should be within the specifications. If

out of specification, loosen lock nut and adjust

by turning adjusting nut. Be sure to tighten lock

nut securely after adjustment.

Condition

When carburetor and

coolant are cold;

When carburetor and

coolant are warm;

Cable play

10 - 15 mm

(0.4 - 0.6 in.)

3-5mm

(0.12 - 0.20 in.)

1. Accelerator cable

2. Cable play

3. Lock nut

4. Adjusting nut

Fig. 4- l-4 1 Accelerator cable play

4-19

Page 135 of 962

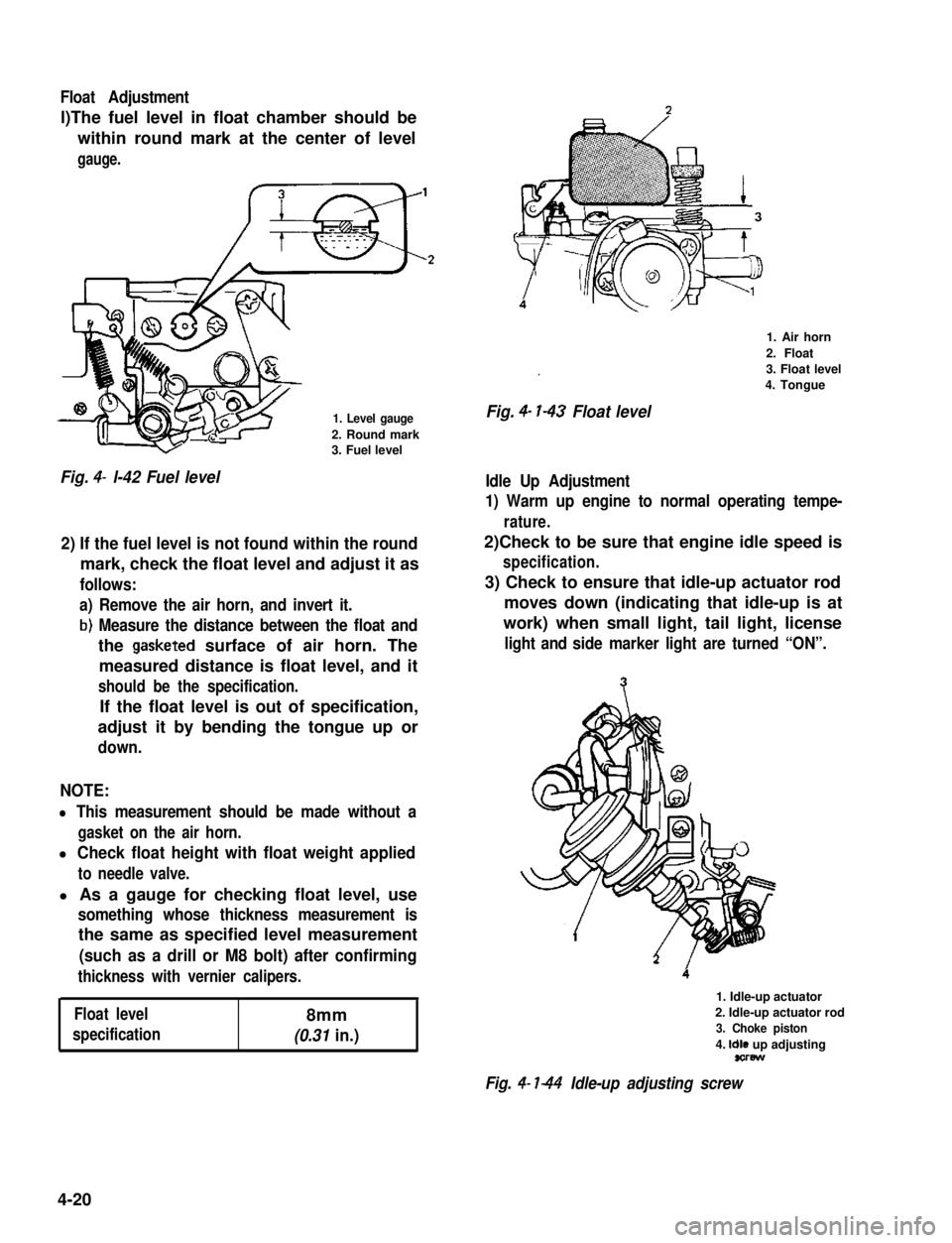

Float Adjustment

l)The fuel level in float chamber should be

within round mark at the center of level

gauge.

1. Level gauge

2. Round mark3. Fuel level

Fig. 4- l-42 Fuel level

2) If the fuel level is not found within the round

mark, check the float level and adjust it as

follows:

a) Remove the air horn, and invert it.

b) Measure the distance between the float and

the gasketed surface of air horn. The

measured distance is float level, and it

should be the specification.

If the float level is out of specification,

adjust it by bending the tongue up or

down.

NOTE:

l This measurement should be made without a

gasket on the air horn.

l Check float height with float weight applied

to needle valve.

l As a gauge for checking float level, use

something whose thickness measurement is

the same as specified level measurement

(such as a drill or M8 bolt) after confirming

thickness with vernier calipers.

Float level8mm

specification(0.31 in.)

.

Fig. 4- l-43 Float level

1. Air horn

2. Float

3. Float level

4. Tongue

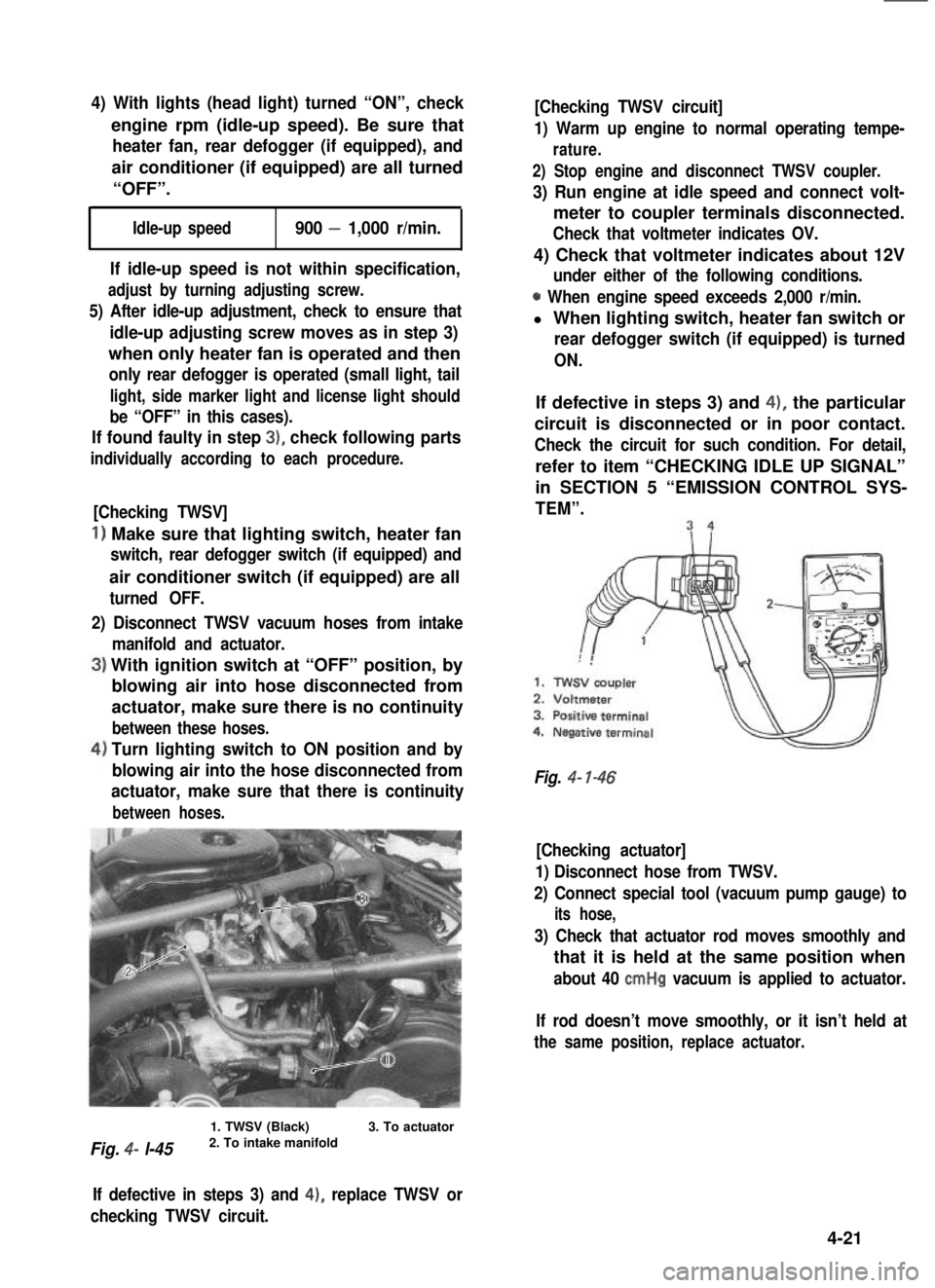

Idle Up Adjustment

1) Warm up engine to normal operating tempe-

rature.

2)Check to be sure that engine idle speed is

specification.

3) Check to ensure that idle-up actuator rod

moves down (indicating that idle-up is at

work) when small light, tail light, license

light and side marker light are turned “ON”.

1. Idle-up actuator

2. Idle-up actuator rod

3. Choke piston

4. Idle up adjustingsorew

Fig. 4- l-44 Idle-up adjusting screw

4-20

Page 136 of 962

4) With lights (head light) turned “ON”, check

engine rpm (idle-up speed). Be sure that

heater fan, rear defogger (if equipped), and

air conditioner (if equipped) are all turned

“OFF”.

Idle-up speed900 - 1,000 r/min.

If idle-up speed is not within specification,

adjust by turning adjusting screw.

5) After idle-up adjustment, check to ensure that

idle-up adjusting screw moves as in step 3)

when only heater fan is operated and then

only rear defogger is operated (small light, tail

light, side marker light and license light should

be “OFF” in this cases).

If found faulty in step 3), check following parts

individually according to each procedure.

[Checking TWSV]

1) Make sure that lighting switch, heater fan

switch, rear defogger switch (if equipped) and

air conditioner switch (if equipped) are all

turned OFF.

2) Disconnect TWSV vacuum hoses from intake

manifold and actuator.

With ignition switch at “OFF” position, by

blowing air into hose disconnected from

actuator, make sure there is no continuity

between these hoses.

Turn lighting switch to ON position and by

blowing air into the hose disconnected from

actuator, make sure that there is continuity

between hoses.

Fig. 4- l-45

1. TWSV (Black)2. To intake manifold3. To actuator

[Checking TWSV circuit]

1) Warm up engine to normal operating tempe-

rature.

2) Stop engine and disconnect TWSV coupler.

3) Run engine at idle speed and connect volt-

meter to coupler terminals disconnected.

Check that voltmeter indicates OV.

4) Check that voltmeter indicates about 12V

under either of the following conditions.

0 When engine speed exceeds 2,000 r/min.

l When lighting switch, heater fan switch or

rear defogger switch (if equipped) is turned

ON.

If defective in steps 3) and 4), the particular

circuit is disconnected or in poor contact.

Check the circuit for such condition. For detail,

refer to item “CHECKING IDLE UP SIGNAL”

in SECTION 5 “EMISSION CONTROL SYS-

TEM”.

Fig. 4- l-46

[Checking actuator]

1) Disconnect hose from TWSV.

2) Connect special tool (vacuum pump gauge) to

its hose,

3) Check that actuator rod moves smoothly and

that it is held at the same position when

about 40 cmHg vacuum is applied to actuator.

If rod doesn’t move smoothly, or it isn’t held at

the same position, replace actuator.

If defective in steps 3) and 4), replace TWSV or

checking TWSV circuit.

4-21

Page 137 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual Ambient temperatureClearance

Fig. 4-l-47

Choke Adjustment

Perform following check and adjustments with

air intake case removed when engine is cold.

[Choke valve]

1) Check choke valve for smooth moveme SUZUKI GRAND VITARA 1987 Service Repair Manual Ambient temperatureClearance

Fig. 4-l-47

Choke Adjustment

Perform following check and adjustments with

air intake case removed when engine is cold.

[Choke valve]

1) Check choke valve for smooth moveme](/img/20/57437/w960_57437-136.png)

Ambient temperatureClearance

Fig. 4-l-47

Choke Adjustment

Perform following check and adjustments with

air intake case removed when engine is cold.

[Choke valve]

1) Check choke valve for smooth movement by

pushing it with a finger.

Fig. 4-l-48 Choke valve

2) Make sure that choke valve is closed almost

completely when ambient temperature is

below 25°C (77” F) and engine is cold.

3) Check to ensure that choke valve to carbure-

tor bore clearance is within following specifi-

cations when engine is cool.

I.6 mmC&n*?.:.. \

NOTE:

As ambient temperature or engine coolant

temperature rises high, clearance increases.

1. Choke valve2. Thickness gauge

Fig. 4- 149 Choke valve to carbure tar bore

clearance

4) If clearance is found excessively large or

small in the above check, check strangler

spring, choke piston and each link in choke

system for smooth operation. Lubricate

choke valve shaft and each link with spray

lubricant if necessary.

Fig. 4-l-50

4-22

Page 138 of 962

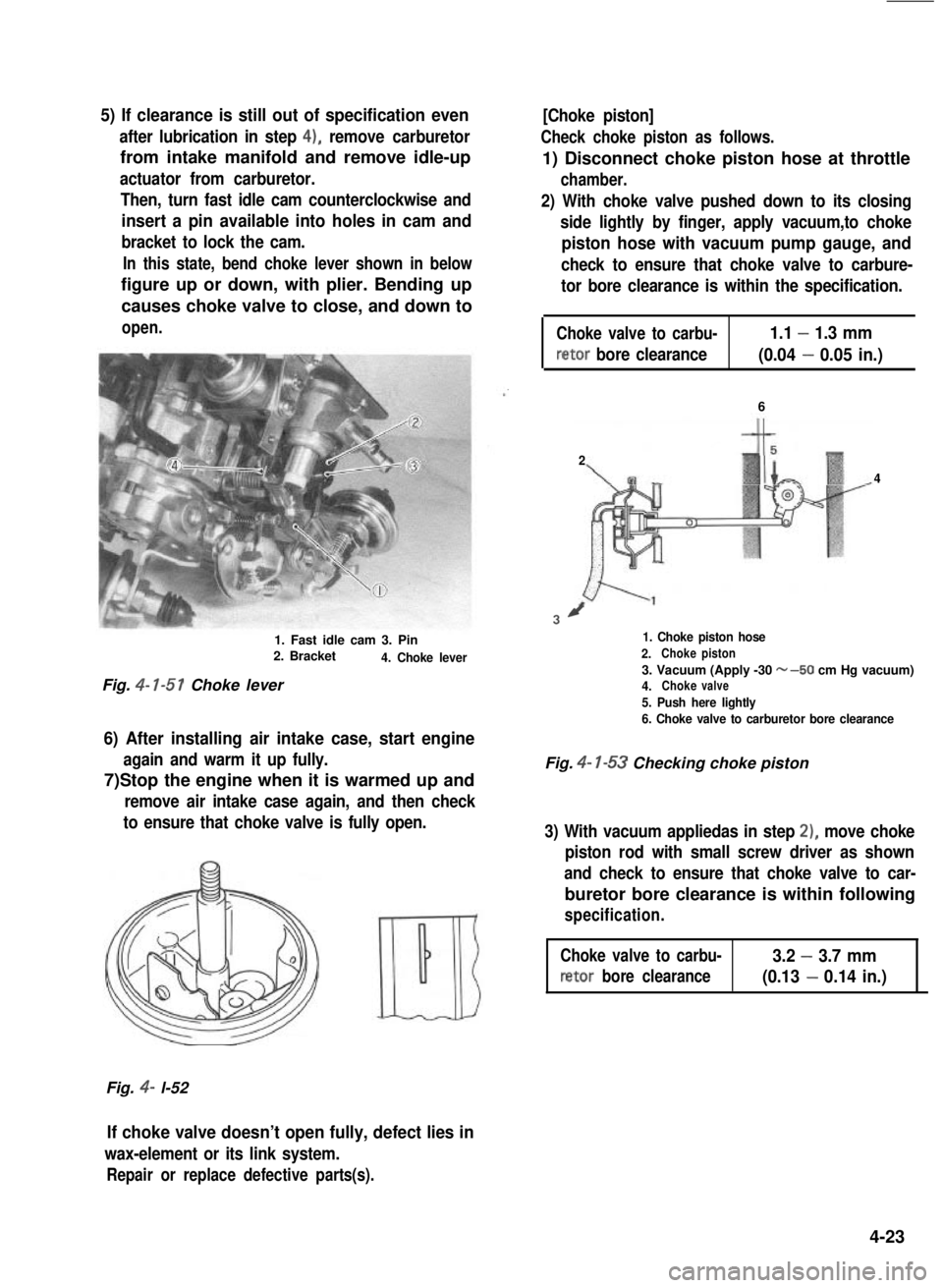

5) If clearance is still out of specification even

after lubrication in step 4), remove carburetor

from intake manifold and remove idle-up

actuator from carburetor.

Then, turn fast idle cam counterclockwise and

insert a pin available into holes in cam and

bracket to lock the cam.

In this state, bend choke lever shown in below

figure up or down, with plier. Bending up

causes choke valve to close, and down to

open.

1. Fast idle cam 3. Pin2. Bracket4. Choke lever

Fig. 4- l-51 Choke lever

6) After installing air intake case, start engine

again and warm it up fully.

7)Stop the engine when it is warmed up and

remove air intake case again, and then check

to ensure that choke valve is fully open.

Fig. 4- l-52

[Choke piston]

Check choke piston as follows.

1) Disconnect choke piston hose at throttle

chamber.

2) With choke valve pushed down to its closing

side lightly by finger, apply vacuum,to choke

piston hose with vacuum pump gauge, and

check to ensure that choke valve to carbure-

tor bore clearance is within the specification.

Choke valve to carbu-1.1 - 1.3 mm

retor bore clearance(0.04 - 0.05 in.)

6

2

4

3/

1. Choke piston hose

2.Chokepiston

3. Vacuum (Apply -30 w-50 cm Hg vacuum)4.Chokevalve

5. Push here lightly

6. Choke valve to carburetor bore clearance

Fig. 4- l-53 Checking choke piston

3) With vacuum appliedas in step 2), move choke

piston rod with small screw driver as shown

and check to ensure that choke valve to car-

buretor bore clearance is within following

specification.

Choke valve to carbu-3.2 - 3.7 mm

retor bore clearance(0.13 - 0.14 in.)

If choke valve doesn’t open fully, defect lies in

wax-element or its link system.

Repair or replace defective parts(s).

4-23

Page 139 of 962

1.Vacuum (Apply-30w-50cmHgvacuum)

2. Choke piston rod3.Screw driver

4. Choke valve to carburetor bore clearance

Fig. 4- l-54 Moving choke piston rod

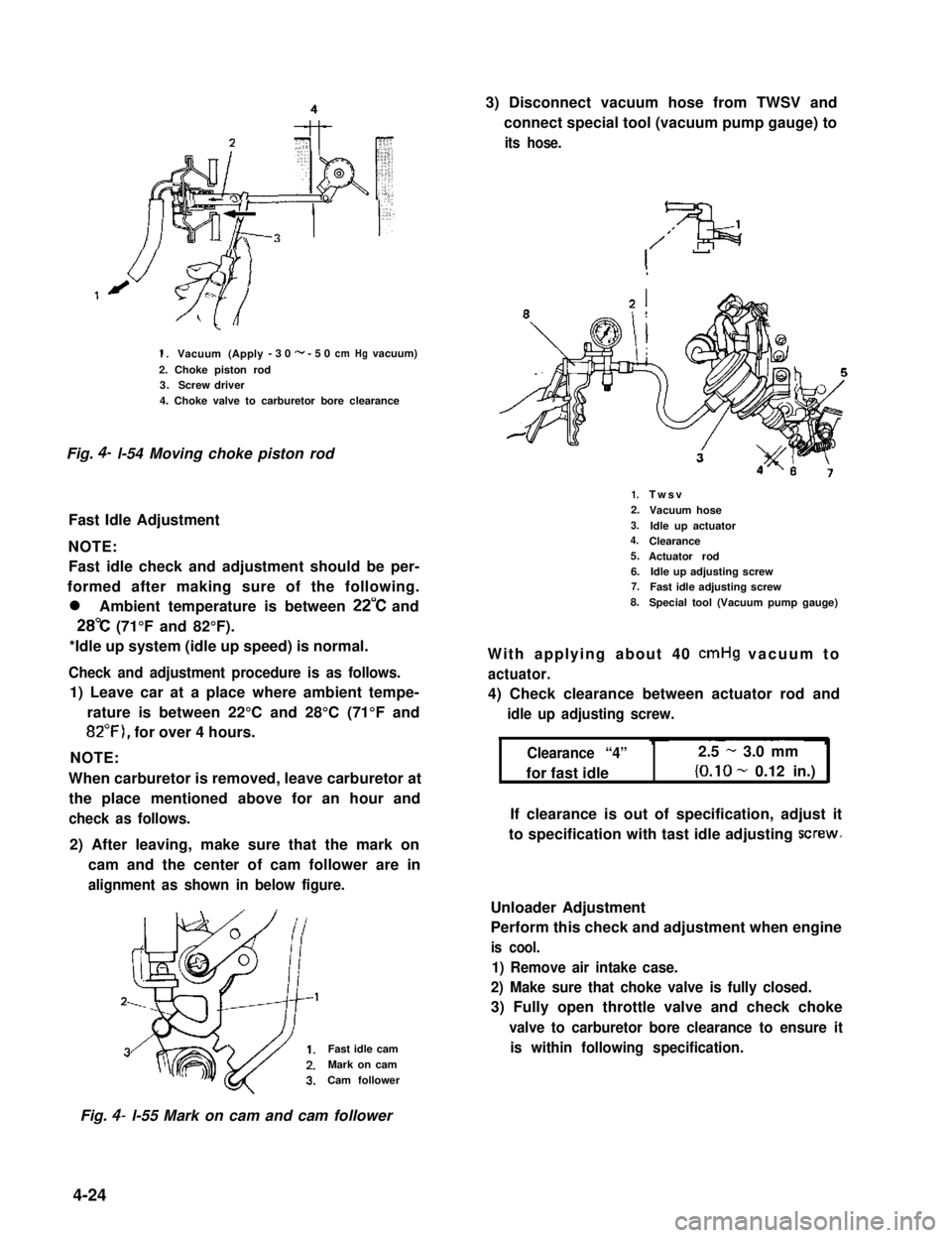

Fast Idle Adjustment

NOTE:

Fast idle check and adjustment should be per-

formed after making sure of the following.

l Ambient temperature is between 22°C and

28°C (71°F and 82°F).

*Idle up system (idle up speed) is normal.

Check and adjustment procedure is as follows.

1) Leave car at a place where ambient tempe-

rature is between 22°C and 28°C (71°F and

82”F), for over 4 hours.

NOTE:

When carburetor is removed, leave carburetor at

the place mentioned above for an hour and

check as follows.

2) After leaving, make sure that the mark on

cam and the center of cam follower are in

alignment as shown in below figure.

Fast idle cam

Mark on cam

Cam follower

3) Disconnect vacuum hose from TWSV and

connect special tool (vacuum pump gauge) to

its hose.

,

1.2.

3.4.

5.

6.7.

8.

Twsv

Vacuum hose

Idle up actuatorClearanceActuator rodIdle up adjusting screwFast idle adjusting screw

Special tool (Vacuum pump gauge)

With applying about 40 cmHg vacuum to

actuator.

4) Check clearance between actuator rod and

idle up adjusting screw.

Clearance “4”

for fast idle

2.5 - 3.0 mm

(O.lO- 0.12 in.)

If clearance is out of specification, adjust it

to specification with tast idle adjusting screw-

Unloader Adjustment

Perform this check and adjustment when engine

is cool.

1) Remove air intake case.

2) Make sure that choke valve is fully closed.

3) Fully open throttle valve and check choke

valve to carburetor bore clearance to ensure it

is within following specification.

Fig. 4- l-55 Mark on cam and cam follower

4-24

Page 140 of 962

4) If clearance is out of specification, adjust by

bending the unloader arm indicated in belowfigure.

‘

Choke valve to carbu-2.5 - 3.2 mm

retor bore clearance(0.10 - 0.12 in.)

Checking Secondary System

1) Remove air intake case.

2) Disconnect hose @ from 3 way joint, and

connect vacuum pump gauge.

3) Open primary throttly valve fully.

4) Check if secondary throttle valve opens smoothly and is held there when vacuum

(10 cmHg) is applied to actuator.

5) Disconnect hose @ from 3 way joint and

connect vacuum pump gauge to its hose.

Plug hose @ with finger.

. 6) Turn ignition switch to “ON” position and

open primary throttle valve fully. 5 or 6

seconds later, make the .same check as in

above step 4).

1. Unloader arm

2. Fast idle cam

3. Accelerator cable

Fig. 4-

7-57

Unloader lever arm

Checking Acceleration Pump

1) Remove air intake case.

2) Make sure that fuel comes out of pump

discharge nozzle when accelerator pedal is

depressed.

Fig. 4- l-59 2. Hose

4. vsv

If check result in step 4) is not satisfactory,

check VTV, and if that in step 6) is not satis-

factory, check VSV.

If not satisfactory in either step 4) or 6) and both

VTV and VSV are in good condition, replace

actuator.

[VTV (Vacuum Transmitting Valve)]

Remove VTV. Use a vacuum pump gauge for

VTV check. If pointer of vacuum pump gauge reacts as described below in each condition,

VTV is in good condition.

1

I, Pump discharge nozzle

2. Choke,valve

Fig. 4- 1-58 Pump discharge nozzle With vacuum pump gauge set at Brown side of

VTV, when pump is operated, pointer doesn’t

move (remains at zero position).

4- 25