check engine SUZUKI GRAND VITARA 1987 Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 184 of 962

[Checking function of oxygen sensor and feed back system1

If oxygen sensor fails to send signal to the ECM, the feed back system does not operate. While the feed

back system is at work, the ECM sends out the feed back signal, and in this condition, after warming up

engine to normal operating temperature, when the cancel switch or check switch, is turned ON, the “CHECK

ENGINE” light in the instrument cluster flashes. If the “CHECK ENGINE” light does not flash in such

conditions as described above, check the feed back system for function according to the following pro-

cedure.

NOTE:

Except for Canadian specification vehicle, also when mileage sensor is turned ON (the odometer indicates

50,000, 80,000 or 100,000 miles), the “CHECK ENGINE” light flashes. If the “CHECK ENGINE” light

does not flash in such condition, check the feed back system for function according to the following

procedure.

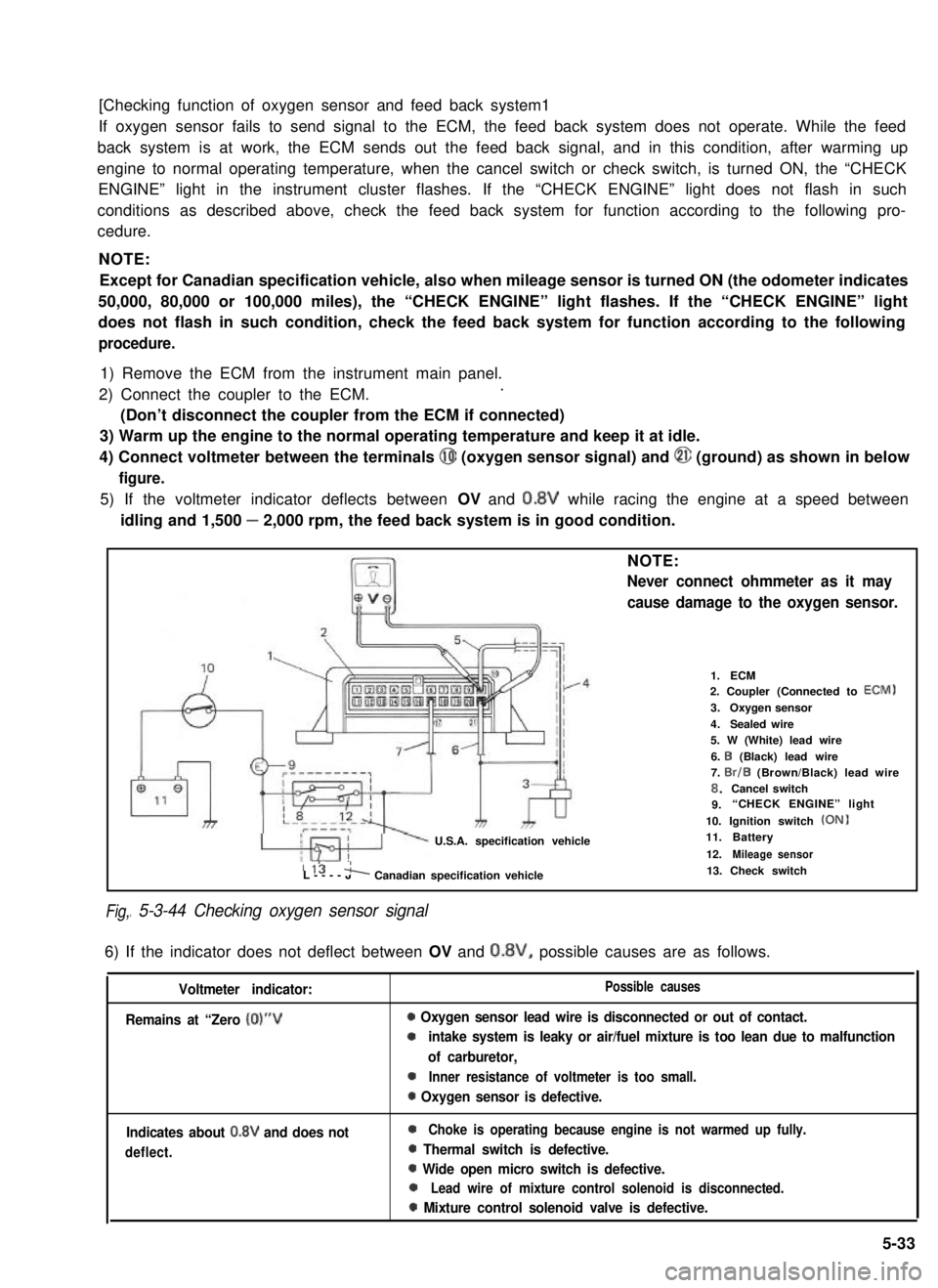

1) Remove the ECM from the instrument main panel.

2) Connect the coupler to the ECM..

(Don’t disconnect the coupler from the ECM if connected)

3) Warm up the engine to the normal operating temperature and keep it at idle.

4) Connect voltmeter between the terminals @I (oxygen sensor signal) and @ (ground) as shown in below

figure.

5) If the voltmeter indicator deflects between OV and 0.8V while racing the engine at a speed between

idling and 1,500 - 2,000 rpm, the feed back system is in good condition.

Fig,

NOTE:

Never connect ohmmeter as it may

cause damage to the oxygen sensor.

U.S.A. specification vehicle

1.ECM2. Coupler (Connected to ECM)

3.Oxygen sensor

4.Sealed wire5. W (White) lead wire

6. I3 (Black) lead wire7. Br/B (Brown/Black) lead wire8.Cancel switch9.“CHECK ENGINE” light

10. Ignition switch (ON)11.Battery

12.Mileage sensor115 'L----JA Canadian specification vehicle

I 5-3-44 Checking oxygen sensor signal

13. Check switch

6) If the indicator does not deflect between OV and 0.8V, possible causes are as follows.

Voltmeter indicator:

Remains at “Zero (0)“V

Possible causes

0 Oxygen sensor lead wire is disconnected or out of contact.

0intake system is leaky or air/fuel mixture is too lean due to malfunction

of carburetor,

0Inner resistance of voltmeter is too small.

0 Oxygen sensor is defective.

Indicates about 0.8V and does not

deflect.

0Choke is operating because engine is not warmed up fully.

0 Thermal switch is defective.

0 Wide open micro switch is defective.

0Lead wire of mixture control solenoid is disconnected.

0 Mixture control solenoid valve is defective.

5-33

Page 185 of 962

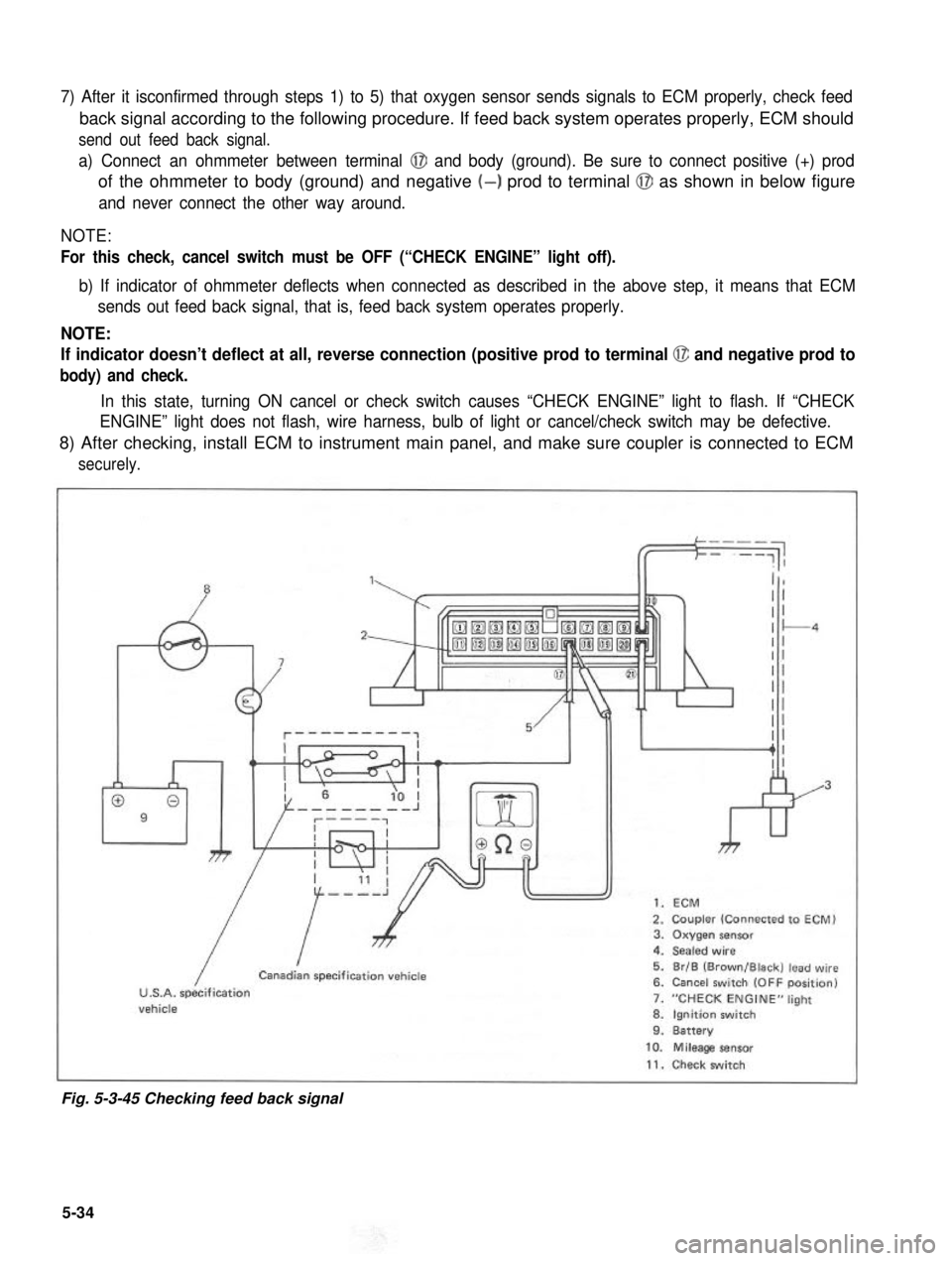

7) After it isconfirmed through steps 1) to 5) that oxygen sensor sends signals to ECM properly, check feed

back signal according to the following procedure. If feed back system operates properly, ECM should

send out feed back signal.

a) Connect an ohmmeter between terminal @I and body (ground). Be sure to connect positive (+) prod

of the ohmmeter to body (ground) and negative (-) prod to terminal @J as shown in below figure

and never connect the other way around.

NOTE:

For this check, cancel switch must be OFF (“CHECK ENGINE” light off).

b) If indicator of ohmmeter deflects when connected as described in the above step, it means that ECM

sends out feed back signal, that is, feed back system operates properly.

NOTE:

If indicator doesn’t deflect at all, reverse connection (positive prod to terminal @ and negative prod to

body) and check.

In this state, turning ON cancel or check switch causes “CHECK ENGINE” light to flash. If “CHECK

ENGINE” light does not flash, wire harness, bulb of light or cancel/check switch may be defective.

8) After checking, install ECM to instrument main panel, and make sure coupler is connected to ECM

securely.

”1,

009

7

kr

1. ECM

2. Coupler (Connected to ECM)3. Oxygen sensor4. Sealed wire

5. Br/B (Brown/Black) lead wire6. Cancel switch (OFF position)

7. “CHECK ENGINE” light

8. Ignition switch9. Battery

/

ICanadian specification vehicle

U.S.A. specificationvehicle

10. Mileage sensor

11. Check switch

Fig. 5-3-45 Checking feed back signal

5-34

Page 186 of 962

![SUZUKI GRAND VITARA 1987 Service Manual PDF [Checking idle-up signal]

The idle-up system operates when any of the small lights (such as tail light, side marker light and license

light), heater fan and rear defogger is put in operation. If the i SUZUKI GRAND VITARA 1987 Service Manual PDF [Checking idle-up signal]

The idle-up system operates when any of the small lights (such as tail light, side marker light and license

light), heater fan and rear defogger is put in operation. If the i](/img/20/57437/w960_57437-185.png)

[Checking idle-up signal]

The idle-up system operates when any of the small lights (such as tail light, side marker light and license

light), heater fan and rear defogger is put in operation. If the idle-up actuator fails to operate even when

any of such equipments is put in operation, check if signal is sent to the ECM according to the following

procedure.

1) Disconnect the coupler from the ECM.

2) Turn ON the ignition switch but don’t run the engine.

3) Connect a voltmeter between the @ terminal and the body (ground) as shown in below figure. If the

voltmeter indicates 11 - 14V when each equipment is operated individually, it means that idle-up

signal is sent to the ECM.

If the voltmeter does not indicate 11- 14V, the particular circuit is disconnected or in poor contact.

Check the circuit for such conditions.

4) After checking, connect the coupler to ECM securely.

1.Coupler

2. 3.Small Heater lights fan

4. Rear defogger (if equipped)5. Ignition switch (ON)6. Battery

7. Br/Y (Brown/Yellow)

4

&

lead wire

Fig. 5-3-46 Checking idle-up signal

5-35

Page 187 of 962

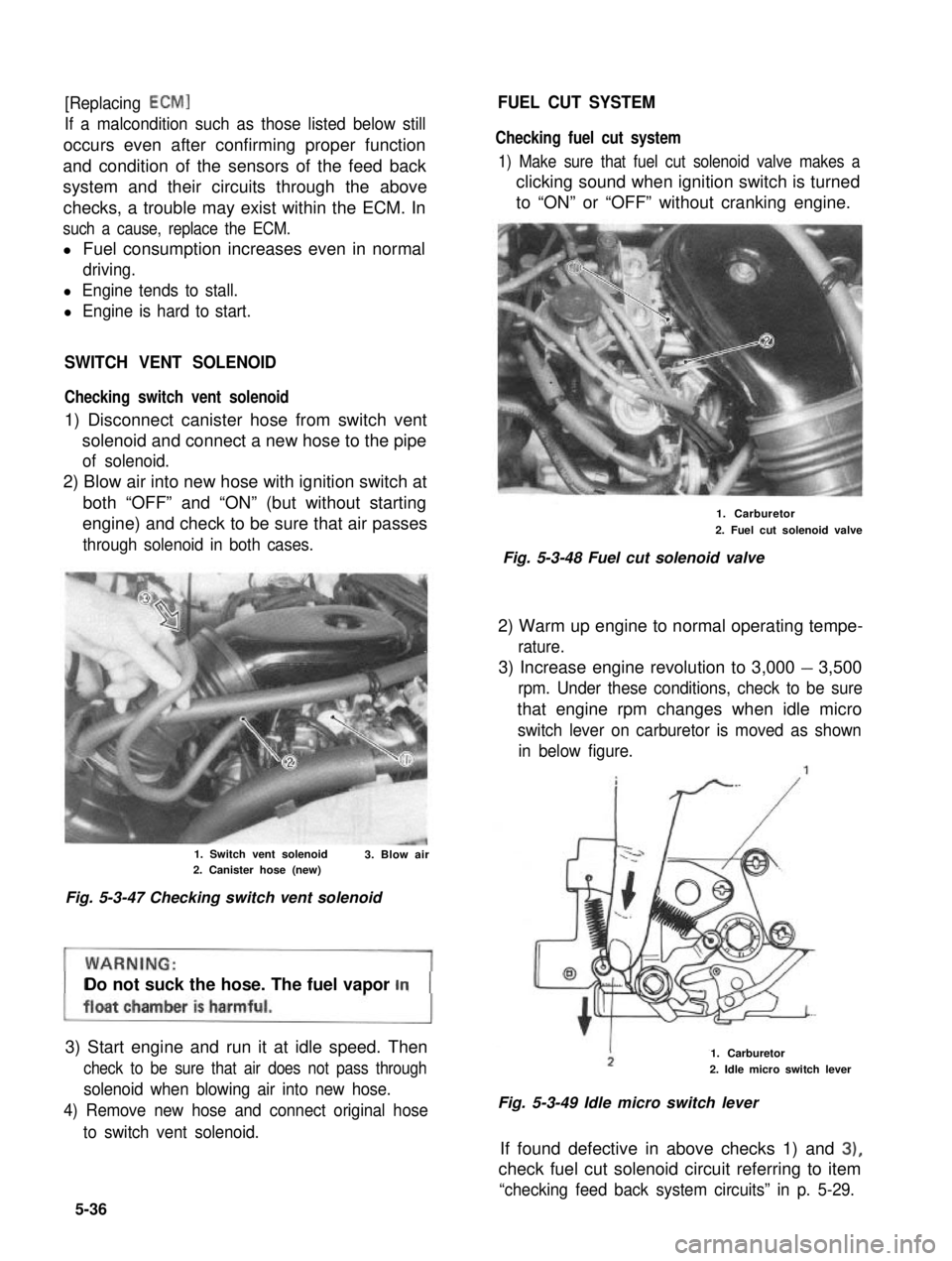

[Replacing ECMIFUEL CUT SYSTEM

If a malcondition such as those listed below still

occurs even after confirming proper function

and condition of the sensors of the feed back

system and their circuits through the above

checks, a trouble may exist within the ECM. In

such a cause, replace the ECM.

l Fuel consumption increases even in normal

Checking fuel cut system

1) Make sure that fuel cut solenoid valve makes a

clicking sound when ignition switch is turned

to “ON” or “OFF” without cranking engine.

driving.

l Engine tends to stall.

l Engine is hard to start.

SWITCH VENT SOLENOID

Checking switch vent solenoid

1) Disconnect canister hose from switch vent

solenoid and connect a new hose to the pipe

of solenoid.

2) Blow air into new hose with ignition switch at

both “OFF” and “ON” (but without starting

engine) and check to be sure that air passes

through solenoid in both cases.

1. Carburetor

2. Fuel cut solenoid valve

Fig. 5-3-48 Fuel cut solenoid valve

2) Warm up engine to normal operating tempe-

rature.

3) Increase engine revolution to 3,000 - 3,500

rpm. Under these conditions, check to be sure

that engine rpm changes when idle micro

switch lever on carburetor is moved as shown

in below figure.

1. Switch vent solenoid2. Canister hose (new)3. Blow air

Fig. 5-3-47 Checking switch vent solenoid

Do not suck the hose. The fuel vapor m

3) Start engine and run it at idle speed. Then

check to be sure that air does not pass through

solenoid when blowing air into new hose.

4) Remove new hose and connect original hose

to switch vent solenoid.

1. Carburetor

2. Idle micro switch lever

Fig. 5-3-49 Idle micro switch lever

If found defective in above checks 1) and 3),

check fuel cut solenoid circuit referring to item

“checking feed back system circuits” in p. 5-29.

5-36

Page 188 of 962

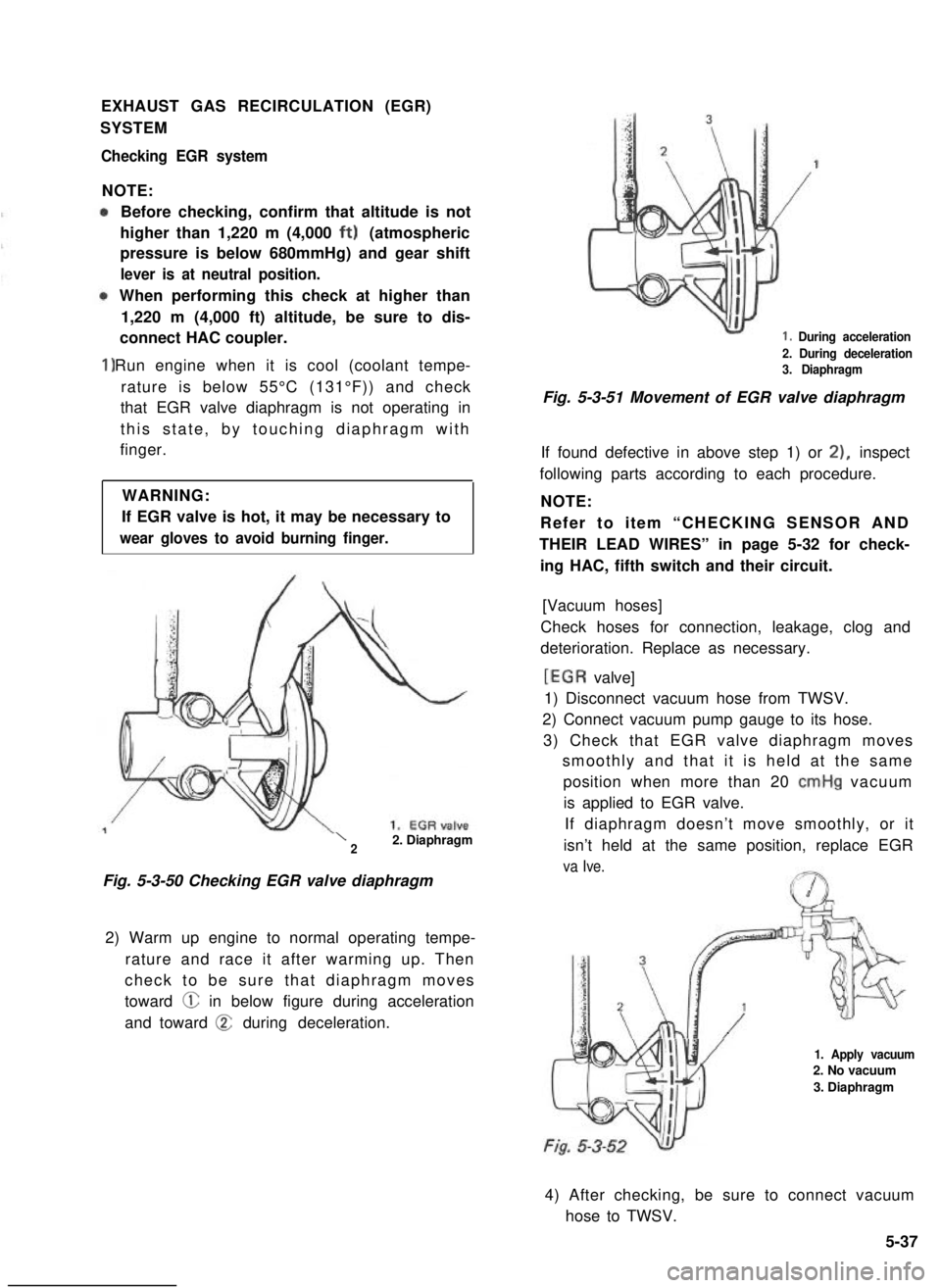

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM

Checking EGR system

NOTE:

1)

Before checking, confirm that altitude is not

higher than 1,220 m (4,000 ft) (atmospheric

pressure is below 680mmHg) and gear shift

lever is at neutral position.

When performing this check at higher than

1,220 m (4,000 ft) altitude, be sure to dis-

connect HAC coupler.

Run engine when it is cool (coolant tempe-

rature is below 55°C (131°F)) and check

that EGR valve diaphragm is not operating in

this state, by touching diaphragm with

finger.

WARNING:

If EGR valve is hot, it may be necessary to

wear gloves to avoid burning finger.

\22. Diaphragm

Fig. 5-3-50 Checking EGR valve diaphragm

2) Warm up engine to normal operating tempe-

rature and race it after warming up. Then

check to be sure that diaphragm moves

toward @ in below figure during acceleration

and toward @ during deceleration.

1. During acceleration

2. During deceleration3. Diaphragm

Fig. 5-3-51 Movement of EGR valve diaphragm

If found defective in above step 1) or 21, inspect

following parts according to each procedure.

NOTE:

Refer to item “CHECKING SENSOR AND

THEIR LEAD WIRES” in page 5-32 for check-

ing HAC, fifth switch and their circuit.

[Vacuum hoses]

Check hoses for connection, leakage, clog and

deterioration. Replace as necessary.

[EGR valve]

1) Disconnect vacuum hose from TWSV.

2) Connect vacuum pump gauge to its hose.

3) Check that EGR valve diaphragm moves

smoothly and that it is held at the same

position when more than 20 cmHg vacuum

is applied to EGR valve.

If diaphragm doesn’t move smoothly, or it

isn’t held at the same position, replace EGR

va Ive.

1. Apply vacuum2. No vacuum

3. Diaphragm

4) After checking, be sure to connect vacuum

hose to TWSV.

5-37

Page 189 of 962

![SUZUKI GRAND VITARA 1987 Service Manual PDF [Bi-metal vacuum switching valve (BVSV)]

NOTE:

For the rough check of the operation, BVSV

can be checked by warming up or cooling down

the engine without being removed from the

intake manifold.

The ch SUZUKI GRAND VITARA 1987 Service Manual PDF [Bi-metal vacuum switching valve (BVSV)]

NOTE:

For the rough check of the operation, BVSV

can be checked by warming up or cooling down

the engine without being removed from the

intake manifold.

The ch](/img/20/57437/w960_57437-188.png)

[Bi-metal vacuum switching valve (BVSV)]

NOTE:

For the rough check of the operation, BVSV

can be checked by warming up or cooling down

the engine without being removed from the

intake manifold.

The check procedure is the same as the follow-

ing except item 11, 2) and 5).

1) Drain cooling system when engine is cold.

2) Disconnect vacuum hoses and remove BVSV

from intake manifold.

3) While keeping BVSV cool (below 53°C

(127” F)), blow nozzle “3”. Air should not

come out of nozzle “4”.

1

2

I

JlrII

Fig. 5-3-53 Checking B VSV 11)

4)‘While keeping BVSV warm

1. BVSV

2. Cool water3. Blow air(nozzle)4. “No air”(nozzle)

5. Thermometer

(above 65” C

(149°F)) in hot water, blow nozzle “3”.

Air should come out of nozzle “4”.

6

Fig. 5-3-54 Checking B VSV (2)

[ EG R modu latorl

1) Check filter for contamination and damage.

Using compressed air, clean filter.

1. EGR modulator

2. Filter

Fig. 5-3-55 Filter of EGR modulator

2) Remove EGR modulator and plug nozzle

with your finger. Blow air into another nozzle

and check that air passes through to air

filter side freely.

1. EGR modulator2. Blow air3. Air filter

Fig. 5-3-56 Checking EGR modulator (1)

1.BVSV

2.Hot water3.Blow air(nozzle)4.Air (nozzle)

5.Thermometer6.Heater

5) Reinstall BVSV to intake manifold. Before

installing, wind sealing tape on its thread.

6) Connect vacuum hoses.

5-38

Page 193 of 962

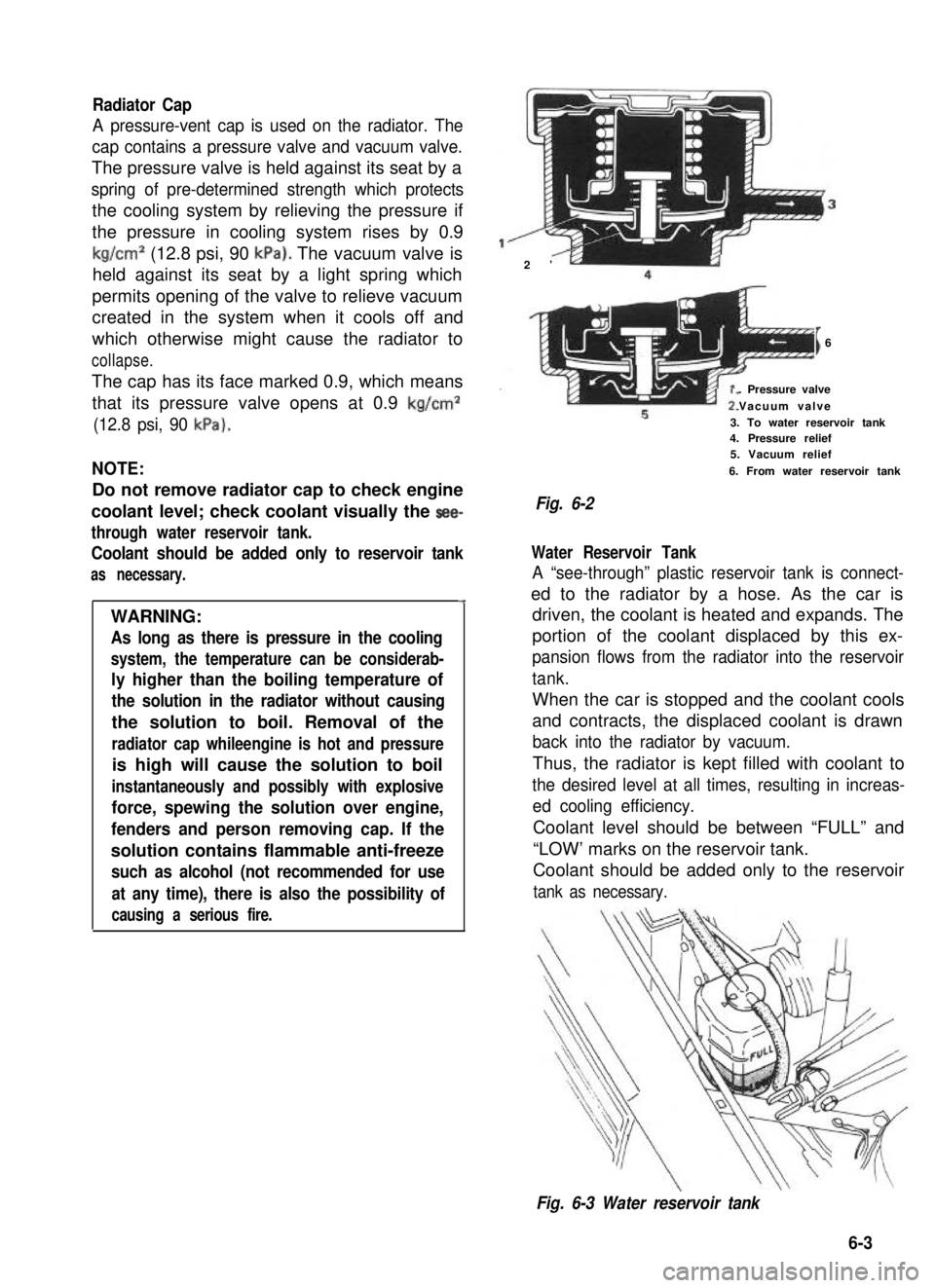

Radiator Cap

A pressure-vent cap is used on the radiator. The

cap contains a pressure valve and vacuum valve.

The pressure valve is held against its seat by a

spring of pre-determined strength which protects

the cooling system by relieving the pressure if

the pressure in cooling system rises by 0.9

kg/cm2 (12.8 psi, 90 kPa). The vacuum valve is

held against its seat by a light spring which

permits opening of the valve to relieve vacuum

created in the system when it cools off and

which otherwise might cause the radiator to

collapse.

The cap has its face marked 0.9, which means

that its pressure valve opens at 0.9 kg/cm2

(12.8 psi, 90 kPa).

NOTE:

Do not remove radiator cap to check engine

coolant level; check coolant visually the see-

through water reservoir tank.

Coolant should be added only to reservoir tank

as necessary.

4

WARNING:

As long as there is pressure in the cooling

system, the temperature can be considerab-

ly higher than the boiling temperature of

the solution in the radiator without causing

the solution to boil. Removal of the

radiator cap whileengine is hot and pressure

is high will cause the solution to boil

instantaneously and possibly with explosive

force, spewing the solution over engine,

fenders and person removing cap. If the

solution contains flammable anti-freeze

such as alcohol (not recommended for use

at any time), there is also the possibility of

causing a serious fire.

2’

I6

. Pressure valve

Vacuum valve

3. To water reservoir tank4. Pressure relief5. Vacuum relief

6. From water reservoir tank

Fig. 6-2

Water Reservoir Tank

A “see-through” plastic reservoir tank is connect-

ed to the radiator by a hose. As the car is

driven, the coolant is heated and expands. The

portion of the coolant displaced by this ex-

pansion flows from the radiator into the reservoir

tank.

When the car is stopped and the coolant cools

and contracts, the displaced coolant is drawn

back into the radiator by vacuum.

Thus, the radiator is kept filled with coolant to

the desired level at all times, resulting in increas-

ed cooling efficiency.

Coolant level should be between “FULL” and

“LOW’ marks on the reservoir tank.

Coolant should be added only to the reservoir

tank as necessary.

Fig. 6-3 Water reservoir tank

6-3

Page 197 of 962

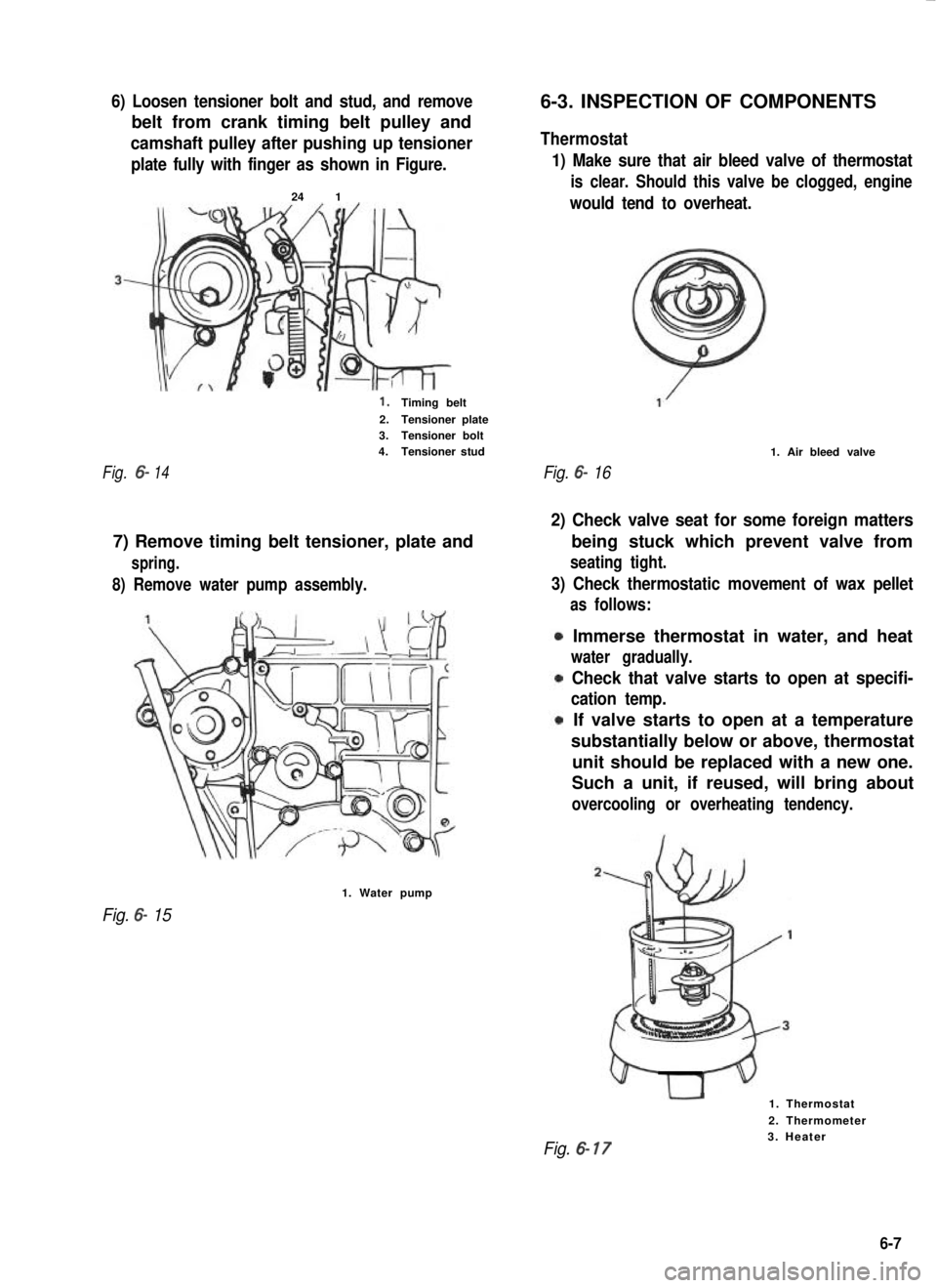

6) Loosen tensioner bolt and stud, and remove

belt from crank timing belt pulley and

camshaft pulley after pushing up tensioner

plate fully with finger as shown in Figure.

24 1

1.Timing belt

2.Tensioner plate3.Tensioner bolt4.Tensioner stud

Fig.6-14

8) Remove water pump assembly.

7) Remove timing belt tensioner, plate and

spring.

1. Water pump

Fig. 6- 15

6-3. INSPECTION OF COMPONENTS

Thermostat

1) Make sure that air bleed valve of thermostat

is clear. Should this valve be clogged, engine

would tend to overheat.

Fig. 6- 16

1. Air bleed valve

2) Check valve seat for some foreign matters

3) Check thermostatic movement of wax pellet

being stuck which prevent valve from

seating tight.

as follows:

Immerse thermostat in water, and heat

water gradually.

Check that valve starts to open at specifi-

cation temp.

If valve starts to open at a temperature

substantially below or above, thermostat

unit should be replaced with a new one.

Such a unit, if reused, will bring about

overcooling or overheating tendency.

1. Thermostat

2. Thermometer

Fig. 6- 173. Heater

6-7

Page 200 of 962

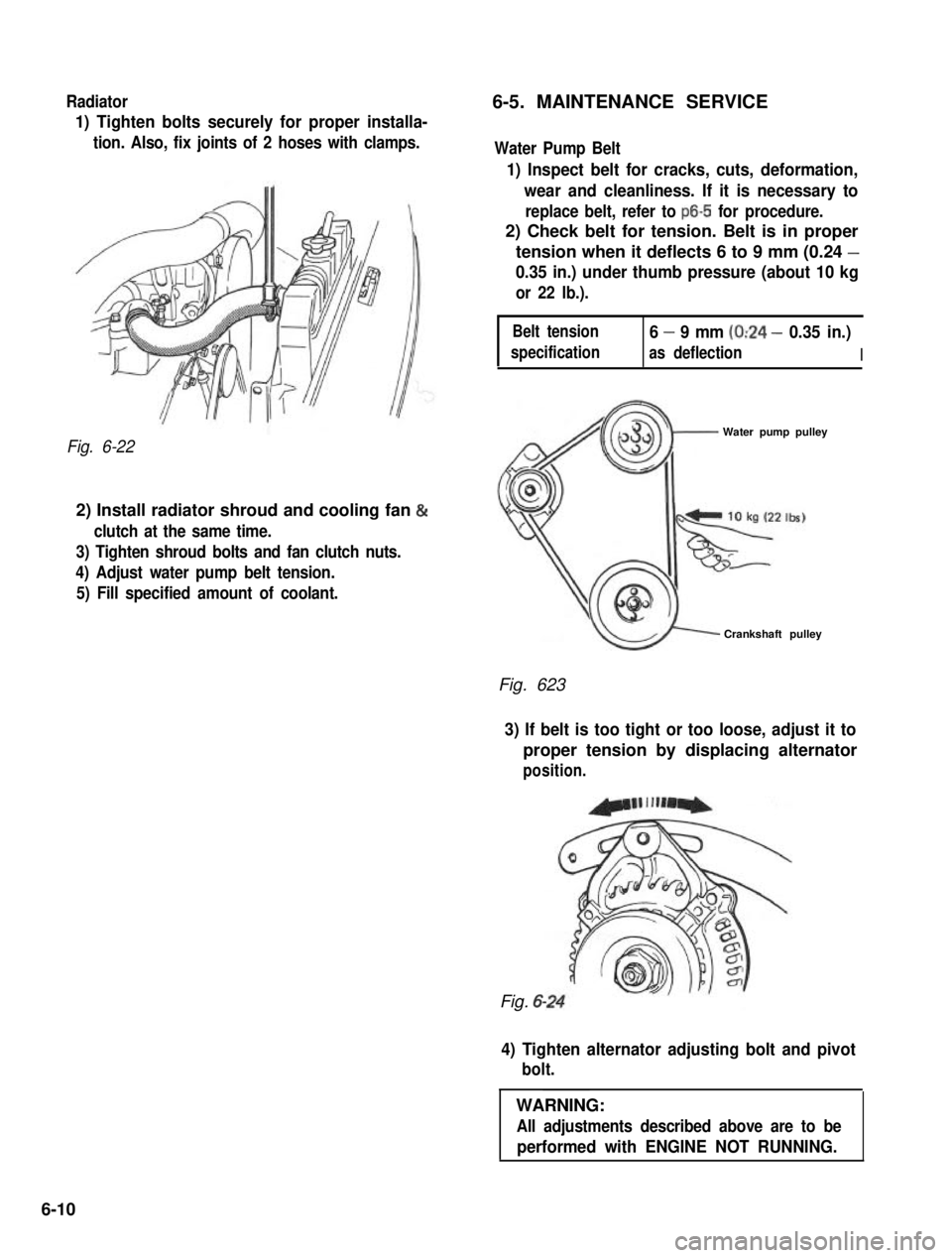

Radiator6-5. MAINTENANCE SERVICE

1) Tighten bolts securely for proper installa-

tion. Also, fix joints of 2 hoses with clamps.

Fig. 6-22

2) Install radiator shroud and cooling fan &

clutch at the same time.

3) Tighten shroud bolts and fan clutch nuts.

4) Adjust water pump belt tension.

5) Fill specified amount of coolant.

Water Pump Belt

1) Inspect belt for cracks, cuts, deformation,

wear and cleanliness. If it is necessary to

replace belt, refer to ~6-5 for procedure.

2) Check belt for tension. Belt is in proper

tension when it deflects 6 to 9 mm (0.24 -

0.35 in.) under thumb pressure (about 10 kg

or 22 lb.).

Belt tension

specification

6 - 9 mm (0:24 - 0.35 in.)

as deflectionI

Water pump pulley

Crankshaft pulley

Fig. 623

3) If belt is too tight or too loose, adjust it to

proper tension by displacing alternator

position.

Fig. 6-

4) Tighten alternator adjusting bolt and pivot

bolt.

WARNING:

All adjustments described above are to be

performed with ENGINE NOT RUNNING.

6-10

Page 201 of 962

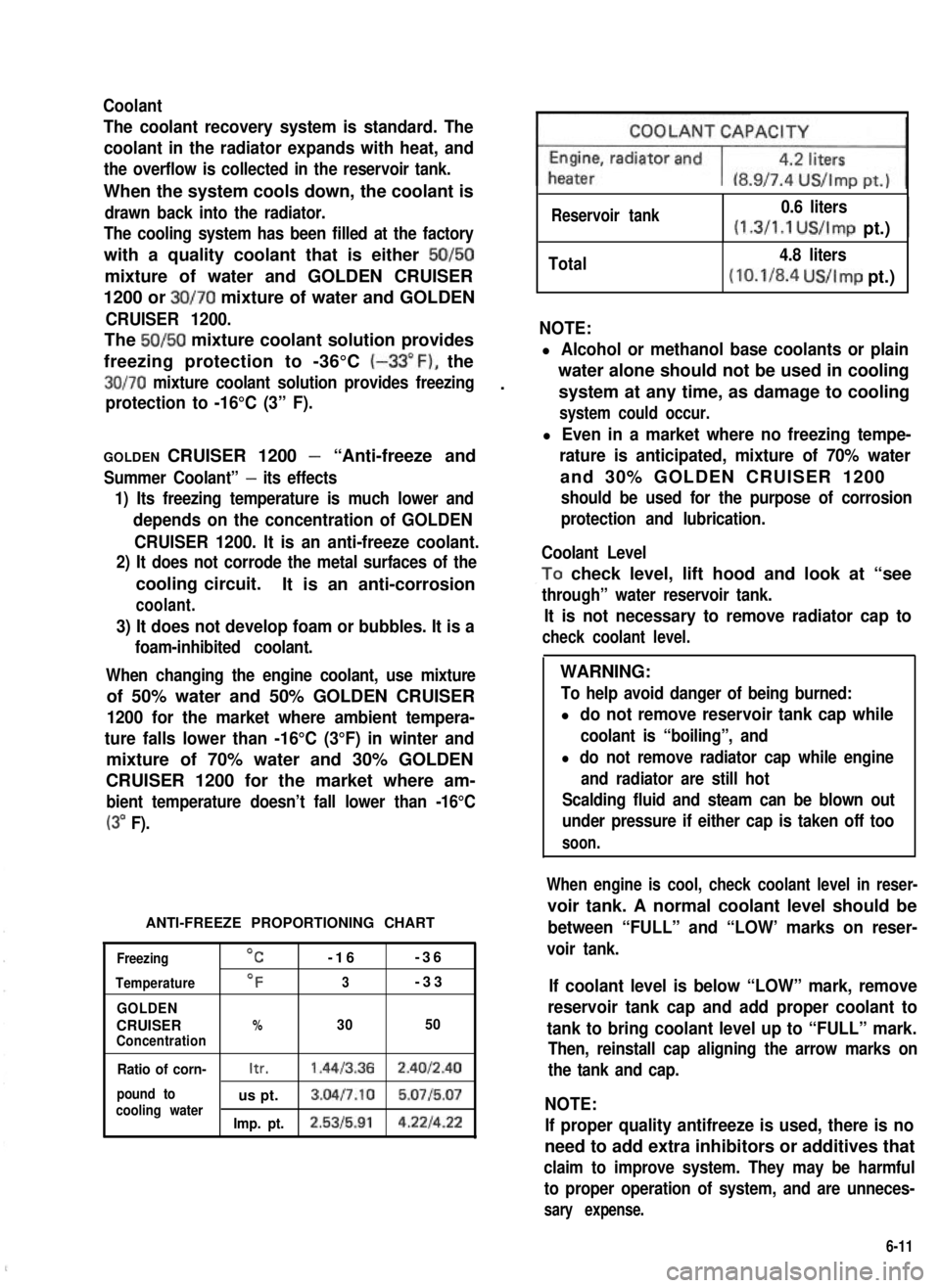

Coolant

The coolant recovery system is standard. The

coolant in the radiator expands with heat, and

the overflow is collected in the reservoir tank.

When the system cools down, the coolant is

drawn back into the radiator.

The cooling system has been filled at the factory

with a quality coolant that is either 50/50

mixture of water and GOLDEN CRUISER

1200 or 30/70 mixture of water and GOLDEN

CRUISER 1200.

The 50/50 mixture coolant solution provides

freezing protection to -36°C (-33”F), the

30/70 mixture coolant solution provides freezing.

protection to -16°C (3” F).

GOLDEN CRUISER 1200 - “Anti-freeze and

Summer Coolant” - its effects

1) Its freezing temperature is much lower and

depends on the concentration of GOLDEN

CRUISER 1200. It is an anti-freeze coolant.

2) It does not corrode the metal surfaces of the

cooling circuit.It is an anti-corrosion

coolant.

3) It does not develop foam or bubbles. It is a

foam-inhibited coolant.

When changing the engine coolant, use mixture

of 50% water and 50% GOLDEN CRUISER

1200 for the market where ambient tempera-

ture falls lower than -16°C (3°F) in winter and

mixture of 70% water and 30% GOLDEN

CRUISER 1200 for the market where am-

bient temperature doesn’t fall lower than -16°C

(3” F).

ANTI-FREEZE PROPORTIONING CHART

Freezing

Temperature

GOLDEN

CRUISERConcentration

OC-16-36

OF3-33

%3050

Ratio of corn-Itr.1.4413.362.4012.40

pound tous pt.3.04l7.10 5.0715.07cooling waterImp. pt.2.5315.914.221422

Reservoir tank0.6 liters

(1.3/1.1 US/Imp pt.)I

Total4.8 liters

(10.1/8.4 US/Imp pt.)

NOTE:

l Alcohol or methanol base coolants or plain

water alone should not be used in cooling

system at any time, as damage to cooling

system could occur.

l Even in a market where no freezing tempe-

rature is anticipated, mixture of 70% water

and 30% GOLDEN CRUISER 1200

should be used for the purpose of corrosion

protection and lubrication.

Coolant Level

,To check level, lift hood and look at “see

through” water reservoir tank.

It is not necessary to remove radiator cap to

check coolant level.

WARNING:

To help avoid danger of being burned:

l do not remove reservoir tank cap while

coolant is “boiling”, and

l do not remove radiator cap while engine

and radiator are still hot

Scalding fluid and steam can be blown out

under pressure if either cap is taken off too

soon.

When engine is cool, check coolant level in reser-

voir tank. A normal coolant level should be

between “FULL” and “LOW’ marks on reser-

voir tank.

If coolant level is below “LOW” mark, remove

reservoir tank cap and add proper coolant to

tank to bring coolant level up to “FULL” mark.

Then, reinstall cap aligning the arrow marks on

the tank and cap.

NOTE:

If proper quality antifreeze is used, there is no

need to add extra inhibitors or additives that

claim to improve system. They may be harmful

to proper operation of system, and are unneces-

sary expense.

6-11