SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 431 of 962

BLEEDING BRAKES

NOTE:

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted surface,

immediately wipe fluid from paint and clean

painted surface.

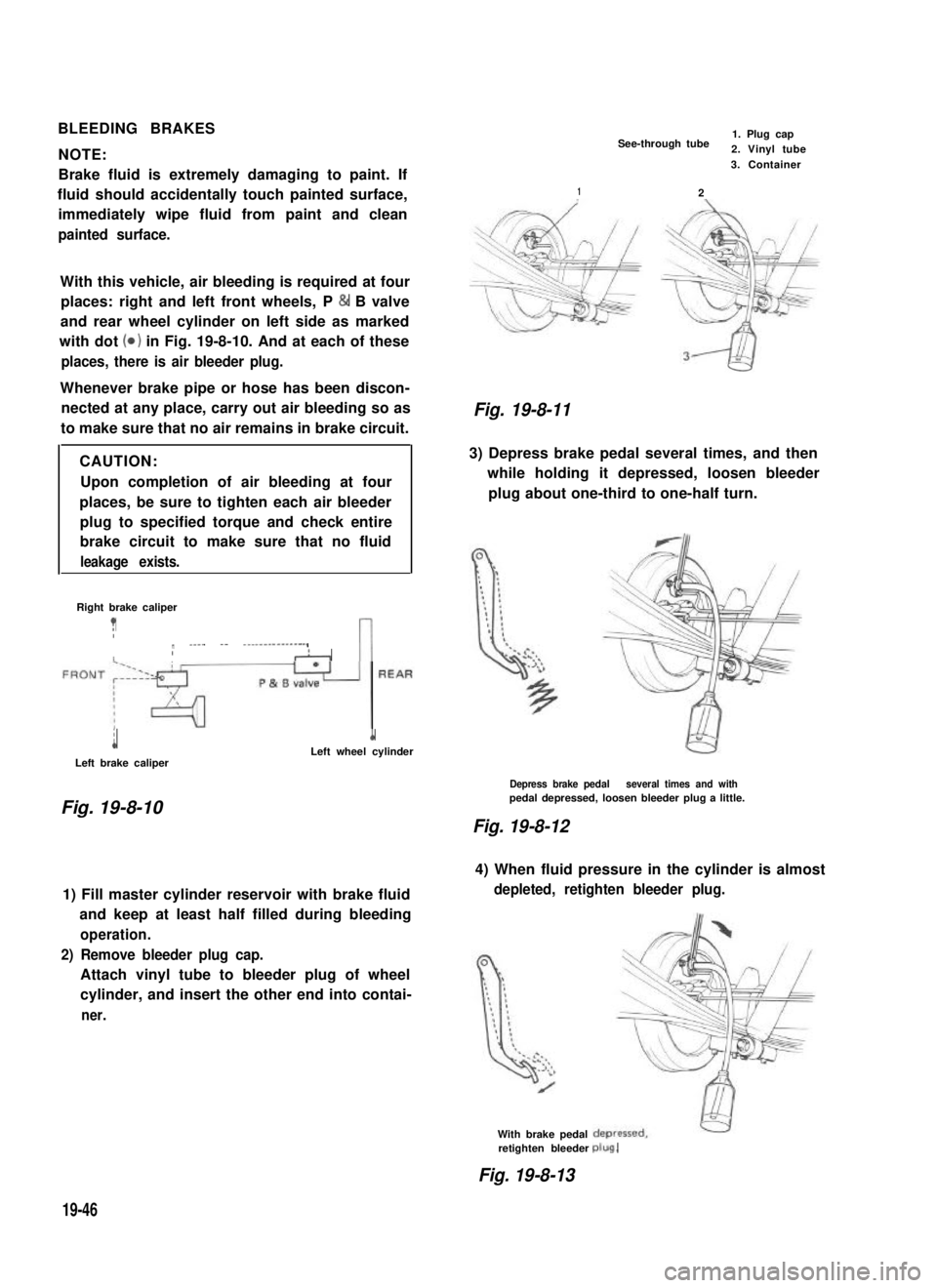

With this vehicle, air bleeding is required at four

places: right and left front wheels, P & B valve

and rear wheel cylinder on left side as marked

with dot (0) in Fig. 19-8-10. And at each of these

places, there is air bleeder plug.

Whenever brake pipe or hose has been discon-

nected at any place, carry out air bleeding so as

to make sure that no air remains in brake circuit.

CAUTION:

Upon completion of air bleeding at four

places, be sure to tighten each air bleeder

plug to specified torque and check entire

brake circuit to make sure that no fluid

leakage exists.

Right brake caliper

?Ir ____ -- ---------------,IIAn

i

Left brake caliper

1Left wheel cylinder

Fig. 19-8-10

1) Fill master cylinder reservoir with brake fluid

and keep at least half filled during bleeding

operation.

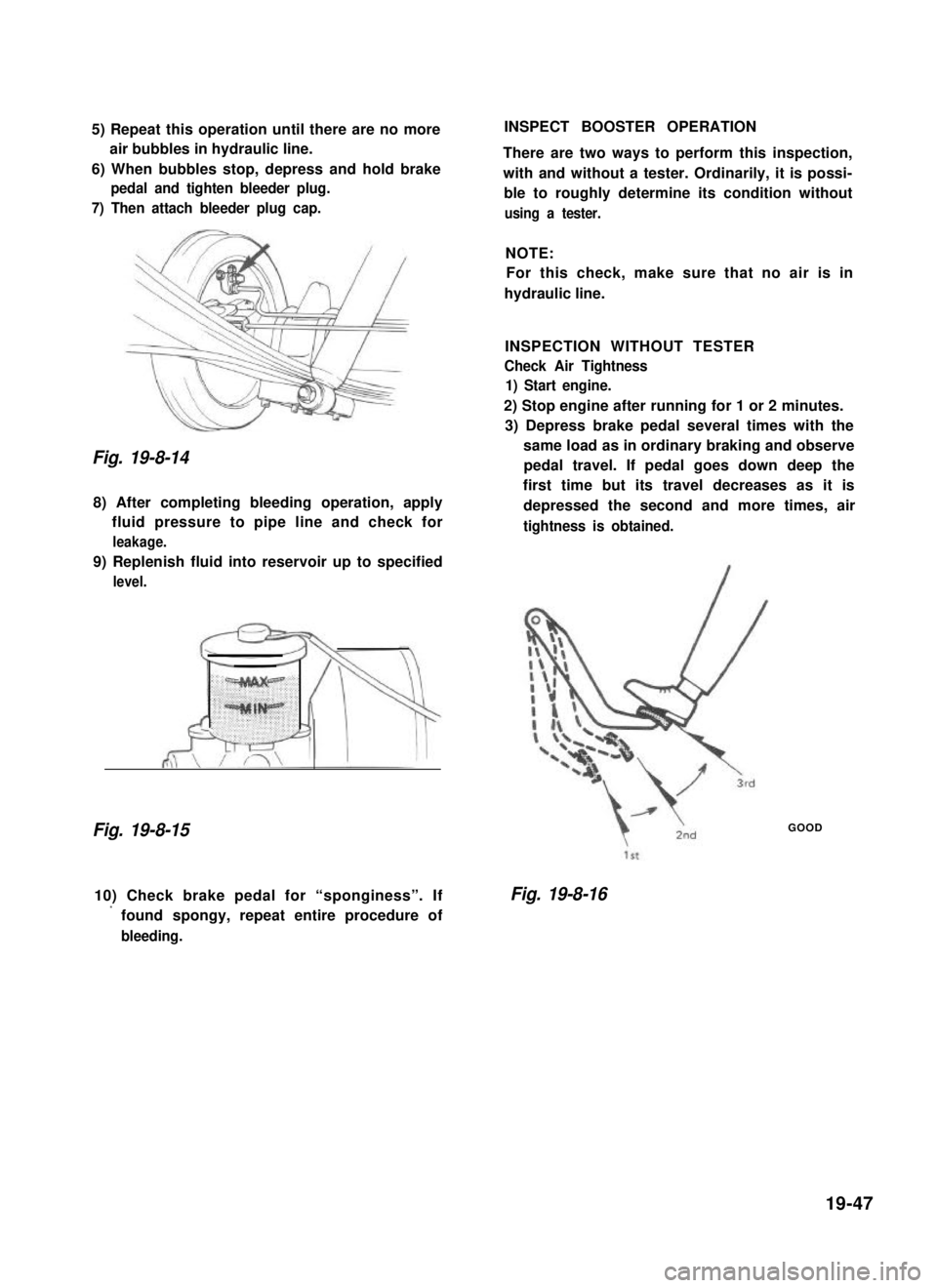

2) Remove bleeder plug cap.

Attach vinyl tube to bleeder plug of wheel

cylinder, and insert the other end into contai-

ner.

See-through tube1. Plug cap2. Vinyl tube

2

3. Container

1

Fig. 19-8-11

3) Depress brake pedal several times, and then

while holding it depressed, loosen bleeder

plug about one-third to one-half turn.

Depress brake pedal several times and withpedal depressed, loosen bleeder plug a little.

Fig. 19-8-12

4) When fluid pressure in the cylinder is almost

depleted, retighten bleeder plug.

With brake pedalretighten bleederplug.

Fig. 19-8-13

19-46

Page 432 of 962

5) Repeat this operation until there are no more

air bubbles in hydraulic line.

6) When bubbles stop, depress and hold brake

pedal and tighten bleeder plug.

7) Then attach bleeder plug cap.

Fig. 19-8-14

8) After completing bleeding operation, apply

fluid pressure to pipe line and check for

leakage.

9) Replenish fluid into reservoir up to specified

level.

Fig. 19-8-15

INSPECT BOOSTER OPERATION

There are two ways to perform this inspection,

with and without a tester. Ordinarily, it is possi-

ble to roughly determine its condition without

using a tester.

NOTE:

For this check, make sure that no air is in

hydraulic line.

INSPECTION WITHOUT TESTER

Check Air Tightness

1) Start engine.

2) Stop engine after running for 1 or 2 minutes.

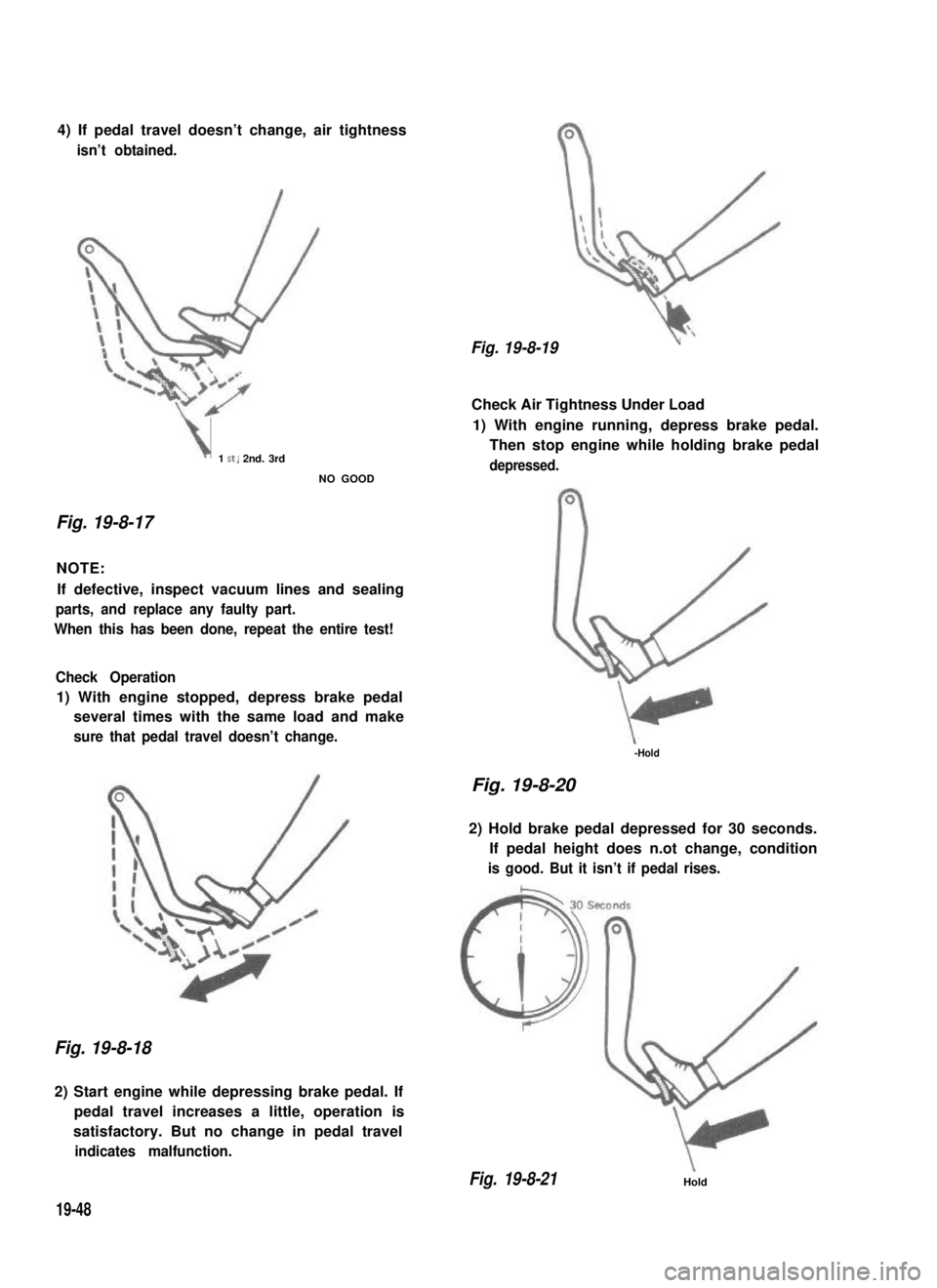

3) Depress brake pedal several times with the

same load as in ordinary braking and observe

pedal travel. If pedal goes down deep the

first time but its travel decreases as it is

depressed the second and more times, air

tightness is obtained.

GOOD

10) Check brake pedal for “sponginess”. If

’ found spongy, repeat entire procedure of

bleeding.

Fig. 19-8-16

19-47

Page 433 of 962

4) If pedal travel doesn’t change, air tightness

isn’t obtained.

\1 St, 2nd. 3rd

NO GOOD

Fig. 19-8-17

NOTE:

If defective, inspect vacuum lines and sealing

parts, and replace any faulty part.

When this has been done, repeat the entire test!

Check Operation

1) With engine stopped, depress brake pedal

several times with the same load and make

sure that pedal travel doesn’t change.

Fig. 19-8-19 \

Check Air Tightness Under Load

1) With engine running, depress brake pedal.

Then stop engine while holding brake pedal

depressed.

-Hold

Fig. 19-8-20

2) Hold brake pedal depressed for 30 seconds.

If pedal height does n.ot change, condition

is good. But it isn’t if pedal rises.

Fig. 19-8-18

2) Start engine while depressing brake pedal. If

pedal travel increases a little, operation is

satisfactory. But no change in pedal travel

indicates malfunction.

Fig. 19-8-21Hold

19-48

Page 434 of 962

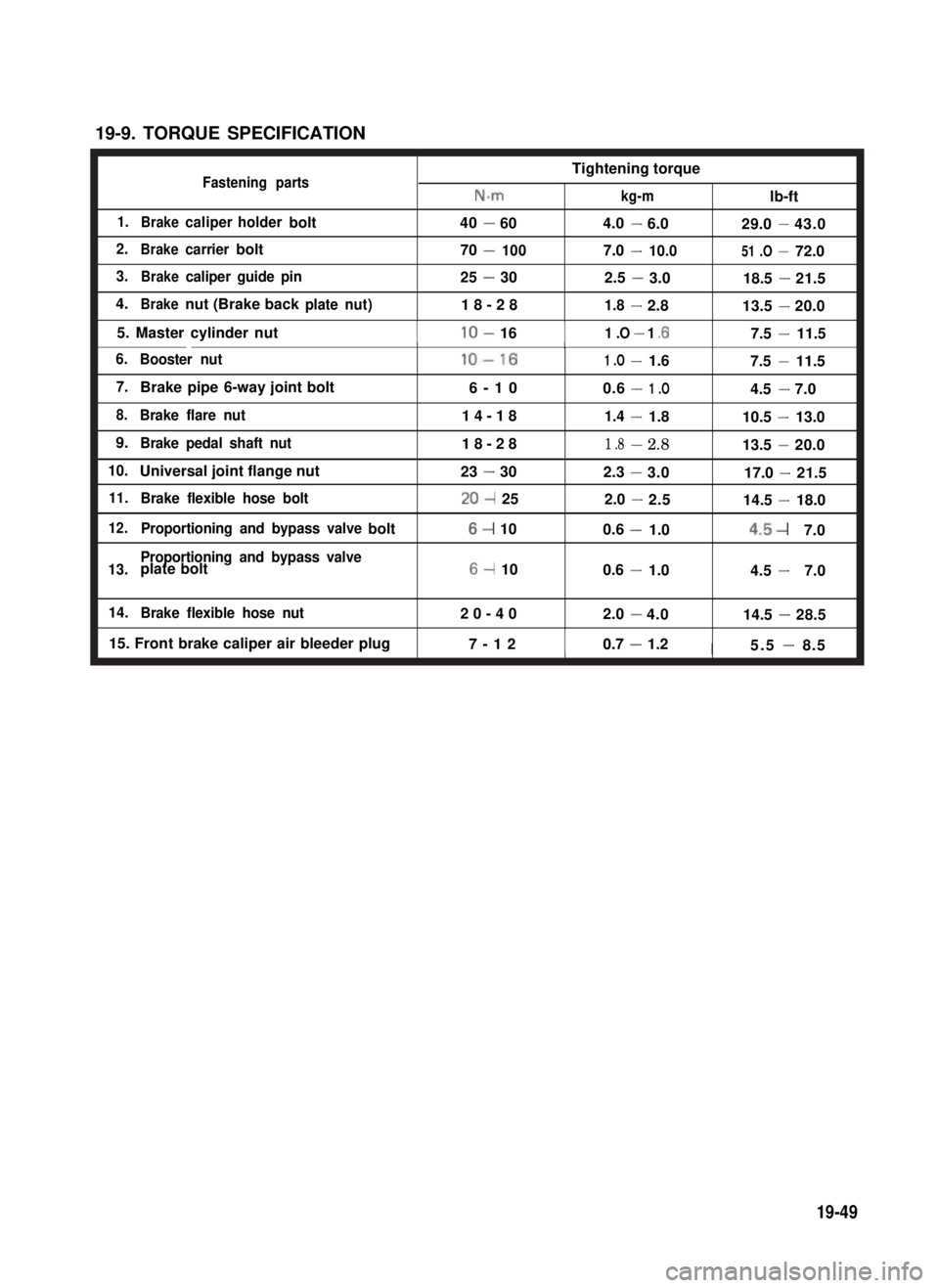

19-9. TORQUE SPECIFICATION

Tightening torqueFastening partsN.mkg-mlb-ft

1.Brakecaliperholderbolt40-604.0-6.029.0-43.0

2.Brakecarrierbolt70-1007.0-10.051 .O-72.0

3.Brakecaliper guide pin25 - 302.53.018.5--21.5

4.Brakenut (Brake backplatenut)18-281.8-2.813.5-20.0

5. Master cylinder nutIlo- 16I1 .O - 1 .6I7.5 - 11.5I

6.Booster nutlo-161 .O-1.67.5 -11.5

7.Brake pipe 6-way joint bolt6-100.6-1 .O4.5 -7.0

8.Brake flare nut14-181.4-1.810.5 -13.0

9.Brake pedal shaft nut18-281 .8-2.813.5 -20.0

10.Universal joint flange nut23 - 302.3-3.017.0 -21.5

11.Brake flexible hose bolt20- 252.0-2.514.5 -18.0

12.Proportioning and bypass valvebolt6- 100.6-1.04.5-7.0

13.Proportioning and bypass valveplate bolt6- 100.6-1.04.5-7.0

14.Brake flexible hose nut20-402.0-4.014.5 -28.5

15. Front brake caliper air bleeder plug7-12I0.7 - 1.2I5.5 - 8.5I

19-49

Page 435 of 962

SECTION 20

BODY SERVICE

CONTENTS

20-1. FRONT DOOR...........................................20-2

DESCRIPTION.........................................20-2

REMOVAL............................................2@3

INSTALLATION........................................20-5

WINDSHIELD............................................20- 8

CLEANlNG............................................20- 8

INSTALLATION........................................20-9

20-3. BACK DOOR (APPLICABLE TO HARD TOP VEHICLE).........20-11

CHASSIS DIMENSIONS...................................20-13

20-2.WINDSHIELD

20-4.

20-2

20-2

20-3

20-5

20-8

20-8

20-9

20-11

20-13

20-1

Page 436 of 962

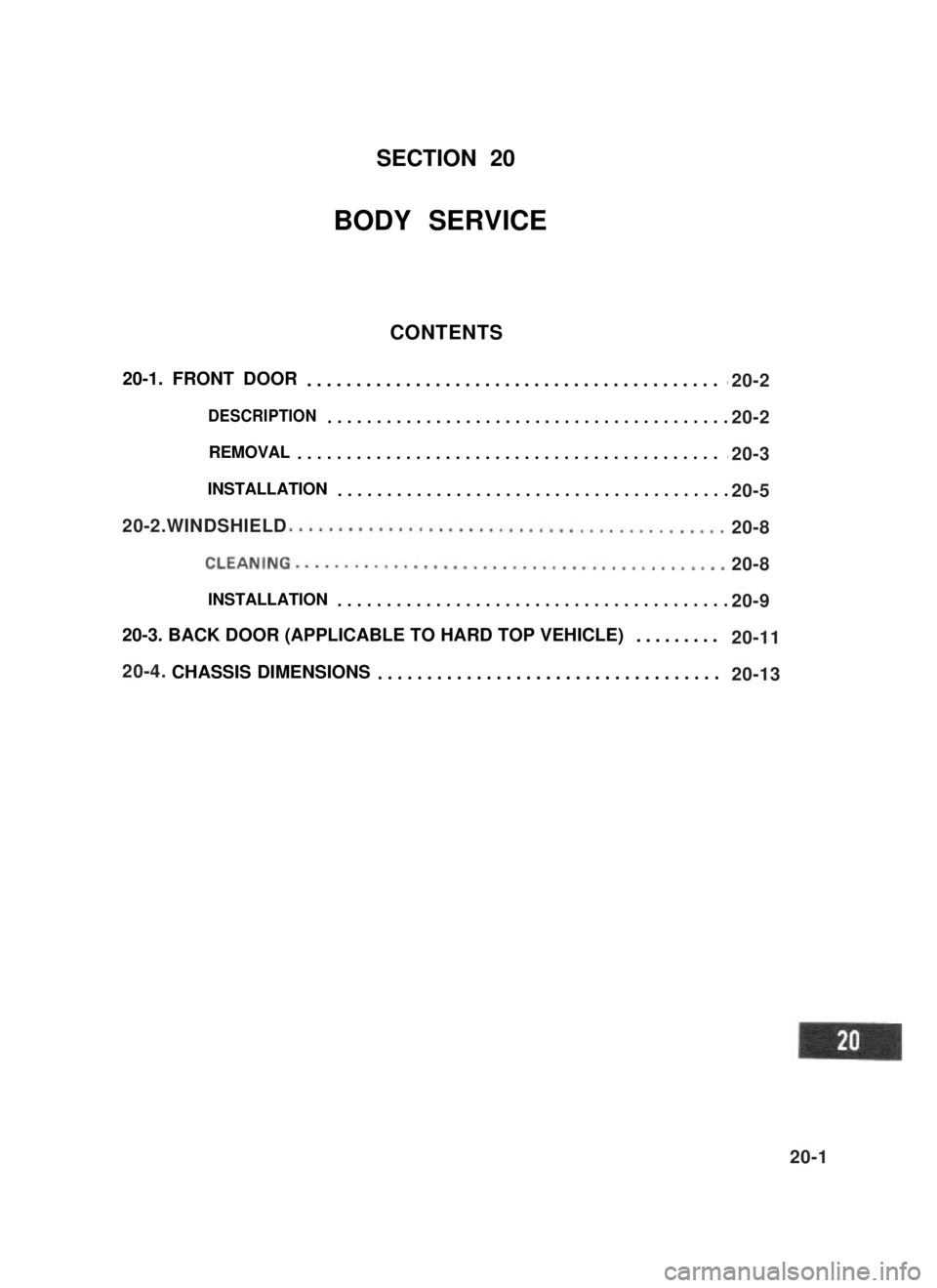

20-1. FRONT DOOR

DESCRIPTION

1. Door open stopper band garnish

2. Door open stopper band

3.Trim protector

4. Front door panel5. Door trim clip6. Door lower hinge

7. Door upper hinge

8.Door weatherstrip9. Door trim board

10.Door glass11. Glass bottom channel

12.Regulator

13. Regulator roller holder

14.Inside handle

15. Door key cylinder

16.Outside handle

17. Door lock ass’y

18. Door lock striker

19.Striker spacer20.Regulator handle 21. Inside handle case

22. Inside pull handle23. Water proof film

Fig. 20-1-1

20-2

Page 437 of 962

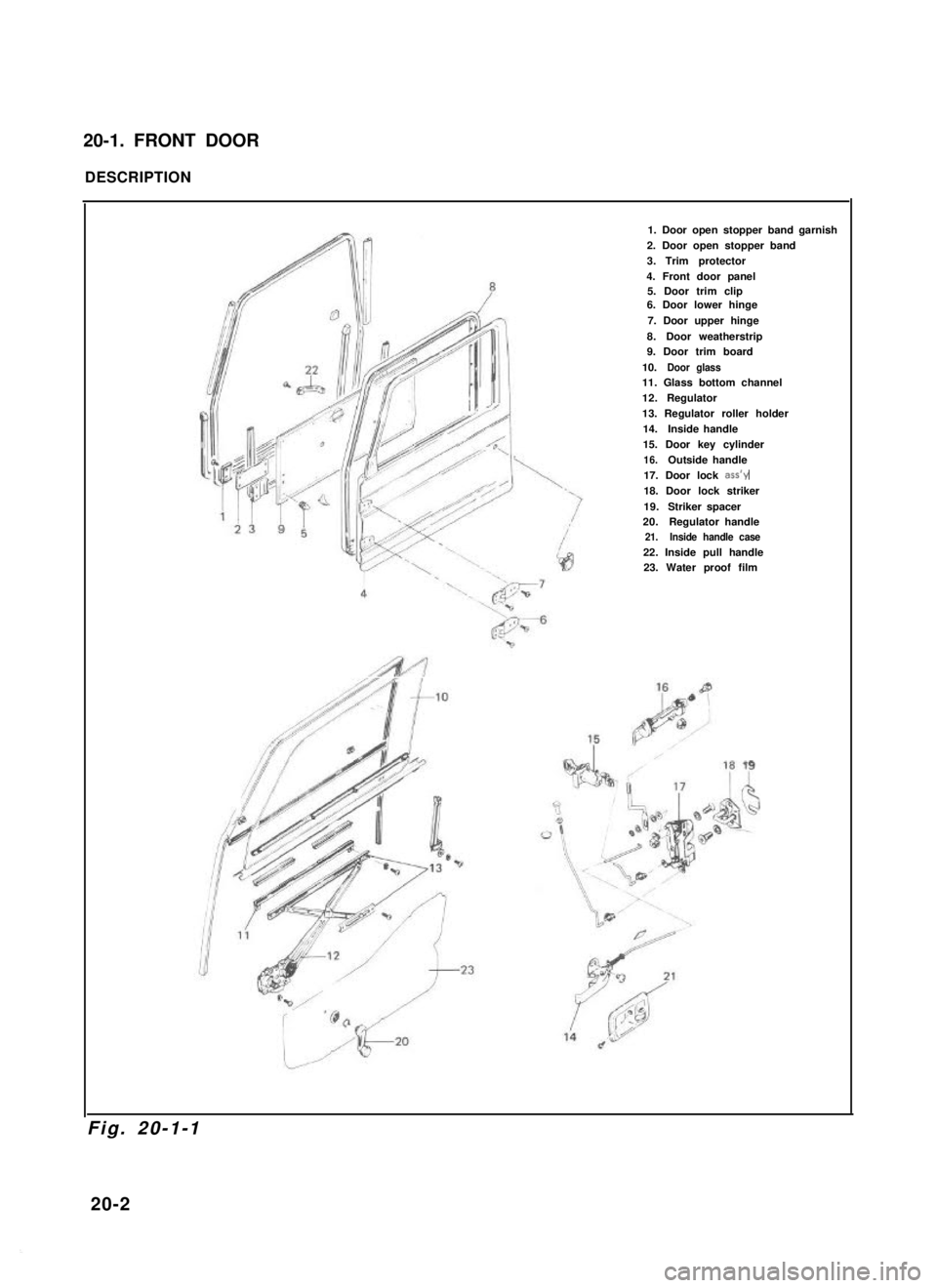

REMOVAL

Door Window Glass

1) Remove door window regulator handle.

Fig. 20-1-2

2) Remove inside handle case.

Fig. 20-1-3

3) Remove inside pull handle.

4) Loosen two screws securing the stopper

band, and take off the band.

5) Remove door trim board.

Fig. 20-1-5

6) Remove the door water proof film.

Fig. 20-1-6

7) Remove the glass inside and outside scrape.

Fig. 20-1-4 Fig. 20-1-7

20-3

Page 438 of 962

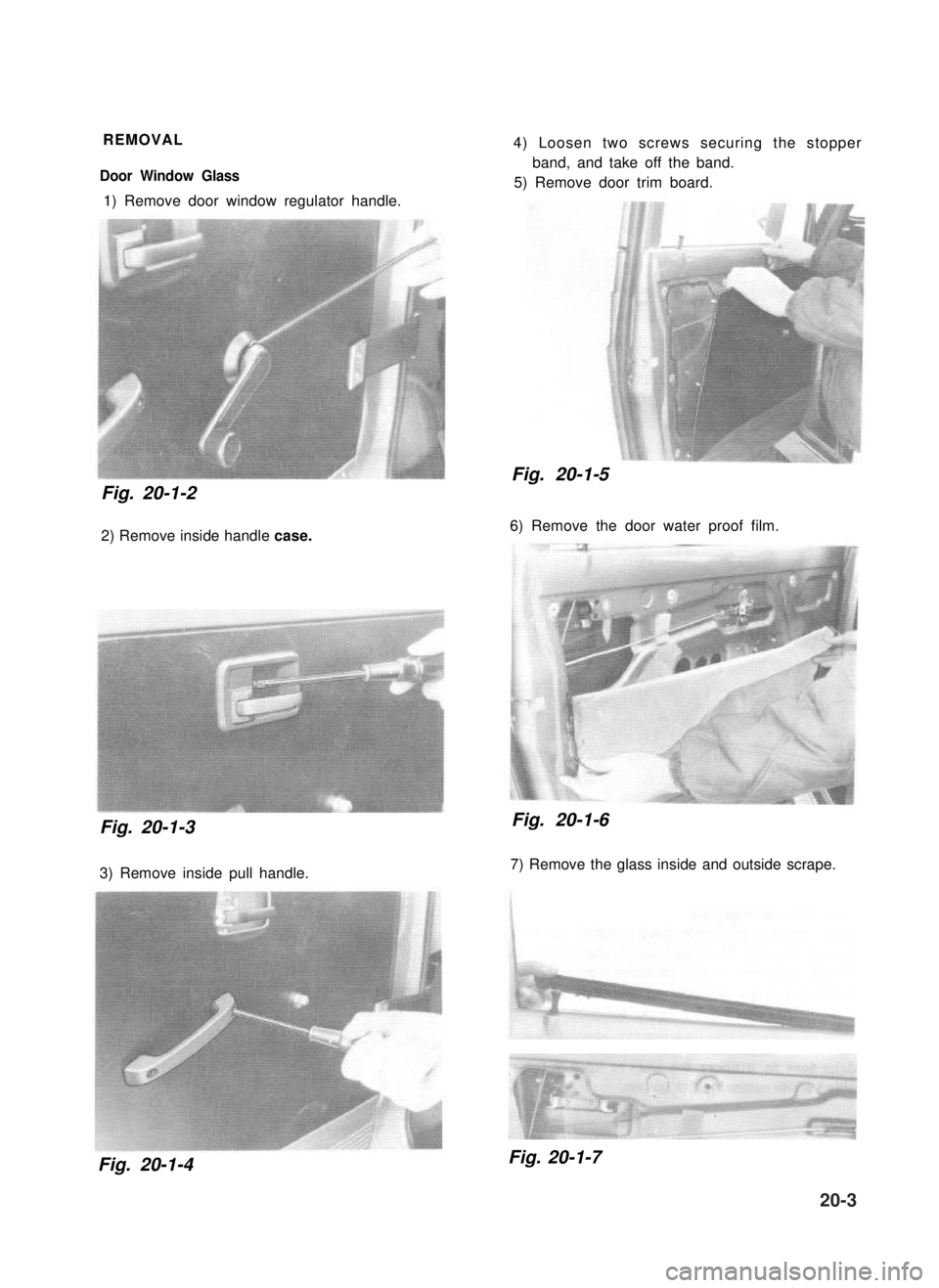

8) Remove 2 screws securing the door window

regulator roller holder (lower side).

Fig. 20-1-10

Fig. 20-1-8

9) Take out the glass.

Fig. 20-1-9

10) Detach glass from bottom channel.

Door Window Regulator

After carrying out door glass removal steps 1)

through 6) and 8), move on to the following

steps to take off the door window regulator.

1) Remove 2 screws securing the door window

regulator roller holder (upper side).

NOTE:

Make sure to support the glass to keep it from

falling while removing the screws.

2) Remove 4 screws securing the window regula-

tor.

Fig. 20-1-11

3) Remove the window regulator.

Fig. 20-1-12

20-4

Page 439 of 962

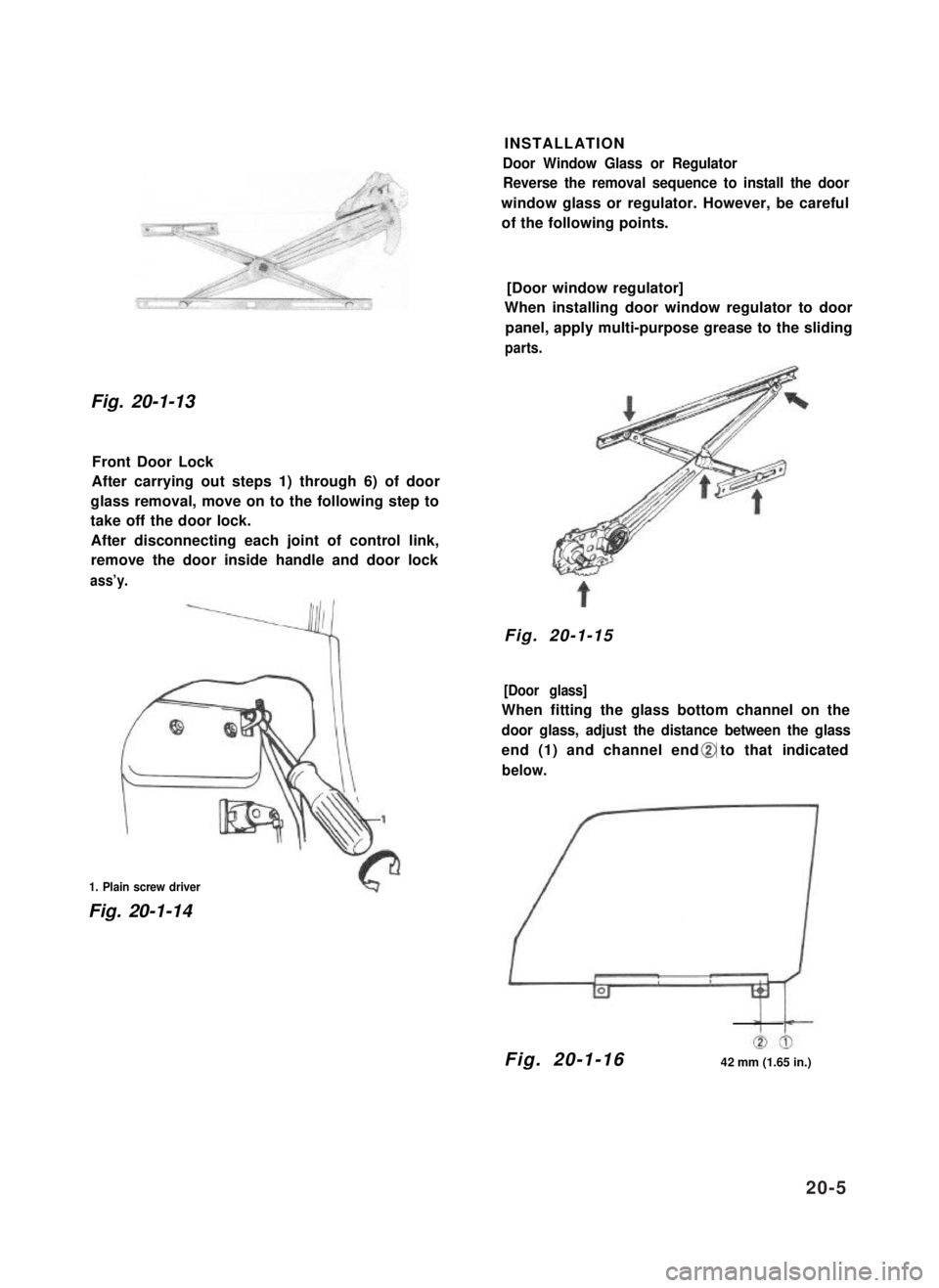

Fig. 20-1-13

Front Door Lock

After carrying out steps 1) through 6) of door

glass removal, move on to the following step to

take off the door lock.

After disconnecting each joint of control link,

remove the door inside handle and door lock

ass’y.

1. Plain screw driver

Fig. 20-1-14

INSTALLATION

Door Window Glass or Regulator

Reverse the removal sequence to install the door

window glass or regulator. However, be careful

of the following points.

[Door window regulator]

When installing door window regulator to door

panel, apply multi-purpose grease to the sliding

parts.

Fig. 20-1-15

[Door glass]

When fitting the glass bottom channel on the

door glass, adjust the distance between the glass

end (1) and channel end to that indicated

below.

Fig. 20-1-1642 mm (1.65 in.)

20-5

Page 440 of 962

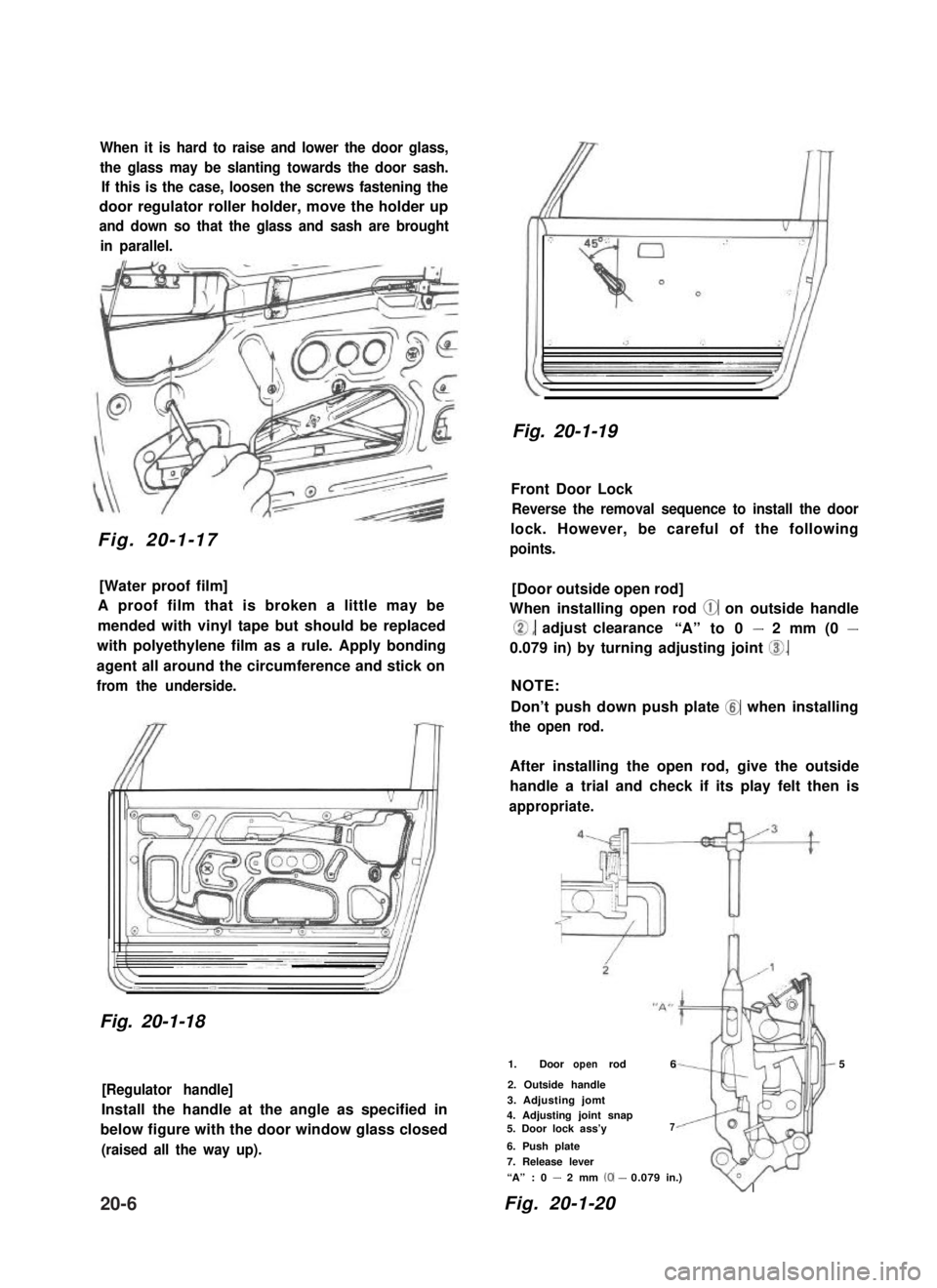

When it is hard to raise and lower the door glass,

the glass may be slanting towards the door sash.

If this is the case, loosen the screws fastening the

door regulator roller holder, move the holder up

and down so that the glass and sash are brought

in parallel.

Fig. 20-1-17

[Water proof film]

A proof film that is broken a little may be

mended with vinyl tape but should be replaced

with polyethylene film as a rule. Apply bonding

agent all around the circumference and stick on

from the underside.

Fig. 20-1-18

[Regulator handle]

Install the handle at the angle as specified in

below figure with the door window glass closed

(raised all the way up).

Fig. 20-1-19

Front Door Lock

Reverse the removal sequence to install the door

lock. However, be careful of the following

points.

[Door outside open rod]

When installing open rod @ on outside handle

0, adjust clearance“A” to 0 - 2 mm (0 -

0.079 in) by turning adjusting joint 0.

NOTE:

Don’t push down push plate @ when installing

the open rod.

After installing the open rod, give the outside

handle a trial and check if its play felt then is

appropriate.

1. Door rodopen65

2. Outside handle

3. Adjusting jomt4. Adjusting joint snap5. Door lock ass’y7

6. Push plate

7. Release lever

“A” : 0 - 2 mm (0-0.079in.)

Fig. 20-1-20

v

20-6