SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 461 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual INSPECTION21-8. OIL PRESSURE LAMP

[Brake fluid level switch]

Use ohmmeter to check switch for resistance

and continuity.

If found defective, replace switch.

The oil pressure lamp circuit consists of t SUZUKI GRAND VITARA 1987 Service Repair Manual INSPECTION21-8. OIL PRESSURE LAMP

[Brake fluid level switch]

Use ohmmeter to check switch for resistance

and continuity.

If found defective, replace switch.

The oil pressure lamp circuit consists of t](/img/20/57437/w960_57437-460.png)

INSPECTION21-8. OIL PRESSURE LAMP

[Brake fluid level switch]

Use ohmmeter to check switch for resistance

and continuity.

If found defective, replace switch.

The oil pressure lamp circuit consists of the oil

pressure switch installed to the cylinder block

and the lamp (warning lamp) inside the combi-

nation meter.

The oil pressure switch so operates that it is

switched OFF when oil pressure is produced by

the started engine and then fed to switch.

Fig. 21-23W/R : White/Red

6 : Black

RI0 : RedlBlack

1. Battery

2. Main switch

3. Fuse4. Oil pressure lamp

6. Oil pressure switch

B/El : Black/Blue

B/W : Black/White

Y/0 : Yellow/Black

W/Y : White/Yellow

Fig. 21-24

INSPECTION

[Oil pressure switch]

Use a ohmmeter to check the switch continuity.

During engine

Running

No continuity

obtained (- 52 1

IAt Engine StopContinuity obtained

(052)

1. To wiring harness

2. Cylinder block

Fig. 21-2521-14

Page 462 of 962

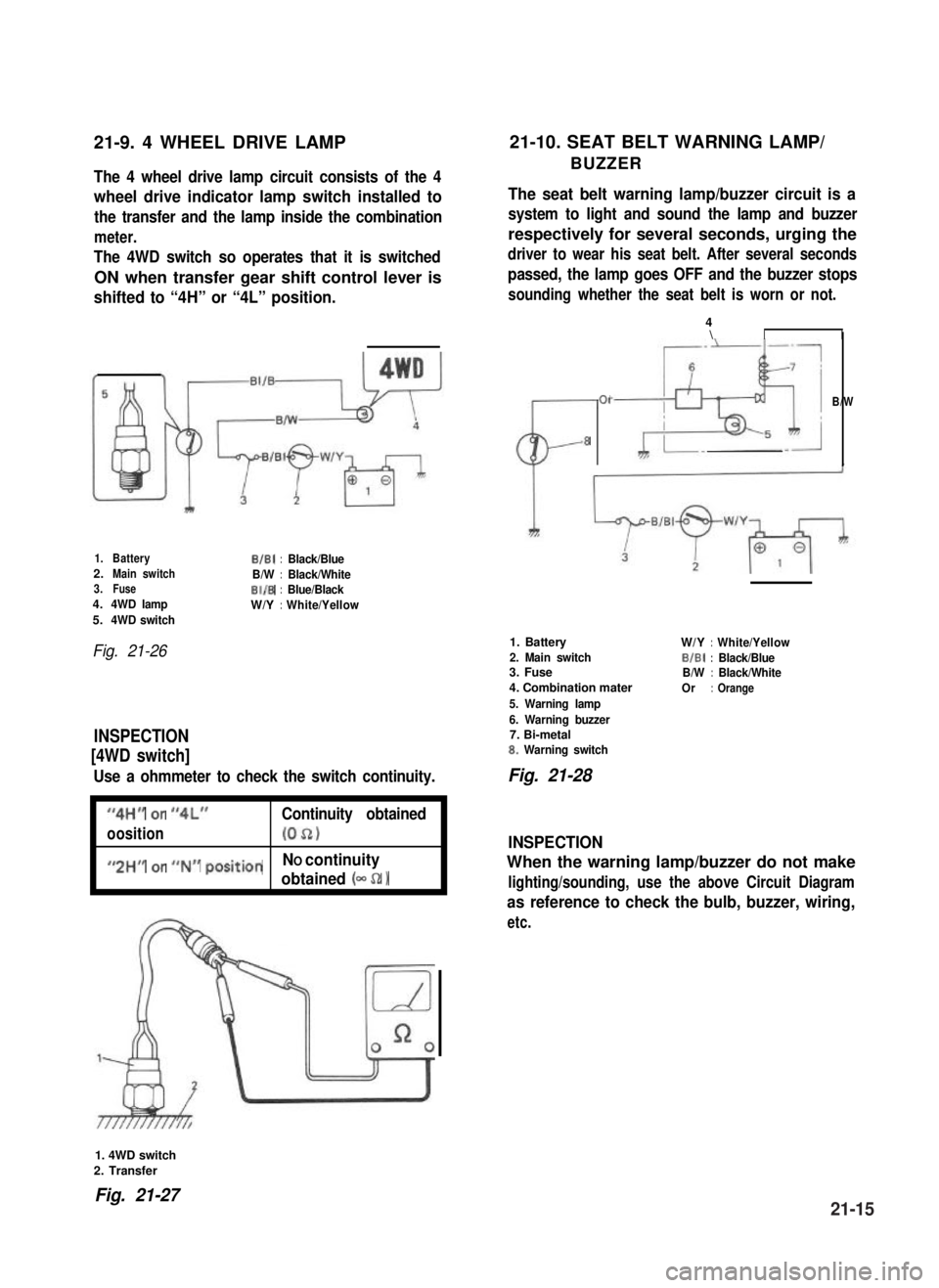

21-9. 4 WHEEL DRIVE LAMP21-10. SEAT BELT WARNING LAMP/

BUZZERThe 4 wheel drive lamp circuit consists of the 4

wheel drive indicator lamp switch installed to

the transfer and the lamp inside the combination

meter.

The 4WD switch so operates that it is switched

ON when transfer gear shift control lever is

shifted to “4H” or “4L” position.

The seat belt warning lamp/buzzer circuit is a

system to light and sound the lamp and buzzer

respectively for several seconds, urging the

driver to wear his seat belt. After several seconds

passed, the lamp goes OFF and the buzzer stops

sounding whether the seat belt is worn or not.

1.BatteryB/B1:Black/Blue2.Main switchB/W:Black/White3.FuseBI/B:Blue/Black4.4WD lampW/Y:White/Yellow5.4WD switch

Fig. 21-26

INSPECTION

[4WD switch]

Use a ohmmeter to check the switch continuity.

I

“4H” or “4L”Continuity obtained

oosition(052)I

I

#,2HM or ##N## positionNO continuity

obtained (- 52 1I

CL-

01

8

4\II

B/W

1. Battery

2. Main switch3. Fuse

4. Combination mater

5. Warning lamp

6. Warning buzzer7. Bi-metal8. Warning switch

W/Y:White/Yellow

BIBI:Black/BlueB/W:Black/White

Or:Orange

Fig. 21-28

INSPECTION

When the warning lamp/buzzer do not make

lighting/sounding, use the above Circuit Diagram

as reference to check the bulb, buzzer, wiring,

etc.

1. 4WD switch

2. Transfer

Fig. 21-2721-15

Page 463 of 962

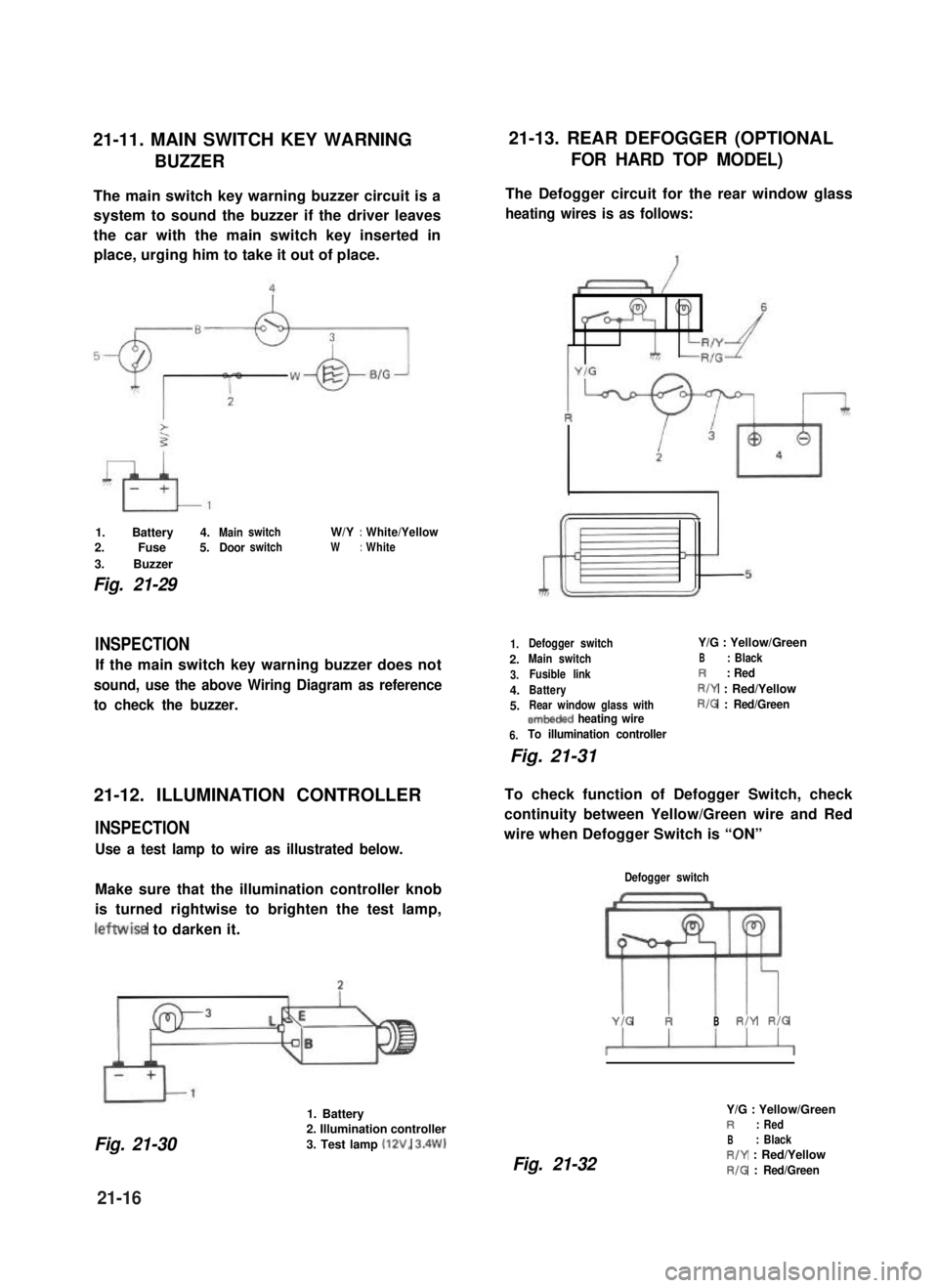

21-11. MAIN SWITCH KEY WARNING21-13. REAR DEFOGGER (OPTIONAL

BUZZERFOR HARD TOP MODEL)

The main switch key warning buzzer circuit is a

system to sound the buzzer if the driver leaves

the car with the main switch key inserted in

place, urging him to take it out of place.

1. Battery 4.MainswitchW/Y:White/Yellow

2. Fuse 5.DoorswitchW:White

3. Buzzer

Fig. 21-29

INSPECTION

If the main switch key warning buzzer does not

sound, use the above Wiring Diagram as reference

to check the buzzer.

21-12. ILLUMINATION CONTROLLER

INSPECTION

Use a test lamp to wire as illustrated below.

Make sure that the illumination controller knob

is turned rightwise to brighten the test lamp,

leftwise to darken it.

1. Battery

Fig. 21-30

2. Illumination controller

3. Test lamp (12V, 3.4W)

The Defogger circuit for the rear window glass

heating wires is as follows:

1.

2.

3.

4.

5.

6.

Defogger switchY/G : Yellow/Green

Main switchB: Black

Fusible linkR: Red

BatteryR/Y : Red/Yellow

Rear window glass withR/G : Red/Greenembeded heating wire

To illumination controller

Fig. 21-31

To check function of Defogger Switch, check

continuity between Yellow/Green wire and Red

wire when Defogger Switch is “ON”

Defogger switch

YIG RBR/Y RIG

Fig. 21-32

Y/G : Yellow/GreenR: Red

B: BlackR/Y : Red/Yellow

R/G : Red/Green

21-16

Page 464 of 962

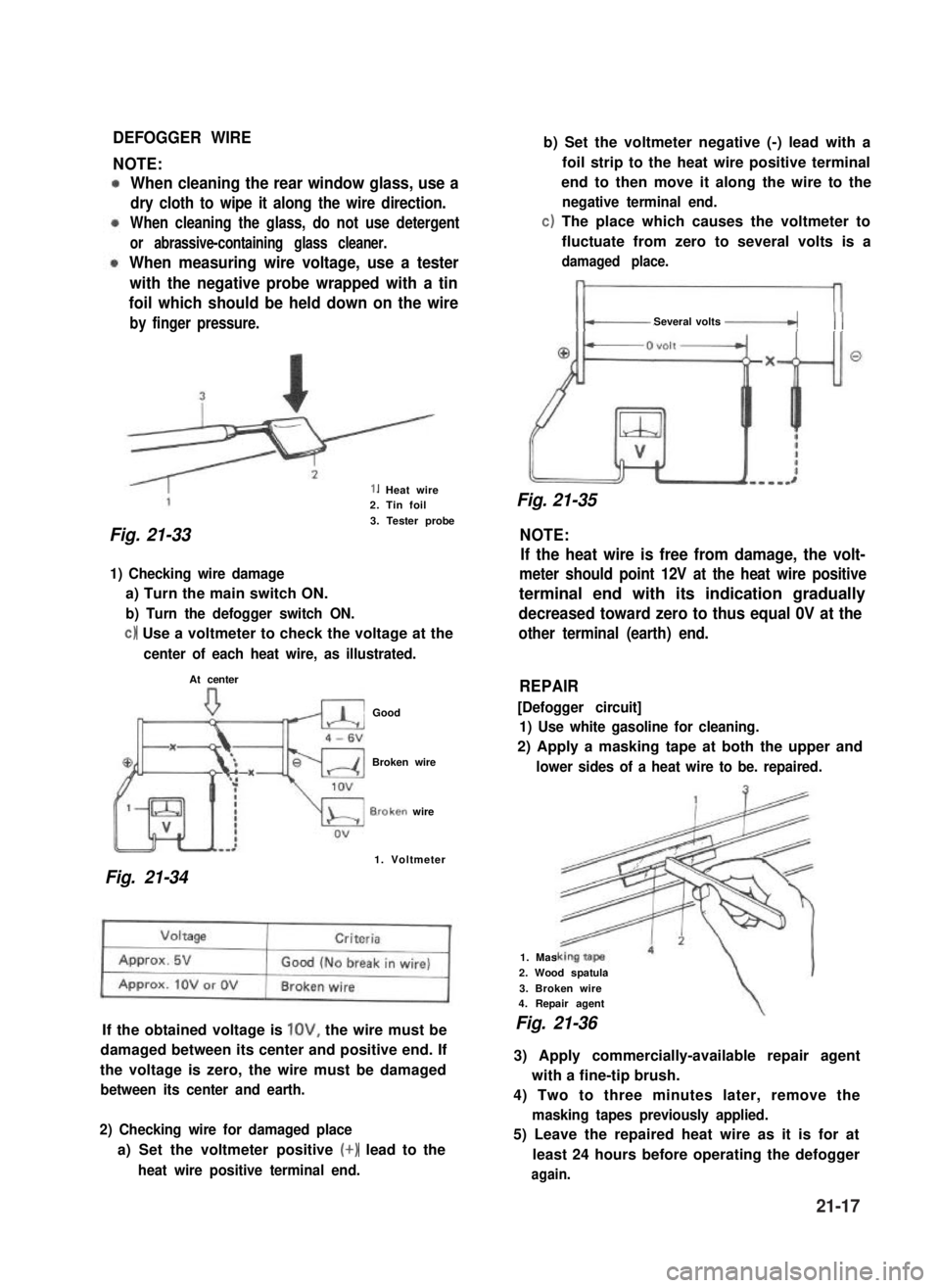

DEFOGGER WIRE

NOTE:

When cleaning the rear window glass, use a

dry cloth to wipe it along the wire direction.

When cleaning the glass, do not use detergent

or abrassive-containing glass cleaner.

When measuring wire voltage, use a tester

with the negative probe wrapped with a tin

foil which should be held down on the wire

by finger pressure.

1. Heat wire2. Tin foil

3. Tester probe

Fig. 21-33 NOTE:

1) Checking wire damage

a) Turn the main switch ON.

b) Turn the defogger switch ON.

c) Use a voltmeter to check the voltage at the

center of each heat wire, as illustrated.

At center

Good

Broken wire

B.roken wire

1. Voltmeter

Fig. 21-34

If the obtained voltage is lOV, the wire must be

damaged between its center and positive end. If

the voltage is zero, the wire must be damaged

between its center and earth.

2) Checking wire for damaged place

a) Set the voltmeter positive (+) lead to the

heat wire positive terminal end.

b) Set the voltmeter negative (-) lead with a

foil strip to the heat wire positive terminal

end to then move it along the wire to the

negative terminal end.

c) The place which causes the voltmeter to

fluctuate from zero to several volts is a

damaged place.

Several volts -_(( (

Fig. 21-35

If the heat wire is free from damage, the volt-

meter should point 12V at the heat wire positive

terminal end with its indication gradually

decreased toward zero to thus equal 0V at the

other terminal (earth) end.

REPAIR

[Defogger circuit]

1) Use white gasoline for cleaning.

2) Apply a masking tape at both the upper and

lower sides of a heat wire to be. repaired.

1. Mas

2. Wood spatula

3. Broken wire4. Repair agent

Fig. 21-36

3) Apply commercially-available repair agent

with a fine-tip brush.

4) Two to three minutes later, remove the

masking tapes previously applied.

5) Leave the repaired heat wire as it is for at

least 24 hours before operating the defogger

again.

21-17

Page 465 of 962

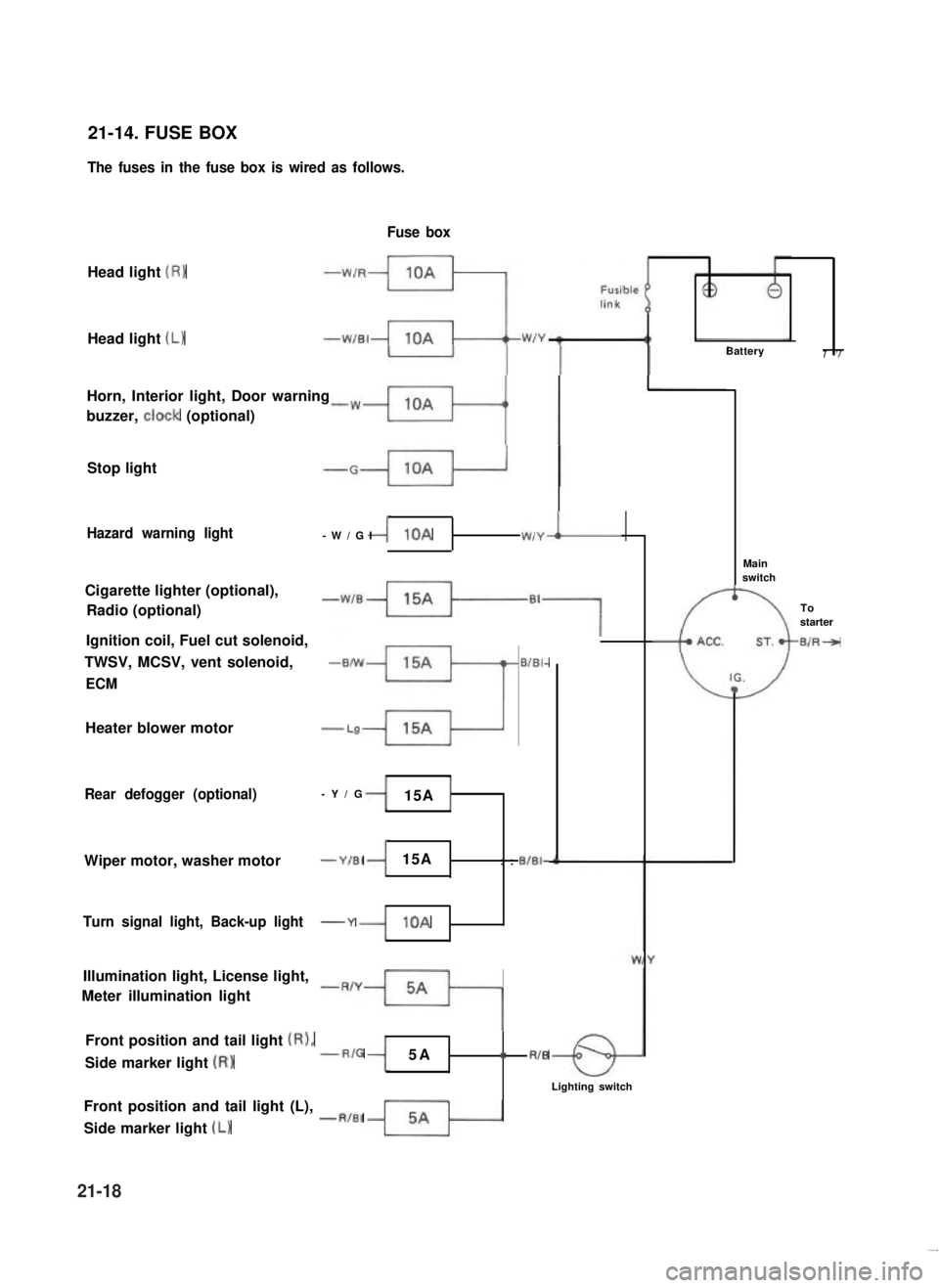

21-14. FUSE BOX

The fuses in the fuse box is wired as follows.

Head light (R)

Fuse box

Head light (L)Battery7

Horn, Interior light, Door warning

buzzer, ctock (optional)

Stop light

Hazard warning light-W/GI10AW,YI

Cigarette lighter (optional),

Radio (optional)

-w’B++-B7Ignition coil, Fuel cut solenoid,

TWSV, MCSV, vent solenoid,-B/W15A

3

BIBI-

ECM

Heater blower motor-L9

Rear defogger (optional)-Y/G15A

Wiper motor, washer motor-Y/El15A:: BIBI-

Turn signal light, Back-up light-Y10A

Illumination light, License light,

Meter illumination light

-R’y++lFront position and tail light (RI,

Side marker light (RI--RIG5A:: RIB

Lighting switch

Front position and tail light (L), --R,a,

Side marker light (L)

-t

-c

Mainswitch

Tostarter

B/R--,

-

21-18

Page 466 of 962

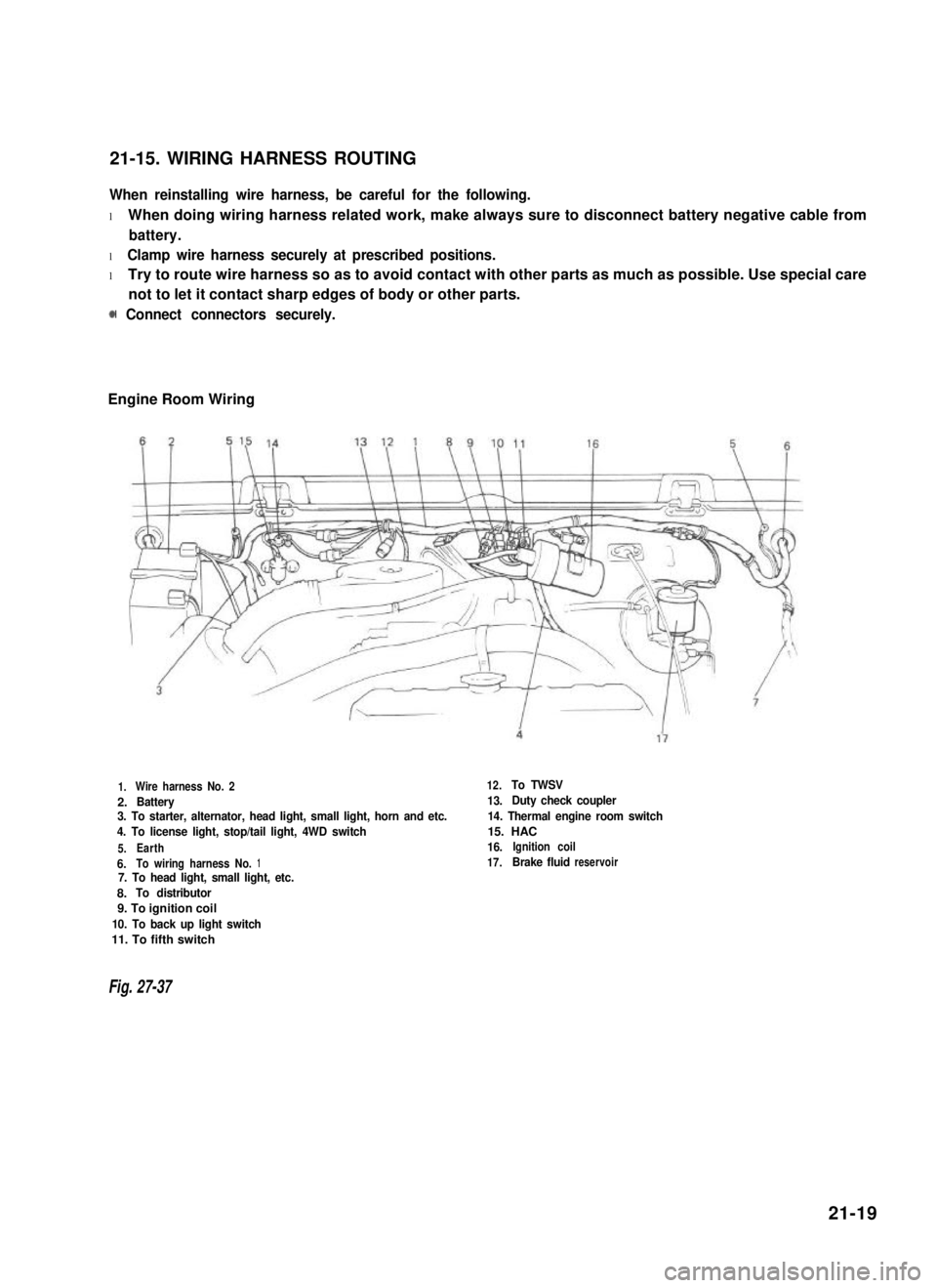

21-15. WIRING HARNESS ROUTING

When reinstalling wire harness, be careful for the following.

l When doing wiring harness related work, make always sure to disconnect battery negative cable from

battery.

l Clamp wire harness securely at prescribed positions.

l Try to route wire harness so as to avoid contact with other parts as much as possible. Use special care

not to let it contact sharp edges of body or other parts.

0 Connect connectors securely.

Engine Room Wiring

1.Wire harness No. 2

2.Battery3. To starter, alternator, head light, small light, horn and etc.

4. To license light, stop/tail light, 4WD switch

5.Earth

6.To wiring harness No.17. To head light, small light, etc.

8.To distributor

9. To ignition coil

10. To back up light switch

11. To fifth switch

12.To TWSV

13.Duty check coupler

14. Thermal engine room switch

15. HAC

16.Ignition coil

17.Brake fluidreservoir

Fig. 27-37

21-19

Page 467 of 962

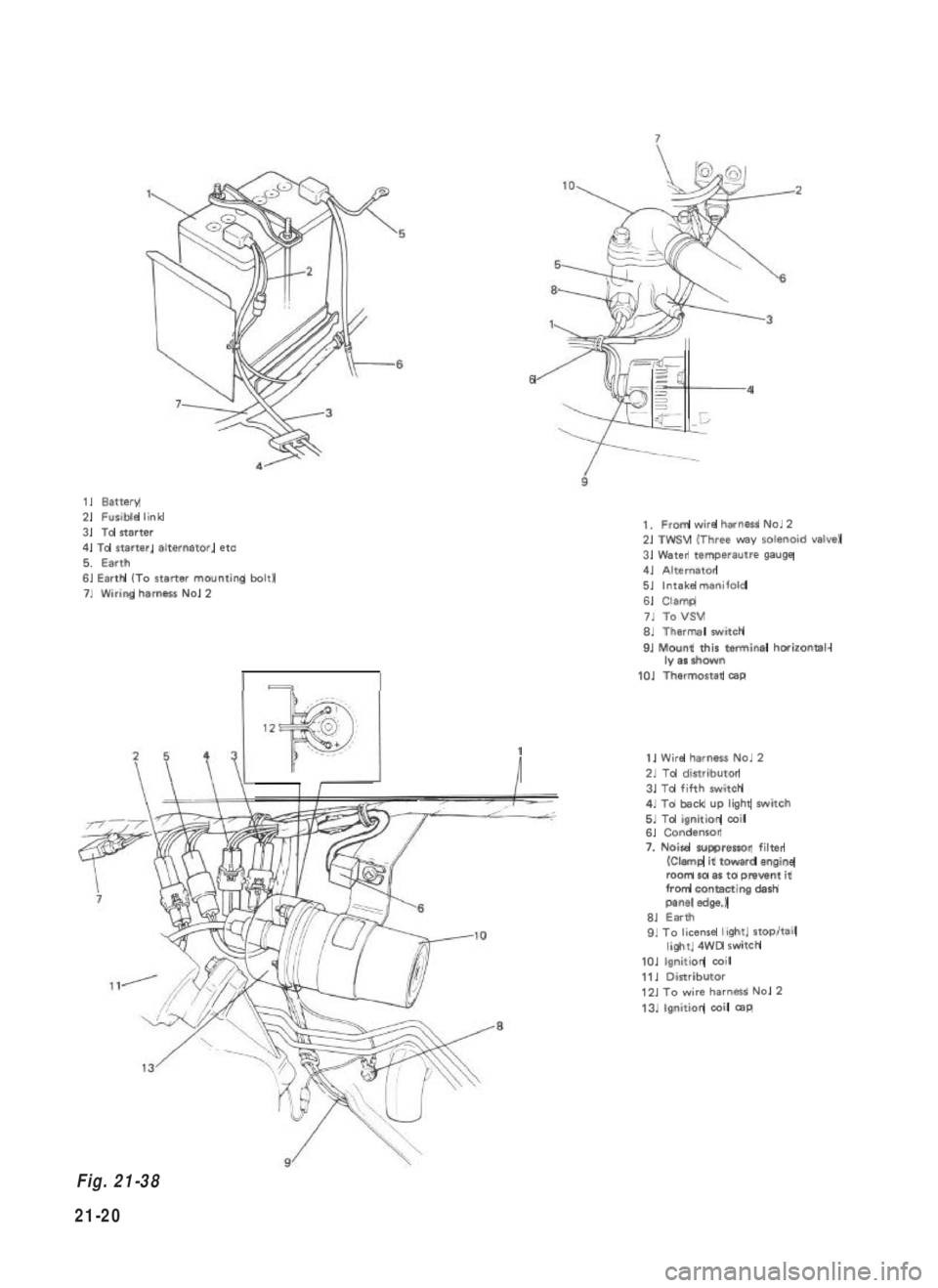

1.Battery2.Fusible link

3.To starter

4. To starter, alternator, etc

5.Earth6. Earth (To starter mounting bolt)7.Wiring harnessNo.2

64

1

I

1.From wire harnessNo.22. TWSV (Three way solenoid valve)

3. Water temperautre gauge4.Alternator5.Intake manifold

6.Clamp

7.ToVSV6.Thermal switch

9. Mount this terminal horizontal-ly as shown

10.Thermostat cap

1. Wire harness No. 2

2. To distributor

3. To fifth switch4. To back up light switch5. To ignition coil6. Condensor

7. Noise suppressor filter(Clamp it toward engineroom so as to prevent itfrom contacting dashpanel edge.)6. Earth9. To license light, stop/taillight, 4WD switch

10. Ignition coil

11. Distributor12. To wire harness No. 2

13. Ignition coil cap

Fig. 21-38

21-20

Page 468 of 962

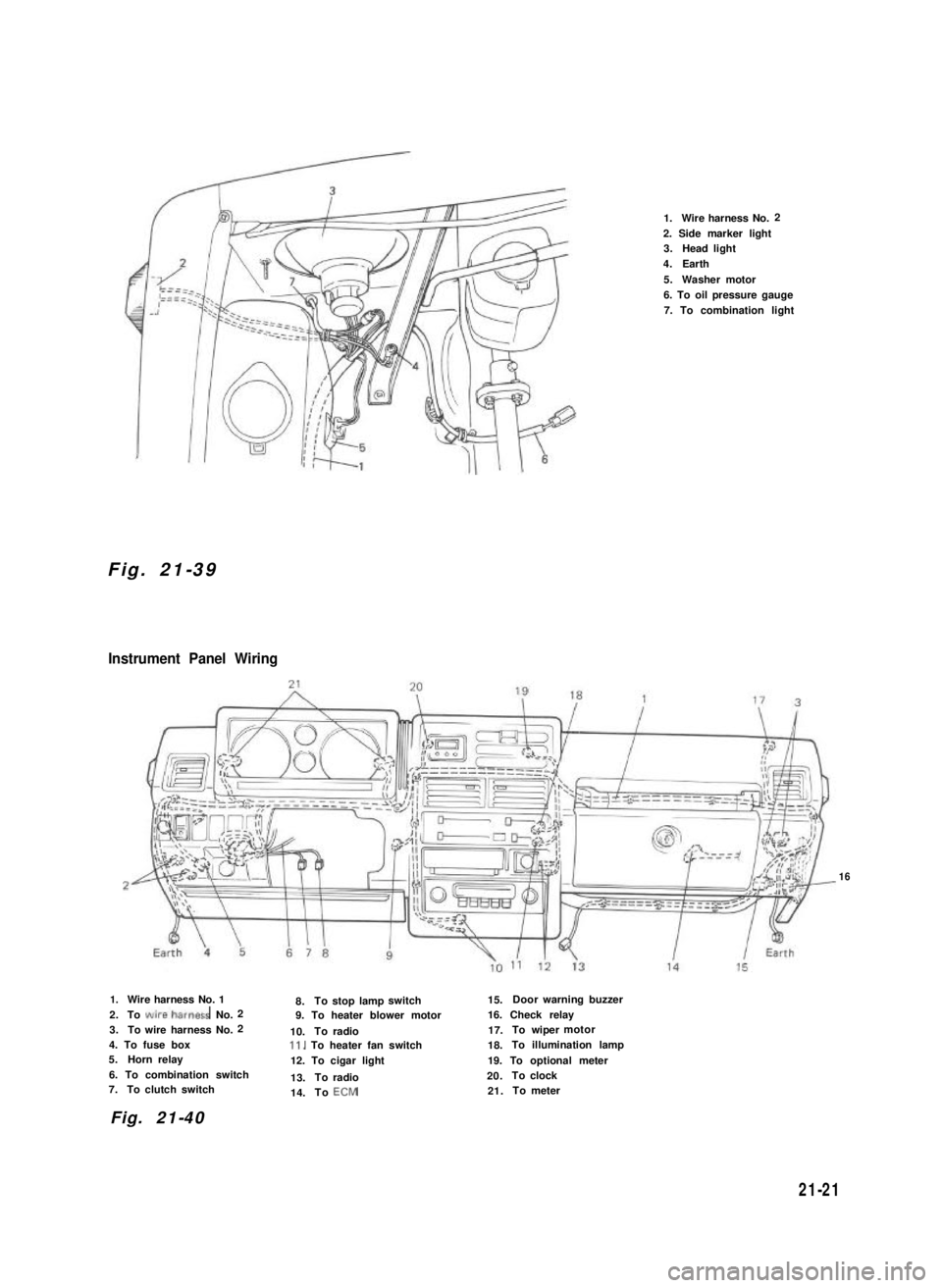

Fig. 21-39

Instrument Panel Wiring

1.Wire harness No.2

2. Side marker light3.Head light

4.Earth

5.Washer motor

6. To oil pressure gauge

7. To combination light

16

1.Wire harness No. 1

2.To wire~harness No.2

3.To wire harness No.2

4. To fuse box5.Horn relay

6. To combination switch7.To clutch switch

8.Tostop lampswitch15.Doorwarning buzzer

9. To heater blower motor16. Check relay

10.Toradio17.To wipermotor

Il. To heater fan switch18.To illumination lamp

12. To cigar light19. To optional meter

13.Toradio20.Toclock

14.ToECM21.Tometer

Fig. 21-40

21-21

Page 469 of 962

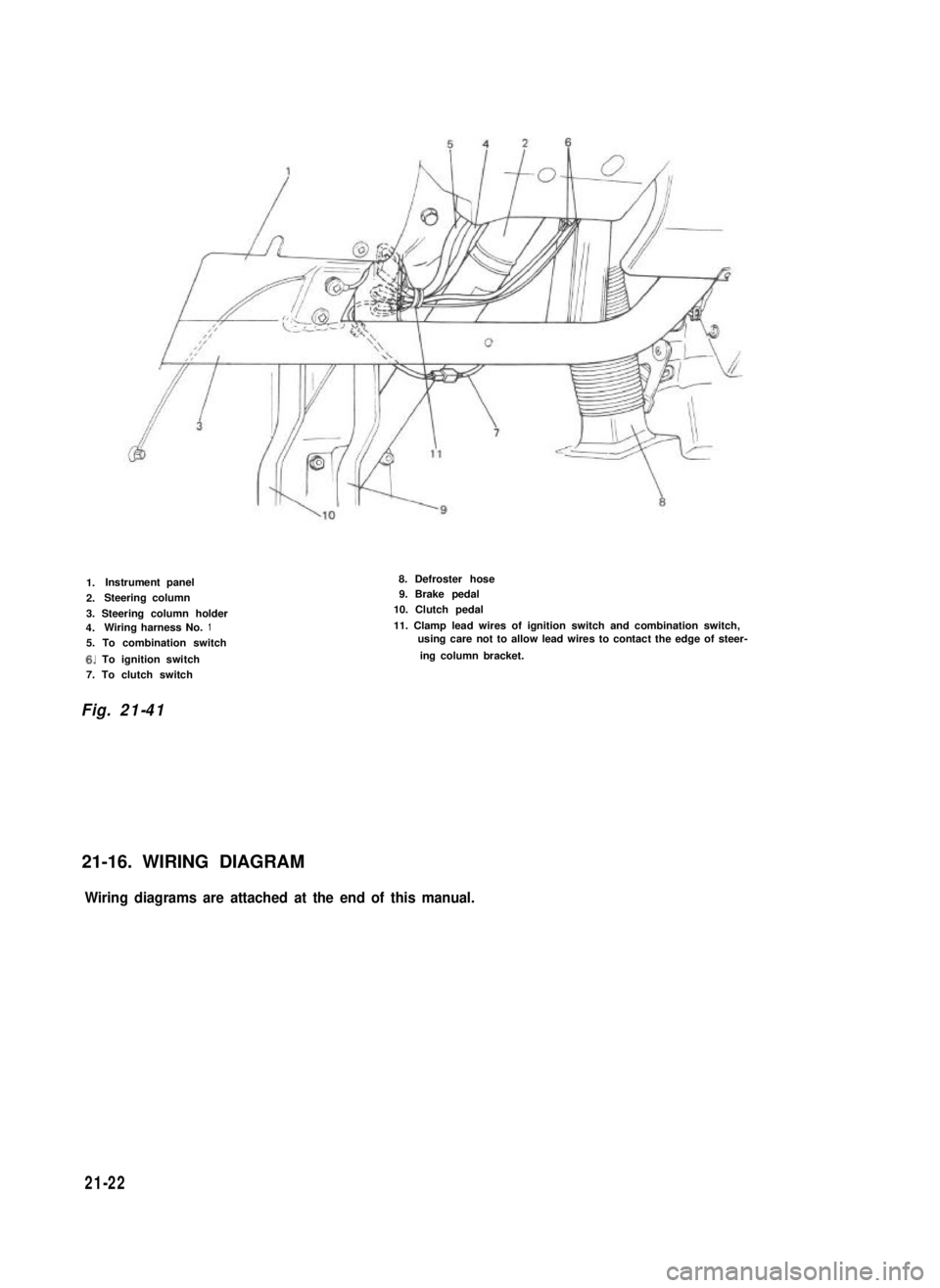

1.Instrument panel

2.Steering column

3. Steering column holder4.Wiring harness No.1

5. To combination switch

6. To ignition switch

7. To clutch switch

8. Defroster hose9. Brake pedal

10. Clutch pedal

11. Clamp lead wires of ignition switch and combination switch,using care not to allow lead wires to contact the edge of steer-

ing column bracket.

Fig. 21-41

21-16. WIRING DIAGRAM

Wiring diagrams are attached at the end of this manual.

21-22

Page 470 of 962

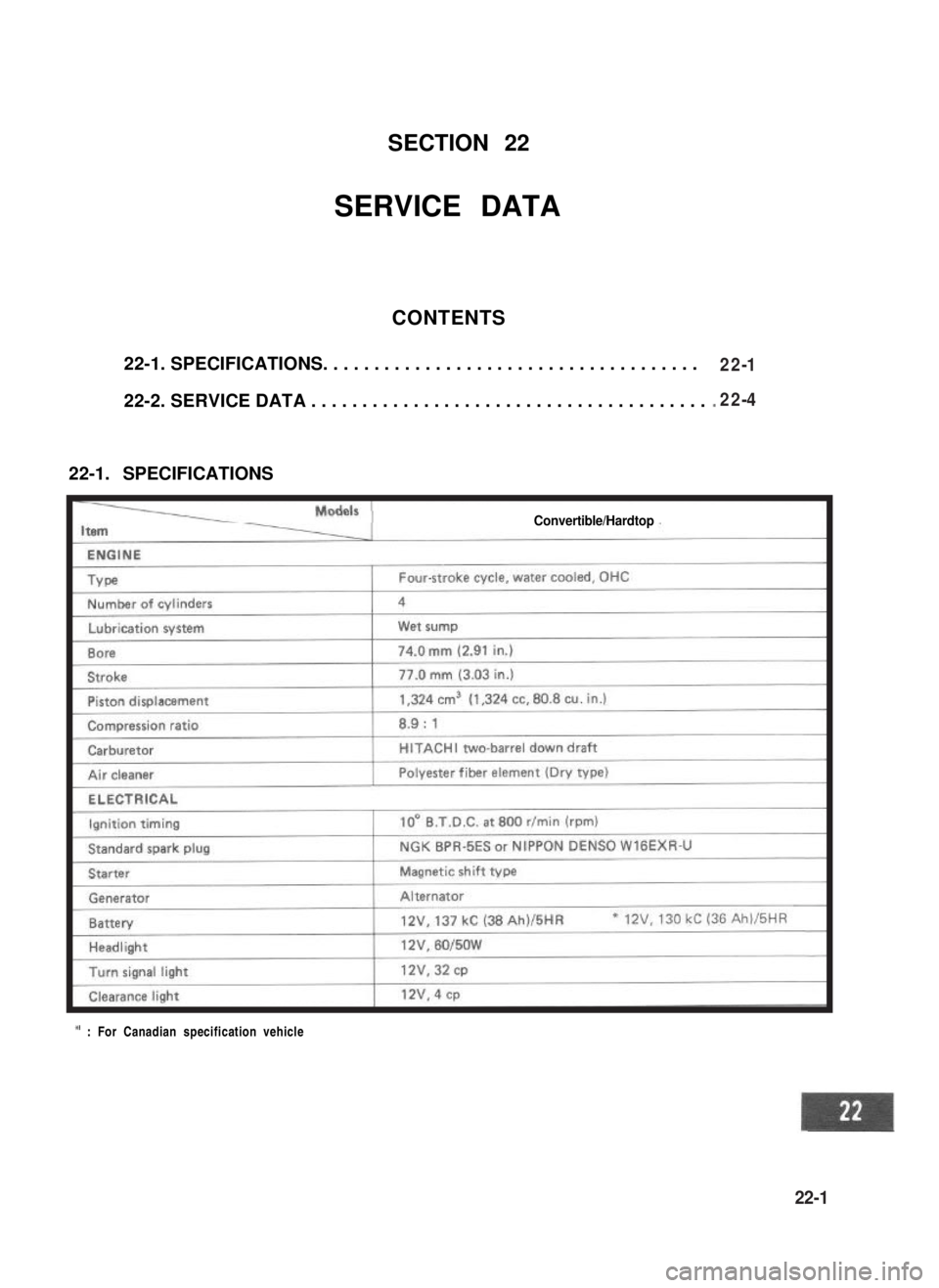

SECTION 22

SERVICE DATA

CONTENTS

22-1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22-2. SERVICE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22-1. SPECIFICATIONS

Convertible/Hardtop

* : For Canadian specification vehicle

22-1

22-4

22-1