SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 421 of 962

2,

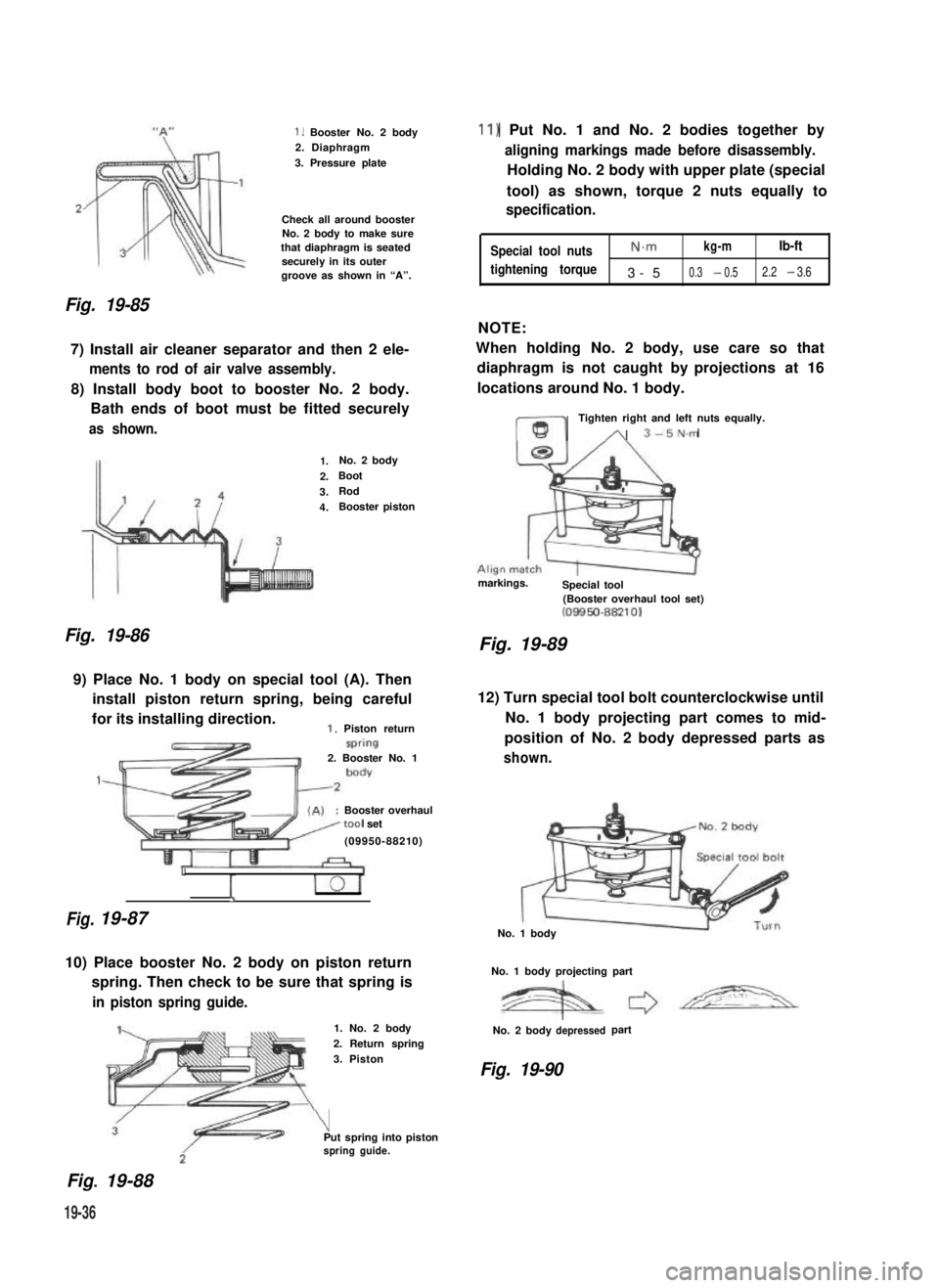

Fig. 19-85

1. Booster No. 2 body2. Diaphragm

3. Pressure plate

Check all around boosterNo. 2 body to make surethat diaphragm is seatedsecurely in its outergroove as shown in “A”.

7) Install air cleaner separator and then 2 ele-

ments to rod of air valve assembly.

8) Install body boot to booster No. 2 body.

Bath ends of boot must be fitted securely

as shown.

Fig. 19-86

1.No. 2 body

2.Boot

3.Rod

4.Booster piston

9) Place No. 1 body on special tool (A). Then

install piston return spring, being careful

for its installing direction.1. Piston return

Fig.

2. Booster No. 1

:Booster overhaultool set

(09950-88210)

1

I

19-87

10) Place booster No. 2 body on piston return

spring. Then check to be sure that spring is

in piston spring guide.

Fig.. 19-88

1. No. 2 body

2. Return spring

3. Piston

\Put spring into pistonspring guide.

11) Put No. 1 and No. 2 bodies together by

aligning markings made before disassembly.

Holding No. 2 body with upper plate (special

tool) as shown, torque 2 nuts equally to

specification.

Special tool nutsN.mkg-mlb-ft

tightening torque3-50.3 - 0.52.2 - 3.6

NOTE:

When holding No. 2 body, use care so that

diaphragm is not caught by projections at 16

locations around No. 1 body.

ml

Tighten right and left nuts equally.

A 3-5N.m

markings.Special tool(Booster overhaul tool set)(08850-88210)

Fig. 19-89

12) Turn special tool bolt counterclockwise until

No. 1 body projecting part comes to mid-

position of No. 2 body depressed parts as

shown.

No. 1 body

No. 1 body projecting part

No. 2 bodydepressedpart

Fig. 19-90

19-36

Page 422 of 962

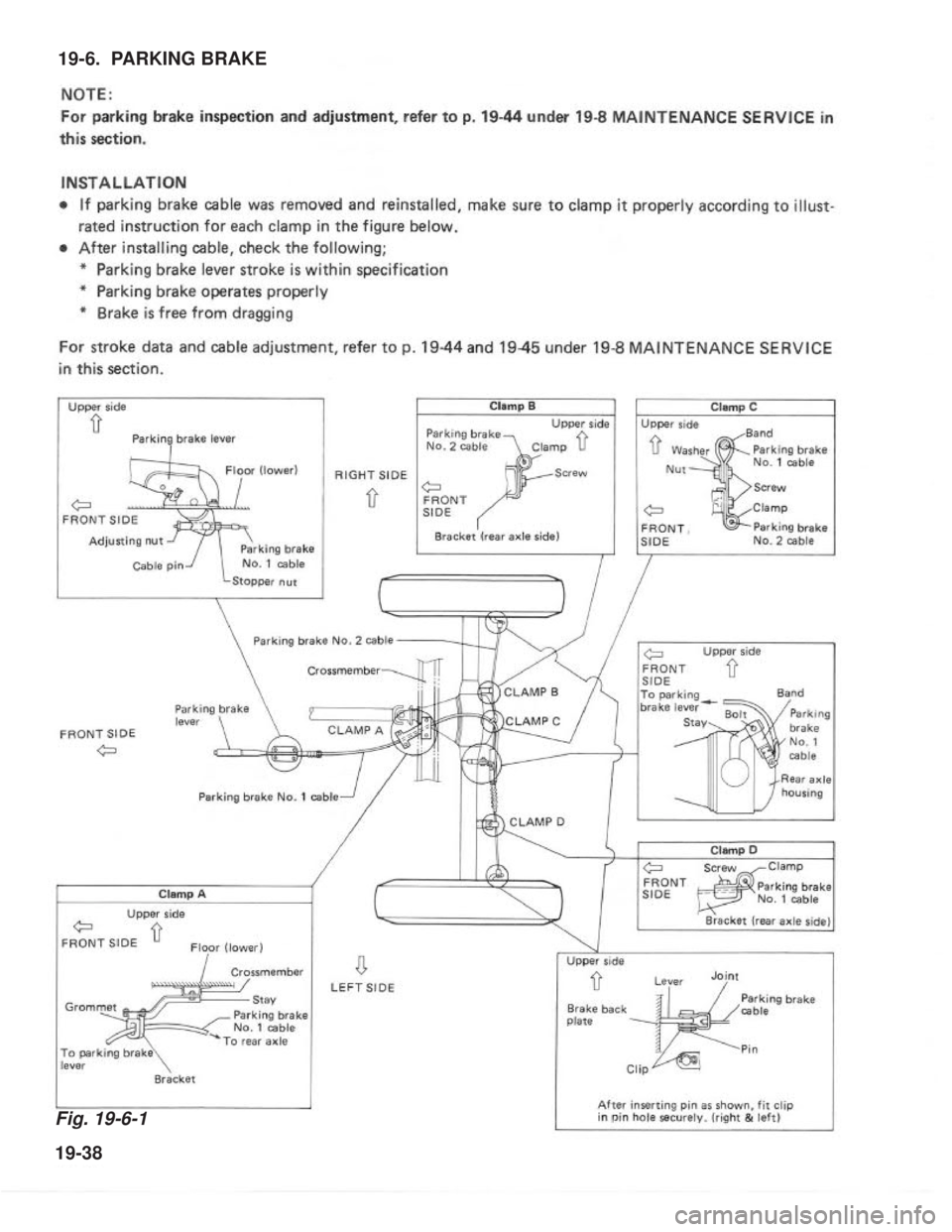

13) Remove booster from special tool and

install push rod clevis so that below measure-

ment “A” is obtained and torque nut to

specification.

-41. Clevis

2. Nut

Gasket20 - 30 N

“A”

125.5- 126.5mm(4.94 - 4.98 in.)\

.rnkg-m).5 lb-ft)

Fig. 19-91

14) Insert piston rod into booster piston.

NOTE:

Whenever booster was disassembled, make sure

to check clearance between piston rod and

INSTALLATION

NOTE:

See NOTE at the beginning of this section.

Adjust clearance between booster piston rod

and master cylinder piston with special tool.

(See page 19-33.)

Check length of push rod clevis. (Refer to

Fig. 19-91).

1) Install booster to dash panel as shown. Then

connect booster push rod clevis to pedal arm

with pin and split pin.

2) Torque booster attaching nuts to specifica-

tion.

3) Install master cylinder to booster and torque

attaching nuts to specification.

4) Connect 2 brake pipes and torque flare nuts

to specification. (See p. 19-29).

5) Fill reservoir with specified fluid.

6) Bleed air from brake system. (See BLEEDING

BRAKES on p. 19-46).

7) After installing, check pedal height and play.

(See p. 19-43).

master cylinder piston after reassembly. (For

details, refer to p. 19-33.)

20 30 N.m-(2.0 - 3.0 kg-m)(14.5 - 21.5 lb-ftl

10 - 16 N.m(1.0-1.6 kg-m)(7.5 - 11.5 lb-ft)

Fig. 19-9219-37

Page 423 of 962

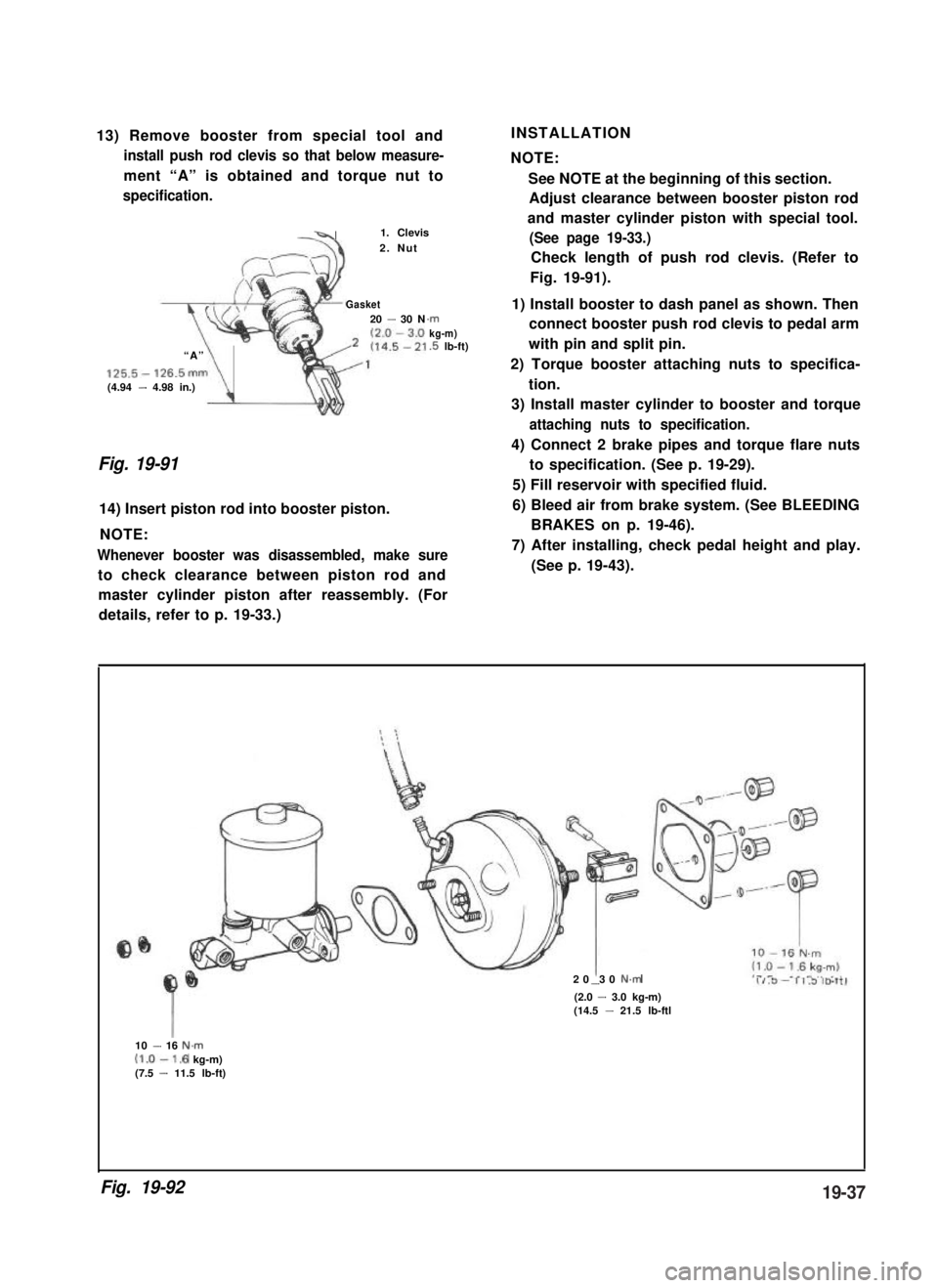

Fig. 19-6-1

19-38

19-6. PARKING BRAKE

Page 424 of 962

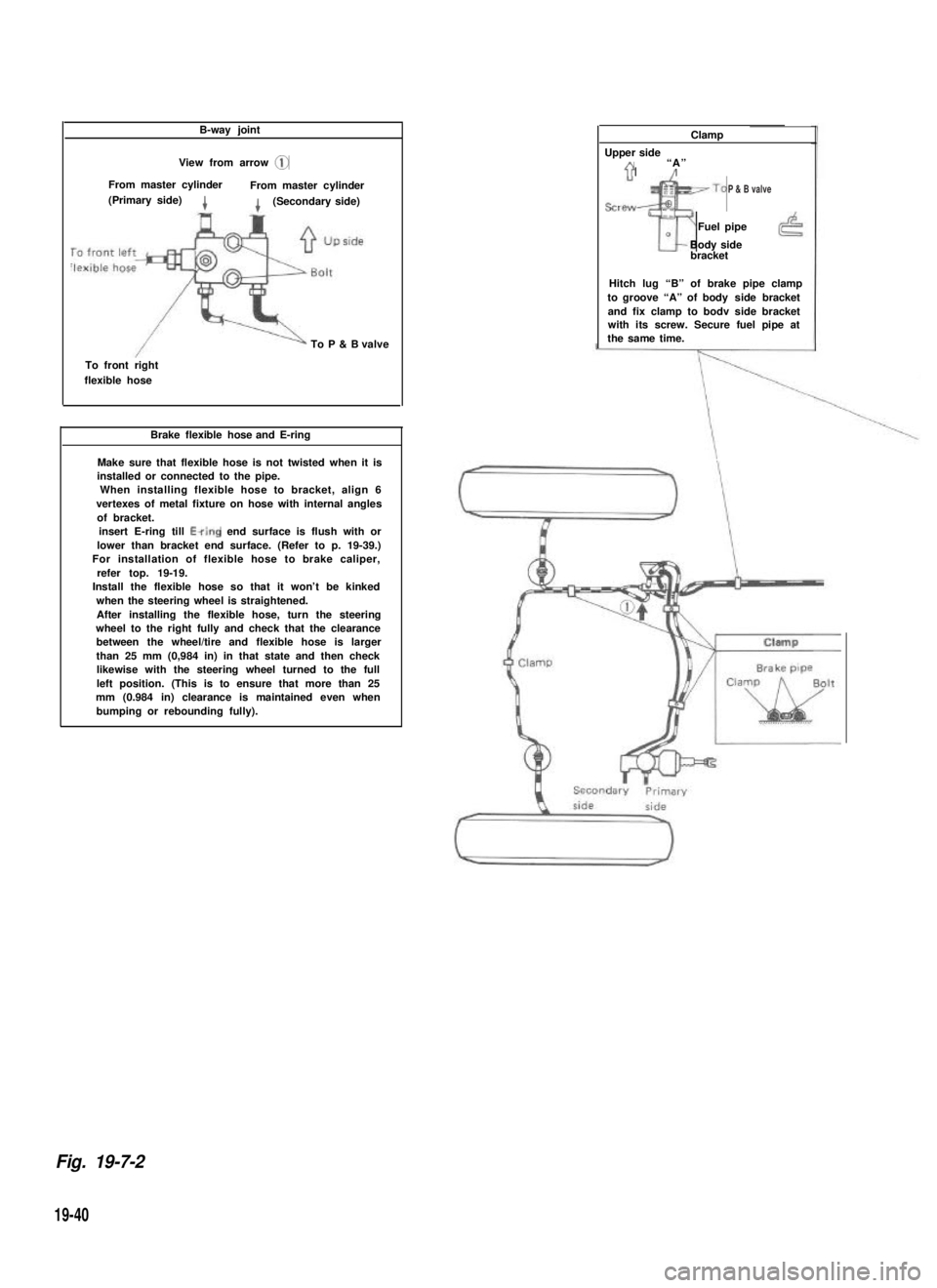

19-7. BRAKE PIPES AND HOSES

REMOVAL AND INSTALLATION

1) Take out fluid with a cyringe or such.

2) Clean dirt and foreign material from both

hose end or pipe end fittings. Remove brake

hose or pipe.

3) Reverse removal procedure for brake hose

or pipe installation.When installing hose,

make sure that it has no twists or kinks.

Inspect to see that hose doesn’t make contact

with any part of suspension. Check in extreme

right and extreme left turn conditions. If

hose makes .any contact, remove and correct.

Fill and maintain brake fluid level in reser-

voir. Bleed brake system.

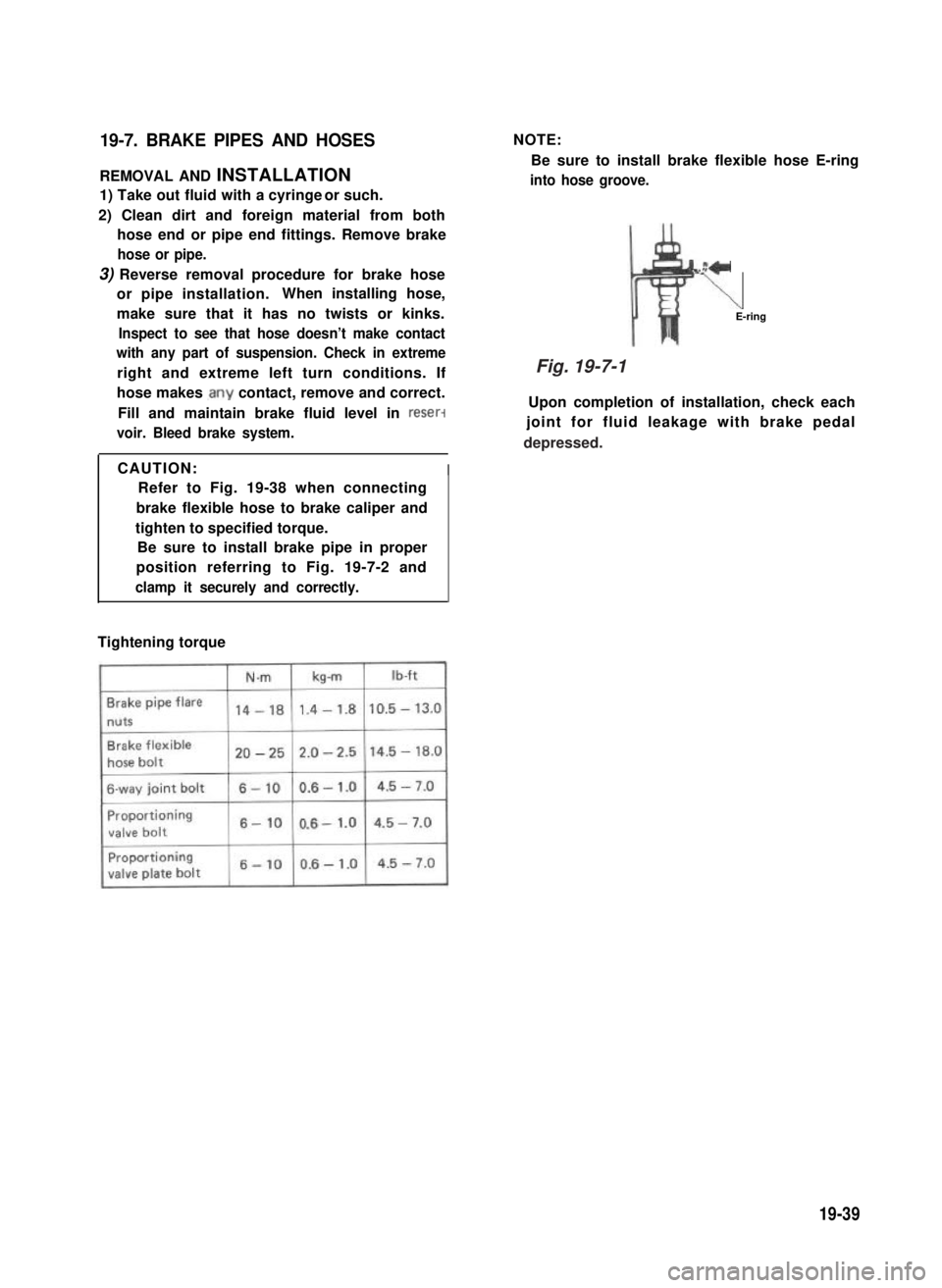

NOTE:

Be sure to install brake flexible hose E-ring

into hose groove.

z+

\E-ring

Upon completion of installation, check each

joint for fluid leakage with brake pedal

CAUTION:I

Refer to Fig. 19-38 when connecting

brake flexible hose to brake caliper and

tighten to specified torque.

Be sure to install brake pipe in proper

position referring to Fig. 19-7-2 and

clamp it securely and correctly.

Tightening torque

19-39

Fig. 19-7-1

depressed.

Page 425 of 962

B-way joint

View from arrow @

From master cylinderFrom master cylinder(Primary side)4(Secondary side)

To P & B valve

To front rightflexible hose

Brake flexible hose and E-ring

Make sure that flexible hose is not twisted when it isinstalled or connected to the pipe.When installing flexible hose to bracket, align 6vertexes of metal fixture on hose with internal anglesof bracket.insert E-ring till Ewing end surface is flush with orlower than bracket end surface. (Refer to p. 19-39.) For installation of flexible hose to brake caliper,refer top. 19-19. Install the flexible hose so that it won’t be kinkedwhen the steering wheel is straightened.After installing the flexible hose, turn the steeringwheel to the right fully and check that the clearancebetween the wheel/tire and flexible hose is largerthan 25 mm (0,984 in) in that state and then checklikewise with the steering wheel turned to the fullleft position. (This is to ensure that more than 25mm (0.984 in) clearance is maintained even whenbumping or rebounding fully).

Clamp

Upper sideA“A”71’/

sre~~To

Tr

Fuel pipe0Body sidebracket

Hitch lug “B” of brake pipe clampto groove “A” of body side bracketand fix clamp to bodv side bracketwith its screw. Secure fuel pipe atthe same time.

Fig. 19-7-2

19-40

P & B valve

Page 426 of 962

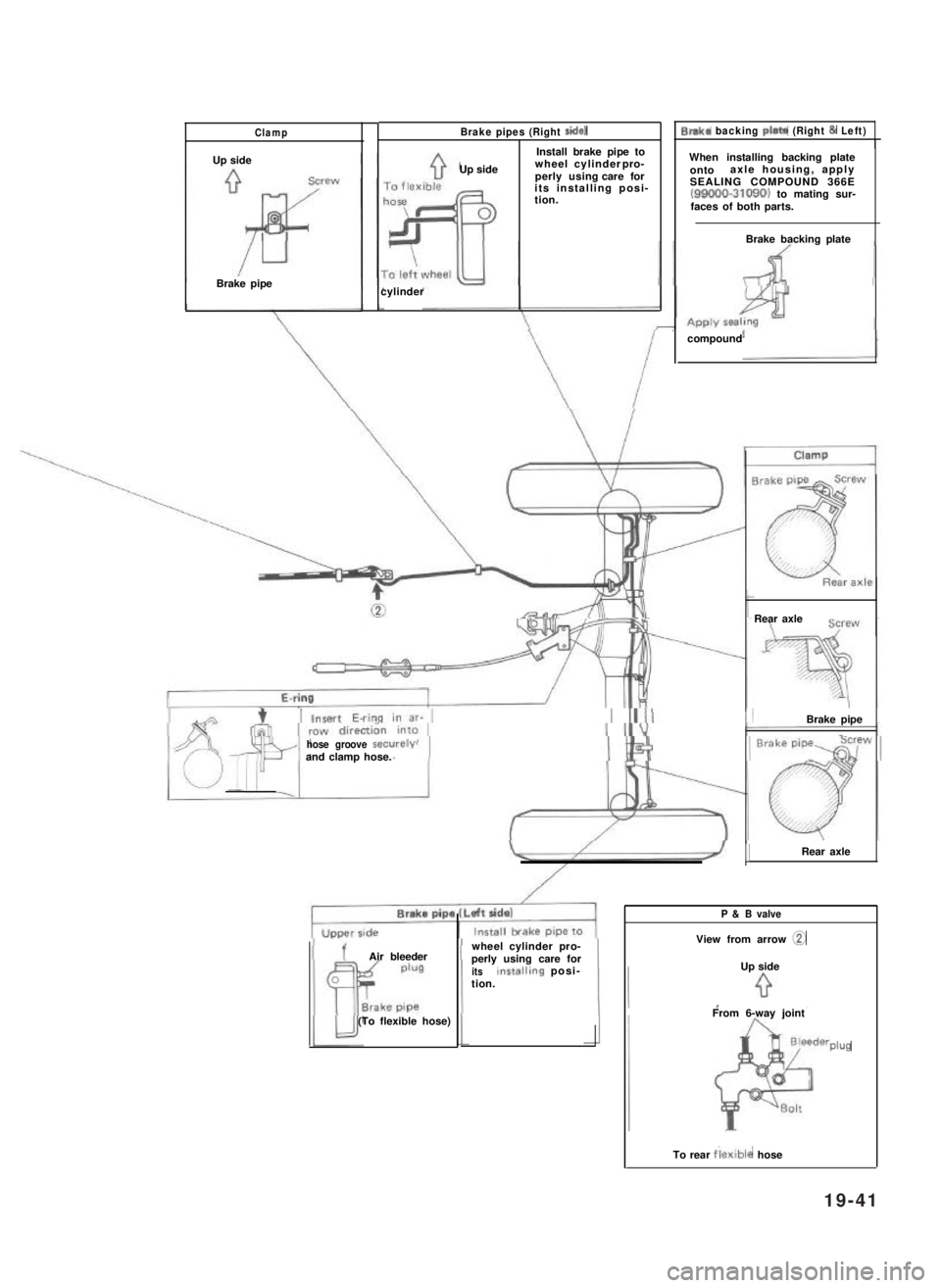

Clamp

Up side

Brake pipe

Brake pipes (Right side)

Install brake pipe to

Up sidewheel cylinder pro-perly using care forits installing posi-tion.

cylinder

Blake backing Plato (Right & Left)

When installing backing plateontoaxle housing, applySEALING COMPOUND 366E(99000-31090) to mating sur-faces of both parts.

Brake backing plate

compound

hose groove securelyand clamp hose.

Air bleeder

(To flexible hose)

wheel cylinder pro-perly using care foritsinstallrng posi-tion.

Rear axle

IBrake pipe

1Rear axle

P & B valve

View from arrow @

Up side

From 6-way joint

Plug

To rear flexible hose

19-41

Page 427 of 962

19-8. MAINTENANCE SERVICE

ROAD TESTING BRAKES

Brakes should be tested on dry, clean, smooth

and reasonably level roadway which is not

crowned. Road test brakes by making brake

applications with both light and heavy pedal

forces at various speeds to determine if the car

stops evenly and effectively.

Also drive car to see if it leads to one side or the

other without brake application. If it does,

check tire pressure, front end alignment and

front suspension attachments for looseness.

See diagnosis chart for other causes.

BRAKE FLUID LEAKS

Check master cylinder fluid levels. While a slight

drop in reservoir level does result from normal

lining wear, an abnormally low level indicates a

leak in the system.In such a case, check the

entire brake system for leakage. If even a slight

evidence of leakage is noted, the cause should be

corrected or defective parts should be replaced.

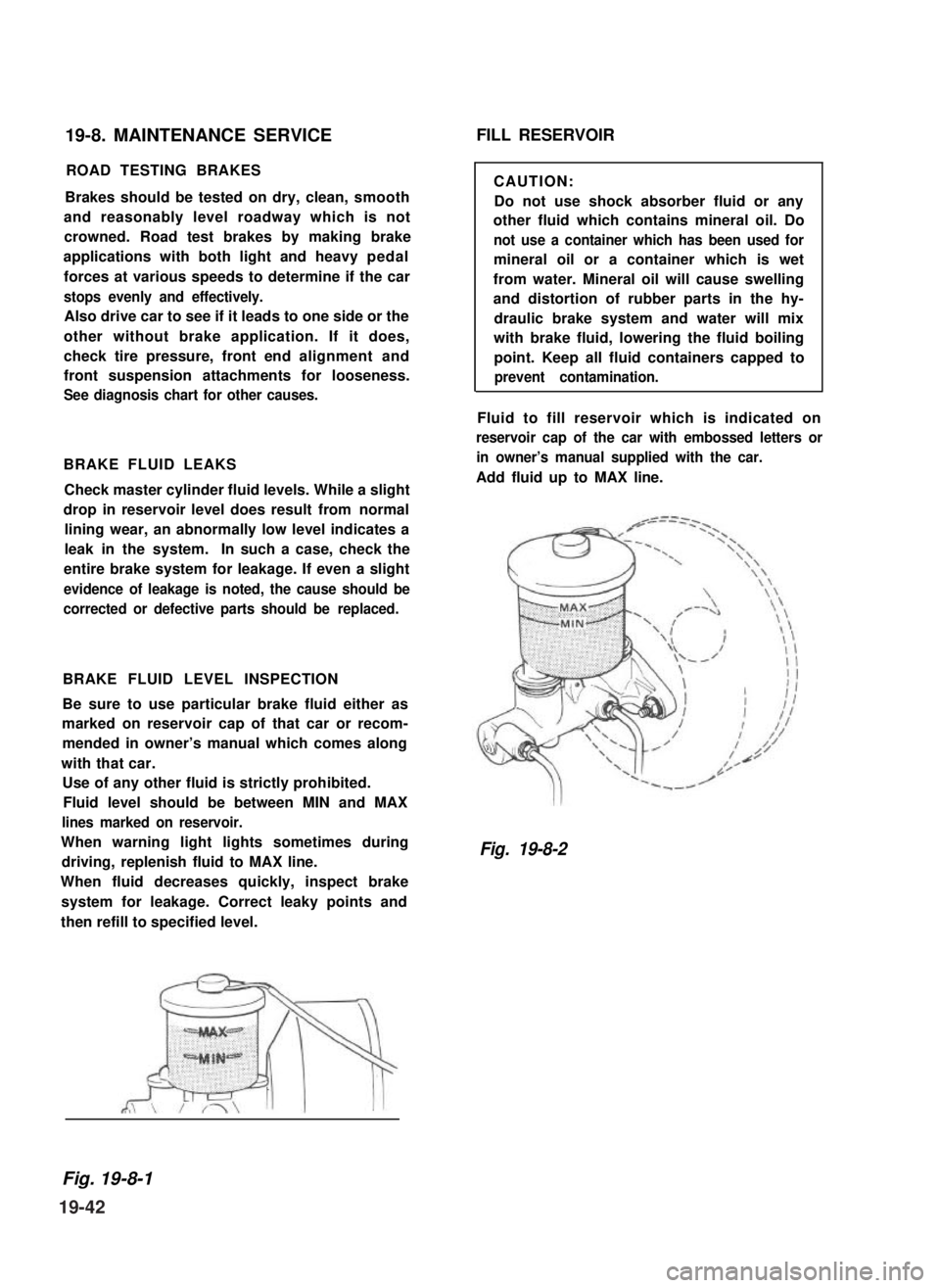

BRAKE FLUID LEVEL INSPECTION

Be sure to use particular brake fluid either as

marked on reservoir cap of that car or recom-

mended in owner’s manual which comes along

with that car.

Use of any other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When warning light lights sometimes during

driving, replenish fluid to MAX line.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

FILL RESERVOIR

CAUTION:

Do not use shock absorber fluid or any

other fluid which contains mineral oil. Do

not use a container which has been used for

mineral oil or a container which is wet

from water. Mineral oil will cause swelling

and distortion of rubber parts in the hy-

draulic brake system and water will mix

with brake fluid, lowering the fluid boiling

point. Keep all fluid containers capped to

prevent contamination.

Fluid to fill reservoir which is indicated on

reservoir cap of the car with embossed letters or

in owner’s manual supplied with the car.

Add fluid up to MAX line.

Fig. 19-8-2

Fig. 19-8-1

19-42

Page 428 of 962

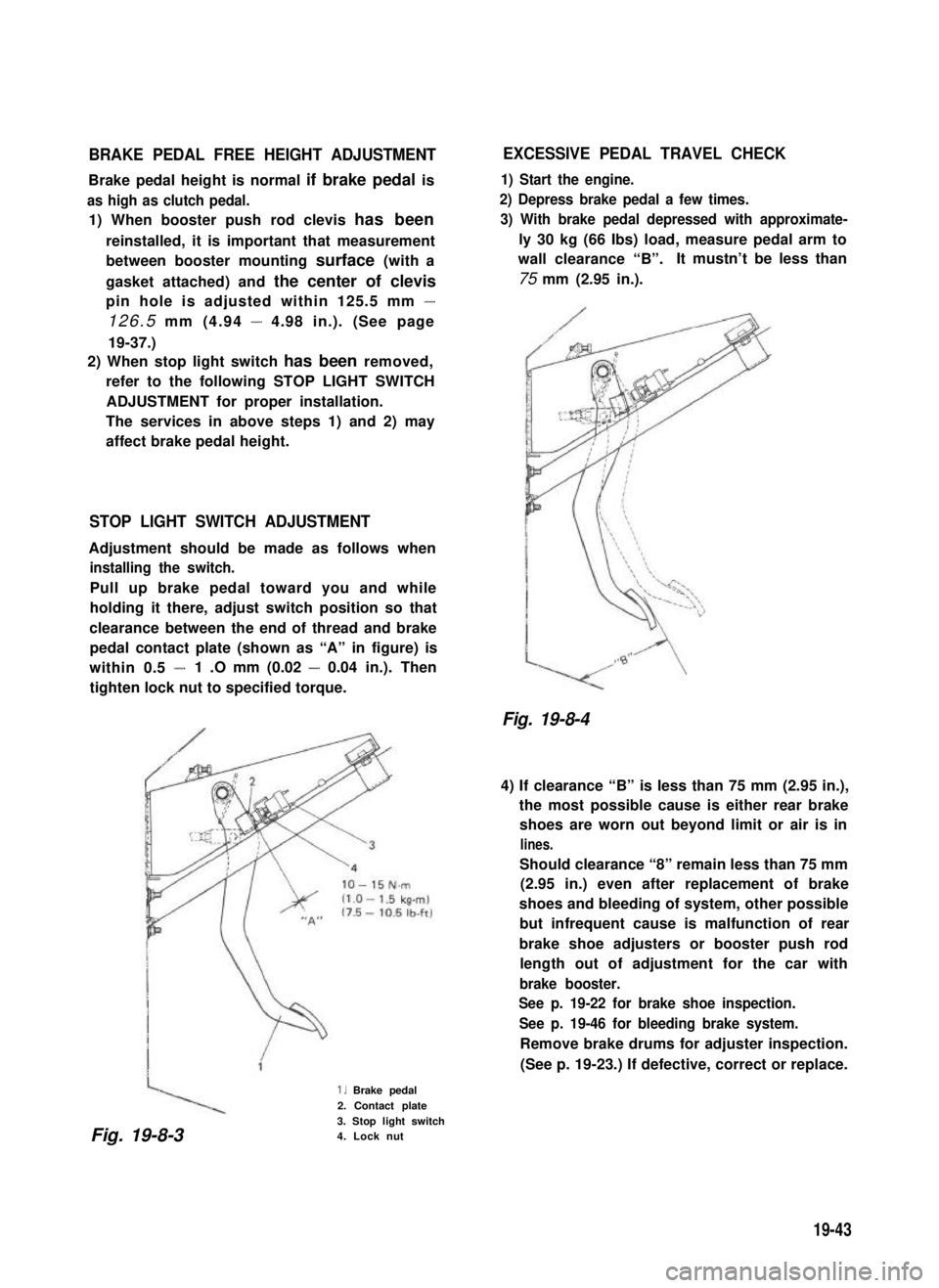

BRAKE PEDAL FREE HEIGHT ADJUSTMENT

Brake pedal height is normal if brake pedal is

as high as clutch pedal.

1) When booster push rod clevis has been

reinstalled, it is important that measurement

between booster mounting surface (with a

gasket attached) and the center of clevis

pin hole is adjusted within 125.5 mm -

126.5 mm (4.94 - 4.98 in.). (See page

19-37.)

2) When stop light switch has been removed,

refer to the following STOP LIGHT SWITCH

ADJUSTMENT for proper installation.

The services in above steps 1) and 2) may

affect brake pedal height.

STOP LIGHT SWITCH ADJUSTMENT

Adjustment should be made as follows when

installing the switch.

Pull up brake pedal toward you and while

holding it there, adjust switch position so that

clearance between the end of thread and brake

pedal contact plate (shown as “A” in figure) is

within 0.5 -1 .O mm (0.02 - 0.04 in.). Then

tighten lock nut to specified torque.

1. Brake pedal

2. Contact plate

3. Stop light switch4. Lock nut

EXCESSIVE PEDAL TRAVEL CHECK

1) Start the engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximate-

ly 30 kg (66 Ibs) load, measure pedal arm to

wall clearance “B”.It mustn’t be less than

75 mm (2.95 in.).

Fig. 19-8-4

4) If clearance “B” is less than 75 mm (2.95 in.),

the most possible cause is either rear brake

shoes are worn out beyond limit or air is in

lines.

Should clearance “8” remain less than 75 mm

(2.95 in.) even after replacement of brake

shoes and bleeding of system, other possible

but infrequent cause is malfunction of rear

brake shoe adjusters or booster push rod

length out of adjustment for the car with

brake booster.

See p. 19-22 for brake shoe inspection.

See p. 19-46 for bleeding brake system.

Remove brake drums for adjuster inspection.

(See p. 19-23.) If defective, correct or replace.

Fig. 19-8-3

19-43

Page 429 of 962

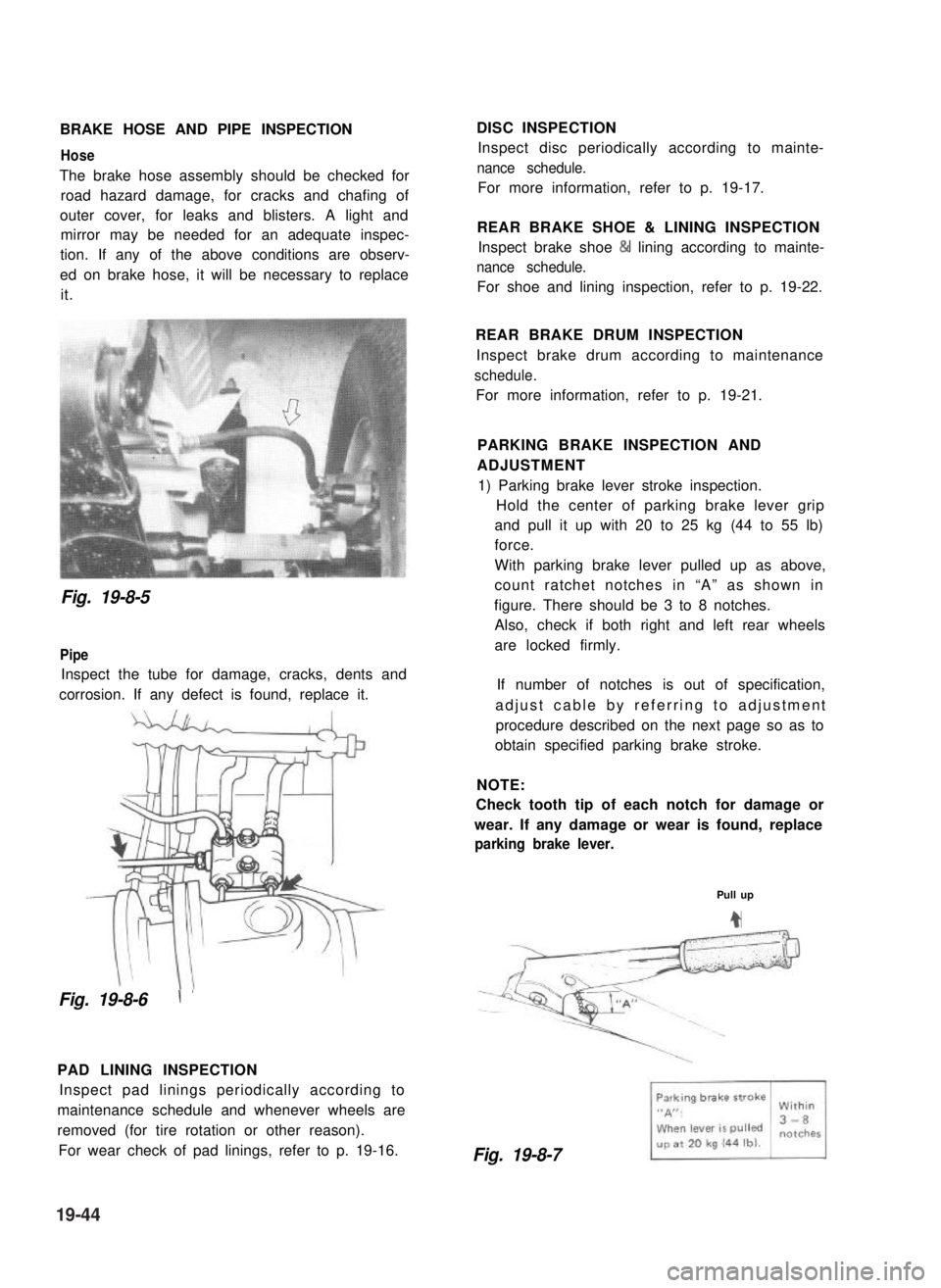

BRAKE HOSE AND PIPE INSPECTION

Hose

The brake hose assembly should be checked for

road hazard damage, for cracks and chafing of

outer cover, for leaks and blisters. A light and

mirror may be needed for an adequate inspec-

tion. If any of the above conditions are observ-

ed on brake hose, it will be necessary to replace

it.

DISC INSPECTION

Inspect disc periodically according to mainte-

nance schedule.

For more information, refer to p. 19-17.

REAR BRAKE SHOE & LINING INSPECTION

Inspect brake shoe & lining according to mainte-

nance schedule.

For shoe and lining inspection, refer to p. 19-22.

Fig. 19-8-5

Pipe

Inspect the tube for damage, cracks, dents and

corrosion. If any defect is found, replace it.

Fig. 19-8-6\ ’

PAD LINING INSPECTION

Inspect pad linings periodically according to

maintenance schedule and whenever wheels are

removed (for tire rotation or other reason).

For wear check of pad linings, refer to p. 19-16.

REAR BRAKE DRUM INSPECTION

Inspect brake drum according to maintenance

schedule.

For more information, refer to p. 19-21.

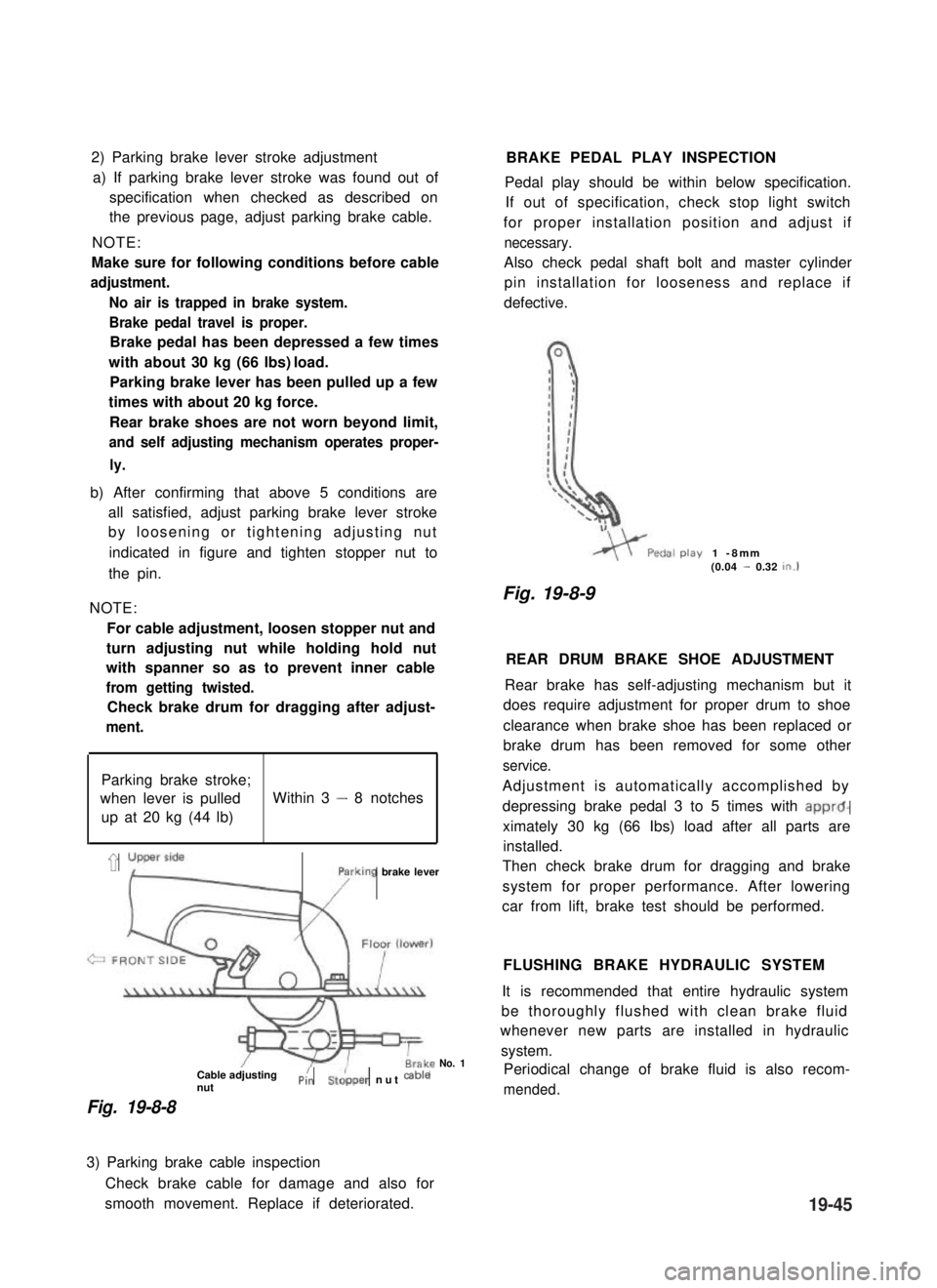

PARKING BRAKE INSPECTION AND

ADJUSTMENT

1) Parking brake lever stroke inspection.

Hold the center of parking brake lever grip

and pull it up with 20 to 25 kg (44 to 55 lb)

force.

With parking brake lever pulled up as above,

count ratchet notches in “A” as shown in

figure. There should be 3 to 8 notches.

Also, check if both right and left rear wheels

are locked firmly.

If number of notches is out of specification,

adjust cable by referring to adjustment

procedure described on the next page so as to

obtain specified parking brake stroke.

NOTE:

Check tooth tip of each notch for damage or

wear. If any damage or wear is found, replace

parking brake lever.

Pull up

4

Fig. 19-8-7

19-44

Page 430 of 962

2) Parking brake lever stroke adjustment

a) If parking brake lever stroke was found out of

specification when checked as described on

the previous page, adjust parking brake cable.

NOTE:

Make sure for following conditions before cable

adjustment.

No air is trapped in brake system.

Brake pedal travel is proper.

Brake pedal has been depressed a few times

with about 30 kg (66 lbs) load.

Parking brake lever has been pulled up a few

times with about 20 kg force.

Rear brake shoes are not worn beyond limit,

and self adjusting mechanism operates proper-

ly.

b) After confirming that above 5 conditions are

all satisfied, adjust parking brake lever stroke

by loosening or tightening adjusting nut

indicated in figure and tighten stopper nut to

the pin.

NOTE:

For cable adjustment, loosen stopper nut and

turn adjusting nut while holding hold nut

with spanner so as to prevent inner cable

from getting twisted.

Check brake drum for dragging after adjust-

ment.

Parking brake stroke;

when lever is pulledWithin 3 - 8 notches

up at 20 kg (44 lb)

’ yLyFrking brake lever

Cable adjustingnutPi:St&per nut cab’e

Fig. 19-8-8

No. 1

BRAKE PEDAL PLAY INSPECTION

Pedal play should be within below specification.

If out of specification, check stop light switch

for proper installation position and adjust if

necessary.

Also check pedal shaft bolt and master cylinder

pin installation for looseness and replace if

defective.

play1 -8mm(0.04 - 0.32tn.1

Fig. 19-8-9

REAR DRUM BRAKE SHOE ADJUSTMENT

Rear brake has self-adjusting mechanism but it

does require adjustment for proper drum to shoe

clearance when brake shoe has been replaced or

brake drum has been removed for some other

service.

Adjustment is automatically accomplished by

depressing brake pedal 3 to 5 times with apprd-

ximately 30 kg (66 Ibs) load after all parts are

installed.

Then check brake drum for dragging and brake

system for proper performance. After lowering

car from lift, brake test should be performed.

FLUSHING BRAKE HYDRAULIC SYSTEM

It is recommended that entire hydraulic system

be thoroughly flushed with clean brake fluid

whenever new parts are installed in hydraulic

system.

Periodical change of brake fluid is also recom-

mended.

3) Parking brake cable inspection

Check brake cable for damage and also for

smooth movement. Replace if deteriorated.19-45