SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 411 of 962

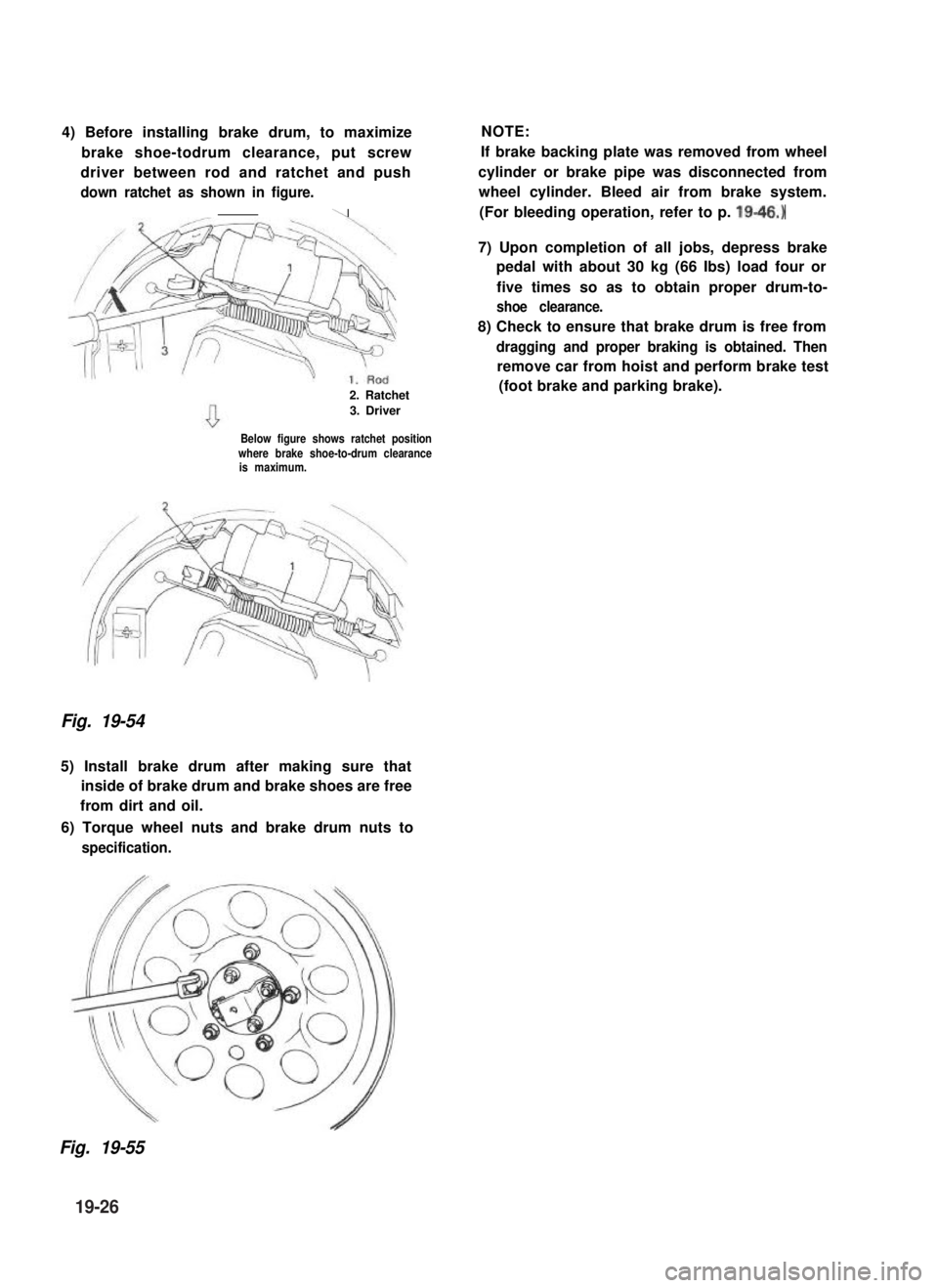

4) Before installing brake drum, to maximize

brake shoe-todrum clearance, put screw

driver between rod and ratchet and push

down ratchet as shown in figure.

\

2. Ratchet

3. Driver

Below figure shows ratchet positionwhere brake shoe-to-drum clearanceis maximum.

Fig. 19-54

5) Install brake drum after making sure that

inside of brake drum and brake shoes are free

from dirt and oil.

6) Torque wheel nuts and brake drum nuts to

specification.

NOTE:

If brake backing plate was removed from wheel

cylinder or brake pipe was disconnected from

wheel cylinder. Bleed air from brake system.

(For bleeding operation, refer to p. 19-46.)

7) Upon completion of all jobs, depress brake

pedal with about 30 kg (66 Ibs) load four or

five times so as to obtain proper drum-to-

shoe clearance.

8) Check to ensure that brake drum is free from

dragging and proper braking is obtained. Then

remove car from hoist and perform brake test

(foot brake and parking brake).

Fig. 19-55

19-26

Page 412 of 962

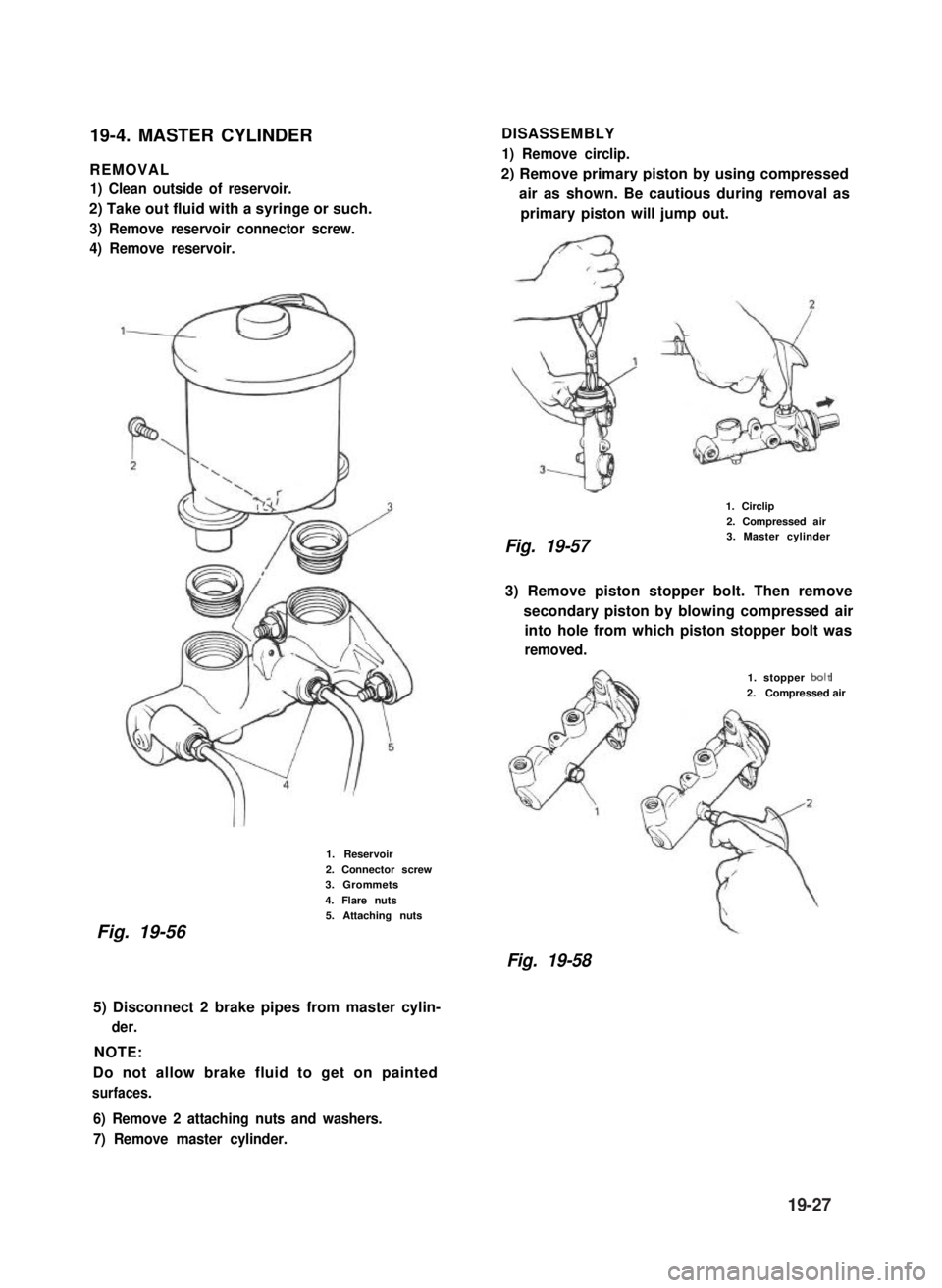

19-4. MASTER CYLINDER

REMOVAL

1) Clean outside of reservoir.

2) Take out fluid with a syringe or such.

3) Remove reservoir connector screw.

4) Remove reservoir.

1. Reservoir

2. Connector screw3. Grommets

4. Flare nuts

5. Attaching nuts

Fig. 19-56

5) Disconnect 2 brake pipes from master cylin-

der.

NOTE:

Do not allow brake fluid to get on painted

surfaces.

6) Remove 2 attaching nuts and washers.

7) Remove master cylinder.

DISASSEMBLY

1) Remove circlip.

2) Remove primary piston by using compressed

air as shown. Be cautious during removal as

primary piston will jump out.

Fig. 19-57

2. Compressed air3. Master cylinder

3) Remove piston stopper bolt. Then remove

secondary piston by blowing compressed air

into hole from which piston stopper bolt was

removed.

1. stopper bolt

2.Compressed air

Fig. 19-58

1. Circlip

19-27

Page 413 of 962

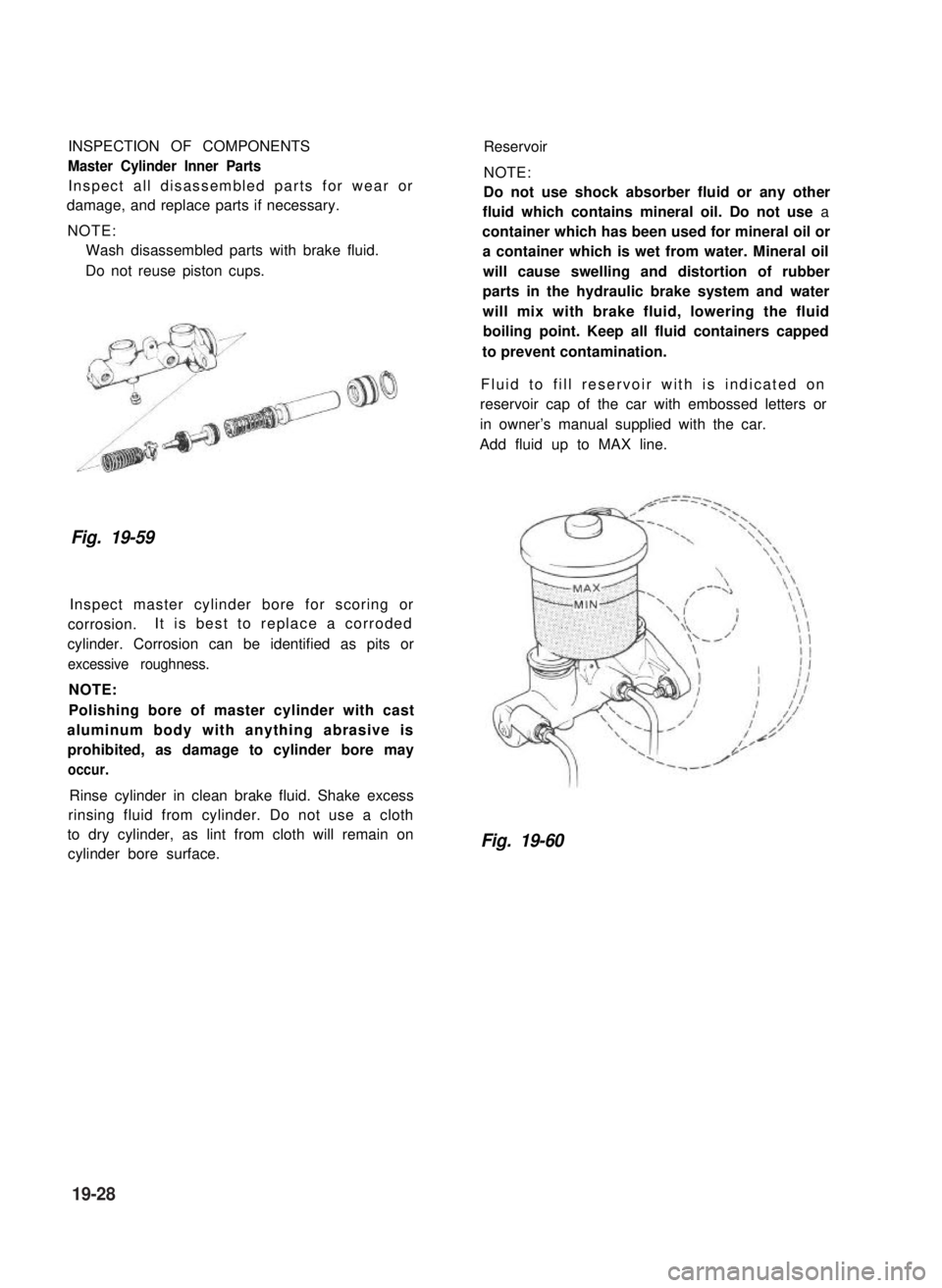

INSPECTION OF COMPONENTS

Master Cylinder Inner Parts

Inspect all disassembled parts for wear or

damage, and replace parts if necessary.

NOTE:

Wash disassembled parts with brake fluid.

Do not reuse piston cups.

Reservoir

NOTE:

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil or

a container which is wet from water. Mineral oil

will cause swelling and distortion of rubber

parts in the hydraulic brake system and water

will mix with brake fluid, lowering the fluid

boiling point. Keep all fluid containers capped

to prevent contamination.

Fluid to fill reservoir with is indicated on

reservoir cap of the car with embossed letters or

in owner’s manual supplied with the car.

Add fluid up to MAX line.

Fig. 19-59

Inspect master cylinder bore for scoring or

corrosion.It is best to replace a corroded

cylinder. Corrosion can be identified as pits or

excessive roughness.

NOTE:

Polishing bore of master cylinder with cast

aluminum body with anything abrasive is

prohibited, as damage to cylinder bore may

occur.

Rinse cylinder in clean brake fluid. Shake excess

rinsing fluid from cylinder. Do not use a cloth

to dry cylinder, as lint from cloth will remain on

cylinder bore surface.Fig. 19-60

19-28

Page 414 of 962

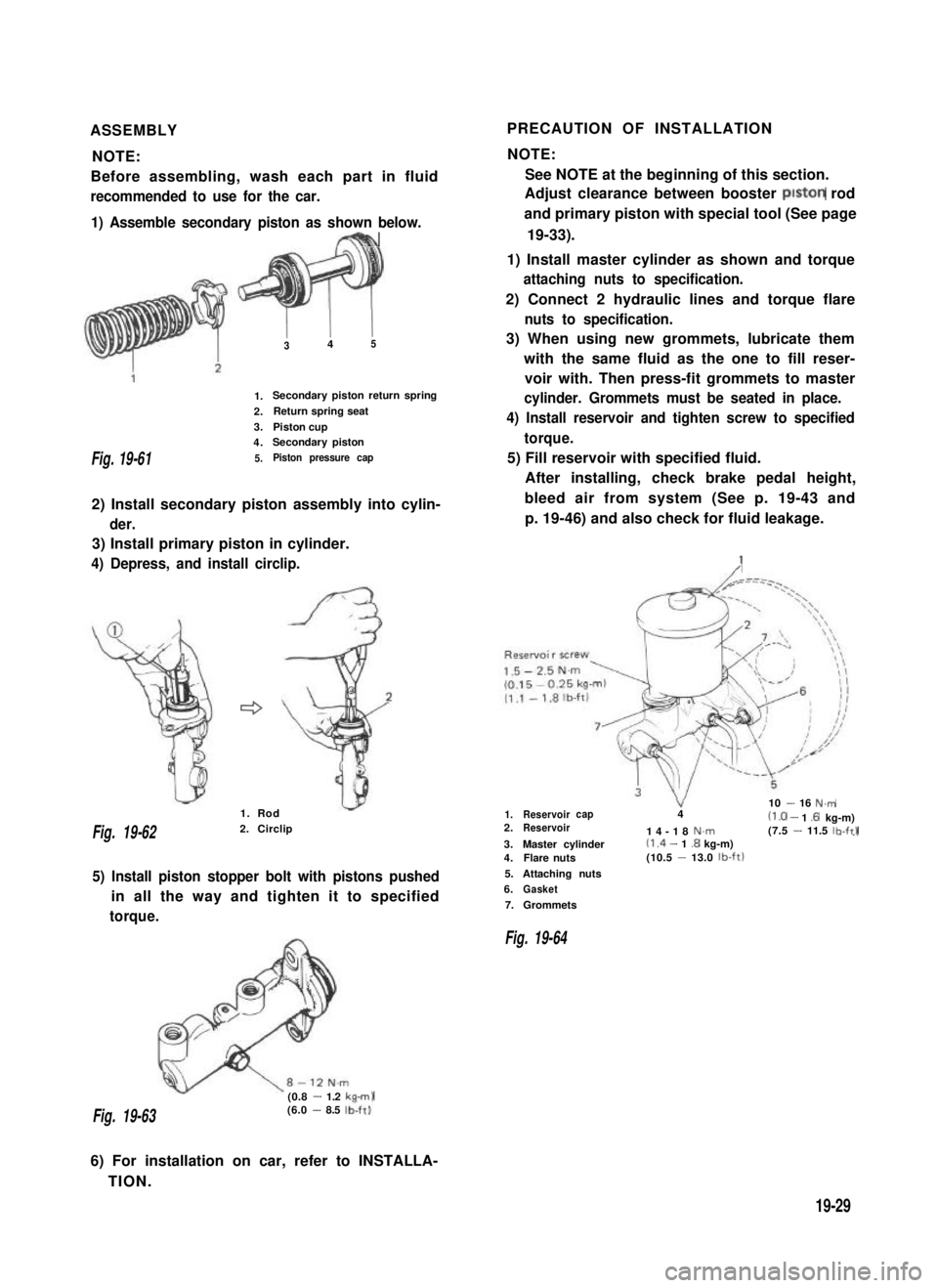

ASSEMBLYPRECAUTION OF INSTALLATION

NOTE:NOTE:

Before assembling, wash each part in fluidSee NOTE at the beginning of this section.

recommended to use for the car.Adjust clearance between booster piston rod

1) Assemble secondary piston as shown below.

FBh

and primary piston with special tool (See page

19-33).

Fig. 19-61

1) Install master cylinder as shown and torque

attaching nuts to specification.

2) Connect 2 hydraulic lines and torque flare

1.

2.

3.

4.

5.

I I345

Secondary piston return spring

Return spring seat

Piston cupSecondary piston

Piston pressure cap

2) Install secondary piston assembly into cylin-

der.

3) Install primary piston in cylinder.

4) Depress, and install circlip.

nuts to specification.

3) When using new grommets, lubricate them

with the same fluid as the one to fill reser-

voir with. Then press-fit grommets to master

cylinder. Grommets must be seated in place.

4) Install reservoir and tighten screw to specified

torque.

5) Fill reservoir with specified fluid.

After installing, check brake pedal height,

bleed air from system (See p. 19-43 and

p. 19-46) and also check for fluid leakage.

:

Fig. 19-622. Circlip

1. Rod

5) Install piston stopper bolt with pistons pushed

in all the way and tighten it to specified

torque.

(0.8 - 1.2 kam)

1.Reservoir10 - 16 N.mcap42.Reservoir(1 .O - 1 .6 kg-m)14-18N.m(7.5 - 11.5 lb-ftl--I3.Master cylinder(1 .4 - 1.8 kg-m)4.Flare nuts(10.5 -13.0 lb-ft)

5.Attaching nuts

6.Gasket

7.Grommets

Fig. 19-64

Fig. 19-63(6.0 - 8.5 lb-ft).

6) For installation on car, refer to INSTALLA-

TION.

19-29

Page 415 of 962

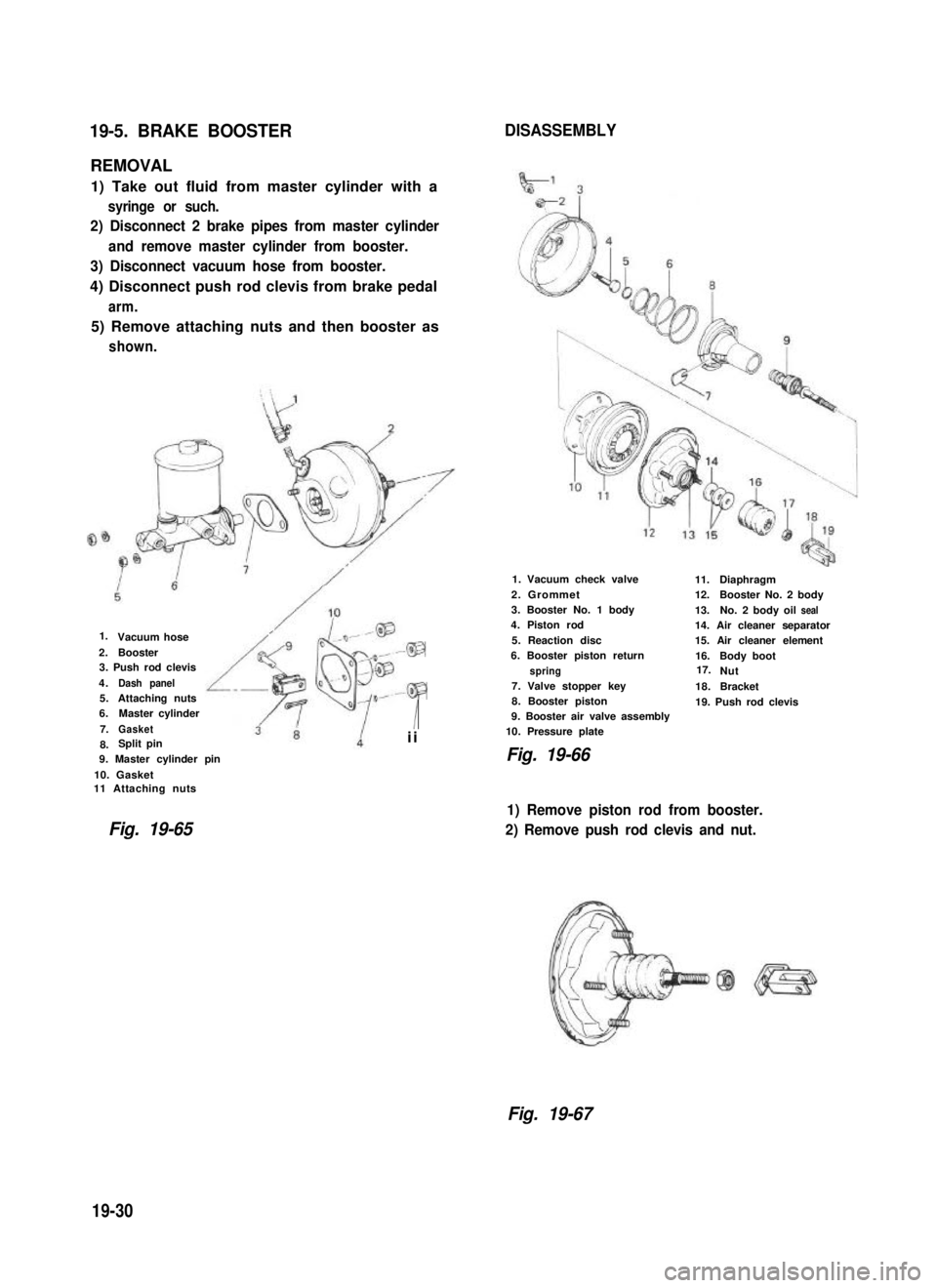

19-5. BRAKE BOOSTERDISASSEMBLY

REMOVAL

1) Take out fluid from master cylinder with a

syringe or such.

2) Disconnect 2 brake pipes from master cylinder

and remove master cylinder from booster.

3) Disconnect vacuum hose from booster.

4) Disconnect push rod clevis from brake pedal

arm.

5) Remove attaching nuts and then booster as

shown.

Vacuum hose

2.Booster3. Push rod clevis

4.Dash panel5.Attaching nuts6.Master cylinder

7.Gasket

8. Split pin

9. Master cylinder pin

10. Gasket11 Attaching nuts

Fig. 19-65

49

-@P

Iii

1. Vacuum check valve

2. Grommet3. Booster No. 1 body4. Piston rod

5. Reaction disc6. Booster piston return

spring7. Valve stopper key8. Booster piston9. Booster air valve assembly10. Pressure plate

Fig. 19-66

11.Diaphragm12.Booster No. 2body

13.No. 2 body oilseal14. Air cleaner separator15. Air cleaner element

16.Body bootNut

18.Bracket

19. Push rod clevis

1) Remove piston rod from booster.

2) Remove push rod clevis and nut.

Fig. 19-67

19-30

1.

17.

Page 416 of 962

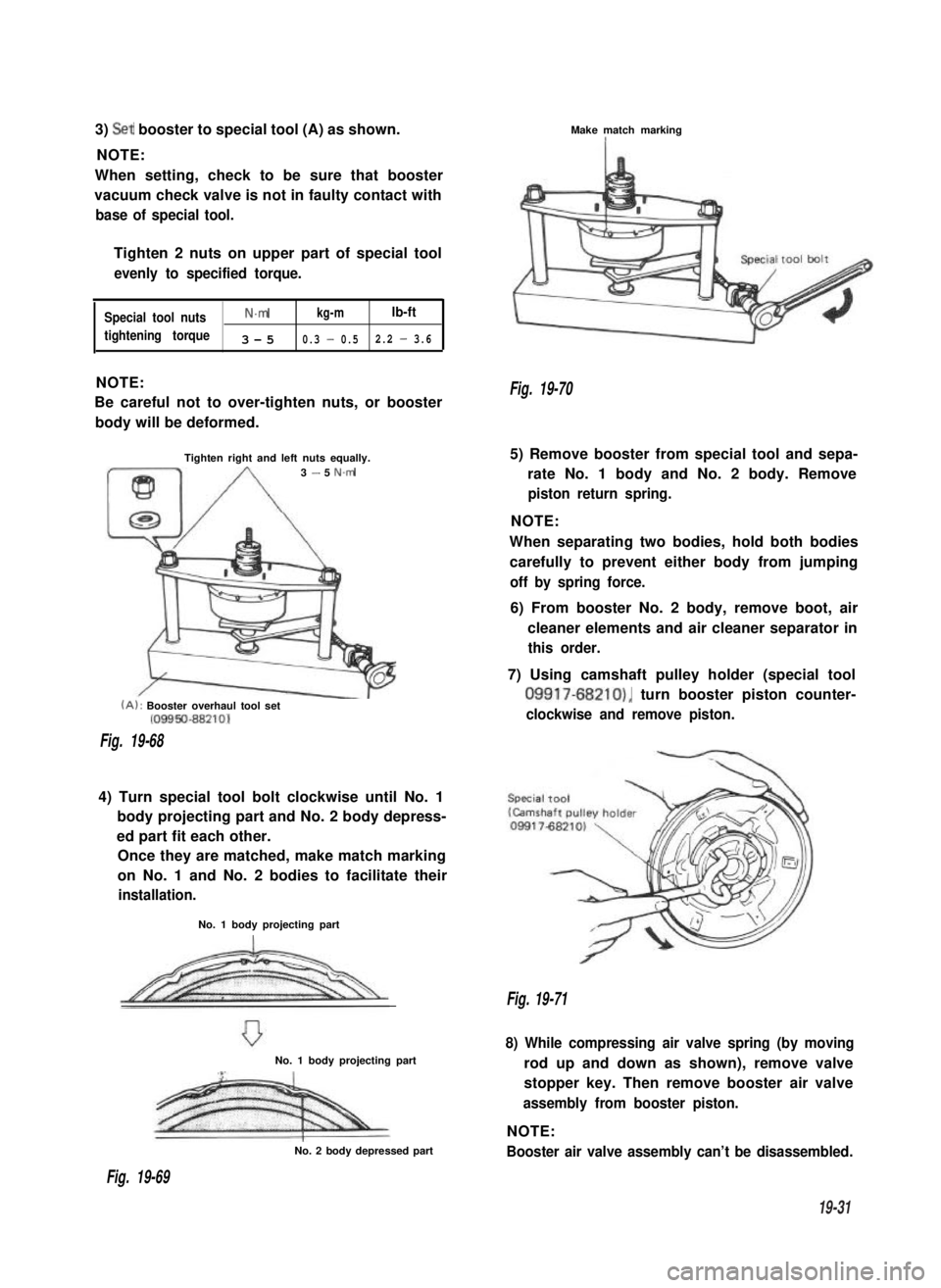

3) Set booster to special tool (A) as shown.

NOTE:

When setting, check to be sure that booster

vacuum check valve is not in faulty contact with

base of special tool.

Tighten 2 nuts on upper part of special tool

evenly to specified torque.

Special tool nutsN.mkg-mlb-ft

tightening torque3-50.3 - 0.52.2 - 3.6

NOTE:

Be careful not to over-tighten nuts, or booster

body will be deformed.

Tighten right and left nuts equally.3 - 5 N.m

(A): Booster overhaul tool set(09950-88210)

Fig. 19-68

4) Turn special tool bolt clockwise until No. 1

body projecting part and No. 2 body depress-

ed part fit each other.

Once they are matched, make match marking

on No. 1 and No. 2 bodies to facilitate their

installation.

No. 1 body projecting part

No. 1 body projecting part

No. 2 body depressed part

Make match markingI

Fig. 19-70

5) Remove booster from special tool and sepa-

rate No. 1 body and No. 2 body. Remove

piston return spring.

NOTE:

When separating two bodies, hold both bodies

carefully to prevent either body from jumping

off by spring force.

6) From booster No. 2 body, remove boot, air

cleaner elements and air cleaner separator in

this order.

7) Using camshaft pulley holder (special tool

09917-68210), turn booster piston counter-

clockwise and remove piston.

Fig. 19-71

8) While compressing air valve spring (by moving

rod up and down as shown), remove valve

stopper key. Then remove booster air valve

assembly from booster piston.

NOTE:

Booster air valve assembly can’t be disassembled.

Fig. 19-69

19-31

Page 417 of 962

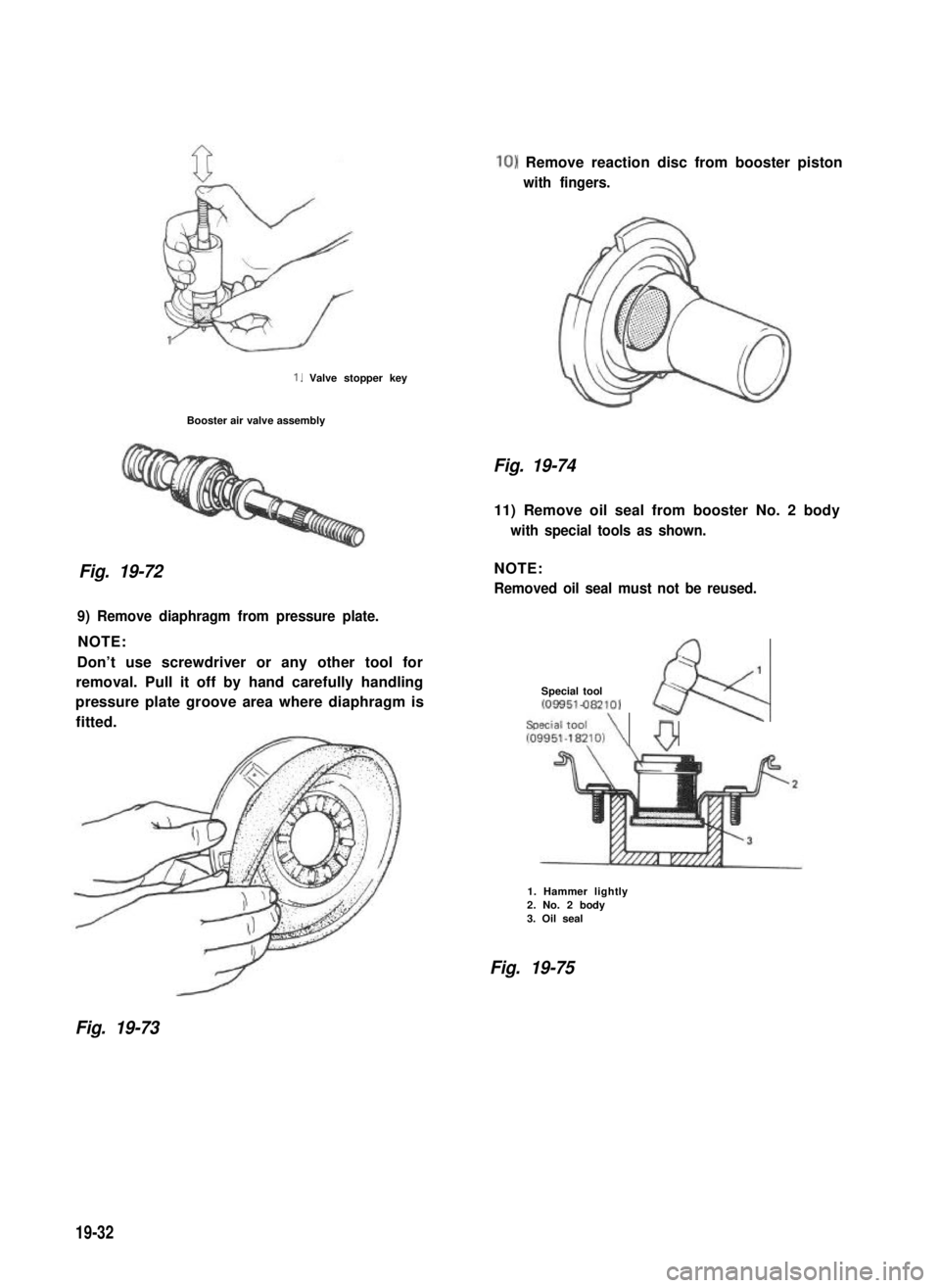

1. Valve stopper key

Booster air valve assembly

Fig. 19-72

10) Remove reaction disc from booster piston

with fingers.

Fig. 19-74

11) Remove oil seal from booster No. 2 body

with special tools as shown.

NOTE:

Removed oil seal must not be reused.

;1

Special tool~09951-082101

Special toolk

109951~W~lO,\ 0

9) Remove diaphragm from pressure plate.

NOTE:

Don’t use screwdriver or any other tool for

removal. Pull it off by hand carefully handling

pressure plate groove area where diaphragm is

fitted.

1. Hammer lightly2. No. 2 body3. Oil seal

Fig. 19-75

Fig. 19-73

19-32

Page 418 of 962

INSPECTION

Inner Parts

NOTE:

After disassembly, soak all metal parts in ethyl

alcohol. Wipe rubber diaphragm and plastic parts

with a clean cloth. Use ethyl alcohol damped

cloth to wipe out heavy dirt Application of

much ethyl alcohol especially to rubber parts is

prohibited.

[ Rubber parts]

Wipe fluid from rubber parts and carefully

inspect each rubber part for cuts, nicks or other

damage. These parts are the key to the control

of air flow. If there is any question as to the

serviceability of rubber parts, REPLACE them.

[Metal parts]

BADLY DAMAGED ITEMS, OR THOSE

WHICH WOULD TAKE EXTENSIVE WORK

OR TIME TO REPAIR, SHOULD BE REPLAC-

ED. IN CASE OF DOUBT, INSTALL NEW

PARTS.

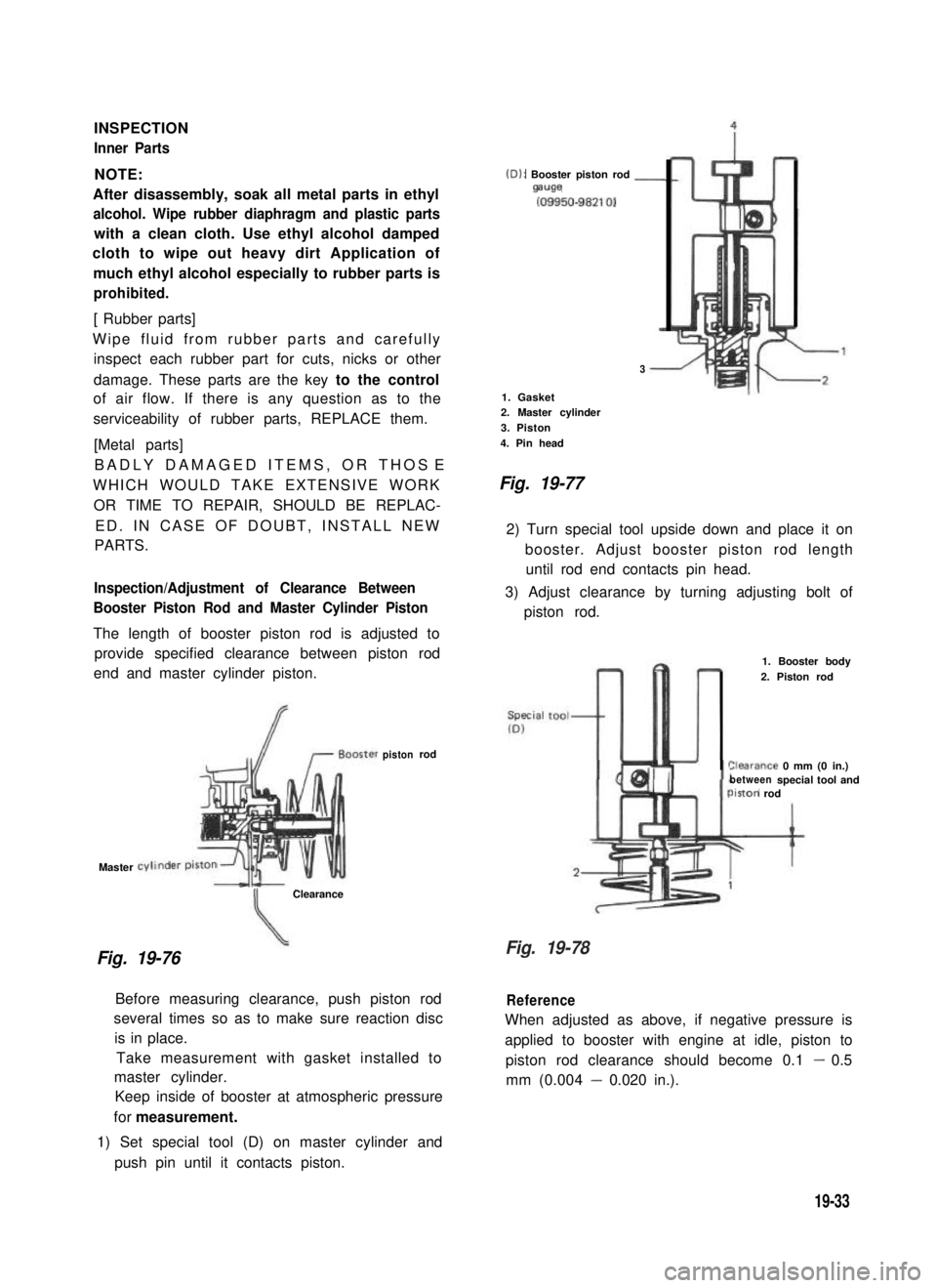

Inspection/Adjustment of Clearance Between

Booster Piston Rod and Master Cylinder Piston

The length of booster piston rod is adjusted to

provide specified clearance between piston rod

end and master cylinder piston.

Master

Fig. 19-76

Clearance

(D): Booster piston rod -mwe

(09950-98210)

3

1. Gasket2. Master cylinder

3. Piston

4. Pin head

Fig. 19-77

2) Turn special tool upside down and place it on

booster. Adjust booster piston rod length

until rod end contacts pin head.

3) Adjust clearance by turning adjusting bolt of

piston rod.

pistonrod

Before measuring clearance, push piston rod

several times so as to make sure reaction disc

is in place.

Take measurement with gasket installed to

master cylinder.

Keep inside of booster at atmospheric pressure

for measurement.

1) Set special tool (D) on master cylinder and

push pin until it contacts piston.

1. Booster body

2. Piston rod

%arance 0 mm (0 in.)betweenspecial tool andiston rod

Reference

When adjusted as above, if negative pressure is

applied to booster with engine at idle, piston to

piston rod clearance should become 0.1 - 0.5

mm (0.004 - 0.020 in.).

19-33

Fig. 19-78

Page 419 of 962

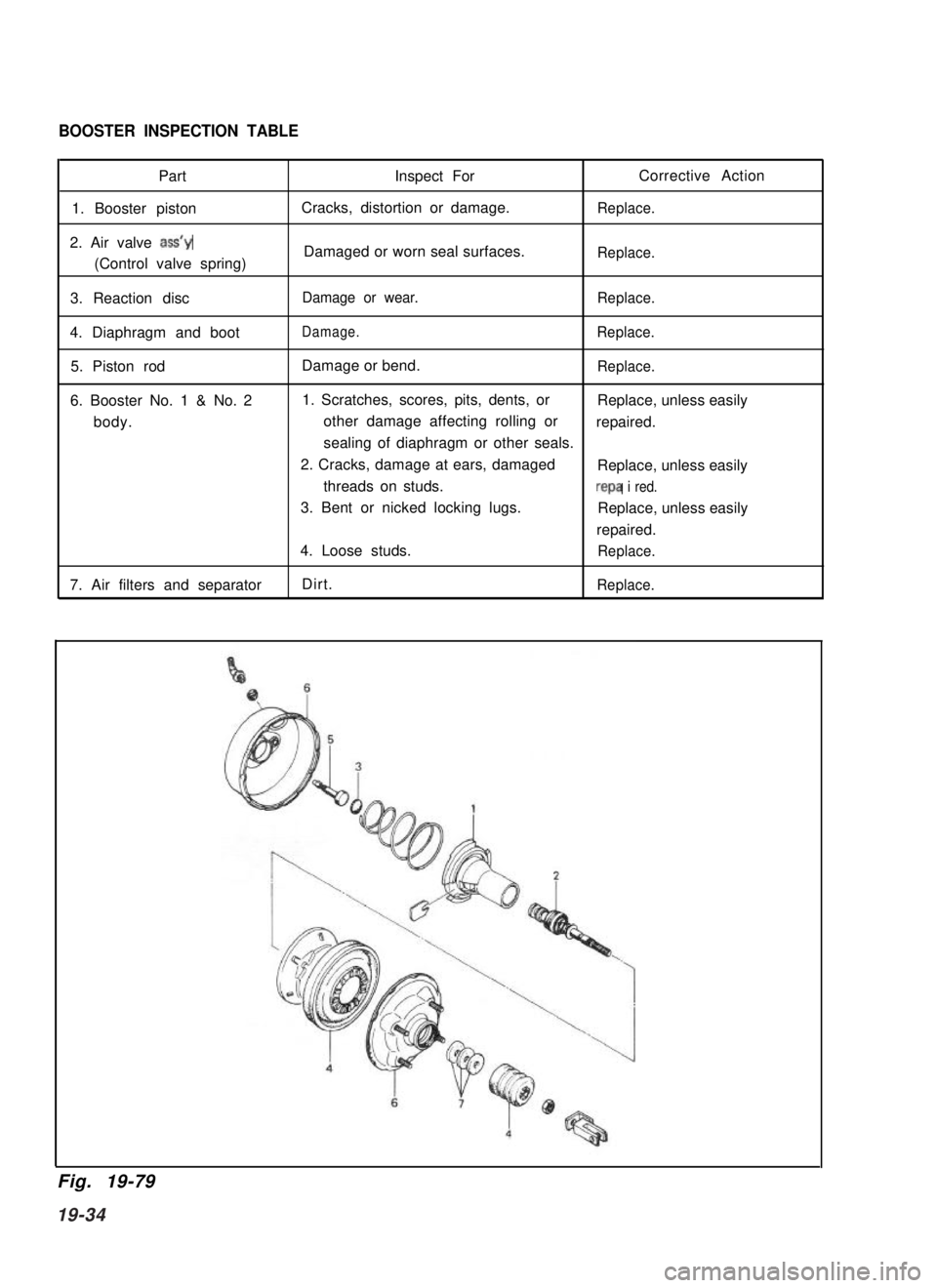

BOOSTER INSPECTION TABLE

Part

1. Booster piston

2. Air valve ass’y

(Control valve spring)

3. Reaction disc

4. Diaphragm and boot

5. Piston rod

6. Booster No. 1 & No. 2

body.

7. Air filters and separator

Inspect ForCorrective Action

Cracks, distortion or damage.Replace.

Damaged or worn seal surfaces.Replace.

Damage or wear.Replace.

Damage.Replace.

Damage or bend.Replace.

1. Scratches, scores, pits, dents, orReplace, unless easily

other damage affecting rolling orrepaired.

sealing of diaphragm or other seals.

2. Cracks, damage at ears, damagedReplace, unless easily

threads on studs.repa i red.

3. Bent or nicked locking lugs.Replace, unless easily

repaired.

4. Loose studs.Replace.

Dirt.Replace.

Fig. 19-79

19-34

Page 420 of 962

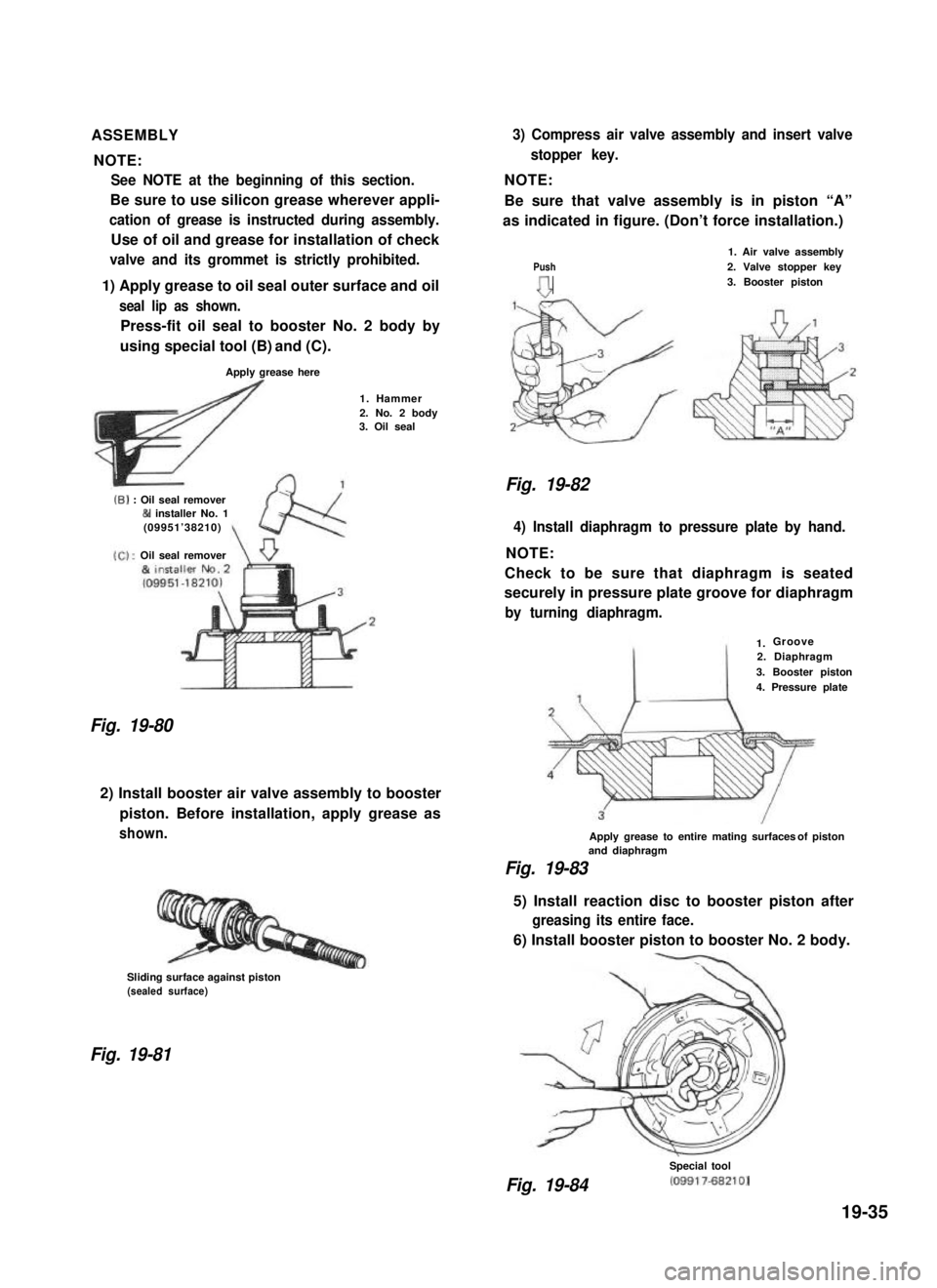

ASSEMBLY

NOTE:

See NOTE at the beginning of this section.

Be sure to use silicon grease wherever appli-

cation of grease is instructed during assembly.

Use of oil and grease for installation of check

valve and its grommet is strictly prohibited.

1) Apply grease to oil seal outer surface and oil

seal lip as shown.

Press-fit oil seal to booster No. 2 body by

using special tool (B) and (C).

Apply grease here

1. Hammer2. No. 2 body3. Oil seal

(6) : Oil seal remover& installer No. 1(09951’38210)

Oil seal remover

Fig. 19-80

2) Install booster air valve assembly to booster

piston. Before installation, apply grease as

shown.

Sliding surface against piston(sealed surface)

Fig. 19-81

3) Compress air valve assembly and insert valve

stopper key.

NOTE:

Be sure that valve assembly is in piston “A”

as indicated in figure. (Don’t force installation.)

Push

n

1. Air valve assembly2. Valve stopper key3. Booster piston

Fig. 19-82

4) Install diaphragm to pressure plate by hand.

NOTE:

Check to be sure that diaphragm is seated

securely in pressure plate groove for diaphragm

by turning diaphragm.

Groove2. Diaphragm

3. Booster piston4. Pressure plate

Apply grease to entire mating surfacesof pistonand diaphragm

Fig. 19-83

5) Install reaction disc to booster piston after

greasing its entire face.

6) Install booster piston to booster No. 2 body.

Fig. 19-84

Special tool

(09917-682101

19-35

1.