Lock SUZUKI GRAND VITARA 2001 2.G Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 464 of 656

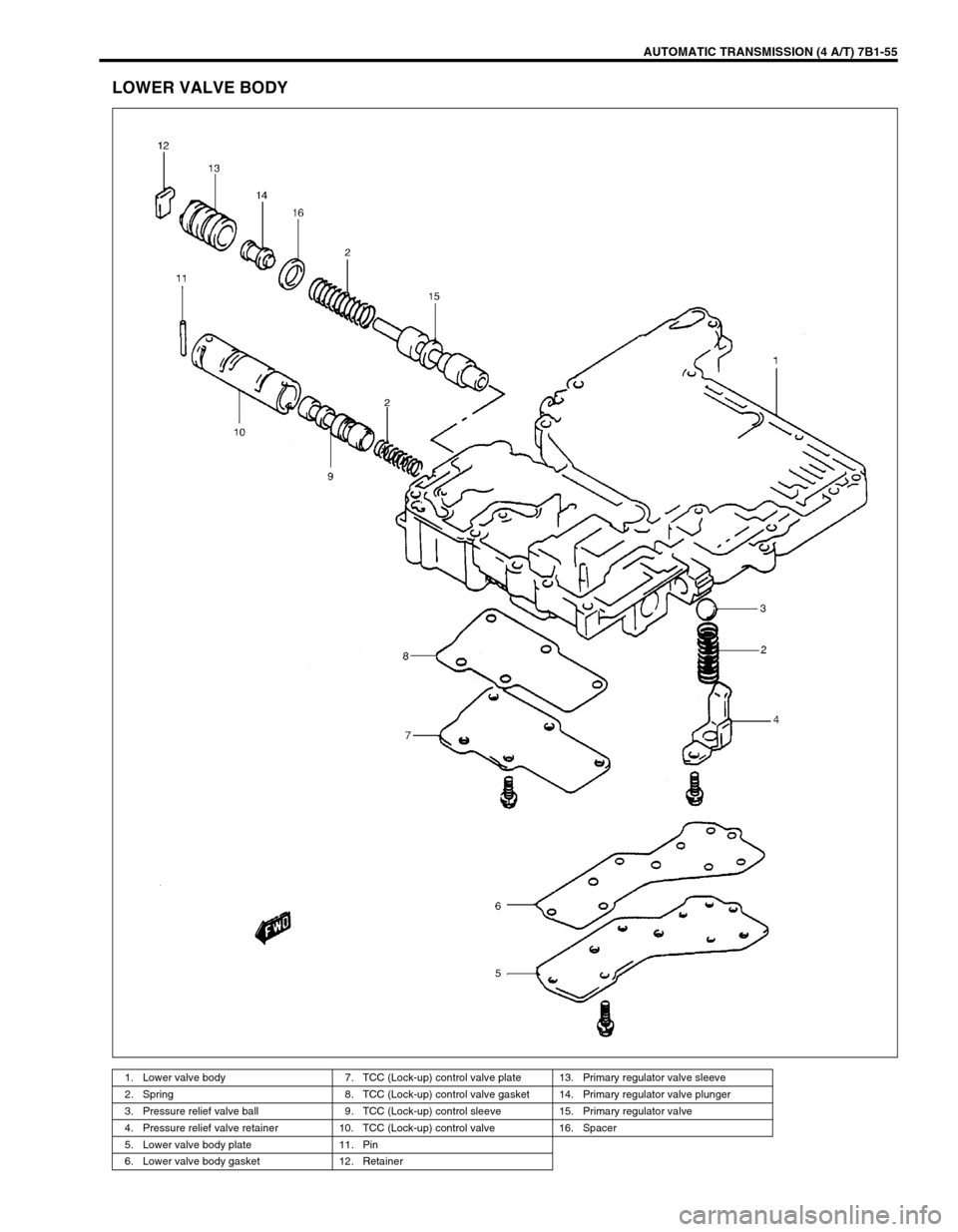

AUTOMATIC TRANSMISSION (4 A/T) 7B1-55

LOWER VALVE BODY

1. Lower valve body 7. TCC (Lock-up) control valve plate 13. Primary regulator valve sleeve

2. Spring 8. TCC (Lock-up) control valve gasket 14. Primary regulator valve plunger

3. Pressure relief valve ball 9. TCC (Lock-up) control sleeve 15. Primary regulator valve

4. Pressure relief valve retainer 10. TCC (Lock-up) control valve 16. Spacer

5. Lower valve body plate 11. Pin

6. Lower valve body gasket 12. Retainer

Page 465 of 656

7B1-56 AUTOMATIC TRANSMISSION (4 A/T)

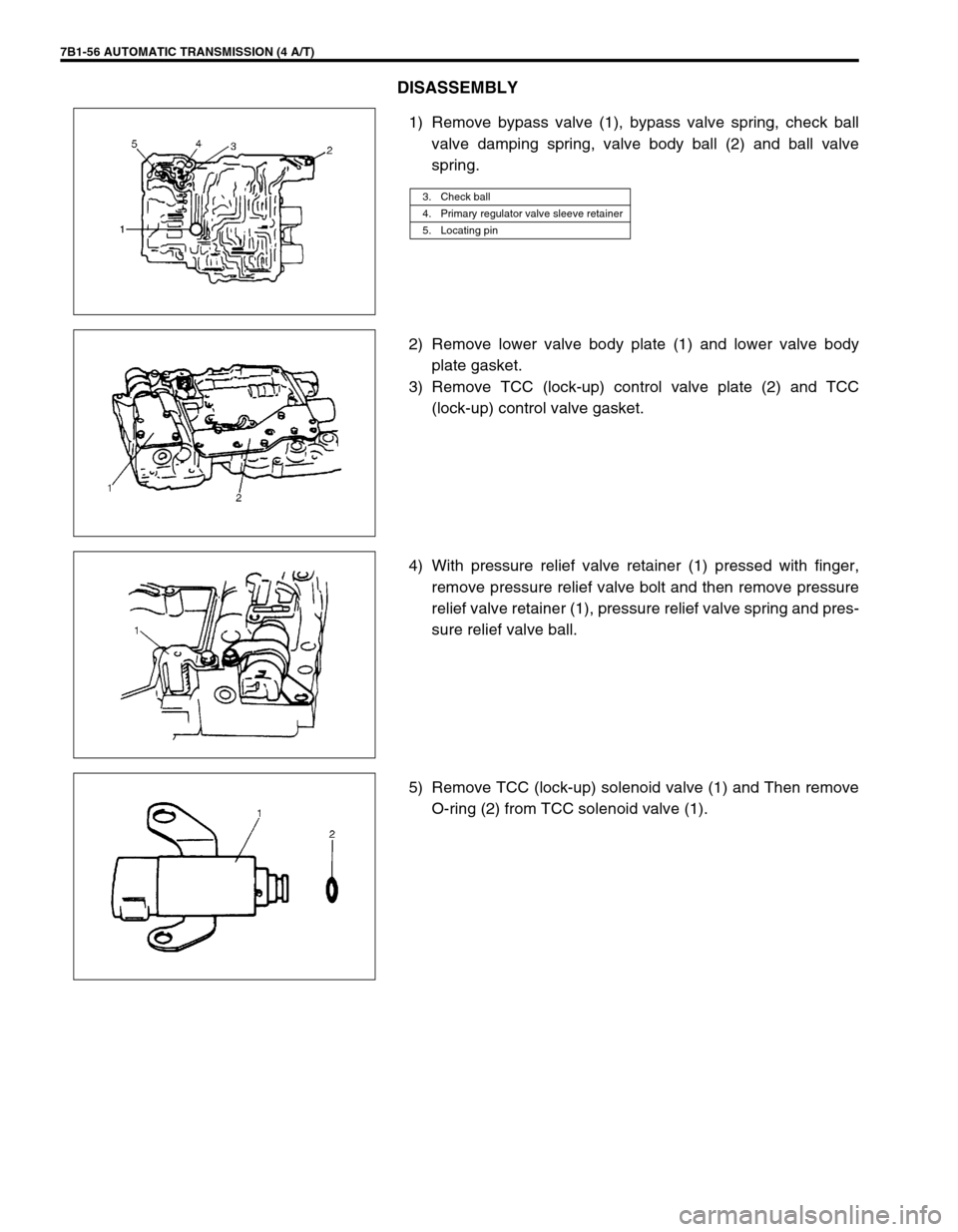

DISASSEMBLY

1) Remove bypass valve (1), bypass valve spring, check ball

valve damping spring, valve body ball (2) and ball valve

spring.

2) Remove lower valve body plate (1) and lower valve body

plate gasket.

3) Remove TCC (lock-up) control valve plate (2) and TCC

(lock-up) control valve gasket.

4) With pressure relief valve retainer (1) pressed with finger,

remove pressure relief valve bolt and then remove pressure

relief valve retainer (1), pressure relief valve spring and pres-

sure relief valve ball.

5) Remove TCC (lock-up) solenoid valve (1) and Then remove

O-ring (2) from TCC solenoid valve (1).

3. Check ball

4. Primary regulator valve sleeve retainer

5. Locating pin

Page 466 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-57

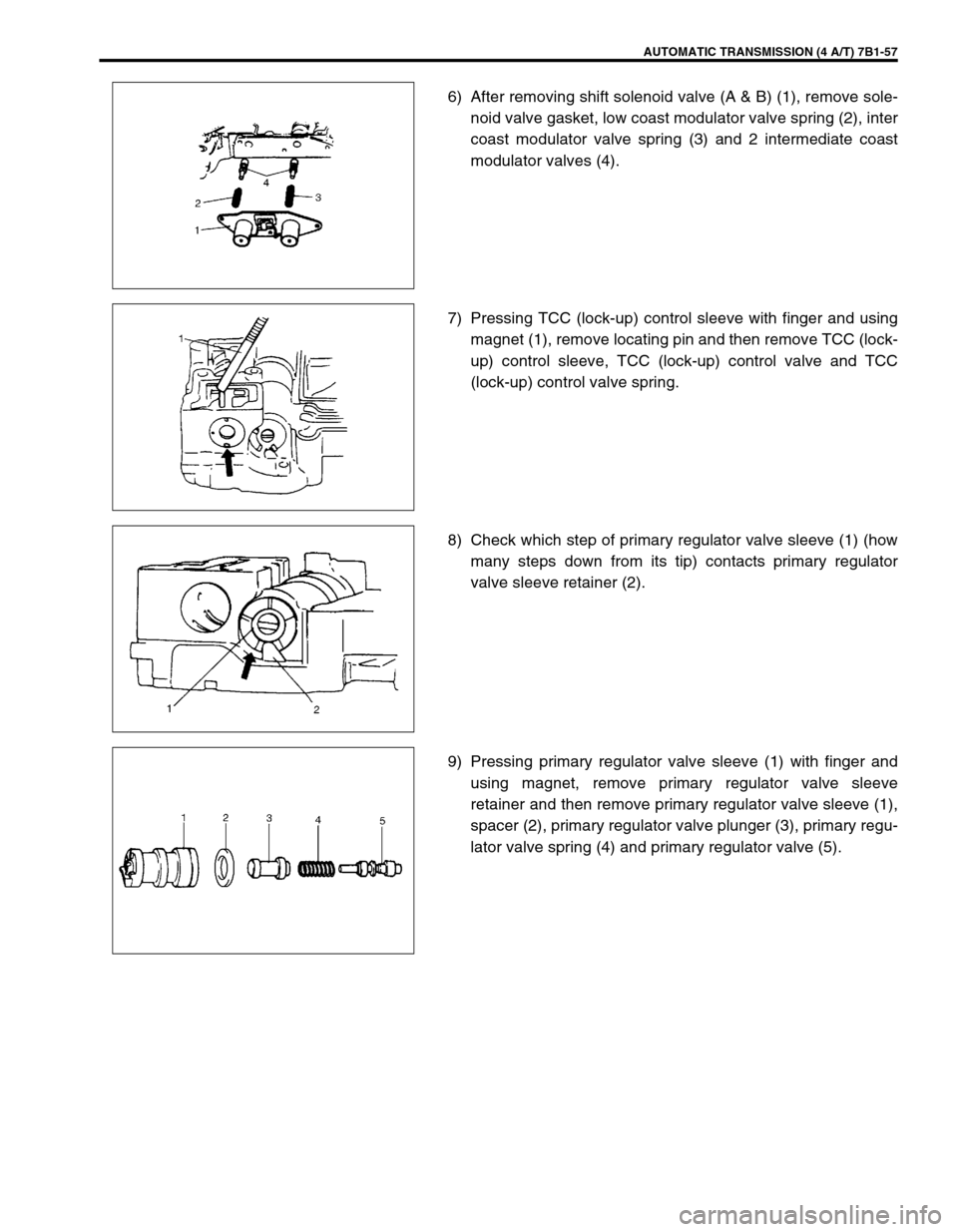

6) After removing shift solenoid valve (A & B) (1), remove sole-

noid valve gasket, low coast modulator valve spring (2), inter

coast modulator valve spring (3) and 2 intermediate coast

modulator valves (4).

7) Pressing TCC (lock-up) control sleeve with finger and using

magnet (1), remove locating pin and then remove TCC (lock-

up) control sleeve, TCC (lock-up) control valve and TCC

(lock-up) control valve spring.

8) Check which step of primary regulator valve sleeve (1) (how

many steps down from its tip) contacts primary regulator

valve sleeve retainer (2).

9) Pressing primary regulator valve sleeve (1) with finger and

using magnet, remove primary regulator valve sleeve

retainer and then remove primary regulator valve sleeve (1),

spacer (2), primary regulator valve plunger (3), primary regu-

lator valve spring (4) and primary regulator valve (5).

Page 467 of 656

7B1-58 AUTOMATIC TRANSMISSION (4 A/T)

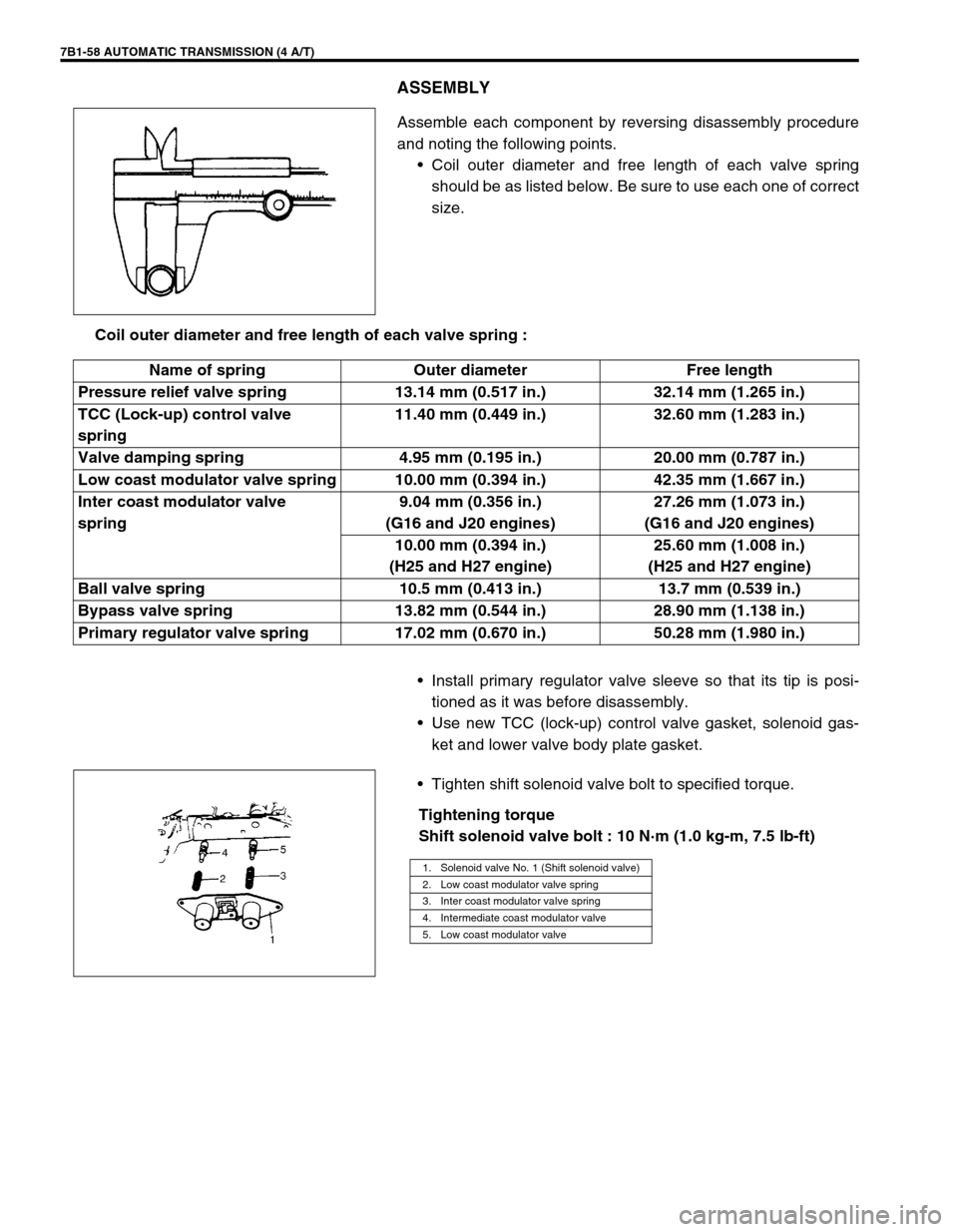

ASSEMBLY

Assemble each component by reversing disassembly procedure

and noting the following points.

•Coil outer diameter and free length of each valve spring

should be as listed below. Be sure to use each one of correct

size.

Coil outer diameter and free length of each valve spring :

•Install primary regulator valve sleeve so that its tip is posi-

tioned as it was before disassembly.

•Use new TCC (lock-up) control valve gasket, solenoid gas-

ket and lower valve body plate gasket.

•Tighten shift solenoid valve bolt to specified torque.

Tightening torque

Shift solenoid valve bolt : 10 N·m (1.0 kg-m, 7.5 lb-ft)

Name of spring Outer diameter Free length

Pressure relief valve spring 13.14 mm (0.517 in.) 32.14 mm (1.265 in.)

TCC (Lock-up) control valve

spring11.40 mm (0.449 in.) 32.60 mm (1.283 in.)

Valve damping spring 4.95 mm (0.195 in.) 20.00 mm (0.787 in.)

Low coast modulator valve spring 10.00 mm (0.394 in.) 42.35 mm (1.667 in.)

Inter coast modulator valve

spring9.04 mm (0.356 in.)

(G16 and J20 engines)27.26 mm (1.073 in.)

(G16 and J20 engines)

10.00 mm (0.394 in.)

(H25 and H27 engine)25.60 mm (1.008 in.)

(H25 and H27 engine)

Ball valve spring 10.5 mm (0.413 in.) 13.7 mm (0.539 in.)

Bypass valve spring 13.82 mm (0.544 in.) 28.90 mm (1.138 in.)

Primary regulator valve spring 17.02 mm (0.670 in.) 50.28 mm (1.980 in.)

1. Solenoid valve No. 1 (Shift solenoid valve)

2. Low coast modulator valve spring

3. Inter coast modulator valve spring

4. Intermediate coast modulator valve

5. Low coast modulator valve

Page 468 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-59

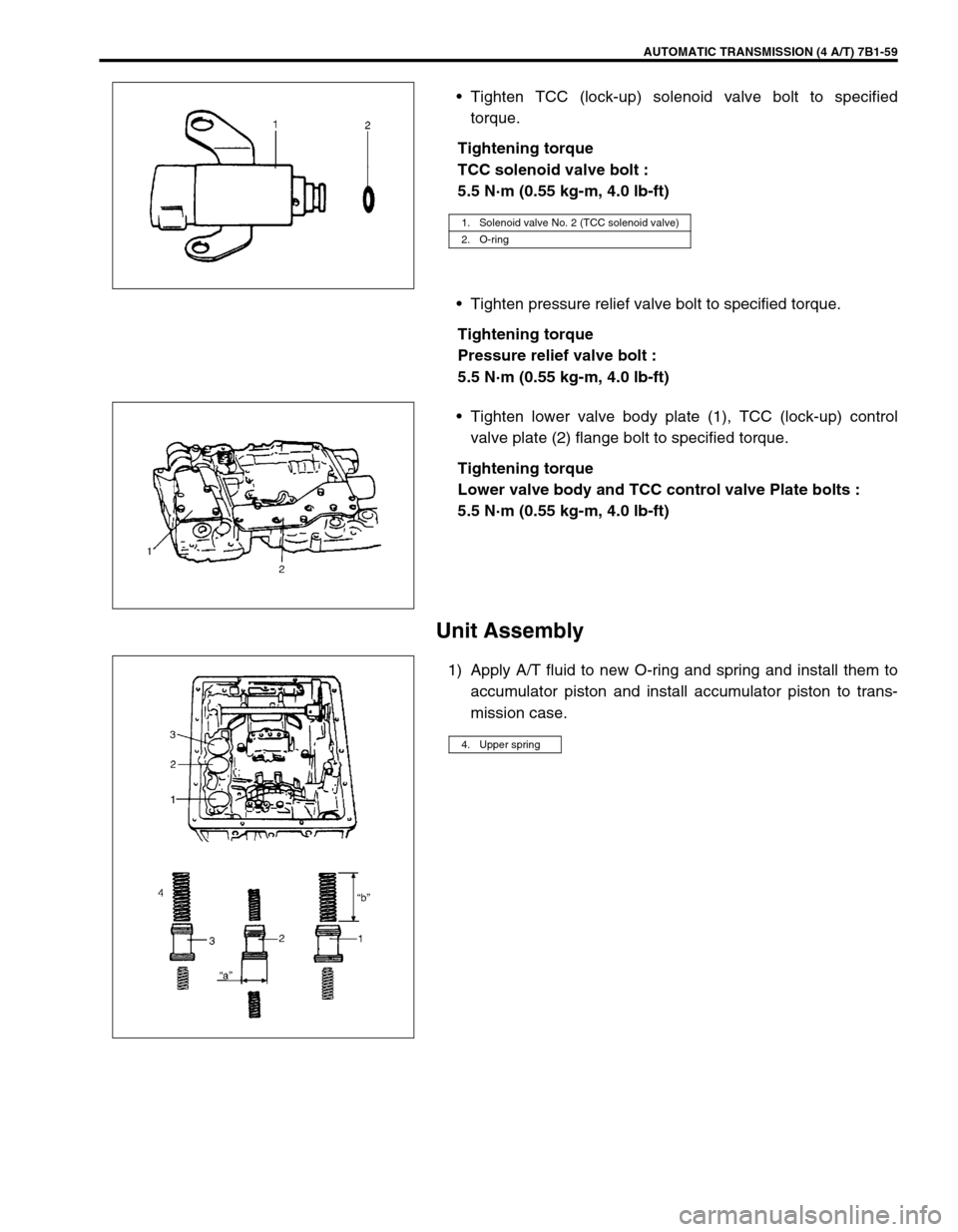

•Tighten TCC (lock-up) solenoid valve bolt to specified

torque.

Tightening torque

TCC solenoid valve bolt :

5.5 N·m (0.55 kg-m, 4.0 lb-ft)

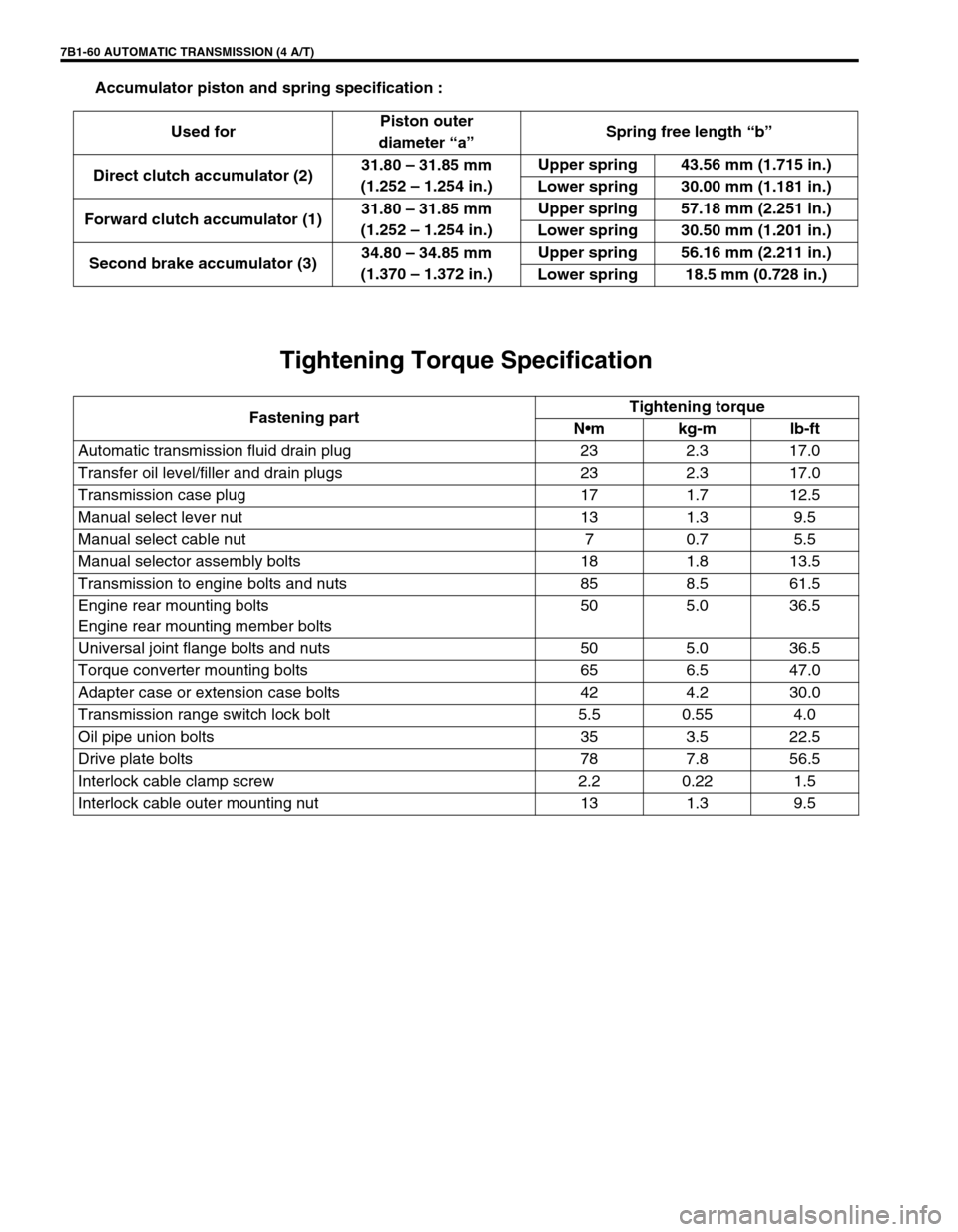

•Tighten pressure relief valve bolt to specified torque.

Tightening torque

Pressure relief valve bolt :

5.5 N·m (0.55 kg-m, 4.0 lb-ft)

•Tighten lower valve body plate (1), TCC (lock-up) control

valve plate (2) flange bolt to specified torque.

Tightening torque

Lower valve body and TCC control valve Plate bolts :

5.5 N·m (0.55 kg-m, 4.0 lb-ft)

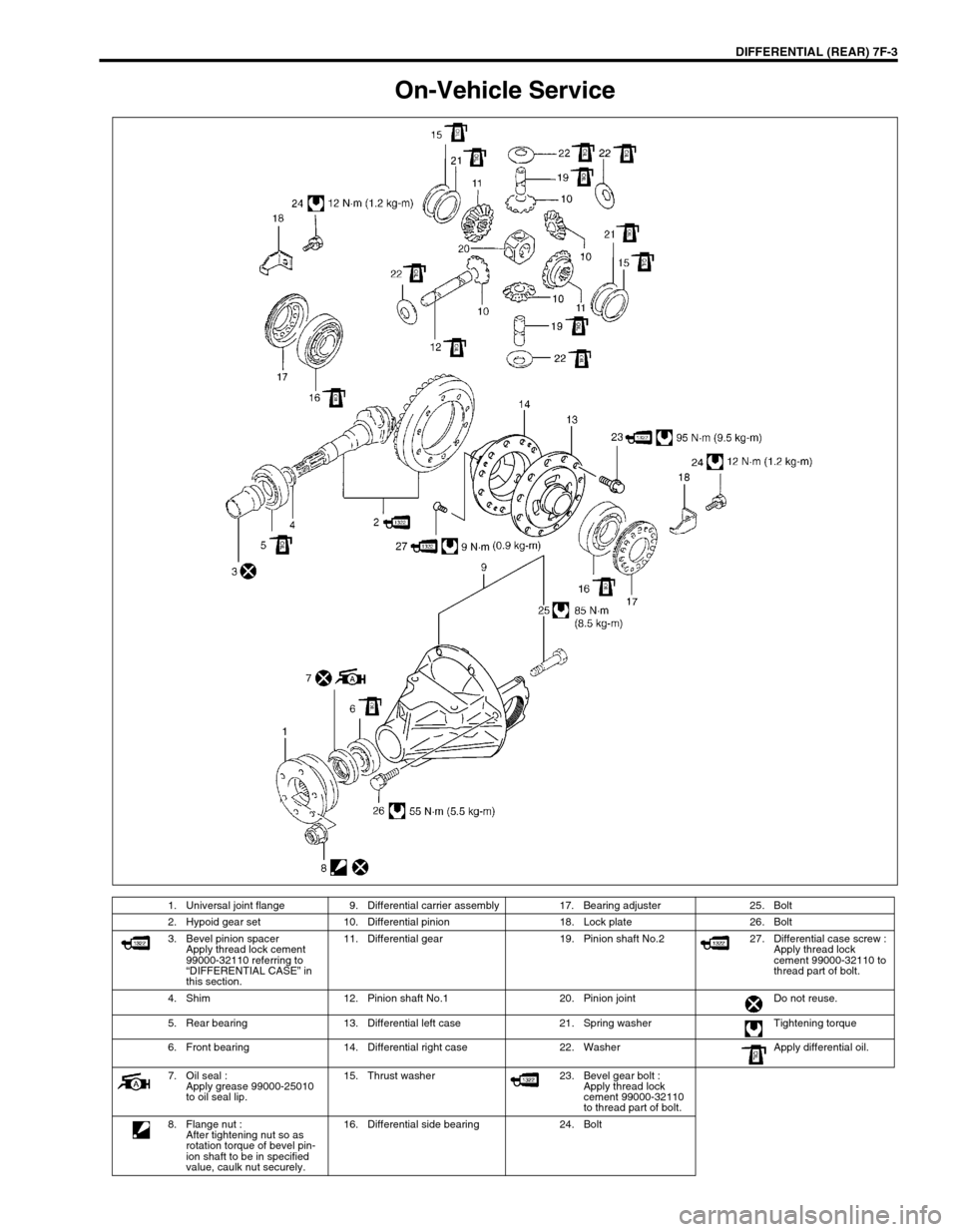

Unit Assembly

1) Apply A/T fluid to new O-ring and spring and install them to

accumulator piston and install accumulator piston to trans-

mission case.

1. Solenoid valve No. 2 (TCC solenoid valve)

2. O-ring

4. Upper spring

Page 469 of 656

7B1-60 AUTOMATIC TRANSMISSION (4 A/T)

Accumulator piston and spring specification :

Tightening Torque Specification

Used forPiston outer

diameter “a”Spring free length “b”

Direct clutch accumulator (2)31.80 – 31.85 mm

(1.252 – 1.254 in.)Upper spring 43.56 mm (1.715 in.)

Lower spring 30.00 mm (1.181 in.)

Forward clutch accumulator (1)31.80 – 31.85 mm

(1.252 – 1.254 in.)Upper spring 57.18 mm (2.251 in.)

Lower spring 30.50 mm (1.201 in.)

Second brake accumulator (3)34.80 – 34.85 mm

(1.370 – 1.372 in.)Upper spring 56.16 mm (2.211 in.)

Lower spring 18.5 mm (0.728 in.)

Fastening partTightening torque

Nm kg-m lb-ft

Automatic transmission fluid drain plug 23 2.3 17.0

Transfer oil level/filler and drain plugs 23 2.3 17.0

Transmission case plug 17 1.7 12.5

Manual select lever nut 13 1.3 9.5

Manual select cable nut 7 0.7 5.5

Manual selector assembly bolts 18 1.8 13.5

Transmission to engine bolts and nuts 85 8.5 61.5

Engine rear mounting bolts

Engine rear mounting member bolts50 5.0 36.5

Universal joint flange bolts and nuts 50 5.0 36.5

Torque converter mounting bolts 65 6.5 47.0

Adapter case or extension case bolts 42 4.2 30.0

Transmission range switch lock bolt 5.5 0.55 4.0

Oil pipe union bolts 35 3.5 22.5

Drive plate bolts 78 7.8 56.5

Interlock cable clamp screw 2.2 0.22 1.5

Interlock cable outer mounting nut 13 1.3 9.5

Page 488 of 656

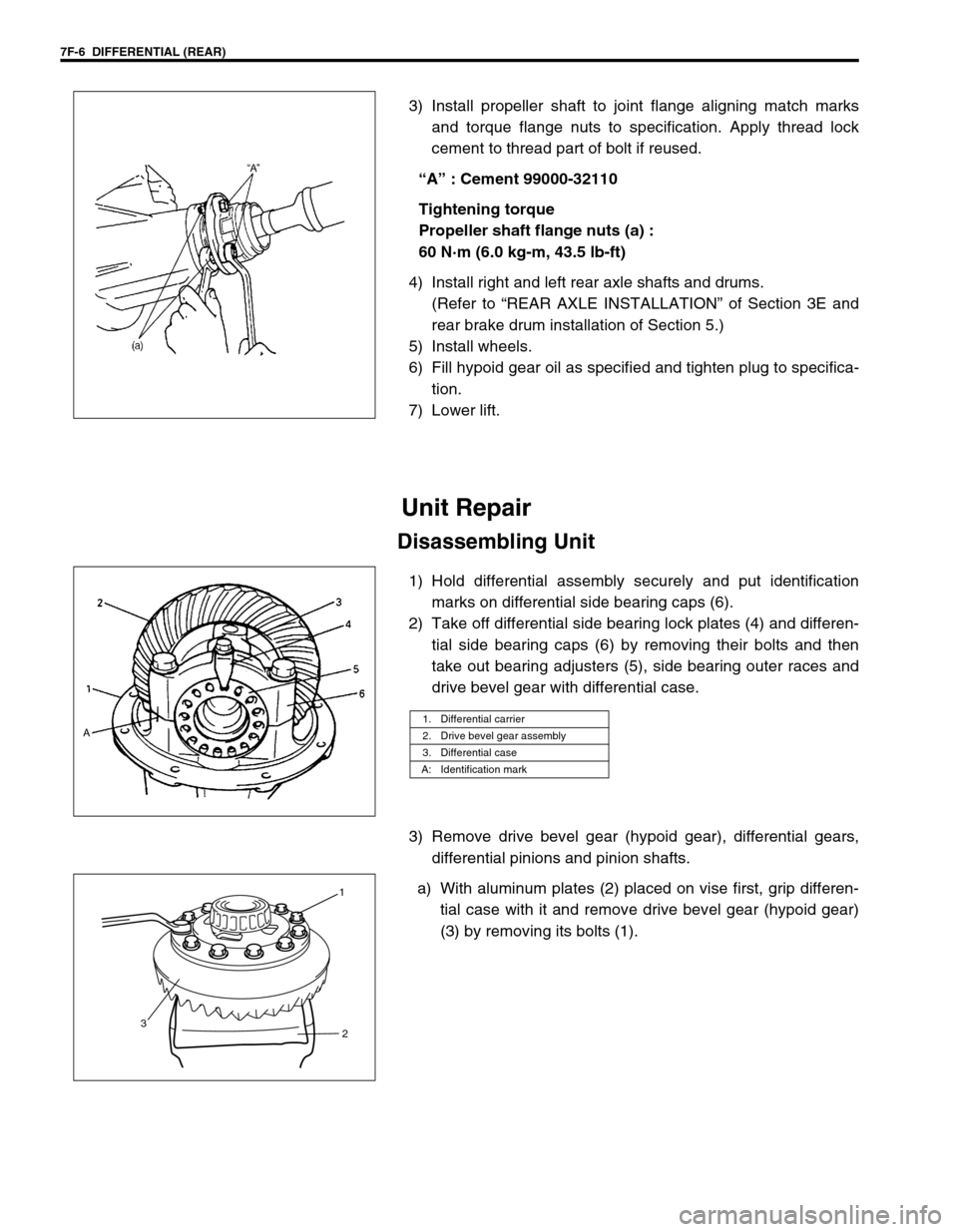

DIFFERENTIAL (REAR) 7F-3

On-Vehicle Service

1. Universal joint flange 9. Differential carrier assembly 17. Bearing adjuster 25. Bolt

2. Hypoid gear set 10. Differential pinion 18. Lock plate 26. Bolt

3. Bevel pinion spacer

Apply thread lock cement

99000-32110 referring to

“DIFFERENTIAL CASE” in

this section.11. Differential gear 19. Pinion shaft No.2 27. Differential case screw :

Apply thread lock

cement 99000-32110 to

thread part of bolt.

4. Shim 12. Pinion shaft No.1 20. Pinion joint Do not reuse.

5. Rear bearing 13. Differential left case 21. Spring washer Tightening torque

6. Front bearing 14. Differential right case 22. Washer Apply differential oil.

7. Oil seal :

Apply grease 99000-25010

to oil seal lip.15. Thrust washer 23. Bevel gear bolt :

Apply thread lock

cement 99000-32110

to thread part of bolt.

8. Flange nut :

After tightening nut so as

rotation torque of bevel pin-

ion shaft to be in specified

value, caulk nut securely.16. Differential side bearing 24. Bolt

Page 491 of 656

7F-6 DIFFERENTIAL (REAR)

3) Install propeller shaft to joint flange aligning match marks

and torque flange nuts to specification. Apply thread lock

cement to thread part of bolt if reused.

“A” : Cement 99000-32110

Tightening torque

Propeller shaft flange nuts (a) :

60 N·m (6.0 kg-m, 43.5 lb-ft)

4) Install right and left rear axle shafts and drums.

(Refer to “REAR AXLE INSTALLATION” of Section 3E and

rear brake drum installation of Section 5.)

5) Install wheels.

6) Fill hypoid gear oil as specified and tighten plug to specifica-

tion.

7) Lower lift.

Unit Repair

Disassembling Unit

1) Hold differential assembly securely and put identification

marks on differential side bearing caps (6).

2) Take off differential side bearing lock plates (4) and differen-

tial side bearing caps (6) by removing their bolts and then

take out bearing adjusters (5), side bearing outer races and

drive bevel gear with differential case.

3) Remove drive bevel gear (hypoid gear), differential gears,

differential pinions and pinion shafts.

a) With aluminum plates (2) placed on vise first, grip differen-

tial case with it and remove drive bevel gear (hypoid gear)

(3) by removing its bolts (1).

1. Differential carrier

2. Drive bevel gear assembly

3. Differential case

A: Identification mark

1

3

2

Page 496 of 656

DIFFERENTIAL (REAR) 7F-11

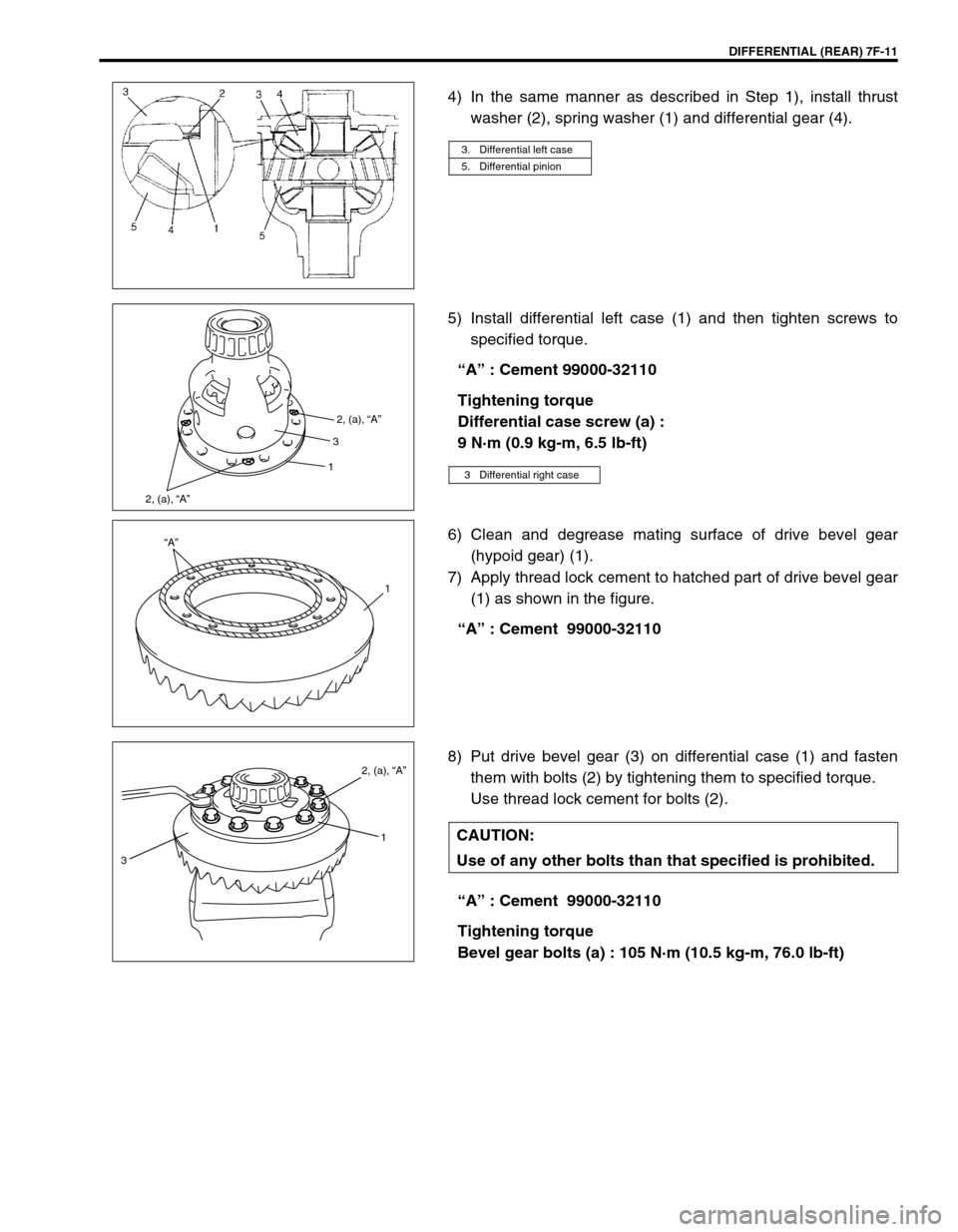

4) In the same manner as described in Step 1), install thrust

washer (2), spring washer (1) and differential gear (4).

5) Install differential left case (1) and then tighten screws to

specified torque.

“A” : Cement 99000-32110

Tightening torque

Differential case screw (a) :

9 N·m (0.9 kg-m, 6.5 lb-ft)

6) Clean and degrease mating surface of drive bevel gear

(hypoid gear) (1).

7) Apply thread lock cement to hatched part of drive bevel gear

(1) as shown in the figure.

“A” : Cement 99000-32110

8) Put drive bevel gear (3) on differential case (1) and fasten

them with bolts (2) by tightening them to specified torque.

Use thread lock cement for bolts (2).

“A” : Cement 99000-32110

Tightening torque

Bevel gear bolts (a) : 105 N·m (10.5 kg-m, 76.0 lb-ft)

3. Differential left case

5. Differential pinion

3 Differential right case1

2, (a), “A”

32, (a), “A”

“

A”

1

CAUTION:

Use of any other bolts than that specified is prohibited.1

2, (a), “A”

3

Page 500 of 656

DIFFERENTIAL (REAR) 7F-15

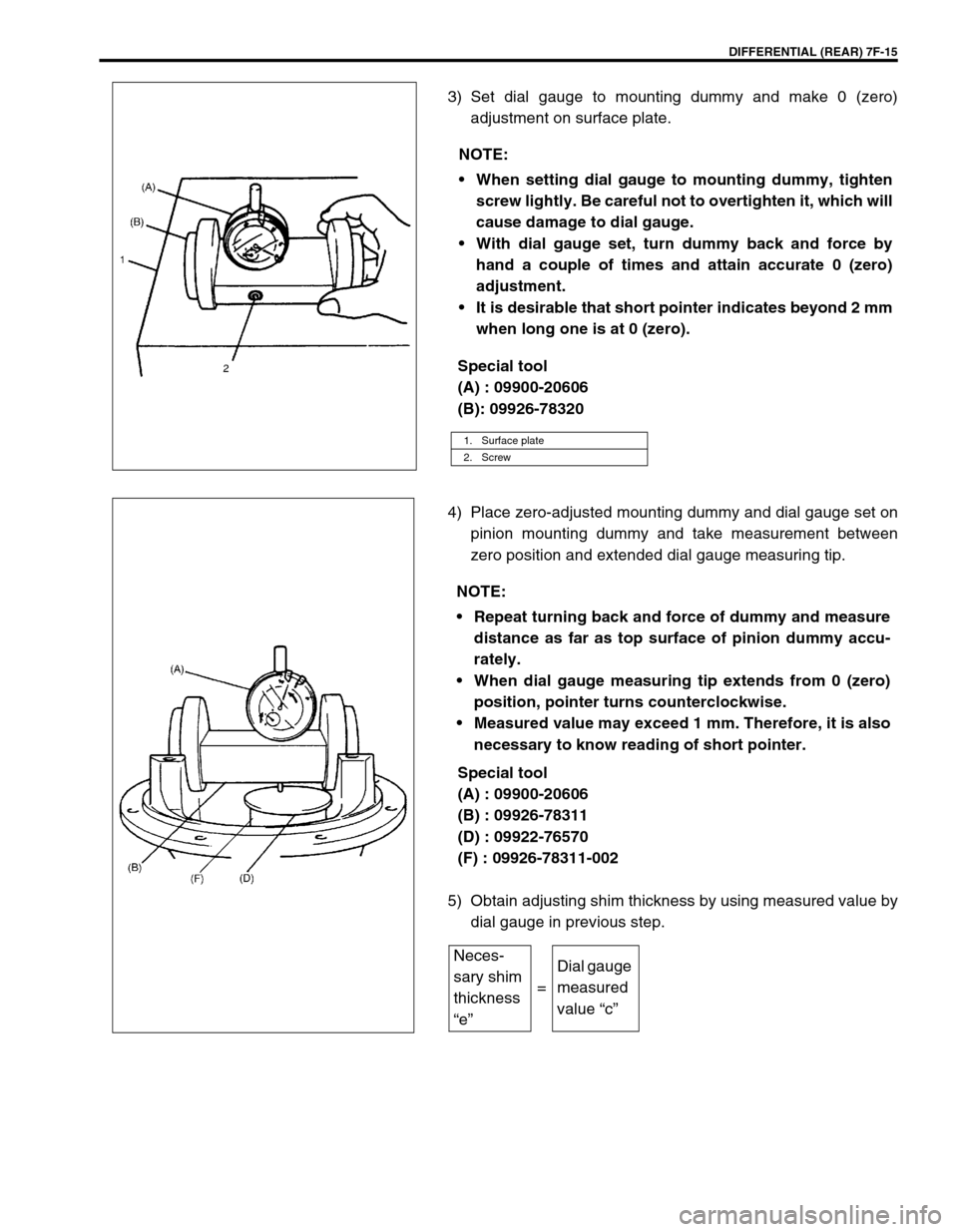

3) Set dial gauge to mounting dummy and make 0 (zero)

adjustment on surface plate.

Special tool

(A) : 09900-20606

(B): 09926-78320

4) Place zero-adjusted mounting dummy and dial gauge set on

pinion mounting dummy and take measurement between

zero position and extended dial gauge measuring tip.

Special tool

(A) : 09900-20606

(B) : 09926-78311

(D) : 09922-76570

(F) : 09926-78311-002

5) Obtain adjusting shim thickness by using measured value by

dial gauge in previous step. NOTE:

When setting dial gauge to mounting dummy, tighten

screw lightly. Be careful not to overtighten it, which will

cause damage to dial gauge.

With dial gauge set, turn dummy back and force by

hand a couple of times and attain accurate 0 (zero)

adjustment.

It is desirable that short pointer indicates beyond 2 mm

when long one is at 0 (zero).

1. Surface plate

2. Screw

NOTE:

Repeat turning back and force of dummy and measure

distance as far as top surface of pinion dummy accu-

rately.

When dial gauge measuring tip extends from 0 (zero)

position, pointer turns counterclockwise.

Measured value may exceed 1 mm. Therefore, it is also

necessary to know reading of short pointer.

Neces-

sary shim

thickness

“e”=Dial gauge

measured

value “c”