Downloaded from www.Manualslib.com manuals search engine 6E-40 ENGINE AND EMISSION CONTROL SYSTEM

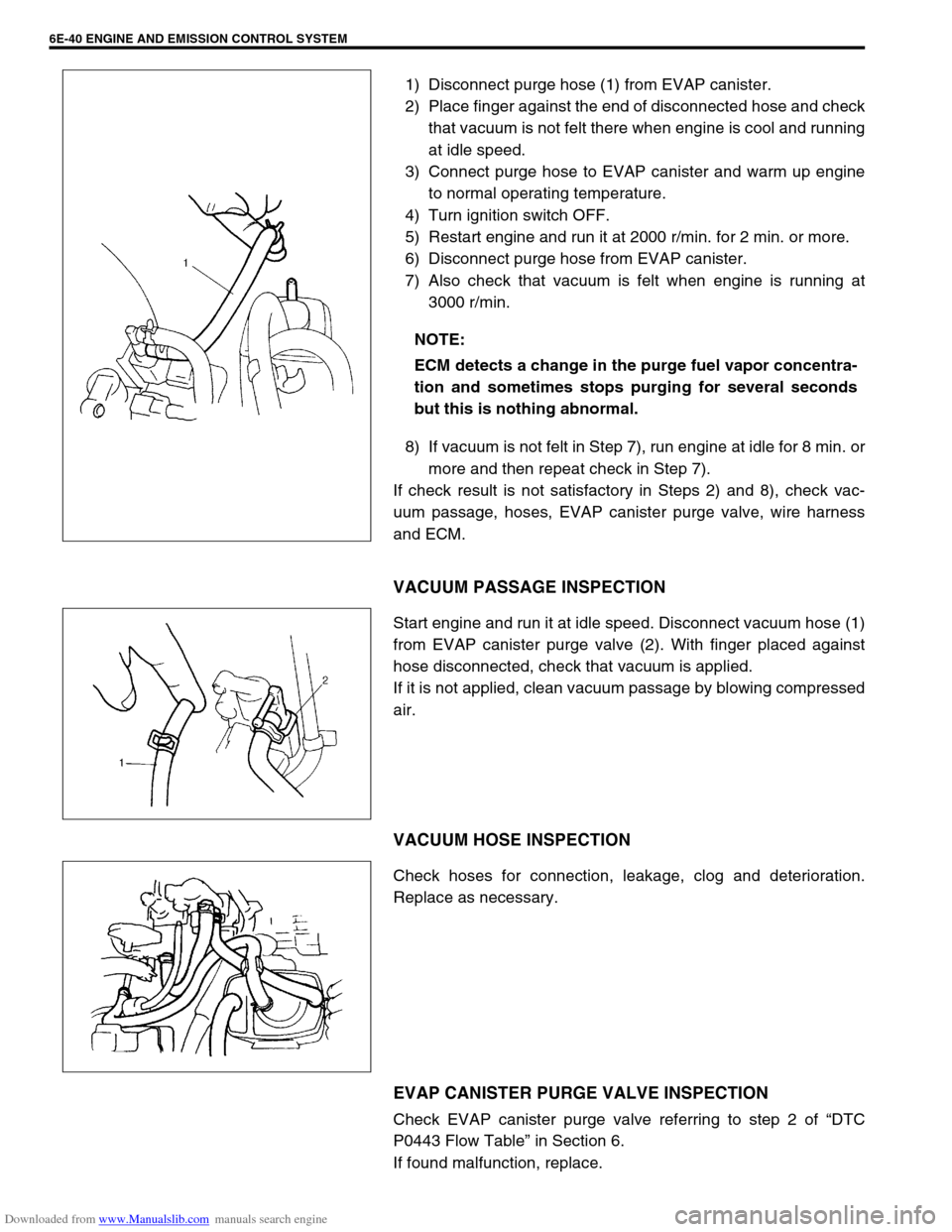

1) Disconnect purge hose (1) from EVAP canister.

2) Place finger against the end of disconnected hose and check

that vacuum is not felt there when engine is cool and running

at idle speed.

3) Connect purge hose to EVAP canister and warm up engine

to normal operating temperature.

4) Turn ignition switch OFF.

5) Restart engine and run it at 2000 r/min. for 2 min. or more.

6) Disconnect purge hose from EVAP canister.

7) Also check that vacuum is felt when engine is running at

3000 r/min.

8) If vacuum is not felt in Step 7), run engine at idle for 8 min. or

more and then repeat check in Step 7).

If check result is not satisfactory in Steps 2) and 8), check vac-

uum passage, hoses, EVAP canister purge valve, wire harness

and ECM.

VACUUM PASSAGE INSPECTION

Start engine and run it at idle speed. Disconnect vacuum hose (1)

from EVAP canister purge valve (2). With finger placed against

hose disconnected, check that vacuum is applied.

If it is not applied, clean vacuum passage by blowing compressed

air.

VACUUM HOSE INSPECTION

Check hoses for connection, leakage, clog and deterioration.

Replace as necessary.

EVAP CANISTER PURGE VALVE INSPECTION

Check EVAP canister purge valve referring to step 2 of “DTC

P0443 Flow Table” in Section 6.

If found malfunction, replace.NOTE:

ECM detects a change in the purge fuel vapor concentra-

tion and sometimes stops purging for several seconds

but this is nothing abnormal.

Downloaded from www.Manualslib.com manuals search engine CRANKING SYSTEM 6G-7

Specifications

Voltage 12 volts

Output 0.9 kW 1.2 kW

Rating 30 seconds

Direction of rotation Clockwise as viewed from pinion side

Brush length 12.3 mm (0.48 in.) 12.3 mm (0.48 in.)

Number of pinion teeth 8

Performance Condition Guarantee

Around at

20° C (68 °F)No load characteristic 11.0 V90 A maximum

2,800 rpm minimum90 A maximum

2,500 rpm minimum

Load characteristic8.0 V

200 A4.8 N·m (0.48 kg-m,

3.5 lb-ft) minimum

1,260 rpm minimum–

7.5 V

300 A–10.5 N·m (1.05 kg-m,

7.6 lb-ft) minimum

880 rpm minimum

Locked rotor current3.5 V550 A maximum

12.2 N·m (1.22 kg-m,

8.8 lb-ft) minimum–

4.0 V–760 A maximum

19.5 N·m (1.95 kg-m,

14.1 lb-ft) minimum

Magnetic switch operating voltage 8 volts maximum