radiator cap SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 569 of 698

6A1-68 ENGINE MECHANICAL (M13 ENGINE)

UNIT REPAIR OVERHAUL

ENGINE ASSEMBLY

REMOVAL

1) Relieve fuel pressure according to procedure described in

Section 6.

2) Disconnect negative and positive cables at battery.

3) Remove engine hood after disconnecting windshield washer

hose.

4) Remove right and left side engine under covers.

5) Remove A/C compressor belt (if equipped).

6) Remove water pump belt.

7) Drain engine oil, transmission oil or A/T fluid (for A/T vehicle)

and transfer oil (for 4WD vehicle).

8) Drain coolant.

9) Remove air cleaner assembly, resonator and hoses referring

to “AIR CLEANER ASSEMBLY AND RESONATOR”.

10) With hose connected, detach A/C compressor from its

bracket (if equipped). WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.

NOTE:

Suspend removed A/C compressor at a place where no

damage will be caused during removal and installation of

engine assembly.

Page 591 of 698

6B-2 ENGINE COOLING

GENERAL DESCRIPTION

The cooling system consists of the radiator cap, radiator, coolant reservoir tank, hoses, water pump, cooling fan

and thermostat. The radiator is of tube-and-fin type.

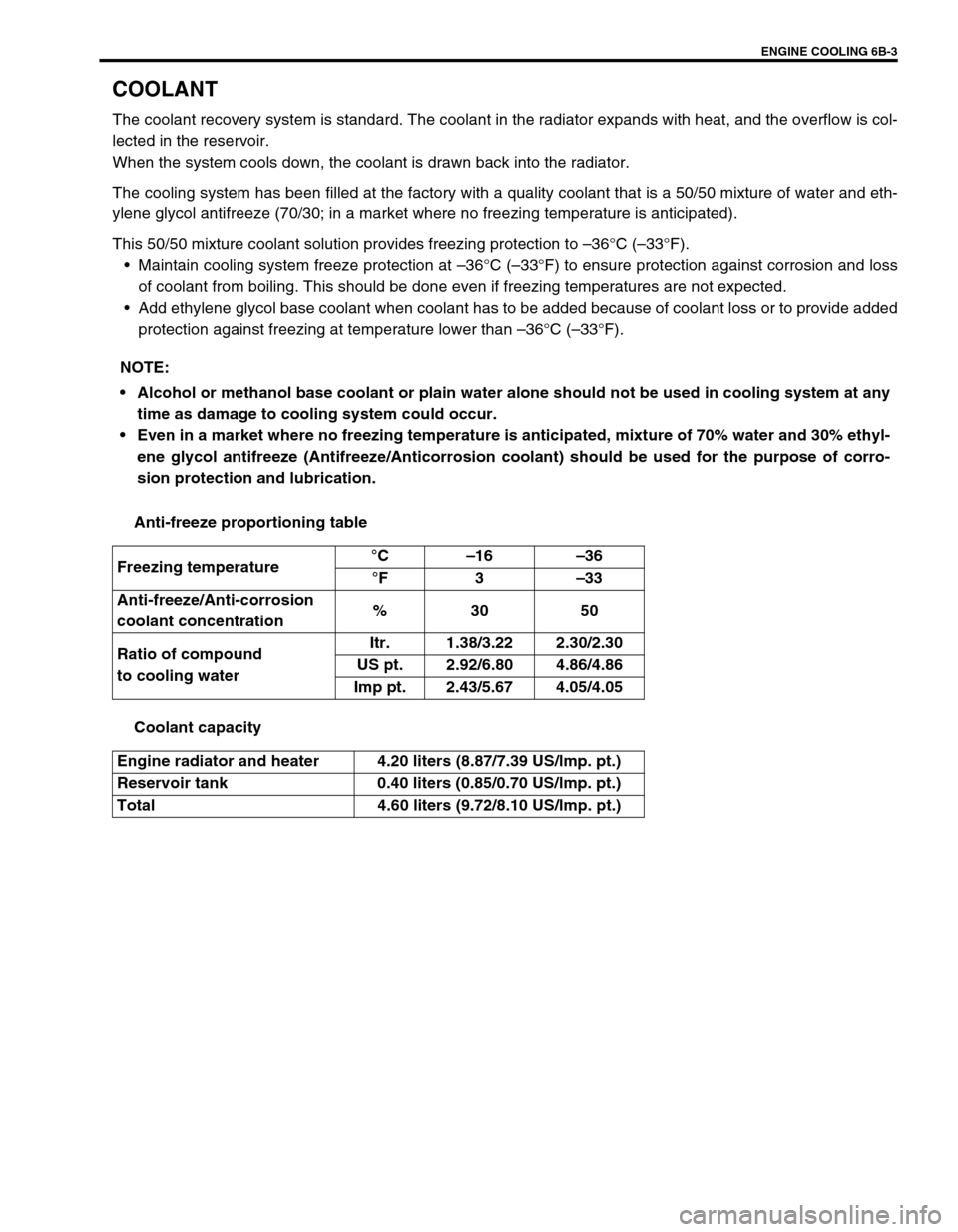

COOLING SYSTEM CIRCULATION

While the engine is warmed up (thermostat closed), coolant circulates as follows.

When coolant is warmed up to normal temperature and the thermostat opens, coolant passes through the radi-

ator core to be cooled as well as the above flow circuit.

1. Radiator inlet hose 5. Water pump 9. Heater outlet hose

2. Radiator outlet hose 6. Throttle body (Fast idle control plunger) 10. Radiator

3. Water inlet pipe 7. Engine

4. Thermostat 8. Heater inlet hose

Water pump Cylinder block

Thermostat closedCylinder head Water intake pipeThrottle body

Heater unit

Page 592 of 698

ENGINE COOLING 6B-3

COOLANT

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the overflow is col-

lected in the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has been filled at the factory with a quality coolant that is a 50/50 mixture of water and eth-

ylene glycol antifreeze (70/30; in a market where no freezing temperature is anticipated).

This 50/50 mixture coolant solution provides freezing protection to –36°C (–33°F).

Maintain cooling system freeze protection at –36°C (–33°F) to ensure protection against corrosion and loss

of coolant from boiling. This should be done even if freezing temperatures are not expected.

Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added

protection against freezing at temperature lower than –36°C (–33°F).

Anti-freeze proportioning table

Coolant capacity NOTE:

Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

Even in a market where no freezing temperature is anticipated, mixture of 70% water and 30% ethyl-

ene glycol antifreeze (Antifreeze/Anticorrosion coolant) should be used for the purpose of corro-

sion protection and lubrication.

Freezing temperature°C–16–36

°F3–33

Anti-freeze/Anti-corrosion

coolant concentration%30 50

Ratio of compound

to cooling waterItr. 1.38/3.22 2.30/2.30

US pt. 2.92/6.80 4.86/4.86

Imp pt. 2.43/5.67 4.05/4.05

Engine radiator and heater 4.20 liters (8.87/7.39 US/lmp. pt.)

Reservoir tank 0.40 liters (0.85/0.70 US/lmp. pt.)

Total 4.60 liters (9.72/8.10 US/lmp. pt.)

Page 593 of 698

6B-4 ENGINE COOLING

DIAGNOSIS

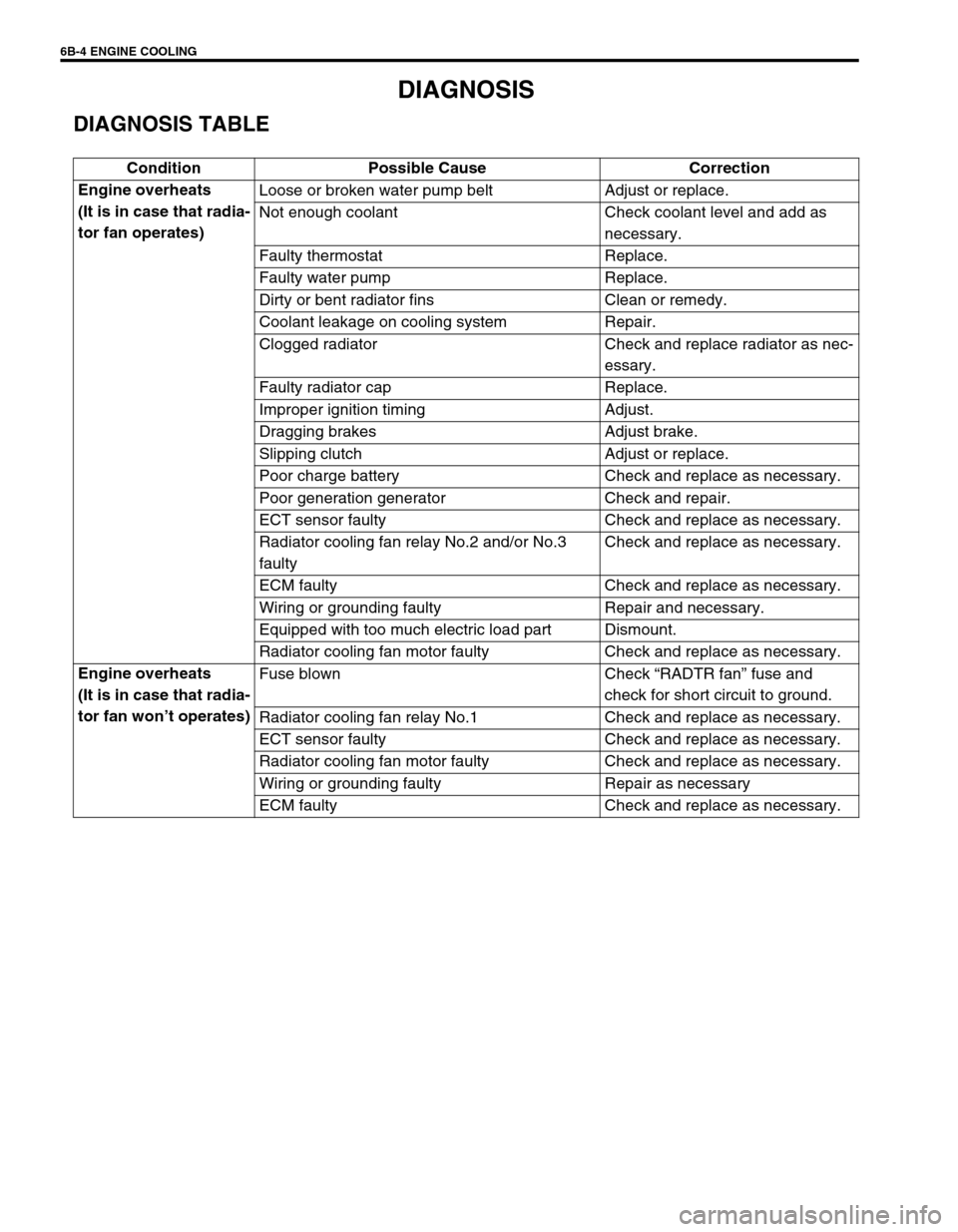

DIAGNOSIS TABLE

Condition Possible Cause Correction

Engine overheats

(It is in case that radia-

tor fan operates)Loose or broken water pump belt Adjust or replace.

Not enough coolant Check coolant level and add as

necessary.

Faulty thermostat Replace.

Faulty water pump Replace.

Dirty or bent radiator fins Clean or remedy.

Coolant leakage on cooling system Repair.

Clogged radiator Check and replace radiator as nec-

essary.

Faulty radiator cap Replace.

Improper ignition timing Adjust.

Dragging brakes Adjust brake.

Slipping clutch Adjust or replace.

Poor charge battery Check and replace as necessary.

Poor generation generator Check and repair.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan relay No.2 and/or No.3

faultyCheck and replace as necessary.

ECM faulty Check and replace as necessary.

Wiring or grounding faulty Repair and necessary.

Equipped with too much electric load part Dismount.

Radiator cooling fan motor faulty Check and replace as necessary.

Engine overheats

(It is in case that radia-

tor fan won’t operates)Fuse blown Check “RADTR fan” fuse and

check for short circuit to ground.

Radiator cooling fan relay No.1 Check and replace as necessary.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan motor faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary

ECM faulty Check and replace as necessary.

Page 595 of 698

6B-6 ENGINE COOLING

MAINTENANCE

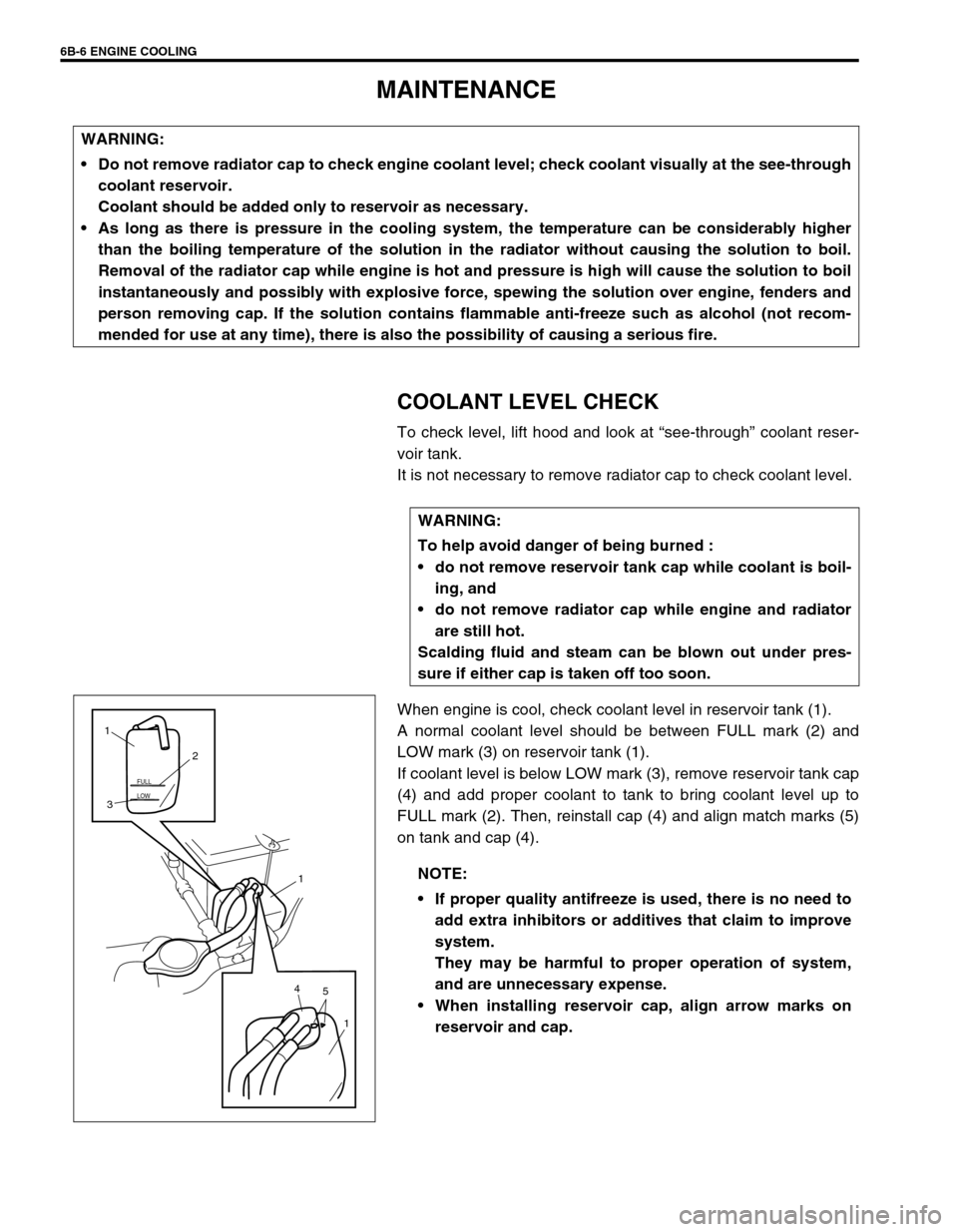

COOLANT LEVEL CHECK

To check level, lift hood and look at “see-through” coolant reser-

voir tank.

It is not necessary to remove radiator cap to check coolant level.

When engine is cool, check coolant level in reservoir tank (1).

A normal coolant level should be between FULL mark (2) and

LOW mark (3) on reservoir tank (1).

If coolant level is below LOW mark (3), remove reservoir tank cap

(4) and add proper coolant to tank to bring coolant level up to

FULL mark (2). Then, reinstall cap (4) and align match marks (5)

on tank and cap (4). WARNING:

Do not remove radiator cap to check engine coolant level; check coolant visually at the see-through

coolant reservoir.

Coolant should be added only to reservoir as necessary.

As long as there is pressure in the cooling system, the temperature can be considerably higher

than the boiling temperature of the solution in the radiator without causing the solution to boil.

Removal of the radiator cap while engine is hot and pressure is high will cause the solution to boil

instantaneously and possibly with explosive force, spewing the solution over engine, fenders and

person removing cap. If the solution contains flammable anti-freeze such as alcohol (not recom-

mended for use at any time), there is also the possibility of causing a serious fire.

WARNING:

To help avoid danger of being burned :

do not remove reservoir tank cap while coolant is boil-

ing, and

do not remove radiator cap while engine and radiator

are still hot.

Scalding fluid and steam can be blown out under pres-

sure if either cap is taken off too soon.

NOTE:

If proper quality antifreeze is used, there is no need to

add extra inhibitors or additives that claim to improve

system.

They may be harmful to proper operation of system,

and are unnecessary expense.

When installing reservoir cap, align arrow marks on

reservoir and cap.

LOW FULL

5 41

1 32 1

Page 596 of 698

ENGINE COOLING 6B-7

ENGINE COOLING SYSTEM INSPECTION

AND SERVICE

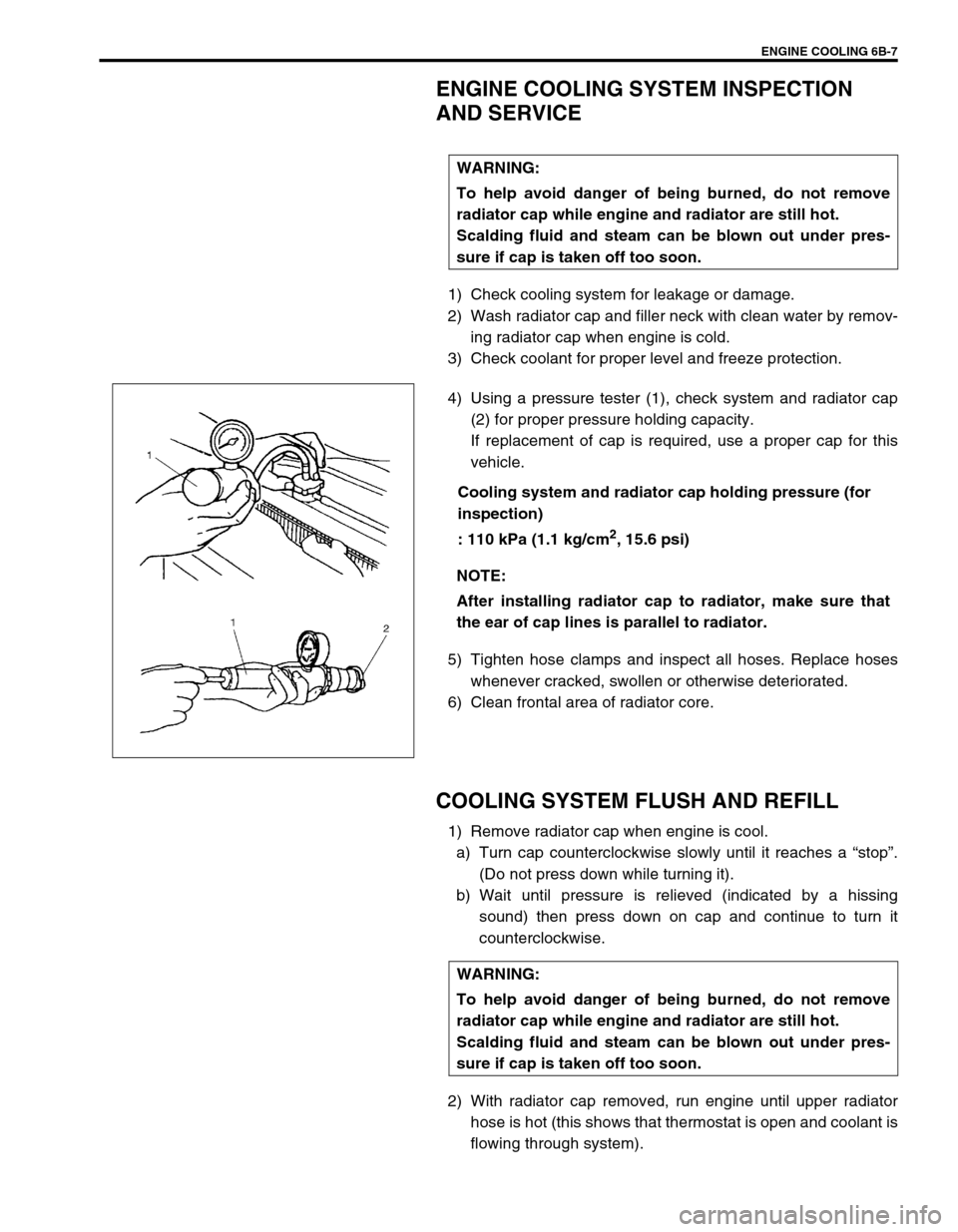

1) Check cooling system for leakage or damage.

2) Wash radiator cap and filler neck with clean water by remov-

ing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

4) Using a pressure tester (1), check system and radiator cap

(2) for proper pressure holding capacity.

If replacement of cap is required, use a proper cap for this

vehicle.

Cooling system and radiator cap holding pressure (for

inspection)

: 110 kPa (1.1 kg/cm

2, 15.6 psi)

5) Tighten hose clamps and inspect all hoses. Replace hoses

whenever cracked, swollen or otherwise deteriorated.

6) Clean frontal area of radiator core.

COOLING SYSTEM FLUSH AND REFILL

1) Remove radiator cap when engine is cool.

a) Turn cap counterclockwise slowly until it reaches a “stop”.

(Do not press down while turning it).

b) Wait until pressure is relieved (indicated by a hissing

sound) then press down on cap and continue to turn it

counterclockwise.

2) With radiator cap removed, run engine until upper radiator

hose is hot (this shows that thermostat is open and coolant is

flowing through system). WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.

NOTE:

After installing radiator cap to radiator, make sure that

the ear of cap lines is parallel to radiator.

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.

Page 597 of 698

6B-8 ENGINE COOLING

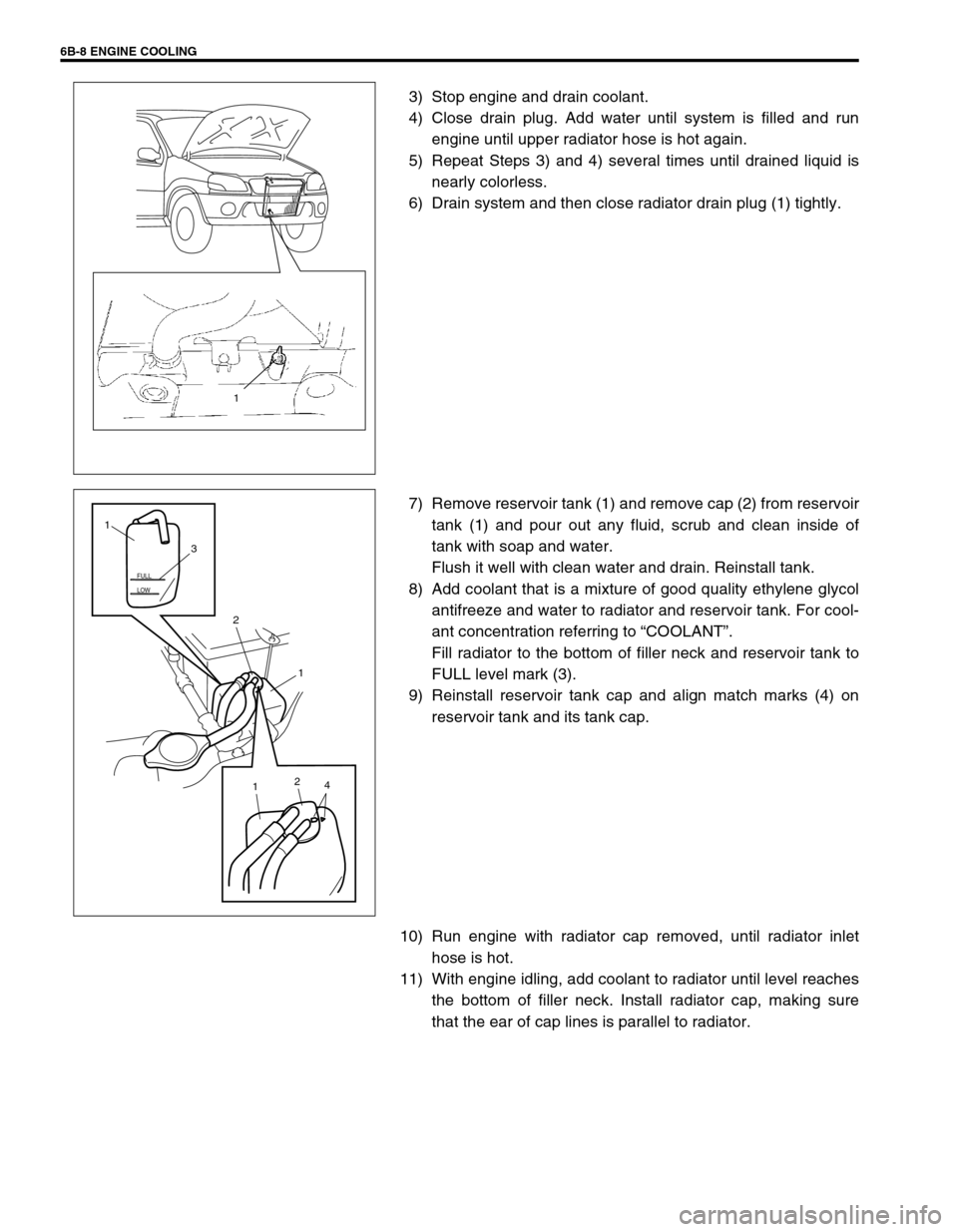

3) Stop engine and drain coolant.

4) Close drain plug. Add water until system is filled and run

engine until upper radiator hose is hot again.

5) Repeat Steps 3) and 4) several times until drained liquid is

nearly colorless.

6) Drain system and then close radiator drain plug (1) tightly.

7) Remove reservoir tank (1) and remove cap (2) from reservoir

tank (1) and pour out any fluid, scrub and clean inside of

tank with soap and water.

Flush it well with clean water and drain. Reinstall tank.

8) Add coolant that is a mixture of good quality ethylene glycol

antifreeze and water to radiator and reservoir tank. For cool-

ant concentration referring to “COOLANT”.

Fill radiator to the bottom of filler neck and reservoir tank to

FULL level mark (3).

9) Reinstall reservoir tank cap and align match marks (4) on

reservoir tank and its tank cap.

10) Run engine with radiator cap removed, until radiator inlet

hose is hot.

11) With engine idling, add coolant to radiator until level reaches

the bottom of filler neck. Install radiator cap, making sure

that the ear of cap lines is parallel to radiator.

1

LOW FULL

4 1

1 3

2

2 1

Page 598 of 698

ENGINE COOLING 6B-9

WATER PUMP/GENERATOR DRIVE BELT TENSION INSPECTION AND

ADJUSTMENT

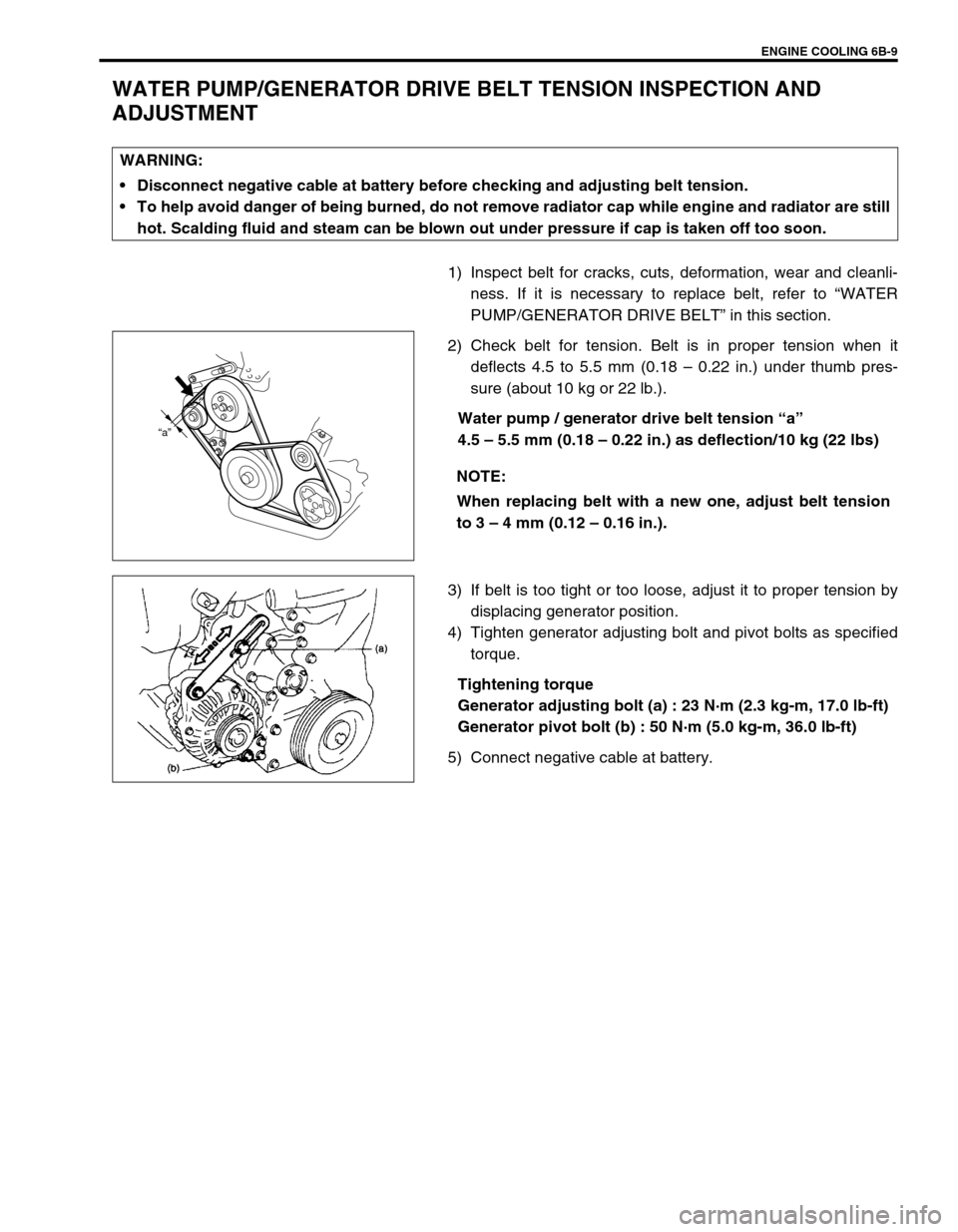

1) Inspect belt for cracks, cuts, deformation, wear and cleanli-

ness. If it is necessary to replace belt, refer to “WATER

PUMP/GENERATOR DRIVE BELT” in this section.

2) Check belt for tension. Belt is in proper tension when it

deflects 4.5 to 5.5 mm (0.18 – 0.22 in.) under thumb pres-

sure (about 10 kg or 22 lb.).

Water pump / generator drive belt tension “a”

4.5 – 5.5 mm (0.18 – 0.22 in.) as deflection/10 kg (22 lbs)

3) If belt is too tight or too loose, adjust it to proper tension by

displacing generator position.

4) Tighten generator adjusting bolt and pivot bolts as specified

torque.

Tightening torque

Generator adjusting bolt (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Generator pivot bolt (b) : 50 N·m (5.0 kg-m, 36.0 lb-ft)

5) Connect negative cable at battery. WARNING:

Disconnect negative cable at battery before checking and adjusting belt tension.

To help avoid danger of being burned, do not remove radiator cap while engine and radiator are still

hot. Scalding fluid and steam can be blown out under pressure if cap is taken off too soon.

NOTE:

When replacing belt with a new one, adjust belt tension

to 3 – 4 mm (0.12 – 0.16 in.).

“a”

Page 599 of 698

6B-10 ENGINE COOLING

ON-VEHICLE SERVICE

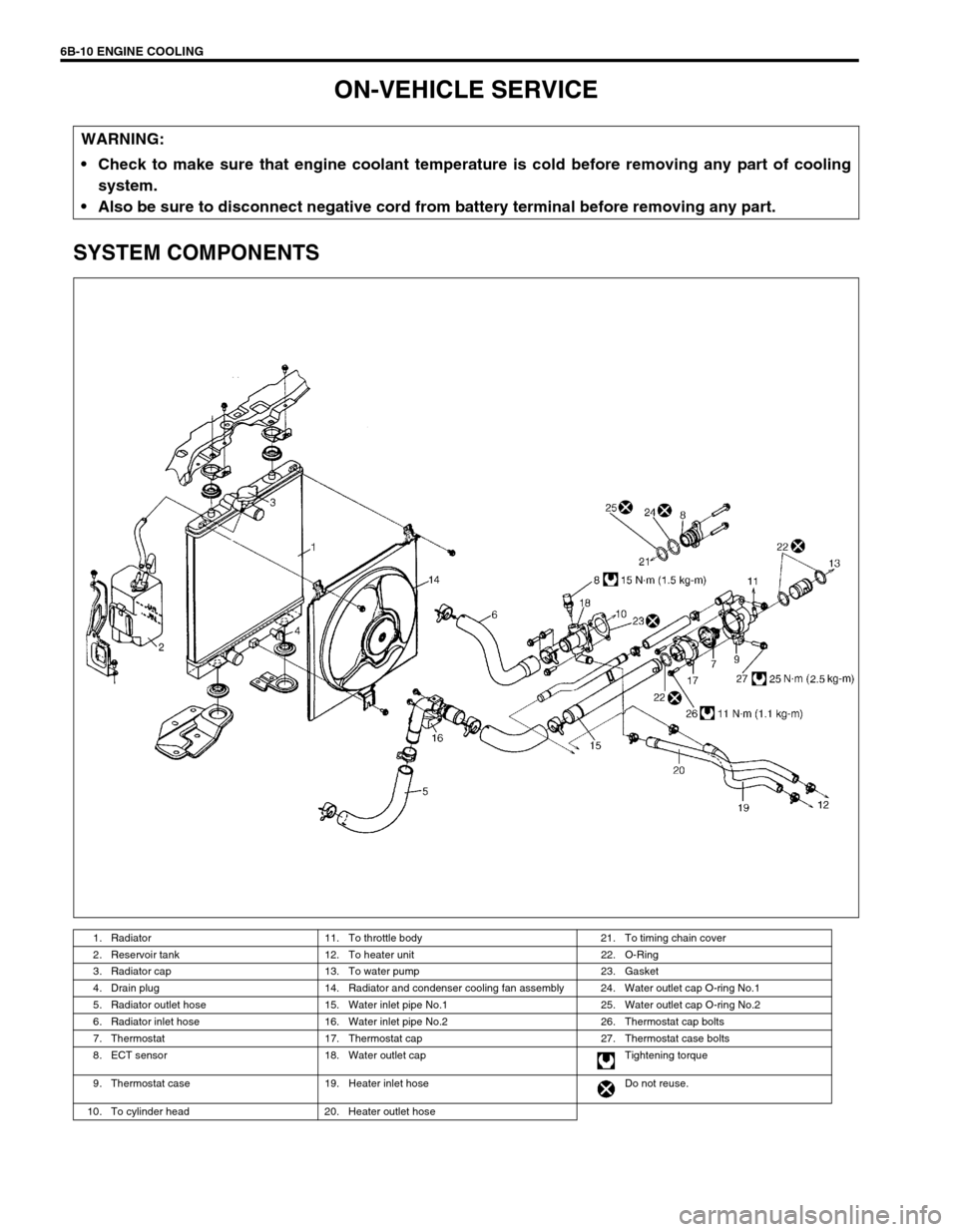

SYSTEM COMPONENTS

WARNING:

Check to make sure that engine coolant temperature is cold before removing any part of cooling

system.

Also be sure to disconnect negative cord from battery terminal before removing any part.

1. Radiator 11. To throttle body 21. To timing chain cover

2. Reservoir tank 12. To heater unit 22. O-Ring

3. Radiator cap 13. To water pump 23. Gasket

4. Drain plug 14. Radiator and condenser cooling fan assembly 24. Water outlet cap O-ring No.1

5. Radiator outlet hose 15. Water inlet pipe No.1 25. Water outlet cap O-ring No.2

6. Radiator inlet hose 16. Water inlet pipe No.2 26. Thermostat cap bolts

7. Thermostat 17. Thermostat cap 27. Thermostat case bolts

8. ECT sensor 18. Water outlet cap Tightening torque

9. Thermostat case 19. Heater inlet hose Do not reuse.

10. To cylinder head 20. Heater outlet hose

Page 600 of 698

ENGINE COOLING 6B-11

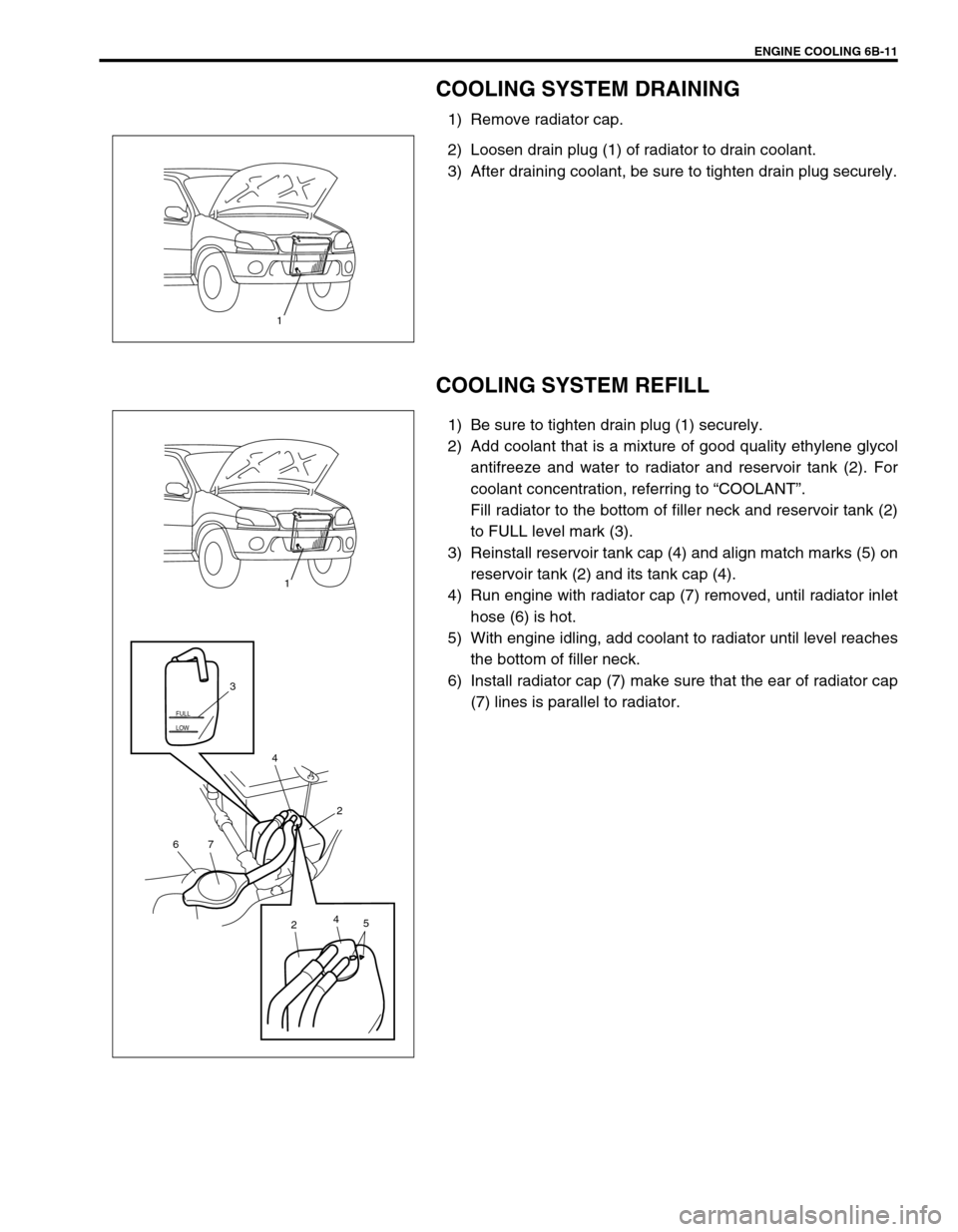

COOLING SYSTEM DRAINING

1) Remove radiator cap.

2) Loosen drain plug (1) of radiator to drain coolant.

3) After draining coolant, be sure to tighten drain plug securely.

COOLING SYSTEM REFILL

1) Be sure to tighten drain plug (1) securely.

2) Add coolant that is a mixture of good quality ethylene glycol

antifreeze and water to radiator and reservoir tank (2). For

coolant concentration, referring to “COOLANT”.

Fill radiator to the bottom of filler neck and reservoir tank (2)

to FULL level mark (3).

3) Reinstall reservoir tank cap (4) and align match marks (5) on

reservoir tank (2) and its tank cap (4).

4) Run engine with radiator cap (7) removed, until radiator inlet

hose (6) is hot.

5) With engine idling, add coolant to radiator until level reaches

the bottom of filler neck.

6) Install radiator cap (7) make sure that the ear of radiator cap

(7) lines is parallel to radiator.

1

LOW FULL

5 2

7 6

2 3

4

4

1