display SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 484 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-115

INSPECTION

Fig. 1 for Step 3Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Is SUZUKI scan tool available? Go to Step 3. Go to Step 4.

3 Check PNP Signal (“D” range signal).

1) Connect SUZUKI scan tool to DLC with igni-

tion switch OFF. See Fig. 1.

2) Turn ignition switch ON and check PNP sig-

nal (“P/N” or “D” range) on display when

shifting selector lever to each range.

Is “D” range on display (Is 0 – 1 V indicated) no

matter which of “R”, “D”, “2” and “L” range posi-

tions selector lever may be at? See Table 1.Intermittent trouble or

faulty ECM. Check for

intermittent referring to

“Intermittent and poor

connection” in Section 0A.Go to Step 5.

4 Check PNP Signal (“D” range signal).

1) Turn ignition switch ON.

2) Check voltage at terminal C41-14 (Case of

TYPE A. See NOTE) or G02-6 (Case of

TYPE B. See NOTE) of ECM connector

connected. See Fig. 2.

Is “D” range on display (Is 0 – 1 V indicated) no

matter which of “R”, “D”, “2” and “L” range posi-

tions selector lever may be at? See Table 1.Intermittent trouble or

faulty ECM. Check for

intermittent referring to

“Intermittent and poor

connection” in Section 0A.Go to Step 5.

5Is “P/N range on display (Is 10 – 14 V indicated)

when selector lever is at one of “R”, “D”, “2” and

“L” range positions only?Check transmission range

switch and circuits refer-

ring to section 7B.Go to Step 6.

6 Check PNP Signal Circuit.

1) Turn ignition switch OFF.

2) Disconnect TCM connectors.

3) Check for proper connection to TCM at ter-

minal C44-8.

4) If OK, then check voltage at terminal

C44-8 in TCM connector disconnected, with

ignition switch ON.

Is it 10 – 14 V? See Fig. 3“GRN/ORN” circuit open,

poor transmission range

switch connector connec-

tion, select cable malad-

justed, transmission

range sensor malad-

justed or transmission

range sensor malfunction.

If all above are OK, sub-

stitute a known-good

TCM and recheck.“LT BLU” (Case of TYPE

A. See NOTE) or “GRN

RED” (Case of TYPE B.

See NOTE) circuit open or

poor C41-14 (Case of

TYPE A. See NOTE) or

G02-6 (Case of TYPE B.

See NOTE) connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

Page 492 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-123

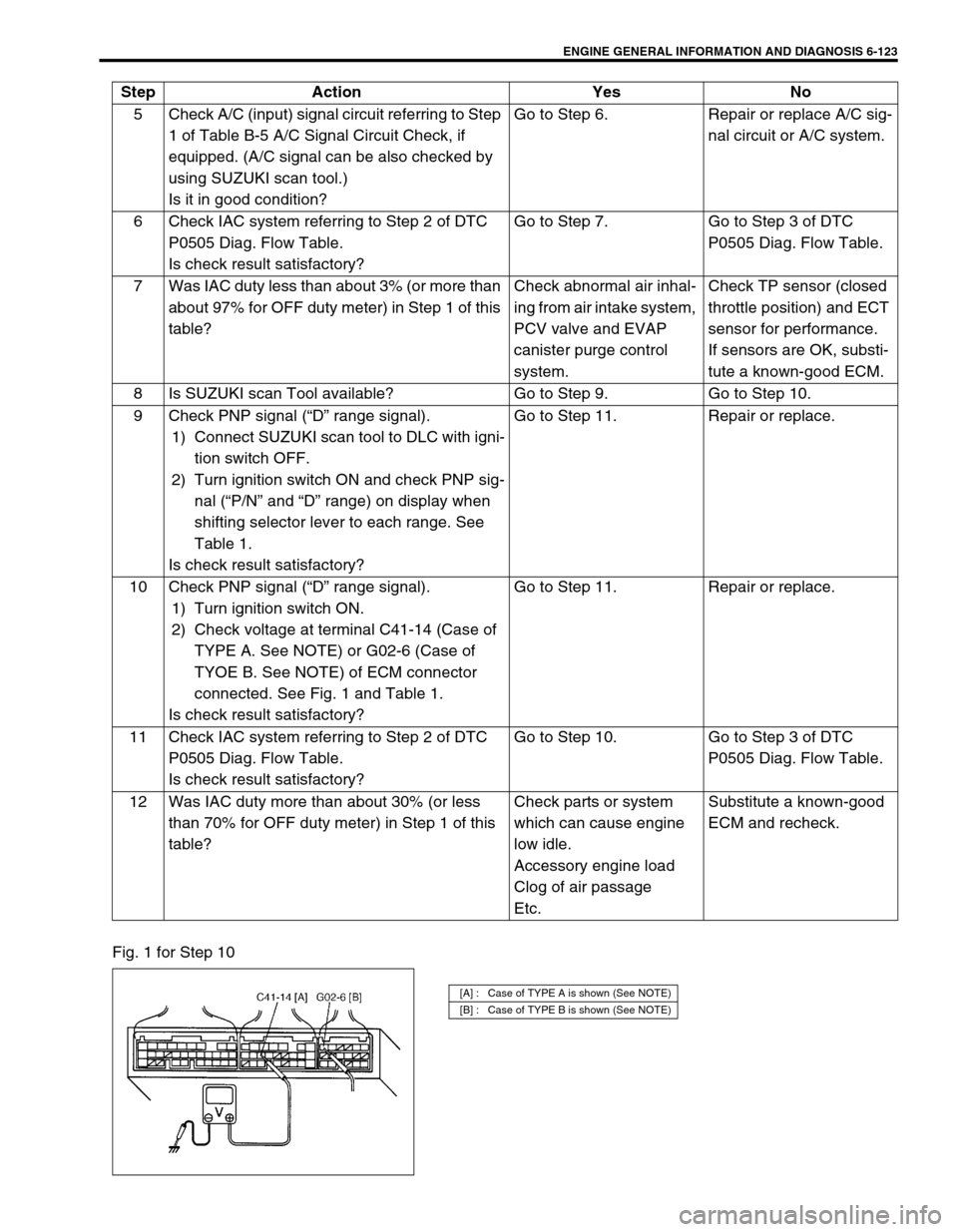

Fig. 1 for Step 105 Check A/C (input) signal circuit referring to Step

1 of Table B-5 A/C Signal Circuit Check, if

equipped. (A/C signal can be also checked by

using SUZUKI scan tool.)

Is it in good condition?Go to Step 6. Repair or replace A/C sig-

nal circuit or A/C system.

6 Check IAC system referring to Step 2 of DTC

P0505 Diag. Flow Table.

Is check result satisfactory?Go to Step 7. Go to Step 3 of DTC

P0505 Diag. Flow Table.

7 Was IAC duty less than about 3% (or more than

about 97% for OFF duty meter) in Step 1 of this

table?Check abnormal air inhal-

ing from air intake system,

PCV valve and EVAP

canister purge control

system.Check TP sensor (closed

throttle position) and ECT

sensor for performance.

If sensors are OK, substi-

tute a known-good ECM.

8 Is SUZUKI scan Tool available? Go to Step 9. Go to Step 10.

9 Check PNP signal (“D” range signal).

1) Connect SUZUKI scan tool to DLC with igni-

tion switch OFF.

2) Turn ignition switch ON and check PNP sig-

nal (“P/N” and “D” range) on display when

shifting selector lever to each range. See

Table 1.

Is check result satisfactory?Go to Step 11. Repair or replace.

10 Check PNP signal (“D” range signal).

1) Turn ignition switch ON.

2) Check voltage at terminal C41-14 (Case of

TYPE A. See NOTE) or G02-6 (Case of

TYOE B. See NOTE) of ECM connector

connected. See Fig. 1 and Table 1.

Is check result satisfactory?Go to Step 11. Repair or replace.

11 Check IAC system referring to Step 2 of DTC

P0505 Diag. Flow Table.

Is check result satisfactory?Go to Step 10. Go to Step 3 of DTC

P0505 Diag. Flow Table.

12 Was IAC duty more than about 30% (or less

than 70% for OFF duty meter) in Step 1 of this

table?Check parts or system

which can cause engine

low idle.

Accessory engine load

Clog of air passage

Etc.Substitute a known-good

ECM and recheck. Step Action Yes No

[A] : Case of TYPE A is shown (See NOTE)

[B] : Case of TYPE B is shown (See NOTE)

Page 493 of 698

6-124 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Table 1 for Step 9 and 10

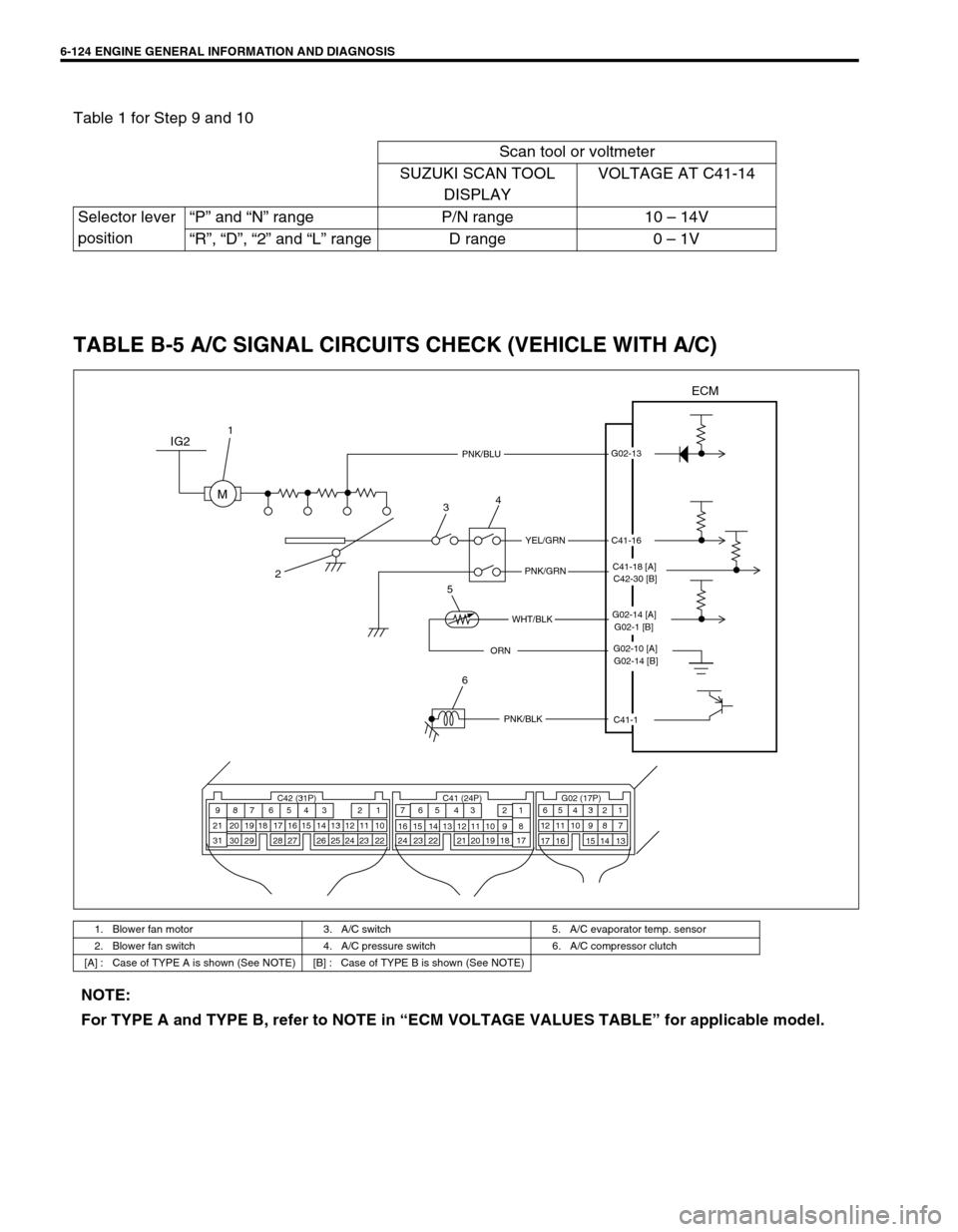

TABLE B-5 A/C SIGNAL CIRCUITS CHECK (VEHICLE WITH A/C)

Scan tool or voltmeter

SUZUKI SCAN TOOL

DISPLAYVOLTAGE AT C41-14

Selector lever

position“P” and “N” range P/N range 10 – 14V

“R”, “D”, “2” and “L” range D range 0 – 1V

1. Blower fan motor 3. A/C switch 5. A/C evaporator temp. sensor

2. Blower fan switch 4. A/C pressure switch 6. A/C compressor clutch

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

IG2

M

ECM

PNK/BLU

YEL/GRN

PNK/GRN

WHT/BLK

ORN

PNK/BLK

G02-13

C41-16

C41-1

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

1

234

5

6

C41-18 [A]

C42-30 [B]

G02-14 [A]

G02-1 [B]

G02-14 [B] G02-10 [A]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Page 497 of 698

![SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual 6-128 ENGINE GENERAL INFORMATION AND DIAGNOSIS

TABLE B-7 RADIATOR FAN CONTROL SYSTEM CHECK

INSPECTION

1. Radiator fan relay No.1 3. Radiator fan relay No.3 [A] : Case of TYPE A is shown (See NOTE)

2. SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual 6-128 ENGINE GENERAL INFORMATION AND DIAGNOSIS

TABLE B-7 RADIATOR FAN CONTROL SYSTEM CHECK

INSPECTION

1. Radiator fan relay No.1 3. Radiator fan relay No.3 [A] : Case of TYPE A is shown (See NOTE)

2.](/img/20/7606/w960_7606-496.png)

6-128 ENGINE GENERAL INFORMATION AND DIAGNOSIS

TABLE B-7 RADIATOR FAN CONTROL SYSTEM CHECK

INSPECTION

1. Radiator fan relay No.1 3. Radiator fan relay No.3 [A] : Case of TYPE A is shown (See NOTE)

2. Radiator fan relay No.2 4. Radiator fan [B] : Case of TYPE B is shown (See NOTE)

BATT

80A30A

15A

BLKBLU/WHT

ECM

BLK/ORN

BLK/ORNC42-1

C42-3

L+

L–

H– H+

BLU

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C41-18

GRN/RED [B]PPL/YEL [A]

BLK/RED

BLU/WHT

BLU/RED

BLK

BLU

BLU/BLK

PPL/YEL

BLU/REDBLK/YEL

BRN/WHT

1

2

34

G02-3 [A]

C41-9 [B]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Step Action Yes No

1 Check Fan Control System.

1) Connect scan tool to DLC with ignition switch OFF.

2) Start engine and select “DATA LIST” mode on scan

tool.

3) Warm up engine until coolant temp. is 97.5°C, 208°F or

higher and A/C switch turn OFF. (If engine coolant

temp. does not rise, check engine cooling system or

ECT sensor.) See Fig. 1.

Is radiator cooling fan started when engine coolant temp.

reached above temp.?Radiator cooling fan

control system is in

good condition.Go to Step 2.

2 Check Radiator Fan Relay and Its Circuit.

1) Check DTC and pending DTC with scan tool.

Is DTC P0480 displayed?Go to DTC P0480 Diag.

Flow Table.Go to Step 3.

3 Check Radiator Fan Relays.

1) Turn ignition switch OFF and remove radiator cooling

fan relays. (No.1 – No.3)

2) Check for proper connection to relay at terminals “c”

and “d”.

3) If OK, check that there is continuity between “c” and “d”

when battery is connected to terminals “a” and “b”. See

Fig. 2.

Is check result satisfactory?Go to Step 4. Replace radia-

tor fan relay(s).

Page 657 of 698

6E1-36 ENGINE AND EMISSION CONTROL SYSTEM

OUTPUT SIGNALS OF THROTTLE VALVE OPENING

AND ENGINE COOLANT TEMP. (VEHICLE WITH A/T

ONLY)

THROTTLE VALVE OPENING SIGNAL INSPECTION

Check throttle valve opening (throttle position) signal referring to

step 1 of DTC P1700 (No.32 or 33) Flow Table in Section 7B. If

check result is not satisfactory, check each wire harness, circuit

connections and TP sensor.

ENGINE COOLANT TEMP. SIGNAL INSPECTION

Check engine coolant temp. signal referring to step 1 of DTC

P1705 (NO.51) Flow Table in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connection and ECT sensor.

EMISSION CONTROL SYSTEM

EGR SYSTEM

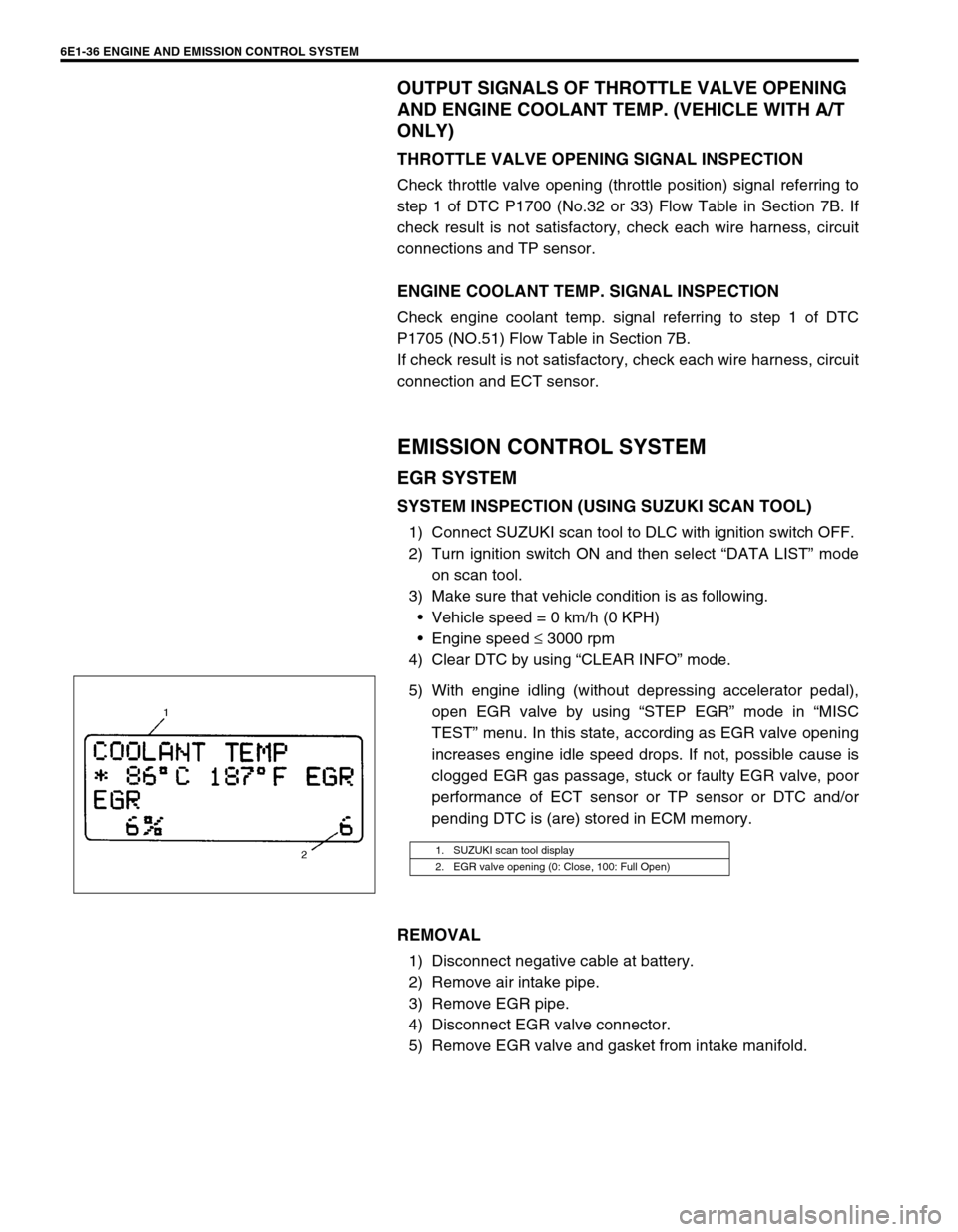

SYSTEM INSPECTION (USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

2) Turn ignition switch ON and then select “DATA LIST” mode

on scan tool.

3) Make sure that vehicle condition is as following.

Vehicle speed = 0 km/h (0 KPH)

Engine speed ≤ 3000 rpm

4) Clear DTC by using “CLEAR INFO” mode.

5) With engine idling (without depressing accelerator pedal),

open EGR valve by using “STEP EGR” mode in “MISC

TEST” menu. In this state, according as EGR valve opening

increases engine idle speed drops. If not, possible cause is

clogged EGR gas passage, stuck or faulty EGR valve, poor

performance of ECT sensor or TP sensor or DTC and/or

pending DTC is (are) stored in ECM memory.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from intake manifold.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full Open)