SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 631 of 698

6E1-10 ENGINE AND EMISSION CONTROL SYSTEM

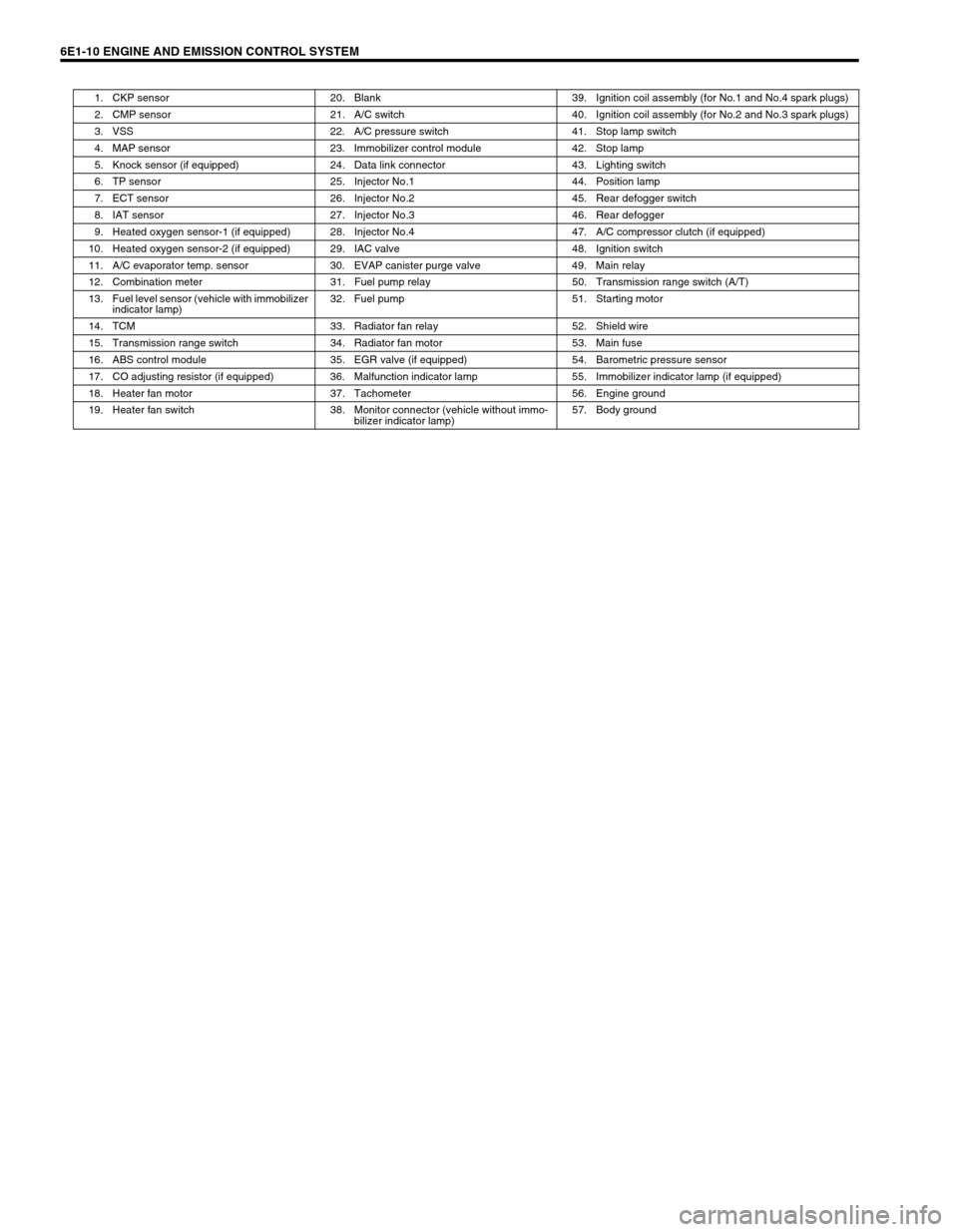

1. CKP sensor 20. Blank 39. Ignition coil assembly (for No.1 and No.4 spark plugs)

2. CMP sensor 21. A/C switch 40. Ignition coil assembly (for No.2 and No.3 spark plugs)

3. VSS 22. A/C pressure switch 41. Stop lamp switch

4. MAP sensor 23. Immobilizer control module 42. Stop lamp

5. Knock sensor (if equipped) 24. Data link connector 43. Lighting switch

6. TP sensor 25. Injector No.1 44. Position lamp

7. ECT sensor 26. Injector No.2 45. Rear defogger switch

8. IAT sensor 27. Injector No.3 46. Rear defogger

9. Heated oxygen sensor-1 (if equipped) 28. Injector No.4 47. A/C compressor clutch (if equipped)

10. Heated oxygen sensor-2 (if equipped) 29. IAC valve 48. Ignition switch

11. A/C evaporator temp. sensor 30. EVAP canister purge valve 49. Main relay

12. Combination meter 31. Fuel pump relay 50. Transmission range switch (A/T)

13. Fuel level sensor (vehicle with immobilizer

indicator lamp)32. Fuel pump 51. Starting motor

14. TCM 33. Radiator fan relay 52. Shield wire

15. Transmission range switch 34. Radiator fan motor 53. Main fuse

16. ABS control module 35. EGR valve (if equipped) 54. Barometric pressure sensor

17. CO adjusting resistor (if equipped) 36. Malfunction indicator lamp 55. Immobilizer indicator lamp (if equipped)

18. Heater fan motor 37. Tachometer 56. Engine ground

19. Heater fan switch 38. Monitor connector (vehicle without immo-

bilizer indicator lamp)57. Body ground

Page 632 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-11

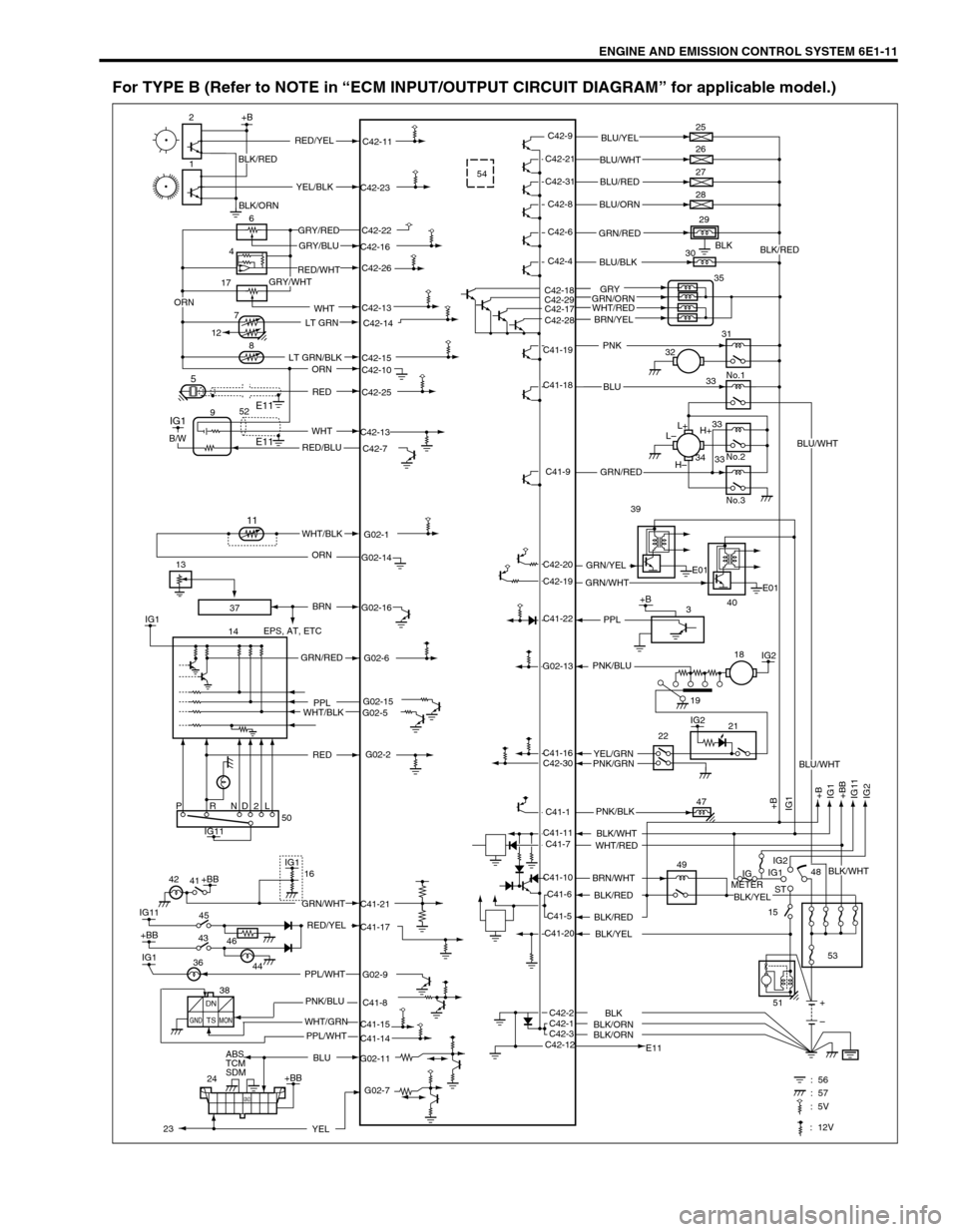

For TYPE B (Refer to NOTE in “ECM INPUT/OUTPUT CIRCUIT DIAGRAM” for applicable model.)

37

54

BLK

C42-18

C42-29

C42-17

C42-28

C42-13

17

2+B

1

6

8

5

IG1

IG1

14C42-9

C42-11

C42-23

C42-22

C42-16

C42-26

C42-14

C42-15

C42-10

C42-25

C42-13

C42-7

G02-1

G02-14

G02-16

G02-6

G02-15

G02-5

G02-2

C41-21

C41-17

G02-9

C41-8

C41-14 C41-15

G02-11C42-21

C42-31

C42-8

C42-6

C42-4

C41-19

C41-18

C41-9

C41-22

G02-13

C41-16

C42-30

C41-1

C41-10

C41-6

C41-5

C41-20

C42-1 C42-2

C42-3

C42-12 C41-11

C41-73E01

E01 C42-20

C42-19L+

L–

H–H+ 25

26

27

28

29

30

35

31

No.1

No.2

No.3 32

33

33

33 34

IG2

IG2

+B

+B

IG1

+BB

IG11

IG2 IG1

21

47

49

IG

METERIG1

ST

15IG2

48

53

E11+

– 2218

PRND2L

IG11

IG11

+BB

IG145 41

ABS

TCM

SDM

24IG1

+BB50

16

E11

E1194

7

12

52

+BB

GND

: 56 : 57

11

+B RED/YELBLU/YEL

BLU/WHT

BLU/RED

BLU/ORN

GRN/RED

BLU/BLK

PNK

BLU

GRN/RED

GRN/YEL39

40 GRN/WHT

PPL

YEL/GRN PNK/BLU

PNK/GRN

PNK/BLK

BLK/WHT

WHT/RED

BRN/WHT

BLK/RED

BLK/RED

BLK/YEL

BLK/ORNBLK

BLK/ORN YEL/BLK

GRY/RED

GRY/BLU

RED/WHT

GRY/WHT

LT GRN

LT GRN/BLK

ORN

RED

WHT

RED/BLU

WHT/BLK

ORN

BRN

EPS, AT, ETC

GRN/RED

PPL

WHT/BLK

GRN/WHT

RED/YEL

PPL/WHT

PNK/BLU

WHT/GRN

BLU

B/W

RED

42

46 43

44 36

DN

TS

GND MON

PPL/WHT 38

G02-7

YEL

BLK/RED

GRY

GRN/ORN

BRN/YEL

51

23

13WHT

19

ORN

: 5V

: 12V

BLU/WHT

BLK/WHT

BLU/WHT

BLK/YEL

BLK/RED

BLK/ORN

WHT/RED

Page 633 of 698

6E1-12 ENGINE AND EMISSION CONTROL SYSTEM

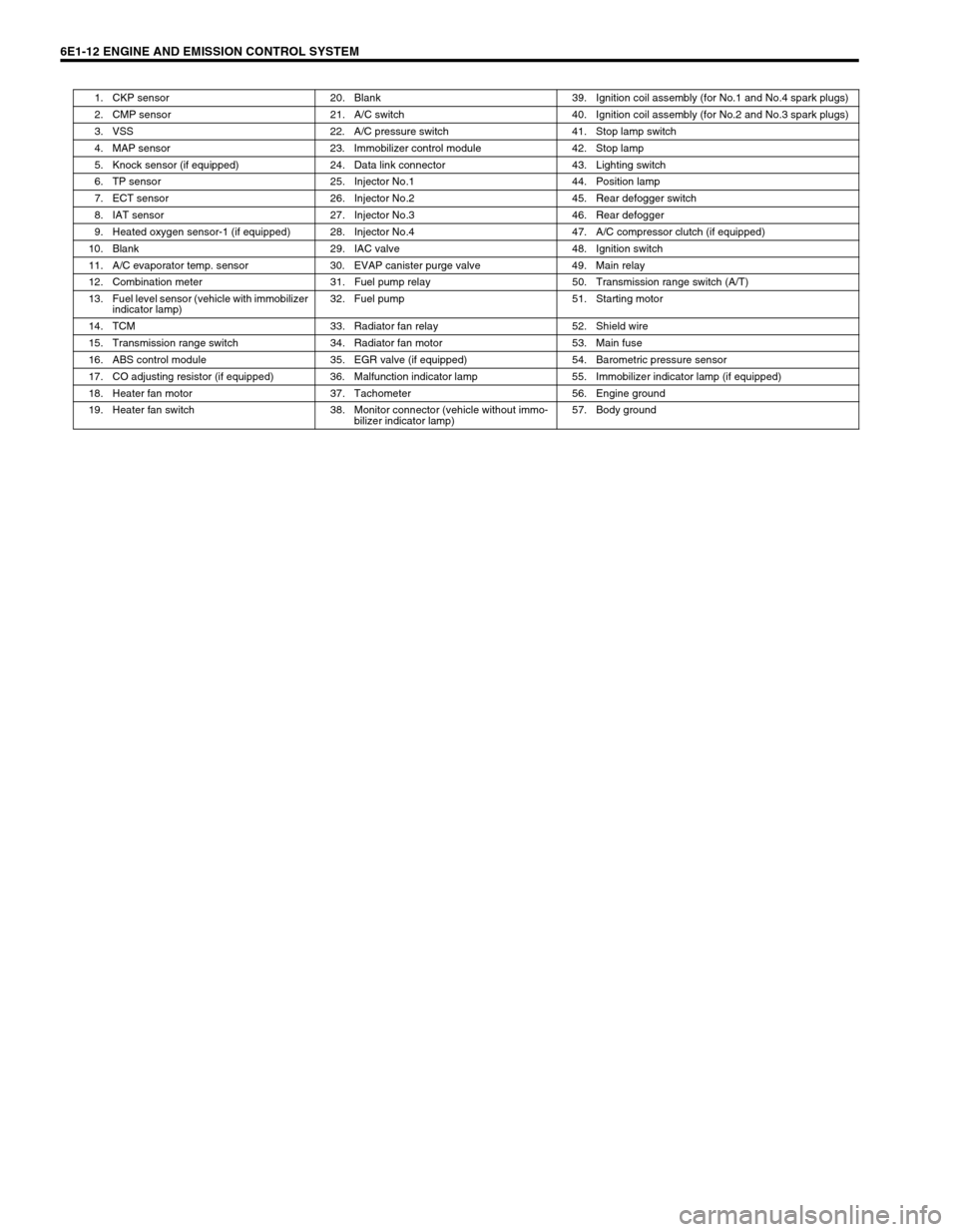

1. CKP sensor 20. Blank 39. Ignition coil assembly (for No.1 and No.4 spark plugs)

2. CMP sensor 21. A/C switch 40. Ignition coil assembly (for No.2 and No.3 spark plugs)

3. VSS 22. A/C pressure switch 41. Stop lamp switch

4. MAP sensor 23. Immobilizer control module 42. Stop lamp

5. Knock sensor (if equipped) 24. Data link connector 43. Lighting switch

6. TP sensor 25. Injector No.1 44. Position lamp

7. ECT sensor 26. Injector No.2 45. Rear defogger switch

8. IAT sensor 27. Injector No.3 46. Rear defogger

9. Heated oxygen sensor-1 (if equipped) 28. Injector No.4 47. A/C compressor clutch (if equipped)

10. Blank 29. IAC valve 48. Ignition switch

11. A/C evaporator temp. sensor 30. EVAP canister purge valve 49. Main relay

12. Combination meter 31. Fuel pump relay 50. Transmission range switch (A/T)

13. Fuel level sensor (vehicle with immobilizer

indicator lamp)32. Fuel pump 51. Starting motor

14. TCM 33. Radiator fan relay 52. Shield wire

15. Transmission range switch 34. Radiator fan motor 53. Main fuse

16. ABS control module 35. EGR valve (if equipped) 54. Barometric pressure sensor

17. CO adjusting resistor (if equipped) 36. Malfunction indicator lamp 55. Immobilizer indicator lamp (if equipped)

18. Heater fan motor 37. Tachometer 56. Engine ground

19. Heater fan switch 38. Monitor connector (vehicle without immo-

bilizer indicator lamp)57. Body ground

Page 634 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-13

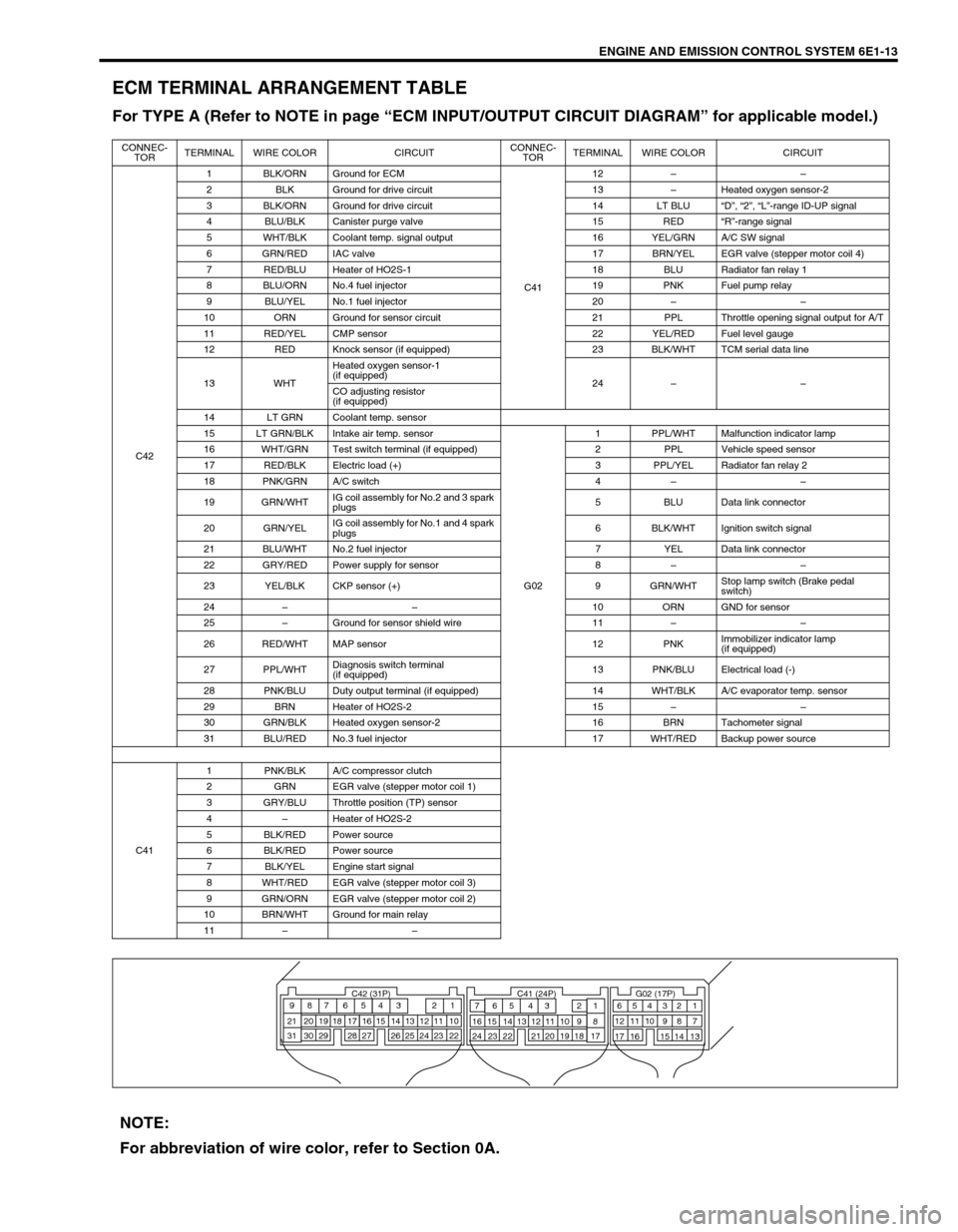

ECM TERMINAL ARRANGEMENT TABLE

For TYPE A (Refer to NOTE in page “ECM INPUT/OUTPUT CIRCUIT DIAGRAM” for applicable model.)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

C421 BLK/ORN Ground for ECM

C4112––

2 BLK Ground for drive circuit 13–Heated oxygen sensor-2

3 BLK/ORN Ground for drive circuit 14 LT BLU“D”, “2”, “L”-range ID-UP signal

4 BLU/BLK Canister purge valve 15 RED“R”-range signal

5 WHT/BLK Coolant temp. signal output 16 YEL/GRN A/C SW signal

6 GRN/RED IAC valve 17 BRN/YEL EGR valve (stepper motor coil 4)

7 RED/BLU Heater of HO2S-1 18 BLU Radiator fan relay 1

8 BLU/ORN No.4 fuel injector 19 PNK Fuel pump relay

9 BLU/YEL No.1 fuel injector 20––

10 ORN Ground for sensor circuit 21 PPL Throttle opening signal output for A/T

11 RED/YEL CMP sensor 22 YEL/RED Fuel level gauge

12 RED Knock sensor (if equipped) 23 BLK/WHT TCM serial data line

13 WHTHeated oxygen sensor-1

(if equipped)

24––

CO adjusting resistor

(if equipped)

14 LT GRN Coolant temp. sensor

15 LT GRN/BLK Intake air temp. sensor

G021 PPL/WHT Malfunction indicator lamp

16 WHT/GRN Test switch terminal (if equipped) 2 PPL Vehicle speed sensor

17 RED/BLK Electric load (+) 3 PPL/YEL Radiator fan relay 2

18 PNK/GRN A/C switch 4––

19 GRN/WHTIG coil assembly for No.2 and 3 spark

plugs5 BLU Data link connector

20 GRN/YELIG coil assembly for No.1 and 4 spark

plugs6 BLK/WHT Ignition switch signal

21 BLU/WHT No.2 fuel injector 7 YEL Data link connector

22 GRY/RED Power supply for sensor 8––

23 YEL/BLK CKP sensor (+) 9 GRN/WHTStop lamp switch (Brake pedal

switch)

24––10 ORN GND for sensor

25–Ground for sensor shield wire 11––

26 RED/WHT MAP sensor 12 PNKImmobilizer indicator lamp

(if equipped)

27 PPL/WHTDiagnosis switch terminal

(if equipped)13 PNK/BLU Electrical load (-)

28 PNK/BLU Duty output terminal (if equipped) 14 WHT/BLK A/C evaporator temp. sensor

29 BRN Heater of HO2S-2 15––

30 GRN/BLK Heated oxygen sensor-2 16 BRN Tachometer signal

31 BLU/RED No.3 fuel injector 17 WHT/RED Backup power source

C411 PNK/BLK A/C compressor clutch

2 GRN EGR valve (stepper motor coil 1)

3 GRY/BLU Throttle position (TP) sensor

4–Heater of HO2S-2

5 BLK/RED Power source

6 BLK/RED Power source

7 BLK/YEL Engine start signal

8 WHT/RED EGR valve (stepper motor coil 3)

9 GRN/ORN EGR valve (stepper motor coil 2)

10 BRN/WHT Ground for main relay

11––

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

NOTE:

For abbreviation of wire color, refer to Section 0A.

Page 635 of 698

6E1-14 ENGINE AND EMISSION CONTROL SYSTEM

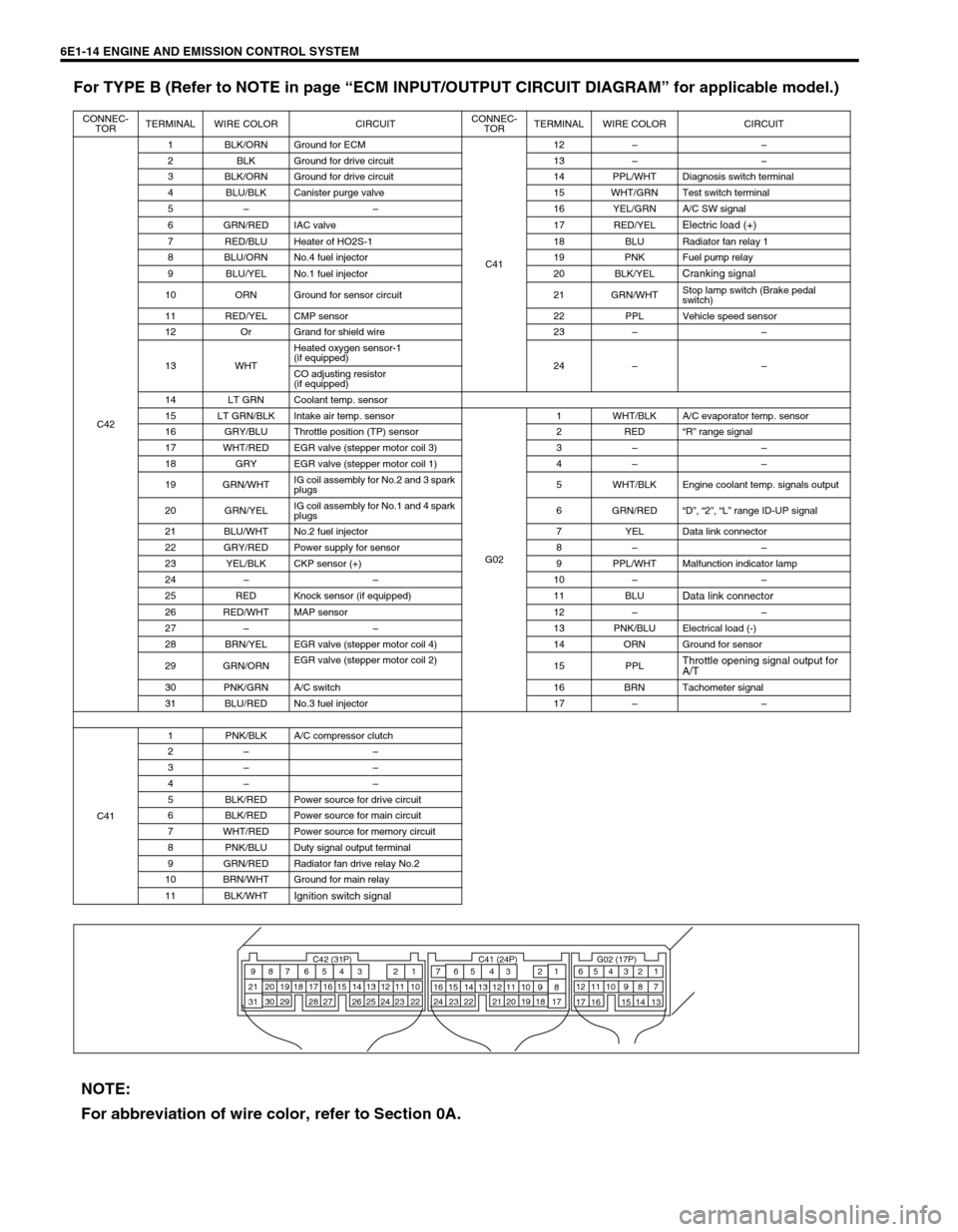

For TYPE B (Refer to NOTE in page “ECM INPUT/OUTPUT CIRCUIT DIAGRAM” for applicable model.)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

C421 BLK/ORN Ground for ECM

C4112––

2 BLK Ground for drive circuit 13––

3 BLK/ORN Ground for drive circuit 14 PPL/WHT Diagnosis switch terminal

4 BLU/BLK Canister purge valve 15 WHT/GRN Test switch terminal

5––16 YEL/GRN A/C SW signal

6 GRN/RED IAC valve 17 RED/YEL

Electric load (+)

7 RED/BLU Heater of HO2S-1 18 BLU Radiator fan relay 1

8 BLU/ORN No.4 fuel injector 19 PNK Fuel pump relay

9 BLU/YEL No.1 fuel injector 20 BLK/YEL

Cranking signal

10 ORN Ground for sensor circuit 21 GRN/WHTStop lamp switch (Brake pedal

switch)

11 RED/YEL CMP sensor 22 PPL Vehicle speed sensor

12 Or Grand for shield wire 23––

13 WHTHeated oxygen sensor-1

(if equipped)

24––

CO adjusting resistor

(if equipped)

14 LT GRN Coolant temp. sensor

15 LT GRN/BLK Intake air temp. sensor

G021 WHT/BLK A/C evaporator temp. sensor

16 GRY/BLU Throttle position (TP) sensor 2 RED“R” range signal

17 WHT/RED EGR valve (stepper motor coil 3) 3––

18 GRY EGR valve (stepper motor coil 1) 4––

19 GRN/WHTIG coil assembly for No.2 and 3 spark

plugs5 WHT/BLK Engine coolant temp. signals output

20 GRN/YELIG coil assembly for No.1 and 4 spark

plugs6 GRN/RED“D”, “2”, “L” range ID-UP signal

21 BLU/WHT No.2 fuel injector 7 YEL Data link connector

22 GRY/RED Power supply for sensor 8––

23 YEL/BLK CKP sensor (+) 9 PPL/WHT Malfunction indicator lamp

24––10––

25 RED Knock sensor (if equipped) 11 BLU

Data link connector

26 RED/WHT MAP sensor 12––

27––13 PNK/BLU Electrical load (-)

28 BRN/YEL EGR valve (stepper motor coil 4) 14 ORN Ground for sensor

29 GRN/ORNEGR valve (stepper motor coil 2)

15 PPL

Throttle opening signal output for

A/T

30 PNK/GRN A/C switch 16 BRN Tachometer signal

31 BLU/RED No.3 fuel injector 17––

C411 PNK/BLK A/C compressor clutch

2––

3––

4––

5 BLK/RED Power source for drive circuit

6 BLK/RED Power source for main circuit

7 WHT/RED Power source for memory circuit

8 PNK/BLU Duty signal output terminal

9 GRN/RED Radiator fan drive relay No.2

10 BRN/WHT Ground for main relay

11 BLK/WHT

Ignition switch signal

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

NOTE:

For abbreviation of wire color, refer to Section 0A.

Page 636 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-15

ON-VEHICLE SERVICE

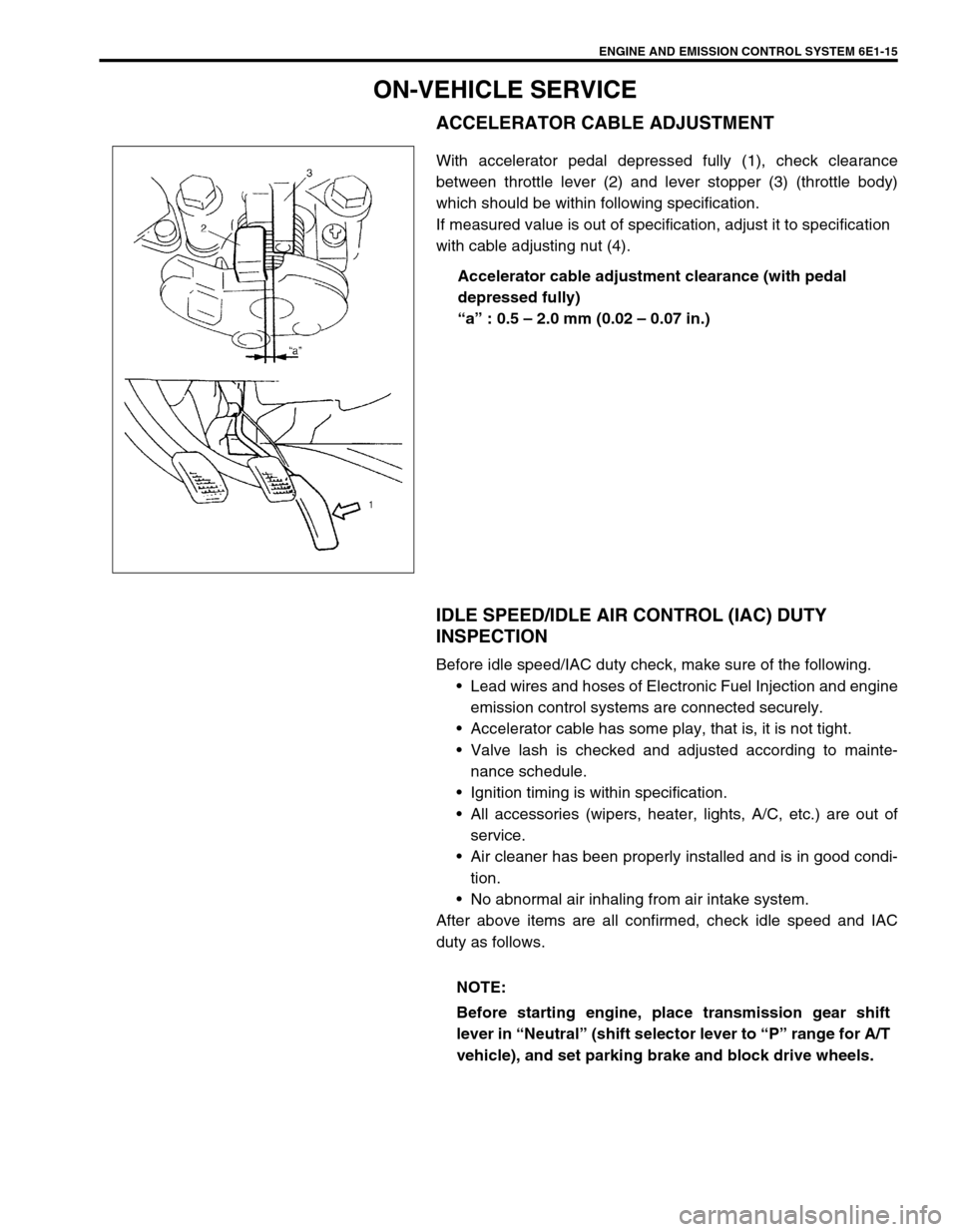

ACCELERATOR CABLE ADJUSTMENT

With accelerator pedal depressed fully (1), check clearance

between throttle lever (2) and lever stopper (3) (throttle body)

which should be within following specification.

If measured value is out of specification, adjust it to specification

with cable adjusting nut (4).

Accelerator cable adjustment clearance (with pedal

depressed fully)

“a” : 0.5 – 2.0 mm (0.02 – 0.07 in.)

IDLE SPEED/IDLE AIR CONTROL (IAC) DUTY

INSPECTION

Before idle speed/IAC duty check, make sure of the following.

Lead wires and hoses of Electronic Fuel Injection and engine

emission control systems are connected securely.

Accelerator cable has some play, that is, it is not tight.

Valve lash is checked and adjusted according to mainte-

nance schedule.

Ignition timing is within specification.

All accessories (wipers, heater, lights, A/C, etc.) are out of

service.

Air cleaner has been properly installed and is in good condi-

tion.

No abnormal air inhaling from air intake system.

After above items are all confirmed, check idle speed and IAC

duty as follows.

NOTE:

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

vehicle), and set parking brake and block drive wheels.

Page 637 of 698

6E1-16 ENGINE AND EMISSION CONTROL SYSTEM

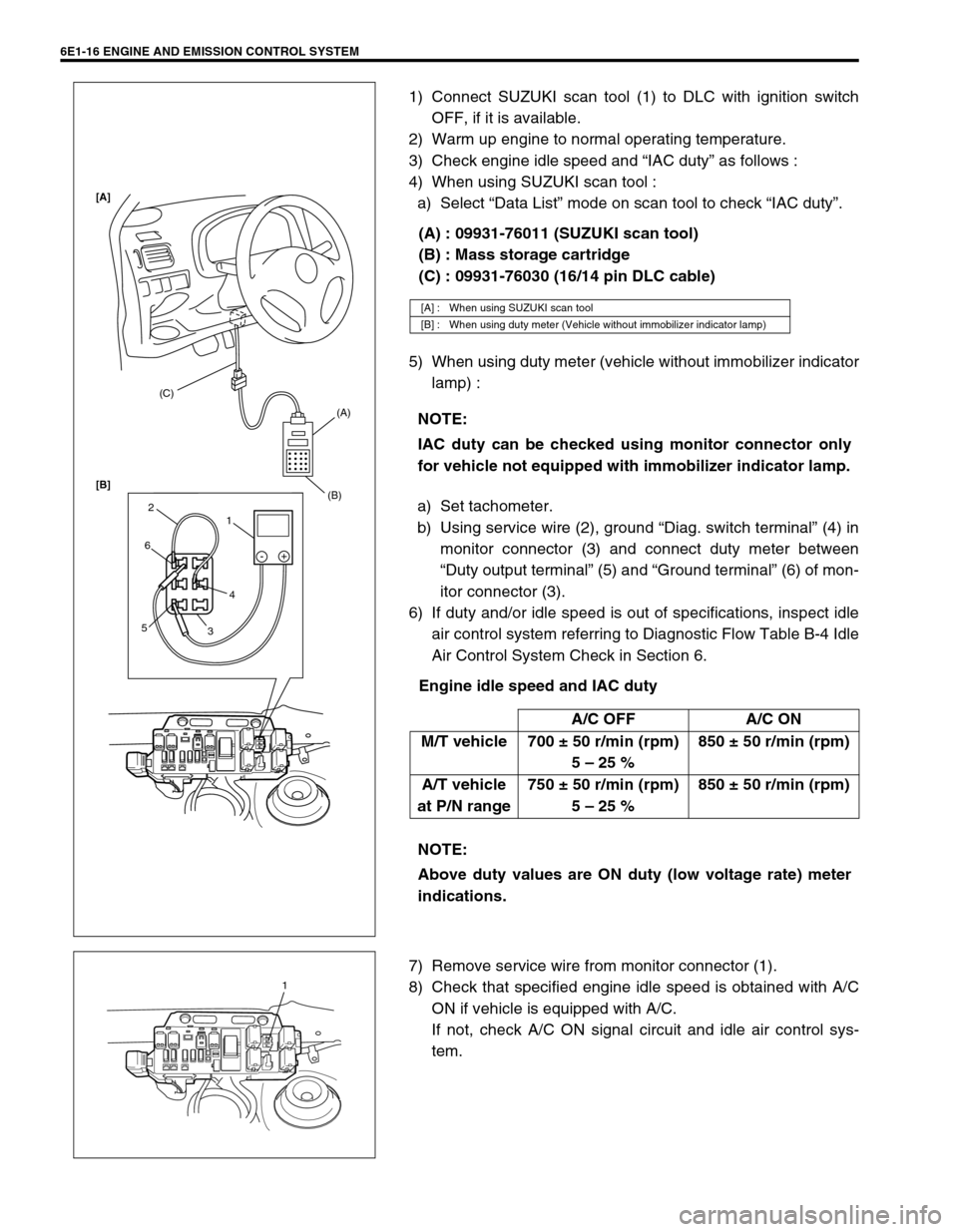

1) Connect SUZUKI scan tool (1) to DLC with ignition switch

OFF, if it is available.

2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC duty” as follows :

4) When using SUZUKI scan tool :

a) Select “Data List” mode on scan tool to check “IAC duty”.

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Mass storage cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

5) When using duty meter (vehicle without immobilizer indicator

lamp) :

a) Set tachometer.

b) Using service wire (2), ground “Diag. switch terminal” (4) in

monitor connector (3) and connect duty meter between

“Duty output terminal” (5) and “Ground terminal” (6) of mon-

itor connector (3).

6) If duty and/or idle speed is out of specifications, inspect idle

air control system referring to Diagnostic Flow Table B-4 Idle

Air Control System Check in Section 6.

Engine idle speed and IAC duty

7) Remove service wire from monitor connector (1).

8) Check that specified engine idle speed is obtained with A/C

ON if vehicle is equipped with A/C.

If not, check A/C ON signal circuit and idle air control sys-

tem.

[A] : When using SUZUKI scan tool

[B] : When using duty meter (Vehicle without immobilizer indicator lamp)

NOTE:

IAC duty can be checked using monitor connector only

for vehicle not equipped with immobilizer indicator lamp.

A/C OFF A/C ON

M/T vehicle 700 ± 50 r/min (rpm)

5 – 25 %850 ± 50 r/min (rpm)

A/T vehicle

at P/N range750 ± 50 r/min (rpm)

5 – 25 %850 ± 50 r/min (rpm)

NOTE:

Above duty values are ON duty (low voltage rate) meter

indications.

(C)

(A)

(B)

1 2

6

54

3-+

[A]

[B]

1

Page 638 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-17

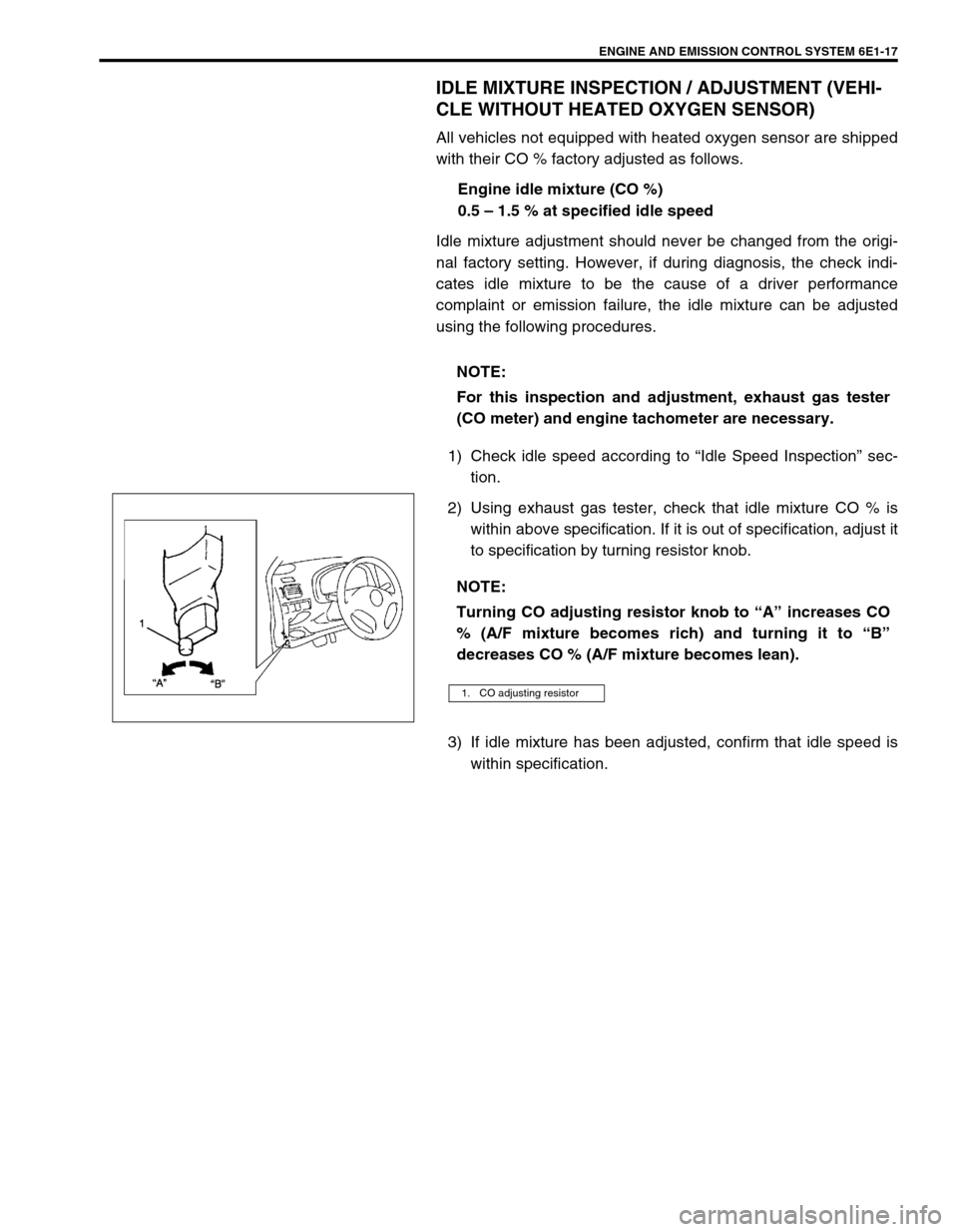

IDLE MIXTURE INSPECTION / ADJUSTMENT (VEHI-

CLE WITHOUT HEATED OXYGEN SENSOR)

All vehicles not equipped with heated oxygen sensor are shipped

with their CO % factory adjusted as follows.

Engine idle mixture (CO %)

0.5 – 1.5 % at specified idle speed

Idle mixture adjustment should never be changed from the origi-

nal factory setting. However, if during diagnosis, the check indi-

cates idle mixture to be the cause of a driver performance

complaint or emission failure, the idle mixture can be adjusted

using the following procedures.

1) Check idle speed according to “Idle Speed Inspection” sec-

tion.

2) Using exhaust gas tester, check that idle mixture CO % is

within above specification. If it is out of specification, adjust it

to specification by turning resistor knob.

3) If idle mixture has been adjusted, confirm that idle speed is

within specification. NOTE:

For this inspection and adjustment, exhaust gas tester

(CO meter) and engine tachometer are necessary.

NOTE:

Turning CO adjusting resistor knob to “A” increases CO

% (A/F mixture becomes rich) and turning it to “B”

decreases CO % (A/F mixture becomes lean).

1. CO adjusting resistor

Page 639 of 698

6E1-18 ENGINE AND EMISSION CONTROL SYSTEM

AIR INTAKE SYSTEM

THROTTLE BODY

ON-VEHICLE INSPECTION

Check that throttle valve lever (1) moves smoothly.

REMOVAL

1) Disconnect negative cable at battery.

2) Drain cooling system.

3) Disconnect accelerator cable (1) from throttle valve lever.

4) Disconnect IAT sensor connector and remove air cleaner

assembly with air cleaner outlet hose.

1. Throttle body 4. Gasket 7. TP sensor screws

2. Throttle stop screw 5. Idle air control valve Tightening torque

3. TP sensor 6. IAC valve screws Do not reuse.

Page 640 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-19

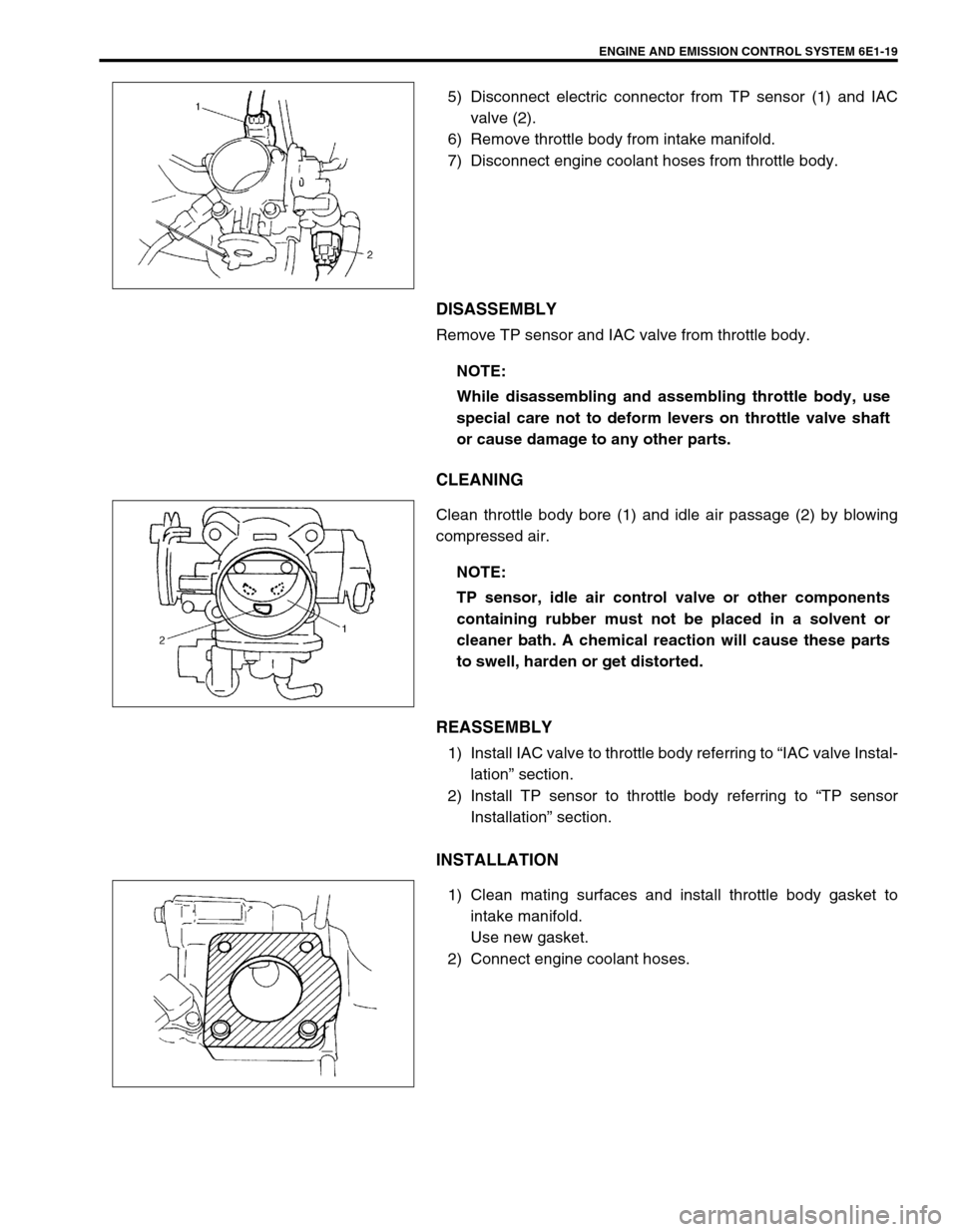

5) Disconnect electric connector from TP sensor (1) and IAC

valve (2).

6) Remove throttle body from intake manifold.

7) Disconnect engine coolant hoses from throttle body.

DISASSEMBLY

Remove TP sensor and IAC valve from throttle body.

CLEANING

Clean throttle body bore (1) and idle air passage (2) by blowing

compressed air.

REASSEMBLY

1) Install IAC valve to throttle body referring to “IAC valve Instal-

lation” section.

2) Install TP sensor to throttle body referring to “TP sensor

Installation” section.

INSTALLATION

1) Clean mating surfaces and install throttle body gasket to

intake manifold.

Use new gasket.

2) Connect engine coolant hoses.

NOTE:

While disassembling and assembling throttle body, use

special care not to deform levers on throttle valve shaft

or cause damage to any other parts.

NOTE:

TP sensor, idle air control valve or other components

containing rubber must not be placed in a solvent or

cleaner bath. A chemical reaction will cause these parts

to swell, harden or get distorted.