SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 651 of 698

6E1-30 ENGINE AND EMISSION CONTROL SYSTEM

ENGINE COOLANT TEMPERATURE SENSOR (ECT

SENSOR)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Drain coolant referring to Section 6B.

3) Remove air intake pipe.

4) Disconnect connector from ECT sensor.

5) Remove ECT sensor (1) from thermostat case.

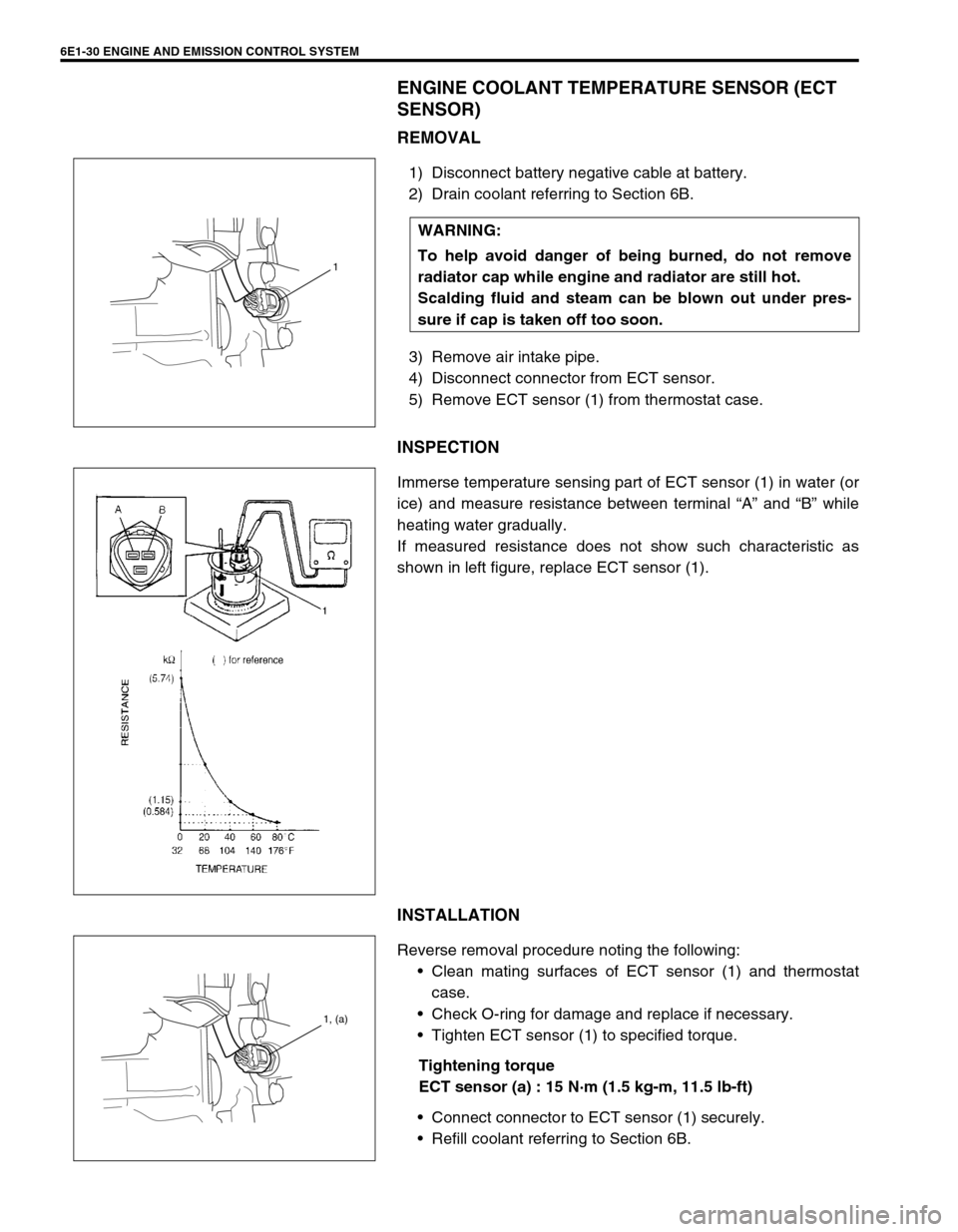

INSPECTION

Immerse temperature sensing part of ECT sensor (1) in water (or

ice) and measure resistance between terminal “A” and “B” while

heating water gradually.

If measured resistance does not show such characteristic as

shown in left figure, replace ECT sensor (1).

INSTALLATION

Reverse removal procedure noting the following:

Clean mating surfaces of ECT sensor (1) and thermostat

case.

Check O-ring for damage and replace if necessary.

Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a) : 15 N·m (1.5 kg-m, 11.5 lb-ft)

Connect connector to ECT sensor (1) securely.

Refill coolant referring to Section 6B. WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.

1

1, (a)

Page 652 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-31

HEATED OXYGEN SENSOR (HO2S-1 AND HO2S-2)

OXYGEN SENSOR HEATER INSPECTION

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between terminals

“V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

Resistance of oxygen sensor heater

HO2S-1 : 5.0 – 6.4

Ω at 20°C (68°F)

HO2S-2 : 11.7 – 14.3

Ω at 20°C (68°F)

3) Connect sensor connector securely.

REMOVAL

1) Disconnect negative cable at battery.

2) For HO2S-1, disconnect connector of heated oxygen sensor

and release its wire harness from clamps, then remove front

bumper and heat insulator panel.

3) For HO2S-2, disconnect connector of heated oxygen sensor

and release its wire harness from clamp and hoist vehicle.

4) Remove heated oxygen sensor (1) from exhaust manifold or

exhaust pipe.

INSTALLATION

Reverse removal procedure noting the following.

Tighten heated oxygen sensor (1) to specified torque.

Tightening torque

Heated oxygen sensor (a) : 45 N·m (4.5 kg-m, 32.5 lb-ft)

Connect connector of heated oxygen sensor (1) and clamp

wire harness securely.

After installing heated oxygen sensor (1), start engine and

check that no exhaust gas leakage exists. NOTE:

Temperature of sensor affects resistance value largely.

Make sure that sensor heater is at correct temperature.

1. Viewed from terminal side

WARNING:

To avoid danger of being burned, do not touch exhaust

system when system is hot. Oxygen sensor removal

should be performed when system is cool.

[A] : HO2S-1

[B] : HO2S-2

Page 653 of 698

6E1-32 ENGINE AND EMISSION CONTROL SYSTEM

CAMSHAFT POSITION SENSOR

INSPECTION

Check camshaft position sensor referring to DTC P0340 (No.15)

Diag. Flow Table in Section 6. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect connector from camshaft position sensor.

3) Remove camshaft position sensor from cylinder head.

INSTALLATION

1) Check that O-ring is free from damage.

2) Check that camshaft position sensor and signal rotor teeth

are free from any metal particles and damage.

3) Install camshaft position sensor to cylinder head.

Tightening torque

Camshaft position sensor bolt

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

4) Connect connector to it securely.

5) Connect negative cable to battery.

CRANKSHAFT POSITION SENSOR

INSPECTION

Check crankshaft position sensor referring to step 1 and 2 of DTC

P0335 (No.23) Flow Table. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove generator drive belt, loosen pivot bolt and move

generator outward.

3) Disconnect connector from crankshaft position sensor.

4) Remove crankshaft position sensor (1) from cylinder block.

INSTALLATION

1) Check to make sure that crankshaft position sensor and pul-

ley teeth are free from any metal particles and damage.

2) Install crankshaft position sensor to cylinder block.

3) Connect connector to it securely.

4) Adjust generator belt tension, refer to Section 6B.

5) Connect negative cable to battery.

Page 654 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-33

VEHICLE SPEED SENSOR (VSS)

INSPECTION

Check vehicle speed sensor referring to step 3 of DTC P0500

(No.16) Flow Table. If malfunction is found, replace.

REMOVAL/INSTALLATION

Refer to Section 7A.

FUEL LEVEL SENSOR (GAUGE)

INSPECTION

Refer to Section 8.

REMOVAL/INSTALLATION

Refer to Section 6C.

KNOCK SENSOR (IF EQUIPPED)

INSPECTION

Check knock sensor referring to DTC P0325 (No.17) Flow Table.

If malfunction is found, replace.

REMOVAL/INSTALLATION

Refer to Section 6A.

MAIN RELAY, FUEL PUMP RELAY AND RADIATOR

FAN RELAY NO.1

INSPECTION

1) Disconnect negative cable at battery.

2) Remove main relay (1), fuel pump relay (2) and radiator fan

control relay No.1 (3) from vehicle.

3) Check that there is no continuity between terminal “C” and

“D”. If there is continuity, replace relay.

4) Connect battery positive (+) terminal to terminal “B” of relay.

Connect battery negative (–) terminal “A” of relay.

Check continuity between terminal “C” and “D”.

If there is no continuity when relay is connected to the bat-

tery, replace relay.

“D” “B”“A”“C”

3

1

2

Page 655 of 698

6E1-34 ENGINE AND EMISSION CONTROL SYSTEM

FUEL CUT OPERATION

INSPECTION

1) Warm up engine to normal operating temperature.

2) While listening to sound of injector (1) by using sound scope

(2) or such, increase engine speed to higher than 3,000 r/

min.

3) Check to make sure that sound to indicate operation of injec-

tor stops when throttle valve is closed instantly and it is

heard again when engine speed is reduced to less than

about 2,000 r/min.

RADIATOR FAN CONTROL SYSTEM

SYSTEM INSPECTION

Check system for operation referring to Flow Table B-7 in Section

6.

If radiator fan fails to operate properly, check relay, radiator fan

and electrical circuit.

RADIATOR FAN RELAY NO. 2 AND NO.3

INSPECTION

1) Disconnect negative cable at battery.

2) Remove relay(s) from connector(s).NOTE:

Before inspection, check to make sure that gear shift

lever is in neutral position (with A/T model, selector lever

in “P” range), A/C is OFF and that parking brake lever is

pulled all the way up.

WARNING:

Keep hands, tools, and clothing away from engine cool-

ing fan to help prevent personal injury. This fan is electric

and can come on whether or not the engine is running.

The fan can start automatically in response to the ECT

sensor with the ignition switch in the “ON” position.

1. Radiator fan relay No. 2

2. Radiator fan relay No. 3

1

2

Page 656 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-35

3) Check resistance between each two terminals as in table

below.

If check results are as specified, proceed to next operation

check. If not, replace.

Radiator fan relay No.2 and No.3 resistance

4) Check that there is continuity between terminals “A” and “B”

when battery is connected to terminals “C” and “D”.

If malfunction is found, replace.

RADIATOR FAN INSPECTION

1) Check continuity between each terminals.

If there is no continuity, replace radiator fan motor.

2) Connect battery to radiator fan motor coupler as shown in

figure, then check that the radiator fan motor operates

smoothly and that fan speed varies.

If radiator fan motor does not operate smoothly, replace

motor.TERMINALS RESISTANCE

Between A and B

∞ (Infinity)

Between C and D 70 – 110

Ω at 20°C (68°F)

Page 657 of 698

6E1-36 ENGINE AND EMISSION CONTROL SYSTEM

OUTPUT SIGNALS OF THROTTLE VALVE OPENING

AND ENGINE COOLANT TEMP. (VEHICLE WITH A/T

ONLY)

THROTTLE VALVE OPENING SIGNAL INSPECTION

Check throttle valve opening (throttle position) signal referring to

step 1 of DTC P1700 (No.32 or 33) Flow Table in Section 7B. If

check result is not satisfactory, check each wire harness, circuit

connections and TP sensor.

ENGINE COOLANT TEMP. SIGNAL INSPECTION

Check engine coolant temp. signal referring to step 1 of DTC

P1705 (NO.51) Flow Table in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connection and ECT sensor.

EMISSION CONTROL SYSTEM

EGR SYSTEM

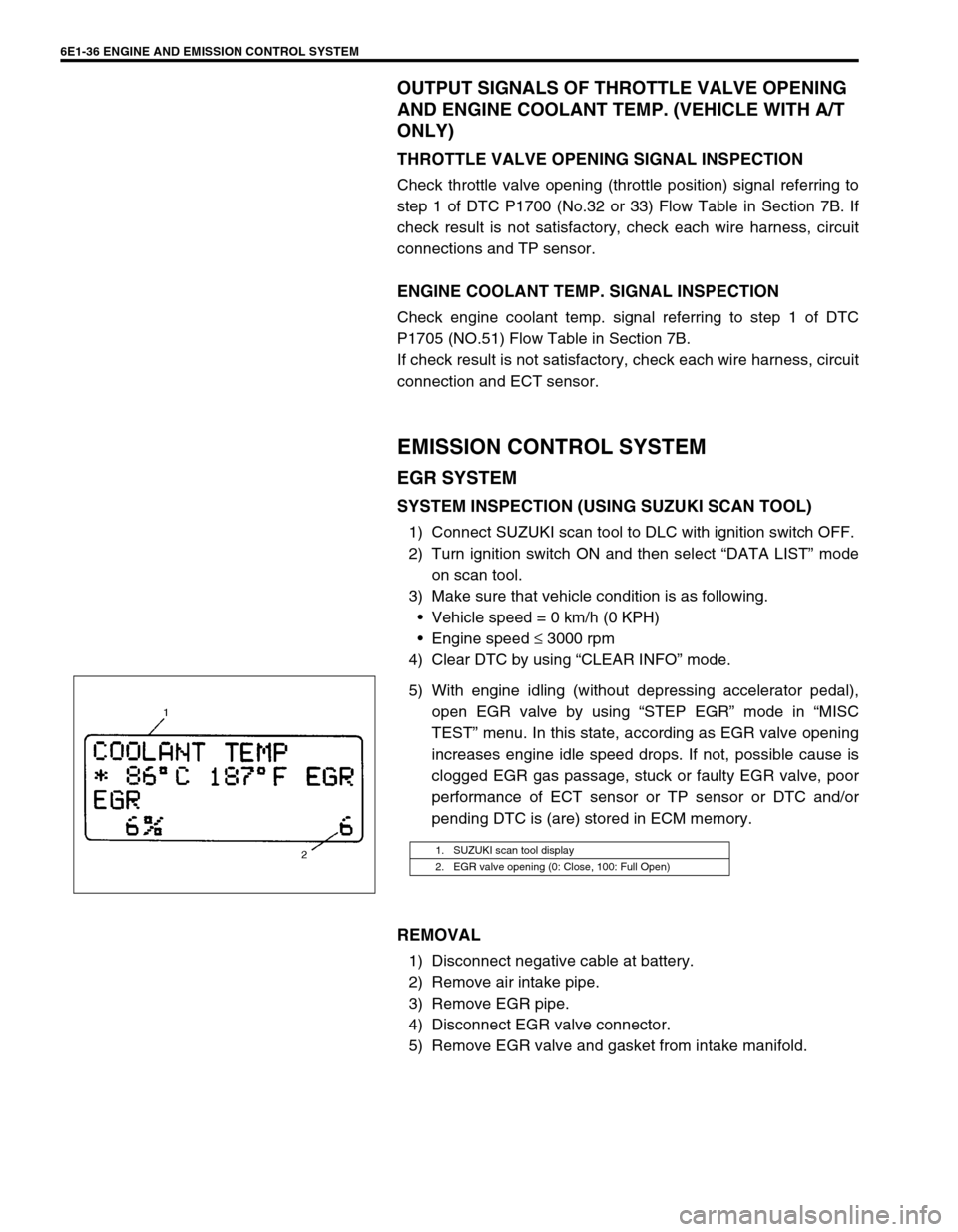

SYSTEM INSPECTION (USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

2) Turn ignition switch ON and then select “DATA LIST” mode

on scan tool.

3) Make sure that vehicle condition is as following.

Vehicle speed = 0 km/h (0 KPH)

Engine speed ≤ 3000 rpm

4) Clear DTC by using “CLEAR INFO” mode.

5) With engine idling (without depressing accelerator pedal),

open EGR valve by using “STEP EGR” mode in “MISC

TEST” menu. In this state, according as EGR valve opening

increases engine idle speed drops. If not, possible cause is

clogged EGR gas passage, stuck or faulty EGR valve, poor

performance of ECT sensor or TP sensor or DTC and/or

pending DTC is (are) stored in ECM memory.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from intake manifold.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full Open)

Page 658 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-37

INSPECTION

1) Check resistance between following terminals of EGR valve

(1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance

2) Remove carbon from EGR valve gas passage.

3) Inspect valve (2), valve seat and rod for fault, cracks, bend or

other damage.

If found faulty, replace EGR valve assembly.

INSTALLATION

Reverse removal procedure noting following.

Clean mating surface of valve and intake manifold.

Use new gaskets.

EVAPORATIVE EMISSION CONTROL SYSTEM

EVAP CANISTER PURGE INSPECTION

1) Disconnect purge hose (1) from EVAP canister.

2) Place finger against the end of disconnected hose and check

that vacuum is not felt there when engine is cool and running

at idle speed.Terminal Standard resistance

A – B

C – B

F – E

D – E 20 – 24

Ω

NOTE:

Do not use any sharp–edged tool to remove carbon.

Be careful not to damage or bend EGR valve (1), valve

seat (3) and rod.

NOTE:

Before inspection, check to make sure that gear shift

lever is in neutral position (with A/T model, selector lever

in “P” range) and that parking brake lever is pulled all the

way up.

Page 659 of 698

6E1-38 ENGINE AND EMISSION CONTROL SYSTEM

3) Connect purge hose to EVAP canister and warm up engine

to normal operating temperature.

4) Disconnect purge hose from EVAP canister.

5) Also check that vacuum is felt when engine is running at idle

speed.

If check result is not satisfactory, check vacuum passage,

hoses, EVAP canister purge valve, wire harness and ECM.

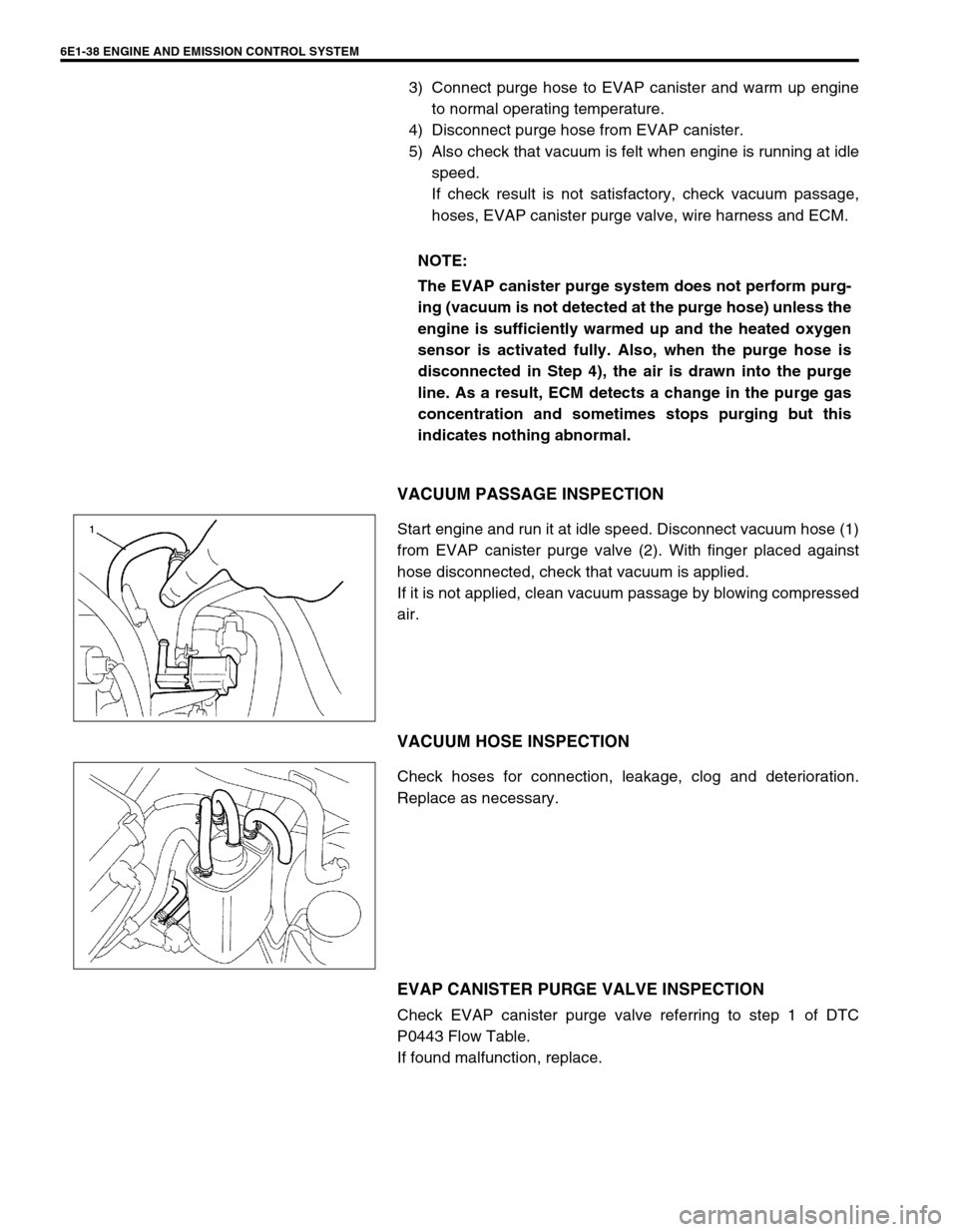

VACUUM PASSAGE INSPECTION

Start engine and run it at idle speed. Disconnect vacuum hose (1)

from EVAP canister purge valve (2). With finger placed against

hose disconnected, check that vacuum is applied.

If it is not applied, clean vacuum passage by blowing compressed

air.

VACUUM HOSE INSPECTION

Check hoses for connection, leakage, clog and deterioration.

Replace as necessary.

EVAP CANISTER PURGE VALVE INSPECTION

Check EVAP canister purge valve referring to step 1 of DTC

P0443 Flow Table.

If found malfunction, replace.NOTE:

The EVAP canister purge system does not perform purg-

ing (vacuum is not detected at the purge hose) unless the

engine is sufficiently warmed up and the heated oxygen

sensor is activated fully. Also, when the purge hose is

disconnected in Step 4), the air is drawn into the purge

line. As a result, ECM detects a change in the purge gas

concentration and sometimes stops purging but this

indicates nothing abnormal.

Page 660 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-39

EVAP CANISTER INSPECTION

1) Check outside of EVAP canister visually.

2) Disconnect vacuum hoses from EVAP canister.

3) Check that there should be no restriction of flow through

purge pipe (1) and air pipe (2) when air is blown (4) into tank

pipe (3).

If any faulty condition is found in above inspection, replace.

PCV SYSTEM

PCV HOSE INSPECTION

Check hoses for connection, leakage, clog and deterioration.

Replace as necessary.

PCV VALVE INSPECTION

1) Disconnect PCV valve (1) from cylinder head cover and

install plug to head cover hole.

2) Run engine at idle.

3) Place your finger over end of PCV valve (1) to check for vac-

uum.

If there is no vacuum, check for clogged valve. Replace as

necessary. WARNING:

DO NOT SUCK nozzles on EVAP canister. Fuel vapor

inside EVAP canister is harmful.

NOTE:

Be sure to check that there is no obstruction in PCV

valve or its hoses before checking IAC duty, for

obstructed PCV valve or hose hampers its accurate

adjustment.