brake SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 63 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-21

TIME LAG TEST

This test is to check conditions of clutch, reverse brake and fluid

pressure. “Time lag” means time elapsed since select lever is

shifted with engine idling till shock is felt.

1) With chocks placed in front and behind front and rear wheels

respectively, depress brake pedal.

2) Start engine.

3) With stop watch ready, shift select lever from “N” to “D”

range and measure time from that moment till shock is felt.

4) Similarly measure time lag by shifting select lever from “N” to

“R” range.

Specification for time lag

“N”

→

→ → → “D” : Less than 1.0 sec.

“N”

→

→→ → “R” : Less than 1.2 sec.

NOTE:

Make sure that selector cable is properly adjusted.

When repeating this test, be sure to wait at least

minute after select lever is shifted back to “N” range.

Engine should be warmed up fully for this test.

Test result Possible cause

When “N” →

“D”

time lag exceeds specification.Low line pressure

Worn rear clutch

Worn 1st & 2nd brake

When “N” →

“R”

time lag exceeds specification.Low line pressure

Worn rear clutch

Worn direct clutch

Worn reverse brake

Page 64 of 447

7B-22 AUTOMATIC TRANSMISSION (4 A/T)

LINE PRESSURE TEST

Purpose of this test is to check operating conditions of each part

by measuring fluid pressure in fluid pressure line.

Line pressure test requires following conditions.

Automatic fluid is at normal operating temperature (70 –

80°C /158 – 176°F).

Fluid is filled to proper level (between FULL and LOW on

dipstick).

1) Apply parking brake securely and place chocks against

wheels.

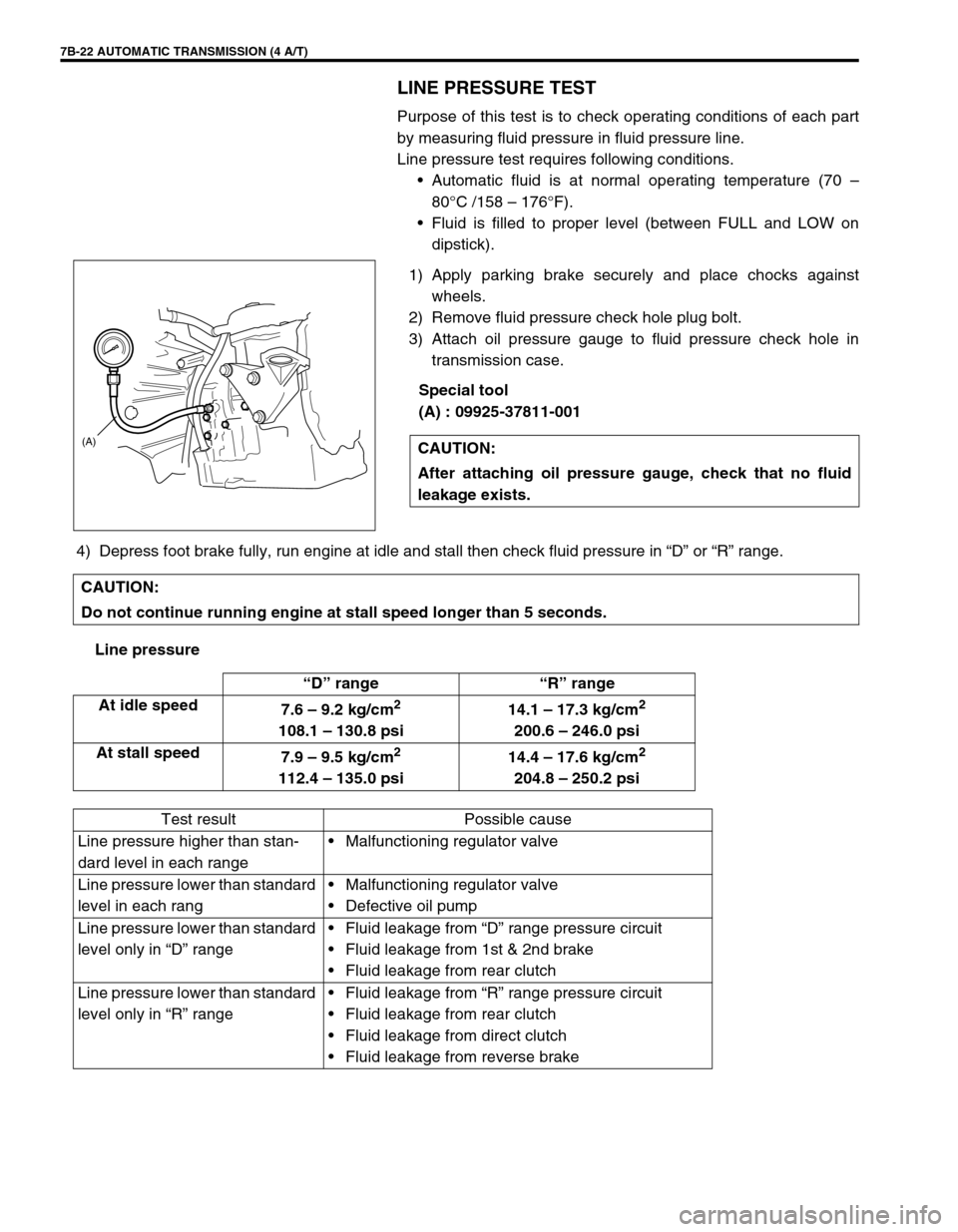

2) Remove fluid pressure check hole plug bolt.

3) Attach oil pressure gauge to fluid pressure check hole in

transmission case.

Special tool

(A) : 09925-37811-001

4) Depress foot brake fully, run engine at idle and stall then check fluid pressure in “D” or “R” range.

Line pressureCAUTION:

After attaching oil pressure gauge, check that no fluid

leakage exists.

(A)

CAUTION:

Do not continue running engine at stall speed longer than 5 seconds.

“D” range “R” range

At idle speed

7.6 – 9.2 kg/cm

2

108.1 – 130.8 psi14.1 – 17.3 kg/cm

2

200.6 – 246.0 psi

At stall speed

7.9 – 9.5 kg/cm

2

112.4 – 135.0 psi14.4 – 17.6 kg/cm

2

204.8 – 250.2 psi

Test result Possible cause

Line pressure higher than stan-

dard level in each rangeMalfunctioning regulator valve

Line pressure lower than standard

level in each rangMalfunctioning regulator valve

Defective oil pump

Line pressure lower than standard

level only in “D” rangeFluid leakage from “D” range pressure circuit

Fluid leakage from 1st & 2nd brake

Fluid leakage from rear clutch

Line pressure lower than standard

level only in “R” rangeFluid leakage from “R” range pressure circuit

Fluid leakage from rear clutch

Fluid leakage from direct clutch

Fluid leakage from reverse brake

Page 65 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-23

ENGINE BRAKE TEST

1) While driving vehicle in 3rd gear of “D” range, shift select lever down to “2” range and check if engine brake

operates.

2) In the same way as in Step 1), check engine brake for operation when select lever is shifted down to “L”

range.

3) Engine brake should operate in above test.

“P” RANGE TEST

1) Stop vehicle on a slope, shift select lever to “P” range and at the same time apply parking brake.

2) After stopping engine, depress brake pedal and release parking brake.

3) Then, release brake pedal gradually and check that vehicle remains stationary.

4) Depress brake pedal and shift select lever to “N” range.

5) Then, release brake pedal gradually and check that vehicle moves.WARNING:

Before test, make sure that there is no vehicle behind so as to pre-

vent rear-end collision.

Test result Possible cause

Fails to operate when shifted down to “2”

rangeDefective shift switch

1st & 2nd brake defective

Direct clutch defective

Fails to operate when shifted down to “L”

range

WARNING:

Before test, check to make sure no one is around vehicle or

down on a slope and keep watchful for safety during test.

Test result Possible cause

Vehicle moves at “P” range or

remains stationary at “N” rangeDefective parking lock pawl or

spring

Page 96 of 447

7B-54 AUTOMATIC TRANSMISSION (4 A/T)

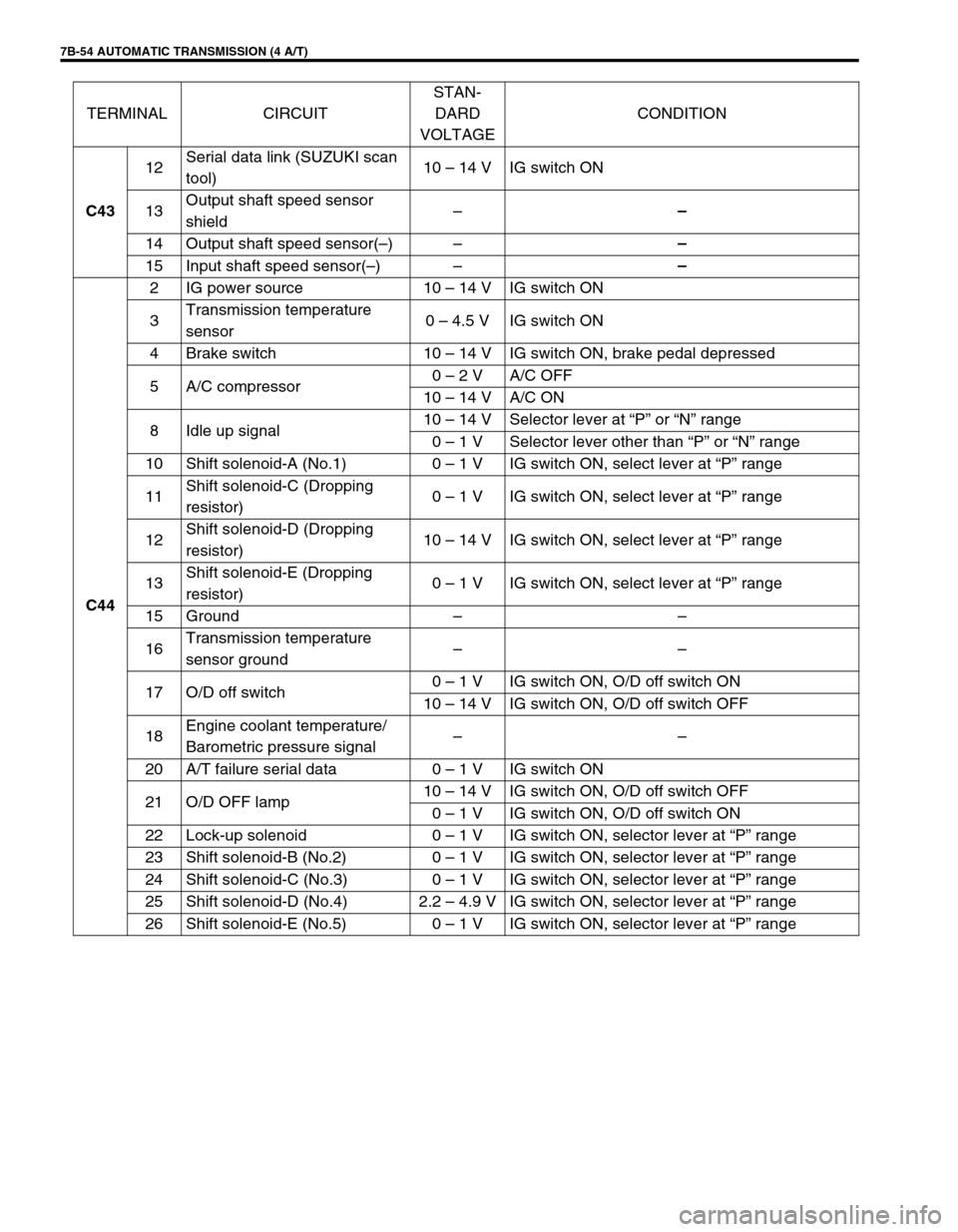

C4312Serial data link (SUZUKI scan

tool)10 – 14 V IG switch ON

13Output shaft speed sensor

shield––

14 Output shaft speed sensor(–)––

15 Input shaft speed sensor(–)––

C442 IG power source 10 – 14 V IG switch ON

3Transmission temperature

sensor0 – 4.5 V IG switch ON

4 Brake switch 10 – 14 V IG switch ON, brake pedal depressed

5 A/C compressor0 – 2 V A/C OFF

10 – 14 V A/C ON

8 Idle up signal10 – 14 V Selector lever at “P” or “N” range

0 – 1 V Selector lever other than “P” or “N” range

10 Shift solenoid-A (No.1) 0 – 1 V IG switch ON, select lever at “P” range

11Shift solenoid-C (Dropping

resistor)0 – 1 V IG switch ON, select lever at “P” range

12Shift solenoid-D (Dropping

resistor)10 – 14 V IG switch ON, select lever at “P” range

13Shift solenoid-E (Dropping

resistor)0 – 1 V IG switch ON, select lever at “P” range

15 Ground––

16Transmission temperature

sensor ground––

17 O/D off switch0 – 1 V IG switch ON, O/D off switch ON

10 – 14 V IG switch ON, O/D off switch OFF

18Engine coolant temperature/

Barometric pressure signal––

20 A/T failure serial data 0 – 1 V IG switch ON

21 O/D OFF lamp10 – 14 V IG switch ON, O/D off switch OFF

0 – 1 V IG switch ON, O/D off switch ON

22 Lock-up solenoid 0 – 1 V IG switch ON, selector lever at “P” range

23 Shift solenoid-B (No.2) 0 – 1 V IG switch ON, selector lever at “P” range

24 Shift solenoid-C (No.3) 0 – 1 V IG switch ON, selector lever at “P” range

25 Shift solenoid-D (No.4) 2.2 – 4.9 V IG switch ON, selector lever at “P” range

26 Shift solenoid-E (No.5) 0 – 1 V IG switch ON, selector lever at “P” range TERMINAL CIRCUITSTAN-

DARD

VOLTAGECONDITION

Page 97 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-55

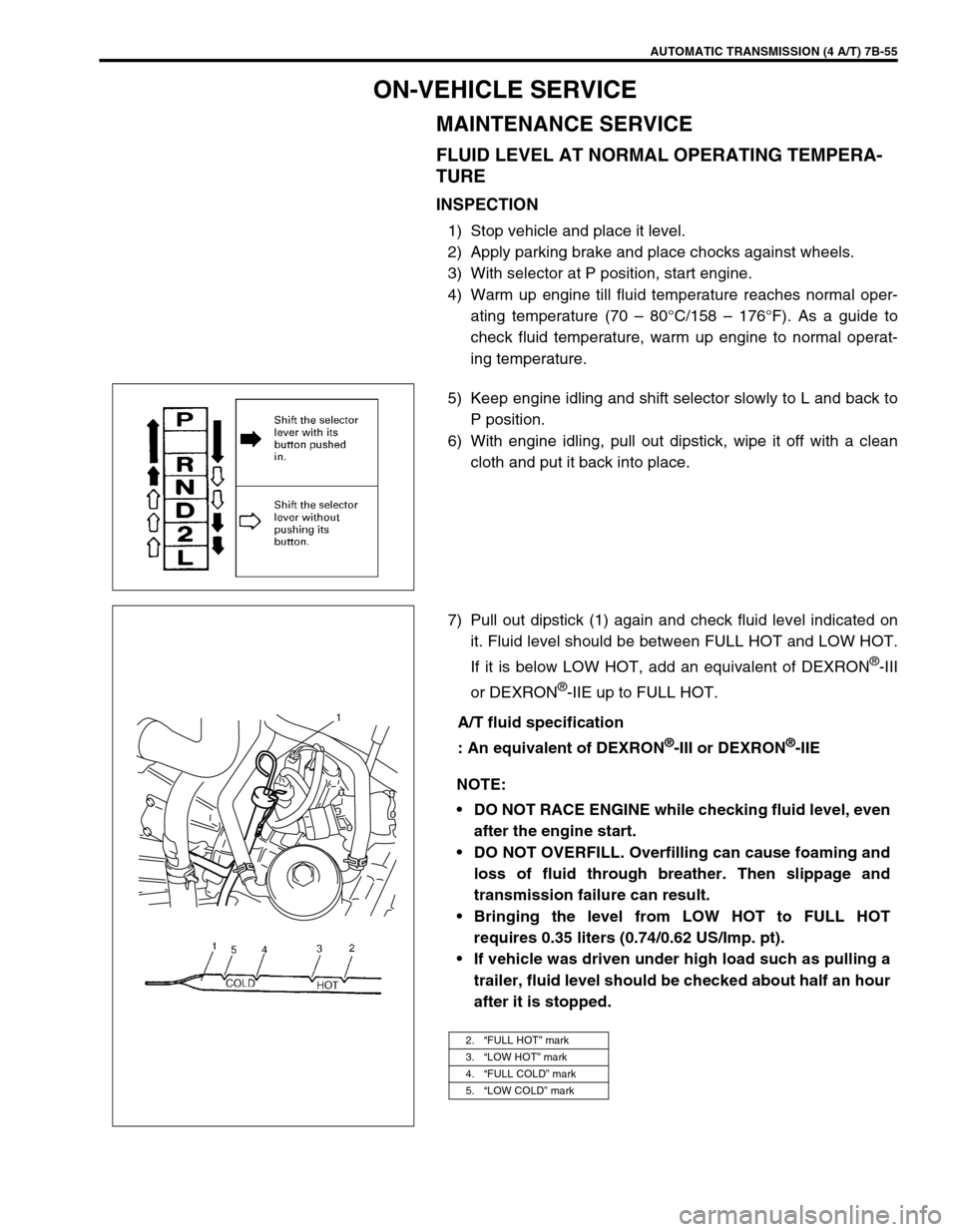

ON-VEHICLE SERVICE

MAINTENANCE SERVICE

FLUID LEVEL AT NORMAL OPERATING TEMPERA-

TURE

INSPECTION

1) Stop vehicle and place it level.

2) Apply parking brake and place chocks against wheels.

3) With selector at P position, start engine.

4) Warm up engine till fluid temperature reaches normal oper-

ating temperature (70 – 80°C/158 – 176°F). As a guide to

check fluid temperature, warm up engine to normal operat-

ing temperature.

5) Keep engine idling and shift selector slowly to L and back to

P position.

6) With engine idling, pull out dipstick, wipe it off with a clean

cloth and put it back into place.

7) Pull out dipstick (1) again and check fluid level indicated on

it. Fluid level should be between FULL HOT and LOW HOT.

If it is below LOW HOT, add an equivalent of DEXRON

®-III

or DEXRON

®-IIE up to FULL HOT.

A/T fluid specification

: An equivalent of DEXRON

®-III or DEXRON®-IIE

NOTE:

DO NOT RACE ENGINE while checking fluid level, even

after the engine start.

DO NOT OVERFILL. Overfilling can cause foaming and

loss of fluid through breather. Then slippage and

transmission failure can result.

Bringing the level from LOW HOT to FULL HOT

requires 0.35 liters (0.74/0.62 US/Imp. pt).

If vehicle was driven under high load such as pulling a

trailer, fluid level should be checked about half an hour

after it is stopped.

2.“FULL HOT” mark

3.“LOW HOT” mark

4.“FULL COLD” mark

5.“LOW COLD” mark

1

Page 102 of 447

7B-60 AUTOMATIC TRANSMISSION (4 A/T)

SELECTOR CABLE

REMOVAL

1) Remove parking brake lever cover.

2) Remove console box.

3) Disconnect selector cable from selector lever and then

detach from bracket.

4) Remove clip and disconnect selector cable from transmis-

sion.

5) Remove selector housing from dash panel.

INSTALLATION

Install selector cable by reversing removal procedure.

The important steps in installation are as follows.

Apply grease to pin and cable joint.

Tighten bolts and nut in upper figure to specified torque.

Adjusting procedure is as follows.

1. Selector lever assembly 6. Clip

2. Selector cable 7. Selector housing bolt

3. Selector housing 8. Shift control lever pin

: Apply lithium grease 99000-25010 to all around pin (0.15 g)

4. Cable bracket 9. Selector lever pin

: Apply lithium grease 99000-25010 to all around pin (0.15 g)

5. Shift control lever Tightening torque

Page 112 of 447

7B-70 AUTOMATIC TRANSMISSION (4 A/T)

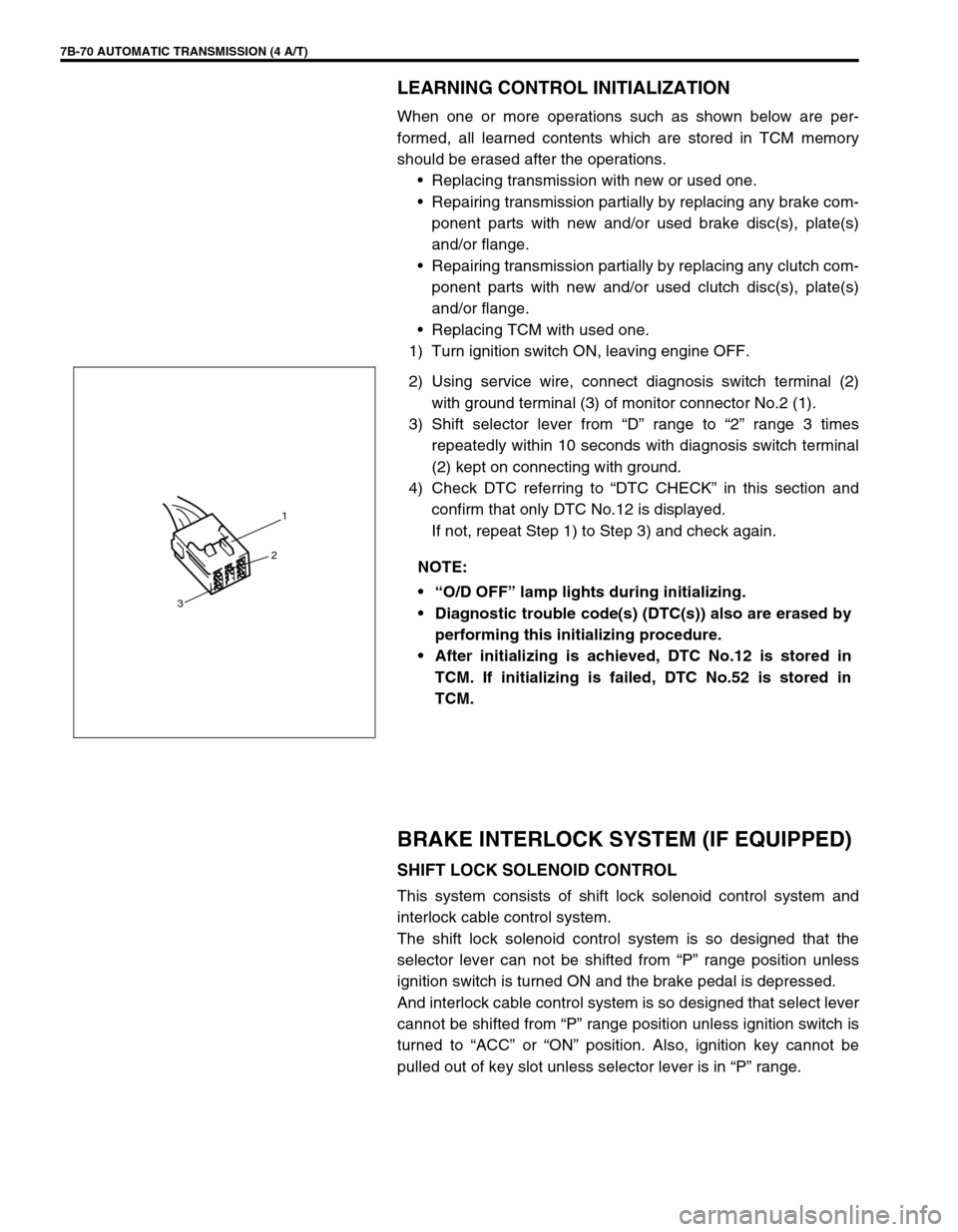

LEARNING CONTROL INITIALIZATION

When one or more operations such as shown below are per-

formed, all learned contents which are stored in TCM memory

should be erased after the operations.

Replacing transmission with new or used one.

Repairing transmission partially by replacing any brake com-

ponent parts with new and/or used brake disc(s), plate(s)

and/or flange.

Repairing transmission partially by replacing any clutch com-

ponent parts with new and/or used clutch disc(s), plate(s)

and/or flange.

Replacing TCM with used one.

1) Turn ignition switch ON, leaving engine OFF.

2) Using service wire, connect diagnosis switch terminal (2)

with ground terminal (3) of monitor connector No.2 (1).

3) Shift selector lever from “D” range to “2” range 3 times

repeatedly within 10 seconds with diagnosis switch terminal

(2) kept on connecting with ground.

4) Check DTC referring to “DTC CHECK” in this section and

confirm that only DTC No.12 is displayed.

If not, repeat Step 1) to Step 3) and check again.

BRAKE INTERLOCK SYSTEM (IF EQUIPPED)

SHIFT LOCK SOLENOID CONTROL

This system consists of shift lock solenoid control system and

interlock cable control system.

The shift lock solenoid control system is so designed that the

selector lever can not be shifted from “P” range position unless

ignition switch is turned ON and the brake pedal is depressed.

And interlock cable control system is so designed that select lever

cannot be shifted from “P” range position unless ignition switch is

turned to “ACC” or “ON” position. Also, ignition key cannot be

pulled out of key slot unless selector lever is in “P” range. NOTE:

“O/D OFF” lamp lights during initializing.

Diagnostic trouble code(s) (DTC(s)) also are erased by

performing this initializing procedure.

After initializing is achieved, DTC No.12 is stored in

TCM. If initializing is failed, DTC No.52 is stored in

TCM.

1

2

3

Page 113 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-71

SHIFT LOCK SOLENOID MANUAL RLEASE

Without using brake pedal, shift lock can be moved by pushing

shift lock solenoid cam (1) with screw driver or like through hole

(2). (To shift selector lever from “P” range to any other position,

turn ignition switch to “ACC” or “ON” position.)

INSPECTION

1) Check to make sure that selector lever cannot be moved to

any other range from “P” range position when ignition switch

key is at “ACC” position, at “LOCK” position (or it is removed

from keyhole of ignition switch) or brake pedal is not

depressed.

2) Shift selector lever to “P” range position, release knob button

and check for the following.

Ignition key can be turned between “LOCK” and “ACC” posi-

tions back and forth and also it can be removed from ignition

switch.

With shift lock solenoid cam (1) moved in arrow direction and

ignition key turned to “ACC” position, selector lever can be

shifted from “P” range position to any other range.

With shift lock solenoid cam moved in arrow direction and

ignition key turned to “LOCK” position, selector lever can not

be shifted from “P” range position to any other range.

1

2

1

Page 114 of 447

7B-72 AUTOMATIC TRANSMISSION (4 A/T)

When ignition switch is turned “ON” and brake pedal is

depressed, selector lever can be shifted from “P” range posi-

tion to any other range.

3) With ignition lever shifted to any position other than “P”

range, check that ignition key cannot be turned “LOCK” posi-

tion and it cannot be removed from ignition switch unless it is

at “LOCK” position.

KEY INTERLOCK CABLE (IF EQUIPPED)

1. selector lever 3. key inter lock cable

2. knob button 4. key cylinder

NOTE:

Don’t bend interlock cable excessively when removing and installing it, or system will not operate

correctly.

Page 117 of 447

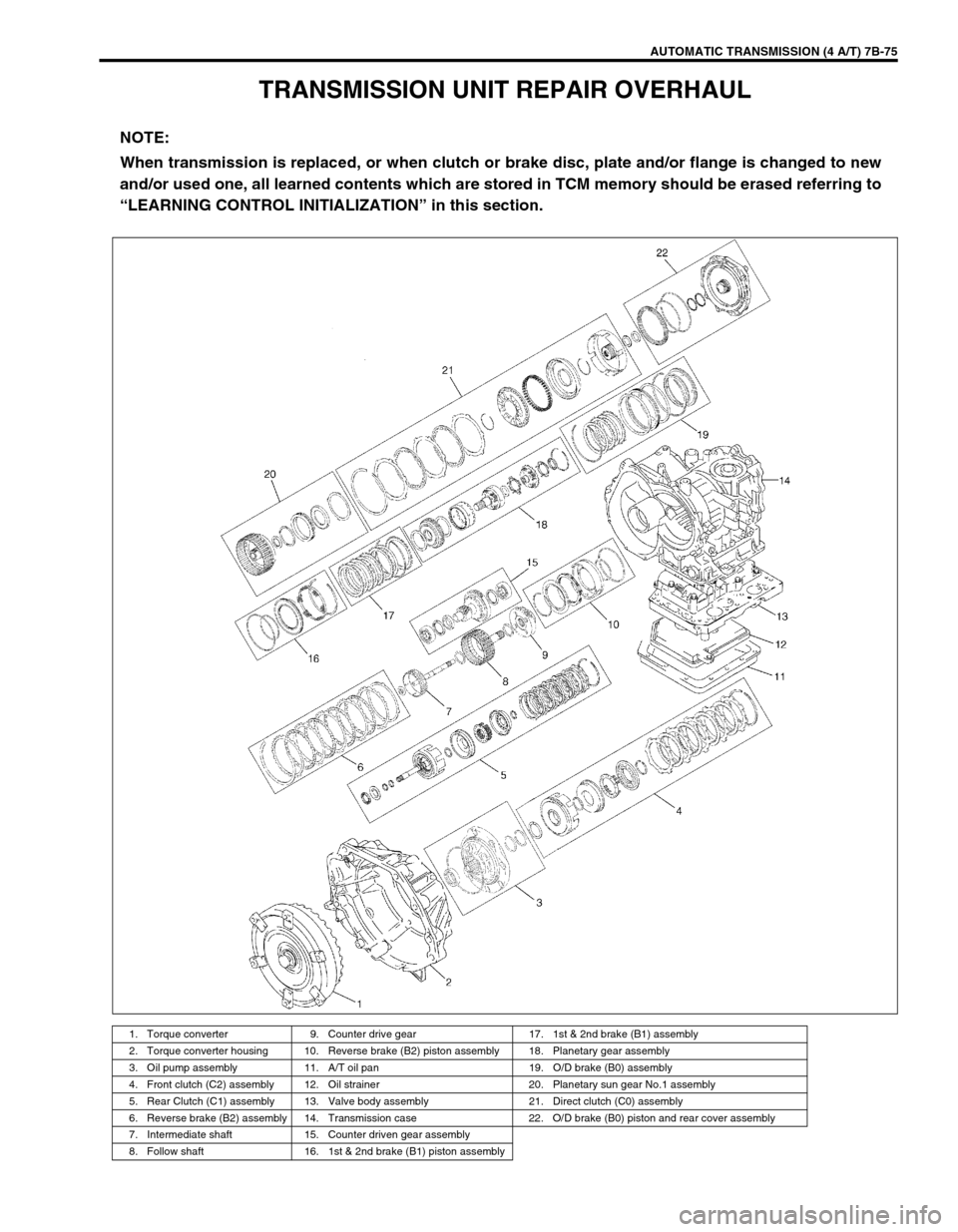

AUTOMATIC TRANSMISSION (4 A/T) 7B-75

TRANSMISSION UNIT REPAIR OVERHAUL

NOTE:

When transmission is replaced, or when clutch or brake disc, plate and/or flange is changed to new

and/or used one, all learned contents which are stored in TCM memory should be erased referring to

“LEARNING CONTROL INITIALIZATION” in this section.

1. Torque converter 9. Counter drive gear 17. 1st & 2nd brake (B1) assembly

2. Torque converter housing 10. Reverse brake (B2) piston assembly 18. Planetary gear assembly

3. Oil pump assembly 11. A/T oil pan 19. O/D brake (B0) assembly

4. Front clutch (C2) assembly 12. Oil strainer 20. Planetary sun gear No.1 assembly

5. Rear Clutch (C1) assembly 13. Valve body assembly 21. Direct clutch (C0) assembly

6. Reverse brake (B2) assembly 14. Transmission case 22. O/D brake (B0) piston and rear cover assembly

7. Intermediate shaft 15. Counter driven gear assembly

8. Follow shaft 16. 1st & 2nd brake (B1) piston assembly