brake SUZUKI SWIFT 2000 1.G Transmission Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 124 of 447

7B-82 AUTOMATIC TRANSMISSION (4 A/T)

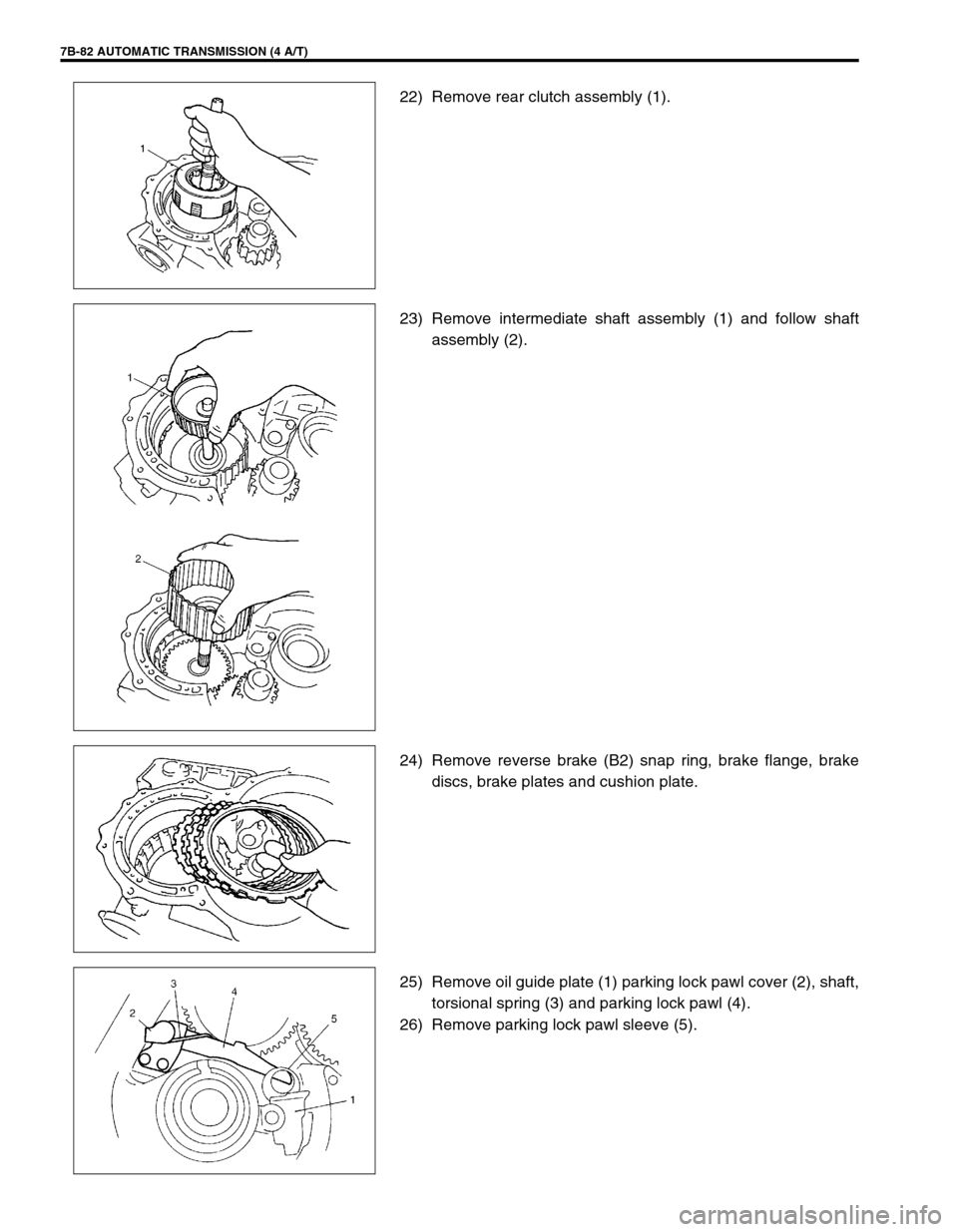

22) Remove rear clutch assembly (1).

23) Remove intermediate shaft assembly (1) and follow shaft

assembly (2).

24) Remove reverse brake (B2) snap ring, brake flange, brake

discs, brake plates and cushion plate.

25) Remove oil guide plate (1) parking lock pawl cover (2), shaft,

torsional spring (3) and parking lock pawl (4).

26) Remove parking lock pawl sleeve (5).

Page 126 of 447

7B-84 AUTOMATIC TRANSMISSION (4 A/T)

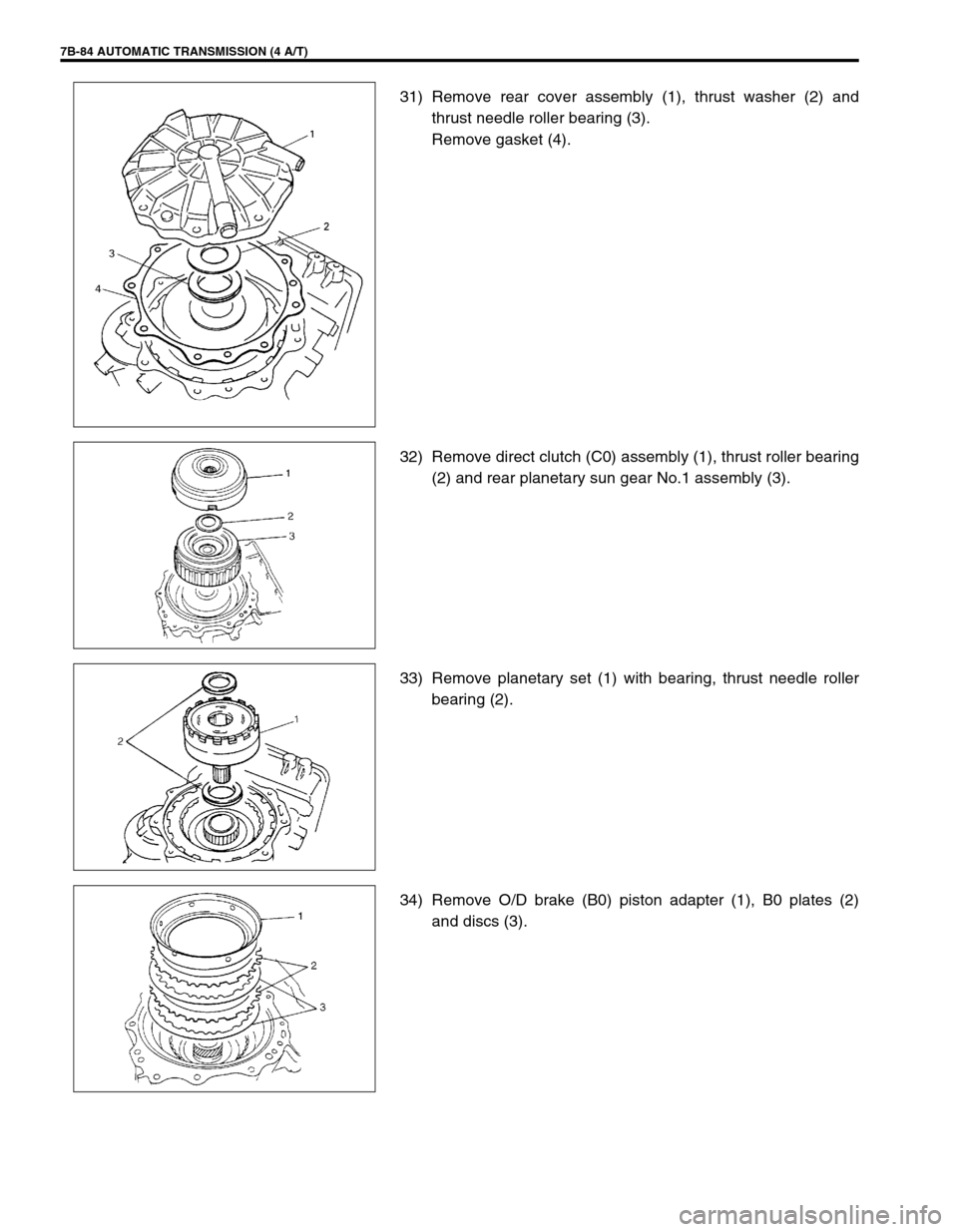

31) Remove rear cover assembly (1), thrust washer (2) and

thrust needle roller bearing (3).

Remove gasket (4).

32) Remove direct clutch (C0) assembly (1), thrust roller bearing

(2) and rear planetary sun gear No.1 assembly (3).

33) Remove planetary set (1) with bearing, thrust needle roller

bearing (2).

34) Remove O/D brake (B0) piston adapter (1), B0 plates (2)

and discs (3).

Page 127 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-85

35) Remove planetary sun gear No.2 (1) and thrust needle roller

bearing (2).

36) Remove snap ring, then remove brake flange and disc.

37) Remove snap ring, then remove brake discs and plates (B1

brake).

38) Remove snap ring (1), then O/D brake return spring seat (2),

return spring (3) and spring retainer (4).

39) Remove snap ring (1) then remove 1st & 2nd brake piston

return spring subassembly (2) and 1st & 2nd brake piston

(3).

To remove 1st & 2nd brake piston, force low-pressure com-

pressed air (1 kg/cm

2, 15 psi, 100 kPa, max) into hole (5)

shown in figure and pop out 1st & 2nd brake piston into a

rag.

4. Air gun

Page 128 of 447

7B-86 AUTOMATIC TRANSMISSION (4 A/T)

40) Remove counter drive gear (1).

41) Use hydraulic press (8) and special tool to compress wave

spring (4), then remove snap ring (1).

Special tool

(A) : 09926-96040

42) Remove reverse brake piston seat (3), wave spring (4) and

reverse brake piston (5).

To remove reverse brake piston, force low-pressure com-

press air (1 kg/cm

2, 15 psi, 100 kPa, max) into hole (7)

shown in figure, and pop out piston into a rag.

NOTE:

Do not compress wave spring more than necessary.

Do not reuse snap ring (1).

2. Flat end rod or the like

6. Air gun

Page 129 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-87

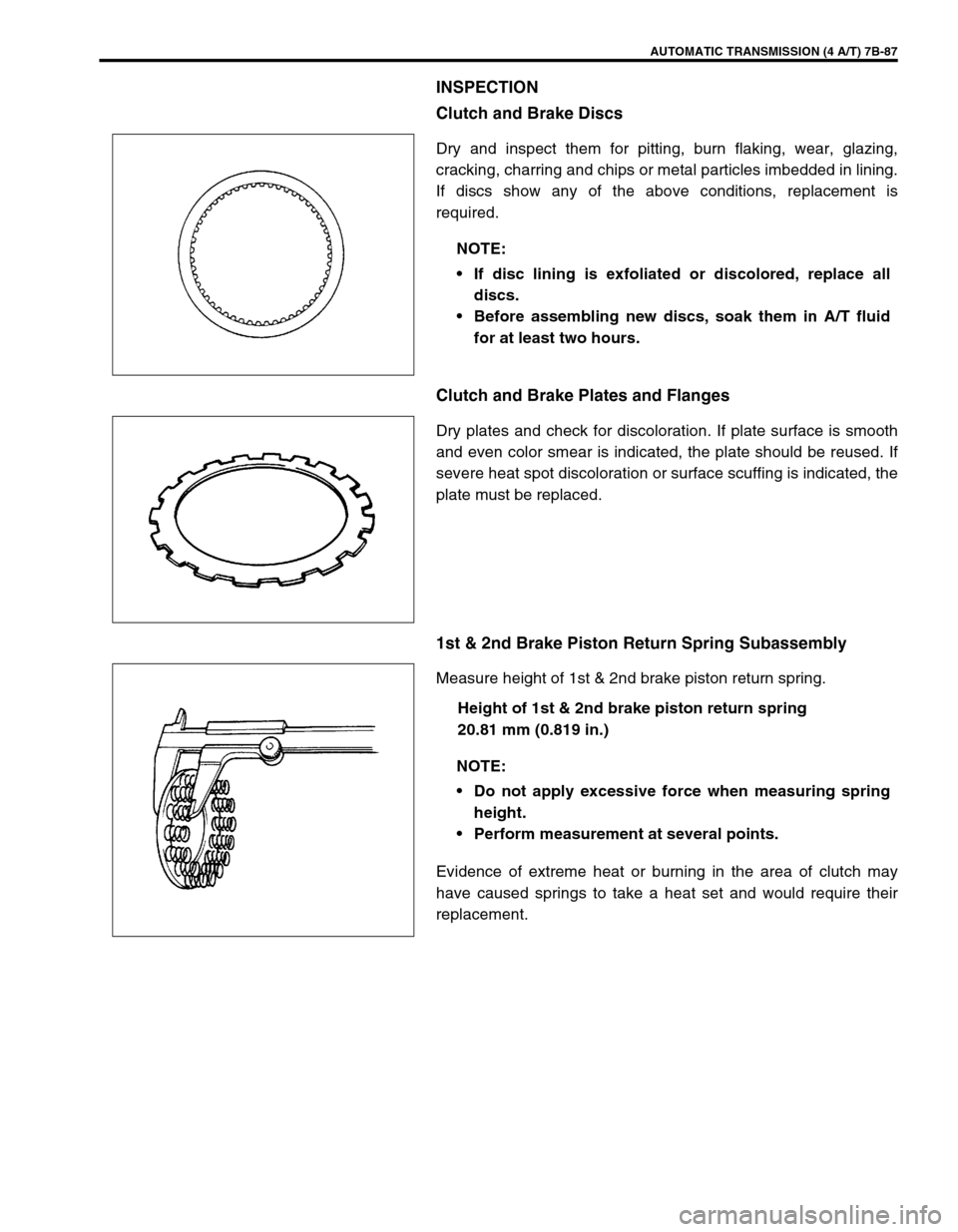

INSPECTION

Clutch and Brake Discs

Dry and inspect them for pitting, burn flaking, wear, glazing,

cracking, charring and chips or metal particles imbedded in lining.

If discs show any of the above conditions, replacement is

required.

Clutch and Brake Plates and Flanges

Dry plates and check for discoloration. If plate surface is smooth

and even color smear is indicated, the plate should be reused. If

severe heat spot discoloration or surface scuffing is indicated, the

plate must be replaced.

1st & 2nd Brake Piston Return Spring Subassembly

Measure height of 1st & 2nd brake piston return spring.

Height of 1st & 2nd brake piston return spring

20.81 mm (0.819 in.)

Evidence of extreme heat or burning in the area of clutch may

have caused springs to take a heat set and would require their

replacement.NOTE:

If disc lining is exfoliated or discolored, replace all

discs.

Before assembling new discs, soak them in A/T fluid

for at least two hours.

NOTE:

Do not apply excessive force when measuring spring

height.

Perform measurement at several points.

Page 130 of 447

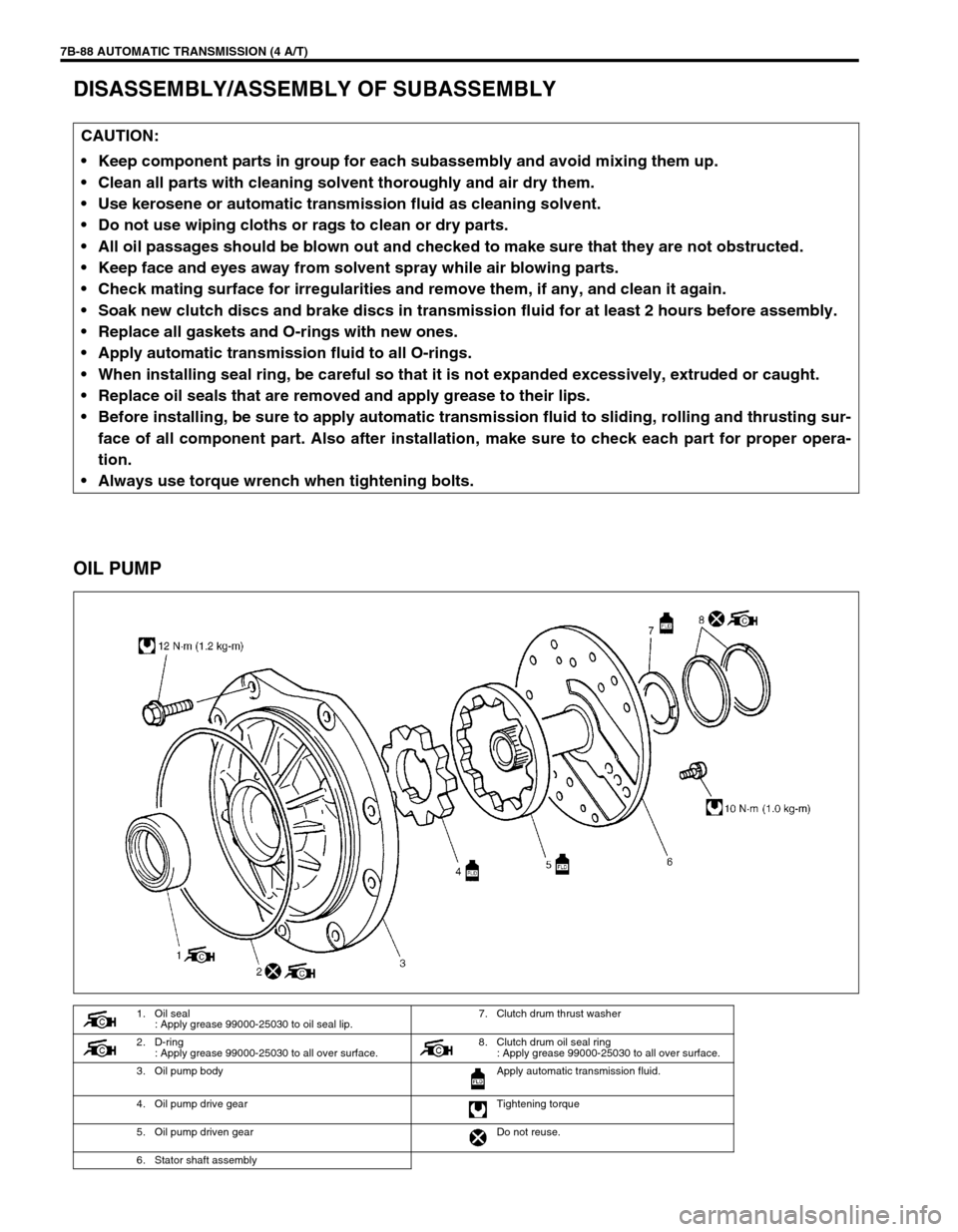

7B-88 AUTOMATIC TRANSMISSION (4 A/T)

DISASSEMBLY/ASSEMBLY OF SUBASSEMBLY

OIL PUMP

CAUTION:

Keep component parts in group for each subassembly and avoid mixing them up.

Clean all parts with cleaning solvent thoroughly and air dry them.

Use kerosene or automatic transmission fluid as cleaning solvent.

Do not use wiping cloths or rags to clean or dry parts.

All oil passages should be blown out and checked to make sure that they are not obstructed.

Keep face and eyes away from solvent spray while air blowing parts.

Check mating surface for irregularities and remove them, if any, and clean it again.

Soak new clutch discs and brake discs in transmission fluid for at least 2 hours before assembly.

Replace all gaskets and O-rings with new ones.

Apply automatic transmission fluid to all O-rings.

When installing seal ring, be careful so that it is not expanded excessively, extruded or caught.

Replace oil seals that are removed and apply grease to their lips.

Before installing, be sure to apply automatic transmission fluid to sliding, rolling and thrusting sur-

face of all component part. Also after installation, make sure to check each part for proper opera-

tion.

Always use torque wrench when tightening bolts.

1. Oil seal

: Apply grease 99000-25030 to oil seal lip.7. Clutch drum thrust washer

2. D-ring

: Apply grease 99000-25030 to all over surface. 8. Clutch drum oil seal ring

: Apply grease 99000-25030 to all over surface.

3. Oil pump body Apply automatic transmission fluid.

4. Oil pump drive gear Tightening torque

5. Oil pump driven gear Do not reuse.

6. Stator shaft assembly

Page 157 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-115

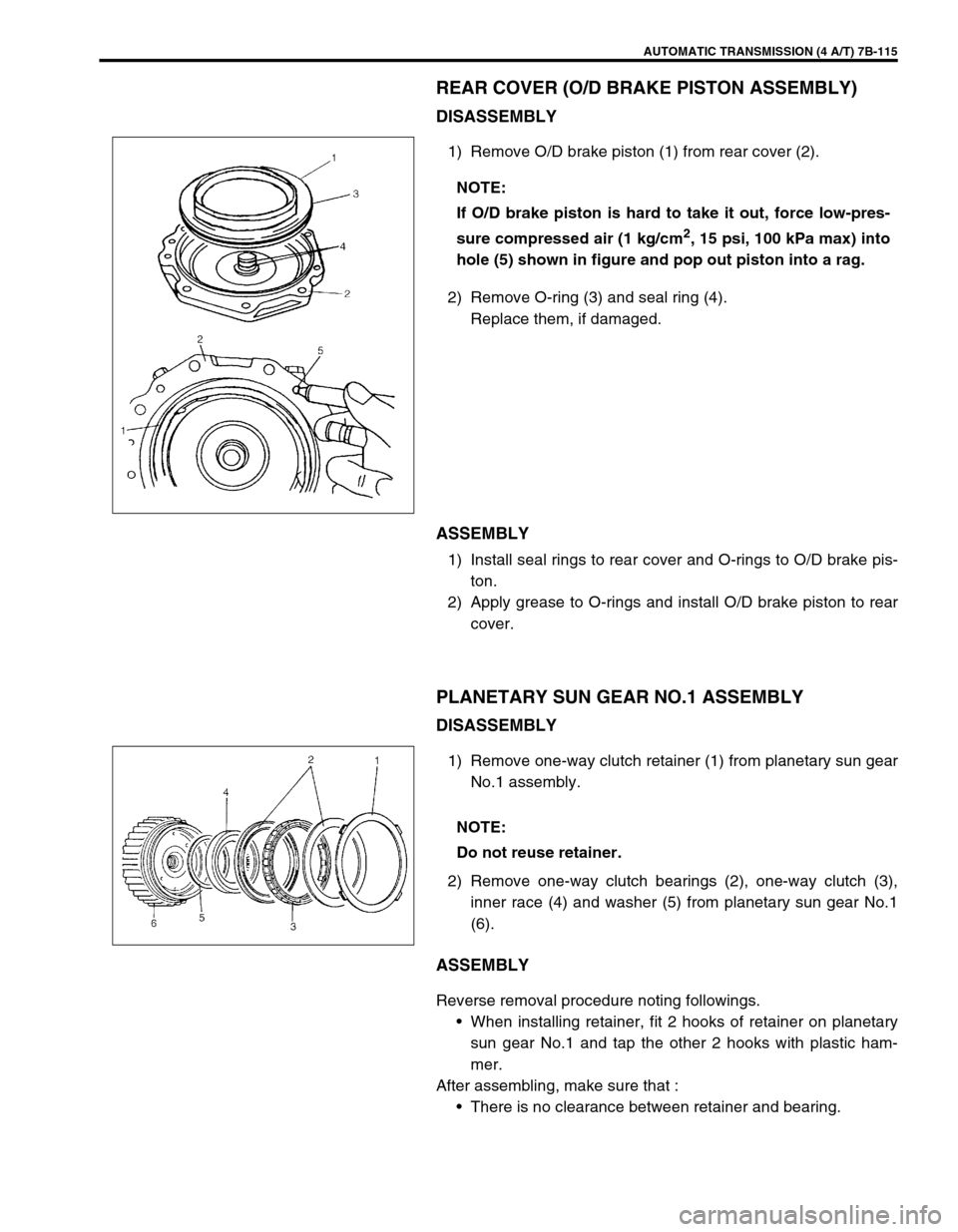

REAR COVER (O/D BRAKE PISTON ASSEMBLY)

DISASSEMBLY

1) Remove O/D brake piston (1) from rear cover (2).

2) Remove O-ring (3) and seal ring (4).

Replace them, if damaged.

ASSEMBLY

1) Install seal rings to rear cover and O-rings to O/D brake pis-

ton.

2) Apply grease to O-rings and install O/D brake piston to rear

cover.

PLANETARY SUN GEAR NO.1 ASSEMBLY

DISASSEMBLY

1) Remove one-way clutch retainer (1) from planetary sun gear

No.1 assembly.

2) Remove one-way clutch bearings (2), one-way clutch (3),

inner race (4) and washer (5) from planetary sun gear No.1

(6).

ASSEMBLY

Reverse removal procedure noting followings.

When installing retainer, fit 2 hooks of retainer on planetary

sun gear No.1 and tap the other 2 hooks with plastic ham-

mer.

After assembling, make sure that :

There is no clearance between retainer and bearing. NOTE:

If O/D brake piston is hard to take it out, force low-pres-

sure compressed air (1 kg/cm

2, 15 psi, 100 kPa max) into

hole (5) shown in figure and pop out piston into a rag.

NOTE:

Do not reuse retainer.

Page 160 of 447

7B-118 AUTOMATIC TRANSMISSION (4 A/T)

2) Install new oil seal to transmission case.

Use special tool to press-fit oil seal until oil seal end face is

flush with transmission case end face.

Special tool

(F) : 09913-75510

UNIT ASSEMBLY

CAUTION:

Automatic transmission consists of highly precise parts. As even a flaw in a small part may cause

oil leakage or decrease in function, check each part carefully before installation.

Clean all parts with compressed air. Never use wiping cloths or rags.

Before assembling new clutch discs and brake band, soak them in automatic transmission fluid for

at least 2 hours.

Be sure to use new gaskets and O-rings.

Lubricate O-rings with automatic transmission fluid.

Apply automatic transmission fluid on sliding or rotating surfaces of the parts before assembly.

Use yellow petrolatum grease or Suzuki Super Grease C to retain parts in place.

Be sure to install thrust bearings and races in correct direction and position.

Make sure that snap ring ends are not aligned with one of cutouts and are installed in groove cor-

rectly.

Do not use adhesive cements on gaskets and similar parts.

Be sure to torque each bolt and nut to specification.

Page 161 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-119

1) Install new O-rings (inside (5) and outside (6)) to reverse

brake piston (4), and apply grease to them.

“A” : Grease 99000-25030

2) Install reverse brake piston (4), wave spring (3) and reverse

brake piston seat (2) to transmission case.

3) Install new snap ring (1) by compressing wave spring thru

reverse brake piston seat with hydraulic press (8) and spe-

cial tool.

Special tool

(A) : 09926-96040

4) Install counter drive gear (1).

Tightening torque

Counter drive gear installing bolts

(a) : 5.5 N·m (0.55 kg-m, 4.0 lb-ft) NOTE:

Don’t compress wave spring more than necessary or it

may get damaged.

7. Flat end rod or the like

2. Transmission case

Page 162 of 447

7B-120 AUTOMATIC TRANSMISSION (4 A/T)

5) Install new inner and outer O-rings (4) to 1st & 2nd brake

piston (3) and apply grease to them.

“A” : Grease 99000-25030

6) Install 1st & 2nd brake piston (3) to transmission case, in

such way that the side with spring holes comes to the top.

Make sure that the O-rings are not twisted or caught.

7) Place 1st & 2nd brake piston return spring subassembly (2)

on piston (3). Make sure that each spring fits the holes on

the piston.

8) Push down return spring subassembly and install snap ring

(1).

9) Install 1st & 2nd brake (B1) discs and plates in following

order.

(1) Plate →

(2) Disc →

(3) Plate →

(4) Disc →

(5) Plate →

(6) Disc →

(7) Plate →

(8) Disc

10) Hold above parts with snap ring.

11) Install brake flange (1) and snap ring (2) to transmission

case (3). CAUTION:

Check that the opening of snap ring does not face the

cored-hole (5) of the transmission case.

NOTE:

The flat surface of the flange comes to the top (must face

O/D brake piston).