oil SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 20 of 447

7A-20 MANUAL TRANSMISSION

11) Tapping input shaft end with plastic hammer, push it out as

assembly from case a little, then take out input shaft assem-

bly (1), counter shaft assembly (2), high speed gear shift

shaft (3) and low speed gear shift shaft (4) all at once.

12) Remove counter shaft left bearing cup from left case.

13) Remove differential side left oil seal also from left case.

RIGHT CASE

1) Remove differential gear assembly (1) from right case (2).

2) Remove bolt and then pull out VSS (3).

3) If input shaft right bearing has been left in right case, pull it

out by using special tools.

Remove input shaft oil seal (1) by using special tools.

Special tool

(A) : 09930-30104

(B) : 09923-74510

4) Also pull out countershaft right bearing cup (2) by using spe-

cial tools.

Special tool

09941-64511

09923-30104

Page 21 of 447

MANUAL TRANSMISSION 7A-21

SUB ASSEMBLY SERVICE

RIGHT CASE

1) Install input shaft oil seal (1) facing its spring side upward.

Use special tool and hammer for installation and apply

grease to oil seal lip.

“B” : Grease 99000-25010

Special tool

(A) : 09951-76010

2) Install countershaft right bearing cup (2) by using special

tools and hammer.

Special tool

(B) : 09924-74510

(C) : 09925-68210

LEFT CASE

1) If input oil gutter has been removed, install it with bolt to

which thread lock cement have been applied.

“A” : Thread lock cement 99000-32110

Tightening torque

Oil gutter bolt (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

2) Install differential side left oil seal (1) facing its spring side

inward until it becomes flush with case surface by using spe-

cial tool with hammer, and then apply grease to its lip.

“B” : Grease 99000-25010

Special tool

(A) : 09913-75510

3) Install counter shaft left bearing cup into case bore by tap-

ping it with plastic hammer lightly. NOTE:

Before installation, wash each part and apply specified

gear oil to sliding faces of bearing and gear.

Page 23 of 447

MANUAL TRANSMISSION 7A-23

INSPECTION AND REASSEMBLY

1) Clean all components thoroughly, inspect them for any

abnormality and replace with new ones as necessary.

2) If synchronizer parts need to be repaired, check clearance

“a” between ring (2) and gear (1), each chamfered tooth of

gear, ring and sleeve, then determine parts replacement.

Clearance between synchronizer ring and gear

Standard “a” : 1.0 – 1.4 mm (0.039 – 0.055 in.)

Service limit “a” : 0.5 mm (0.019 in.)

3) To ensure lubrication, air blow oil holes (1) and make sure

that they are free from any obstruction.

4) Fit high speed synchronizer sleeve (4) to hub (3), insert 3

keys (2) in it and then set springs (1) as shown in figure.

Synchronizer key installation position

: A = B

5) Drive in right bearing (1) to input shaft (2) by using special

tool and hammer.

Special tool

(A) : 09913-80112

NOTE:

No specific direction is assigned to each key but it is

assigned as sleeve & hub assembly.

Size of high speed synchronizer sleeve, hub, keys and

springs is between those of low speed and 5th speed

ones.

[A] : 3rd gear side

C : Long flange

D : Key way

E : Projecting end

Page 24 of 447

7A-24 MANUAL TRANSMISSION

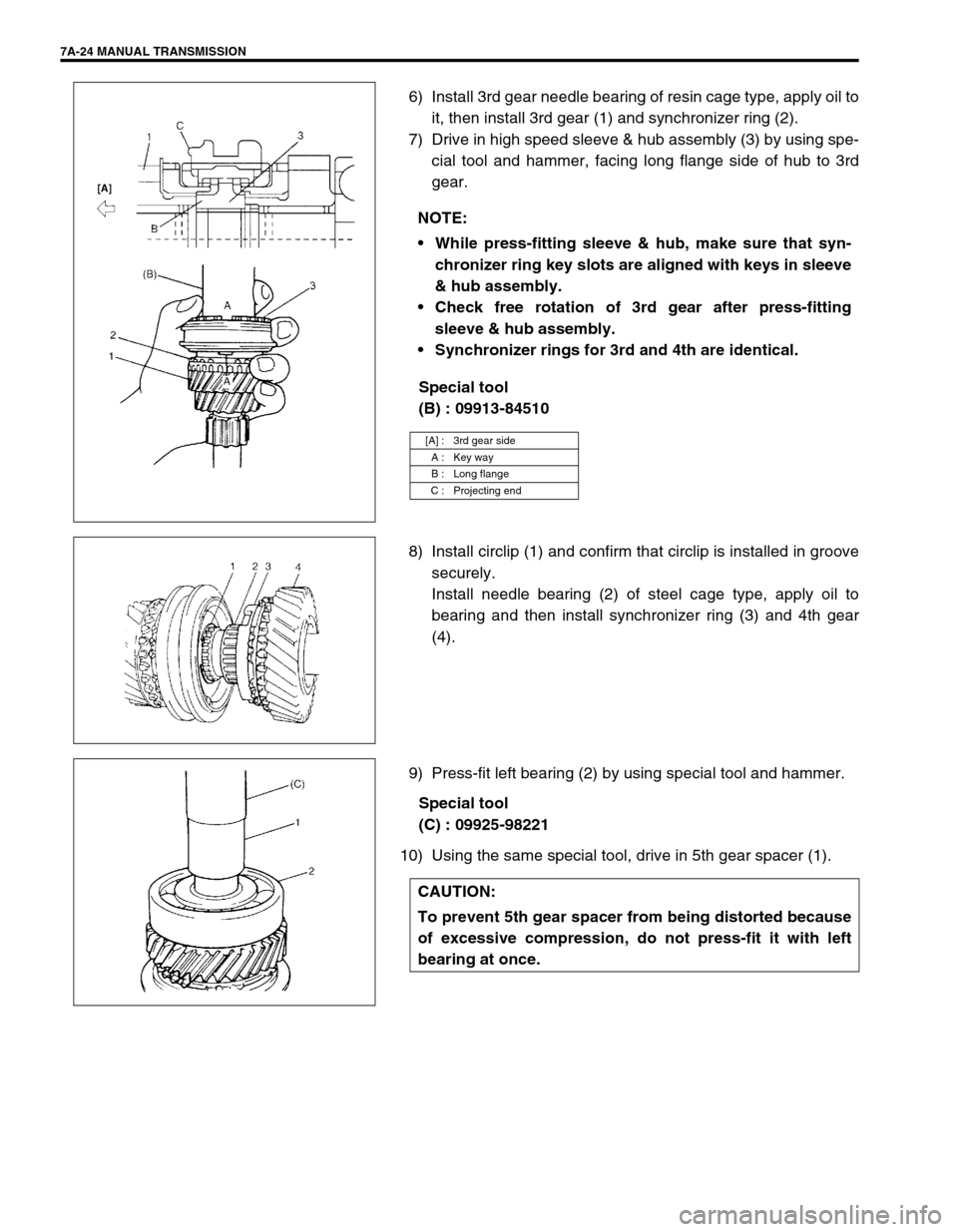

6) Install 3rd gear needle bearing of resin cage type, apply oil to

it, then install 3rd gear (1) and synchronizer ring (2).

7) Drive in high speed sleeve & hub assembly (3) by using spe-

cial tool and hammer, facing long flange side of hub to 3rd

gear.

Special tool

(B) : 09913-84510

8) Install circlip (1) and confirm that circlip is installed in groove

securely.

Install needle bearing (2) of steel cage type, apply oil to

bearing and then install synchronizer ring (3) and 4th gear

(4).

9) Press-fit left bearing (2) by using special tool and hammer.

Special tool

(C) : 09925-98221

10) Using the same special tool, drive in 5th gear spacer (1).NOTE:

While press-fitting sleeve & hub, make sure that syn-

chronizer ring key slots are aligned with keys in sleeve

& hub assembly.

Check free rotation of 3rd gear after press-fitting

sleeve & hub assembly.

Synchronizer rings for 3rd and 4th are identical.

[A] : 3rd gear side

A : Key way

B : Long flange

C : Projecting end

CAUTION:

To prevent 5th gear spacer from being distorted because

of excessive compression, do not press-fit it with left

bearing at once.

Page 26 of 447

7A-26 MANUAL TRANSMISSION

8) Remove right bearing cone (2) by using puller (3), metal stick

(1) and press.

INSPECTION AND REASSEMBLY

1) Clean all components thoroughly, inspect them for any

abnormality and replace with new ones as necessary.

2) If synchronizer parts need to be repaired, check clearance

“a” between ring (2) and gear (1), each chamfered tooth of

gear, ring and sleeve, then determine parts replacement.

Clearance between synchronizer ring and gear

Standard “a” : 1.0 – 1.4 mm (0.039 – 0.055 in.)

Service limit “a” : 0.5 mm (0.019 in.)

3) Put the synchronizer outer ring (1), inner ring (3) and the

cone (2) together and then measure the step difference

between the outer ring and the inner ring. And also check

each chamfered tooth of gear and synchronizer ring and

replace with new one, if necessary. Also, check gear tooth.

Difference between synchronizer outer ring and inner ring

Standard “b” : 1.0 – 1.4 mm (0.039 – 0.055 in.)

Service limit “b” : 0.5 mm (0.019 in.)

4) To ensure lubrication, air blow oil holes (1) and make sure

that they are free from any obstruction.

Page 27 of 447

MANUAL TRANSMISSION 7A-27

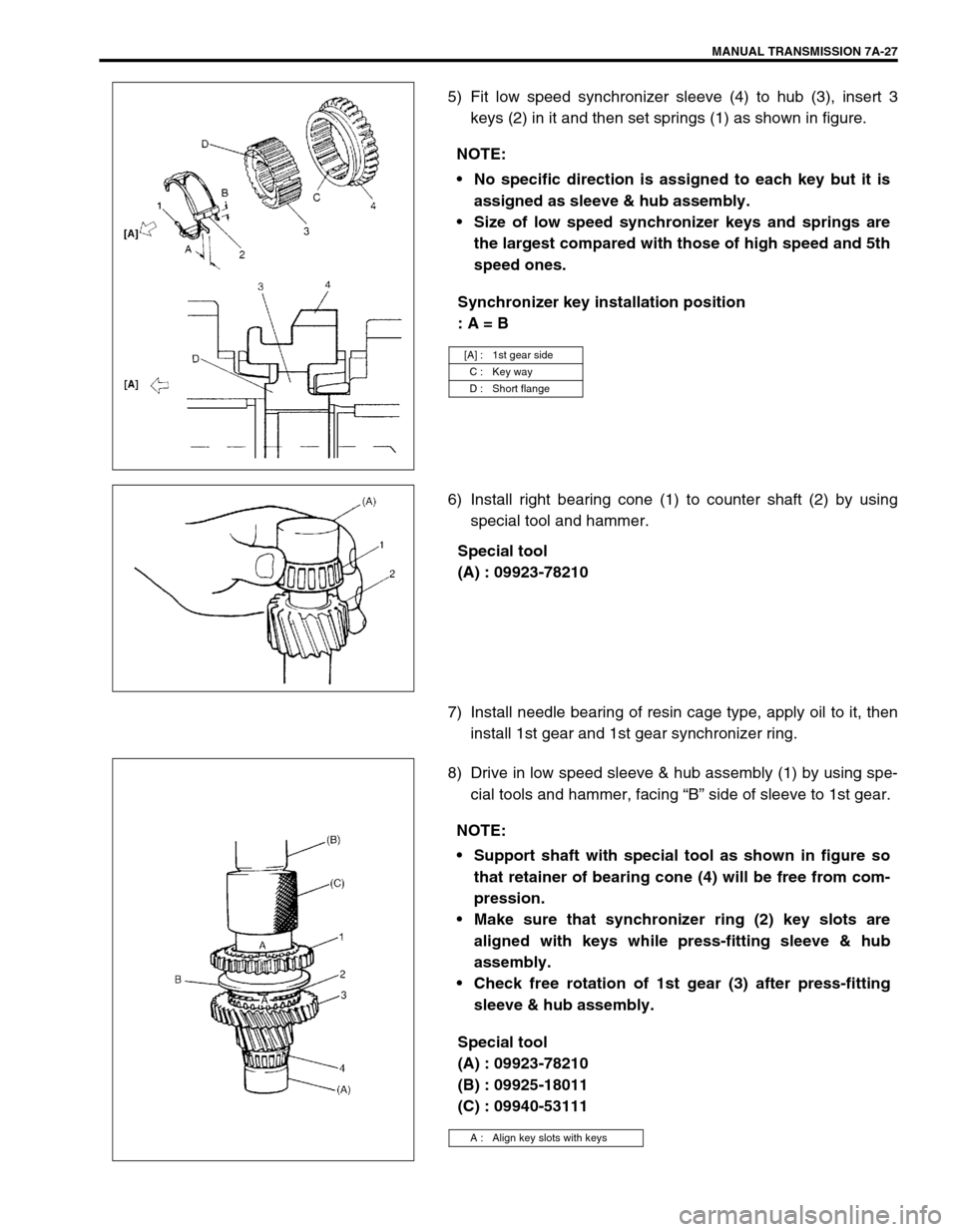

5) Fit low speed synchronizer sleeve (4) to hub (3), insert 3

keys (2) in it and then set springs (1) as shown in figure.

Synchronizer key installation position

: A = B

6) Install right bearing cone (1) to counter shaft (2) by using

special tool and hammer.

Special tool

(A) : 09923-78210

7) Install needle bearing of resin cage type, apply oil to it, then

install 1st gear and 1st gear synchronizer ring.

8) Drive in low speed sleeve & hub assembly (1) by using spe-

cial tools and hammer, facing “B” side of sleeve to 1st gear.

Special tool

(A) : 09923-78210

(B) : 09925-18011

(C) : 09940-53111 NOTE:

No specific direction is assigned to each key but it is

assigned as sleeve & hub assembly.

Size of low speed synchronizer keys and springs are

the largest compared with those of high speed and 5th

speed ones.

[A] : 1st gear side

C : Key way

D : Short flange

NOTE:

Support shaft with special tool as shown in figure so

that retainer of bearing cone (4) will be free from com-

pression.

Make sure that synchronizer ring (2) key slots are

aligned with keys while press-fitting sleeve & hub

assembly.

Check free rotation of 1st gear (3) after press-fitting

sleeve & hub assembly.

A : Align key slots with keys

Page 28 of 447

7A-28 MANUAL TRANSMISSION

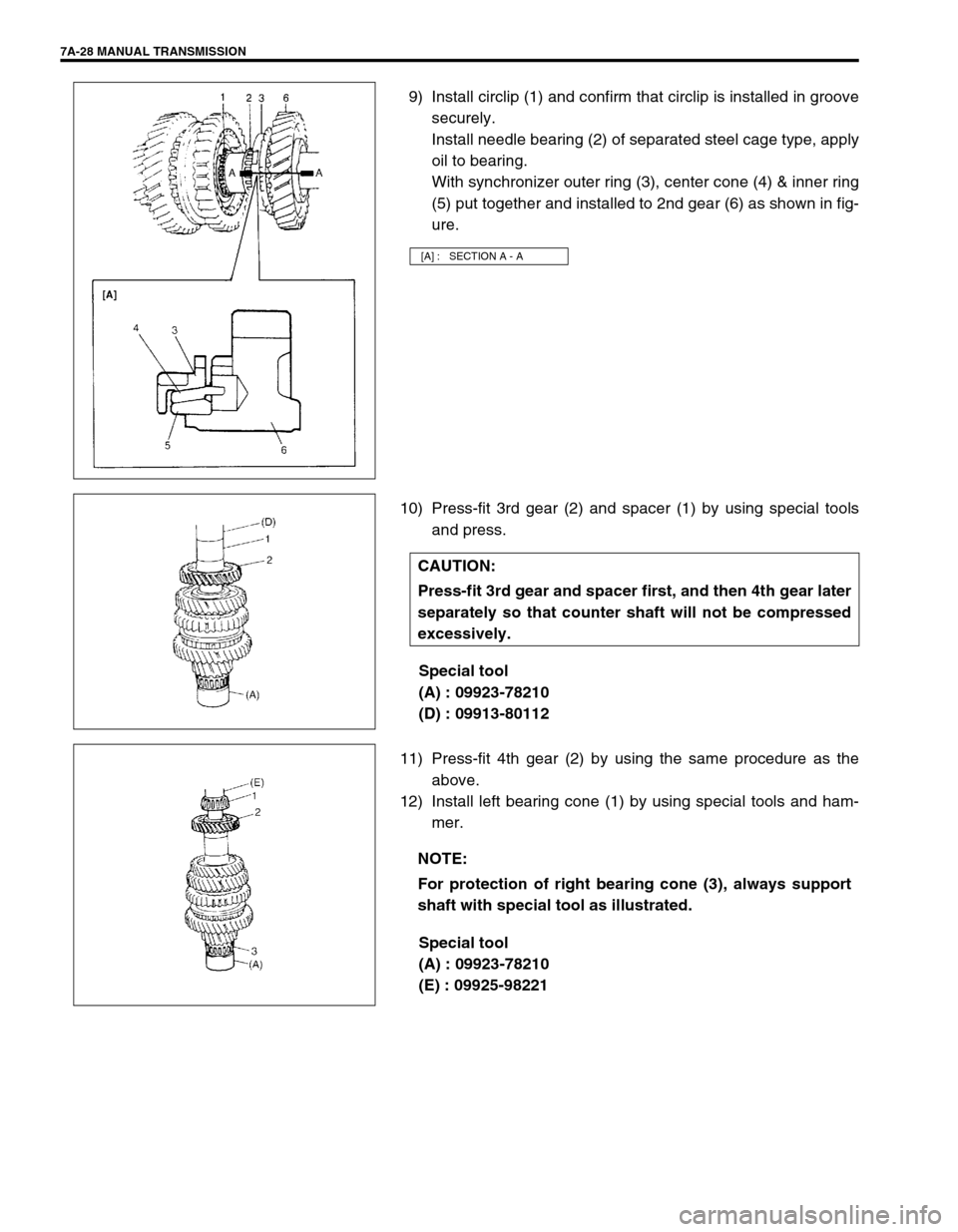

9) Install circlip (1) and confirm that circlip is installed in groove

securely.

Install needle bearing (2) of separated steel cage type, apply

oil to bearing.

With synchronizer outer ring (3), center cone (4) & inner ring

(5) put together and installed to 2nd gear (6) as shown in fig-

ure.

10) Press-fit 3rd gear (2) and spacer (1) by using special tools

and press.

Special tool

(A) : 09923-78210

(D) : 09913-80112

11) Press-fit 4th gear (2) by using the same procedure as the

above.

12) Install left bearing cone (1) by using special tools and ham-

mer.

Special tool

(A) : 09923-78210

(E) : 09925-98221

[A] : SECTION A - A

CAUTION:

Press-fit 3rd gear and spacer first, and then 4th gear later

separately so that counter shaft will not be compressed

excessively.

NOTE:

For protection of right bearing cone (3), always support

shaft with special tool as illustrated.

Page 30 of 447

7A-30 MANUAL TRANSMISSION

2) Insert each gear shift shaft into case and check that it moves

smoothly. If it doesn’t, correct by using oilstone, reamer or

the like.

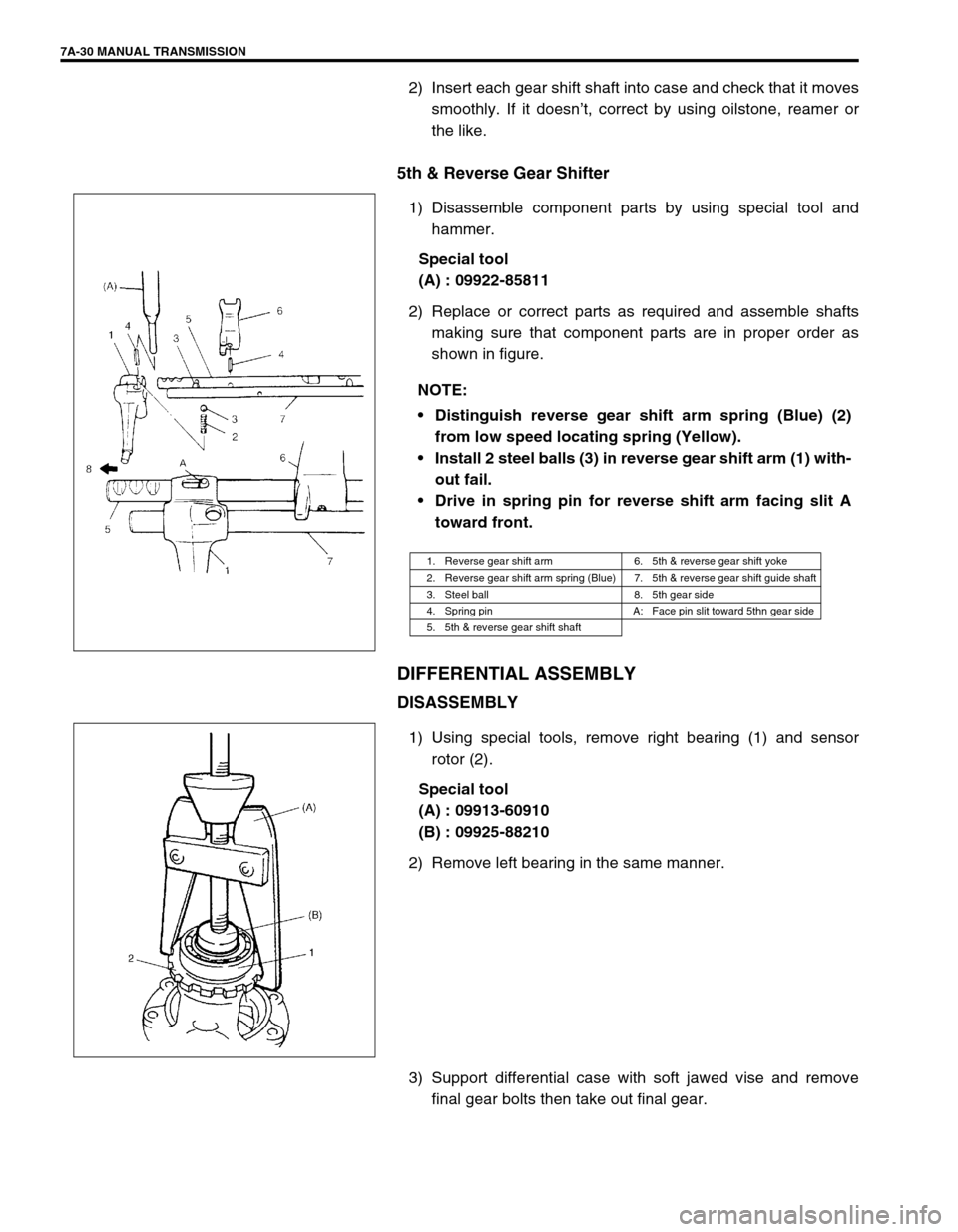

5th & Reverse Gear Shifter

1) Disassemble component parts by using special tool and

hammer.

Special tool

(A) : 09922-85811

2) Replace or correct parts as required and assemble shafts

making sure that component parts are in proper order as

shown in figure.

DIFFERENTIAL ASSEMBLY

DISASSEMBLY

1) Using special tools, remove right bearing (1) and sensor

rotor (2).

Special tool

(A) : 09913-60910

(B) : 09925-88210

2) Remove left bearing in the same manner.

3) Support differential case with soft jawed vise and remove

final gear bolts then take out final gear. NOTE:

Distinguish reverse gear shift arm spring (Blue) (2)

from low speed locating spring (Yellow).

Install 2 steel balls (3) in reverse gear shift arm (1) with-

out fail.

Drive in spring pin for reverse shift arm facing slit A

toward front.

1. Reverse gear shift arm 6. 5th & reverse gear shift yoke

2. Reverse gear shift arm spring (Blue) 7. 5th & reverse gear shift guide shaft

3. Steel ball 8. 5th gear side

4. Spring pin A: Face pin slit toward 5thn gear side

5. 5th & reverse gear shift shaft

Page 33 of 447

MANUAL TRANSMISSION 7A-33

UNIT ASSEMBLY

DIFFERENTIAL TO LEFT CASE

ASSEMBLY

1) Install differential assembly (1) into right case (2).

2) Insert VSS (3) with grease applied to its O-ring, then tighten

it with bolt.

Grease 99000-25010

3) Join input shaft (5), countershaft (4), low speed gear shift

shaft (2) and high speed gear shift shaft (3) assemblies all

together, then install them into right case (1).

4) Install 5th & reverse gear shift shaft (1) with 5th & reverse

gear shift guide shaft (2) into right case (5). Reverse gear

shift arm (4) has to be joined with reverse gear shift lever (3)

at the same time.

5) Place reverse gear shift lever, fasten it with bolts after apply-

ing thread lock cement.

“A” : Thread lock cement 99000-32110

Tightening torque

Revers gear shift lever bolts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Distance between lever end and shaft bore

“a” : 5 mm (0.2 in.)

CAUTION:

Take care not to damage oil seal lip by input shaft, or oil

leakage may take place.

NOTE:

Input shaft right bearing on shaft can be installed into

right case by tapping shaft with plastic hammer.

Check to make sure that counter shaft is engaged with

final gear while installing.

NOTE:

When installing reverse gear shift lever, set it as the

following specification.

Page 37 of 447

MANUAL TRANSMISSION 7A-37

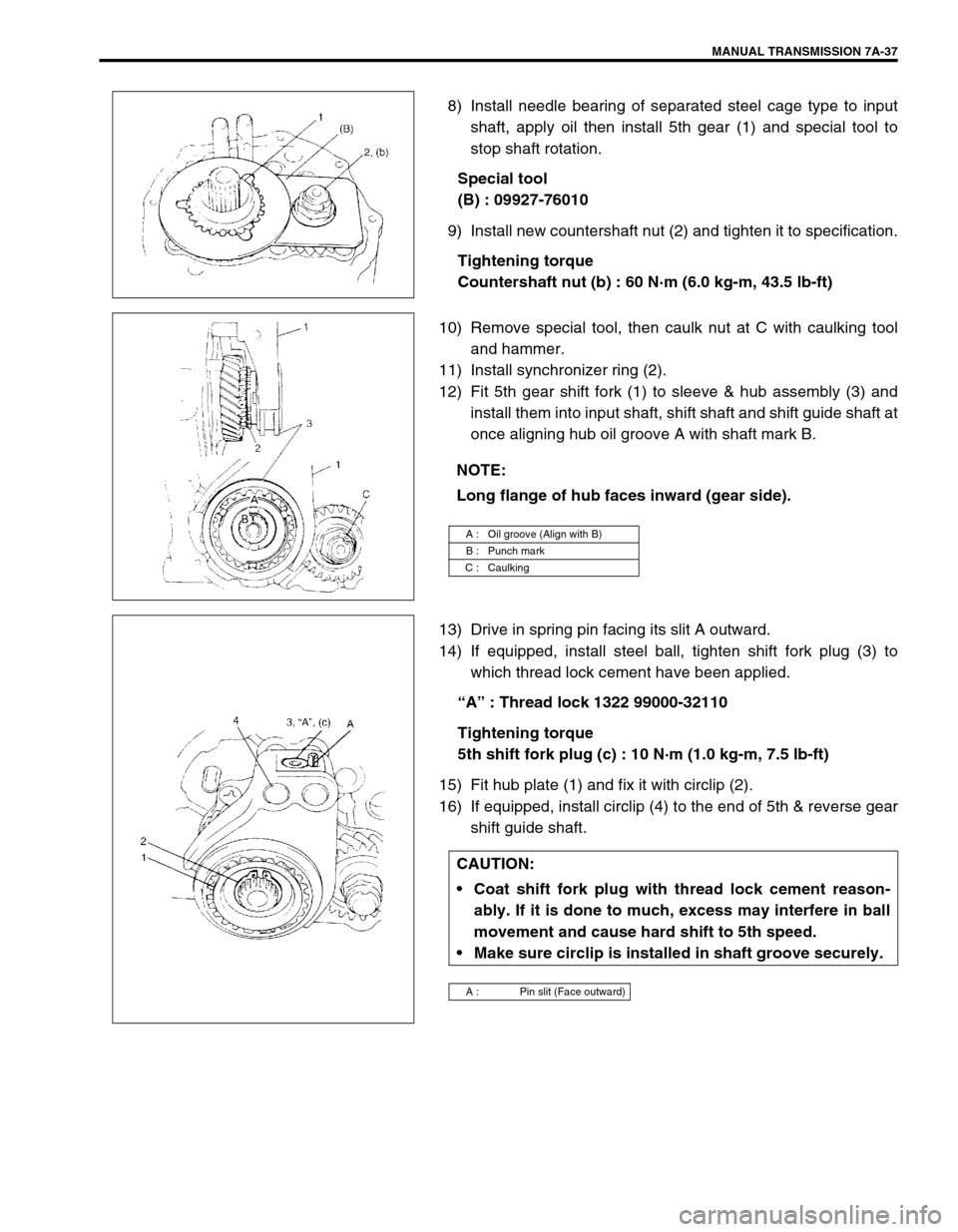

8) Install needle bearing of separated steel cage type to input

shaft, apply oil then install 5th gear (1) and special tool to

stop shaft rotation.

Special tool

(B) : 09927-76010

9) Install new countershaft nut (2) and tighten it to specification.

Tightening torque

Countershaft nut (b) : 60 N·m (6.0 kg-m, 43.5 lb-ft)

10) Remove special tool, then caulk nut at C with caulking tool

and hammer.

11) Install synchronizer ring (2).

12) Fit 5th gear shift fork (1) to sleeve & hub assembly (3) and

install them into input shaft, shift shaft and shift guide shaft at

once aligning hub oil groove A with shaft mark B.

13) Drive in spring pin facing its slit A outward.

14) If equipped, install steel ball, tighten shift fork plug (3) to

which thread lock cement have been applied.

“A” : Thread lock 1322 99000-32110

Tightening torque

5th shift fork plug (c) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

15) Fit hub plate (1) and fix it with circlip (2).

16) If equipped, install circlip (4) to the end of 5th & reverse gear

shift guide shaft.

NOTE:

Long flange of hub faces inward (gear side).

A : Oil groove (Align with B)

B : Punch mark

C : Caulking

CAUTION:

Coat shift fork plug with thread lock cement reason-

ably. If it is done to much, excess may interfere in ball

movement and cause hard shift to 5th speed.

Make sure circlip is installed in shaft groove securely.

A : Pin slit (Face outward)